Page 1

Instructions - Parts

ti11985a

CGM with DeviceNet connector shown

Communications

Gateway Module

3A6338B

Installation Kit

For use with Electric Fixed Ratio (EFR) systems to provide fieldbus communications

abilities. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual and in your system manual

before using the equipment. Save these

instructions.

EN

Page 2

B

C

AA

AB

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CGM Software . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

EFR and PLC Connection . . . . . . . . . . . . . . . . . . 5

Gateway Screens . . . . . . . . . . . . . . . . . . . . . . . . 5

Available Internal Data . . . . . . . . . . . . . . . . . . . . . . 8

Automation Inputs (signals from EFR system to

PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Automation Outputs (signals from PLC to EFR

system) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CGM General Timing Diagrams . . . . . . . . . . . . 12

Appendix A - I/O Signal Descriptions . . . . . . . . . 19

Automation Inputs (signals from EFR system to

PLC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Automation Outputs (signals from PLC to EFR

System) . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix B - Data Exchanged . . . . . . . . . . . . . . . 24

EFR Data Exchange Elements . . . . . . . . . . . . . 25

Appendix C - Sequence Step Data Exchange . . . 30

EFR Sequence Step Data Exchange Elements 31

Appendix D - Error Number Requiring

Acknowledgment . . . . . . . . . . . . . . . . . . . . . . 32

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 34

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 34

Overview

The Communications Gateway Module (CGM) provides

a control link between the Electric Fixed Ratio (EFR)

system and a selected fieldbus. This provides the

means for report monitoring and control by external

automation systems.

NOTE: The following system network configuration files

are available at help.graco.com.

• EDS file: DeviceNet or Ethernet/IP fieldbus

networks

• GSD file: PROFIBUS fieldbus networks

• GSDML: PROFINET fieldbus networks

• ACD file: DeviceNet or Ethernet/IP fieldbus

networks

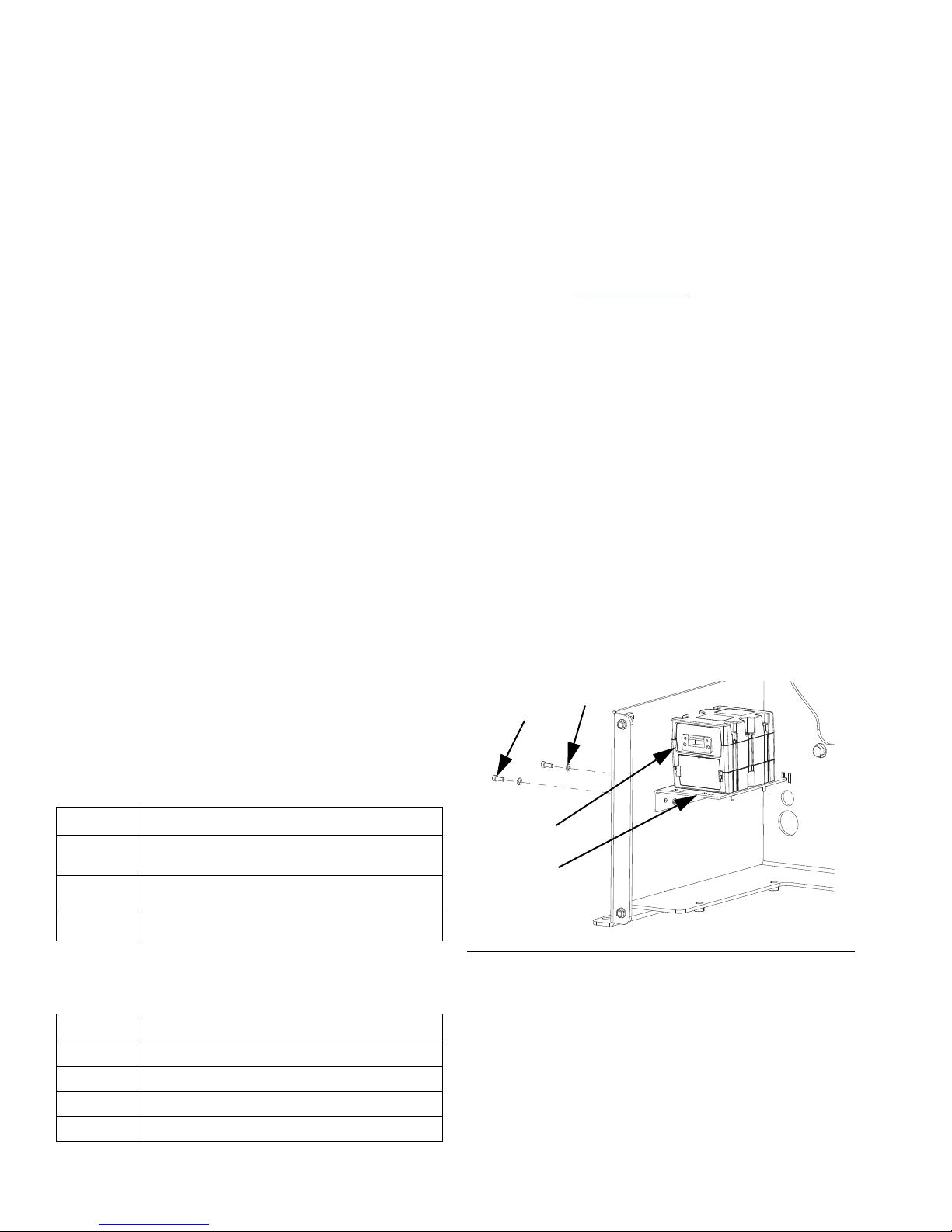

The following components are included in the CGM

Installation Kit.

Ref. Description Qty.

ACGM Kit

AA Gateway Module

AB Mounting Bracket

B Screw, #10-32 x .50

C Washer, #10, Nylon

D Communication Cable (not shown)

1

1

1

2

2

1

Related Manuals

Manual Description

312864

3A6165

406987 GCA CAN Cables, Reference

Models

Part Description

25B127 DeviceNet CGM Kit

26A700 EtherNet/IP CGM Kit

26A701 PROFIBUS CGM Kit

26A702 PROFINET CGM Kit

2 3A6338B

Communications Gateway Module,

Instructions - Parts

Electric Fixed Ratio Proportioner, Setup Operation

FIG. 1

CGM Software

The following software is must be installed on the CGM

module to work properly with the EFR CGM map

19A796.

