Page 1

Operation

Drywall Feed Pump

- For Water-Based Materials Only -

Read all warnings and instructions

Maximum Working Pressure 2500 psi (17.2 MPa, 172 bar)

Model: 257100

3A0245A

ti14873a

Page 2

Warning

Warning

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent, in work area can ignite or explode. To help prevent fire and explosion:

• Keep work area free of debris, including solvent, rags and gasoline.

• Ground equipment in the work area. See Grounding instructions.

• If there is static sparking or you feel a shock, stop spraying immediately. Do not use equipment

until you identify and correct the problem.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use water-based materials. Use fluids and solvents that are compatible with equipment wetted

parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

2 3A0245A

Page 3

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

Warning

3A0245A 3

Page 4

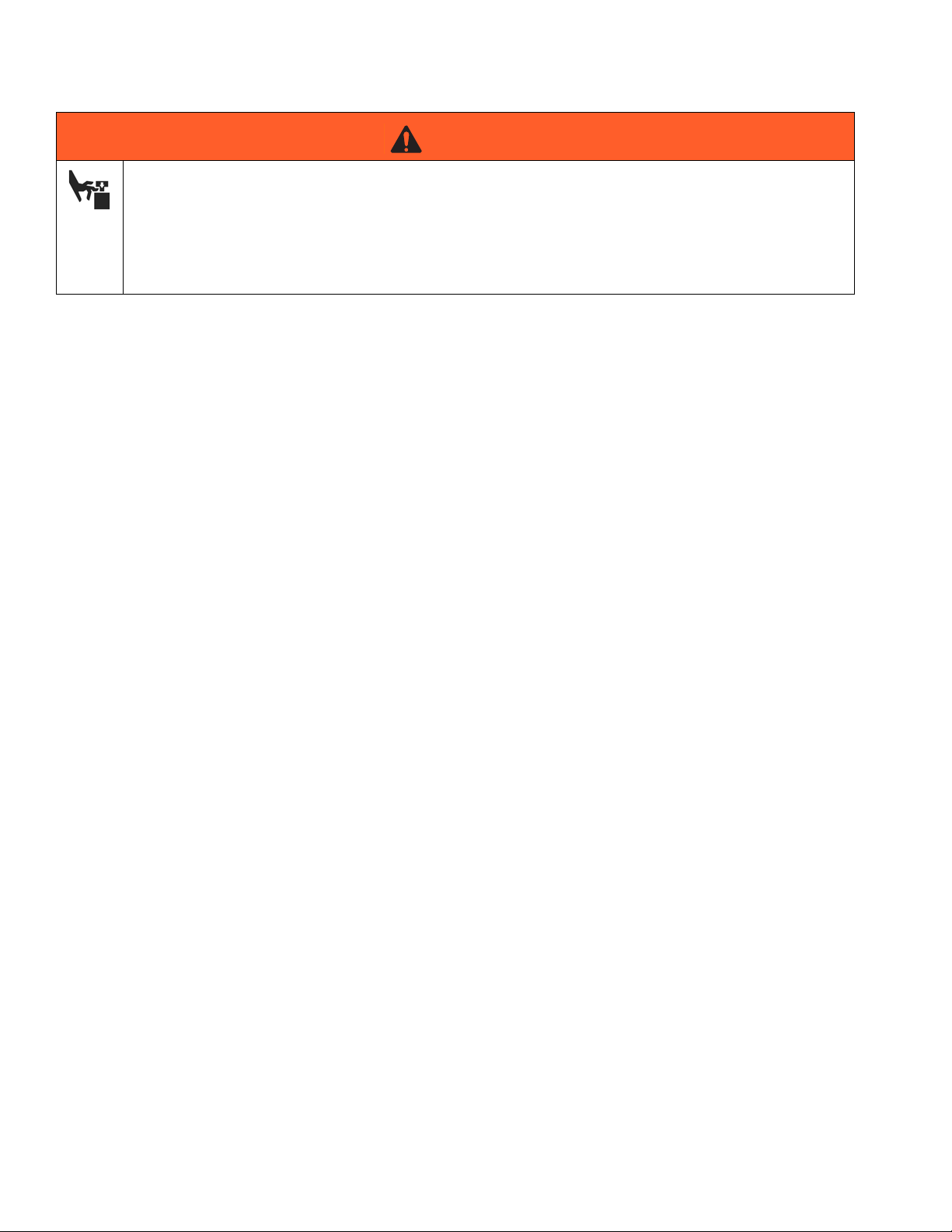

Component Identification

Component Identification

1

2

3

4

5

11

10

9

8

6

7

1 Pump Module

2 Prime/Tool Fill/Recirculation Valve

3 Flow Knob

4 15/20 Amp Switch

5 ON/OFF Switch

6 Material Hoses

7Pump

8 Pump Inlet Cover

9 Hopper Plug

10 Hopper

11 Pump Connector

ti14874a

4 3A0245A

Page 5

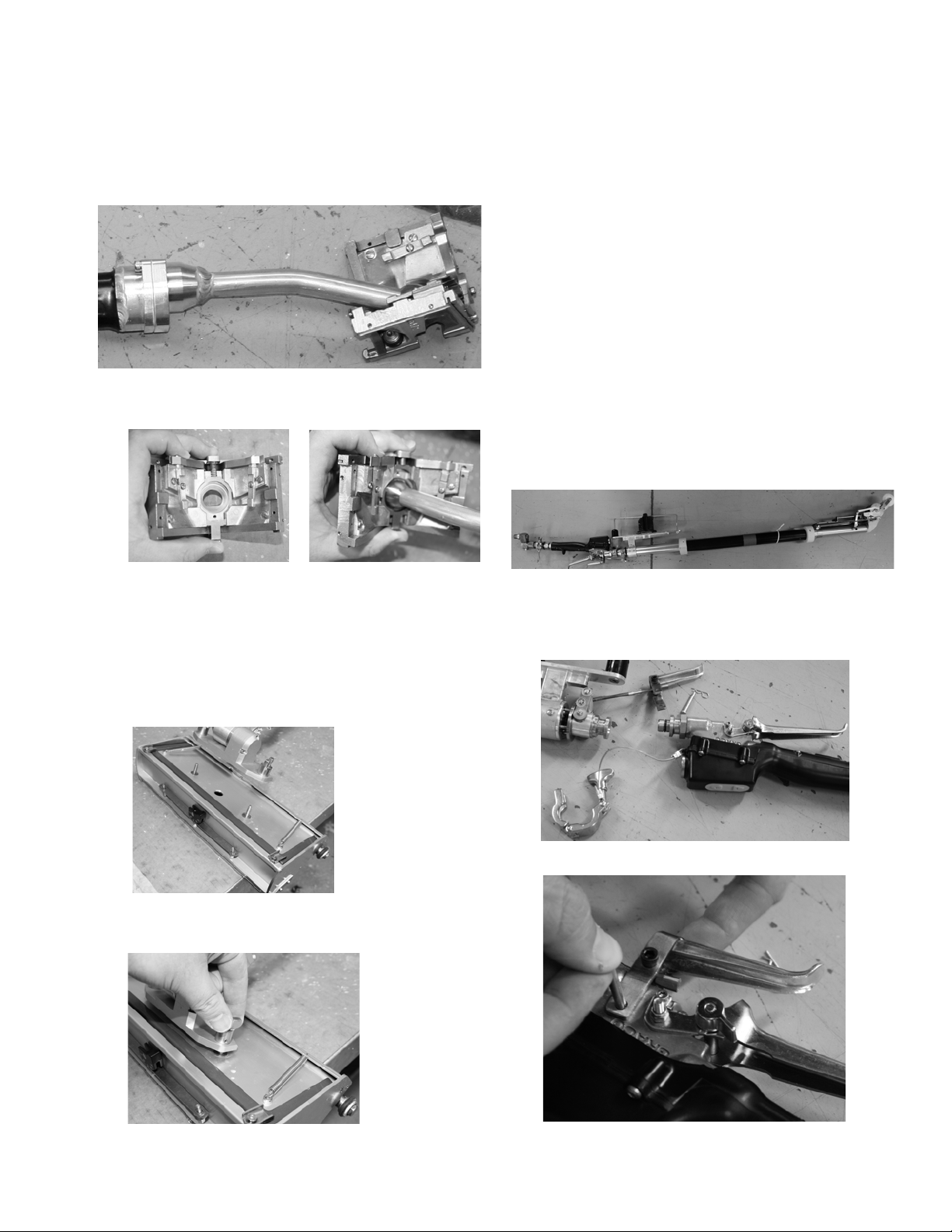

Finishing Tools

Corner Finisher

1. Press pin on top of corner finisher and install onto

valve.

