Page 1

Operation, Repair, Parts

Renegade TSP

3A6884B

Torque Series Pump

Renegade TSP is a hydraulic power pack for use with bolt torquing wrenches only.

For professional use only.

Not approved for use in explosive atmospheres or hazardous (classified) locations.

Models: 17U632, 17U633, 17U634, 17U635

10,000 psi (68.9 MPa, 700 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual and on the unit before using

the equipment. Be familiar with the controls and the proper usage of the

equipment. Save these instructions.

EN

Page 2

Contents

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pendant Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fill Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Prime TSP Power Pack Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connect Hose and Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hose Prime Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Main Menu Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Change Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Select Control Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Secondary Menu (Stored Data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Recycling and Disposal at End of Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-Way, Poppet Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Pressure Set Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pressure Relief Valve Replacement (1,500 and 12,000 PSI) . . . . . . . . . . . . . . 33

4-Way Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Transducer Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Pendant Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wiring Diagram - 120V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Wiring Diagram - 230V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Renegade TSP Torque Series Pump Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Manifold Assembly Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Motor Assembly Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Control Box Parts - 120V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Control Box Parts - 230V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Radio Frequency Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2 3A6884B

Page 3

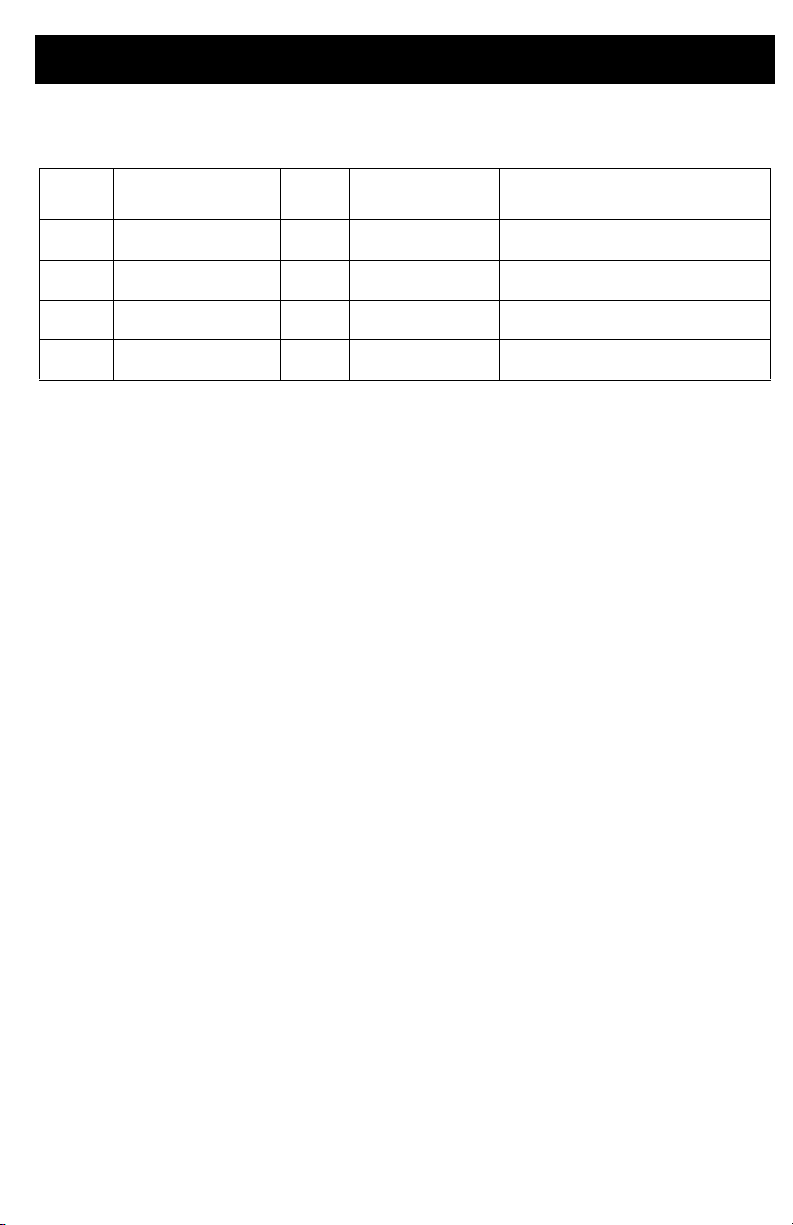

Models

Models

Model

No. Name Voltage Pendant

17U632

17U633

17U634

17U635

Renegade TSP

Torque Series Pump

Renegade TSP

Torque Series Pump

Renegade TSP

Torque Series Pump

Renegade TSP

Torque Series Pump

120V

120V

230V

230V

Corded 10,000 psi (68.9 MPa, 700 bar)

Wireless 10,000 psi (68.9 MPa, 700 bar)

Corded 10,000 psi (68.9 MPa, 700 bar)

Wireless 10,000 psi (68.9 MPa, 700 bar)

Maximum Working Pressure

psi (MPa, bar)

3A6884B 3

Page 4

Warnings

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual where

applicable.

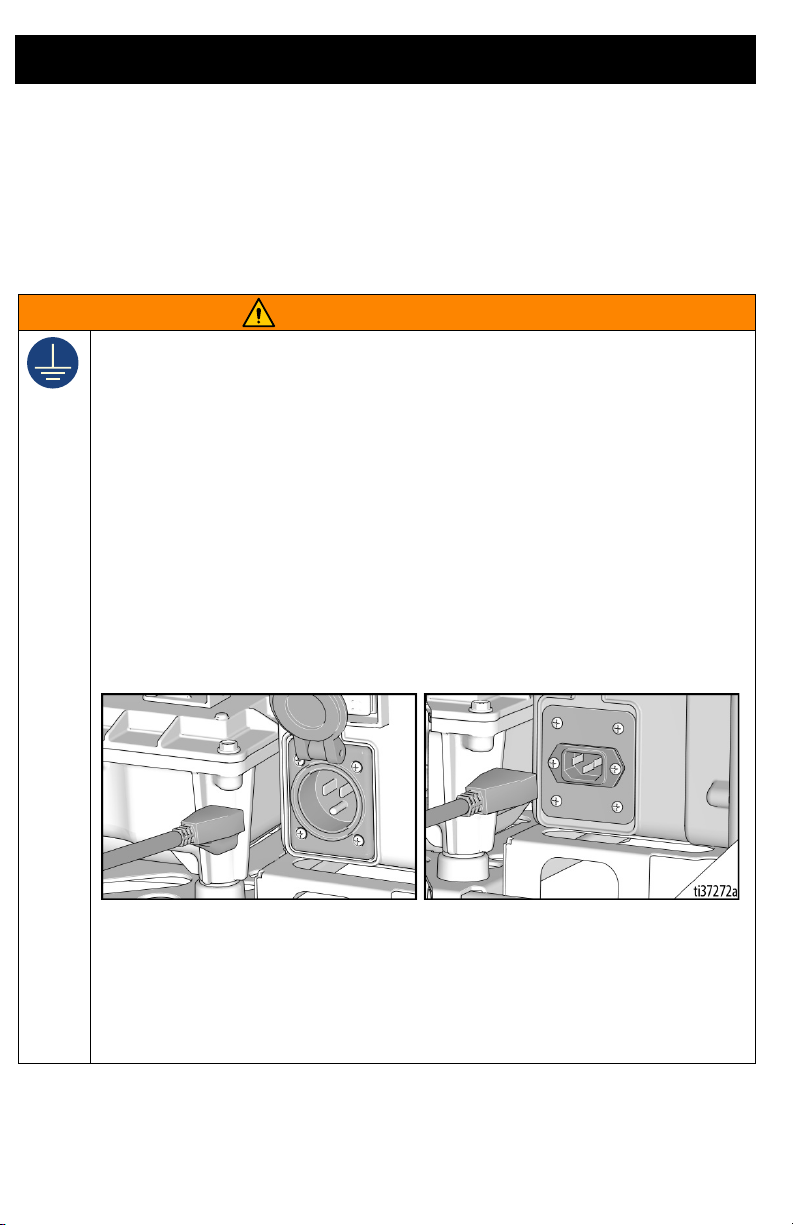

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces

the risk of electric shock by providing an escape wire for the electric current. This product is

equipped with an appropriate grounding electrical inlet. This product must be plugged into an

outlet that is properly installed and grounded in accordance with all local codes and regulations.

• Improper installation of the grounding electrical inlet is able to result in a risk of electric

shock.

