Page 1

Instructions/Parts

™

AirPro

EFX Automatic

313869B

Spray Gun

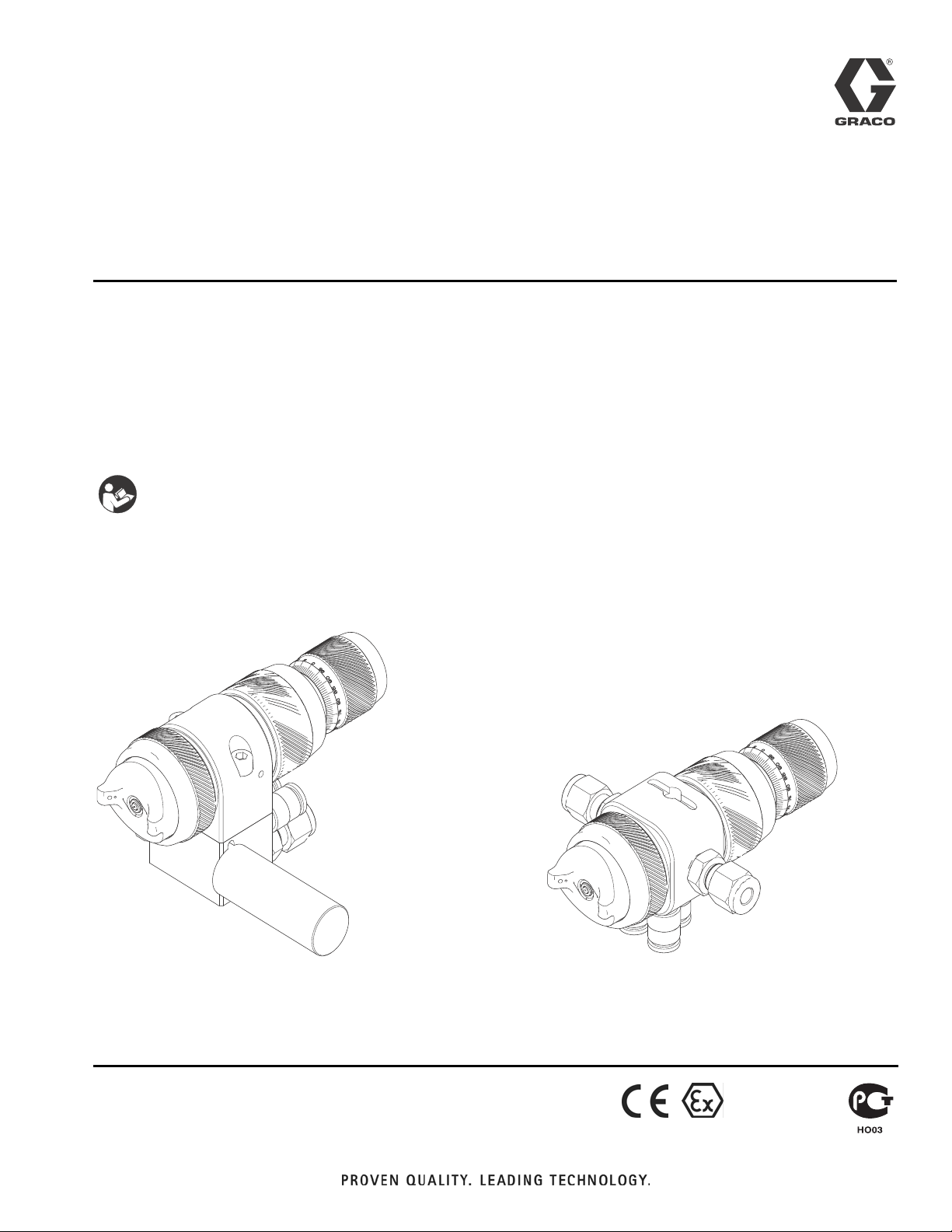

Conventional, HVLP, HiTEch, and LVMP automatic guns for small component finishing

applications. For professional use only.

100 psi (0.7 MPa, 7 bar) Maximum Working Fluid Pressure

100 psi (0.7 MPa, 7 bar) Maximum Working Air Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

See page 2 for model information.

ENG

Guns with manifold

TI14428A

TI14427A

Guns without manifold

II 2 G c IIB T6

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Selection Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gun Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Proper Needle/Nozzle Selection . . . . . . . . . . . . . 6

Models With Manifolds . . . . . . . . . . . . . . . . . . . . 7

Models Without Manifolds . . . . . . . . . . . . . . . . . . 7

Air Caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Sample Pattern Sizes and Shapes . . . . . . . . . . . 8

Needle Assembly Identification . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ventilate Spray Booth . . . . . . . . . . . . . . . . . . . . 10

Configure Gun and Manifold . . . . . . . . . . . . . . . 10

Ground System . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mount Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect Air Line . . . . . . . . . . . . . . . . . . . . . . . . 13

Connect Fluid Hose . . . . . . . . . . . . . . . . . . . . . 15

Flush Spray Gun . . . . . . . . . . . . . . . . . . . . . . . . 16

Position Air Cap . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjust Spray Pattern . . . . . . . . . . . . . . . . . . . . . 16

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Relief Procedure . . . . . . . . . . . . . . . . 18

Apply Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Daily Gun Care . . . . . . . . . . . . . . . . . . . . . . . . . 19

General System Maintenance . . . . . . . . . . . . . . 20

Clean and Flush Gun . . . . . . . . . . . . . . . . . . . . . 20

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Mounting Hole Layouts . . . . . . . . . . . . . . . . . . . . . 30

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Spray Pattern Test Report . . . . . . . . . . . . . . . . . 35

