Page 1

Instructions-Parts

ChemSafe™ 205

Air-Operated

1/4–inch hig

Not approved for use in European explosive atmosphere locations.

100 psi (0.7 MPa, 7.0 bar) Maximum Air

Supply Pressure

100 psi (0.7 MPa, 7.0 bar) Maximum

Fluid Working Pressure

h purity pump for industrial applications.For professional use only.

Important

Read all warnings and instructions in this manual. Save these

instructions.

Safety Instructions

Diaphragm Pump

334792E

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Warnings ........................................................... 3

Configuration Number Matrix............................... 6

Installatio

Operation........................................................... 13

Maintenance ...................................................... 15

n.......................................................... 8

General Info

Tighten Fast

Tips to Reduc

Mount The Pu

Ground The S

Air Lines...................................................... 10

Air Exhaust

Fluid Suppl

Fluid Outl

Tighten Fasteners........................................ 13

Flush the Pump Before First Use .................. 13

Start and Adjust the Pump............................ 13

Pressure Relief Procedure............................ 14

Pump Shutdown .......................................... 14

Maintenance Schedule................................. 15

Lubrication................................................... 15

rmation ..................................... 8

eners........................................ 8

e Cavitation............................. 8

mp ......................................... 9

ystem ..................................... 10

Ventilation ................................. 11

y Line ......................................... 12

et Line........................................... 12

Tighten Threaded Connections..................... 15

Flushing and Storage ................................... 15

Troubleshooting.................................................. 16

Repair................................................................ 18

Disassemble

Disassemble

Reassemble

Reassemble

Torque Instructions............................................. 22

Notes................................................................. 23

Parts.................................................................. 24

Kits.................................................................... 26

Dimensions ........................................................ 27

Performan

Technical Data ...................................................29

Graco Standard ChemSafe Pump

ce Charts............................................ 28

Warranty............................................... 30

the Fluid Section...................... 18

the Center Section ................... 19

the Center Section.................... 19

the Fluid Section....................... 20

2

334792E

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific

risks. When these symbols appear in the body of this manual or on warning labels, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where applicable.

WARNING

FIRE AND EX

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

•Keepwork

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

•Useonly

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use

equipment until you identify and correct the problem.

• Keepaw

• Route exhaust away from all ignition sources. If diaphragm ruptures, fluid may be exhausted

with air.

c charge may build up on plastic parts during cleaning and could discharge and ignite

Stati

flamma

• Clean plastic parts only in well ventilated area.

• Do not

• Do not operate electrostatic guns in equipment work area.

ble vapors. To help prevent fire and explosion:

PLOSION HAZARD

area free of debris, including solvent, rags and gasoline.

grounded hoses.

orking fire extinguisher in the work area.

cleanwithadrycloth.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin

and cause serious injury.

low the Pressure Relief Procedure when you stop spraying/dispensing and before

•Fol

aning, checking, or servicing equipment.

cle

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

334792E 3

Page 4

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can ca

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed

system compo

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

•Turnoffall

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

•Makesure

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kin

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

THERMAL

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure

due to the thermal expansion. Over-pressurization can result in equipment rupture and serious

injury.

use death or serious injury.

the maximum working pressure or temperature rating of the lowest rated

nent. See Technical Data in all equipment manuals.

equipment and follow the Pressure Relief Procedure when equipment is not in use.

all equipment is rated and approved for the environment in which you are using it.

k or over bend hoses or use hoses to pull equipment.

EXPANSION HAZARD

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

TIC PARTS CLEANING SOLVENT HAZARD

PLAS

Many solvents can degrade plastic parts and cause them to fail, which could cause serious

injury or property damage.

• Use only compatible water-based solvents to clean plastic structural or pressure-containing

parts.

•SeeTechnical Data in this and all other equipment instruction manuals. Read fluid and

solvent manufacturer’s MSDSs and recommendations.

4

334792E

Page 5

WARNING

TOXIC FLUID OR FUMES HAZARD

Warnings

Toxic fluids o

inhaled, or s

• Read MSDSs to know the specific hazards of the fluids you are using.

• Route exhaus

the air.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid

severe burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

•Protect

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

r fumes can cause serious injury or death if splashed in the eyes or on skin,

wallowed.

t away from work area. If diaphragm ruptures, fluid may be exhausted into

ive eyewear, and hearing protection.