• When repair or replacement of the electrical inlet is required, do not connect the grounding

wire to either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes

is the grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not

completely understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the electrical inlet. Only connect the product to an extension cord having the

same configuration as the electrical inlet.

• This product is for use on a nominal 120V or 230V circuit and has a grounding electrical

inlet as illustrated in the figure below.

• Do not use a 3-to-2 adapter with this product.

• Extension Cords:

• Use only a 3-wire extension cord that has a grounding plug and a grounding receptacle that

mates with the electrical inlet on the product.

• Make sure your extension cord is not damaged. Use 12 AWG (2.5 mm

the current that the product draws.

2

) minimum to carry

• An undersized cord results in a drop in line voltage and loss of power and overheating.

4 3A6884B

Page 5

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure leaks are able to inject oil into the body and cause serious bodily injury that can

result in amputation. In the event that injection occurs, get immediate surgical treatment.

• Do not handle pressurized hoses. Escaping oil under pressure can penetrate the skin,

causing serious injury.

• Do not stop or deflect leaks with your hand, body, glove or rag.

• Do not leave the unit energized or under pressure while unattended. When the unit is not

in use, turn off the unit and follow the Pressure Relief Procedure.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

•

This system is capable of producing 10,000 psi (68.9 MPa, 700 bar). Use Graco replacement

parts or accessories that are rated at a minimum of 10,000 psi (68.9 MPa, 700 bar).

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the

controls.

FIRE AND EXPLOSION HAZARD

Flammable fumes in work area can ignite or explode. To help prevent fire and explosion:

• This equipment generates sparks. Do not use in explosive atmospheres or hazardous

(classified) locations.

• Use only in well-ventilated areas.

• Do not plug or unplug power cords, or turn power or light switches on or off, when

flammable fumes are present.

• Keep work area free of debris, including solvent, rags, and gasoline.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at

all times.

• Stay alert and watch what you are doing.

• Do not leave the unit energized or under pressure while unattended. When the unit is not

in use, turn off the unit and follow the Pressure Relief Procedure.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Avoid damaging hydraulic hoses. Avoid sharp bends and kinks when routing hydraulic

hoses. Do not kink or over-bend the hose. Using a bent or kinked hose will cause severe

back-pressure. Sharp bends or kinks will cause internal damage to the hose leading to

premature hose failure.

• Do not drop heavy objects on hydraulic hoses. A sharp impact may result in internal

damage to the hose. Applying pressure to a damaged hose may cause it to rupture.

• Do not expose the hose to temperatures or to pressures in excess of those specified by

the hose manufacturer.

• Do not use the hose as a strength member to pull or lift the equipment.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• The system operating pressure must not exceed the pressure rating of the lowest rated

piece in the system.

•

Make sure all equipment is rated and approved for the environment in which you are using it.

3A6884B 5

Page 6

Warnings

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect extension cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on electrical inlet and extension cords.

• Store indoors.

LIFTING HAZARD

This equipment is heavy. To avoid injury, lift using:

• Two persons, or

• A hoist attach to the Lift Point.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Before checking, moving, or servicing equipment, follow the Pressure Relief Procedure

and disconnect all power sources.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eye wear and hearing protection.

6 3A6884B

Page 7

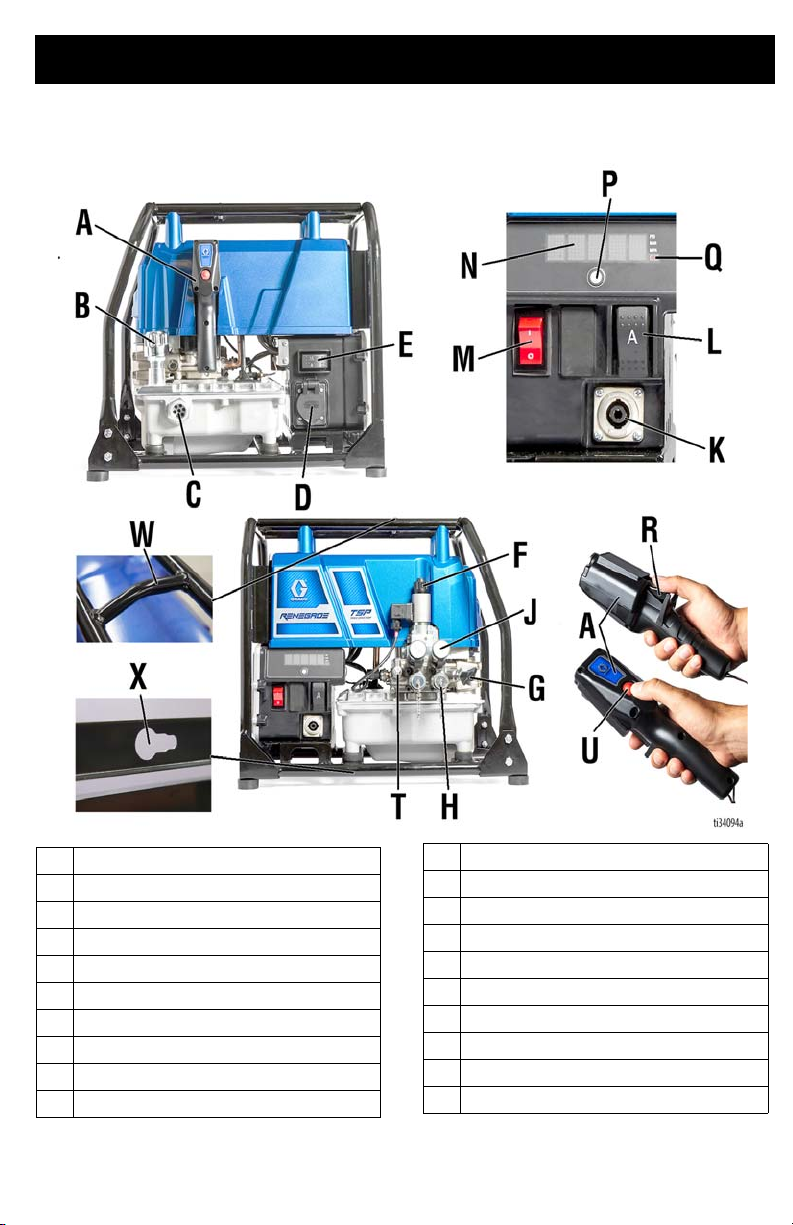

Component Identification

Component Identification

A

Pendant

B

Oil Fill Cap (Breather)

C

Oil Level Sight

D

Electrical Inlet

E

15/20A Switch (120V only)

F

Pressure Relief Button

G

Pressure Setting Valve

H

Hose Connection – Advance

J

Hose Connection – Return

K

Pendant Connector

3A6884B 7

L

Manual Advance Switch

M

On/Off Switch

N

Display

P

Display Button

Q

Wireless Remote Signal Indicator

R

Pendant Advance Switch

T

Pressure Gauge Port

U

Pump Stop Switch

W

Lift Point

X

Pump Rod Puller

Page 8

Component Identification

Controls and Indicators

Item Description

On/Off Switch Turns TSP power pack on or off.

15A/20A Switch

(120V only)

Pressure Setting Valve Controls pressure at the tool. Turn clockwise to increase pressure.

Pressure Relief Button Relieves pressure in the system (pressure goes to zero).

Manual Advance Switch

or Pendant Advance

Switch

Display Shows pressure and other control information.

Display Button Cycles Display through display information.

Pendant Pump Stop

Switch

Sets TSP power pack to either 15A or 20A. Select setting based on

your circuit rating. Select 20A when a 20A circuit is available. Using the

20A setting provides the maximum performance. Select 15A when a

15A circuit is available.

Activates pump to advance the tool when pressed.

Stops pump early if pump stop is needed.

8 3A6884B

Page 9

Grounding

The equipment must be grounded to

reduce the risk of electric shock. Improper

grounding can cause electric shock.

Grounding provides an escape wire for the

electric current.

All electrical wiring must be done by a

qualified electrician and comply with all

local codes and regulations.

Grounding

Power Requirements

100-120 VAC, 50/60 Hz, 15A/20A, single

phase.

220-240 VAC, 50/60 Hz, 10A, single phase.

Extension Cords

Use a 3-wire extension cord with an

undamaged ground contact.

Use a 3-wire, 12 AWG (2.5 mm

extension cord. Longer cords and higher

gauge cords reduce performance.

