Page 1

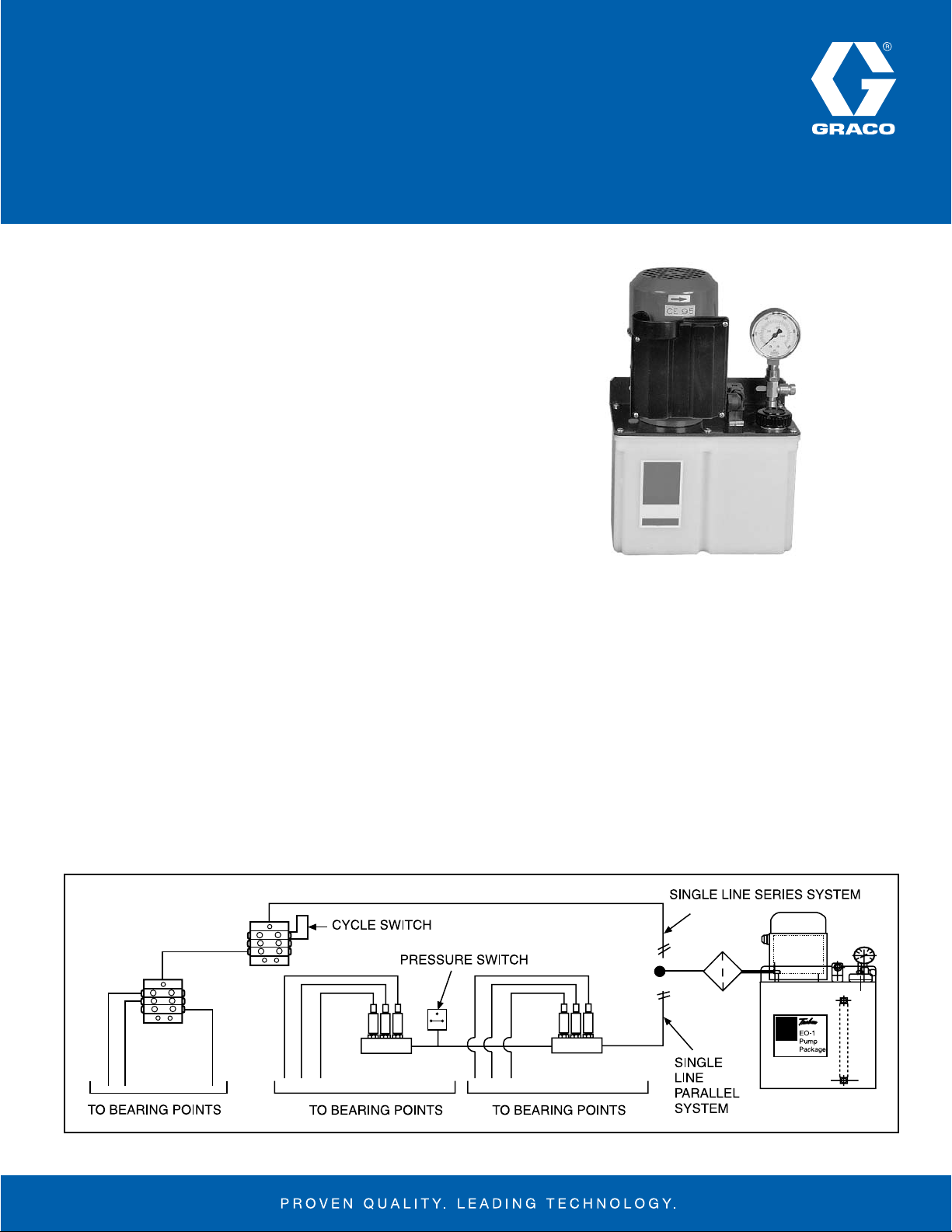

EO-1 Pump Packages

DESCRIPTION

EO-1 is a versatile series of pumping units designed for use with

virtually any type of intermittent lube system requiring oil flow up

to 12 in3/min (200 cc/min). Each of these lube packages consists of

a 115 or 230 volt AC, 50/60 Hz, single phase electric motor direct

coupled to a gear pump and mounted on a steel or plastic reservoir.