334792E 5

Page 6

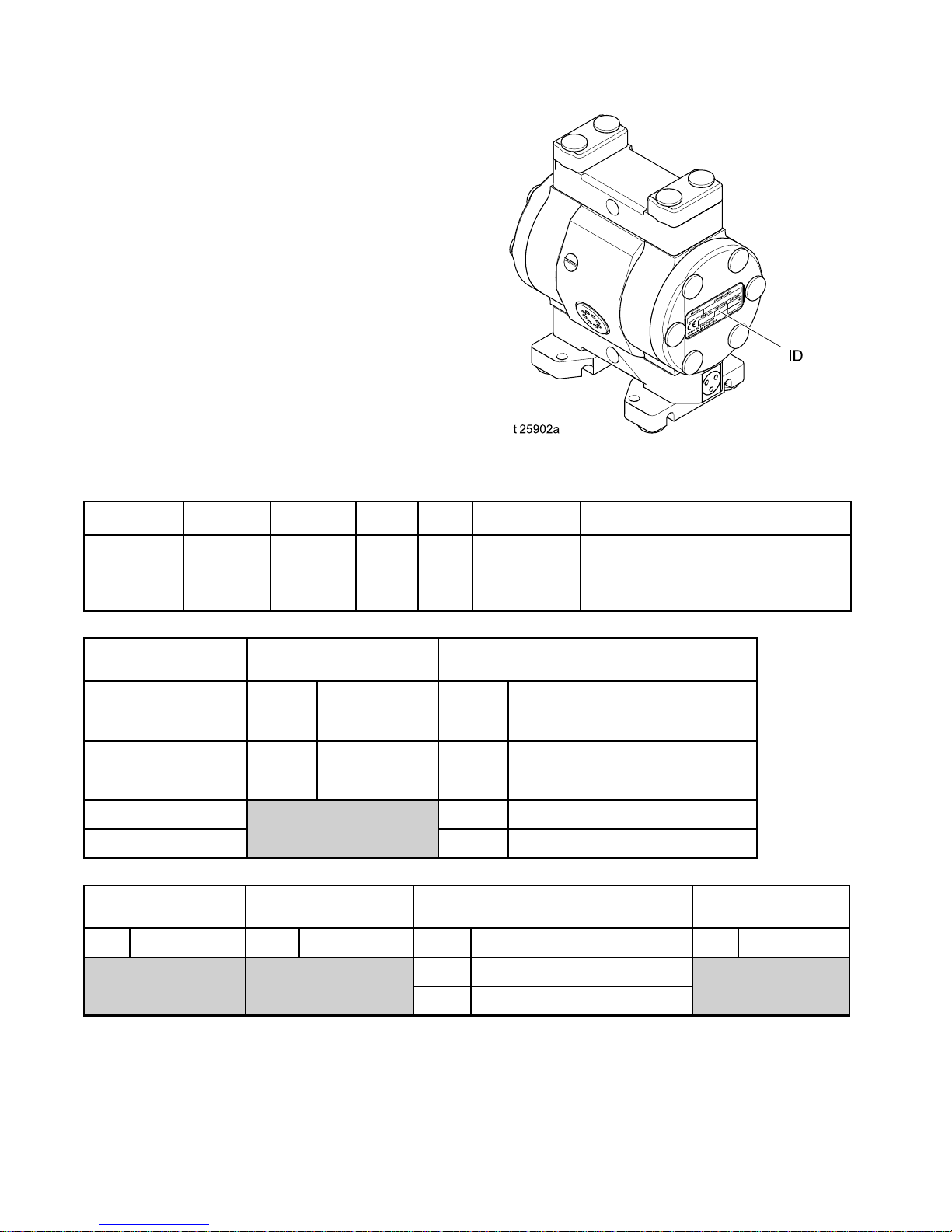

Configuration Nu

mber Matrix

Configuration

Number

Matrix

Check the iden

Configuratio

following ma

pump.

Sample Con

205PT P01A PT3

Pump

Model

tification plate (ID) for the

n Number of your pump. Use the

trix to define the components of your

figuration Number:

