Page 1

EZ Greaser

Installation Instructions

The EZ Greaser® lubrication system is designed to lubricate 8, 14,

or 16 points from a single fitting—all at the same time from one

convenient location. The EZ Greaser ensures that you are getting

the proper amount of lubricant to each fitting – every time. Each

kit comes complete with the items necessary for installation so

you can get back on the road quickly and stay on the road.

IMPORTANT: Pre-grease all lube points before installing the

system. Make sure that each lube point will accept grease from a

grease gun with minimum effort. This system can deliver grease

at pressures up to 1500 psi. If a fitting requires extreme effort to

inject grease, it must be fixed before attaching the EZ Greaser to

that point.

NOTE: Do not plug any outlets on the EZ Greaser block. The

block will not operate correctly.

INSTALLATION

Verify the number of lubrication points and locations and 1.

inspect to ensure lube points will accommodate use of the

included threaded fittings. Optional press-in fittings are

available from your EZ Greaser Distributor. See vehicle layout

on page 3.

Install mounting plate either by welding or bolting to a spot 2.

that allows easy access to the grease fitting on the top of

the block and within ten (10) feet of the furthest lube point.

Mount block to the mounting plate

Using the included diagrams, route the tubing lines to 5.

the appropriate points following the color scheme on the

diagrams. Bundle tubes together when routing tubes from

the block to the lube points. Use wire ties every 6-8 inches

and anchor to the frame and steering components making

sure the tubes move with these objects. This will assure that

the tubes stay in place under normal operating conditions.

IMPORTANT: Allow ample slack for tube movement and ease

of installation. A self-aligned captured ferrule is supplied

with all 3/16" fittings. It is not necessary to remove the nut

and ferrule to seat the tube into the fitting. Care should be

taken to make sure the tube is well seated into each fitting

before tightening.

Attach the Orange tube from the Tri-tube bundle to the Upper 6.

King Pin grease fitting. Attach the Blue tube to the Lower

King Pin grease fitting. Attach Black tube to Tie Rod grease

fitting. This fitting should be pointing towards the rear of the

vehicle and on a 45° angle toward the inside centerline of the

vehicle. Repeat for other side of the vehicle. Do not attach

grease tubes to hydraulic brake lines.

Attach single Black tubes to front and rear Drag Link grease 7.

fittings. Allow for movement of the arm. Be sure to secure

the line to the steering arm so that line moves when steering

the vehicle but does not rub or slide against frame, shock

absorber or steering components. Tubes and steering

components should move as one (1) unit.

Remove all the existing grease fittings from the points to 3.

be attached to the EZ Greaser and replace with fittings

according to the diagrams for the specific kit.

Prepare tubing:4.

Cut the outside sheath on multi-tube bundles back to a.

the point where this bundle meets the first lube point.

Be careful not to puncture or cut the tubes. Use a

“Romex” stripper to help prevent this damage.

Peel back the outside sheath rolling it back on itself b.

and cut off the excess. Be careful not to nick or cut the

remaining tubes.

Align tubing with fitting and make a clean square cut c.

with an anvil style cutter.

Attach other tubes to spring pins and spring hangers as 8.

required.

OPERATING INSTRUCTIONS

Remove the dust cover protective cap from the grease fitting

on the divider module. Ensure the fitting is free from dirt and

contamination and connect a grease gun or low volume power

grease gun to the grease fitting. Pump a manual gun one time

for each lube point in the system: 8 strokes for 8-point system,

14 strokes for the 14-point system, and 16 strokes for a 16-point

system. Wipe off the end of the fitting and put the protective cap

back onto the fitting. Repeat every 2-3 weeks or more often when

operating the vehicle in wet or high dust environments to flush out

contaminants with fresh grease.