The plug must be plugged into an outlet that

is properly installed and grounded in

accordance with all local codes and

regulations.

Do not modify plug! If it will not fit in outlet,

have grounded outlet installed by a qualified

electrician. Do not use an adapter.

2

) minimum

3A6884B 9

Page 10

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

To help prevent serious injury from

pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure before

cleaning, checking, or servicing the

equipment.

NOTE: The TSP power pack is designed to

automatically relieve pressure when the

pump motor stops.

1. Verify displayed pressure goes to zero

when motor stops.

2. If pressure is not zero, then press

Pressure Relief Button.

3. Verify pressure has dropped to zero.

4. If you suspect that pressure has not

been fully relieved, rotate the Pressure

Setting Valve counterclockwise until

rotation stops.

10 3A6884B

Page 11

Setup

FULL

Setup

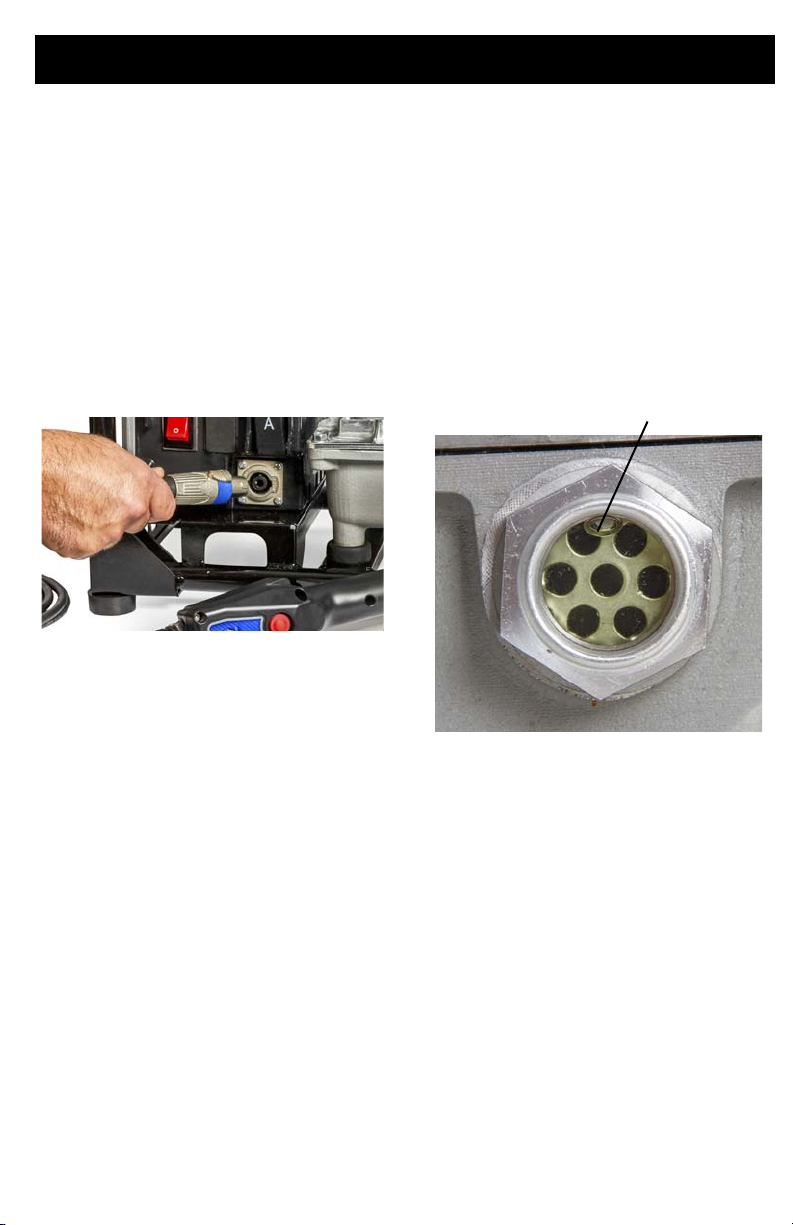

Pendant Setup

Corded Pendant

Attach Corded Pendant by lining up the tab

on the plug with the socket located on the

power pack control. Insert the plug and turn

clockwise until you hear the lock click. The

Corded Pendant must be selected to be the

active control, see Select Control Device

page 17.

Wireless Pendant

The Wireless Pendant must be selected to be

the active control. See Select Control

Device page 17.

Fill Oil Tank

Unit is shipped without hydraulic oil. Before

the first use, fill tank with hydraulic oil, see

Recommended Oil Temperature Ranges

for Various Hydraulic Oil Weights

1. Remove Oil Fill Cap.

2. Add hydraulic oil until oil is visible at the

top of the Sight Glass.

3. Replace Oil Fill Cap.

page 52.

3A6884B 11

Page 12

Setup

Modes

The TSP power pack has three modes:

prime, calibration, and operation.

The prime mode removes air from the pump.

The calibration mode calibrates the

pressure sensor. See Calibration

Procedure page 28.

The operation mode is the normal mode in

which the TSP power pack is ready to torque

bolts.

Prime TSP Power Pack Procedure

Priming is required after initial oil fill or pump

replacement. Unit may also require priming

when displayed control pressure reading

fluctuates continuously.

1. Disconnect hoses, if attached.

2. Plug in TSP power pack.

3. Turn ON/OFF switch to ON position.

4. Turn Pressure Setting Valve

counterclockwise until rotation stops.

This is the zero pressure setting.

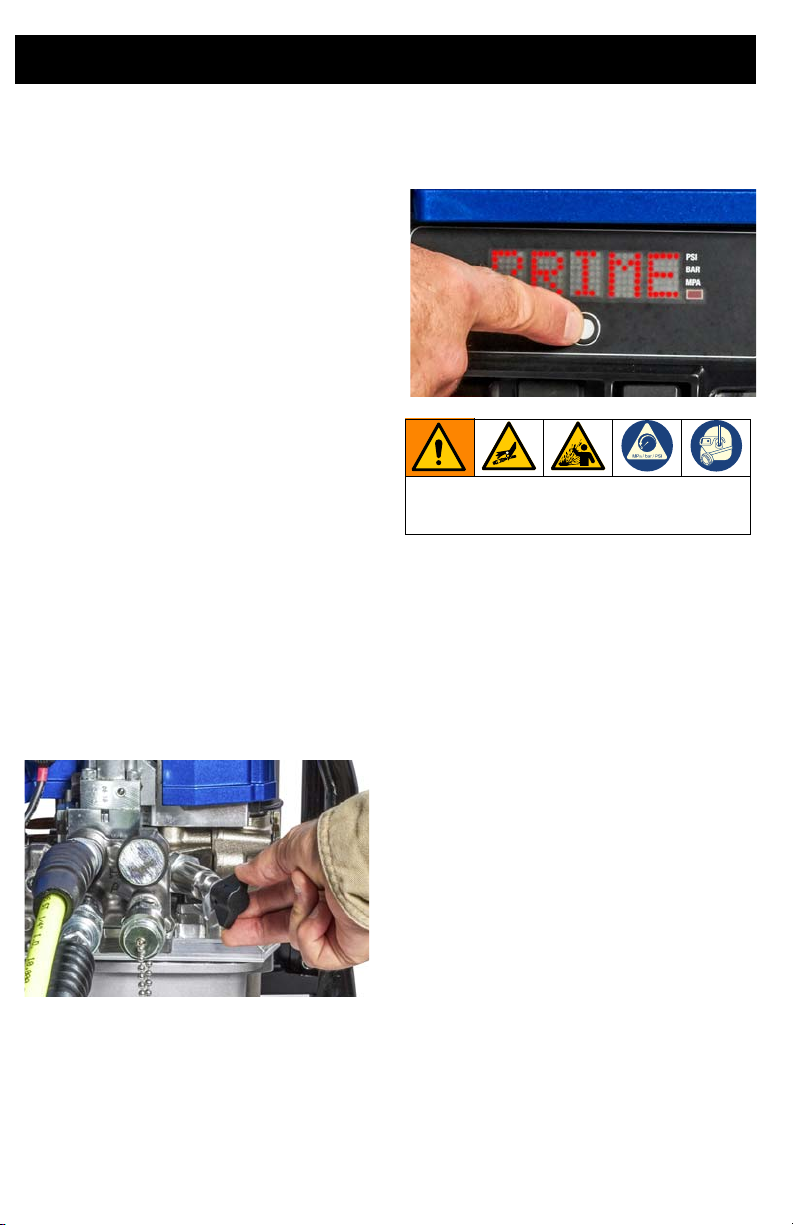

5. Cycle through primary menu by short

pressing the control Display Button until

PRIME appears on Display.