Center

Section

and Air

Valve

Fluid

Covers

and

Manifol

205PT-P01APT3PTPTPOPT

PT PT

Seats

ds

Balls Diaphrag

PO

PT

ms

Manifold and Seat Seals

Pump

205PT

1/4 in.PTFE

205 UH

. UHMWPE

1/4 in

Seat Material

PTFE

PT

Center Section and Air

Valve Material

P01A

P03A

Ball Material Diaphragm Material

PT

Polypropylene

center with npt

air inlet

ropylene

Polyp

rwith

cente

ir inlet

bspt a

PTFE

Fluid Covers and Manifolds

PT3

PT4

UH3

UH4

BN

EP

PO

PTFE, npt

PTFE,

UHMWPE, npt

UHMWPE, bspt

N

Buna

EPDM

E Overmolded

PTF

bspt

Manifold and Seat

Seal Material

PTFE

PT

6 334792E

Page 7

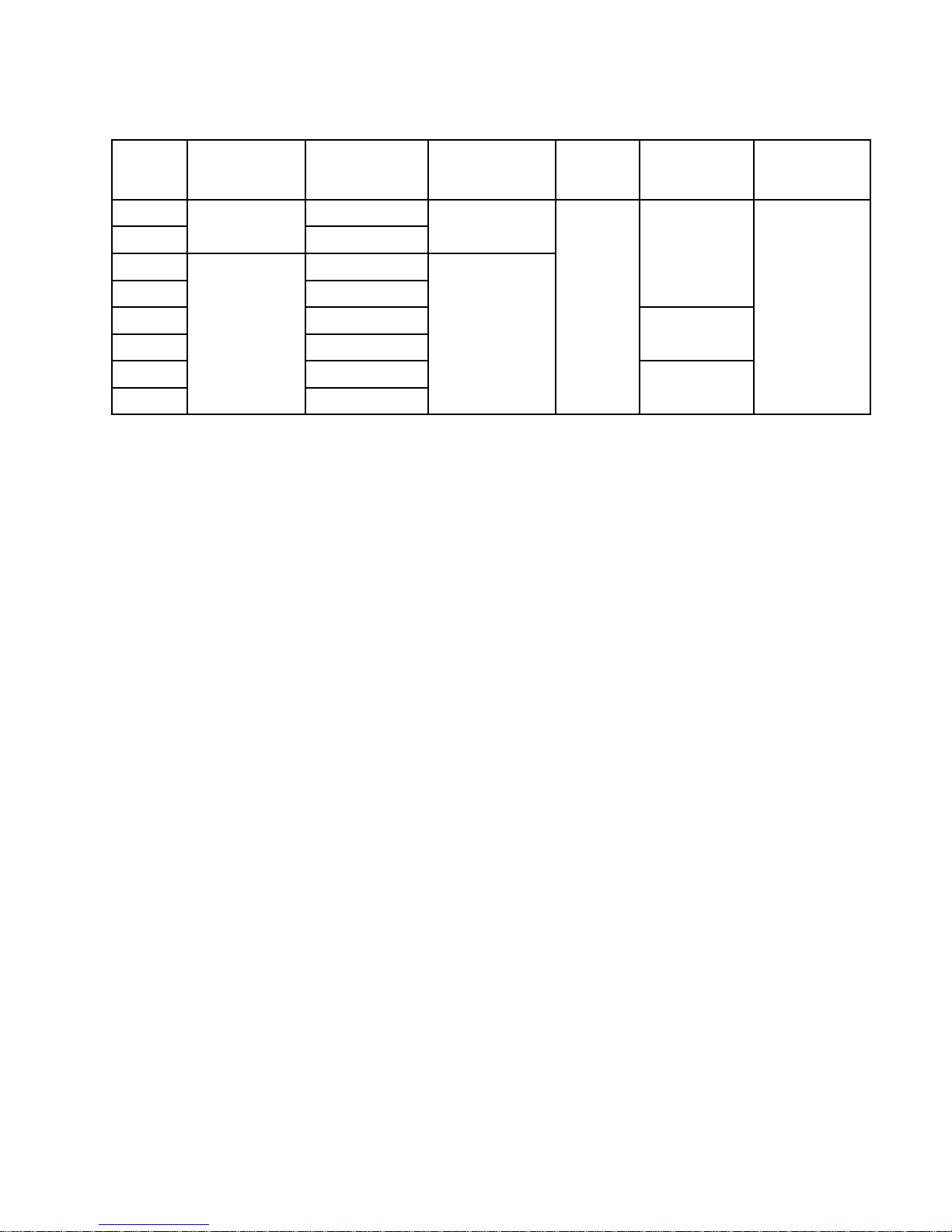

Models

Configuration Nu

mber Matrix

Model Pump

24X430

24X429

24X511

24X509

24X532

24X533

24X508

24X507

1/4 in. PTFE

1/4 in.

UHMWPE

Air & Fluid

Connection

Threads

bspt

npt

bspt

npt

bspt

npt

bspt

npt

Fluid Covers &

Manifolds

PTFE

UHMW

Balls &

Seats

PTFE

Diaphragm

PTFE/EPDM

Overmolded

EPDM

Buna N

Manifold Seal

PTFE

334792E

7

Page 8

Installation

Installation

General Information

The Typical I

selecting an

your Graco di

system to sui

Graco Parts

are adequat

system’s re

Reference letters in the text, for example (A), refer to

the callouts in the figures.

Variations in color between the plastic components

of this pump are normal. Color variation does not

affect the performance of the pump.

Storage: P

upon deli

Flushing

nstallation shown is only a guide for

d installing system components. Contact

stributor for assistance in planning a

t your needs. Always use Genuine

and accessories. Be sure all accessories

ely sized and pressure rated to meet the

quirements.

umps that are not put into operation

very must be stored appropriately. See

and Storage, page 15.

Tighten Fasteners

Before m

first tim

Remove

Torque

Replac

operat

pump ha

in ther

or if t

tempe

ounting and using the pump for the

e, check and retorque all external bolts.

all protective bolt covers (37). Follow

Instructions, page 22, to tighten all bolts.

e the bolt covers (37). After the first day of

ion, retorque the bolts. Retorque the bolts if the

s been idle for an extended time, been used

mal cycling applications, been disassembled,

here is a large difference between environmental

ratures and fluid temperatures.

Tips to Reduce Cavitation

Cavitation i

collapse of b

or excessive

including pi

balls, and s

the pump. Ca

both result

Cavitation depends on the vapor pressure of the

pumped liquid, the system suction pressure, and the

velocity pressure. It can be reduced by changing any

of these factors.

1. Reduce vapor pressure: Decrease the

temperature of the pumped liquid.

2. Increase suction pressure:

a. Lower the

b. Reduce t

c. Increas

3. Reduce

the pum

Pumped liquid viscosity is also very important but

normally is controlled by factors that are process

dependent and cannot be changed to reduce

cavitation. Viscous liquids are more difficult to pump

and more prone to cavitation.

n an AODD pump is the formation and

ubbles in the pumped liquid. Frequent

cavitation can cause serious damage,

tting and early wear of fluid chambers,

eats. It may result in reduced efficiency of

vitation damage and reduced efficiency

in increased operating costs.

installed position of the pump

relative

piping.

length t

fittings

to the liquid level in the supply.

he friction length of the suction

Remember that fittings add friction

o the piping. Reduce the number of

to reduce the friction length.

e the size of the suction piping.

liquid velocity: Slow the cyclic rate of

p.

8 334792E

Graco recommends taking all the above factors

into account in system design. To maintain pump

efficiency, supply only enough air pressure to the

pump to achieve the required flow.

o distributors can supply site specific

Grac

estions to improve pump performance and

sugg

ce operating costs.

redu

Page 9

Mount The Pump

To avoid serious injury from toxic fluid or fumes:

• Ventilate to a remote area. The pump

exhaust air may contain contaminants. See

Air Exhaust Ventilation, page 11.

• Never move or lift a pump under pressure. If

dropped, the fluid section may rupture. Always

follow the Pressure Relief Procedure, page 14,

before moving or lifting the pump.

1. Mount the pump so the exhaust port remains

clear of the production area. Exhaust air may

contain debris and condensation from the air

supply and air chamber.

Installation

2. Be sure the mounting surface can support the

weight of the pump, hoses, and accessories, as

well as the stress caused during operation.

3. For all mountings, be sure the pump is secured

with screws through the mounting feet. Always

mount the pump upright.

4. Make sure the surface is flat and that the pump

doesn’t wobble.