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

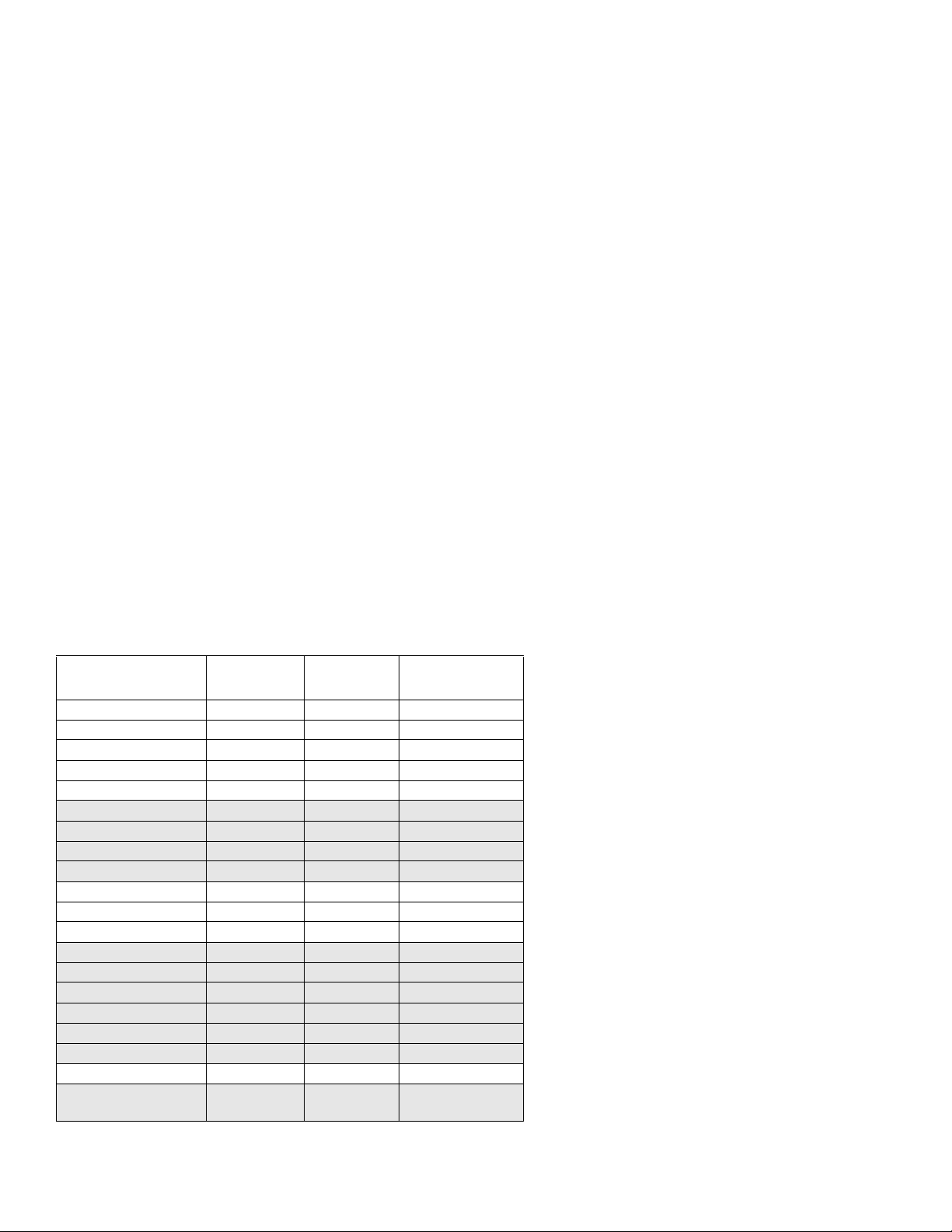

Models

Orifice Size

Spray Type

Conventional

Conventional

Conventional

Conventional

Conventional

HVLP

HVLP

HVLP

HVLP

HiTEch

HiTEch

HiTEch

LV MP

LV MP

LV MP

LV MP

LV MP

LV MP

Air Brush

Gun without needle,

nozzle, or air cap

* Needle tip and nozzle exit constructed from tungsten carbide.

in. (mm)

0.028 (0.7) 24B857 24B877

0.035 (0.9) 24B858 24B878

0.043 (1.1) 24B859 24B879

0.051 (1.3) 24B860 24B880

0.059 (1.5) 24B861* -----

0.020 (0.5) 24B862 -----

0.028 (0.7) 24B863 24B881

0.043 (1.1) 24B864 24B882

0.051 (1.3) 24B865 24B883

0.028 (0.7) 24B866 24B884

0.039 (1.0) 24B867* 24B885*

0.059 (1.5) 24B868* 24B886*

0.020 (0.5) 24B869 24B887

0.028 (0.7) 24B870 24B888

0.035 (0.9) 24B871 24B889

0.043 (1.1) 24B872 24B890

0.051 (1.3) 24B873 24B891

0.059 (1.5) 24B874* -----

0.028 (0.7) 24B875 24B892

N/A 24B876 24B893

Models with

Manifold**

Models without

Manifold

** Models with manifold have fully stainless steel fluid passages.

2 313869B

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers

to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings

may be found throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric

lamps, and plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when

flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

313869B 3

Page 4

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See

Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s

warnings. For complete information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn

off all equipment and follow the Pressure Relief Procedure when equipment is

not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately

with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and

hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the

eyes or on skin and cause serious injury.

• Follow the Pressure Relief Procedure when you stop spraying and before clean-

ing, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immedi-

ately.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can

cause serious chemical reaction and equipment rupture. Failure to follow this warning

can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocar-

bon solvents or fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum. Contact

your material supplier for compatibility.

4 313869B

Page 5

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on

skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to appli-

cable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when

in the operating area of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and burns. This equipment

includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and sol-

vent manufacturer.

313869B 5

Page 6

Selection Charts

Selection Charts

TERMS

Light Fluid: Up to 18 seconds with No. 2 Zahn

cup (20 centipoise)

Medium Fluid:19 to 28 seconds with No. 2

Zahn cup (20-64 centipoise)

Heavy Fluid: Greater than 28 seconds with

No. 2 Zahn cup (greater than 64 centipoise) --

2.8 Volatile Organic Compounds, High-solid

Polyurethanes, Heavy Waterborne Enamels

Gun Selection

HVLP Guns

An HVLP gun is a high transfer efficiency gun

that limits the air pressure at the air cap to

10 psi (0.07 MPa, 0.7 bar) maximum. In some

areas, an HVLP gun is required for compliance

with environmental standards. See the Air Cap

chart, page 8, for maximum inlet pressure.

Proper Needle/Nozzle Selection

The spray gun's needle/nozzle kits range in

size to provide different fluid flow rates. As a

general guideline, use the fluid nozzle that will

give the required flow with the needle fully triggered at a fluid pressure of 5–20 psi

(0.035–0.14 MPa, 0.35–1.4 bar).

• For low flow rates or light viscosity fluid,

select the smaller nozzle sizes.