High-pressure leaks are able to inject oil

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

6. Press the Advance Switch on selected

control device to start prime mode. 90

will appear on the Display and will count

down in seconds as the prime procedure

automatically occurs.

NOTE: Press Display Button or Pump Stop

Switch any time while in prime mode to

cancel the procedure.

NOTE: TSP power pack will automatically

return to operation mode when prime

procedure is complete.

7. To ensure the TSP power pack is

primed, set pressure to 8000 psi and

press the Advance Switch on selected

control device. The Display pressure

reading should be steady at 8000 +/- 50

psi. If pressure fluctuations are 100 psi or

greater, the Prime TSP Power Pack

Procedure should be repeated.

8. Inspect for leaks. If leaking occurs,

tighten all fittings and repeat the Prime

TSP Power Pack Procedure.

9. Check hydraulic fluid level.

12 3A6884B

Page 13

Setup

Connect Hose and Tool

The TSP power pack uses flush-face

quick-release couplings that are durable and

easy to clean. To connect hose and tool,

follow the steps below.

1. Wipe the mating surfaces of the

couplings on the TSP power pack and

the hoses with a clean rag before making

connection.

2. Connect the hoses from the TSP power

pack to the hydraulic tool.

NOTE: When making connections, do not

over stretch the hoses or bend hoses at a

sharp angle.

Hose Prime Procedure

Prime and flush the hoses each time a hose

is replaced or when swapping tools.

Continuous use of a hose and tool

combination should not require a prime and

flush procedure unless the hoses lose oil.

1. Turn ON/OFF switch to OFF position.

2. Connect hoses to the manifold on the

TSP power pack.

3. Connect hoses together at tool end of

the hose.

4. Turn ON/OFF switch to ON position.

5. Set pressure control to minimum

pressure.

6. Run the TSP power pack for 30 seconds

to purge the air from the hoses.

7. Check hydraulic oil level. Fluid level

should be at the top of the oil level sight

glass. Add oil as needed.

3A6884B 13

Page 14

Operation

Operation

FIRE AND EXPLOSION WARNING

To avoid serious injury, do not use in

explosive atmospheres or hazardous

(classified) locations.

High pressure leaks are able to inject oil

into the body and cause serious bodily

injury. Before each use, inspect hydraulic

lines, fittings, and hoses for breaks,

cracks, worn spots, bulges, kinks and any

other damage. Replace damaged lines,

fittings, or hoses immediately. Never

attempt to repair the damaged parts.

1. Determine desired torque for your

application (nut or bolt specifications

based on the specific project

recommendations or standards

required).

2. Determine desired pump pressure by

referencing wrench specifications for

torque and pressure.

3. Connect hoses and wrench to TSP

power pack. Only use hoses and

wrenches rated at a minimum of 10,000

psi (68.9 MPa, 700 bar).

4. Plug extension cord into TSP power

pack.

AMPUTATION OR CRUSH HAZARD

Unexpected pump activation can cause

serious injury. Ensure hands are clear of

wrench crush points when activating TSP

power pack.

5. Turn ON/OFF switch to ON position.

High-pressure leaks are able to inject oil

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

6. Activate TSP power pack with the

selected control device; see Select

Control Device page 17. While holding

Advance Switch, adjust Pressure

Setting Valve until desired pump

pressure is shown on Display or gauge.

NOTE: Inspect for leaks. If leaking occurs,

tighten all fittings and repeat the Prime TSP

Power Pack Procedure page 12.

7. Attach wrench to nut or bolt per wrench

manufacturer’s specifications.

8. Activate TSP power pack by pressing

and holding Advance Switch until end of

wrench stroke. End of stroke is indicated

either by the wrench, the pack pressure

rising rapidly, the nut stopping, or some

combination of these factors.

9. Release Advance Switch and wrench

will automatically return.

10. Repeat steps 8 and 9 until job is

complete.

14 3A6884B

Page 15

Operation

Shut Down

1. Turn ON/OFF switch to OFF position.

Unplug the TSP power pack.

2. Disconnect hoses from TSP power pack.

Cleaning

Proper care and maintenance is

recommended for best experience with the

TSP power pack. For proper maintenance

activity and intervals, see Maintenance page

19.

To clean, wipe TSP power pack and hoses

with a rag to remove any accumulated oil and

dirt after every use.

Wash TSP power pack with mild soap and

water as needed. High pressure washing is

not recommended.

3A6884B 15

Page 16

Display

Display

Main Menu Operation

1. Turn power ON. Display will show

as unit powers on.

2. Once powered on, Display will show

PRESSURE (in PSI, bar, or MPa - as

selected). Refer to Change Display

Units page 17.

3. Short press Display Button and SET

HOURS will scroll past on screen.

NOTE: SET HOURS is a resettable hour

meter that may be used to monitor oil change

intervals.

4. Short press Display Button and

LIFETIME HOURS will scroll past on

screen.

NOTE: LIFETIME HOURS displays a lifetime

hour meter and cannot be reset.

5. Short press Display Button and name of

the selected control device will scroll

past on screen. If no control device is

selected, SELECT CONTROL DEVICE

will scroll past on screen.

a. Press and hold Display Button to

select control device. Refer to

Select Control Device page 17.

6. Short press Display Button and PRIME

will scroll past on screen.

a. Press and hold Display Button to

reset hours to 0.

16 3A6884B

a. Press and Hold Display Button to

enter prime mode. Refer to Prime

TSP Power Pack Procedure page

12.

7. Short press Display Button to return to

PRESSURE screen.

Page 17

Display

Change Display Units

NOTE: To change display units you must be

in the pressure screen with the pressure

display at zero.

1. Press and hold the Display Button for

5 seconds to change pressure units (psi,

bar, MPa) to desired units. Selection of

bar or MPa changes gallons to liters x 10.

Select Control Device

1. Short press Display Button three times to

move to SELECT CONTROL DEVICE

mode.

2. Press the Advance Switch on desired

control device to select it. Options

available are:

a. Manual Advance Switch.

b. Corded Pendant.

c. Wireless Pendant.

NOTE: The TSP power pack may be paired

with only one control at any time. Any

previously selected devices will be ignored

when a new device is selected.

3A6884B 17

Page 18

Display

Secondary Menu (Stored Data)

NOTE: Secondary Menu contains the

calibration procedure plus information that

may be useful during troubleshooting or

repair.

1. To enter Secondary Menu turn power

switch on while holding Display Button.

Continue to hold Display Button until

CALIBRATE appears.

2. CALIBRATE scrolls past on the Display.

4. Short press Display Button and

SOFTWARE REVISION scrolls past on

the Display.

5. Short press Display Button and LAST

CODE scrolls past on the Display.

a. Press and hold Display Button and

CLEAR will appear for three

seconds on the Display. NO CODE

STORED will then scroll past on

the Display.

a. Press and hold button to enter

CALIBRATION mode. Refer to

Calibration Procedure page 28

for calibration instructions.

b. Short press Display Button to return

3. Short press Display Button and SERIAL

NUMBER scrolls past on the Display.

18 3A6884B

to the CALIBRATE screen.

Page 19

Maintenance

Maintenance

Routine maintenance is important to ensure proper operation of your TSP power pack.

Maintenance includes performing routine actions that keep your TSP power pack in operation

and prevent trouble in the future.

Activity Interval

Inspect pump, hoses, and tools for damage or leaks.

Inspect fan opening for blockage. Daily.

Pressure calibration. Per company, customer, or job

Change hydraulic oil. 40 motor hours.

Recycling and Disposal at End of Life

At the end of the product’s useful life,

dismantle and recycle it in a responsible

manner.

Preparation:

•

Perform the Pressure Relief

Procedure, page 10.

• Drain and dispose of fluids according to

applicable regulations. Refer to the

material manufacturer’s Safety Data

Sheet.

Daily.

specification.

Dismantle and recycle:

•

Remove motors, circuit boards,

displays, and other electronic

components. Remove the battery from

the wireless pendant. Recycle

according to applicable regulations.

• Do not dispose of electronic

components with household or

commercial waste.

• Deliver remaining product to a recycling

facility.

3A6884B 19

Page 20

Troubleshooting

Troubleshooting

1. Follow Pressure Relief Procedure

page 10, before troubleshooting or

repairing TSP power pack.