Finishing Tools

2. Place flat box at end of joint.

3. Lead with handle and draw the tool along the joint.

4. Near middle of the joint, remove flat box from joint

surface with a sweeping motion.

5. Reverse hand positions and begin again at other

end of joint.

6. Again draw flat box along joint up to previous

stopping point and remove box from joint surface

with a sweeping motion.

7. Use drywall knife to detail seams and overlap.

Automatic Taping Tool

2. Work from bottom to top of vertical angles and from

one end to other on ceiling angles.

3. Use drywall knife to detail corner and ceiling angle

intersections.

Flat Finishing Box

1. Install valve over two screws on box and tighten two

wing nuts.

NOTE: Fine flow rate adjustments can be made using

buttons on valve handle.

1. Install trigger assembly and sanitary clamp.

2. Insert pin into trigger assembly.

3A0245A 5

Page 6

Pressure Relief Procedure

3. Insert cotter pin.

4. Place one hand on control tube and one hand at

bottom of mud tub while in use.

5. Place tape at bottom of joint (slide tube forward to

feed tape).

Pressure Relief Procedure

1. Turn flow control knob OFF.

6. Lead with head of taper to make tracking easier.

Large trigger feeds material through tool. Small

trigger retracts creasing wheel.

7. Roll tape over seam with only one wheel in contact

with wall until approximately three inches from end

of seam.

8. Stop completely and pull tube back to cut tape.

9. Use drywall knife to detail seams and overlap.

NOTE: Clean all tools thoroughly after every use. Use a

brush and water to remove all joint compound from

tools. Once tools have been cleaned, lightly oil using

any light machine oil.

2. Point applicator into hopper and trigger to relieve

pressure.

3. Fluid from pressure relief valve can splash in eyes

or skin and cause serious injury. Keep hands clear

of pressure relief valve. Wear safety glasses.

6 3A0245A

Page 7

Operation

GROUNDING INSTRUCTIONS

This appliance is rated more than 15 A and is for use

on a circuit having a nominal rating of 120 V and is factory equipped with a specific electric cord and plug. No

adapter should be used with this appliance. If the appliance must be reconnected for use on a different type of

electric circuit, the reconnection should be made by

qualified service personnel; and after the reconnection,

the appliance should comply with all local codes and

ordinances.

Consult a qualified electrician if there is any doubt as to

whether an outlet box is properly grounded.

Operation

Setup

1. Connect pump module to hopper and cart. Tighten

knob on front of pump module and clamp other end

to hopper.

ti11679a

2. Connect power cord. Turn ON/OFF to OFF.

ti2810a

ti11678a

ti11673a

ti4265a

Do NOT tamper with relief valve or devices that control

maximum pressure control during normal operation.

Bodily injury and/or damaged to equipment can occur.

FCC Notice (FCC ID: JHICED1)

Model Number: DFS150

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

• This device may not cause harmful interference.

• This device must accept any interference that may

be received, including interference that may cause

undesired operation.

Changes or modifications not expressly approved by

Graco, Inc. could void the user's authority to operate this

equipment.

IC Notice (IC: 4840ACED1)

This product meets the applicable Industry Canada

technical specifications/Le présent materiel est conforme aux specifications techniques applicables

d’Industrie Canada.

ti4265a

3. Connect material hose to outlet.

NOTE: Up to 150 ft of 1/2 in. hose plus 15 ft. x 1/4

in. can be connected to the unit. If desired flow rate

is not obtainable, reduce hose length or add additional water to mud mixture.

4. Select 15A/20A setting based on your circuit rating.

5. Connect Z swivel.

6. Connect selected finishing tool to Z swivel using

supplied sanitary clamps.

“Learn” the Valve

This unit performs differently depending on which valve

is being used. Each time you change valves, perform

the following steps so the unit can “Learn” the valve.

1. Turn flow control knob down (but not OFF).

2. Push digital display button 3 times until LEARN

appears on display screen.

3. Pull trigger on valve.

4. OK should then appear on display screen (if not,

see Troubleshooting).

3A0245A 7

Page 8

Operation

Startup

Pump Material

NOTICE

Do not use with quick-set materials. They can

harden inside the unit and hose.

1. Mix material in separate bucket. Gradually add

water and mix until desired consistency is achieved.