A wide range of reservoir sizes are available and all are equipped

with a low level switch as standard. These pump assemblies are

rated for service up to 580 psi (40 bar). See "Specifications" for

additional details.

FEATURES

Built in vent valve permits use with single line parallel •

systems.

And adjustable internal relief protects pump from excessive •

pressures. Factory set at 580 psi (40 bar).

OPERATION

Reservoir with removable covers, sized at 0.8, 1.6, 2.0 and 3.2 •

gallons (3, 6 and 12 liters).

Reservoir has a visual level gauge, pressure gauge and filler/•

strainer with screw on cap.

Motor and low level switch meet EEC requirements (CE Mark •

compliance).

The motor/pump assembly on an EO-1 pump package runs

whenever power is applied. On/off cycles are achieved by using an

optional timer that has user selectable off and on times or control

can be via the machine PLC where available and desired.

APPLICATIONS

The EO-1 is ideal for small to medium size series progressive of

parallel systems requiring intermittent metered lubrication with an

electrically driven pump. Combined with Trabon series progressive

divider valves, LubriSystem Injectors, or Injecto-Flo Piston

Distributors, the EO-1 can be operated on a timer, cycle switch, or

pressure switch controlled cycle for precision lubrication.

Figure 1

Page 2

Trabon® EO-1 Pump Packages

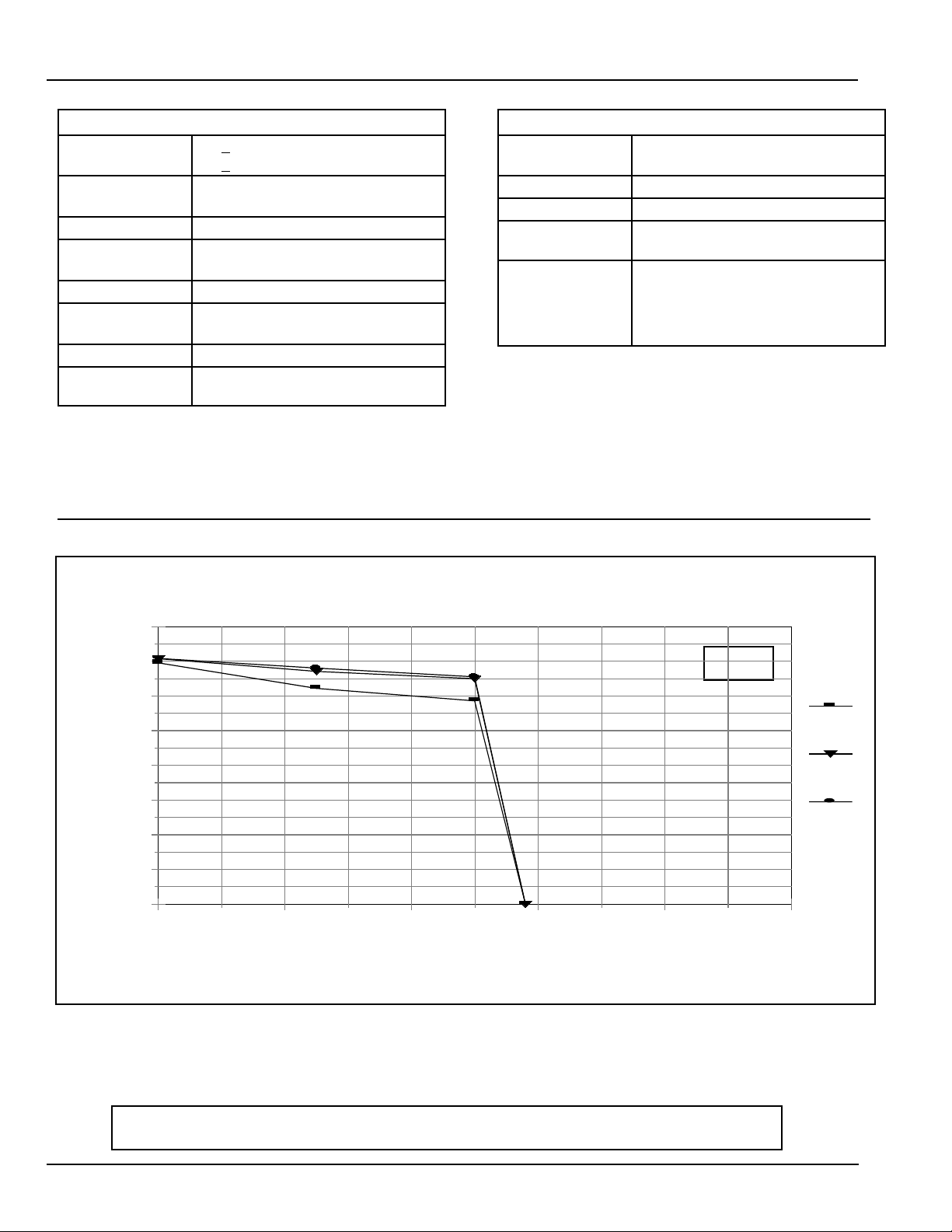

350 SUS

2500 SUS

7500 SUS

0 200 400 600 800 1000

(13.8) (27.6) (41.4) (55.2) (69.0)

(262.2) 16

(229.5) 14

(196.7) 12

(163.9) 10

(131.1) 8

(98.3) 6