2. Check all possible problems and causes

before disassembling TSP power pack.

Problem Cause Solution

Unit does not start when plugged in

and power switch is “ON”.

Motor stops under load. Low Voltage. Reset circuit breaker, if tripped.

Blowing circuit breakers. Pump is exceeding circuit

Motor runs but unit will not pump

oil.

Pump does not reach full pressure. Bad transducer. Test with gauge on gauge port to very.

Pump stalls at ~4500 psi. Poppet valve not functioning

Extension cord. Check

extension cord continuity

with ohmmeter.

Low Voltage.

Meter must read: 85-130

VAC (120V),.

Meter must read: 170-260

VAC (240V).

Circuit breaker has tripped. Reset circuit breaker.

breaker rating.

Pump is not primed. Perform Prime TSP Power Pack

Low hydraulic oil level. Add oil see, Fill Oil Tank page 11.

High-pressure pump issue. Replace high-pressure pump. see Pump

Pressure set valve issue. Replace pressure set valve, see

High-pressure relief valve

issue.

4-way valve issue. Replace 4-way valve, see 4-Way Valve

properly.

Replace extension cord.

Reset circuit breaker.

Try another outlet.

Use a heavier gauge extension cord.

Turn off other electric loads.

Use a heavier gauge extension cord.

Make certain that the 15A/20A Switch is

set to the correct position for the circuit

that the unit is plugged in to (120V only).

Set 15A/20A Switch to 15A setting (120V

only).

Procedure page 12.

Replace transducer, see Transducer

Replacement page 37.

Replacement page 30.

Pressure Set Valve Replacement page

33.

Replace high-pressure relief valve, see

Pressure Relief Valve Replacement

(1,500 and 12,000 PSI) page 33.

Replacement page 34.

Replace poppet valve, see 2-Way,

Poppet Valve Replacement page 32.

20 3A6884B

Page 21

Troubleshooting

Problem Cause Solution

Maximum pressure is ~3,300 psi. High pressure pump issue. Replace high pressure pump, see Pump

Unit runs slow. Air in hydraulic system. Check oil level and fill as needed. Perform

Unit set to 15A setting (120V

only).

Hose connection filter

plugged.

Hi-flow pump issue. Replace hi-flow pump, see Pump

High pressure pump issue. Replace high pressure pump, see Pump

4-way valve issue. Replace 4-way valve, see 4-Way Valve

Unit builds full pressure, but torque

wrench fails to advance.

Torque wrench fails to retract. Return flow from wrench is

Pressure indicator does not read

zero (0) psi/bar when pump is

stopped.

TSP power pack does not run at all.

Display shows CODE 03.

Torque is greater than

wrench capacity at full

pressure.

Advance flow line to wrench

is restricted or blocked.

restricted or blocked.

Pressure not relieved. Perform Pressure Relief Procedure

Pressure indicator or gauge

is out of calibration.

Transducer connection

issue (control board is not

detecting a pressure signal).

Replacement page 30.

Prime TSP Power Pack Procedure page

12 and Hose Prime Procedure page 13.

Connect to a 20 Amp circuit and set

switch to 20A setting.

Switch hose connection to other

connectors. Replace filter fitting as

needed.

Replacement page 30.

Replacement page 30.

Replacement page 34.

Use a torque wrench with a larger

capacity.

Check hose couplers for full engagement.

Check hose couplers for full engagement.

page 10.

Replace pressure transducer or

recalibrate with Calibration Procedure

page 28.

1. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

2. Check transducer connection.

3. Disconnect transducer from

connector. Check to see if transduce r

contacts are clean and secure.

4. Reconnect transducer and

connector. Connect power, turn TSP

power pack ON and press Advance

Switch. If TSP power pack does not

run, set TSP power pack to OFF and

proceed to next step.

5. Connect a confirmed working

transducer to transducer connector.

6. Turn TSP power pack ON and press

Advance Switch. If TSP power pack

runs, install new transducer. Replace

control board if TSP power pack does

not run.

3A6884B 21

Page 22

Troubleshooting

Problem Cause Solution

TSP power pack does not run at all.

Display shows CODE 04.

Control board detected

voltage surges.

1. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

2. Locate a good voltage supply to

prevent damage to electronics.

TSP power pack does not run at all.

Display shows CODE 05.

Control is commanding

motor to run, but motor shaft

does not rotate.

1. Remove pumps and try to run TSP

power pack. If motor runs, check for

locked or frozen pump or dr ive train. If

TSP power pack does not run,

continue to step 2.

2. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

3. Remove top half of shroud frame and

shroud.

4. Set TSP power pack to OFF and spin

pump crank 1/2 turn. Restart TSP

power pack. If TSP power pack runs,

replace control board. If TSP power

pack does not run, continue to step 5.

5. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

6. Open control box by removing 8

screws that attach control assembly

to control box. Locate motor

connector (large 6-pin connector)

and disconnect.

7. Perform Spin Test: Test at large

6-pin motor field connector. Test

motor by placing a jumper across pins

1 & 2. Rotate motor fan at about 2

revolutions per second. A cogging

resistance to motion should be felt at

the crank. The motor should be

replaced if no resistance is felt.

Repeat for pin combinations 1 & 3

and 2 & 3. Pin 4 (the green wire) is not

used in this test. If all spin test is

positive, continue to step 6 (see

connections below).

22 3A6884B

Page 23

Troubleshooting

Problem Cause Solution

3A6884B 23

Page 24

Troubleshooting

Resistance Table:

TSP Power Pack 0 ohms

Problem Cause Solution

TSP power pack does not run at all.

Display shows CODE 05.

Control is commanding

motor to run, but motor shaft

does not rotate.

8. Perform Field Short Test: Test at

large 6-pin motor field connector.

There should not be continuity from

pin 4, the ground wire, and any of the

remaining pins. If motor field

connector tests fail, replace motor.

9. Check Motor Thermal Switch:

Unplug thermal wires. Set meter to

ohms. Meter should reach the proper

resistance across pins 5 & 6.

24 3A6884B

Page 25

Problem Cause Solution

Resistance Table:

TSP Power Pack 0 ohms

TSP power pack does not run at all.

Display shows CODE 06.

Troubleshooting

Motor overheated. Note: Motor must be cooled down for the

test.

1. Keep TSP power pack in cooler

location with good ventilation. Make

sure motor air intake is not blocked.

2. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

3. Open control box by removing 8

screws that attach control assembly

to control box.

4. Check thermal switch inside control

box.

5. Disconnect 6-pin connector. Make

sure contacts are clean and secure.

Measure resistance of the thermal

switch (thermal switch is across pins

5 & 6). If reading is not correct,

replace motor.

6. Check Motor Thermal Switch:

Unplug thermal wires. Set meter to

ohms. Meter should reach the proper

resistance across pins 5 & 6.

7. Reconnect 6-pin connector. Connect

power, turn TSP power pack ON and

press Advance Switch. If TSP power

pack does not run, replace control

board.

3A6884B 25

Page 26

Troubleshooting

Problem Cause Solution

TSP power pack does not run at all.

Display shows CODE 08.

Incoming voltage too low for

TSP power pack operation.

1. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

2. Remove other equipment that uses

the same circuit.

3. Locate a good voltage supply to

avoid damage to electronics.

TSP power pack does not run at all.

Display shows CODE 10.

TSP power pack does not run at all.

Display shows CODE 12.

TSP power pack does not run at all.

Display shows CODE 15.

Control board is over

heating.

Excessive current protection

enabled.

Motor not spinning (no

current to motor).

1. Make sure motor air intake is not

blocked.

2. Make sure fan is securely attached

to motor shaft.

3. Replace control board.

4. Replace motor.

Cycle power on and off.

1. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

2. Remove top half of shroud frame and

shroud.

3. Set TSP power pack to OFF and spin

pump crank 1/2 turn. Restart TSP

power pack. If TSP power pack runs,

replace control board. If TSP power

pack does not run, continue to step 5.

4. Turn power on. If code continues,

replace control board.

26 3A6884B

Page 27

Problem Cause Solution

TSP power pack does not run at all.

Display shows CODE 16.

TSP power pack does not run at all.

Display shows CODE 17.

Motor position sensor not

working.

TSP power pack plugged

into wrong voltage.

Troubleshooting

1. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

2. Open control box by removing 8

screws that attach control assembly

to control box.

3. Disconnect motor position sensors

and inspect for damage at

connectors.