2. Add mixed material to hopper.

7. Place head of tool over waster bucket and trigger

valve until material flows from tool head. Once all

water has been flushed from hose and tool, position

tool head over hopper until flow rate is determined.

8. Apply a couple of test coats to determine proper

flow speed on sprayer. Fine adjustments can be

made on valve handle to increase or decrease flow

speed.

ti11670a

3. Place deflect er into hopper to recirculated material.

NOTE: Keep deflector shield wet once it is in use.

4. Turn sprayer power ON and flip prime valve fully

clockwise to prime pump. Place material hose and

drain line in hopper.

ti14876a

5. After unit is primed, place prime valve in APPLY

FINISH position.

Fill Tools With Material

Fill Box

1. Remove tool-fill flange.

2. Install box fill adapter.

3. Place slot of box over box fill nozzle.

6. Turn flow knob clockwise to increase material flow.

4. Turn Prime Valve to TOOL FILL position.

8 3A0245A

Page 9

5. Turn flow control knob fully clockwise until box is

filled with material.

6. Turn flow control knob fully counter-clockwise.

Fill Taper

1. Install taper-fill adapter.

2. Place material inlet of taper over nozzle of taper-fill

adapter.

Operation

3. Turn Prime Valve to TOOL FILL position.

4. Turn control knob fully clockwise.

5. Place fingers inside top of taper. When you feel the

plunger rise to the top, turn flow control knob fully

counter-clockwise.

3A0245A 9

Page 10

Operation

Bleed System Pressure

Install Prime Valve

1. Tighten prime valve into manifold (use thread sealant on housing threads). Torque to 190 to 210 in-lb.

1. Turn flow knob to fully counterclockwise.

2. Place deflector in hopper or suitable container.

3. Place prime valve in RELIEF position.

Remove Prime Valve

1. Use 3/32 in. punch and hammer to tap out handle

pin (pliers may be required to pull out handle pin).

2. Use crescent wrench to unscrew prime valve handle.

3. Clear out any material that is lodged in valve or

manifold.

2. Install prime valve base. Pin in base must align with

hole in manifold.

3. Orient .096 in. hole in drain valve stem vertically.

4. Place drain valve over drain valve base with handle

in “apply” mode.

5. Use hammer to tap drain valve handle pin back into

place.

10 3A0245A

Page 11

Cleanup

Cleanup

2. Hang drain line mount onto material bucket. Turn

pump to drain position and pump unused material

from hopper and hose.

NOTICE

Do not use with quick-set materials. They can

harden inside the unit and hose.

Storage - Less Than 24 Hours

1. Perform Pressure Relief Procedure, page 6 (valve

in down position).

2. Remove tool from valve. Clean all tools or use supplied tool caps.

3. Remove hopper lid and use water bottle to spray

enough water mist to cover top layer of material.

ti11802a

4. Clean hopper sides to material level. Cover material

in hopper with hopper cover.

ti11801a

ti8794a

3. Scrape material remaining in hopper into pump to

be pumped from sprayer.

ti11760a

4. Turn pump control fully counter-clockwise to shut

pump off.

ti8793a

5. Fill material hopper with water and run pump to

flush hose and valve. Use standard garden hose

with nozzle to wash sprayer body.

Storage - More Than 24 Hours

1. Perform Pressure Relief Procedure, page 6 (valve

in down position).

3A0245A 11

6. Shut pump off.

ti11670a

Page 12

Cleanup

7. Remove drain plug from hopper. Flush with water.

Clean and install drain plug.

ti11804a

NOTE: Cap plug must not be inserted into the female

side of the connector on the Z swivel. Residual pressure

can cause the cap plug to lose the seal. To ensure that

the cap plug properly seals, use cap plug on the inline

gun outlet.

8. Wash all tools.

11. Add additional water and repeat steps 13 - 14,

if necessary.

ti11670a

12. Remove drain plug from hopper. Flush with water.

Clean and install drain plug.

13. Rotate pump control to shut pump off.

ti8793a

9. Turn pump control clockwise to start pump.

ti8794a

10. Run pump until clean water flows from applicator.

Continue until hopper is empty.

ti14878a

12 3A0245A

Page 13

Cleanup

Troubleshooting

Motor Won’t Operate

PROBLEM CAUSE SOLUTION

Basic Fluid Pressure Problems Pressure control knob setting. Motor will not

run if at minimum setting (fully counterclockwise).

