Page 1

Instructions - Parts

Compact Dyna-Star

Electric Pump 35 lb

®

3A6998C

(5 Gallon) Pail Kit

For adapting an Electric Compact Dyna-Star Pump for use with a 35 lb (5 gallon) bucket.

For professional use only.

Not approved for use in explosive atmospheres or hazardous (classified) locations.

Assembly and use of the 35 lb

(5 Gallon) pail option for models

CD1030, CD1031, CD1032, CD1130,

CD1131, CD1132, CD1231, CD1332

Important Safety Instructions

Read all warnings and instructions in

this manual and in the Compact

Dyna-Star Electric Pump instruction

manual before using the equipment.

Save all instructions.

EN

Related Manuals

3A6941 - Compact Dyna-Star Electric Pump Manual

3A6932 - Compact Dyna-Star Auto-Fill Shut Off Kit

3A7035 - Compact Dyna-Star Pump Cable

Page 2

Contents

Contents

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Air Purge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Initial Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 8

Change the Grease Bucket . . . . . . . . . . . . . . . . . . . 9

When Grease Bucket is Empty....................... 9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 3A6998C

Page 3

Installation

Installation

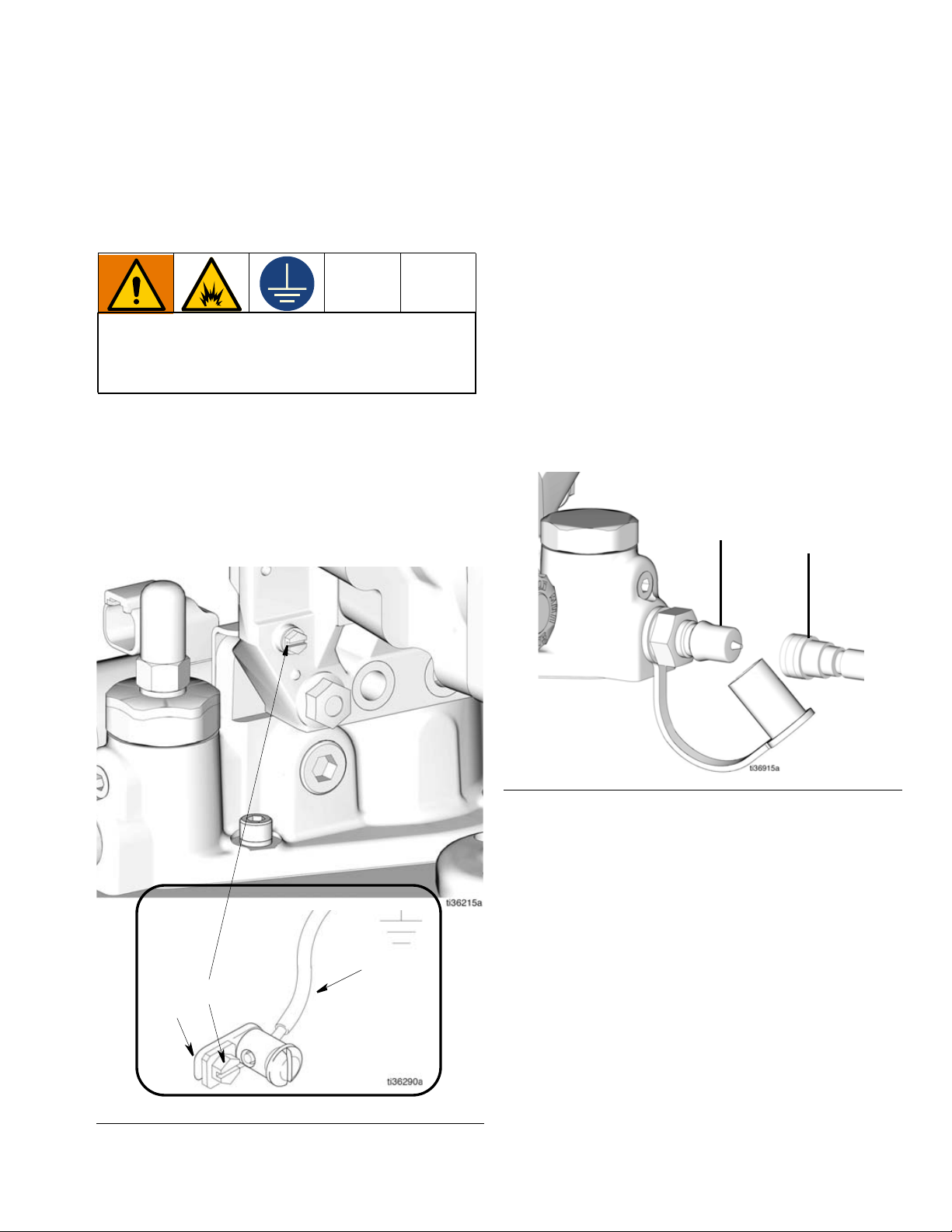

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes

to ignite or explode. Grounding provides an escape

wire for the electric current.