• 17P796, version 3.01.004

Page 3

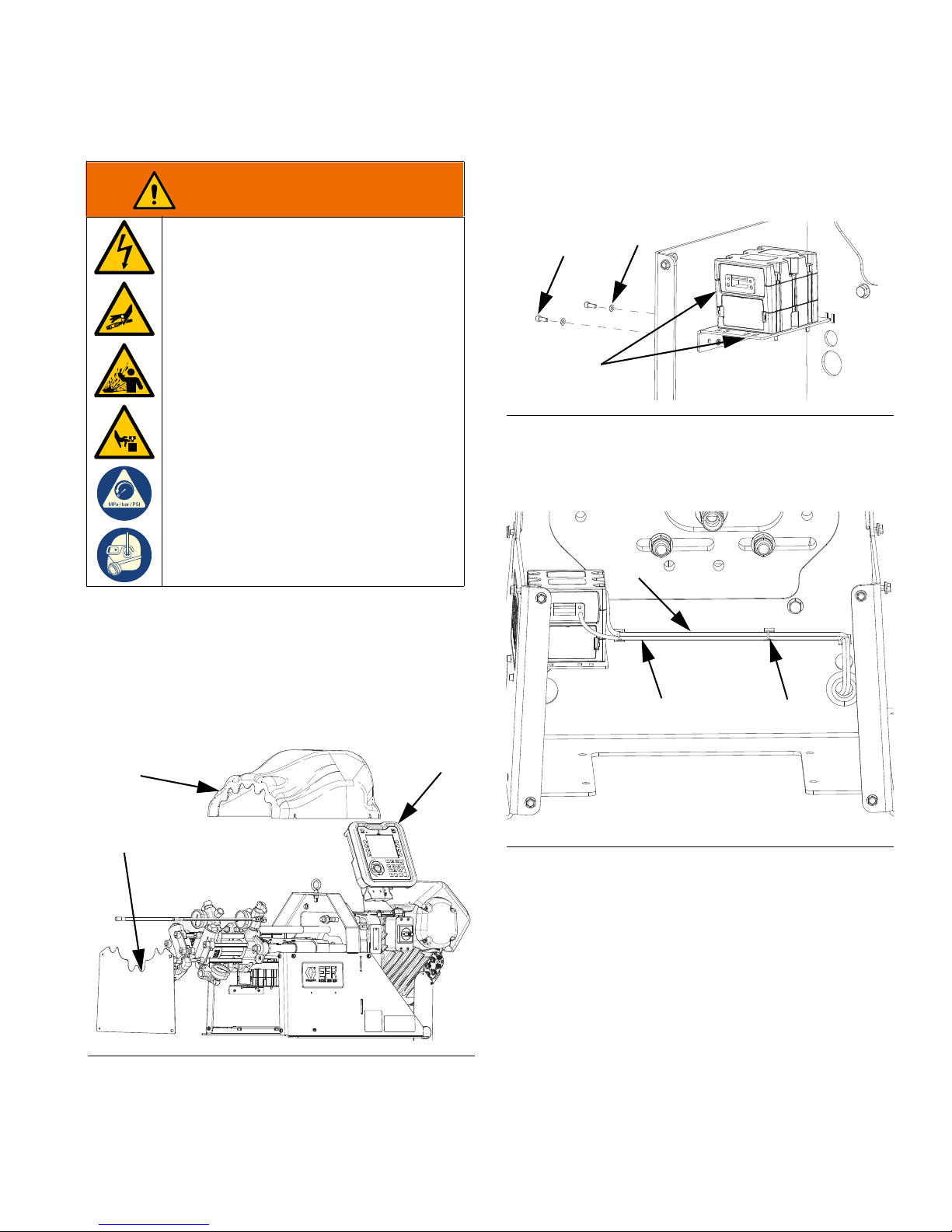

Installation

WARNING

F

E

G

A

B

C

CAN H

J

ELECTRIC SHOCK HAZARD

To avoid electric shock, make sure the

system power is OFF before connecting or

disconnecting CAN cables.

PRESSURIZED FLUID HAZARD

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection, splashing fluid

and moving parts, follow Pressure Relief

Procedure when you stop spraying and

before cleaning, checking or servicing the

equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment

when in the work area to help prevent

serious injury, including eye injury, hearing

loss, inhalation of toxic fumes, and burns.

Installation

3. Mount the CGM Kit (A) inside the system frame with

two screws (B) and washers (C).

FIG. 3

4. Secure cables (CAN, J) to the frame using the cable

ties (H) provided, and route them through the

protected opening as shown in F

IG. 4.

1. Ensure the system power is OFF and pressure has

been relieved. Follow the Pressure Relief Procedure

in the Electric Fixed Ratio Proportioner, Setup Operation manual.

2. Remove the pump yoke shroud (F) and frame cover

(G) from the EFR system.

FIG. 4

FIG. 2

3A6338B 3

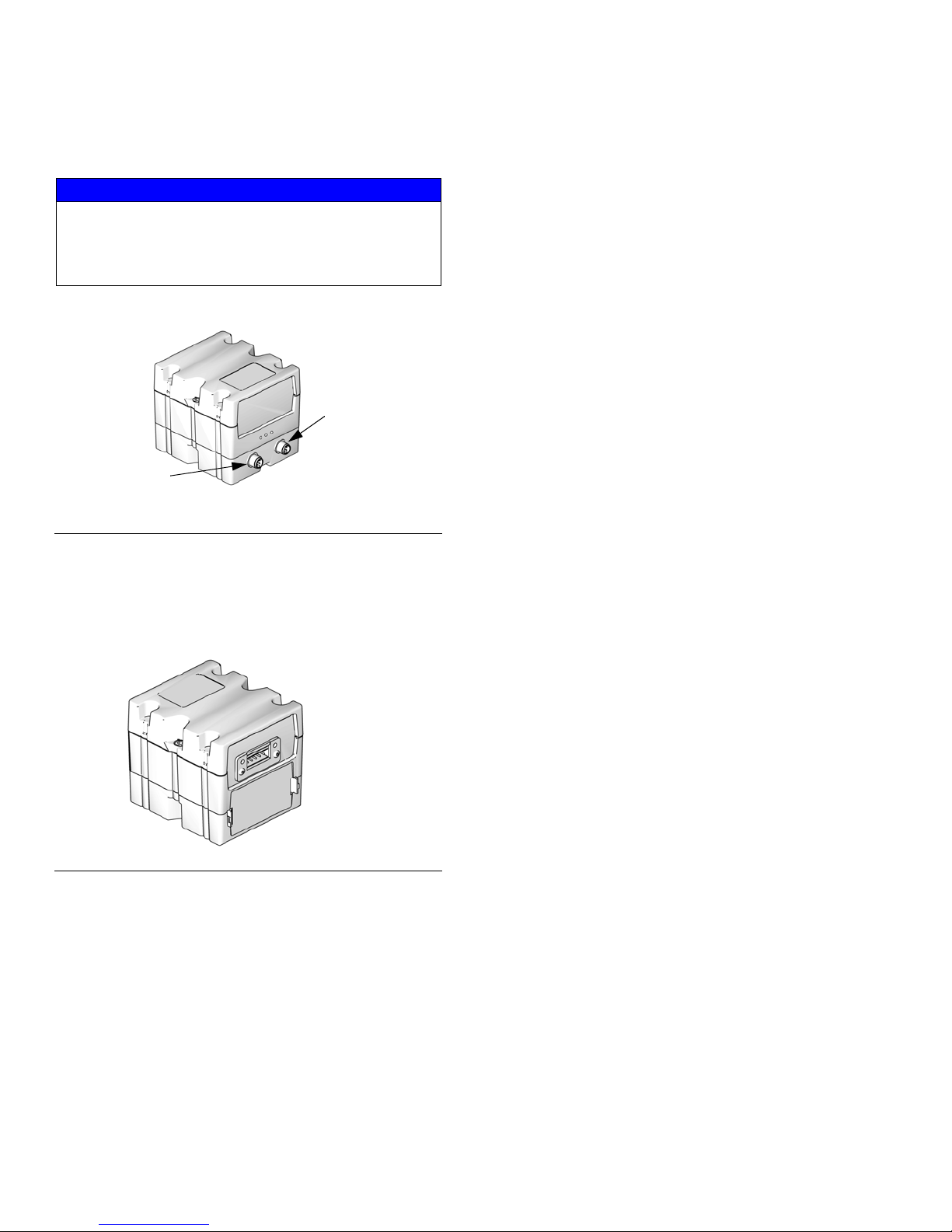

Page 4

Installation

CAN

Connector 1

ti11972a

CAN

Connector 2

ti11985a

5. Connect the CAN cable from either CAN connection

on the CGM to port 2 on the EFR.

NOTICE

Ensure the CAN cable is connected to the appropriate

CAN connection. Failure to connect the CAN cable to

the correct CAN connection can result in damage to

the CGM module.

FIG. 5: Cable Connections

6. If used, connect the Ethernet, DeviceNet, or

PROFIBUS cable (J) to the CGM as applicable.

Connect the other end of the cable to the FieldBus

device.

7. Reinstall the pump yoke shroud (F) and the frame

cover (G) onto the EFR system.

8. Perform the Install or Update Data Map procedure

in the Communications Gateway Module,

Instructions – Parts manual.

9. See Available Internal Data on page 8 for details

regarding the FieldBus pinout setup.

10. Perform the Setup procedure on page 5 to

configure the fieldbus.

NOTE: To produce an accurate dispense, the dispense

valve must be controlled directly by the EFR. See the

Electric Fixed Ratio Proportioner, Setup - Operation

manual for I/O integration of the dispense valve with the

EFR.

NOTE: See Automation Outputs (signals from PLC

to EFR System) on page 22 for information on

triggering a dispense through the EFR using the CGM.

FIG. 6: Cable Connections

4 3A6338B

Page 5

Setup

Setup

EFR and PLC Connection

Verify the PLC connection parameters are setup

correctly.

NOTE: The connection between the EFR and PLC will

not be made if the PLC connection parameters are not

set up correctly.

Standard Gateway Map: 19A796

Comm. Format Data-SINT

Input Assembly Instance 100

Input Byte Size 42

Output Assembly Instance 150

Output Byte Size 22

Gateway Screens

The Gateway screens are used to configure the

fieldbus. These screens are shown only if a CGM is

correctly installed in your system. See Installation on

page 3.

