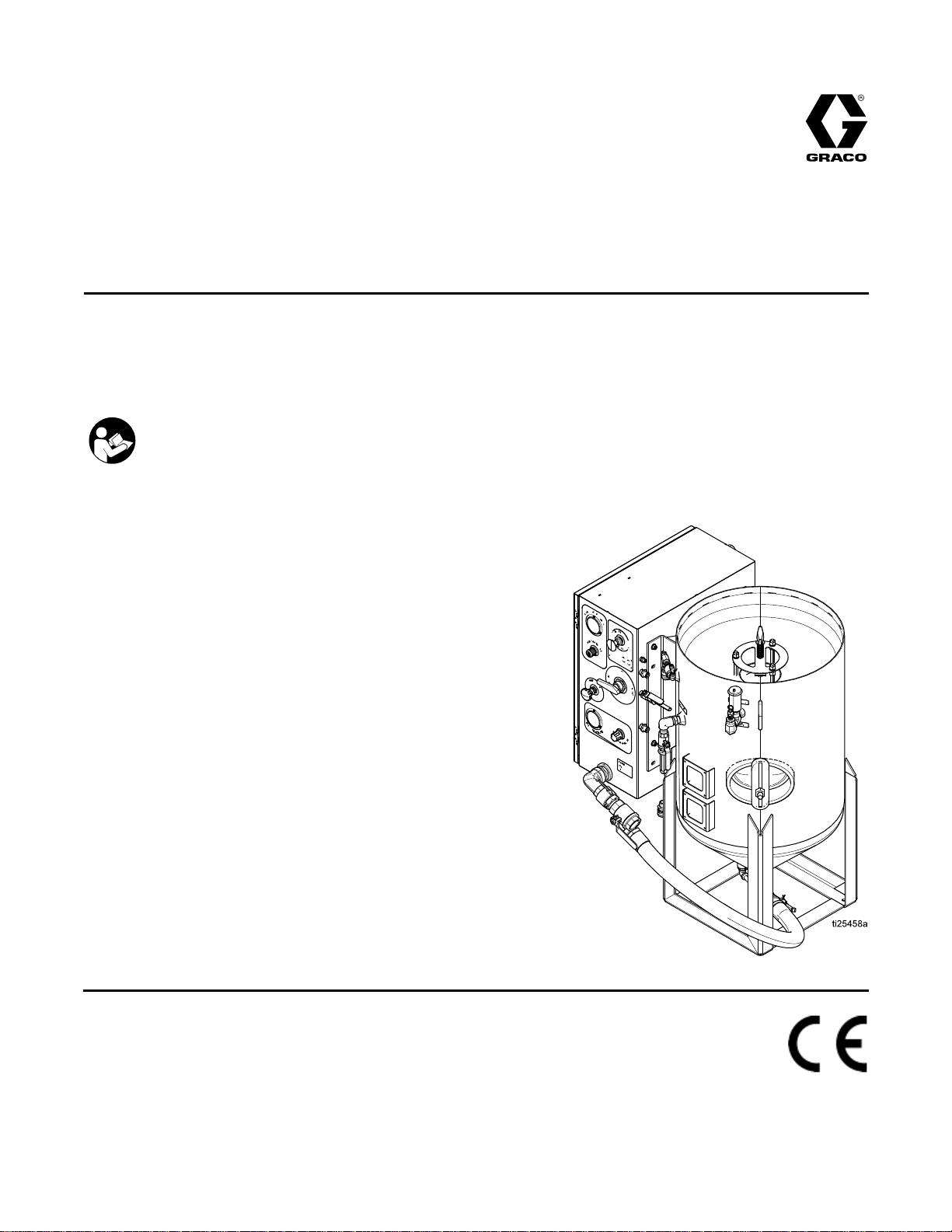

Graco EcoQuip 300, EQ300C, EcoQuip 600, EQ60XC, EQ600C Operation, Repair, And Parts

...

Operation,Repair,andParts

EcoQuip

EcoQuip EcoQuip

Blast

Blast Blast

Vapor

Vapor Vapor

or

or or

125

125 125

Working

Working Working

See

See See

abrasive

abrasive abrasive

hazardous

hazardous hazardous

Important

Important Important

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

psi

psi psi

page

page page

System

System System

blast

blast blast

locations.

locations. locations.

Safety

Safety Safety

(8.6

bar,

(8.6 (8.6

bar, bar,

Pressure

Pressure Pressure

for

Model

2 22for for

Model Model

Vapor

Vapor Vapor

Abrasive

Abrasive Abrasive

334667G

EN

system.

system. system.

Instructions

Instructions Instructions

0.86

0.86 0.86

For

professional

For For

professional professional

MPa)

MPa) MPa)

Maximum

Maximum Maximum

information.

information. information.

use

only.