4. Reconnect sensor.

5. Turn power ON. If code continues,

replace motor.

1. Set TSP power pack to OFF and

disconnect power to TSP power

pack.

2. Locate a good voltage supply to avoi d

damage to electronics.

3A6884B 27

Page 28

Repair

Repair

Calibration Procedure

The TSP power pack should be re-calibrated

after replacing the transducer or control

assembly. The TSP power pack should also

be re-calibrated as needed based on your

company’s business practices and if you

suspect the TSP power pack is not operating

correctly.

NOTE: This procedure requires the use of a

high precision calibration gauge or data

acquisition system to be used as a calibration

standard. It is recommended to leave hoses

attached to the TSP power pack while

calibrating.

1. Connect the calibration high precision

gauge or data acquisition system to the

pressure gauge port or one of the

advance ports of the hose distribution

manifold.

2. Power up the TSP power pack, but do

not press the Advance Switch.

3. Make sure that the pressure set valve is

fully relieved and all pressure in the TSP

power pack is relieved; see Pressure

Relief Procedure, page 10. There

should be zero pressure in the TSP

power pack.

4. Enter the secondary menu, see

Secondary Menu (Stored Data) page

18.

5. CALIBRATE scrolls on the Display.

6. Press and hold the Display Button for a

few seconds to start the calibration

procedure. Calibration mode has been

entered when RUN TO 8000 PSI

PRESS DISPLAY BUTTON TO SAVE

scrolls on the Display.

28 3A6884B

Page 29

Repair

7. Press the TSP power pack Advance

Switch. Set pressure to 8000 psi per the

calibration gauge or data acquisition

system. While keeping the power pack

running at 8000 psi, press the Display

Button to lock in the 8000 psi value for

the controller.

NOTE: If calibration procedure is successful,

DONE will display on the screen for three

seconds, and then pack will return to normal

operation mode.

NOTE: If the calibration procedure was

unsuccessful, the following message will

scroll on the Display: CALIBRATION

FAILED. Press Display Button to continue.

Perform Pressure Relief Procedure page

10, then cycle power to the TSP power pack

and retry calibration procedure.

NOTE: If calibration procedure is never

successful, replace pressure transducer; see

Transducer Replacement page 37.

3A6884B 29

Page 30

Repair

Pump Replacement

Tools Required: 13 mm wrench.

Pump Removal

(High flow displacement pump shown)

Pump removal includes disassembling the

pump guard and pump bolts and removing

the pump.

1. Perform Pressure Relief Procedure,

page 10 and disconnect power to the

TSP power pack. Tilt unit 90 degrees

backwards to keep oil from running out

when pump is removed.

2. Remove the pump guard (50) and

retaining bolt (43).

3. Remove pump bolts (qty 6).

4. Slowly slide pump out of the drive

housing. Allow filter to drain into

reservoir during removal.

30 3A6884B

Page 31

Repair

Pump Installation

(High flow displacement pump shown)

Pump installation includes securing the pump

and connecting to the fluid inlet and outlet.

1. Install pump tank o-ring and manifold

seals.

2. Slide pump assembly into drive housing

while ensuring the piston rod head is

properly aligned in the assembly

housing.

Failure to properly align piston rod head into

housing during reassembly could severely

damage the TSP power pack during

operation.

NOTE: Adjust pump rod length with pump rod

puller if needed.

NOTICE

3A6884B 31

Page 32

Repair

3. Attach pump housing to manifold with

four screws and flat washers. Torque

screws to 50-70 in-lbs. (5.6-7.9 N

4. Attach pump housing to reservoir with

two screws and flat washers. Torque to

20-25 ft-lbs (27.1-33.4 N•m).

5. Replace pump guard (50) with retaining

bolt (43).

•m).

2-Way, Poppet Valve Replacement

Tools Required: Phillips screwdriver, 7/8 in.

wrench, 3/4 in. wrench.

1. Perform Pressure Relief Procedure,

page 10 and disconnect power to the

TSP power pack.

2. Remove top half of frame and shroud.

3. Completely loosen Phillips screw from

terminal. Remove the terminal.

4. Remove top 3/4 in. top retaining nut and

discard.

32 3A6884B

Page 33

Repair

5. Lift the black solenoid to gain clearance

to the 7/8 in. hex on the body of the

poppet valve. Loosen and remove.

6. Install new solenoid valve without the

new 3/4 in. top retaining nut.

7. Torque the 7/8 in. hex to 19-21 ft. lbs

(25.8-28.5 N•m).

8. Reinstall the top 3/4 in. retaining nut,

torque to 4-5 ft. lbs (5.4-6.8 N•m).

9. Reconnect the terminal and tighten

Phillips head screw.

Pressure Set Valve Replacement

Tools Required: 1-1/16 in. wrench.

1. Perform Pressure Relief Procedure,

page 10 and disconnect power to the

TSP power pack.

2. Use a 1-1/16 in. wrench to loosen.

3. Remove plastic protective cap from new

valve. Ensure washer remains on new

valve.

4. Screw in new valve by hand. Tighten to

57-61 ft. lb (77.2-82.7 N

•m).

Pressure Relief Valve Replacement (1,500 and 12,000 PSI)

Tools Required: 16 mm wrench.

1. Perform Pressure Relief Procedure,

page 10 and disconnect power to the

TSP power pack.

2. Loosen and remove valve with 16 mm

wrench.

3. Replace new valve and torque to 50-55

ft. lbs (67.8-74.6 N

•m).

10. Reinstall shroud and top half of frame.

1,500 psi relief valve shown

3A6884B 33

Page 34

Repair

4-Way Valve Replacement

Tools Required: Phillips screwdriver, 5 mm

Allen wrench, 10 mm wrench.

Remove 4-Way Valve

1. Perform Pressure Relief Procedure,

page 10 and disconnect power to the

TSP power pack.

2. Remove top half of frame and shroud.

4. Remove finger-tight nut on top of valve.

Remove coil from valve.

5. Use a 5 mm Allen wrench to remove the

four M6 screws that secure the 4-Way

Valve to the diverter block. Remove the

4-way valve. Save the M6 screws for

reuse later.

3. Using a Phillips screwdriver, fully loosen

retainer screw. Pull plug off from the

valve.

34 3A6884B

Page 35

Repair

6. Use a 5 mm Allen wrench to remove the

three M6 screws that secure the diverter

block to the manifold. Remove the

diverter block.

7. Make certain the old o-rings are

removed from the manifold.

NOTICE

Failure to remove existing o-rings from

manifold could result in equipment damage

if multiple o-rings are re-installed into the

valve manifold upon reassembly.

Install 4-Way Valve

1. Remove finger-tight nut on top of new

valve. Remove coil from new valve.

2. Using a 5 mm Allen wrench, carefully

separate the 4-way valve from the

diverter block. Ensure o-rings remain in

place on 4-way valve. Set valve aside on

a clean surface.

3. To remove the protective cover from the

bottom of the diverter block remove the

three hex nuts. Dispose of the three hex

nuts and protective cover.

3A6884B 35

Page 36

Repair

4. Ensure new o-rings are installed in

diverter block and remain in place.

Position diverter block on the manifold.

Align the three screws in the diverter

block with the corresponding holes in the

manifold. Secure with the three M6

screws. Torque to 6-8 ft-lbs (8.1-10.8

N•m).

5. Reattach coil on to valve. Tighten plastic

nut finger-tight to top of valve.

6. Position the 4-way valve on the diverter

block, it will only fit in one position.

Secure with the four M6 screws. Torque

to 6-8 ft-lbs (8.1-10.8 N•m).

7. Remove and dispose of plastic cover

over the plug on the terminal of new

valve.

8. Attach wire harness into terminal on

4-way valve, secure by tightening the

retaining screw.

36 3A6884B

Page 37

Repair

Transducer Replacement

Tools Required: 15/16 in. wrench.

Remove Transducer

1. Perform Pressure Relief Procedure

page 10 and disconnect power to the

TSP power pack.

2. Lift connector locking tab on transducer

electrical connector.

3. Unplug electrical connector from

transducer.

4. Use 15/16 in. wrench to remove

transducer from the manifold.

Install Transducer

1. Apply sealant to transducer threads.

2. Start threading transducer into the

manifold.

3. Using a 15/16 in. socket, tighten

transducer to 50-55 ft-lbs (68.8-75.6

N•m).

4. Plug electrical connector into the

transducer.