(65.6) 4

(32.8) 2

0

Output (in3/Min.) (cc/Min.)

SPECIFICATION

Motor Voltage 115 + 10% VAC, 50/60 Hz, 1ø

230 + 10% VAC, 50/60 Hz, 1ø

Current Consumption 4.3A in-rush, 2.15A running @ 110 VAC, 1ø

1.9A in-rush, 0.9A running @ 220 VAC, 1ø

Motor Power 1/12 HP

Motor Speed 1680 RPM @ 60 Hz, 1ø

1340 RPM @ 50 Hz, 1ø

Pump Flow Rate 12 in

Pressure Relief valve protected 145-650 psi (10-45 bar)

Oil Viscosity ISO 50-1500 (SUS 250-5000)

Operation Intermittent, 20% Duty Cycle @ max pressure

3

/min (200 cc/min), see chart below

Factory set @ 580 psi (40 bar)

(650 psi)

L12605

Low Level Switch 10 watt @ 110/220 VAC, 50/60 Hz, 1 pH

Contacts (normal closed, held open)

Suction Strainer 100 mesh screen

Pressure Gauge 0-850 psi (0-60 bar)

Electrical

Connections

Reservoir Material

Translucent Plastic 1 gallon polypropylene

Metal Painted steel with guarded glass level tube

Wire terminals in motor junction box, screw

terminals in Low Level Switch connector

2 gallon glass filled nylon 6-6

Test oils = Mobile DTE Light - 158 SUS @ 1000F (350 SUS @ 700F), Mobilgear 629 - 750 SUS @ 1000F

(2500 SUS @ 700F), Mobilgear 634 - 2337 SUS @ 1000F (7500 SUS @ 700F)

EO-1 PUMP

OUTPUT -VS- BACKPRESSURE

BACKPRESSURE PSI (BAR)

Figure 2

RELIEF VALVE

SET AT 580 PSI

Page 2

Page 3

Trabon® EO-1 Pump Packages

W2

U2 V2

U1

V1

W1

FA N

SHAFT

L12605

INSTALLATION DATA

Mounting

The entire lube package is installed with two 1/4" screws that pass

through holes in the mounting flange at the top of the reservoir.

Mounting dimensions are given in Figure 3 and Table 1.