5. For ease of operation and service, mount the

pump so air inlet, fluid inlet and fluid outlet ports

are easily accessible.

ssories/Components Not Supplied

Acce

A Air supply line J Air inlet port

B

C Air filter/regulator assembly

D

E

F

GF

H

d-type master air valve (required

Blee

our pump)

for y

Master air valve (to isolate the

filter/regulator for service)

Grounded flexible fluid supply line

Fluid drain valve (required for your

pump)

luid shutoff valve

rounded, flexible fluid outlet line

G

334792E 9

em Components

Syst

K

L Fluid inlet port

M Fluid outlet port

N

ust port and muffler

Exha

Mounting feet

Page 10

Installation

Ground The Sys

The equipment must be grounded to reduce the

risk of static sparking. Static sparking can cause

fumes to ignite or explode. Grounding provides an

escape wire for the electrical current.

• Always ground the entire fluid system as

described below.

• The pumps are not conductive. Any system

used to pump flammable fluids must be properly

grounded.

• Follow your local fire codes.

Before operating the pump, ground the system as

explained below.

• Pump: Always ground the entire fluid system by

making sure the fluid has an electrical path to a

true earth ground.

• Air and fluid hoses: Use only flexible grounded

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity.

• Air compressor: Follow manufacturer’s

recommendations.

• Fluid supply container: Follow local code.

• Solvent pails used when flushing: Follow local

code. Use only conductive metal pails, placed

on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or

cardboard, which interrupts grounding continuity.

tem

Air Lines

1. Install an air

the fluid press

thesameasthe

2. Locate a bleed

the pump and u

sure the valv

and located d

Trapped air can cause the pump to cycle

unexpectedly, which could result in serious

injury from splashing.

3. Locate ano

from all a

them duri

4. An air lin

moisture

5. Install a

the acce

pump air

ID.Ifah

use a lar

regulator and gauge (C) to control

ure. The fluid stall pressure will be

setting of the air regulator.

-typemasterairvalve(B)closeto

se it to relieve trapped air. Be

e is easily accessible from the pump

ownstream from the regulator.

ther master air valve (D) upstream

ir line accessories and use it to isolate

ng cleaning and repair.

e filter (C) removes harmful dirt and

from the compressed air supply.

grounded, flexible air hose (A) between

ssories and the 1/8 npt(f) or 1/8 bspt

inlet. Use a hose with a minimum 1/4 in.

ose longer than 10 ft. (3 m) is required,

ger diameter hose.

Check your system electrical continuity after the

initial installation, and then set up a regular schedule

for checking continuity to be sure proper grounding

is maintained.

10 334792E

Page 11

Installation

Air Exhaust Ventilation

If pumping toxic fluids, you must vent the exhaust

away from people, animals, food handling areas,

and all sources of ignition. Follow all applicable

codes.

NOTE: Do not restrict the air exhaust port. Excessive

exhaust restriction can cause erratic pump operation.

To provide a remote exhaust:

1. Use Kit 17F610 (

separately.

2. Remove the muf

exhaust port (

3. Install the a

4. Install a gro

longer than 1

diameter hos

the hose.

5. Place a cont

linetocatc

If the diaph

will exhaus

NPT) or 17F611 (BSPT), sold

fler (U) from the pump air

K).

daptor from the kit.

unded air exhaust hose (S). If a hose

0 ft. (3 m) is required, use a larger

e. Avoid sharp bends or kinks in

ainer (T) at the end of the air exhaust

h fluid in case a diaphragm ruptures.

ragm ruptures, the fluid being pumped

t with the air.

A Air supply line

J

K Exhaust port U

Air inlet port (not visible)

S Grounded air exhaust hose

T

Container for remote air exhaust

Muffler

334792E

11

Page 12

Installation

Fluid Supply L

1. Use grounded, flexible fluid hoses (E). See

Ground The System, page 10.

2. If the inlet fluid pressure to the pump is more

than 25% of the outlet working pressure, the

ball check valves will not close fast enough,

resulting in inefficient pump operation. Excessive

inlet fluid pressure also will shorten diaphragm

life. Approximately 3–5 psi (0.02–0.03 MPa,

0.21–0.34 bar) should be adequate for most

materials.

ine

3. For maximum suction lift (wet and dry), see

Technical Data, page 29. For best results, always

install the pump as close as possible to the

material source. Minimize suction requirements

to maximize pump performance.

Fluid Outlet

1. Use grounded, flexible fluid hoses. See

Ground The System, page 10,

2. Install a fluid drain valve (F) near the fluid outlet.

3. Install a shutoff valve (G) in the fluid outlet line.

Line

2

1

334792E

Page 13

Operation

Operation

Tighten Faste

Before mounting and using the pump for the

first time, check and retorque all external bolts.

Remove all protective bolt covers (37). Follow

Torque Instructions, page 22, to tighten all bolts.

Replace the bolt covers (37). After the first day of

operation, retorque the bolts. Retorque the bolts if the

pump has been idle for an extended time, been used

in thermal cycling applications, been disassembled,

or if there is a large difference between environmental

temperatures and fluid temperatures.

Flush the P

The pump was tested in water. If water could

contaminate the fluid you are pumping, flush the

pump thoroughly with a compatible solvent. See

Flushing and Storage, page 15.

ners

ump Before First Use

Start and Adju

st the Pump

NOTICE

To avoid dama

pumped fluid

See Technic

1. Be sure the p

Ground The S

2. Check fitti

compatibl

ge to your pump, be certain that all

s are compatible with wetted parts.

al Data, page 29.

ump is properly grounded. See

ystem, page 10.

ngstobesuretheyaretight. Usea

e liquid thread sealant on male threads.

NOTICE

Do not ove

The soft p

3. Place the suction tube (if used) in fluid to be

pumped.

NOTE: If

than 25%

check va

in ineffi

rtighten fluid inlet and outlet fittings.

lastic threads can be stripped easily.

fluid inlet pressure to the pump is more

of outlet working pressure, the ball

lves will not close fast enough, resulting

cient pump operation.

NOTICE

Excess

diaph

4. Place the end of the fluid hose into an appropriate

container.

5. Close the fluid drain valve (F).

6. Back out the air regulator knob and open all

bleed-type master air valves.