5. Verify proper operation and inspect for

leaks. If leaks are found, stop unit and

re-torque transducer.

6. Perform Calibration Procedure page

28.

3A6884B 37

Page 38

Pendant Battery Replacement

CR123A

BATTERY

Pendant Battery Replacement

38 3A6884B

Page 39

Hydraulic Schematic

Hydraulic Schematic

Ref Part Description Ref Part Description

1 19Y114 KIT, repair, manifold 19 19Y104 PUMP, high pressure

2 19Y107 KIT, valve, 4-way, directional 48 195695 FILTER, fluid

3 19Y110 KIT, valve, manual pressure set 49 19Y214 FITTING, filter, 1/4 NPT male

6 19Y353 VALVE, 2-way, poppet 50 17U673 FITTING, QD, male, high

7 19Y108 KIT, transducer, high pressure 54 19Y113 KIT, manifold, distribution

8 17U675 VALVE, pressure relief, 1500 psi 56 17U671 FITTING, QD, female, high

9 17U685 VALVE, pressure relief, 12000

10 17Z470* VALVE, check, high pressure 81 19Y215 FITTING, filter, 1/4 NPT female

11 17U703 RESERVOIR, machined

18 19Y106 PUMP, high flow * Included in kit 19Y114

psi

73 17U696 COOLER, oil

pressure

pressure

3A6884B 39

Page 40

Wiring Diagram - 120V

See Control Box Parts 120V page 48 for 120V

control box wiring

Wiring Diagram - 120V

Ref Part Description Ref Part Description

1 19Y111 KIT, motor, hydraulic power

2 19Y107 KIT, valve, 4-way, directional 27 17U610 BOX, control (120V)

6 19Y353 VALVE, 2-way, poppet 74 19Y115 ASSEMBLY, control

7 19Y108 KIT, transducer, high pressure 79 17U625 HARNESS, main, w/ strain relief

13 17S588 WIRE, green, 16 AWG 8”, #10,

22 17U721 FAN, oil cooler (120V)

40 3A6884B

pack

serrated

26 120660 SWITCH, rocker

85 17U743 ANTENNA, RF

Page 41

Wiring Diagram - 230V

See Control Box

Parts - 230V page

50 for 230V control

box wiring

Wiring Diagram - 230V

Ref Part Description Ref Part Description

1 19Y111 KIT, motor, hydraulic power

2 19Y107 KIT, valve, 4-way, directional 27 17U629 BOX, control (230V)

6 17U666 Valve, 2-way, poppet 74 19Y115 ASSEMBLY, control

7 19Y10 KIT, transducer, high pressure 79 17U625 HARNESS, main, w/ strain relief

13 17S588 WIRE, green, 16 AWG 8”, #10,

22 18B723 FAN, oil cooler (230V)

pack

serrated

26 120660 SWITCH, rocker

85 17U743 ANTENNA, RF

3A6884B 41

Page 42

Renegade TSP Torque Series Pump Parts

Ref. Torque Ref. Torque Ref. Torque

20-25 ft-lbs (27.1-33.4 N•m) 30-40 in-lbs (3.4-4.5 N•m) 110-120 in-lbs

(12.4-13.6 N•m)

40-45 in-lbs (5.1-6.2 N•m) 10-12 in-lbs (1.1-1.4 N•m)

95-105 in-lbs

(10.7-11.9 N•m)

40-45 in-lbs (4.5-5.1 N•m)

513249191021

Renegade TSP Torque Series Pump Parts

42 3A6884B

Page 43

Renegade TSP Torque Series Pump Parts

Renegade TSP Torque Series Pump Parts List

Ref. Part Description Qty.

1 19Y111 KIT, motor, hydraulic

power pack

14 100132 WASHER, flat 8

15 119695 DAMPENER, engine

mount

16 19Y252 FRAME, bottom,

painted

19 19Y251 LABEL, pendant 1

22 17U721 FAN, oil cooler, 120V 1

23 17U722 GUARD, 1

24 17U723 SCREW, shcs, m4 x

70mm

25 108768 SCREW, M8, , cap,

hex head

26 104541 NUT, lock 4

28 17Z490 BUMPER 4

29 131327 BOLT, flange head,

serrated, 1/4

36 18A977 SCREW, hex, hd 4

37 124709 SCREW, hex hd,

flange

38 100718 WASHER 1

39 17Z459 SCREW, grounding 1

45 17U752 COVER, motor,

painted

46 17U745 FRAME, top, painted 1

1

4

1

2

4

4

4

1

Ref. Part Description Qty.

61 PENDANT, complete

61a 18A681 MAGNET, lanyard 1

61b 24F260 KIT, battery cap w/

66 17U756 LABEL, brand 1

67 17U757 LABEL, warning, EN,

70 124757 SCREW, M8x40 2

73 17U696 COOLER, oil 1

89 17U682 LABEL, brand, side 1

96 19Y147 LABEL, operator,

97 19Y369 WIRE, jumper, green 1

99 114993 SCREW, mach, pan

100 105689 NUT, machine hex 1

Replacement safety labels, tags, and cards are

available at no cost.

19Y103 WIRED 1

19Y102 WIRELESS includes

CR123A battery

O-ring

FR, ES

(120V models)

19Y577 LABEL, warning

(230V models)

pendant

wash hd

1

1

1

1

1

2

3A6884B 43

Page 44

Manifold Assembly Parts

Ref. Torque Ref. Torque

50-55 ft-lbs (68.8-75.6 N•m) 6-8 ft-lbs (8.1-10.8 N•m)

57-61 ft-lbs (77-83 N•m) 19-21 ft-lbs (25.8-28.5 N•m)

4-5 ft-lbs (5.4-6.8 N•m)

17284

Manifold Assembly Parts

44 3A6884B

Page 45

Manifold Assembly Parts List

7

Ref. Part Description Qty.

1 19Y114 KIT, repair, manifold 1

2 19Y107 KIT, valve, 4-way,

3 19Y110 KIT, valve, manual,

6 19Y353 VALVE, 2-way,

7 19Y108 KIT, transducer, high

8 17U675 VALVE, pressure

9 17U685 VALVE, pressure

10† 19Y593 KIT, repair, valve,

10a 17Z470 VALVE check,

10b 17U662 GASKET, plug 1

10c 17U661 PLUG, body 1

18 19Y418 LABEL, pressure

49 19Y214 FITTING, filter, 1/4

50 17U673 FITTING, qd, male,

51 17U674 FITTING, qd, cap 2

directional

pressure set

poppet

pressure

relief, 1500 PSI

relief, 12000 PSI

check, hp

high-pressure

control

NPT male

high pressure

1

1

1

1

1

1

2

1

1

1

2

Manifold Assembly Parts

Ref. Part Description Qty.

52† 557897 O-RING, -010, 90d,

53† 104282 O-RING, packing 2

54 19Y113 KIT, manifold,

56 17U671 FITTING, qd, female,

57 17U672 FITTING, qd, plug 2

58* 17Z498 PLUG, pipe 1

59* 110580 SCREW, cap, socket hd4

60* 108050 WASHER, lock, spring 4

81 19Y215 FITTING, filter, 1/4

* Parts included in Kit 19Y113

† Parts included in Kit 19Y114

Parts included in Kit 19Y593

buna

distribution

high pressure

NPT female

8

1

2

1

3A6884B 45

Page 46

Motor Assembly Parts

Ref. Torque Ref. Torque Ref. Torque

190-210 in-lbs

(21.5-23.7 N•m)

95-105 in-lbs

(10.7-11.9 N•m)

10-12 in-lbs (1.1-1.4 N•m)

20-25 ft-lbs (27.1-33.4 N•m) 5-7 ft-lbs (6.8-9.5 N•m) 40-45 ft-lbs (54.2-61.0 N•m)

50-70 in-lbs (5.6-7.9 N•m) 145-155 in-lbs

(16.4-17.5 N•m)

57-61 ft-lbs (77-83 N•m)

155-175 in-lbs (5.6-6.8 N•m) 30-40 in-lbs (3.4-4.5 N•m)

45-55 in-lbs (5.1-6.2 N•m) Cranks to be assembled 180°

out of phase

4

10

19

51123

6

12

26

7139

14

Motor Assembly Parts

46 3A6884B

Page 47

Motor Assembly Parts List

Motor Assembly Parts

Ref. Part Description Qty.