Spray tip or fluid filter may be clogged. Relieve pressure and clear clog or

Basic Mechanical Problems Frozen or hardened paint. Thaw sprayer if water or water-based

Displacement pump connecting rod pin. Pin

must be completely pushed into connecting

rod and retaining spring must be firmly in

groove of pump pin.

Motor. Remove drive housing assembly.

Try to rotate fan by hand.

Basic Electrical Problems Motor control board. Board shuts down and

displays error code.

Electrical supply. Meter must read: 210-255

Vac for 220-240 Vac models;

85-130 Vac for 100-120 Vac models.

Extension cord. Check extension cord continuity with volt meter.

Sprayer power supply cord. Inspect for damage such as broken insulation or wires.

Check that motor leads are securely fastened

and properly mated.

ON/OFF Switch. Connect volt meter between

L1 and L2 terminal on ON/OFF switch. Plug

in sprayer and turn ON. Meter must read:

Slowly increase pressure setting to see

if motor starts.

clean filter; refer to separate gun or tip

instruction manual.

paint has frozen in sprayer. Place

sprayer in warm area to thaw. Do not

start sprayer until thawed completely. If

paint hardened (dried) in sprayer,

replace pump packing. See repair manual.

Push pin into place and secure with

spring retainer.

Replace motor if fan won't turn.

See Control Board Diagnostics.

Reset building circuit breaker; replace

building fuse. Try another outlet.

Replace extension cord.

Replace power supply cord.

Replace loose terminals; crimp to

leads. Be sure terminals are firmly connected. Clean circuit board terminals.

Securely reconnect leads.

Replace ON/OFF switch.

210-255 Vac for 220-240V models

85-130 Vac for 100-120V models.

All terminals for damage or loose fit. Replace damaged terminals and

reconnect securely.

3A0245A 13

Page 14

Cleanup

Motor is Hot and Runs Intermittently

PROBLEM CAUSE SOLUTION

Motor is hot and runs intermittently. Determine if sprayer was operated at

high pressure with small tips, which

causes low motor RPM and excessive

heat build up

Be sure ambient temperature where

sprayer is located is no more than 90°F

and sprayer is not located in direct sun

Decrease pressure setting or increase

tip size.

Move sprayer to shaded, cooler area if

possible.

Low or Fluctuating Output

PROBLEM CAUSE SOLUTION

Low Output Worn spray tip. Follow Pressure Relief Procedure

Warning, then replace tip. See your

separate gun or tip manual.

Verify pump does not continue to stroke

when applicator is turned off.

Filter clogged (If optional filter is

installed).

Material hose length. Longer hose

length reduces sprayer performance.

Pump hopper adapter connections. Tighten any loose connections.

Electrical supply with volt meter. Meter

must read:

210-255 Vac for 220-240 Vac models;

85-130 Vac for 100-120 Vac models.

Low voltages reduce sprayer performance.

Extension cord size and length; must be

at least 1.0 mm2 (12 awg) wire and no

longer than 90 m (295 ft). Longer cord

lengths reduce sprayer performance.

Leads from motor to pressure control

circuit board for damaged or loose

wires or connectors. Inspect wiring

insulation and terminals for signs of

overheating.

Low stall pressure. Turn pressure control knob fully clock-

Plugged Prime Valve Material has dried and plugged the

prime valve

Service pump. Check piston and intake

valves for wear or obstructions.

Relieve pressure. Check and clean filter.

Replace with hose length less than

specified maximum.

Replace pump hopper adapter if

cracked or punctured.

Reset building circuit breaker; replace

building fuse. Repair electrical outlet or

try another outlet.

Replace with a correct, grounded

extension cord.

Be sure male terminal blades are centered and firmly connected to female

terminals. Replace any loose terminal

or damaged wiring. Securely reconnect

terminals.

wise. Make sure pressure control knob

is properly installed to allow full clockwise position. Try a new transducer.

Aim hose into waste pail. Turn prime

valve from tool fill to dump and then

back to tool fill. If valve remain plugged,

see Bleed System Pressure, page 10.

14 3A0245A

Page 15

Cleanup

Troubleshooting

Low or Fluctuating Output

PROBLEM CAUSE SOLUTION

Motor runs and pump strokes 1. Material supply. 1. Refill hopper and re-prime pump.

2. Loose fittings. 2. Tighten; use thread sealant or

sealing tape on threads if necessary.

Motor runs but pump does not

stroke

3. Intake valve ball and piston ball are

seating

properly.