Not

use use

only. only.

approved

Not Not

approved approved

for

use

for for

use use

explosive

in ininexplosive explosive

atmospheres

atmospheres atmospheres

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents

Contents Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

OEMSystemGuidelines.....................................7

SystemComponentIdentication.........................8

EQ300CandEQ600C..................................8

DataTrakControls........................................9

PressureReliefProcedure..................................10

Grounding(ATEXSystemsonly).........................10

Operation...........................................................11

ChecklistBeforeStarting..............................11

LiftingtheSystem........................................11

ConnectingtheBlastHoseandAir

Hose..............................................12

SettingUptheEquipment.............................14

BlastingTips................................................18

UsingtheWashFeature...............................20

RellingthePotwithAbrasive.......................21

ShuttingDown.............................................22

WinterizingtheEquipment............................24

Troubleshooting..................................................25

TroubleshootingExamples...........................28

Repair................................................................30

RepairingtheMainAirRegulator..................30

FlushingtheDiaphragmValve......................31

RepairingtheDiaphragmValve.....................32

CleaningtheAuto-VentValve.......................33

ReplacingtheDataTrakBattery....................34

ReplacingtheDataTrakFuse.......................35

Parts..................................................................36

EQ300CandEQ600C..................................36

Enclosure....................................................38

PressurePot................................................40

BlastHoses.................................................41

HoseSchematic.................................................42

VaporAbrasiveBlastSystemsand

Accessories..........................................43

EcoQuipSystemCongurator.......................43

ModelSeries...............................................44

BlastHoseswithControl

Hoses/Cables.................................45

BlastHoseswithoutControl

Hose/Cables..................................45

BlastControlHoses/Cables..........................46

Nozzles.......................................................46

OtherAccessories........................................46

CommonSpareParts...................................47

Dimensions........................................................48

TechnicalSpecications......................................49

GracoExtendedWarrantyforEcoQuip™

Components.........................................50

2

334667G

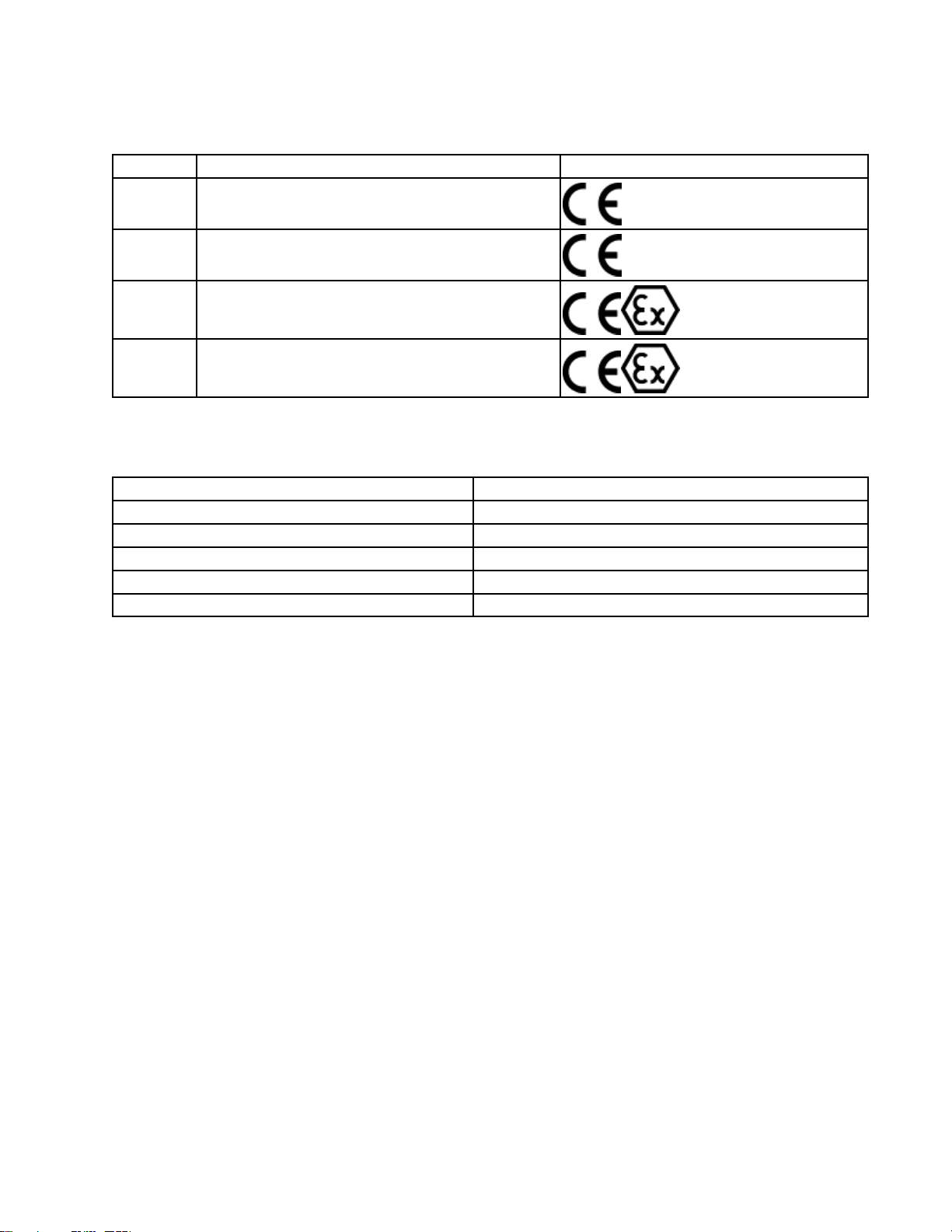

Models

Models

Models Models

Model

Model Model

EQ300CEcoQuip300VaporBlastSystem