7. If the fluid hose has a dispensing device, hold

it open.

8. Slowly increase air pressure with the air regulator

until the pump just starts to cycle. Allow the

pump to cycle slowly until all air is pushed out of

the lines and the pump is primed.

NOT

ju

no

9. If

th

10.Cl

ive fluid inlet pressure can reduce

ragm life.

E: Use lowest possible air pressure to prime,

st enough to cycle the pump. If the pump does

t prime as expected, turn air pressure DOWN.

you are flushing, run the pump long enough to

oroughly clean the pump and hoses.

ose the bleed-type master air valve.

334792E 13

Page 14

Operation

Pressure Reli

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is relieved manually. To help prevent serious

injury from pressurized fluid, such as splashing

in the eyes or on skin, follow the Pressure Relief

Procedure when you stop pumping and before you

clean, check, or service the equipment.

1. Shut off the air supply to the pump.

ef Procedure

2. Open the dispensing valve, if used.

3. Open the fluid drain valve to relieve fluid

pressure. Have a container ready to catch the

drainage.

Pump Shutdow

At the end of the work shift and before you check,

adjust, clean, or repair the system, follow the

Pressure Relief Procedure, page 14.

n

4

1

334792E

Page 15

Maintenance

Maintenance

Maintenance Schedule

Establish a p

based on the p

maintenance

or leakage du

muffler may r

air lines an

performanc

reventive maintenance schedule

ump’s service history. Scheduled

is especially important to prevent spills

e to diaphragm failure. A clogged

estrict pump performance. Inspect

d muffler media regularly to maintain

e.

Lubrication

Thepumpis

to require

packings

under nor

lubricated at the factory. It is designed

no further lubrication for the life of the

. There is no need to add an inline lubricator

mal operating conditions.

Tighten Threaded Connections

Before e

and repl

threade

mounti

necess

guidel

Torque

ach use, check all hoses for wear or damage

ace as necessary. Check to be sure all

d connections are tight and leak-free. Check

ng bolts. Check bolts. Tighten or retorque as

ary. Although pump use varies, a general

ine is to retorque bolts every two months. See

Instructions, page 22.

Flushing and Storage

•Flushbefor

end of the da

equipment

•Flushatth

connector

• Use solven

wetted par

•Alwaysflu

before st

e fluid can dry in the equipment, at the

y, before storing, and before repairing

.

e lowest pressure possible. Check

s for leaks and tighten as necessary.

t that is compatible with the equipment

ts and the material being dispensed.

shthepumpandrelievethepressure

oring it for any length of time.

NOTICE

Flush the pump often enough to prevent the fluid

you are pumping from drying or freezing in the

pump and damaging it.

Storage: Pumpsmustbestoredinanenvironment

where they are clean, dry, and protected from

extreme temperatures, UV radiation, and vibration.

Graco recommends an ambient temperature range of

60°F-80°F (15°C-25°C), with a humidity level below

65%.

334792E 15

Page 16

Troubleshooting

Troubleshooting

Problem Cause Solution

Pump cycles but will not prime.

Pump cycles at stall or fails to hold

pressure at stall.

Pump will not cycle, or cycles once

and stops.

Pump is running too fast, causing

cavitation before prime.

Check valve ball is severely warn

or wedged in seat or manifold.

Seat is severely worn.

Outlet or inlet is clogged.

Inlet or outlet valve is closed.

Inlet fittings or manifolds are loose.

Manifold o-rings are damaged.

Check valve balls, seats or o-rings

are worn.

Spool valve is stuck or dirty.

Air supply pressure too low. Increase air supply pressure.

Spool valve is worn or damaged.

Check valve ball is severely worn

or wedged in seat or manifold.

Dispensing valve is clogged. Relieve pressure and clear valve.

Diaphragm is ruptured. Replace.

Lower inlet pressure.

Replace ball and seat.

Replace ball and seat.

Unclog.

Open.

Tighten.

Replace o-rings.

Replace.

Disassemble and clean air

valve. Use clean dry air.

Replace spool valve.

Replace ball and seat.

Pump operates erratically.

Air bubbles in fluid.

Exhaust air contains fluid being

pumped.

Moisture in exhaust air. Inlet air has high humidity. Use drier air supply.

Suction line is clogged.

Check valve balls are sticky or

leaking.

Diaphragm is ruptured. Replace.

Exhaust is restricted. Remove restriction.

Spool valve is damaged or worn.

Air supply is erratic. Repair air supply.

Exhaust muffler is icing.

Suction line is loose.

Diaphragm is ruptured. Replace.

Manifolds are loose, or seats or

manifold o-rings are damaged.

Diaphragm glide seals or o-rings

are damaged.

Pump is cavitating. Reduce pump speed, increase

Diaphragm is ruptured. Replace.

Inspect; clear.

Clean or replace.

Replace spool valve.

Use drier air supply.

Tighten.

Tighten manifold bolts or replace

seats and/or o-rings.

Replace.

suction hose diameter, or increase

inlet head.

16 334792E

Page 17

Troubleshooting

Problem

Pump exhausts excessive air at

stall.

Pump leaks air externally.

Pump leaks fl

uid externally.

Cause Solution

Spool valve se

als are worn or

Replace.

damaged.

Fluid covers are loose. Retorque.

Diaphragm is damaged. Replace.

Manifold fittings are loose

Retorque.

Fluid covers are loose. Retorque.

Diaphragms

are damaged.

Replace.

334792E

17

Page 18

Repair

Repair

NOTE: Before repairing the pump, follow the

Pressure Relief Procedure, page 14.

Disassemble the Fluid Section

1. Remove all bolt covers (37).

2. Usea3mmAllenwrenchtoremovethebase

plates (12) and the inlet manifold (10).

