Page 1

Instructions - Parts

Communications

Gateway Module

For use with Graco Control Architecture based systems to provide fieldbus

communications capabilities.

Important Safety Instructions

Read all warnings and instructions in the system

operation manual. Savetheseinstructions.

312864B

4003764

Conforms to

UL Std. 508

Certified to CAN/CSA Std.

C22.2 No. 14

TI11985A

Page 2

Models

Contents

Models ...................................2

Component Identification ....................3

Overview ..................................4

Installation ................................4

Setup .....................................5

Troubleshooting ...........................10

Parts ....................................11

Technical Data ............................11

Graco Standard Warranty ...................12

Graco Information ........................12

Models

Communications

Gateway Module Part No. Fieldbus

CGMDN0 DeviceNet

CGMEP0 EtherNet/IP

CGMPB0 PROFIBUS

CGMPN0 PROFINET

To order replacement parts, see Parts on page 11.

To order installation kits for a GracoControl Architecture

based system, see the system operation manual.

2 312864B

Page 3

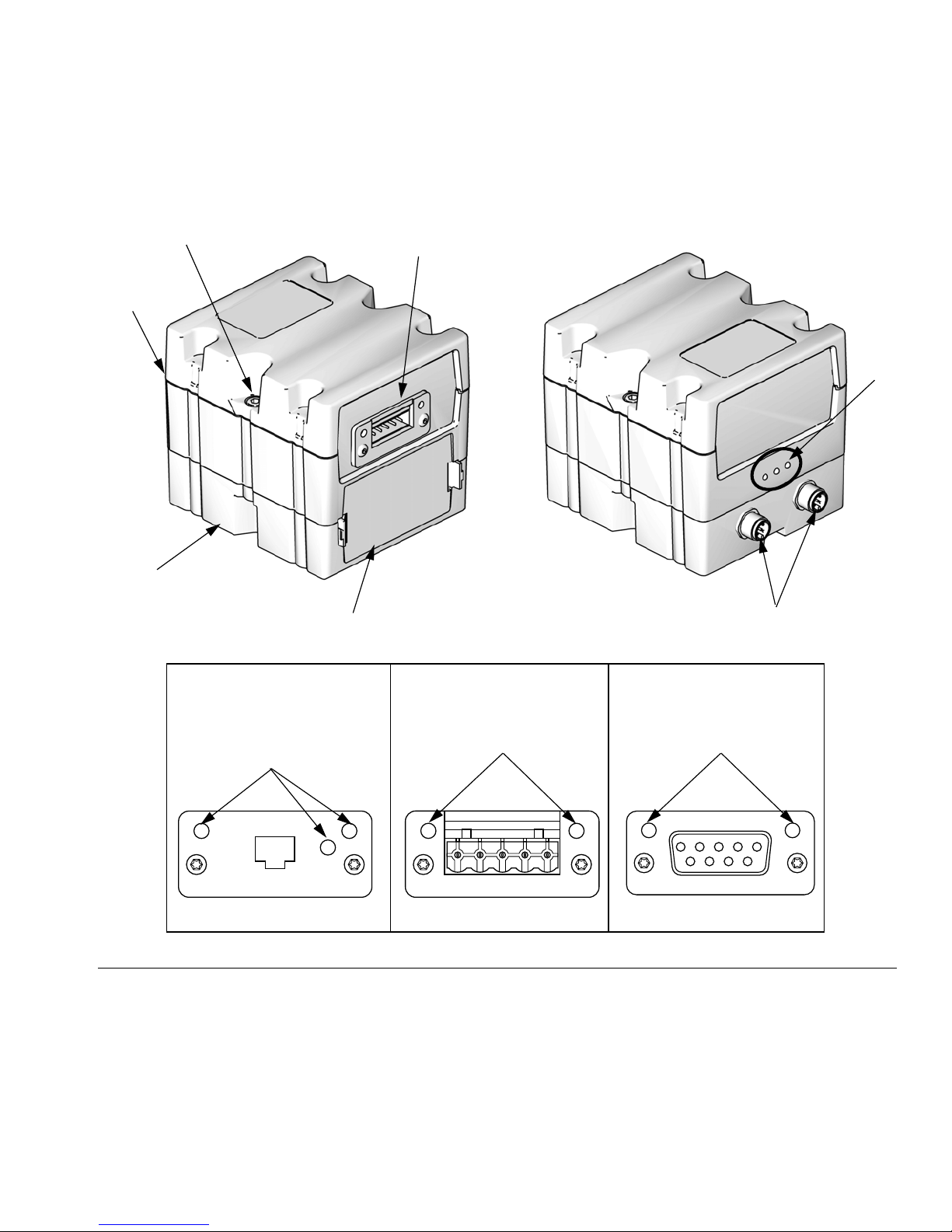

Component Identification

Front Back

D

A

C (see Fieldbus Connector Table)