Page 2

EZ Greaser Installation Instructions L44000

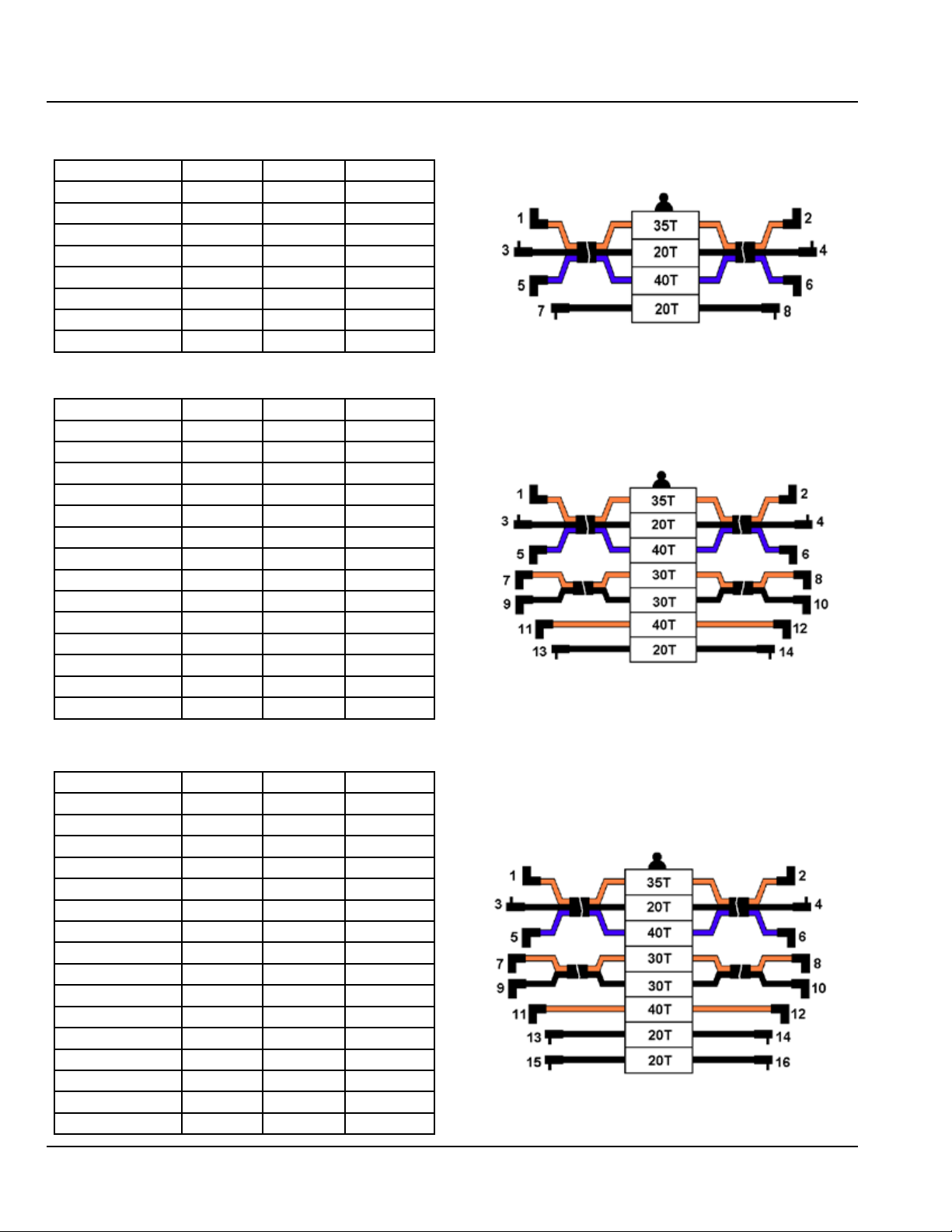

Kit Number 563853 (Old: 550-503-634) 8-Point Manual System

Lube Points Block Size Tube Color Fitting

1 King Pin Upper 35T Orange 1/8 Elbow

2 King Pin Upper 35T Orange 1/8 Elbow

3 Tie Rod 20T Black 1/4 SAE Elbow

4 Tie Rod 20T Black 1/4 SAE Elbow

5 King Pin Lower 40T Blue 1/8 Elbow

6 King Pin Lower 40T Blue 1/8 Elbow

7 Drag Link of Pitman 20T Black 1/4 SAE Elbow

8 Drag Link of Idler 20T Black 1/4 SAE Elbow

Kit Number 563855 (Old: 550-503-636) 14-Point Manual System

Lube Points Block Size Tube Color Fitting

1 King Pin Upper 35T Orange 1/8 Elbow

2 King Pin Upper 35T Orange 1/8 Elbow

3 Tie Rod 20T Black 1/4 SAE Elbow

4 Tie Rod 20T Black 1/4 SAE Elbow

5 King Pin Lower 40T Blue 1/8 Elbow

6 King Pin Lower 40T Blue 1/8 Elbow

7 Spring Hanger 30T Black 1/8 Elbow

8 Spring Hanger 30T Orange 1/8 Elbow

9 Spring Hanger 30T Orange 1/8 Elbow

10 Spring Hanger 30T Black 1/8 Elbow

11 Spring Pin 40T Orange 1/8 Elbow

12 Spring Pin 40T Orange 1/8 Elbow

13 Drag Link 20T Black 1/4 SAE Elbow

14 Drag Link 20T Black 1/4 SAE Elbow

Kit Number 563864 (Old: 550-503-646) 16-Point Manual System

Lube Points Block Size Tube Color Fitting

1 King Pin Upper 35T Orange 1/8 Elbow

2 King Pin Upper 35T Orange 1/8 Elbow

3 Tie Rod 20T Black 1/4 SAE Elbow

4 Tie Rod 20T Black 1/4 SAE Elbow

5 King Pin Lower 40T Blue 1/8 Elbow

6 King Pin Lower 40T Blue 1/8 Elbow

7 Spring Hanger 30T Black 1/8 Elbow

8 Spring Hanger 30T Orange 1/8 Elbow

9 Spring Hanger 30T Orange 1/8 Elbow

10 Spring Hanger 30T Black 1/8 Elbow

11 Spring Pin 40T Orange 1/8 Elbow

12 Spring Pin 40T Orange 1/8 Elbow

13 Drag Link 20T Black 1/4 SAE Elbow

14 Drag Link 20T Black 1/4 SAE Elbow

15 Drag Link 20T Black 1/4 SAE Elbow

16 Drag Link 20T Black 1/4 SAE Elbow

Page 2

Page 3

Typical vehicle layout for 16 point front-end grease fitting locations:

Upper Kingpin

Tie Tubing to

Tie Rod (Black)

Lower King

Pin (Blue)

(Red)

Clamp bolt

Pin (Blue)

Tie Rod (Black)

Drag link

Upper Kingpin (Red)

Follow Air hose from