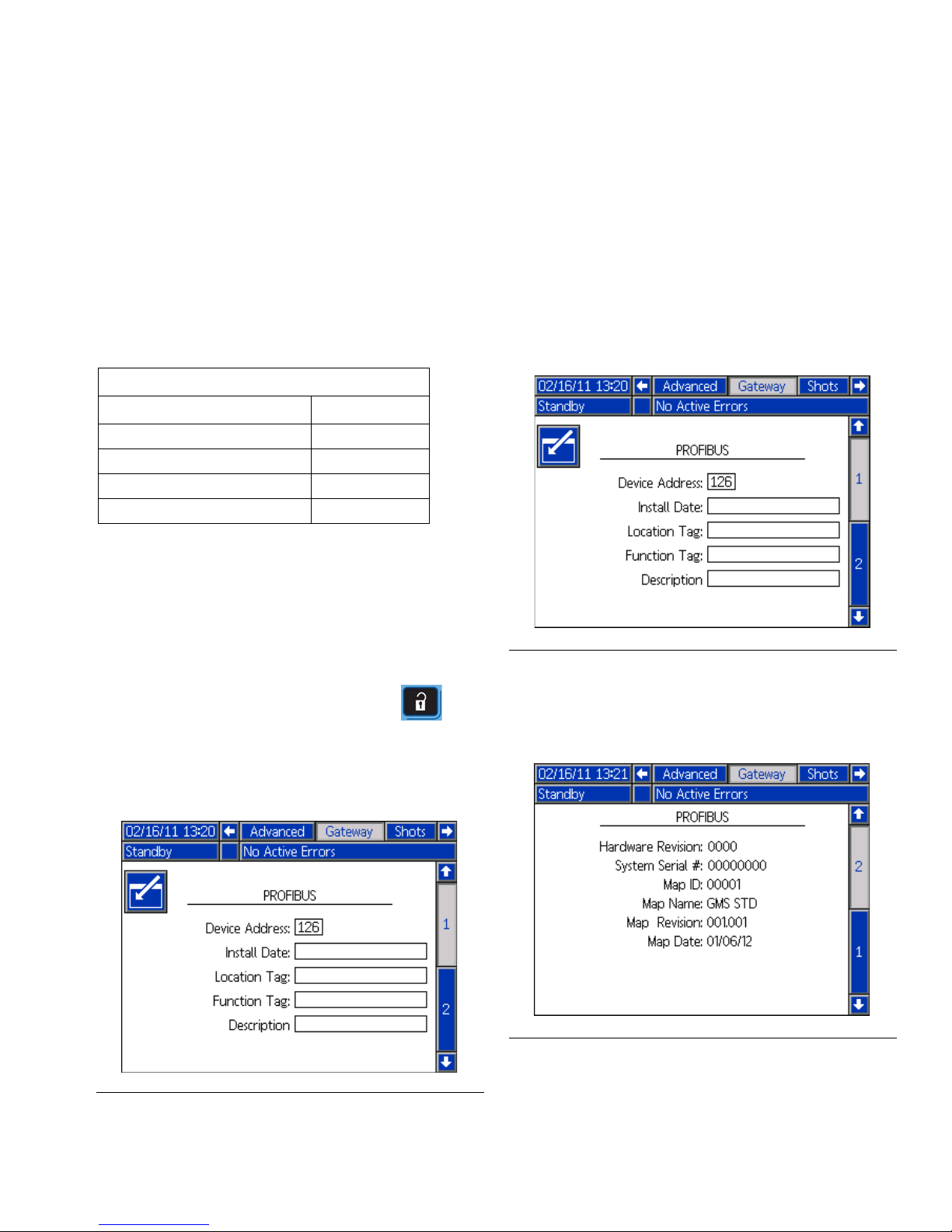

PROFIBUS Fieldbus Screens

These screens are shown only if a PROFIBUS Fieldbus

CGM is installed.

Screen 1

This screen enables the user to set the device address,

install date, location tag, function tag, and description.

FIG. 8: PROFIBUS Fieldbus Screen 1

Screen 2

1. With the system on and enabled, press to

access the Setup screens.

2. Press the left arrow key once to navigate to the

main Gateway screen. See F

FIG. 7: Example Fieldbus Screen

IG. 7.

This screen displays the hardware revision, system

serial number, and data map identification information.

FIG. 9: PROFIBUS Fieldbus Screen 2

3A6338B 5

Page 6

Setup

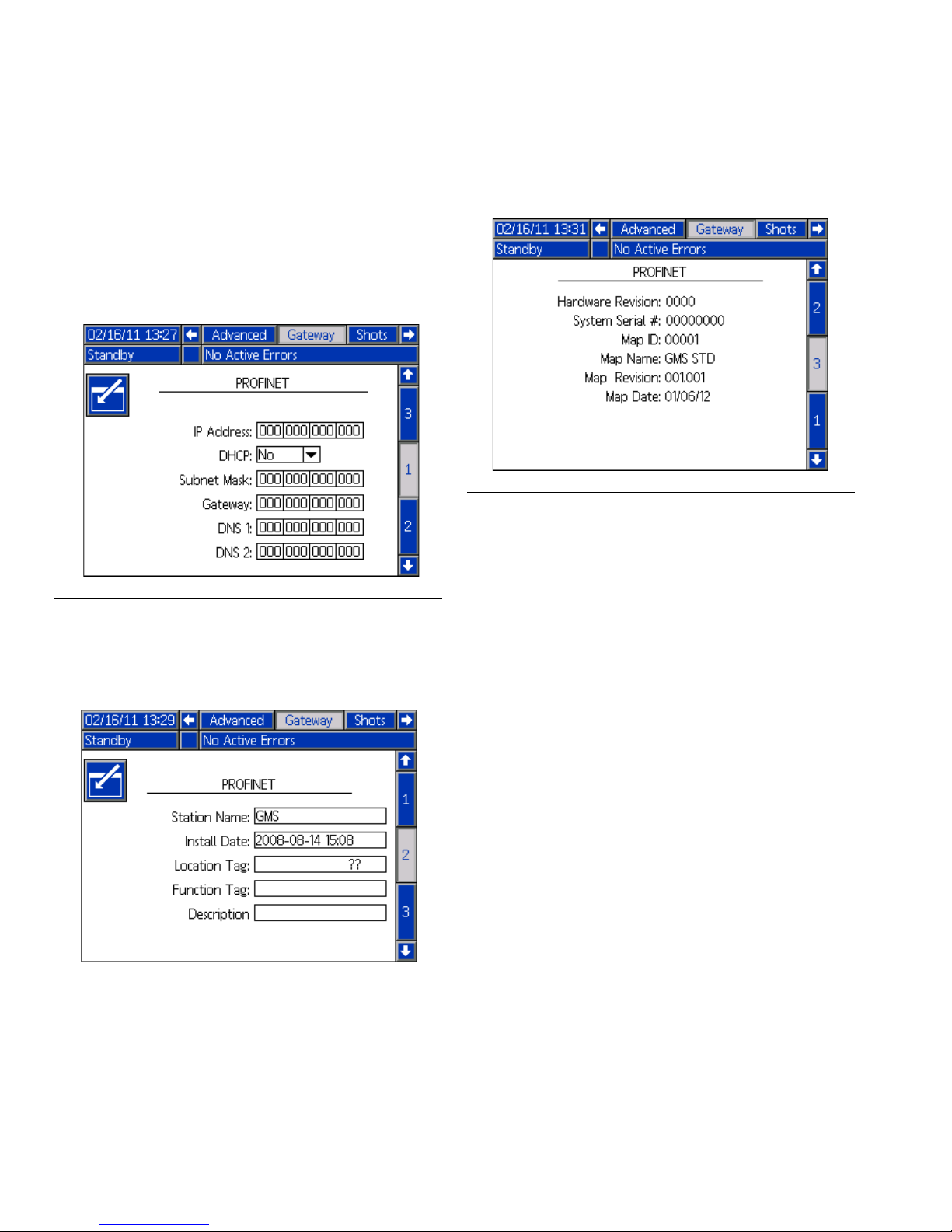

PROFINET Fieldbus Screens

These screens are shown only if a PROFINET Fieldbus

CGM is installed.

Screen 1

This screen enables the user to set the IP Address,

DHCP settings, subnet mask, gateway, and DNS

information.

Screen 3

This screen displays the hardware revision, system

serial number, and data map identification information.

FIG. 12: PROFINET Fieldbus Screen 3

FIG. 10: PROFINET Fieldbus Screen 1

Screen 2

This screen enables the user to set the station name,

install date, location tag, function tag, and description.