EQ600CEcoQuip600VaporBlastSystem

EQ30XCEcoQuip300VaporBlastSystemATEXApproved

EQ60XCEcoQuip600VaporBlastSystemATEXApproved

Related

Related Related

Manuals

Manuals Manuals

Manual

Manual Manual

313840DataTrak

333397Pump

334143

334142

334666

Description

Description Description

Number

Number Number

Approvals

Approvals Approvals

2G

Ex

II IIII2G 2G

Ex Ex

2G

Ex

II IIII2G 2G

Ex Ex

Product

Product Product

EQ300M,EQ600M

EQ100M

EQ200T,EQ400T

IIA

T3

Gb

h hhai aiaiIIA IIA

h hhai aiaiIIA IIA

T3 T3

IIA

T3

T3 T3

X

Gb Gb

X X

Gb

X

Gb Gb

X X

334667G 3

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

SPECIAL

SPECIAL SPECIAL

CONDITIONS

CONDITIONS CONDITIONS

FOR

USE

FOR FOR

USE USE

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Alllabelandmarkingmaterialmustbecleanedwithadampcloth(orequivalent).

DUST

DUST DUST

Useofthisequipmentcanresultinthereleaseofpotentiallyharmfuldustortoxicsubstances

fromtheabrasivebeingused,thecoatingsbeingremoved,andthebaseobjectbeingblasted.

•Foruseonlybysophisticatedusersfamiliarwithapplicablegovernmentalsafetyandindustrial

•Useequipmentonlyinawell-ventilatedarea.

•Wearaproperlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions.

•Followlocalordinancesand/orregulationsfordisposaloftoxicsubstancesanddebris.

AND

DEBRIS

AND AND

DEBRIS DEBRIS

hygieneregulators.

HAZARD

HAZARD HAZARD

Grounding

Instructions,

Instructions, Instructions,

page

page page

10

.

10 10

. .

4

334667G

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Donotusethisequipmentwithouthoserestraintsandcouplerpinsinstalledonallairand

blasthosecouplings.

•Donotblastunstableobjects.Thehighamountofuidowfromthenozzlecanpotentially

moveheavyobjects.

•Donotexceedloadratingoflifteyes.

•Donotoperateequipmentonorstandonanunstablesupport.Keepeffectivefootingand

balanceatalltimes.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

notinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

BURN

BURN BURN

HAZARD

HAZARD HAZARD

MISUSE

MISUSE MISUSE

HAZARD

HAZARD HAZARD

Technical

Specications,

Specications, Specications,

Pressure

page

49

page page

49 49

inallequipmentmanuals.

Relief

Procedure,

Relief Relief

Procedure, Procedure,

page

10

page page

10 10

whenequipmentis

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolvent,inworkareacanigniteorexplode.Tohelppreventre

andexplosion:

•Useequipmentonlyinwellventilatedarea.

•Abrasivematerialexitingblastnozzlecangeneratesparks.Whenammableliquidsareused

neartheblastnozzleorforushingorcleaning,keeptheblastnozzleatleast20feet(6

meters)awayfromexplosivevapors.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

HAZARD

HAZARD HAZARD

334667G 5

Warnings

WARNING

WARNING WARNING

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewearandhearingprotection

•Protectiveclothing,shoes,andgloves

•Properlyt-testedandgovernmentapprovedrespiratorsuitableforthedustconditions

RECOIL

RECOIL RECOIL

Blastnozzlemayrecoilwhentriggered.Ifyouarenotstandingsecurely,youcouldfalland

beseriouslyinjured.