4. Leaking around throat packing nut

which may indicate worn or damaged

packings.

5. Pump rod damage. 5. Repair pump.

1. Displacement pump pin (75) (damaged

or missing).

2. Connecting rod assembly (45) for dam-

age.

3. Gears or drive housing. 3. Inspect drive housing assembly

3. Remove intake and piston valves

and clean. Check balls and seats

for nicks or obstructions; replace

if necessary, page 18. Clean

hopper before using to remove

particles that could clog pump.

4. Replace packing, page 18. Also

check piston valve seat for hardened paint or nicks and replace if

necessary.

1. Replace pump pin if missing. Be

sure retainer spring (76) is fully in

groove all around connecting rod.

2. Replace connecting rod assembly.

and gears for damage and

replace if

necessary.

Electrical Short

PROBLEM CAUSE SOLUTION

Building circuit breaker opens

as soon as sprayer switch is

turned on.

CAUTION

Any short in any part of the

motor power circuit will cause

the control circuit to inhibit

sprayer operation. Correctly

diagnose and repair all shorts

before checking and replacing

control board.

3A0245A 15

1. All electrical wiring for damaged insulation, and all terminals for loose fit or

damage. Also wires between pressure

control and motor.

2. Motor armature for shorts. Inspect

windings for burns

3. Motor control board by performing

motor control board diagnostics. If

diagnostics indicate, substitute with a

good board.

1. Repair or replace any damaged

wiring or terminals. Securely

reconnect all wires.

2. Replace motor.

3. Replace with a new pressure

control board.

Page 16

Cleanup

PROBLEM CAUSE SOLUTION

Building circuit breaker opens

as soon as sprayer is plugged

into outlet and sprayer is NOT

turned on.

1. Basic Electrical Problems on page 13. 1. Perform necessary procedures.

2. For damaged or pinched wires in pres-

2. Replace damaged parts.

sure

control.

Sprayer quits after sprayer

operates for 5 to 10 minutes.

1. Basic Electrical Problems. 1. Perform necessary procedures.

2. Electrical supply with volt meter.

Meter must read:

2. If voltage is too high, do not operate sprayer until corrected.

210-255 Vac for 220-240 Vac models;

85-130 Vac for 100-120 Vac models.

16 3A0245A

Page 17

Wiring Diagram

Thermal

Switch

Motor

Motor

Leads

Motor

Sensor

Leads

Digital Display

Potentiometer

Black

Pressure

Transducer

20A 15A

1595 Switch

Wiring Diagram

ti114889a

green/ground

ON/OFF

Black

white

Black +

green/ground

Switch

Power Plug

Technical Data

Power requirements 15A/20A

Motor HP (W) 2.5 (1864)

Maximum fluid working pressure 2500 psi (17.2 MPa, 172 bar)

Hopper capacity

Maximum 28 gallons (106 liters)

Operating 24 gallons (91 liters)

Maximum delivery with texture material 1.0 to 1.7 gpm (3.8 to 6.4 lpm)

Maximum hose length 150 ft of 1/2 in. hose

Fluid outlet size 1/2 in. NPT female swivel

Dimensions

Length 40 to 55 in. (102 cm to 140 cm) with handle

Width 22 in. (56 cm)

Height 31 in. (79 cm)

Weight

Without hoses or applicator 141 lb (64 kg)

With hoses and applicator 166 lb (75 kg)

Wetted parts Buna-N, aluminum, brass, polyethylene, neoprene, stainless steel, nickel-plated carbon steel, fluoro-

elastomer, nickel-plated iron, wool felt, tungsten carbide, PTFE, nylon, zinc-plated carbon steel, paper,

Sound data for sprayer

Sound pressure level *

Sound power level †

* Measured while spraying at 1 m.

† Measured per ISO-3744.

PVC, UHMWPE, leather, rubber

3A0245A 17

Page 18

Warranty

Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any

special, extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part

of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment

with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental

or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject

to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder,

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présent document ainsi que de tous les documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite de ou en

rapport, directement ou indirectement, avec les procédures concernées, sera en anglais.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

18 3A0245A

Page 19

TO PLACE AN ORDER, contact your Graco distributor, or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English, French, Spanish, Dutch, German mm 313XXX

International Offices: Belgium, Korea, China, Japan

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

http://www.graco.com

3A0245A 19

Loading...

Loading...