FIG. 11: PROFINET Fieldbus Screen 2

6 3A6338B

Page 7

Setup

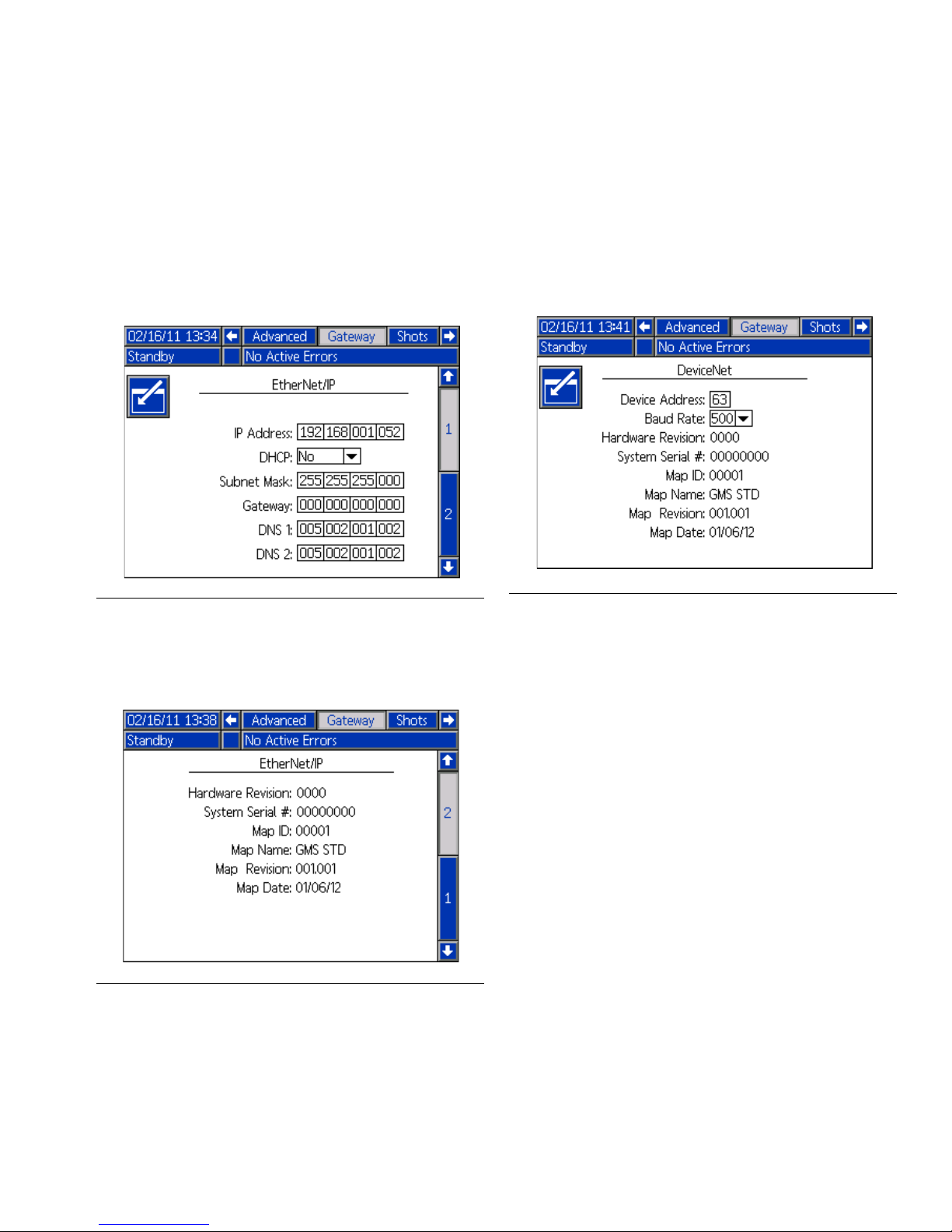

EtherNet/IP Fieldbus Screens

These screens are shown only if an EtherNet/IP

Fieldbus CGM is installed.

Screen 1

This screen enables the user to set the IP address,

DHCP settings, subnet mask, gateway, and DNS

information.

FIG. 13: EitherNet/IP Fieldbus Screen 1

DeviceNet Fieldbus Screen

This screen is shown only if a DeviceNet Fieldbus CGM

is installed.

This screen enables the user to set the device address

and baud rate, as well as view the hardware revision,

system serial number, and data map identification

information.

FIG. 15: DeviceNet Fieldbus Screen

Screen 2

This screen displays the hardware revision, system

serial number, and data map identification information.

FIG. 14: EtherNet/IP Fieldbus Screen 2

3A6338B 7

Page 8

Available Internal Data

Available Internal Data

See Appendix A - I/O Signal Descriptions on page 19

for additional details regarding each input/output.

Unless stated otherwise:

• In each instance, bytes are stored in little endian

order (most significant to least significant).

• PROFIBUS and PROFINET data must be mirrored

by the PLC to get the correct data out on the PLC

side. When the data is mirrored, the least significant

byte is inserted into the most significant spot, and

the most significant byte is inserted into the least

significant spot.

- Example: If the data is a binary number with

0011100110110111, mirroring it to get the

correct data out of the PROFIBUS or

PROFINET will result in 0111101110010011.

• Values are subject to the same maximum and

minimum restrictions as the ADM.

NOTE: Automation Outputs can be monitored by the

corresponding Automation Inputs to verify the EFR

received the data correctly.

8 3A6338B

Page 9

Automation Inputs (signals from EFR system to PLC)

Available Internal Data

Instance ID Description Data Type BIT

1 Heartbeat To PLC Boolean 0

2 System On Boolean 1

3 System Ready Boolean 2

4 Active Alarms Boolean 3

5 Active Deviations Boolean 4

6 Active Advisories Boolean 5

7 Current Sequence is Playing Boolean 6

8 Current Sequence is Paused Boolean 7

9 Current Sequence is Stopped Boolean 8

10 Dispense Valve Open Boolean 9

11 System is Priming Boolean 10

12 System is Purging Boolean 11

13 System is Parking Boolean 12

14 System is Depressurizing Boolean 13

15 Gel Shot is Running Boolean 14

16 EFR is Dispensing Boolean 15

17 {Reserved Bits} Boolean 16-23 2

18 {Reserved Bits} Boolean 24-31 3

19 Current Active Sequence uint8 0-7 4

20 Current Step of the Active Sequence uint8 0-7 5

21 Time Remaining to Complete Step (XX.X s) uint16

22 Red Pump Outlet Pressure (XXXX.X bar) uint16

23 Blue Pump Outlet Pressure (XXXX.X bar) uint16

24 Red Pump Inlet Pressure (XXXX.X bar) uint16

25 Blue Pump Inlet Pressure (XXXX.X bar) uint16

26 Pump Flow Rate (XXXX cc/min) uint16

27 Active Error Number Requiring Acknowledgment uint8 0-7 18

28

29 Data Exchanged Element Selected uint8 0-7 21

30 Data Exchanged Element Value uint16

31 Selected Step of the Active Sequence uint8 0-7 24

32 Selected Step Amount (XXXX.XX) uint32

Active Operator Mode Dispense Flow Rate

(XXXX cc/min)

uint16

0-7 6

8-15 7

0-7 8

8-15 9

0-7 10

8-15 11

0-7 12

8-15 13

0-7 14

8-15 15

0-7 16

8-15 17

0-7 19

8-15 20

0-7 22

8-15 23

0-7 25

8-15 26

16-23 27

24-31 28

Input Byte

Index’s

0

1

3A6338B 9

Page 10

Available Internal Data

Instance ID Description Data Type BIT

33 Selected Step Shot Type uint8 0-7 29

34 Selected Step Flow Rate (XXXX cc/min) uint16

35 Selected Step Calibration (XX.XX) uint16

0-7 30

8-15 31

0-7 32

8-15 33

0-7 34

36 Total Sequence Amount Requested (XXXX.XX cc) uint32

8-15 35

16-23 36

24-31 37

0-7 38

37 Total Sequence Amount Dispensed (XXXX.XX cc) uint32

8-15 39

16-23 40

24-31 41

Input Byte

Index’s

10 3A6338B

Page 11

Automation Outputs (signals from PLC to EFR system)

Available Internal Data

Instance ID Description Data Type BIT

1 System Enable Request Boolean 0

2 System Shutdown Request Boolean 1

3 Start Current Sequence/Step, Trigger Operator Mode Boolean 2

4 Pause Current Sequence Boolean 3

5 Stop Current Sequence Boolean 4

6 Priming Request Boolean 5

7 Purge Request Boolean 6

8 Parking Request Boolean 7

9 Depressurizing Request Boolean 8

10 {Reserved Bits} Boolean 9-15

11 {Reserved Bits} uint8 0-7 2

12 Desired Active Sequence uint8 0-7 3

13 Acknowledging of the Active Error Number uint8 0-7 4

14

15 Data Exchanged Element Desired uint8 0-7 7

16

17 Desired Step of the Active Sequence uint8 0-7 10

19

19 Desired Step Shot Type uint8 0-7 15

20

21

22

Desired Operator Mode Dispense Flow Rate (XXXX

cc/min)

Data Exchanged Element Desired Value

Desired Step Amount (XXXX.XX)

Desired Step Flow Rate (XXXX cc/min)

Desired Step Calibration (XX.XX)

{Reserved Word}

uint16

uint16

uint32

uint16

uint16

uint16

0-7 5

8-15 6

0-7 8

8-15 9

0-7 11

8-15 12

16-23 13

24-31 14

0-7 16

8-15 17

0-7 18

8-15 19

0-7 20

8-15 21

Output Byte

Index’s

0

1

3A6338B 11

Page 12

Available Internal Data

CGM General Timing Diagrams

NOTE: A 50ms delay is suggested between each CGM signal.

NOTE: In the diagrams shown below, the ID# corresponds to the Instance ID in the Automation Inputs and Outputs

table.

When the Priming Request bit is ON, the EFR will start priming as long as the System On bit is also ON. If the

System On bit or the Priming Request bit is OFF, the EFR will stop priming.

12 3A6338B

Page 13

Available Internal Data

When the Parking Request bit is ON, the EFR will start parking as long as the System On bit is also ON. If the

System On bit or the Parking Request bit is OFF, the EFR will stop parking.

3A6338B 13

Page 14

Available Internal Data

When the Purge Request bit is ON, the EFR will start purging as long as the System On bit is also ON. If the System

On bit or the Purge Request bit is OFF, the EFR will stop purging.

The purge flow rate can be modified quickly through the data exchange.