• For high flow rates or high viscosity fluid,

select the larger nozzle sizes.

• For abrasive fluids, the gun models with

tungsten carbide needle tip and nozzle are

recommended.

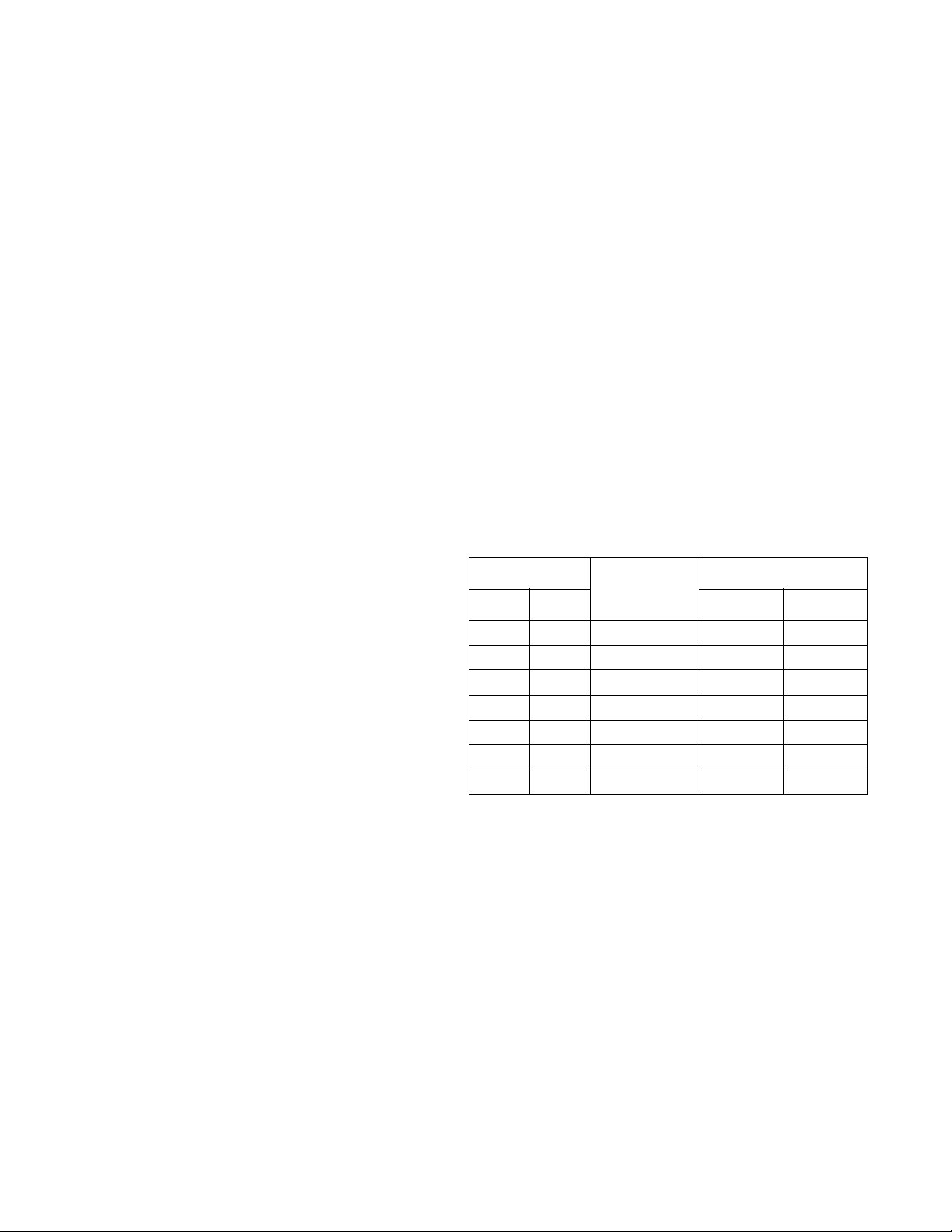

Orifice Size

in. mm oz/min cc/min

Viscosity

Flow

LVMP Guns

An LVMP gun is a high transfer efficiency gun

that has been tested to have a transfer efficiency greater than or equal to HVLP guns. In

addition, the LVMP air cap consumes much

less air than the HVLP air cap. Graco LVMP

guns have no restrictions on air cap pressures.

Conventional Guns

A conventional gun has excellent atomization

and high production rates typically with some

reduction in transfer efficiency.

HiTEch Guns

A HiTEch gun is a high transfer efficiency gun

with excellent atomization. Graco HiTEch guns

have no restrictions on air cap pressures.