Component Identification

F

B

E

Fieldbus ConnectorsTable (C)

PROFINET

or

EtherNet/IP

G

TI11814A TI11815A TI11816A

FIG.1:

Key:

A Communications Gateway Module

B Base

C Fieldbus Connector

D Module Connection Screws

E Access Cover

F Module Status LEDs

G Fieldbus Status LEDs (see descriptions on page 6)

H CAN Connectors

TI11985A

DeviceNet

TI11972A

H

PROFIBUS

G G

312864B 3

Page 4

Overview

Overview

Module Description

The Communications Gateway Module (CGM) provides

a control link between Graco ControlArchitecture based

systems and a selected fieldbus.This provides the

means for remote monitoring and control by external

automation systems.

Data provided by the CGM to the fieldbus depends on

which Graco Control Architecture based system and

fieldbus are connected. A data map supplied on a map

token is defined for this pairing. Once the data map has

been loaded into the CGM,it is stored internally,and the

map token is no longer required for operation.

Data Exchange

Data is available by block transfer, cyclic transfer,

change of state triggered, and explicit access to individual attributes as defined by the fieldbus specification.

NOTE:

The following system network configuration files are

available at www.graco.com

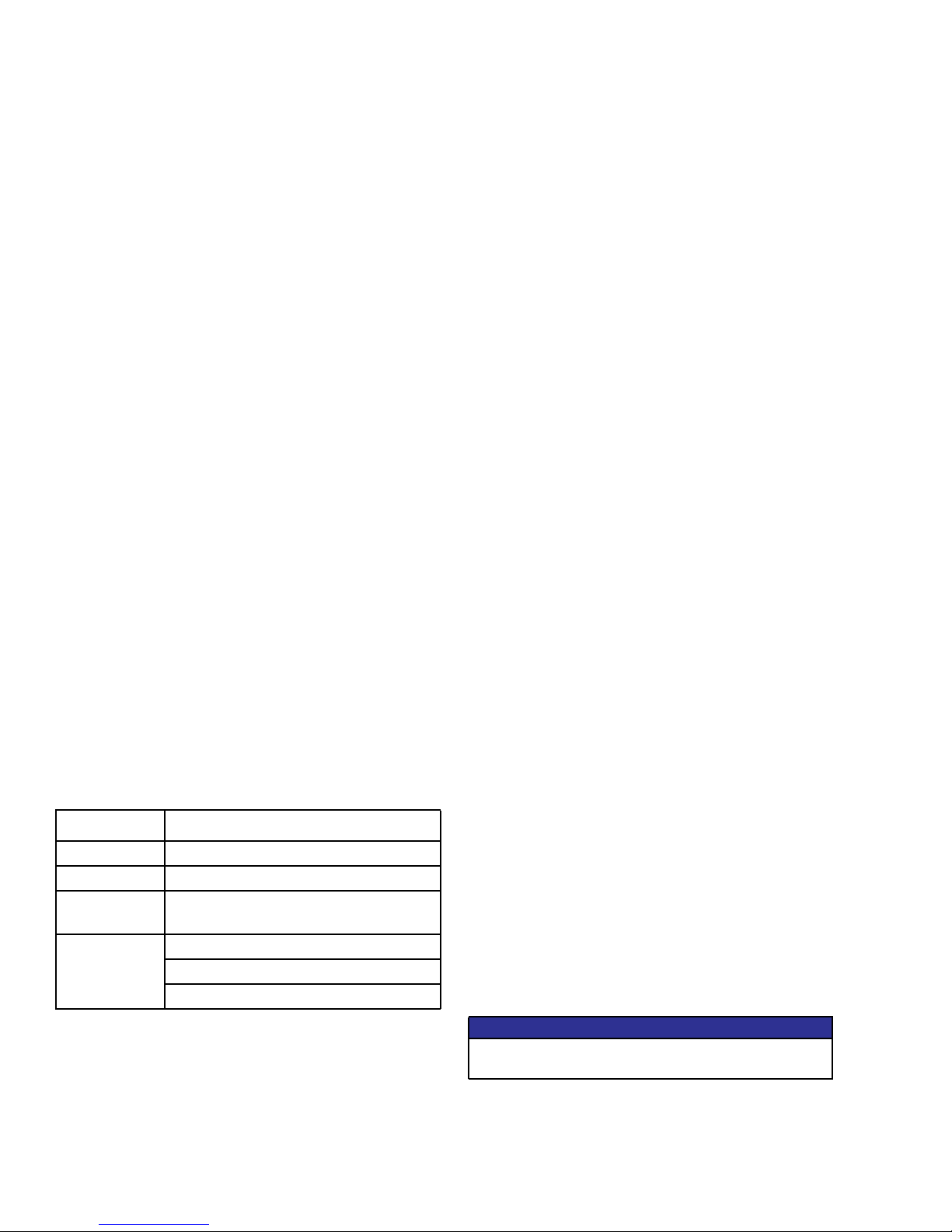

Module Requirements

Power Supply

The CGM requires a 12-30 VDC @ 0.2 A power supply.

Refer to the system manual for system level power supply guidelines.

Environment Conditions