When the Depressurizing Request bit is ON, the EFR will start depressurizing. The EFR will only stop depressurizing

if the Depressurizing Request bit if OFF.

14 3A6338B

Page 15

Available Internal Data

If the sequence is not in operator mode, a pulse on the Start Current Sequence/Step, Trigger Operator Mode bit will

play the active sequence.

Sending the Desired Active Sequence byte is optional. If the The Desired Active Sequence byte is not sent, the

current active sequence stored in the EFR will be used.

3A6338B 15

Page 16

Available Internal Data

If there is a step in operator mode throughout the active sequence, the EFR will only dispense that step if the Start

Current Sequence/Step, Trigger Operator Mode bit remains ON. Once the Start Current Sequence/Step, Trigger

Operator Mode bit is OFF, the EFR will continue with the active sequence.

Sending the Desired Active Sequence byte is optional. If the The Desired Active Sequence byte is not sent, the

current active sequence stored in the EFR will be used.

16 3A6338B

Page 17

Available Internal Data

An ON pulse across the Stop Current Sequence bit will stop the active sequence.

Sending the Desired Active Sequence byte is optional. If the The Desired Active Sequence byte is not sent, the

current active sequence stored in the EFR will be used.

3A6338B 17

Page 18

Available Internal Data

An ON pulse across the System Shutdown Request bit will stop the sequence and turn the System On bit OFF,

making the system inactive.

A toggle OFF followed by a toggle ON of the System Enabled Request bit will put the system back into the active

state after the EFR has shut down.

The Sequence Data must be read before the EFR

finishes running another sequence. If the Sequence

Data is not read before finishing the sequence, the data

will be overwritten with new Sequence Data.

The Sequence Data consists of:

• Total Sequence Amount Requested

• Total Sequence Amount Dispensed

• Sequence Start Outlet Pressure for Red Pump

• Sequence Start Outlet Pressure for Blue Pump

• Sequence End Outlet Pressure for Red Pump

• Sequence End Outlet Pressure for Blue Pump

• Sequence Inlet Pressure for Red Pump

• Sequence Inlet Pressure for Blue Pump

18 3A6338B

Page 19

Appendix A - I/O Signal Descriptions

Appendix A - I/O Signal Descriptions

This section provides details about the CGM Automation Input and Output Signals.

Automation Inputs (signals from EFR system to PLC)

Heartbeat to PLC

Heartbeat to PLC is a Boolean signal that toggles at a

frequency of 1 Hz. This signal toggles so the PLC can

confirm the EFR is connected.

NOTE: The EFR is monitoring the fieldbus connection

as well. If the fieldbus connection stops transferring

data, the EFR will automatically shut down.

System On

System On is a Boolean signal that represents the

active state of the machine.

NOTE: The system must be ON or active for the

machine to dispense.

System Ready

System Ready State is a Boolean signal that represents

when the machine is ready to receive the next

command.

NOTE: the system will not be ready to receive the next

command if the EFR is dispensing, loading a sequence,

or if an active alarm is present.

Active Advisories

Active Advisories is a Boolean signal that represents the

active advisories on the EFR.

NOTE: When an advisory is present, the EFR is warning

the operator of potential problem(s) that may need

attention in the future to avoid shutdown time.

Current Sequence is Playing

Current Sequence is Playing is a Boolean signal that

represents when the sequence is dispensing/running.

Current Sequence is Paused

Current Sequence is Paused is a Boolean signal that

represents when the sequence is paused.

Current Sequence is Stopped

Current Sequence is Stopped is a Boolean signal that

represents when the sequence is stopped.

Dispense Valve Open

Dispense Valve Open is a Boolean signal that

represents when the valve is open.

Active Alarms

Active Alarms is a Boolean signal that represents the

active alarms on the EFR.

NOTE: When an alarm is present, the EFR requires the

operator’s attention and will shut down immediately.

Active Deviations

Active Deviations is a Boolean signal that represents the

active deviations on the EFR.

NOTE: When a deviation is present, the EFR is warning

the operator of potential problem(s) that may need

immediate attention to avoid shutdown time.

3A6338B 19

System is Priming

System is Priming is a Boolean signal that represents

when the system is priming.

System is Purging

System is Purging is a Boolean signal that represents

when the system is purging.

System is Parking

System is Parking is a Boolean signal that represents

when the system is parking.

System is Depressurizing

System is Depressurizing is a Boolean signal that

represents when the system is depressurizing.

Page 20

Appendix A - I/O Signal Descriptions

Gel Shot is Running

Gel Shot is Running is a Boolean signal that represents

when the system is dispensing as a result of the gel

timer.

EFR is Dispensing

EFR is Dispensing is a Boolean signal that represents

when the system is dispensing.

Current Active Sequence

Current Active Sequence is an integer that represents

the active sequence selected on the EFR.

Example: If the byte has a value of 33, sequence 33 is

the active sequence selected.

Current Step of the Active Sequence

Current Step of the Active Sequence is an integer that

represents the active step the EFR is currently running

on the Current Active Sequence.

Example: If the byte has a value of 4, step 4 is the active

step currently running.

Pump Flow Rate

Pump Flow Rate is a 16bit integer that represents the

current flow rate of the pump.

Active Error Number Requiring

Acknowledgment

See Appendix D - Error Number Requiring

Acknowledgment on page 32.

Active Operator Mode Dispense Flow Rate

Active Operator Mode Dispense Flow Rate is a 16bit

integer that represent the PCL desired flow rate for the

EFR, which is used to override the flow rate of the

operator mode step.

Data Exchange Element Selected

See Appendix B - Data Exchanged on page 24.

Data Exchange Element Value

See Appendix B - Data Exchanged on page 24.

Selected Step of the Active Sequence

Time Remaining to Complete Step

Time Remaining to Complete Step is a 16bit integer that

represents the remaining time required to complete the

Current Step of the Active Sequence.

Red Pump Outlet Pressure

Red Pump Outlet Pressure is a 16bit integer that

represents the outlet pressure on the red pump.

Blue Pump Outlet Pressure

Blue Pump Outlet Pressure is a 16bit integer that

represents the outlet pressure on the blue pump.

Red Pump Inlet Pressure

Red Pump Inlet Pressure is a 16bit integer that

represents the inlet pressure on the red pump.

Blue Pump Inlet Pressure

Blue Pump Inlet Pressure is a 16bit integer that

represents the inlet pressure on the blue pump.

See Appendix C - Sequence Step Data Exchange on

page 30.

Selected Step Amount

See Appendix C - Sequence Step Data Exchange on

page 30.

Selected Step Shot Type

See Appendix C - Sequence Step Data Exchange on

page 30.

Selected Step Flow Rate

See Appendix C - Sequence Step Data Exchange on

page 30.

Selected Step Calibration

See Appendix C - Sequence Step Data Exchange on

page 30.

20 3A6338B

Page 21

Total Sequence Amount Requested

Total Sequence Amount Requested is a 32bit integer

that represent the amount requested by the EFR during

the active sequence. This integer will only be populated

after the active sequence finishes dispensing.

Total Sequence Amount Requested

Total Sequence Amount Dispensed is a 32bit integer

that represent the amount dispensed by the EFR during

the active sequence. This integer will only be populated

after the active sequence finishes dispensing.

Appendix A - I/O Signal Descriptions

3A6338B 21

Page 22

Appendix A - I/O Signal Descriptions

Automation Outputs (signals from PLC to EFR System)

System Enable Request

System Enable Request is a bit used to turn on/activate

the system. It has the same function as the

button. Set this bit to 1 to turn on/activate the system,

and set it to 0 to turn off/deactivate the system.

System Shutdown Request

System Shutdown Request is a bit used to immediately

shut down the system. It has the same function as the

button. Set this bit to 1 to immediately shut down

the EFR. Once the EFR has shut down, set this bit to 0

to clear the shutdown request.

Start Current Sequence/Step, Trigger

Operator Mode

Start Current Sequence/Step, Trigger Operator mode is

a bit used to play and trigger a sequence. Set this bit to

1 to start the sequence. Once the sequence is

dispensing, set this bit to 0 to clear the request.

NOTE: When running in operator mode, this bit must

remain high (1) for operator mode to be triggered. Once

this bit is low (0), operator mode will be stopped and the

EFR will continue with the active sequence.

Pause Current Sequence

Pause Current Sequence is a bit used to pause the

active sequence. Set this bit to 1 to pause the current

active sequence. Once the sequence is paused, set this

bit to 0 to clear the request.

Stop Current Sequence

Stop Current Sequence is a bit used to stop the active

sequence. Set this bit to 1 to stop the current active

sequence. Once the sequence is stopped, set this bit to

0 to clear the request.

Priming Request

Priming Request is a bit used to turn the priming feature

ON and OFF. Set this bit to 1 to start the smart priming

feature. This bit can be set to 0 at any time during smart

priming to stop the smart priming feature.

NOTE: Once the smart priming request is completed,

set this bit to 0.