3. Remove the check seat (21) and ball (22).

Without scratching the inner bore, use a hook to

remove the inlet check cage (20).

4. Turn over the pump.

5. Usea3mmAllenwrenchtoremovetheoutlet

manifold (8) and retainer (11).

6. Without scratching the inner bore, use a hook to

remove the outlet ball retainer (19). Remove the

ball (22) and check seat (21).

7. Reattach the manifold bolts (29) to keep the fluid

cover nuts (18) aligned.

8. Remove the nuts (28) and bolts (24) using two 7

mm sockets, to hold on one side and to turn the

other. The nuts (28) will come off of one side.

Remove the bolts (24).

NOTE: The nuts are permanently affixed to one

end of the bolts.

9. Remove the fluid cover retainers (9) and the fluid

covers (6) from the body (1).

18 334792E

Page 19

Repair

Disassemble t

1. One diaphragm (25) should screw off by hand.

Slide the second diaphragm out with the shaft

(5) still attached.

2. Use the supplied tool (46) to remove the muffler

(14) from the body. Remove all muffler parts.

Inspect the mesh baffle spacers (38) and felt

mufflers (15). Replace as needed.

3. Use the supplied tool (45) to remove the sleeve

caps (3). Remove the shaft glide seal (17) and

o-ring (32) from the ID of the caps. Remove

o-ring (32) from the face of each cap. Remove

the EPDM ring (36) from the seat for each sleeve

cap (3).

4. Use an appropriate-sized socket to press out the

main and center sleeve assemblies (2 & 4).

he Center Section

Reassemble th

1. Install a plug (40) in each of the three unused

ports.

2. Install the muffler media (15 & 38) into the

muffler. Use the new felt mufflers (15‡) supplied

in the rebuild kit. Muffler parts must be placed

in the exact order shown in the illustration. Use

the supplied tool (46) to screw the muffler (14)

into the exhaust port (the port with 2 holes on the

bottom).

3. Lubricate and install an o-ring (32‡) and then the

shaft glide seal (17‡) in the ID of each sleeve cap

(3). Lubricate and install an o-ring (32‡) on the

face of each sleeve cap (3).

4. Lubricate and install an EPDM ring (36‡) into

the seat for the sleeve cap (3), in the center of

the body (1).

5. Apply medium-strength thread locker to the

threads of a sleeve cap (3). Use the tool (45) to

install it into one side of the body just until it is

flush with the surface. Do not overtighten.

e Center Section

334792E 19

Page 20

Repair

6. Turn the center section over. Spread a thin film

of lubricant evenly across the o-rings on the main

and center sleeve assemblies (2 & 4). Be careful

not to plug the air holes. Put the center assembly

(4) inside the main assembly (2), and use an

appropriate-sized socket to press the sleeve

assemblies into the body.

7. Lubricate and install an EPDM ring (36‡) into

the seat for the sleeve cap (3), in the center of

the body (1).

8. Apply medium-strength thread locker to the

threads of the second sleeve cap (3). Use the

tool (45) to install the second sleeve cap (3) into

the body. Tighten just until the cap is flush with

the surface. Do not overtighten.

9. If using new diaphragms, remove the thread

cover on each diaphragm (25†).

10. Tighten the pump shaft (5) onto one diaphragm,

hand tight only. Do not use any tools on the shaft.

11. Lubricate the shaft, then install it in the body.

Turn the diaphragm as you push it in. Then,

tighten the other diaphragm onto the shaft, hand

tight only.

5. Place a belleville washer (27) with the rounded

side toward the nut, then a flat washer (26) on

each tie bolt (24). Thread the first tie bolt (24)

through one fluid cover retainer (9), and then the

second tie bolt (24) through the other fluid cover

retainer (9). This necessary so that the first two

tie bolts come in from opposite sides to help keep

everything together before clamping.

6. Thread a fluid cover (6), the center section

assembly, the other fluid cover (6) onto the first

two tie bolts (24) and between the fluid cover

retainers (9).

Reas

1. Insert the top two fluid cover nuts (18), threaded

2. Thread the manifold bolts (29) a few turns into

3. Repeat steps 1 and 2 for the other fluid cover.

4. Install the fluid covers with the top checks toward

semble the Fluid Section

end first.

the nuts (18), just to keep the nuts from rotating.

the air inlet.

20 334792E

7. Plac

8. Pla

9. As

10.Ca

e the assembly in a clamp or vice. Tighten

e first two tie bolts (24) are exposed on each

so th

. Thread the remaining tie bolts (24) through

side

assembly.

the

ce a flat washer (26), a belleville washer (27),

a nut (28) on each tie bolt. Tighten the bolts

and

d-tight. Do not tighten to torque specification

han

.

yet

semble the bottom checks. Insert the inlet ball

tainer (20†), the ball (22†), and the seat (21†),

re

th the chamfered side down (toward the ball).

wi

refully remove the manifold bolts (29) from

e bottom of the fluid covers (6), keeping nuts

th

8) aligned.

(1

Page 21

11. Align the inlet manifold (10) on the assembly.

Orient the manifold so the inlet port is facing the

correct direction for your application (either the

same as, or the opposite from, the exhaust port).

12. Align the inlet manifold retainers (12). Place a

belleville washer (27), then a washer (26) on

each bolt. The rounded side of the belleville

washer must face toward the head of the

fastener. Install the bolts (29), just hand-tight for

now, then flip the pump over.

13. Assemble the top checks. Insert the seat (21†)

with the chamfered side up, the ball (22†), and

the outlet ball retainer (19†).

14. Carefully remove the manifold bolts (29) from

the top of the fluid covers (6), keeping nuts (18)

aligned.

15. Align the outlet manifold (8) with the dowels on

the top of the body.

16. Align the outlet manifold retainers (11). Place

a belleville washer (27), then a washer (26) on

each bolt. Install the bolts (29) hand-tight.