0.020 0.5 light 0.2-1.7 5-50

0.028 0.7 light 0.3-3.4 10-100

0.035 0.9 light-medium 0.5-5.1 15-150

0.039 1.0 light-medium 0.7-6.8 20-200

0.043 1.1 light-medium 0.8-8.5 25-250

0.051 1.3 medium 1.2-11.8 35-350

0.059 1.5 medium 1.5-15.2 45-450

6 313869B

Page 7

Selection Charts

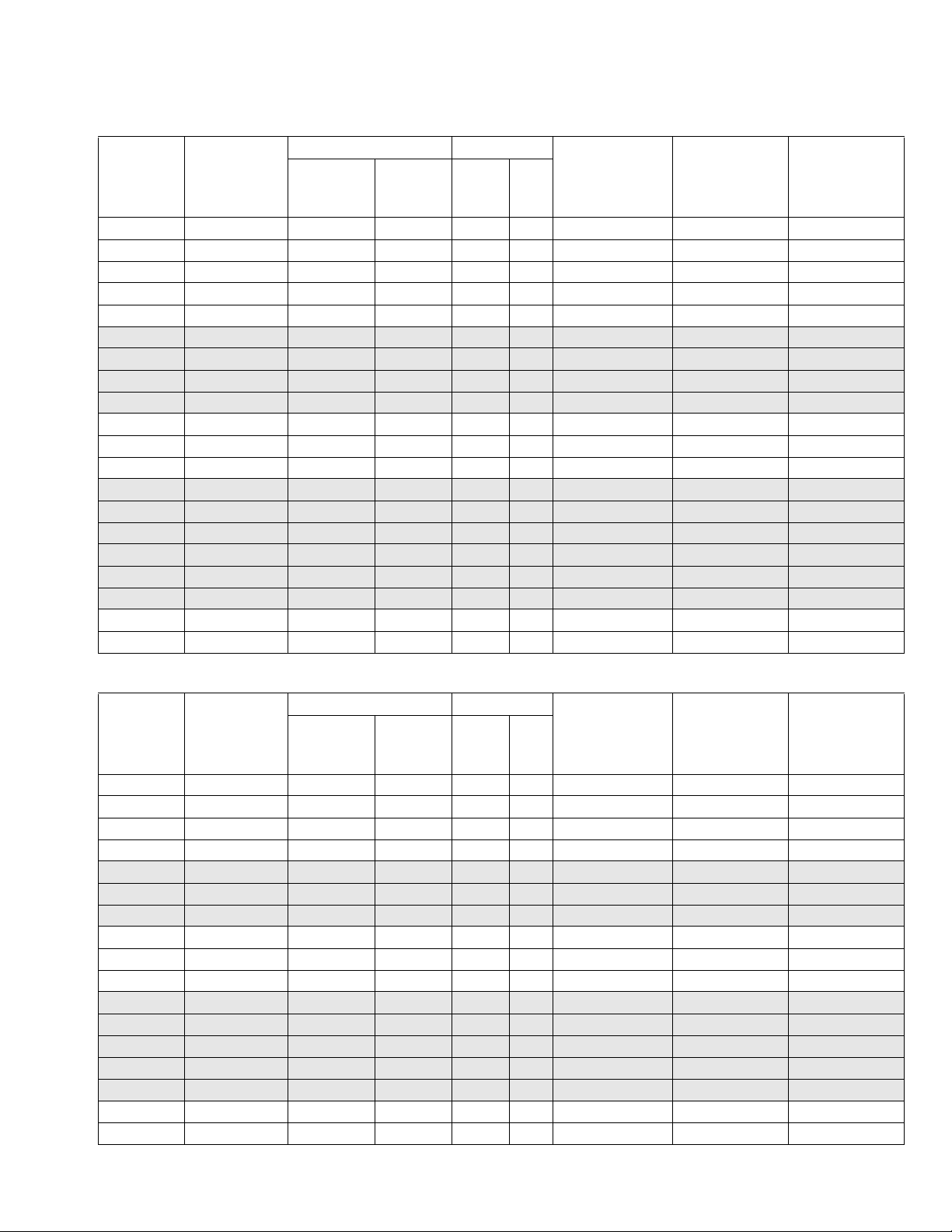

Models With Manifolds

Includes: Orifice Size

Gun

Assembly

Part No. Type

24B857 Conventional 24D177 24C182 0.028 0.7 Stainless Steel Indexing Plastic

24B858 Conventional 24C198 24C182 0.035 0.9 Stainless Steel Indexing Plastic

24B859 Conventional 24C199 24C182 0.043 1.1 Stainless Steel Indexing Plastic

24B860 Conventional 24C200 24C182 0.051 1.3 Stainless Steel Indexing Plastic

24B861 Conventional 24D178 24C182 0.059 1.5 Carbide Indexing Plastic

24B862 HVLP 24D302 24C183 0.020 0.5 Stainless Steel Indexing Plastic

24B863 HVLP 24D179 24C183 0.028 0.7 Stainless Steel Indexing Plastic

24B864 HVLP 24D305 24C183 0.043 1.1 Stainless Steel Indexing Plastic

24B865 HVLP 24D306 24C183 0.051 1.3 Stainless Steel Indexing Plastic

24B866 HiTEch 24D303 24D703 0.028 0.7 Stainless Steel Ultra Precision Stainless Steel

24B867 HiTEch 24C221 24D703 0.039 1.0 Carbide Ultra Precision Stainless Steel

24B868 HiTEch 24C201 24D704 0.059 1.5 Carbide Ultra Precision Stainless Steel

24B869 LV MP 24D277 24C184 0.020 0.5 Stainless Steel Ultra Precision Plastic

24B870 LV MP 24D278 24C184 0.028 0.7 Stainless Steel Ultra Precision Plastic

24B871 LV MP 24D279 24C184 0.035 0.9 Stainless Steel Ultra Precision Plastic

24B872 LV MP 24D280 24C184 0.043 1.1 Stainless Steel Ultra Precision Plastic

24B873 LV MP 24D281 24C184 0.051 1.3 Stainless Steel Ultra Precision Plastic

24B874 LV MP 24D284 24C184 0.059 1.5 Carbide Ultra Precision Plastic

24B875 Air Brush 24C197 24D705 0.028 0.7 Stainless Steel Indexing Plastic

24B876 N/A N/A N/A N/A N/A N/A Indexing Plastic

Needle/

Nozzle Kit

Part No.

Air Cap

with Pin

Part No. in. mm

Construction

of Needle Tip/

Nozzle Exit

Fluid

Adjustment

Knob

Construction

of Fluid

Fitting

Models Without Manifolds

Includes: Orifice Size

Gun

Assembly

Part No. Type

24B877 Conventional 24D177 24C182 0.028 0.7 Stainless Steel Lock Ring Plastic

24B878 Conventional 24C198 24C182 0.035 0.9 Stainless Steel Lock Ring Plastic

24B879 Conventional 24C199 24C182 0.043 1.1 Stainless Steel Lock Ring Plastic

24B880 Conventional 24C200 24C182 0.051 1.3 Stainless Steel Lock Ring Plastic

24B881 HVLP 24D179 24C183 0.028 0.7 Stainless Steel Indexing Plastic

24B882 HVLP 24D305 24C183 0.043 1.1 Stainless Steel Indexing Plastic

24B883 HVLP 24D306 24C183 0.051 1.3 Stainless Steel Indexing Plastic

24B884 HiTEch 24D303 24D703 0.028 0.7 Stainless Steel Ultra Precision Stainless Steel

24B885 HiTEch 24C221 24D703 0.039 1.0 Carbide Ultra Precision Stainless Steel

24B886 HiTEch 24C201 24D704 0.059 1.5 Carbide Ultra Precision Stainless Steel

24B887 LV MP 24D277 24C184 0.020 0.5 Stainless Steel Indexing Plastic

24B888 LV MP 24D278 24C184 0.028 0.7 Stainless Steel Indexing Plastic

24B889 LV MP 24D279 24C184 0.035 0.9 Stainless Steel Indexing Plastic

24B890 LV MP 24D280 24C184 0.043 1.1 Stainless Steel Indexing Plastic

24B891 LV MP 24D281 24C184 0.051 1.3 Stainless Steel Indexing Plastic

24B892 Air Brush 24C197 24D705 0.028 0.7 Stainless Steel Indexing Plastic

24B893 N/A N/A N/A N/A N/A NA Indexing Plastic

Needle/

Nozzle Kit

Part No.