Purging Request

Purging Request is a bit used to turn the purging feature

ON and OFF. Set this bit to 1 to turn the purging feature

ON. When the PLC is ready to stop purging, set this bit

to 0 to turn the purging feature OFF.

Parking Request

Parking Request is a bit used to turn the parking feature

ON and OFF. Set this bit to 1 to start the parking

feature. This bit can be set to 0 at any time while the

pump is parking to stop the parking feature.

NOTE: Once the parking request is completed, set this

bit to 0.

Depressurizing Request

Depressurizing Request is a bit used to turn the

depressurizing feature on and off. Set this bit to 1 to turn

the depressurize feature ON. When the PLC is ready to

stop depressurizing, set this bit to 0 to turn the

depressurizing feature OFF.

Desired Active Sequence

Desired Active Sequence is a byte used to request a

new active sequence. If the value supplied is within the

operable range, the value will be accepted by the EFR

and reflected back to the Current Active Sequence of

the Automation Inputs. The operable range of this byte

corresponds to the number of sequences the EFR can

hold, which is 1 to 50.

22 3A6338B

Acknowledging the Active Error Number

See Appendix D - Error Number Requiring

Acknowledgment on page 32.

Page 23

Desired Operator Mode Dispense Flow

Rate

Desired Operator Mode Dispense Flow Rate is a byte

used to request a new operator mode dispense flow rate

to the EFR. If the value supplied is within the operable

range and the EFR is running in operator mode, the

value will be accepted by the EFR and reflected back to

the Active Operator Mode Dispense Flow Rate of the

Automation Inputs.

Data Exchange Element Desired

See Appendix B - Data Exchanged on page 24.

Data Exchange Element Desired Value

See Appendix B - Data Exchanged on page 24.

Desired Step of the Active Sequence

Appendix A - I/O Signal Descriptions

See Appendix C - Sequence Step Data Exchange on

page 30.

Desired Step Amount

See Appendix C - Sequence Step Data Exchange on

page 30.

Desired Step Shot Type

See Appendix C - Sequence Step Data Exchange on

page 30.

Desired Step Flow Rate

See Appendix C - Sequence Step Data Exchange on

page 30.

Desired Step Calibration

See Appendix C - Sequence Step Data Exchange on

page 30.

3A6338B 23

Page 24

Appendix B - Data Exchanged

Appendix B - Data Exchanged

The Data Exchange is a condensed structure used to read and edit a number of different variables in one data

location. If multiple data exchanges are needed, they must be cycled through.

Below is a timing diagram showing the Data Exchange portion of EFR CGM Map.

NOTE: A 50ms delay is suggested between each CGM signal.

When the PLC needs to use the Data Exchange, the Data Exchange Element Desired must first be sent to the EFR.

Initially, the Data Exchange Element Selected and the Data Exchange Element Value are set to zero to signal the

data in the Data Exchange is invalid. Once the EFR returns the Data Exchange Element Value, followed by the Data

Exchange Element Selected, the PLC can compare the Data Exchange Element Selected to the Data Exchange

Element Desired and confirm the data is correct for the Data Exchange Element Desired. Once the Data Exchange

Automation Inputs are confirmed, the Data Exchanged Element Desired Value can be used to request a new value.

If the value supplied is within the operable range of the element, the EFR will accept the new value and will return

that value to the Data Exchange Element Value.

24 3A6338B

Page 25

EFR Data Exchange Elements

Appendix B - Data Exchanged

Data Exchange Element

(base 10 integer)

1 Dispense Mode uint8

2 ADM Rate Units uint8

3 ADM Pressure Units uint8

4 Pressure Imbalance Alarm Enabled bool

5 Pressure Imbalance Alarm Level (XXXX.X bar) uint16

6 Red Pump Size (XXX.XX cc) uint16

7 Blue Pump Size (XXX.XX cc) uint16

8 Red Pump Specific Gravity (X.XXX g/cc) uint16

9 Blue Pump Specific Gravity (X.XXX g/cc) uint16

10 Gel Timer Enabled bool

11 Gel Timer Idle Period (XX s) uint16

12 Gel Timer Alarm Period (XX s) uint16

13 Gel Timer Repeat Sequence Until (XX cc) uint16

14 Gel Timer Sequence Selected uint8

15 Smart Prime Repeat Until (XX cc) uint16

16 Smart Prime Sequence Selected uint8

17 Purge Flow Rate (XXXX cc/min) uint16

18 Over Pressure Alarm(XXXX.X bar) uint16

20 Integration External Trigger Enabled bool

21 Integration External Trigger Status bool

22 Integration Smart Prime Enabled bool

23 Integration Smart Prime Status bool

24 Integration System Enabled bool

25 Integration System Status bool

26 Integration Analog Flow Rate Enabled bool

27 Integration Analog Flow Rate Status (XXXX mV) bool

28 Integration Sequence Selected Enabled bool

29 Integration Sequence Selected Status uint8

30 Red Pump Cycles (XXXX cycles) uint16

31 Red Pump Lifetime Cycles (XXXX cycles) uint16

32 Blue Pump Cycles (XXXX cycles) uint16

33 Blue Pump Lifetime Cycles (XXXX cycles) uint16

34 Dispense Valve Open Cycles (XXXX cycles) uint16

35 Dispense Valve Open Lifetime Cycles (XXXX cycles) uint16

36 Desired Number of Times to Run the Sequence uint16

37 Actual Number of Times the Sequence has Ran uint16

38 Mixed Material Specific Gravity (X.XXX g/cc) uint16

39 Sequence Start Outlet Pressure for Red Pump (XXXX.X bar) uint16

40 Sequence Start Outlet Pressure for Blue Pump (XXXX.X bar) uint16

41 Sequence End Outlet Pressure for Red Pump (XXXX.X bar) uint16

42 Sequence End Outlet Pressure for Blue Pump (XXXX.X bar) uint16

43 Sequence Inlet Pressure for Red Pump (XXXX.X bar) uint16

44 Sequence Inlet Pressure for Blue Pump (XXXX.X bar) uint16

Description Data Type

3A6338B 25

Page 26

Appendix B - Data Exchanged

Below is a list of explanations of each individual Data

Exchange Element.

Dispense Mode

Dispense Mode tells the EFR system whether the

system is in weight or volume mode. The following

values correspond to the various dispense modes

offered by the EFR.

Value Dispense Mode State

0 Weight Mode

1 Volume Mode

ADM Rate Units

ADM Rate Units tells the EFR system what units the

rate will be displayed in on the ADM. The following

values correspond to the various rate units the EFR

ADM offers.

Value Rate Units State

0 Per Minute

1Per Second

2Per Hour

ADM Pressure Units

ADM Pressure Units tells the EFR system what units the

pressure will be displayed in on the ADM. The following

values correspond to the various pressure units the EFR

ADM offers.

Value Pressure Units State

0PSI

1Bar

Pressure Imbalance Alarm Enabled

Pressure Imbalance Alarm Level

Pressure Imbalance Alarm Level is an integer used to

trigger the pressure imbalance alarm.

Red Pump Size

Red Pump Size is an integer used to define the size of

the red z pump.

Blue Pump Size

Blue Pump Size is an integer used to define the size of

the blue z pump.

Red Specific Gravity

Red Specific Gravity is an integer used to define the

specific gravity of the material in the red z pump.

Blue Specific Gravity

Blue Specific Gravity is an integer used to define the

specific gravity of the material in the blue z pump.

Gel Timer Enabled

Gel Timer Enabled is a boolean that can enable or

disable the Gel Timer feature. The following values

correspond to the different states the Gel Timer boolean

can be set to.

Value Gel Timer Enabled State

0 Not Enabled

1 Enabled

Gel Timer Idle Period

Gel Timer Idle Period is an integer used to define the

idle state of the gel timer before the gel timer causes a

dispense.

Pressure Imbalance Alarm Enabled is a boolean that

can enable or disable the ability to view pressure

imbalances between the red pump and the blue pump.

The following values correspond to the different states

the Pressure Imbalance Alarm boolean can be set to.

Pressure Imbalance

Value

0 Not Enabled

1 Enabled

26 3A6338B

Alarm State

Gel Timer Alarm

Gel Timer Alarm is an integer used to define the alarm

state of the gel timer.

Gel Timer Repeat Unit

Gel Timer Repeat Unit is an integer used to define the

amount of material dispensed for the gel timer shot.

Page 27

Appendix B - Data Exchanged

Gel Timer Sequence Selected

Gel Timer Sequence Selected is an integer used to

define the sequence that will run when the gel timer

expires.

NOTE: To use the active sequence as the selected

sequence for the gel timer, a new value of zero must be

sent across the data exchange. If a new value of zero is

not sent, the number sent across the data exchange will

correspond to the sequence selected for the gel timer.

Smart Prime Repeat Unit

Smart Prime Repeat Unit is an integer used to define

the amount of material dispensed for the smart prime.

Smart Prime Sequence Selected

Smart Prime Sequence Selected is an integer used to

define the sequence that will run when smart prime is

enabled.