17. Follow Torque Instructions, page 22.

18. Replace all bolt covers (37†).

Repair

334792E

Figure 1

21

Page 22

Torque Instructions

Torque Instructions

If fluid cover or manifold bolts have been loosened,

it is important to torque them using the following

procedure to improve sealing.

3. Turn each screw by 1/2 turn or less working in a

crisscross pattern to specified torque.

4. Repeat for fluid manifolds.

NOTICE

Do not over-t

will damage t

NOTE: Alway

torquing flu

1. Remove the protective bolt covers (37) with

a screwdriver. Carefully work the screwdriver

under the lip of each cap and gently pry it off.

2. Start all fluid cover screws a few turns. Then, turn

down each screw just until head contacts cover.

Fluid Cover Screws Fluid Manifold Screws

orque. Tightening the bolts too tight

he pump.

s completely torque fluid covers before

id manifolds.

Fluid Covers 20 in-lb (2.3

Fluid

Manifolds

Assembly

Torque

N∙m)

15 in-lb (1.7

N∙m)

Re-Torque

15 in-lb (1.7

N∙m)

10 in-lb (1.1

N∙m)

2

2

334792E

Page 23

Notes

Notes

334792E 23

Page 24

Parts

Parts

1

2

4

2

uded in all Center and Fluid Section

incl

ild kits.

Rebu

Follow Torque Instructions, page 22.

icate using PFPE grease (17G558);

Lubr

334792E

Page 25

NOTE: Many parts are included in one or more kits.

Please see Kits, page 26, for the complete list of

available kits and their contents.

Parts

Ref

1 17F203

2‡ 17F590

Part Description

BODY

SLEEVE, main;

assembly

3 17F063

4‡ 17F589

CAP, sleeve

SLEEVE, center;

assembly

5‡

6

17F095

SHAFT, diaphragm

COVER, fluid

17F157 PTFE

17F163 UHMWPE

7

17F089

ADAPTER, inlet, 1/8 in.

BSPT

17F088 NPT

8

17F04

17F0

17F0

MANIFOLD, outlet

2

PTFE, BSPT

19

UHMWPE, BSPT

62

PTFE

,NPT

17F021 UHMWPE, NPT

9 17F205

10

17F043

17F020

RETAINER, fluid cover

MANIFOLD, inlet

PTFE, BSPT

UHMWPE, BSPT

17F044 PTFE, NPT

7F022UHMWPE, NPT

1

11 17F206

RETAINER, manifold

12 17F204 PLATE, base 2

13 17F192

PLUG, 1/4 in. (6 mm),

PTFE

14 17F077

15‡ 17F080

17‡ 17F196

18 17F187

CAP, muffler

MUFFLER, felt; 4–pack

SEAL, shaft; 4–pack

NUT, fluid cover,

stainless steel

19† 17F101 RETAINER, ball, outlet

(top); PTFE

20† 17F105 RETAINER, ball, inlet

(bottom); PTFE

Qty

1

1

2

1

1

2

1

1

2

1

2

2

1

1

1

8

2

2

Ref

21†

22† 17F214 BALL, check, 3/8 in.,

Part Description

--

SEAT

Qty

4

1

4–pack, PTFE

24 17F178

25†

BOLT, tie

DIAPHRAGM, 2–pack

6

1

17F207 Buna-n

17F208 EPDM

17F209

26 17F193

PTFE Overmolded

WASHER, 4 mm,

1

stainless steel, 20–pack

27 17F194

WASHER, belleville,

1

0.375 in. diameter;

50–pack

28 17F179 NUT, hex, M4 x 0.7 12

29 17F180

SCREW, cap, socket

8

head, M4 x 0.7 x 60 mm

30 17F190FEET,

31 17F197

O-RI

2–pa

32‡ 17F198

O-RI

6–p

35 17F201

O-R

3–p

36‡

37† 17F225

--

EP

PL

di

38 17F079

S

3

40 17F191

PLUG, 1/4 in. npt

rubber, 4–pack

NG, #12, EPDM,

ck

NG, #13, EPDM,

ack

ING, #21, EPDM,

ack

DM RING, 0.06 in.

UG, cap, 0.47

ameter, 20–pack

PACER, baffle, mesh;

–pack

1

1

1

2

2

1

1

3

41 17F188 PIN, 0.26 x 0.27 3

43▲ 17F418 LABEL, warning 1

44▲ 17F419 LABEL, warning,

1

multilingual

45 17F796

TOOL, wrench, sleeve

1

cap

46 17F795

TOOL, wrench, muffler

1

cap

47†‡

17G558 LUBRICANT, PFPE

1

334792E 25

Page 26

Kits

▲

Replacement Warning labels, signs, tags, and

cards are available at no cost.

†

Parts included in Fluid Section Rebuild Kit, sold

separately. See Kits, page 26, for the correct

kit for your pump.

‡

Parts included in Center Section Rebuild Kit

17F112, sold separately.

Kits

Center Section Rebuild Kit 17F112

Kit Includes:

Ref.

2

4

5

15

17

32

36 EPDM ring 2

47 PFPE Lubricant 1

Fluid Section Rebuild Kits 17F113, 17F114, and

17F118

Kits Include:

Ref.

19

20 Inlet Ball Retainer 2

21

22

25

37

47 PFPE Lubricant 1

Description

Main Slee

Center S

Diaphra

Felt Muf

Shaft S

#13 O-r

Description

Outlet Ball Retainer

Seat

Check Ball

Diaphragm

PTFE Overmolded (Kit 17F113)

EPDM (Kit 17F114)

Buna-n (Kit 17F118)

Cap Plug

ve Assembly

leeve Assembly

gm Shaft

fler

eal

ing

Qty

1

1

1

2

2

4

Qty

2

4

4

2

20

Air Motor Assembly Kit 17F596

Kit Includes:

Ref.