PROTECTIVE

PROTECTIVE PROTECTIVE

HAZARD

HAZARD HAZARD

EQUIPMENT

EQUIPMENT EQUIPMENT

6 334667G

OEMSystemGuidelines

OEM

OEM OEM

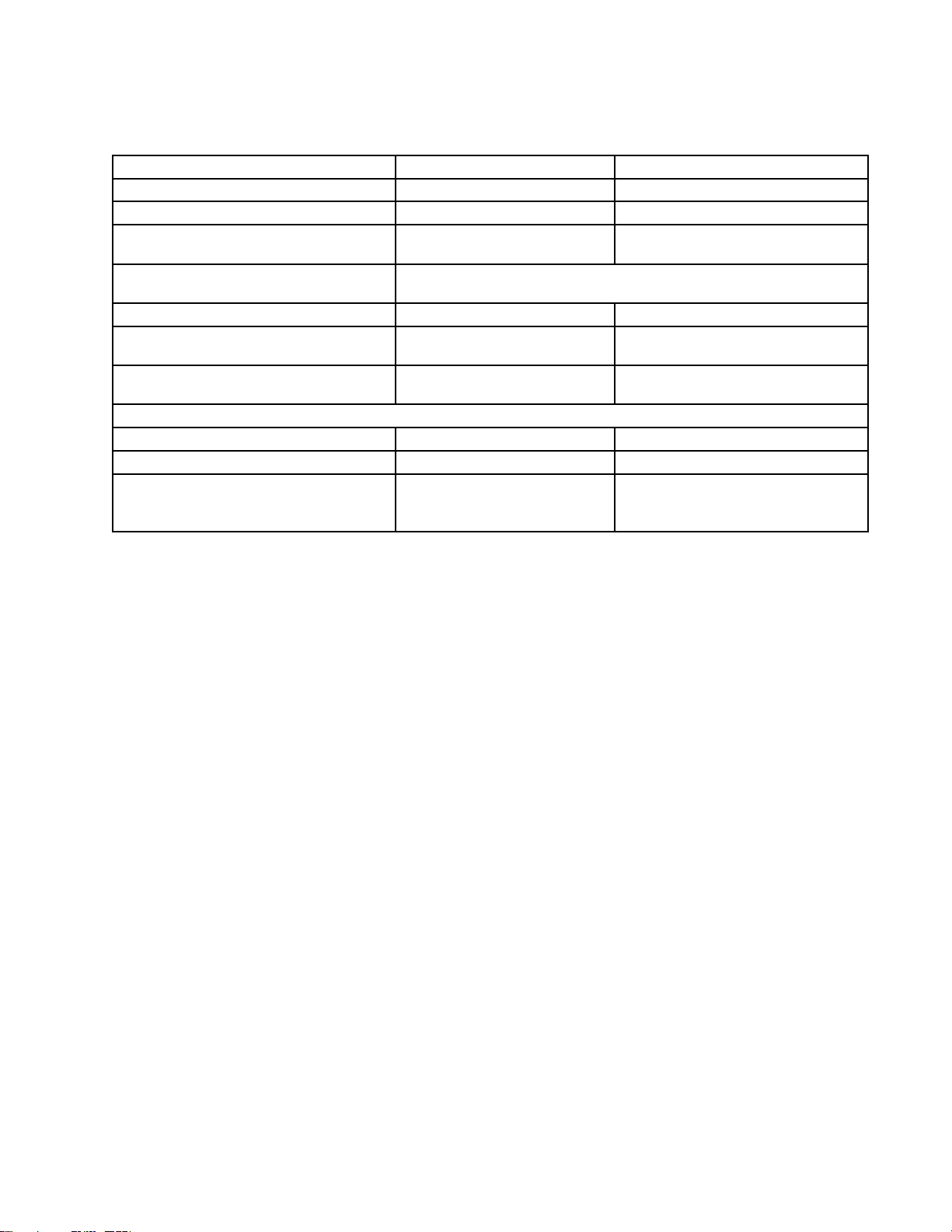

SystemWeight(Dry)

SystemWeight(Wet)

WaterTankSize(mustbewater

compatible)

PumpInletFittingDixon6EM6-Bquickdisconnectinterchangeincluded

MinimumID3/4in.1.9cm

MaximumRecommendedPumpInlet

HoseLength

Maximumrecommendedrisefromwater

tankoutlettopumpinlet

AvailableGracoInlethoses(w/quickdisconnectinterchanges)

17C032

EQ1848

AvailableGracowatertankshutoffvalve

assembly(3/4"NPTmaleto6EM6-B

quickdisconnect)

Forairinlethoserecommendations,seeTechnicalSpecications,page49.

System

System System

Guidelines

Guidelines Guidelines

U.S.

U.S. U.S.

450lb204kg

1600lb726kg

100gallon(recommended)378liter(recommended)

(3/4"NPTalsoonpump)

5ft

16in.41cm

19in.length48cm

36in.length91cm

EQ5131EQ5131

Metric

Metric Metric

4.5m

SeeVaporAbrasiveBlastSystemsandAccessories,page43forGracorecommendedblasthosesand

nozzles.

Forsystemdimensionsandmountinglocations,seeDimensions,page48.