Refer to the system manual for guidelines regarding

environment conditions for the CGM.

Installation

The CGM is available for use with all Graco Control

Architecture based systems that have compatible

design. Each CGM requires the following to operate ina

system:

• Mounting hardware

• Map token

• Fieldbus files

• EDS file: DeviceNet or Ethernet/IP fieldbus networks

• GSD file: PROFIBUS fieldbus networks

• SDML: PROFINET fieldbus networks

Module Status LED Signals

Signal Description

Green on System is powered up

Yellow Internal communication in progress

Red

Solid

*Red

(7 flashes)

*The red LED (F) will flash a code, pause, then repeat.

See Diagnostic Information on page 10.

NOTE:

Verify that you are using the correct token for your system and reinstall token. If fails, order new token.

CGM hardware failure

Data map load failure

Incorrect data map for fieldbus type

No data map loaded

If your system is compatible for use with a CGM, install

the supplied CGM as explained in the system operation

manual or installation kit manual.

If the CGM is offered only as an accessory for your system, see Accessories in the system operation manual

for available CGM kits.

Connect Cables

If your system is supplied with the CGM and required

components, connect cables as explainedin the system

operation manual.

If the CGM is offered as an accessory for your system,

connect cables as explained in the CGM mounting kit

manual.

NOTICE

Route cables to avoid interference with moving

parts.