frame to brake can

(Twin No Ta g)

Lower King

L44000EZ Greaser Installation Instructions

Page 3

Curbside Kingpin

Roadside Kingpin

Drag Link

Page 4

HARDWARE KIT CONTENTS ORDERING INFORMATION

Description No. of Pieces Kit Part No. Kit Old Part No. Part No. Old Part No.

Elbow 3/16 TX x 1/8 P 4

Connector 3/16 T x 1/8 PM 6 556644 435-460-030

Elbow ST 1/8 Pipe 2 15K783 509-110-000

Elbow ST 1/4-28 SAE 1/8 FP 4 15K740 550-400-800

MSP MTG Bracket 1 557967 550-402-770

Tie Straps – 100 per pack 1 563770 550-402-340

563853 550-503-634

556638 435-440-030

Elbow 3/16 TX x 1/8 P 10

Connector 3/16 T x 1/8 PM 4 556644 435-460-030

Elbow ST 1/8 Pipe 2 15K783 509-110-000

Elbow ST 1/4-28 SAE 1/8 FP 4 15K740 550-400-800

MSP MTG Bracket 1 557967 550-402-770

Tie Straps – 100 per pack 1 563770 550-402-340

Elbow 3/16 TX x 1/8 P 10

Connector 3/16 T x 1/8 PM 6 556644 435-460-030

Elbow ST 1/8 Pipe 2 15K783 509-110-000

Elbow ST 1/4-28 SAE 1/8 FP 6 15K740 550-400-800

MSP MTG Bracket 1 557967 550-402-770

Tie Straps – 100 per pack 1 563770 550-402-340

SPARE PARTS

Description Part No. Old Part No.

Elbow, Street,

1/4-28 SAE x

1/8 FP

15K740 550-400-800

563855 550-503-636

563864 550-503-646

556638 435-440-030

556638 435-440-030

Male 90º Elbow

Connector, 3/16

in, 1/8 NPT

556638 435-440-030

Male Connector,

3/16 in Tube,

1/8 in NPT

Elbow, Street,

18 in NPT to 1/8

in NPT

Distribution Lines, 3/16 in OD Tubing Bundles Prefilled

3 Tube Bundle,

15 ft

2 Tube Bundle,

15 ft

1 Tube Orange,

20 ft

1 Tube Black,

15 ft

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

556644 435-460-030

15K783 509-110-000

563794 550-450-950

563792 550-450-930

563993 550-450-820

564087 550-450-220

OPTIONAL CONNECTORS FOR NON-REMOVABLE

GREASE FITTINGS

Nylon Tie Straps

(11.5 in), 100

pcs

Zerk Adaptors,

3/16 in Tube

Conn. Straight

Zerk Adaptors,

3/16 in Tube

Conn. Elbow

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

563770 550-402-340

550-402-870

550-402-860

©2006-2009 Graco Inc. Form No. L44000 Rev. B 3/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...