FRONT

A

B

Table 1

RESERVOIR

SIZE

.8 Gal. (3L) Plastic 12.76 (324) 7.25 (184)

1.6 Gal. (6L) Plastic 16.50 (419)

1.6 Gal. (6L) Metal 16.44 (4.18)

3.2 Gal. (12L) Metal 16.44 (418)

A

DIM

B

DIMC DIMD DIME DIM

11.00

(279)

10.94

(278)

10.94

(278)

5.31

(135)

5.31

(135)

5.91

(150)

7.76

(197)

7.28

(185)

7.28

(185)

7.28

(185)

8.21

(209)

9.06

(230)

9.06

(230)

9.13

(232)

9.13

(232)

EO-1

Pump

Package

TOP

6MM TUBE

(M12 X 1)

DISCHARGE

PORT

MOUNTING HOLE

CONFIGURATION

6.89

(175)

6.30

(160)

Figure 3.

E

RELIEF VALVE ADJUSTMENT

FILL CAP

LOW LEVEL

SIDE

C

D

Electrical Hookup

Figure 4 is a simplified schematic for the entire pumping unit. The

electrical hookups are shown in Figures 5a, 5b and 5c. Wiring to

the motor and switch should be with 16 AWG stranded wire and

insulation rated for 115/230 VAC and 1050C.

Figure 4.

VENT VALVE

GAUGE

M

LOW LEVEL

SYSTEM SCHEMATIC

PRESSURE

RELIEF VALVE

LUBE

OUTLET

MOTO TECHNICA 1 PH MOTORS

Figure 5b

INPUT POWER

GND

Figure 5a

CANTONI & ABB MOTORS

FAN

CAPACITOR

U2

Z2

LOW LEVEL SWITCH WIRING

SCHEMATIC

Z1

U1

Figure 5C

COMMON

NC

Page 3

Page 4

ORDERING INFORMATION

Description Part No. Old Part No.

0.8 gallon (3 liter) Plastic Reservoir, 110V 562837 126-400-010

0.8 gallon (3 liter) Plastic Reservoir, 220V 24B427 126-400-020

1.6 gallon (6 liter) Plastic Reservoir, 110V 562839 126-400-030

1.6 gallon (6 liter) Plastic Reservoir, 220V 562840 126-400-040

1.6 gallon (6 liter) Metal Reservoir, 110V 562843 126-400-050

1.6 gallon (6 liter) Metal Reservoir, 220V – 126-400-060

3.2 gallon (12 liter) Metal Reservoir, 110V 562844 126-400-070

3.2 gallon (12 liter) Metal Reservoir, 220V 24B429 126-400-080

NOTE: Motor voltages are 50/60 Hz and single phase.

SPARE PARTS ORDERING INFORMATION

Description Part No. Old Part No.

Adjustable Relief Valve 556015 126-410-007

Gear Pump Only 556013 126-410-005

Low Level Switch Assembly, 0.8 gallon 122117 126-410-013

Low Level Switch Assembly, 1.6/3.2 gallon 556016 126-410-009

Suction Strainer 556014 126-410-006

Motor

110 VAC 556011 126-410-000

220 VAC 556012 126-410-001

Pressure Gauge, 0-850 psi (0-60 bar) – 126-410-011

Adapter, M12 x 1(M) x 1/4 NPTF (FM) – 435-702-471

MAINTENANCE INFORMATION

Normally, the only maintenance required on EO-1 packages is filling the reservoir, and cleaning the suction strainer. Use only fresh,

uncontaminated oil (ISO 18/14 cleanliness level) to fill the reservoir. Check the suction strainer annually, or more often if the pump is becoming

noisy (cavitating) between cleaning. The suction strainer is accessed by removing the reservoir cover. It is also a good idea to periodically verify

pump operation (lube delivery), the calibration of the timer settings and the actuation depth of the low level switch.

Graco endorses the SAE recommendation of ISO 18/14 (ISO 4406)

oil cleanliness for most bearing applications. Some high speed

bearings may require cleaner oil. Consult the bearing manufacturer for

recommendation.

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Contact us today!

To receive product information or talk with a Graco representative,

call 800-533-9655 or visit us online at www.graco.com.

©2006-2009 Graco Inc. Form No. L12605 Rev. B 1/09 Printed in U.S.A. All other brand names or marks are used for identification purposes and are trademarks of their respective owners. All written and

visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

Loading...

Loading...