Air Cap

with Pin

Part No. in. mm

Construction

of Needle Tip/

Nozzle Exit

Fluid

Adjustment

Knob

Construction

of Fluid

Fitting

313869B 7

Page 8

Selection Charts

Air Caps

Nozzle Orifice Recommended

Gun/Manifold

Air Cap

Part No. Type

24C182 Conventional 0.028-0.059 0.7-1.5 43 (0.3, 3.0) Blue-Grey

24C183 HVLP 0.020-0.051 0.5-1.3 15 (0.1, 1.0)* Pewter

24D703 HiTEch 0.028-0.039 0.7-1.0 29 (0.2, 2.0) Black

24D704 HiTEch 0.059 1.5 29 (0.2, 2.0) Black

24C184 LVMP 0.020-0.059 0.5-1.5 43 (0.3, 3.0) Brown

24D705 Air Brush 0.028 0.7 29 (0.2, 2.0) Clear

* Maximum compliant HVLP inlet pressure.

Inlet Pressure

psi (MPa, bar) Air Cap Colorin. mm.

Sample Pattern Sizes and Shapes

Recommended

Nozzle

Air Cap

Part No. Type

24C182 Conventional 0.028 (0.7) 43 (0.3, 3.0) 2.7 (80) 6 (15) Taper 1.0-6.0 (25-152)

24C183 HVLP 0.028 (0.7) 15 (0.1, 1.0) 2.7 (80) 6 (15) Straight 1.0-6.5 (25-165)

24D703 HiTEch 0.028 (0.7) 29 (0.2, 2.0) 2.7 (80) 6 (15) Straight 1.0-6.5 (25-165)

24D704 HiTEch 0.059 (1.5) 29 (0.2, 2.0) 2.7 (80) 6 (15) Straight 1.0-6.5 (25-165)

24C184 LVMP 0.028 (0.7) 43 (0.3, 3.0) 2.7 (80) 6 (15) Straight 1.0-6.5 (25-165)

24D705 Air Brush 0.028 (0.7) 29 (0.2, 2.0) 1.0 (30)

Orifice

in. (mm)

Gun/Manifold

Inlet Pressure

psi (MPa, bar)

Fluid* Flow

Rate

oz/min (cc/min)

Spray

Distance

in (cm)

2 (5)

4 (10) 0.6 (15)

6 (15) 0.7 (19)

Pattern

Shape

Round

Pattern Size*

in. (mm)

0.5 (13)

* Fluid viscosity for these samples was 30 centipoise.

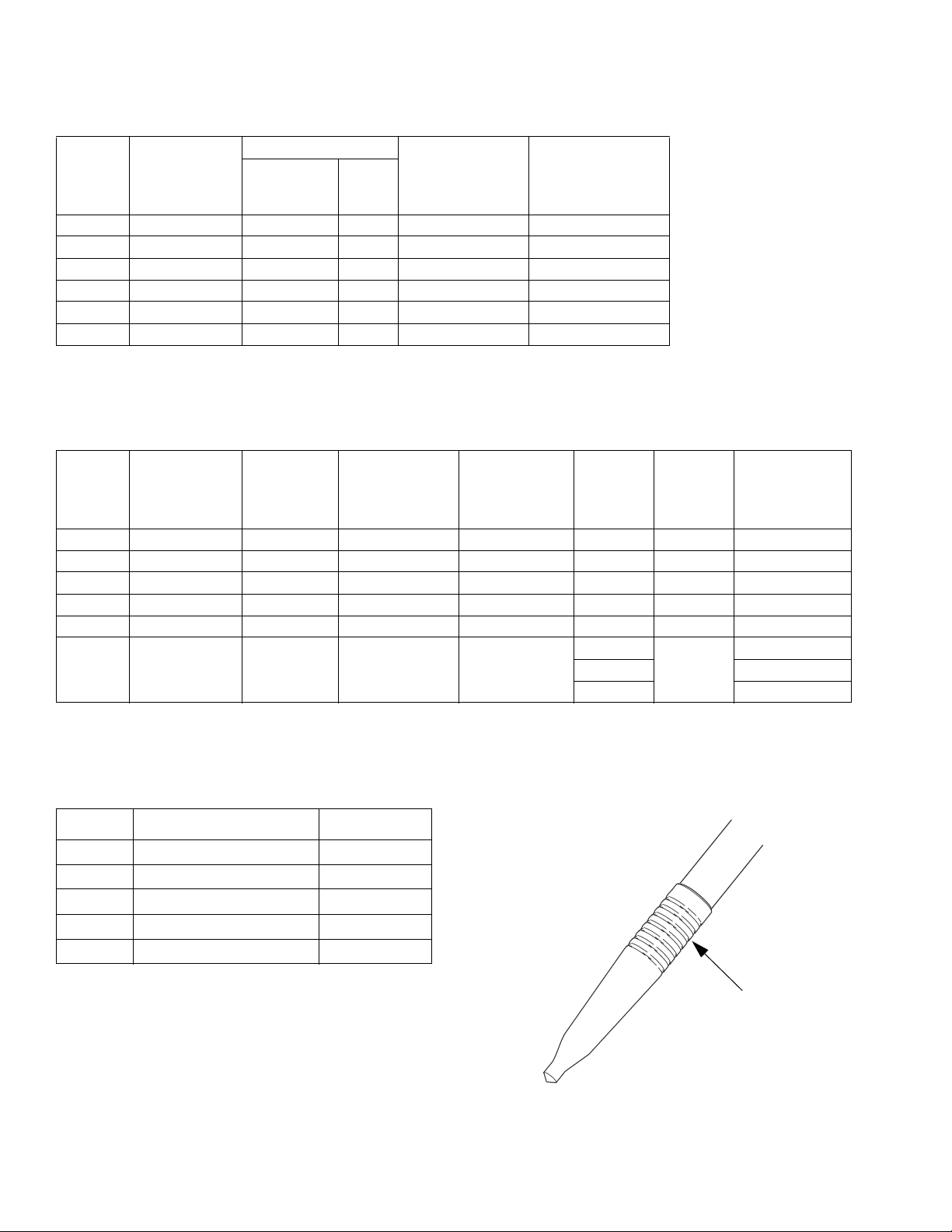

Needle Assembly Identification

Part Needle Assembly Size # of Grooves

24C190 0.5 mm 1

24C191 0.7 mm 2

24C192 0.9 mm 3

24C193 1.1 mm 4

24C194 1.3 mm 5

Grooves

ti14043a

8 313869B

Page 9

Selection Charts

313869B 9

Page 10

Installation

Installation

This spray gun can spray most coatings or finishes currently being used for small component plastic, wood and metal finishing

applications, while easily operating from paint

delivery systems, such as pressure pots or

remote pumps for production line operation.