334667G

7

SystemComponentIdentication

System

System System

EQ300C

EQ300C EQ300C

Component

Component Component

and

EQ600C

and and

EQ600C EQ600C

Identication

Identication Identication

8 334667G

SystemComponentIdentication

Key:

Key: Key:

A

B

B2BlastNozzle

C

EPot

FPop-UpPin

G

HWaterTankLid

JPotDumpValve

KAutoVentValve

L

MAbrasiveBallValve

P

QEmergencyStop

RBlastAirRegulator

S

TPotPressureRegulator

Cart

BlastControlSwitch

BlastHose

WaterTank

BlastCheckValve

ControlBox

AbrasiveMeteringValve

Key:

Key: Key:

U

V

W

XRinseBallValve

Y

Z

ZA

ZB

ZCSupplyAirPressureGauge

ZD

ZEAccessoryExtensionhose

ZFAbrasiveMedia

ZG

ZH

PotPressureGauge

BlastAirPressureGauge

SelectorValve

AirSupplyConnection

BlastConnection

PneumaticControlConnection

ElectricControlConnection(non-ATEX

systemsonly)

DataTrak(seeDataTrakControls,page9)

FillPort

GroundWireandClamp(ATEXSystems

only)

DataTrak

DataTrak DataTrak

Key:

Key: Key:

RK

CRCycle/Rate

BTBatchTotalizer

GTGrandTotalizer

Controls

Controls Controls

ResetKey—Resultsinfaults.Pressand

holdforthreesecondstoclearthebatch

totalizer.

334667G 9

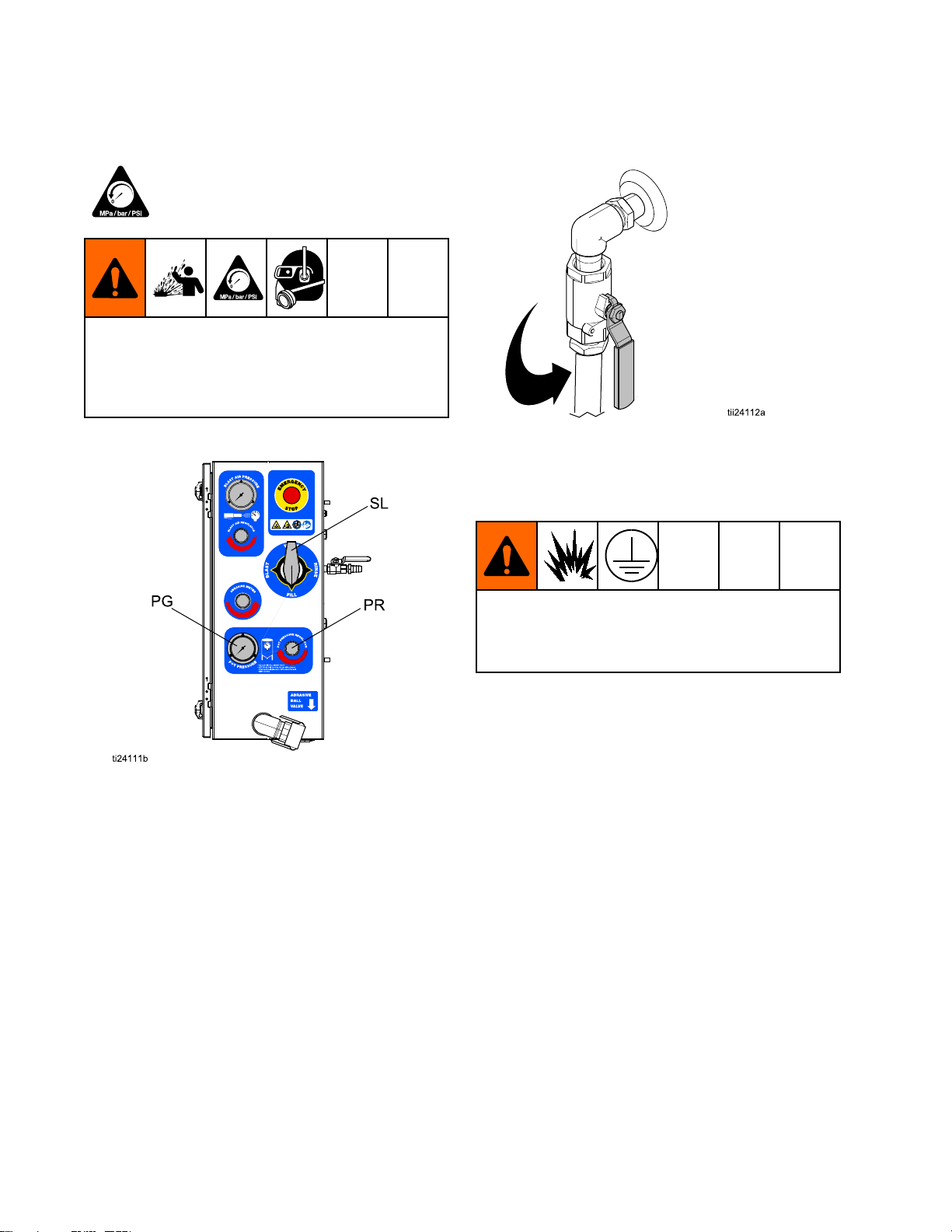

PressureReliefProcedure

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchassplashing

uid,followthePressureReliefProcedurewhen

instructed.

1.Turnthepotpressureregulator(PR)off.

Relief

Relief Relief

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Procedure

Procedure Procedure

6.Turntheselectorvalve(SL)toFILL.

7.Openthedumpvalve.

8.Verifythatthepotpressuregauge(PG)displays

zeropressure.