To ground the pump: Remove the ground screw (Z)

located on the back of the gear box and insert it

through the eye of the ring terminal (W) at end of

ground wire (Y). Fasten the ground screw (Z) back onto

the pump and tighten securely. Connect the other end

of the ground wire (Y) to a true earth ground (FIG. 1). To

order a ground and wire clamp, order Part 222011.

Reference numbers used in the following instructions

correspond to the Parts illustration on page 10. Parts

identified with an alpha character are user provided or

already installed components.

Air Purge

There is air located between the pump tube and the

tube-in-tube. Remove this air by filling it with grease to

prime the pump. If this is not done, the pump may lose

priming during operation.

1. Connect the refill pump to the fill coupler (FIG. 2).

Fill Coupler

Refill Pump

FIG. 2

Y

Z

W

FIG. 1

3A6998C 3

Page 4

Installation

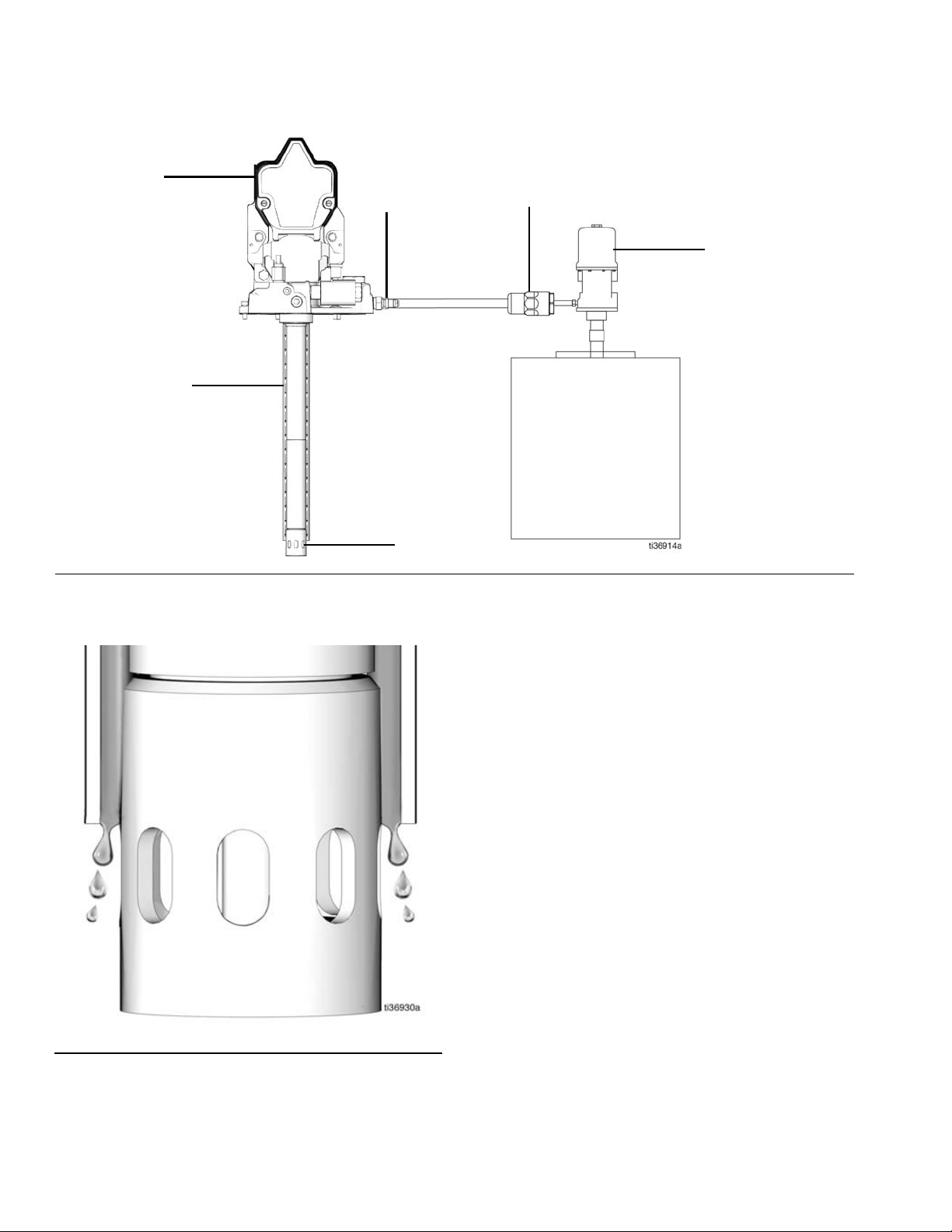

Tube-in-tube

Pump

Fill Coupler

Refill Filter

Refill Pump

Pump Tube

FIG. 3

2. Run the refill pump until grease comes out of the

bottom of the tube-in-tube (FIG. 3 and FIG. 4).