The air regulator must have a minimum air flow

capacity of 30 scfm at 100 psi (0.7 MPa,

7.0 bar) air pressure.

Ventilate Spray Booth

To prevent hazardous concentrations of toxic

and/or flammable vapors, spray only in a properly ventilated spray booth. Do not operate the

spray gun unless ventilation fans are

operating.

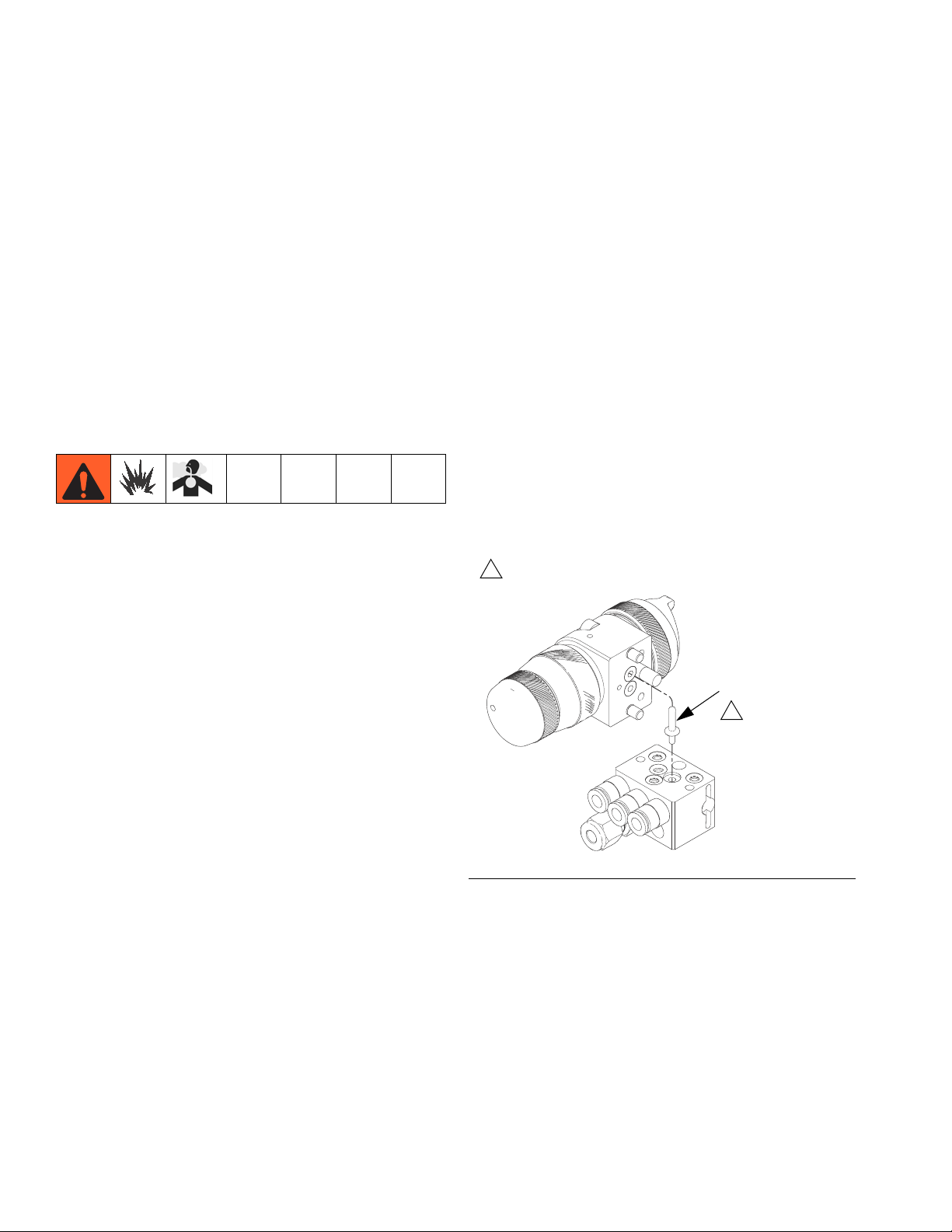

Configure Gun and Manifold

Guns with Manifold

See FIG. 1. The gun is shipped with a fluid plug

(25). To use the gun in a circulating system, do

not install the plug. In a non-circulating system,

install the plug as shown to minimize flush

time.

1. Connect the fluid supply line to one fluid

port fitting and the fluid return line to the

other. The manifold fluid ports are

reversible.

2. Install the gun on the manifold, using the

two screws. Torque the screws evenly to

50 in-lb (5.6 N•m).

1

Do not install when used in circulating systems.

• Check and follow all national, state, and

local codes regarding air exhaust velocity

requirements.

• Check and follow all local safety and fire

codes.

25

1

TI14429A

FIG. 1: Guns with Manifold

10 313869B

Page 11

Installation

Guns without Manifold

The gun is shipped ready for use in a circulating system, with a fitting installed in each fluid

port. Connect the fluid supply line to one fluid

inlet fitting (15) and the fluid return line to the

other.

To use the gun in a non-circulating system,

remove one fitting and replace with plug (33,

shipped loose). Use the 3/16 allen wrench

supplied to tighten the plug.

1

Install for use in a non-circulating system.

2

Use fitting (15) for use in a circulating system.

15

Pump/Fluid Supply

Ground the pump by connecting a ground wire

and clamp between the fluid supply and a true

earth ground as instructed in your separate

pump instruction manual.

Air Compressors and Hydraulic Power

Supplies

Ground the air compressors and hydraulic

power supplies according to the manufacturer

recommendations.