NOTE: To use the active sequence as the selected

sequence for smart prime, a new value of zero must be

sent across the data exchange. If a new value of zero is

not sent, the number sent across the data exchange will

correspond to the sequence selected for the gel timer.

Purge Flow Rate

Purge Flow Rate is an integer used to define the flow

rate at which the Purge Request will dispense.

Integration External Trigger Status

Integration External Trigger Status is a boolean that

shows the status of the Integration Trigger I/O pin. The

following values correspond to the different states of the

Integration External Trigger Status boolean.

Integration Trigger

Value

0Not Active

1 Active

Status State

Integration Smart Prime Enabled

Integration Smart Prime Enabled is a boolean that can

enable usage of the Integration Smart Prime I/O pin.

The following values correspond to the different states

of the Smart Prime Enabled boolean.

Integration Smart Prime

Value

0 Not Enabled

1 Enabled

Enabled State

Integration Smart Prime Status

Integration Smart Prime Status is a boolean that shows

the status of the Integration Smart Prime I/O pin. The

following values correspond to the different states of the

Smart Prime Status boolean.

Over Pressure Alarm

Over Pressure Alarm is an integer used to define the

maximum pressure that can be reached before the EFR

shuts down and returns the error.

Value

0Not Active

1 Active

Integration Smart Prime

Status State

Integration System Enabled

Integration External Trigger Enabled

Integration External Trigger Enabled is a boolean that

can enable usage of the Integration Trigger I/O pin. The

following values correspond to the different states of the

Integration External Trigger Enabled boolean.

Integration Trigger

Value

0 Not Enabled

1 Enabled

3A6338B 27

Enabled State

Integration System Enabled is a boolean that can

enable usage of the Integration System I/O pin. The

following values correspond to the different states of the

Integration System Enabled boolean.

Integration System

Value

0 Not Enabled

1 Enabled

Enabled State

Page 28

Appendix B - Data Exchanged

Integration System Status

Integration System Status is a boolean that shows the

status of the Integration System I/O pin. The following

values correspond to the different states of the

Integration System Status boolean.

Integration System

Value

0Not Active

1 Active

Status State

Integration Analog Flow Rate Enabled

Integration Analog Flow Rate Enabled is a boolean that

can enable usage of the Integration Analog Flow Rate

I/O pin. The following values correspond to the different

states of the Integration Analog Flow Rate Enabled

boolean.

Integration Analog Flow

Value

0 Not Enabled

1 Enabled

Rate Enabled State

Integration Sequence Selected Status

Integration Sequence Selected Status is an integer

used to define the active sequence on the EFR by using

I/O pins on the ADM as bits. When read, the integer

results in the Active Sequence in the EFR system.

Example: If the integer has a value of 2, the Active

Sequence is 2.

NOTE: This integer can only be read by the PLC.

Red Pump Cycles

Red Pump Cycles is an integer used to define the

number of times the red pump has cycled. This can be

reset by sending a value zero from the PLC over the

Data Exchange.

Red Pump Lifetime Cycles

Red Pump Lifetime Cycles is an integer used to define

the number of times the pump has cycled during its

lifetime.

NOTE: This integer can only be read by the PLC.

Integration Analog Flow Rate Status

Integration Analog Flow Rate Status is an integer used

to define the voltage on the Analog Flow Rate I/O pin.

NOTE: This integer can only be read by the PLC.

Integration Sequence Selected Enabled

Integration Sequence Selected Enabled is a boolean

that can enable usage of the Integration Sequence

Selected I/O pins on the ADM. The following values

correspond to the different states of the Sequence

Selected Enabled boolean.

Integration Sequence

Value

0 Not Enabled

1 Enabled

Selected Enabled State

Blue Pump Cycles

Blue Pump Cycles is an integer used to define the

number of times the blue pump has cycled. This can be

reset by sending a value zero from the PLC over the

Data Exchange.

Blue Pump Lifetime Cycles

Blue Pump Lifetime Cycles is an integer used to define

the number of times the pump has cycled during its

lifetime.

NOTE: This integer can only be read by the PLC.

Dispense Valve Cycles

Dispense Valve Cycles is an integer used to define the

number of times the dispense valve has opened. This

can be reset by sending a value zero from the PLC over

the Data Exchange.

Dispense Valve Lifetime Cycles

Dispense Valve Lifetime Cycles is an integer used to

define the number of times the dispense valve has

opened during its lifetime.

28 3A6338B

NOTE: This integer can only be read by the PLC.

Page 29

Appendix B - Data Exchanged

Desired Number of Times to Run the

Sequence

Desired Number of Times to Run the Sequence is an

integer used to define the number of times the

sequence will run.

Example: If the integer is 5, the sequence will run 5

times before the dispense is finished.

Actual Number of Times the Sequence has

Ran

Actual Number of Times the Sequence has Ran is an

integer used to define the number of times the

sequence has run out of the desired number.

Example: If the integer is 10, the sequence has run 10

of X times. X represents the Desired Number of Times

to Run the Sequence.

NOTE: This integer can only be read by the PLC.

Mixed Material Specific Gravity

Mixed Material Specific Gravity is an integer used to

define the specific gravity of the mixed material.

NOTE: This integer can only be read by the PLC.

Sequence End Outlet Pressure for Red

Pump

Sequence End Outlet Pressure for Red Pump is an

integer that represents the outlet pressure of the red

pump once the active sequence is done dispensing.

NOTE: This integer will only be populated after the

active sequence is done dispensing.

NOTE: This integer can only be read by the PLC.

Sequence End Outlet Pressure for Blue

Pump

Sequence End Outlet Pressure for Blue Pump is an

integer that represents the outlet pressure of the blue

pump once the active sequence is done dispensing.

NOTE: This integer will only be populated after the

active sequence is done dispensing.

NOTE: This integer can only be read by the PLC.

Sequence Inlet Pressure for Red Pump

Sequence Inlet Pressure for Red Pump is an integer

that represents the inlet pressure of the red pump for the

current sequence being dispensed.

Sequence Start Outlet Pressure for Red

Pump

Sequence Start Outlet Pressure for Red Pump is an

integer that represents the outlet pressure of the red

pump once the active sequence begins dispensing.

NOTE: This integer will only be populated after the

active sequence is done dispensing.

NOTE: This integer can only be read by the PLC.

Sequence Start Outlet Pressure for Blue

Pump

Sequence Start Outlet Pressure for Blue Pump is an

integer that represents the outlet pressure of the blue

pump once the active sequence begins dispensing.

NOTE: This integer will only be populated after the

active sequence is done dispensing.

NOTE: This integer can only be read by the PLC.

NOTE: This integer will only be populated after the

active sequence is done dispensing.

NOTE: This integer can only be read by the PLC.

Sequence Inlet Pressure for Blue Pump

Sequence Inlet Pressure for Blue Pump is an integer

that represents the inlet pressure of the blue pump for

the current sequence being dispensed.

NOTE: This integer will only be populated after the

active sequence is done dispensing.

NOTE: This integer can only be read by the PLC.

3A6338B 29

Page 30

Appendix C - Sequence Step Data Exchange

Appendix C - Sequence Step Data Exchange

The Sequence Data Exchange is a condensed structure used to read and edit a number of steps in a sequence

across a set of bytes. If multiple steps of sequences are needed, they must be cycled through.

Below is a timing diagram showing the Sequence Step Data Exchange portion of EFR CGM Map.

NOTE: A 50ms delay is suggested between each CGM signal.

When utilizing the Sequence Step Data Exchange, the first element that must be passed to the EFR is the Desired

Step of the Active Sequence. Once the EFR receives that element, the EFR will update the Sequence Step Data

Exchange Automation Inputs Elements for the desired step. After the Sequence Step Data Exchange Automation

Inputs Elements have been updated, the Selected Step of the Active Sequence can be used to confirm the desired

step data has populated the Sequence Step Data Exchange Automation Inputs Elements. Once the data has been

confirmed for the desired step, the Sequence Step Data Exchange Automation Outputs Elements can be used to

request new values to the EFR. If the values supplied are within the operable range of the elements, the EFR will

accept the values and reflect the new values to the corresponding elements of the Sequence Step Data Exchange

Automation Inputs Elements.

30 3A6338B

Page 31

Appendix C - Sequence Step Data Exchange

Sequence Step Data Exchange Automation Inputs

Elements consist of:

• Selected Step of the Active Sequence

• Selected Step Amount

• Selected Step Shot Type

• Selected Step Flow Rate

• Selected Step Calibration

Sequence Step Data Exchange Automation Outputs

Elements consist of:

• Desired Step of the Active Sequence

• Desired Step Amount

• Desired Step Shot Type

• Desired Step Flow Rate

• Desired Calibration

See the EFR Sequence Step Data Exchange

Elements for further explanations of the Sequence Step

Data Exchange Automation Outputs Elements and

Sequence Step Data Exchange Automation Inputs

Elements.

NOTE: If the Desired Step of the Active Sequence

changes, the process of the Sequence Step Data

Exchange will start over again, as shown in the timing

diagram.