4 312864B

Page 5

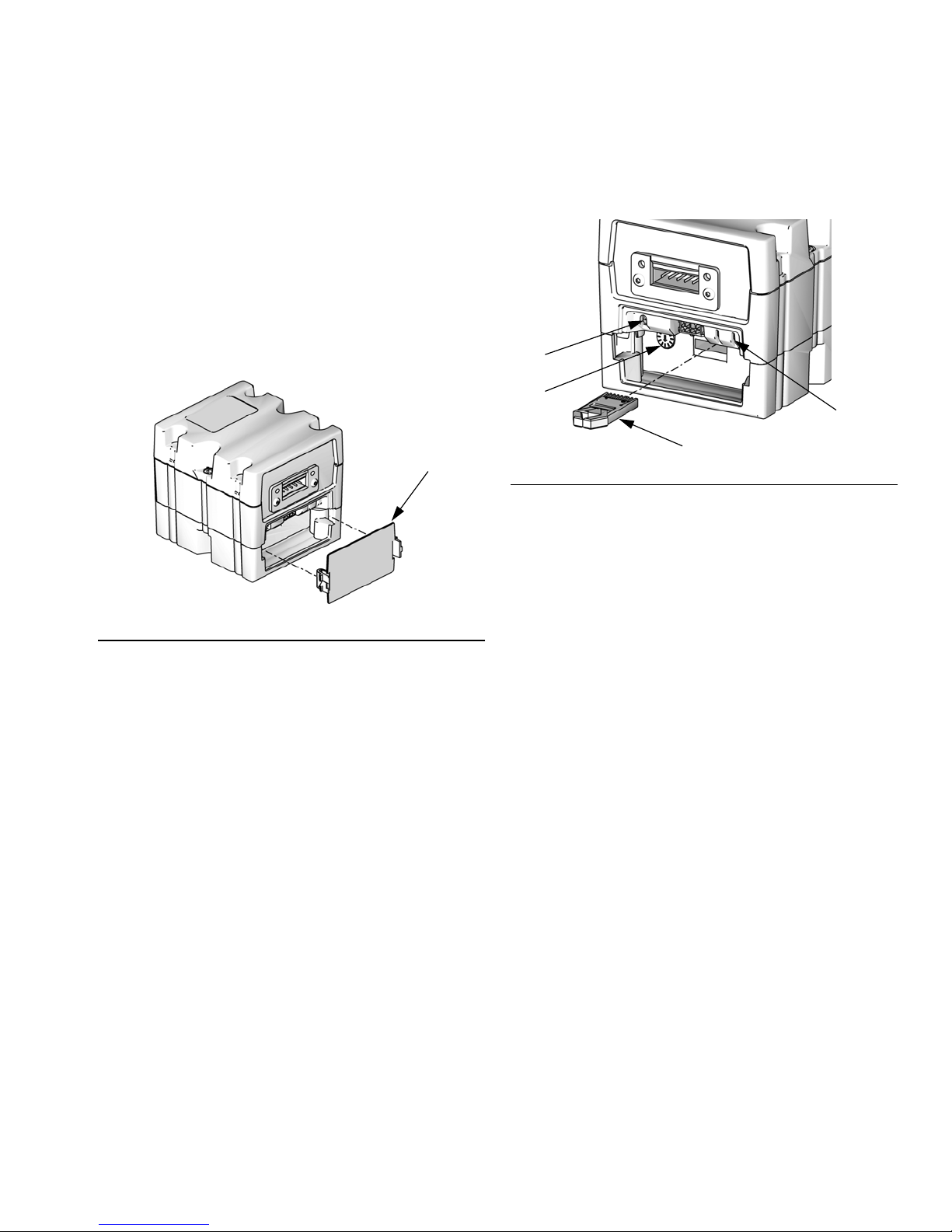

Setup

Setup

Install or Update Data Map

NOTE:

The fieldbus connection is temporarily disabled during

the installation or update of a map token.

1. Ensure system is inactive.

2. Remove access cover (E).

E

TI12319A

FIG.2

3. Insert and press map token (T) firmly into slot.

L

S

M

T

FIG.3

4. Press and hold the map upload push button (M) for

three seconds. The red LED (L) will flash twice,

pause, and repeat once after the data map is successfully uploaded. This may take up to 10 seconds.

NOTE:

The rotary switch (S) has no function for the CGM.

TI12320A

5. Remove token (T). Store in a safe place.

6. Replace access cover (E).

312864B 5

Page 6

Setup

Fieldbus Connectors

PROFINET

MS

NS

FIG.4

The Ethernet interface operates at 100Mbit, full duplex, as required by PROFINET. The Ethernet interface is auto

polarity sensing and auto-crossover capable.

Network Status (NS)

State Description Comments

Off Offline - No power

Green On-line, (RUN) - Connection with IO Controller established

Flashing Green On-line, (STOP) - Connection with IO Controller established

Module Status (MS)

State Description Comments

Link

TI11814A

- No connection with IO Controller

- IO Controller with RUN state

- IO Controller in STOP state

Off Not initialized No power or module in “SETUP” or “NW_INIT” state

Green Normal operation Diagnostic event(s) present

Flashing Green Initialized, diagnostic event(s) present Used by engineering tools to identify node on net-

work

Red Exception error Module in state “EXCEPTION”

Red (1 flash) Configuration error Expected Identification differs from Real Identifica-

tion

Red (2 flashes) IP Address not set Set IP address via system monitor or DNS server

Red (3 flashes) Station Name not set Set Station Name via system monitor

Red (4 flashes) Major Internal Error Cycle system power; replace module

Link/Activity (Link)

State Description

Off No Link, no communication present

Green Link established, no communication present

Green, flashing Link established, communication present

6 312864B

Page 7

EtherNet/IP

Setup

MS

Link

TI11814A

IG.5

F

NS

The Ethernet interface operates at 100Mbit, full duplex, as required by PROFINET. The Ethernet interface is auto

polarity sensing and auto-crossover capable.