1 19Y111 KIT, motor, hydraulic

power pack

2 116074 WASHER, thrust 2

3 107434 BEARING, thrust 2

4 19Y112 KIT, crank, assembled 2

5 17J166 BEARING, thrust 2

6 17U652 HOUSING, drive,

complete

8 17U699 LID, reservoir,

machined

9 17U701 PLATE, diverter,

reservoir

10 17U702 SCREW, fhh, M6 x

20MM

11 17U703 RESERVOIR,

machined

12 17U705 ROD, connecting, high

flow

13 17U707 ROD, connecting, high

pressure

17*† 17U720 O-RING, 128, 70D,

buna

18 19Y106 PUMP, high flow

includes 17, 37, 40, 42,

43, 44, 47, 48, 52, 53,

72

19 19Y104 PUMP, high pressure

includes 17, 37, 41, 42,

43, 44, 47, 48, 52, 53,

72

20 104572 WASHER, lock spring 6

21 117536 SCREW. cap, hex

head

30 17U729 SCREW 4

1

1

1

1

12

1

1

1

2

1

1

6

Ref. Part Description Qty.

31 17U730 FITTING, indicator,

fluid level

32 17U731 CAP, breather, fill 1

33 17U732 O-RING, 382, 70A 1

34 17U733 PLUG, drain 1

37*† 124709 SCREW, hex hd,

flange

40* 17U588 VALVE, inlet check,

high flow

41† 17U606 VALVE, inlet check,

high pressure

42*† 17U593 SUPPORT, inlet

strainer

43*† 107558 SCREW, cap, hex hd 4

44*† 17U744 SCREW, hex, m8 x

55mm

47*† 159346 WASHER 2

48*† 243226 FILTER, fluid 2

52*† 557897 O-RING 5

53*† 104282 O-RING 2

69 17Z489 WASHER, metal,

sealing

71 17S590 GUARD, pump 1

72*† 111003 WASHER, flat 12

75 105676 SCREW, mach, PNH 2

84 17U644 BRACKET, antenna

mount

85 17U743 ANTENNA, RF 1

* Included in Kit 19Y106

† Included in Kit 19Y104

1

7

1

1

2

8

4

1

3A6884B 47

Page 48

Control Box Parts - 120V

Ref. Torque Ref. Torque

10-12 in-lbs (1.1-1.4 N•m) 15-20 in-lbs (1.7-2.3 N•m)

17-21 in-lbs (1.9-2.4 N•m) 40-45 in-lbs (4.5-5.1 N•m)

253

21

Control Box Parts - 120V

48 3A6884B

Page 49

Control Box Parts List

Control Box Parts - 120V

Ref. Part Description Qty.

1 278893 BOX, control, 120V 1

2 17U638 BOARD, assembly,

8 114528 SCREW, mach,

9 17U617 CONNECTOR, power,

10 HARNESS, power 1

17U618 120V

11 17U621 PLATE, backer, power

12 17Z458 STUD, terminal,

13 17S588 WIRE, green, 16 AWG,

14 100166 NUT, full hex 2

15 24Y030 KIT, repair, coil filter,

16 16U215 SCREW, Phillips,

17 17U616 CONNECTOR,

18 17U727 HARNESS, wire,

display

Phillips, PNHD

inlet

240V

connection

ground

8”, #10 serrated

Includes 16

PND, 120V

pendant

board to switches

1

8

1

1

1

1

1

1

1

1

Ref. Part Description Qty.

19 17U620 PLATE, backer,

20 19Y411 COVER, connector 1

22 17U645 SEAL, panel 4

23 17U614 SWITCH, rocker,

24 17U615 SWITCH, two position,

25 17U613 PLUG, hole 1

26 120660 SWITCH, rocker, I/O 1

74 19Y115 CONTROL, assembly,

75 105676 SCREW, mach, PNH 13

76 114391 SCREW, grounding 1

77 17U623 BRACKET, wire 1

78 17U622 WASHER, fender #8 2

79 17U625 HARNESS, main,

88 17U619 LABEL, display 1

pendant connection

advance

15A/20A

120V, Includes 75 and

76

w/strain relief

1

1

1

1

1

3A6884B 49

Page 50

Control Box Parts - 230V

Ref. Torque Ref. Torque

10-12 in-lbs (1.1-1.4 N•m) 15-20 in-lbs (1.7-2.3 N•m)

17-21 in-lbs (1.9-2.4 N•m)

253

Control Box Parts - 230V

50 3A6884B

Page 51

Control Box Parts List

Control Box Parts - 230V

Ref. Part Description Qty.

1 278893 BOX, control, 120V 1

2 17U638 BOARD, assembly,

8 114528 SCREW, mach,

9 17U767 BRACKET, IEC

10 17U637 HARNESS, IEC power

11 17U621 PLATE, backer, power

12 17Z458 STUD, terminal,

13 17S588 WIRE, green, 16 AWG,

14 100166 NUT, full hex 2

15 24W147 BOARD, filter, 230V 1

16 124131 SCREW, mach, pan

17 17U616 CONNECTOR,

display

Phillips, PNHD

connector

inlet

connection

ground

8”, #10 serrated

head

pendant

1

8

1

1

1

1

1

1

1

Ref. Part Description Qty.

18 17U727 HARNESS, wire,

19 17U620 PLATE, backer,

20 19Y411 COVER, connector 1

22 17U645 SEAL, panel 4

23 17U614 SWITCH, rocker,

25 17U613 PLUG, hole 2

26 120660 SWITCH, rocker, I/O 1

74 19Y620 KIT, repair, control

75 105676 SCREW, mach, PNH 13

76 114391 SCREW, grounding 1

77 17U623 BRACKET, wire 1

78 17U622 WASHER, fender #8 2

79 17U625 HARNESS, main,

88 17U619 LABEL, display 1

board to switches

pendant connection

advance

bard, 230V

w/strain relief

1

1

1

1

1

3A6884B 51

Page 52

Technical Specifications

Technical Specifications

Hydraulic Power Pack

US Metric

Pressure

Maximum delivery

Fluid outlet npt

Generator minimum

Motor (brushless DC)

120V, A, Hz

230V, A, Hz

Environmental temperature range -40°–120°F -40°– 49°C

Oil reserve capacity 1 gallon 3.8 liter

Recommended hydraulic oil

Operating oil viscosity range

(centistokes)

Dimensions

Weight (dry) 85 lb 39 kg

Height 17 in. 43 cm

Length 17.75 in. 25 cm

Width 14 in. 36 cm

Ingress Protection

Power pack assembly 44

Pendants 56

Noise (dBa)*

Maximum sound power

Maximum sound pressure

Notes:

*Sound pressure measured 3.1 feet (1 meter) from equipment.

Sound power measured per ISO-3744.

10,000 psi 700 bar, 68.9 MPa

1.7 gpm 6.4 lpm

1/4 in. 1/4 in.

4000 W 4000 W

2 HP 1500 W

20A, 50/60 20A, 50/60

10A, 50/60 10A, 60/60

Grade ISO 10-68

See chart below

94.0 dBa @ 70 psi (0.48 MPa, 4.8 bar)

80.0 dBa @ 70 psi (0.48 MPa, 4.8 bar)

Recommended Oil Temperature Ranges for Various Hydraulic Oil Weights

52 3A6884B

Page 53

Compliance

California Proposition 65

WARNING: This product can expose you to chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm. For more information

go to www.P65Warnings.ca.gov.

Radio Frequency Approvals

Compliance

Transmitter Frequency (all models): 433.92 MHz

Transmitter Power (all models): -9.50 dBm

The enclosed device complies with Part 15 of the FCC Rules and with Industry Canada

license-exempt RSS standard(s). Operation is subject to the following two conditions:(1) this

device may not cause harmful interference and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could

void the user’s authority to operate the equipment.

This equipment is not granted protection against harmful interference and cannot cause

interference on systems properly authorized.

NOTE: FCC/IC Notice (all models)

FCC ID: JHICED2

IC: 4840A-CED2

3A6884B 53

Page 54

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing

its name to be free from defects in material and workmanship on the date of sale to the original purchaser

for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will,

for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or

improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts.

Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco

equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or

materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential

damages for lost profits, lost sales, injury to person or property, or any other incidental or consequential

loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED

BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose,

etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with

reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

54 3A6884B

Page 55

Graco Information

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the

nearest distributor.

3A6884B 55

Page 56

All written and visual data contained in this document reflects the latest product information available at

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6884

the time of publication.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2019, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revision B, January 2020

Loading...

Loading...