2

3

4

17

32

Main Cap Assembly 17F591

Kit Includes:

Ref.

3

17

32

36 EPDM ring 2

Body A

Kit I

Ref.

1Body 1

2

3

4

14

15

17

32

38

40 Pl

41 Pi

Description

Main Slee

Sleeve C

Center S

Shaft Se

#13 O-r

Description

Sleeve Cap

Shaft Seal

#13 O-ring

ssembly Kit 17F605

ncludes:

Descr

Main Sleeve Assembly

Sleeve Cap

Center Sleeve Assembly

Muffler Cap

Felt Muffler

Shaft Seal

#13 O-ring

Mesh Baffle Spacer

ug

n

ve Assembly

ap

leeve Assembly

al

ing

iption

Qty

1

2

1

6

6

Qty

1

1

2

Qty

1

2

1

1

2

2

4

3

3

3

26 334792E

Page 27

Dimensions

Dimensions

Ref. US

A 1.1 in. 28 mm

B 4.3 in. 113 mm

C

D 5.5 in. 139 mm

E 4.2 in. 107 mm

F 6.5 in. 166 mm

G

H 2.5 in

J 2.8 in

K (hole diameter)

2.7 in. 69 mm

.

3.3 in

.

.

.

0.3 in

Metric

83 mm

64 mm

70 mm

7mm

Mountin

g Layout

334792E

27

Page 28

Performance Cha

rts

Performance C

harts

Test Conditions: The pump was tested in water with

the inlet submerged.

(0.69, 6.9)

(0.62, 6.2)

(0.55, 5.5)

(0.49, 4.9)

(0.42, 4.2)

PSI

(0.35, 3.5)

(0.28, 2.8)

(0.21, 2.1)

(0.14, 1.4)

(0.07, 0.7)

Operating Air Pressure

A

100 psi

(0.7 MPa, 7.0 bar)

B

(MPa, bar)

70 psi (0.48 MPa, 4.8 bar)

C

40 psi (0.28 MPa, 2.8 bar)

Fluid Pressure

Approxima

0 62 125 187 250 312

100

90

80

70

60

50

40

30

20

10

0

0.0 0.5

(1.9)

te Cycles per Minute

A

B

C

1.0

(3.8)

Fluid Flow — gpm (lpm)

1.5

(5.7)

2.0

(7.6)

2.5

(9.5)

HowtoReadtheCharts

1. Locate fluid flow rate along

bottom of chart.

2. Follow vertical line up to

intersection with selected

operating air pressure

curve.

3. Follow left to scale to read

fluid outlet pressure (top

chart) or air consumption

(bottom chart)

(m

scfm

3

/min.)

Air Consumption

Approximate Cycles per Minute

0 62 125 187 250 312

9.0

(0.25)

7.2

(0.20)

6.4

(0.18)

5.6

(0.15)

4.8

(0.13)

4.0

(0.11)

3.2

(0.09)

2.4

(0.06)

1.6

(0.04)

0.8

(0.02)

0

0.0 0.5

(1.9)

Fluid Flow — gpm (lpm)

1.0

(3.8)

A

B

C

1.5

(5.7)

2.0

(7.6)

2.5

(9.5)

28 334792E

Page 29

Technical Data

Technical Data

ChemSafe 205 D

Maximum fluid working pressure

Minimum air startup pressure 30 psi 0.21 MPa, 2.1 bar

Fluid inlet

Maximum suction lift (reduced if balls don’t

seat well due to damaged balls or seats,

lightweight balls, or extreme speed of cycling)

Maximum s

Minimum recommended ambient air

temperature for operation and storage.

NOTE: ChemSafe pumps may be operated

in low temperature environments. Take care

to avoid freezing or crystallization of the

fluid inside or outside of the pump. Running

the pump at temperatures below freezing

may accelerate the wear of the elastomer

components in the pump.

Air con

Fluid flow per cycle

Maximum free-flow delivery

and outlet size

sumption at maximum flow

iaphragm Pump

ize pumpable solids

US

100 psi 0.69 MPa, 6.9

1/4 npt 1/4 bspt

Wet: 31.2 ft.

Dry: 6.5 ft.

0.06 in. 1.5 mm

32° F 0° C

2.5 gp

m

m

4.8 scf

0.008 gallons 0.03 liters

Metric

Wet: 9.5 m

Dry: 2 m

0.14 scmm

m

9.5 lp

bar

Maximum pump speed 375 cycles per minute

ht; PTFE [UHMW]

Weig

Wetted Parts PTFE, EPDM, NBR, UHMWPE

imum fluid temperature

Max

PTFE Pumps

MWPE Pumps

UH

oise (dBa)

N

ound power was measured per ISO-9614–2: 1997. Sound pressure was tested 3.28 ft (1 m) from the

S

quipment.

e

Sound Power

At 100 cycles per minute 61 dBa

At 375 cycles per minute 64 dBa

Sound Pressure

At 100 cycles per minute 70 dBa

At 375 cycles per minute 74 dBa

b[3.0lb]

4.1 l

212° F 100° C

158° F 70° C

1.9 k

g[1.4kg]

334792E 29

Page 30

Graco Standard ChemSafe Pump Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for

use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a

period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negl

Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment

with structures, accessories, equipment or materials not supplied by Graco, or the improper design,

manufacture, in

not supplied by

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipme

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages

for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall

be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.),

are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés,

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

igence, accident, tampering, or substitution of non-Graco component parts. Nor shall

stallation, operation or maintenance of structures, accessories, equipment or materials

Graco.

nt does not disclose any defect in material

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

To place an order, contact your Graco Distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English. MM 334792

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2015, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco Headquarters: Minneapolis

www.graco.com

Revision E, April 2018

Loading...

Loading...