Grounding

Grounding Grounding

(ATEX

(ATEX (ATEX

Systems

Systems Systems

only)

only) only)

2.Closetheabrasiveballvalve.

3.Turnthecompressoroff.Closethecompressor

supplyairvalve.

4.Engagetheblastcontrolswitchtorelieve

pressureinthesystem.

5.Verifythattheairpressuregaugereads0psi.

Thendisconnecttheairinlethosefromthe

system.

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Groundingprovidesan

escapewirefortheelectriccurrent.

Systems:

Systems: Systems:

(237686).

Air

and

Air Air

and and

rated,conductivehoseswithamaximumlength

of150ft(45m)combinedhoselengthtoensure

groundingcontinuity.Checktheelectricalresistance

ofthehoses.Ifthetotalresistancetogroundexceeds

29megaohms,replacethehoseimmediately.

Air

Air Air

recommendations.

Usesuppliedgroundwireandclamp

uid

hoses:

uid uid

hoses: hoses:

Compressor:

Compressor: Compressor:

UseonlygenuineGracoATEX

Followmanufacturer’s

10 334667G

Operation

Operation

Operation Operation

Topreventfreezing,thisequipmentisshippedfrom

thefactorywithbluewindshieldwasheruidinside

thesystem.Itisnotnecessarytodrainbefore

using.Disposeoftheuidinaccordancewithlocal

regulations.

Checklist

Checklist Checklist

•Checkthecompressedairsupplyaccordingtoits

operatormanual.Makesuretheairbeingsupplied

iscleanandrelativelyfreeofmoistureandoil

topreventwatercontaminationoftheaircontrol

components.

•Makesureairdeliveryvalvesareclosedbeforethe

airsupplycompressorisstarted.

•Makesureallrequiredhoserestraintsandcoupler

pinsareinworkingconditionandproperlyinstalled.

•Makesuretheequipmentissituatedonlevel

ground.Failuretokeeptheunitonlevelground

willmakeitdifcultorimpossibletopurgeallofthe

airfromthepressurevessel.

•Makesuretheequipmentisproperlysupportedon

asurfacethatcanholditstotalweight.Theweight

ofallpersonnel,thematerialbeingblasted,and

anyabrasivebeingstoredmustalsobeconsidered

(seeTechnicalSpecications,page49).

Before

Before Before

Starting

Starting Starting

•Makesurethatthepotiscleanandfreeofany

internaldebris.

•Makesuretousethecorrecttypeofblastcontrol.

Blastingwith150feet(45m)ormoreofblasthose

requirestheuseofanelectricblastcontrol.An

electricblastcontrolcanalsobeusedonhose

lengthsbelow150feet(45m).

•Makesuretheblasthoseislaidoutasstraightas

possiblebetweentheequipmentandtheworksite

(acoiledblasthosewilluncoilunderpressure).

NOTICE

NOTICE NOTICE

Sharpbendsintheblasthosecouldcausethe

abrasivetowearthroughthehoseandcause

prematurefailureofthehose.

•Makesuretherubbergasketineachhosecoupler

isinworkingcondition.

Lifting

Lifting Lifting

•Liftthesystemwithaliftapparatusrated

appropriatelyfortheweightofthesystem(see

TechnicalSpecications,page49).

•Thesystemcanbeliftedusingtheliftringonthe

potorthecarthandle.

the

System

the the

System System

•Makesurethewatertankwillremainfullysupplied

withcleanwatertoavoidanypossibilityofthe

pumprunningdryduringblasting.

334667G

11

Operation

Connecting

Connecting Connecting

Hose

Hose Hose

EQ30XS

1.EQ30XS EQ30XS

groundingcabletotheexternalgroundstud(ZH)

ontheenclosure,thenconnecttheclamptoa

trueearthground.

2.Alwayspurgetheairsupplyhose15–20seconds

beforeconnectingtheairsupplyhosefromthe

compressor(oron-sitecompressedairsource)

tothepanel.Makesurealldebrisisclearedfrom

thehose.

the

Blast

the the

Blast Blast

and

EQ60XS

and and

EQ60XS EQ60XS

Hose

Hose Hose

only:

only: only:

Connectthe

and

Air

and and

Air Air

3.Connectanappropriatelysizedair

supplyhosetotheairinlet.See

TechnicalSpecications,page49.

NOTE:

NOTE: NOTE:

restraintsandcouplerpinstothequick-coupler

andtheairline.Iftheholesonthequick-coupler

donotalign,thereissomethingwrongandthe

twocouplersarenotcompatible.DO DO

ON

ON ON

resolved.

Makesuretoproperlyinstallhose

THE

AIR

THE THE

AIR AIR

.Seekhelptogetthesituation

DO

NOT

NOT NOT

TURN

TURN TURN

12

334667G

Operation

4.Opentheairsupplyvalve(125psi,8.6Bar,0.86

MPamaximum).Ifnecessary,usearegulatorin

thesupplyairlinetomeetthesespecications.

NOTE:

NOTE: NOTE:

theappropriate appropriate

TechnicalSpecications,page49.