Spray Gun

Ground the spray gun by mounting the manifold to a properly grounded reciprocator, robot,

or stationary mount. Check the electrical resistance between the manifold and a true earth

ground. Resistance must not exceed

1 megohm.

1

33

TI14430A

FIG. 2: Guns without Manifold

2

Ground System

The following grounding instructions are minimum requirements for a system. Your system

may include other equipment or objects that

must be grounded. Check your local electrical

code for detailed grounding instructions for

your area and type of equipment. Your system

must be connected to a true earth ground.

Fluid Supply Container

Ground the fluid supply container according to

local code.

Object Being Sprayed

Ground the object that is being sprayed

according to local code.

Solvent Pails

Ground all solvent pails that are used when

flushing according to local code. Use only conductive metal pails placed on a grounded surface. Do not place the pail on a non-conductive

surface, such as paper or cardboard, which

interrupts the grounding continuity.

313869B 11

Page 12

Installation

Mount Gun

Reciprocating Arm Rod Mount

To mount the gun on a reciprocating arm rod

[0.75 in. (19 mm) diameter maximum], insert

the bar (A) through the hole in the manifold as

shown in FIG. 3.

NOTE: Use the 1/8 in. alignment slot (P) to

assist in orienting the gun.

Secure the gun to the bar by tightening the

mounting screw (B).

C

A

B

FIG. 3: Reciprocating Arm Mount

P

TI14433A

Stationary Support

To mount the gun on a stationary support, refer

to FIG. 4 and to the correct mounting hole layout for your gun, page 30 - 31.

1. Align the gun or manifold with the alignment pins. Locate alignment slot and holes

per the mounting hole layout.

Guns with manifold

C

Guns without manifold

FIG. 4: Stationary Support Mount

TI14434A

TI14435A

2. Secure the gun to the support with two M8

x 1.25 capscrews (C). The screws must be

long enough to engage the threaded holes

to a depth of 1/4 in. (6 mm).

12 313869B

Page 13

Setup

Setup

Connect Air Line

NOTE:

• If your regulated air source does not

have a filter, install an air filter (G) on

each air line to ensure a dry, clean air

supply to the gun. Dirt and moisture can

ruin the appearance of your finished

workpiece. See FIG. 5.

• You must install a separate air pressure

regulator (F) on the CYL, FAN, and

ATOM air lines to control air pressure to

the gun. See FIG. 6 and FIG. 7.

• Install a bleed type air shutoff valve (E)

on each gun air supply line, downstream of the gun air regulator, to shut

off air to the gun.

1. The gun cylinder, fan, and atomization air

must be supplied and regulated separately.

To regulate air remotely, use solenoids (see

FIG. 6 and FIG. 7).

NOTE: The three air inlet fittings accept 6 mm

OD tubing.

2. Connect each air hose (D) to a regulated

air supply line (H).

H

G

FIG. 5: Connect Air Line

FED

ti01990a

313869B 13

Page 14

Setup

Air regulator

ATOMIZING AIR

2-way solenoid

valve

CYLINDER AIR

3-way solenoid

valve

FAN AIR

FIG. 6: Remote Air Regulation using Solenoid (Guns with Manifold)

FAN AIR

CYLINDER AIR

2-way solenoid

TI14444A

valve

2-way solenoid

valve

3-way solenoid

valve

ATOMIZING AIR

TI14445A

2-way solenoid

valve

FIG. 7: Remote Air Regulation using Solenoid (Guns without Manifold)

14 313869B

Page 15

Setup

Connect Fluid Hose

NOTE:

• Before connecting the fluid line, blow it

out with air and flush it with solvent. Use

solvent that is compatible with the fluid

to be sprayed.

• Install a fluid regulator (L) on the fluid

line to control fluid pressure to the gun.

See FIG. 8.

• Install a fluid shutoff valve (M) to shut off

the fluid supply to the gun.

• Filter the fluid line of coarse particles

and sediment to avoid clogging the fluid

nozzle and causing finishing defects.

Inline fluid filter 24B707 is available.

L

In a non-circulating system, remove the

gun fluid outlet fitting (T) and plug the outlet

port with the pipe plug (33) supplied for

guns without manifold. Guns with manifold

use plug 24C211 (25, see page 10).

KEY

N Cylinder Air Inlet: accepts 6 mm OD tubing

P Atomization Air Inlet: 6 mm OD tubing

R Fan Air Inlet: 6 mm OD tubing

S Fluid Inlet: 6 mm OD tubing

T Fluid Outlet (circulating gun only): 6 mm OD tubing

With Manifold

N

RP

K

M

J

ti7016a

FIG. 8: Connect Fluid Hose.

1. Connect the fluid supply hose (J) to the gun

fluid inlet (S), 6 mm OD tube fitting. See

IG. 9.

F

2. Connect the other end of the fluid hose (J)

to a regulated fluid supply outlet (M).

3. In a circulating system, connect a

grounded fluid return hose to the gun fluid

outlet (T). See FIG. 9.

Without Manifold

T (or S)

P

N

FIG. 9: Air and Fluid Ports

S (or T)T (or S)

TI14436A

S (or T)

R

TI14437A

313869B 15

Page 16

Setup

Flush Spray Gun

Before running any paint through the spray

gun:

1. Flush the gun with a solvent that is compatible with the fluid to be sprayed, using the

lowest possible fluid pressure and a

grounded metal container. See Clean and

Flush Gun, page 20.

2. Perform Pressure Relief Procedure,

page 18.

Position Air Cap

Air caps are factory-set with the alignment pin

(A) set to a vertical spray pattern. To change

the air cap to a horizontal spray pattern, use a

1/16 in. hex wrench to unscrew the alignment

pin (A) and relocate it to the horizontal spray

pattern hole. When relocating the pin use low

strength thread locker. Torque to 1.5-2.5 in-lb

(0.2-0.3 N•m). Do not overtighten. Refer to

FIG. 10.

Adjust Spray Pattern

Do not exceed 100 psi (0.7 MPa, 7 bar)

maximum fluid and air pressure. Higher

pressures can cause parts to rupture and

result in serious injury.

Use the fluid pressure regulator to adjust the

spray gun fluid flow. All models are equipped

with a fluid control knob to make precise fluid

flow adjustments.