Network Status (NS)

State Description

Off No power or no IP address

Green On-line, one or more connections established (CIP Class 1 or 3)

Flashing Green On-line, no connections established

Red Duplicate IP address, FATAL error

Flashing Red One or more connections timed out (CIP Class 1 or 3)

Module Status (MS)

State Description

Off No power

Green Controlled by a Scanner in Run state

Flashing Green Not configured, or Scanner in Idle state

Red Major fault (EXCEPTION-state, FATAL error etc.)

Flashing Red Recoverable fault(s)

LINK/Activity (Link)

State Description

Off No link, no activity

Green Link established

Flashing Green Activity

312864B 7

Page 8

Setup

DeviceNet

NS

MS

23451

TI11815A

DC

FIG.6

Network Status (NS)

State Description

Off Not online / No power

Green On-line, one or more connections are established

Flashing Green

On-line, no connections established

(1 Hz)

Red Critical link failure

Flashing Red (1 Hz) One or more connections timed-out

Alternating Red/Green Self test

Module Status (MS)

State Description

Off No power or not initialized

Green Initialized

Flashing Green (1 Hz) Missing or incomplete configuration, device needs com-

missioning

Red Unrecoverable Fault(s)

Flashing Red (1 Hz) Recoverable Fault(s)

Alternating Red/Green Self test

DeviceNet Connector (DC)

Pin Signal Description

1 V- Negative bus supply voltage

2 CAN_L CAN low bus line

3 SHEILD Cable shield

4 CAN_H CAN high bus line

5 V+ Positive bus supply voltage

8 312864B

Page 9

PROFIBUS

Setup

OP

12345

DC

9876

FIG.7

Operation Mode (OP)

State Description

Off Not online / No power

Green On-line, data exchange

Flashing Green On-line, clear

Flashing Red

Parameterization error

(1 flash)

Flashing Red

PROFIBUS Configuration error

(2 flashes)

Status Mode (ST)

ST

TI11816A

State Description

Off No power or not initialized

Green Initialized

Flashing Green Initialized, diagnostic event(s) present

Red Exception error

PROFIBUS Connector (DC)

Pin Signal Description

1- 2- 3 B Line Positive RxD/TxD, RS485 level

4 RTS Request to send

5 GND Bus Ground (isolated)

6 +5V Bus Output +5V termination power (isolated)

7- 8 A Line Negative RxD/TxD, RS485 level

9- Housing Cable Shield Internally connected to the Anybusprotective earth via

cable shield filters according to the PROFIBS standard.

312864B 9

Page 10

Troubleshooting

Troubleshooting

Diagnostic Information

Module Status LED Signal Diagnosis Solution

Red (7 flashes) Data map load failure Verify that you are using the correct

Incorrect data map for fieldbus type

No data map loaded

The red LED (F) will flash a code, pause, then repeat.

token for your system type and reinstall token. If installation fails, order

new token.