Makesuretheairsupplymeets

appropriate

air

air air

ow

requirements.

ow ow

requirements. requirements.

5.Connecttheblasthose,hoserestraints,control

hoses,andcouplerpins.

NOTE:

NOTE: NOTE:

checkalloftheelectricalconnectionsfromthe

paneltotheblastcontrol.

See

Ifyouareusinganelectricblastcontrol,

NOTICE

NOTICE NOTICE

Makesurenoelectricalconnectionswill

beexposedtowater.Exposuretowater

couldcauseashortcircuitanddamagethe

equipment.

334667G 13

Operation

Setting

Setting Setting

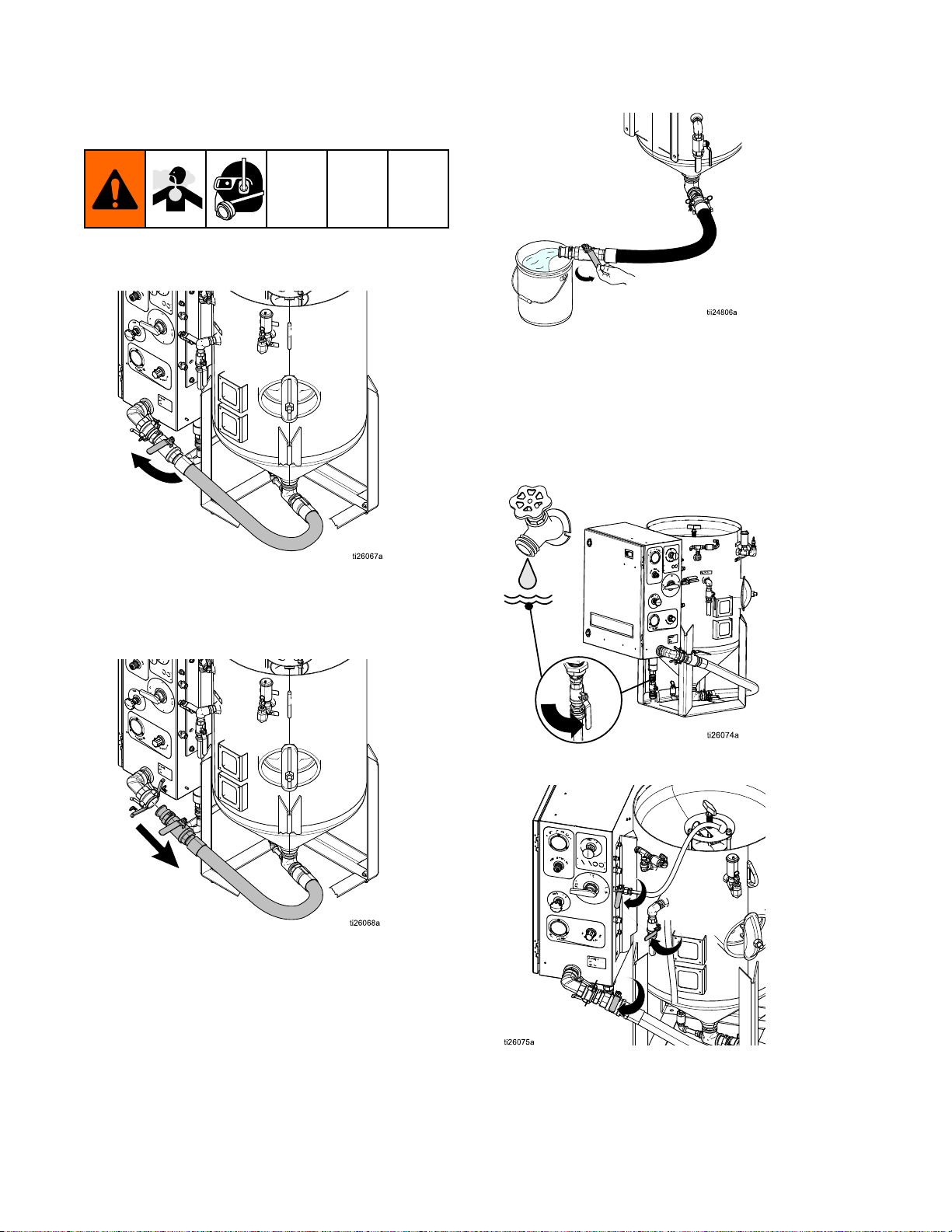

1.Disconnecttheabrasivehoseatthecamand

Up

the

Up Up

groovewiththeabrasiveballvalveclosed.

Equipment

the the

Equipment Equipment

3.Reconnecttheabrasivehose.

4.Disconnectthepumpinlethoseandushthe

watertanktoremoveanyremainingdebris.

Reconnectthepumpinlethose.

5.Fillthewatertankonlywithfreshwater,then

opentheinletballvalve.

NOTE:

NOTE: NOTE:

(especiallyunderpressure),releasingthecam

andgroovewiththeballvalveopenwillcausean

unintentionalreleaseofabrasive.