1

FIG. 4

4 3A6998C

Page 5

Installation

Initial Set-Up

1. Unpack the kit.

2. Remove and discard the cover from the grease

bucket (a) (user supplied).

3. Place the follower plate (5), top side up (label facing

upward), on top of the grease (FIG. 5).

4. Grease the o-ring at the center of the follower plate

(FIG. 5).

5. Firmly press the follower plate down into the grease

to remove all air pockets (FIG. 5).

o-ring

5

a

6. Place the drum cover (1) on top of the follower plate

(5) (FIG. 6).

1

5

FIG. 6

7. Place the gasket (2) over the center of the drum

cover (1) and align the holes (FIG. 7).

FIG. 5

2

1

FIG. 7

3A6998C 5

Page 6

Installation

8. Install the pump (7) on top of the cover, placing it

through the gasket and drum cover(1) (FIG. 8).

7

FIG. 8

9. Align the four washers (8) and four screws (3) with

the pump, gasket and cover (FIG. 9). Use a wrench

to tighten securely.

10. Install the thumb screws (4) into the cover (1) and

tighten securely (FIG. 10).

4

1

1

FIG. 10

11. Remove the bolts and cover from the pump (7) (FIG.

11).

FIG. 9

7

3

8

FIG. 11

6 3A6998C

Page 7

Installation

12. Align the slot in the handle with the key in the hole

on the back of the pump (7), then place the handle

(6) into the hole and key (FIG. 12).

6

7

FIG. 12

13. Secure the handle (6) using the screw (6) and

tighten securely (FIG. 13).

14. Replace the cover on the front of the pump (7), and

secure with the two bolts (FIG. 14).

7

FIG. 14

15. Connect the pump (7) to the main power source.

6

16. For additional information and instructions, refer to

the Compact Dyna-Star Electric Pump Instruction

Manual.

FIG. 13

3A6998C 7

Page 8

Installation

Pressure Relief Procedure

F

WARNING

PRESSURIZED FLUID HAZARD

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop pumping and before

cleaning, checking or servicing the equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the

work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and

burns.

To relieve pressure in the system, use two wrenches

working in opposite directions on the pump outlet

fitting to slowly loosen the fitting only until the fitting is

loose and no more lubricant or air is leaking from the

fitting. (FIG. 15).

FIG. 15

8 3A6998C

Page 9

Change the Grease Bucket

Change the Grease Bucket

NOTE: The pump does not have to be removed from

the cover to change the empty grease bucket.

When Grease Bucket is Empty

Ensure that all power sources are disconnected

before removing the cover.

1. Disconnect the pump (7) from the main power

source. Do not disconnect grounding.

2. Relieve pressure following the Pressure Relief

Procedure, page 8.

3. Loosen the thumb screws (4).

4. Remove the drum cover (1), pump (7) assembly and

follower plate from the empty bucket and set aside.

5. Remove the empty bucket (a) and discard

according to local regulations.

8. Replace the drum cover (1) and pump assembly (7)

on the new bucket, and secure with the thumb

screws (4), and tighten securely (FIG. 17).

7

1

4

FIG. 17

6. Remove and discard the cover from the new grease

bucket (a) (user supplied).

7. Place the follower plate (5), top side up, into the

grease and firmly press on it to remove all air

pockets (FIG. 16).

5

9. Reconnect the pump (7) to the main power source.

FIG. 16

3A6998C 9

Page 10

Parts

Parts

6

7

3

8

2

4

Part No./Description

Ref. Part Description Qty.

1 ◆ Drum cover

2 ◆ Gasket

3 ◆ Screws

4 ◆ Thumb screws

5 25P496 Follower plate

6 287072 Handle with screw

7 Pump

8 ◆ Washers

1

5

1

1

4

3

1

1

1 See manual 3A6941 for pump parts.

4

◆Included in Drum Cover Kit 25R314

10 3A6998C

Page 11

California Proposition 65

California Proposition 65

WARNING: This product can expose you to chemicals known to the State of California to

cause cancer and birth defects or other reproductive harm. For more information, go to

www.P65warnings.ca.gov.

3A6998C 11

Page 12

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2019, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6998

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

Revision C,

February 2021

Loading...

Loading...