Desired/Selected Step Shot Size

Desired/Selected Step Shot Size is a byte used to

define the step type for the Desired Selected Step of the

Active Sequence. The table below shows the

corresponding values and units that can be written or

read from the EFR.

Sequence Step Type

Value

0 Step CC Continue* cc

1 Step Grams Continue* grams

2 Step Seconds Continue* seconds

3 Step CC Break** cc

4 Step Grams Break** grams

5 Step Seconds Break** seconds

6 Operator Mode N/A

* Continue means the EFR will not wait on an external

trigger from the Trigger I/O pin or the Start Current

Sequence/Step, Trigger Operator Mode bit. The EFR

will immediately continue into that step.

** Break means the EFR will wait on an external trigger

from the Trigger I/O pin or the Start Current

Sequence/Step, Trigger Operator mode bit before

moving into that step.

State Units

EFR Sequence Step Data

Exchange Elements

Desired/Selected Step of the Active

Sequence

Desired/Selected Step of the Active Sequence is a byte

used to define the sequence step information that can

be edited or read through the other elements of the

sequence step data exchanged. When reading or

writing to this element, the value will correspond with the

step that can be read or edited.

Example: If 3 is shown, step 3 can be edited or read.

Desired/Selected Step Amount

Desired/Selected Step Amount is a 32bit integer used to

define the step amount for the Desired Selected Step of

the Active Sequence. When reading or writing to this

element, the sequence step amount has two decimal

places, and the units are always reflected by the integer

in Selected Sequence Step Shot Type.

Desired/Selected Step Flow Rate

Desired/Selected Step Flow Rate is a 16bit integer used

to define the step flow rate for the Desired Selected

Step of the Active Sequence.

Desired/Selected Step Calibration

Desired/Selected Step Calibration is a 16bit signed

integer used to define the step calibration for the

Desired Selected Step of the Active Sequence. The

units for this are always reflected by the integer in the

Selected Sequence Step Shot Type.

3A6338B 31

Page 32

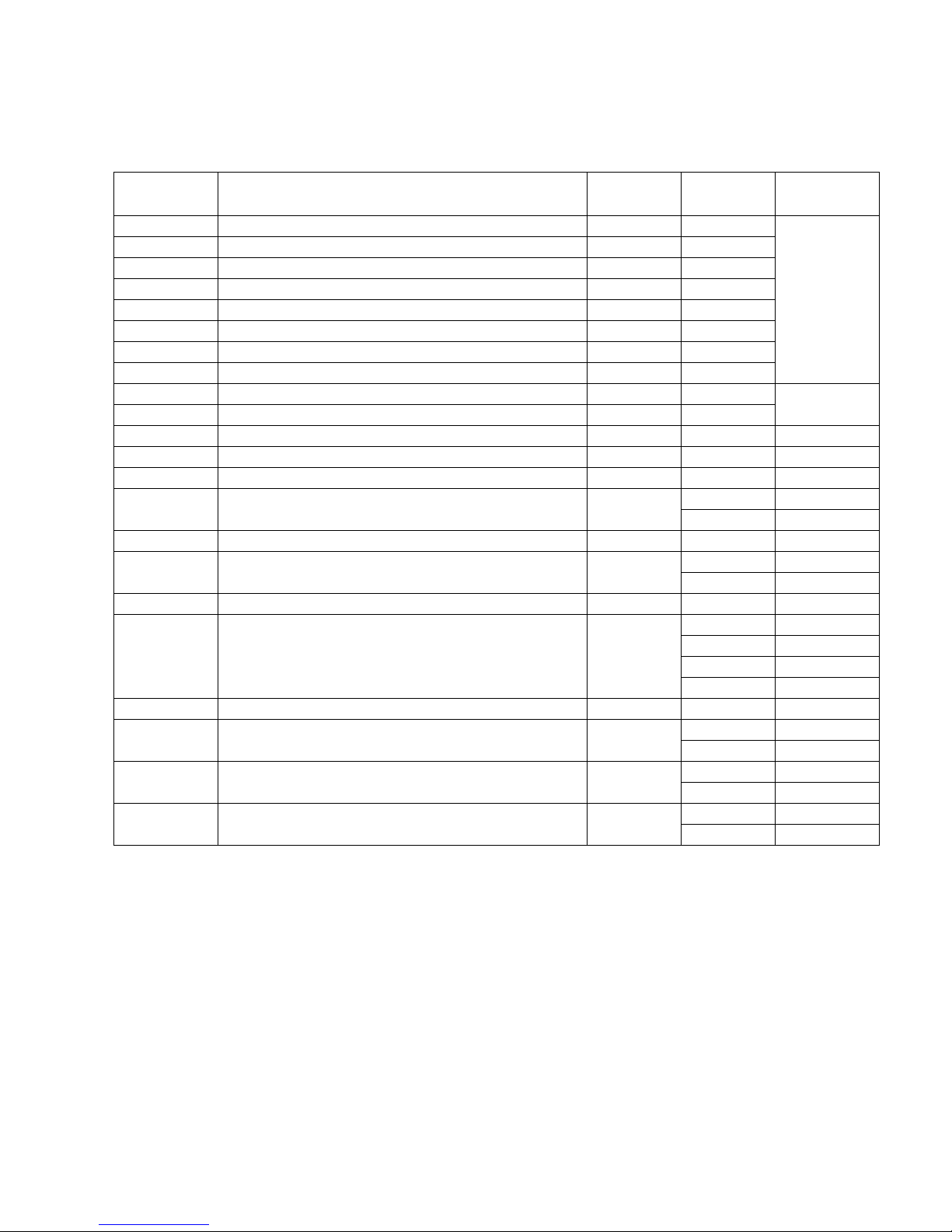

Appendix D - Error Number Requiring Acknowledgment

Appendix D - Error Number Requiring

Acknowledgment

The Error Number Requiring Acknowledgment is a structure that allows the PLC to monitor, acknowledge and clear

errors on the EFR system.

Below is a list of errors the EFR can return through the CGM. If active, each error will return a value to the Active

Error Number Requiring Acknowledgment location of the map. See the Error Value column for the corresponding

value of each error. When an error is returned through the Active Error Number Requiring Acknowledgment location

of the map, the error must be acknowledged. To acknowledge an error, the value of the error that was returned must

be copied to the Acknowledging of the Active Error Number location of the map. Once the error value has been

copied and sent, the EFR will clear the error and will not update the Active Error Number Requiring Acknowledgment

location until the error has been cleared inside the EFR.

NOTE: See the timing diagrams below for information regarding the timing of signals. A 50ms delay is suggested

between each CGM signal.

NOTE: See help.graco.com for further explanation of each error code.

Error Code Error Description Error Type Error Value

P4DA High Pressure Red Side Alarm 1

P4DB High Pressure Blue Side Alarm 2

P6DA Red Pressure Disconnected Alarm 3

P6DB Blue Pressure Disconnected Alarm 4

P7DA Pressure Imbalance Red Side Alarm 5

P7DB Pressure Imbalance Blue Side Alarm 6

V1NX Motor Under Voltage Alarm 8

V4NX Motor Over Voltage Alarm 9

T4NX Motor Temperature Alarm 10

T4NX Motor Board Temperature Alarm 11

WBNX Motor Encoder Alarm 12

WMNX Motor IPC Communication Alarm 13

WMNX Motor Board Hardware Alarm 14

WMNX Motor Board Exception Alarm 15

A4NX Motor Switch Current Alarm 16

P3DA High Pressure Red Side Warning Deviation 17

P3DB High Pressure Blue Side Warning Deviation 18

S1NX Invalided Sequence Step Warning Deviation 19

W5NX Motor Encoder Calibration Warning Deviation 20

CACA ADM Disconnected Advisory 21

CACF FCM Disconnected Advisory 22

CACM Motor Disconnected Advisory 23

CACC CGM Disconnected Advisory 24

CCCC CGM Fieldbus Disconnected Advisory 26

P6FA Inlet Pressure Red Side Disconnected Advisory 27

P6FB Inlet Pressure Blue Side Disconnected Advisory 28

DHDA Leak Detected Red Side Advisory 30

32 3A6338B

Page 33

Appendix D - Error Number Requiring Acknowledgment

DHDB Leak Detected Blue Side Advisory 31

F3NX High Flow Rate Advisory 32

P4FA High Inlet Pressure Red Pump Advisory 33

P4FB High Inlet Pressure Blue Pump Advisory 34

DDDA Red Pump Cavitation Advisory 35

DDDB Blue Pump Cavitation Advisory 36

DBDX Bubble Detected Advisory 37

P4FX High Inlet Pressure Advisory 38

3A6338B 33

Page 34

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

Sealant and Adhesive Dispensing Equipment

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor, go to www.graco.com, or call to identify the nearest

distributor.

If calling from the USA: 1-800-746-1334

If calling from outside the USA: 0-1-330-966-3000

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2018, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6338

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

Revision

B, February 2019

Loading...

Loading...