2.Flushwaterthroughthepotandoutthe

disconnectedabrasiveballvalvebeforellingthe

potwithwaterandabrasive.

Ifthepotcontainswaterandabrasive

6.Closetherinse,dump,andabrasiveballvalves.

14

334667G

Operation

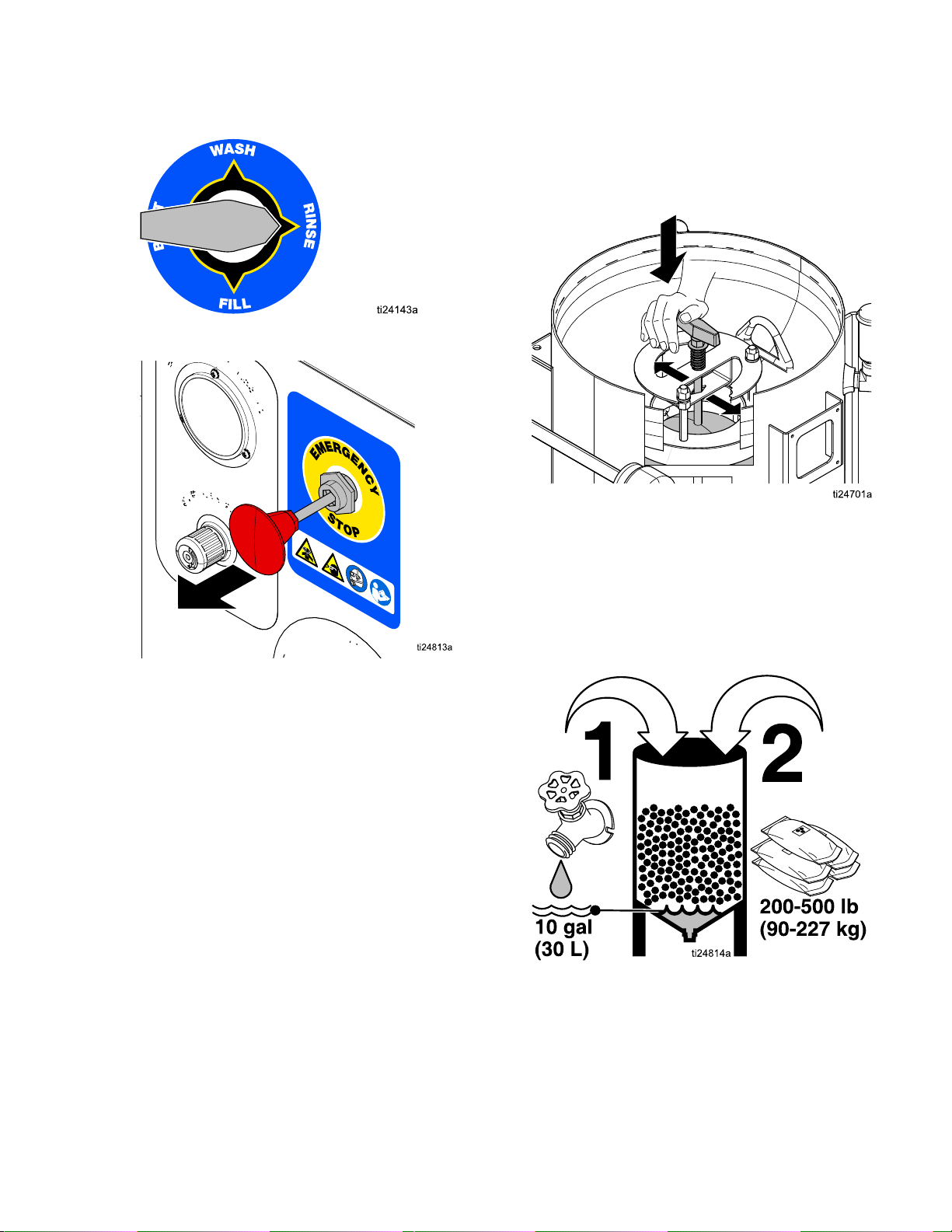

7.TurntheselectorvalvetoRINSE.

8.DisengagetheEmergencyStop.

NOTE:

NOTE: NOTE:

EmergencyStopisdisengaged.

Thewaterpumpwillnotworkunlessthe

9.Alignthepop-uphandlewiththepinslot,and

thenrmlypushandturnthehandle90°afterthe

pinisbelowthebracketslot.Properengagement

ofthepinwillholdthepop-updownuntilitis

released.

10.Add10gallons(30liters)offreshwaterto

thepot.Wearappropriatepersonalprotective

equipment,includinganappropriatelyt-tested

governmentapprovedrespiratorsuitableforthe

dustconditions.Addabrasivematerial(minimum

fourbags,maximumten50lb(23kg)bagsof

high-massabrasive,oreight50lb(23kg)bags

oflowmassabrasive).

11.Useagardenhoseortherinsehosetowashthe

abrasiveintothepotandclearanyabrasivefrom

thepop-upandgasket.

334667G 15

Loading...

Loading...