10 312864B

Page 11

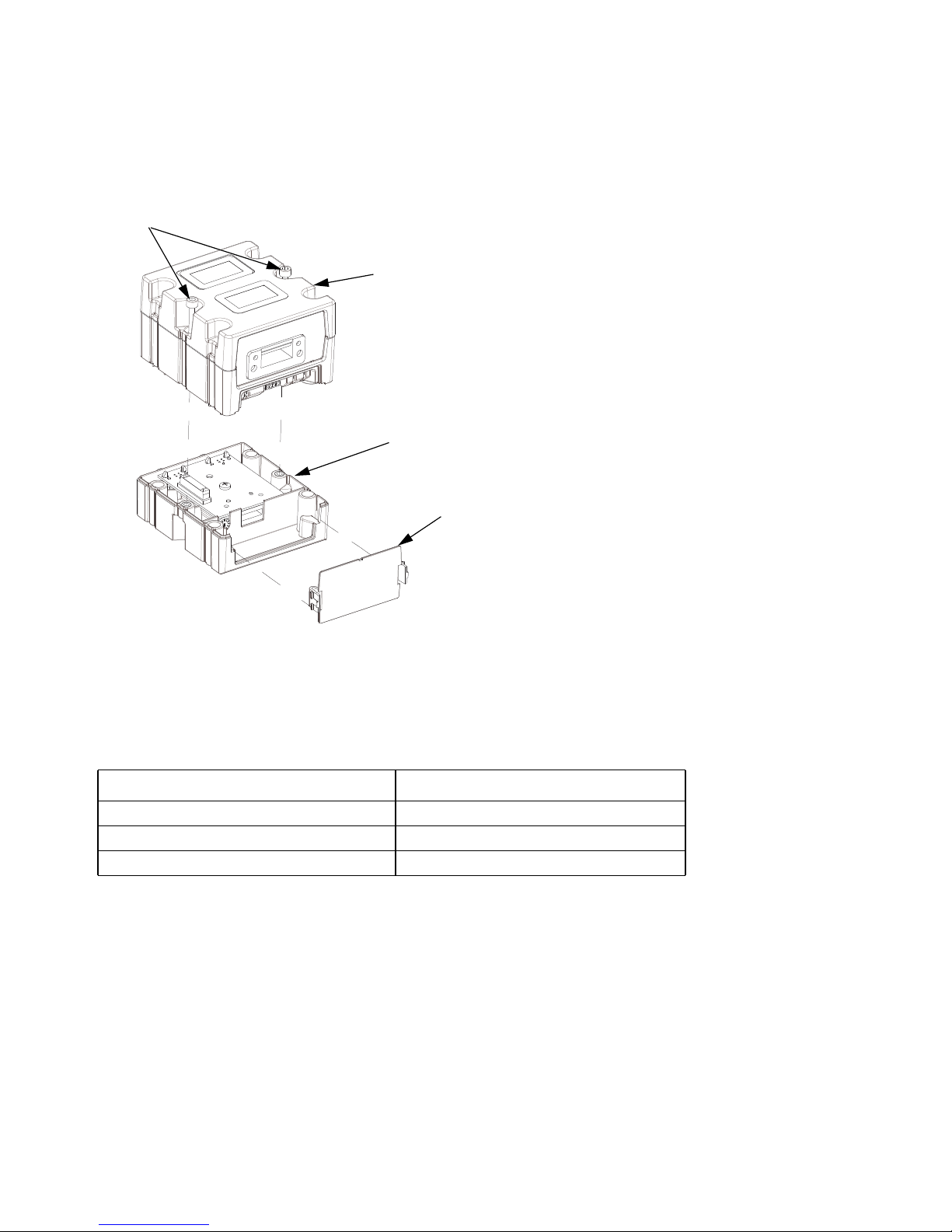

Parts

CGMPB0, CGMPN0, CGMEP0, CGMDN0

Parts

D

Parts

Qty

A

B

E

Ref Part No. Description

A 15V759 MODULE, Gateway,

DeviceNet; CGMDN0 only

15V760 MODULE, Gateway,

EtherNet/IP; CGMEP0 only

15V761 MODULE, Gateway,

PROFIBUS; CGMPB0 only

15V762 MODULE, Gateway,

PROFINET; CGMPN0 only

B 289697 Base 1

D 114135 SCREW, mounting, module connec-

tion

E 277674 COVER, access 1

.

1

1

1

1

2

Technical Data

Category Data

Power requirements 12-30 VDC @ 0.2 A

Weight 12.8 oz.

Dimensions 4.3 in. x 3.8 in. x 3.8 in.

312864B 11

Page 12

Graco StandardWarranty

Graco warrants all equipment referencedinthisdocumentwhichismanufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wearandtear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused bytheincompatibilityofGraco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defectisverified, Graco will repair or replace free of charge any defective parts. Theequipmentwillbereturned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges mayincludethecostsofparts, labor, and transportation.

THISWARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHERWARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITEDTO WARRANTY OF MERCHANTABILITY ORWARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy forany breach of warranty shall be as set forth above.Thebuyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NOWARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO.These items sold, but not manufactured by Graco (such as electric motors, switches,hose, etc.), are subject to

the warranty, if any, of their manufacturer. Gracowillprovide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event willGracobeliable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 orToll Free: 1-800-328-0211 Fax: 612-378-3505

PARA EFETUAR ENCOMENDAS OU PARA ASSISTÊNCIATÉCNICA, contate o seu distribuidor da Graco.

POUR PLACER UNE COMMANDE OU DEMANDER DU SERVICE, contactez votre distributeur Graco.

PARA REMITIR UN PEDIDO O SOLICITAR SERVICIO, póngase en contacto con el distribuidor de Graco.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

This manual contains English. MM 312864

Graco Headquarters: Minneapolis

www.graco.com

Revision B - April 2016

Loading...

Loading...