Follow these steps to establish the correct fluid

flow and air flow:

1. To achieve desired flow, adjust the fluid flow

using the fluid pressure regulator (L)

installed in the gun fluid line. Typical industrial flow rates will vary with regulator pressures from 5 to 30 psi (34 to 210 kPa,

0.3 to 2.1 bar). If the fluid pressure is too

low at the desired flow rate, install a smaller

nozzle. If the fluid pressure is too high,

install a larger nozzle.

For spray guns equipped with the fluid control knob, you can make flow rate changes

at the spray gun. Rotate the fluid control

knob clockwise to reduce the flow.

A

ti8171a

Vertical Pattern

A

Horizontal Pattern

ti8170a

ti8172a

FIG. 10: Position Air Cap

16 313869B

Page 17

L

ti7019a

FIG. 11: Fluid Pressure Regulator

NOTE: A larger fluid nozzle at a reduced fluid

pressure will maintain the same flow rate, but

the fluid stream (velocity) will slow down.

When air is applied, the lower velocity allows

the air to act on the fluid longer, which

improves atomization.

2. Using the air pressure regulator (F), set the

fan and atomizing air supply pressure per

Table 1. Use these suggested settings as a

starting point.

Table 1: Suggested Starting Settings

Spray

Type

Conven-

tional

HVLP 15 (0.1, 1.0) 15 (0.1, 1.0)

HiTEch 29 (0.2, 2.0) 29 (0.2, 2.0)

LVMP 43 (0.3, 3.0) 43 (0.3, 3.0)

Air Brush NA 29 (0.2, 2.0)

Fan Air

psi (MPa, bar)

43 (0.3, 3.0) 43 (0.3, 3.0)

Atomizing Air

psi (MPa, bar)

Setup

NOTE: HVLP Gun Limits

HVLP Guns: local laws may limit the maximum

pressure to 10 psi (70 kPa, 0.7 bar) at the air

cap for compliance. See the table on page 8

for maximum HVLP manifold inlet pressures.

To measure pressure at the air cap, use the

appropriate HVLP Pressure Verification Kit.

F

ti01997

FIG. 12: Air Pressure Regulator

3. Test the spray pattern atomization while

keeping the gun a consistent distance,

about 6 to 8 inches (150 to 200 mm), from

the test piece.

Check the atomization quality. Increase the

gun atomizing air supply pressure with the

air pressure regulator in 5 psi (34 kPa, 0.3

bar) increments until you obtain the desired

atomization.

NOTE: For the best transfer efficiency, use the

lowest setting needed to achieve desired finish

quality.

4. If the spray pattern is too wide or split,

reduce the fan air pressure.

NOTE: Reducing the fan air pressure to 0 psi

(or fully closing the fan adjustment valve) will

produce a round pattern.

To further control the spray pattern, use an

alternate air cap. For a list of available air caps,

see page 8.

313869B 17

Page 18

Operation

Operation

Pressure Relief Procedure

1. Turn off all bleed type air valves and all

other air and fluid supplies to the gun.

2. Trigger the gun into a grounded metal

waste container to relieve fluid pressure.

ti8174a

FIG. 13: Pressure Relief

To achieve best results when applying fluid:

• Keep gun perpendicular and 6 to 8 in.

(150 to 200 mm) from object being

sprayed.

• Use smooth, parallel strokes across sur-

face to be sprayed with 50% overlap.

Incorrect

TI14439A

Apply Fluid

The gun does not have an air shutoff. The air

should be activated before the fluid to ensure

full atomization of fluid and prevent buildup on

the air cap.

Adjust the system control device, if it is automatic, so the gun starts spraying just before

meeting the part and stops as soon as the part

has passed.

Correct

TI14438A

FIG. 14: Correct Spray Method

18 313869B

Page 19

Daily Gun Care

NOTICE

Methylene chloride with formic or propionic

acid is not recommended as a flushing or

cleaning solvent with this gun as it will

damage aluminum and nylon components.

NOTICE

Solvent left in gun air passages could result in a poor quality paint finish. Do not

use any cleaning method which may allow solvent into the gun air passages.

Do not wipe the gun with a cloth soaked

Do not point the gun up while cleaning it.

in solvent; wring out the excess.

Operation

ti8100a

ti4827a

Do not use metal tools to clean the air

cap holes as this may scratch them;

Do not immerse the gun in solvent.

ti8101a

313869B 19

scratches can distort the spray pattern.

ti8175a

Page 20

Operation

General System Maintenance

• Follow the Pressure Relief Procedure,

page 18.

• Clean the fluid and air line filters daily.

• Check for any fluid leakage from the gun

and fluid hoses. Tighten fittings or replace

equipment as needed.

• Flush the gun before changing colors and

whenever you are done operating the gun.

Clean and Flush Gun

1. Follow the Pressure Relief Procedure,

page 18.

2. Shut off the gun fan and atomizing air.

3. Supply a compatible solvent to the gun fluid

inlet.

4. Point the gun down into a grounded metal

container, and flush the gun with solvent

until all traces of paint are removed from

the gun passages.

9. Dip the end of a soft-bristle brush into a

compatible solvent. Do not continuously

soak the brush's bristles with solvent and

do not use a wire brush.

ti4845a

FIG. 15: Use solvent-dipped soft-bristle brush

10.With the gun pointed down, clean the front

of the gun, using the soft-bristle brush and

solvent.

11.Scrub the air cap retaining ring, air cap,

and fluid nozzle with the soft-bristle brush

(see FIG. 16). To clean out air cap holes,

use a soft implement, such as a toothpick,

to avoid damaging critical surfaces. Clean

the air cap and fluid nozzle daily, minimum.

Some applications require more frequent

cleaning.

5. Follow the Pressure Relief Procedure,

page 18.

6. Disconnect the solvent supply.

7. Remove the air cap retaining ring and air

cap.

NOTICE

Trigger the gun whenever you tighten or

remove the nozzle. This keeps the needle

IG. 16: Clean air cap, ring and fluid nozzle

F

ti8176a

seat away from the nozzle seating surface

and prevents the seat from being dam-

12.Install the air cap retaining ring and air cap.

aged.

13.Dampen a soft cloth with solvent and wring

8. Clean the air cap retaining ring, air cap,

and fluid nozzle with solvent.

20 313869B

out the excess. Point the gun down and

wipe off the outside of the gun.

Page 21

Operation

313869B 21

Page 22

Troubleshooting

Troubleshooting

Problem Cause Solution

Spray Pattern Normal pattern. No action necessary.

Right

Spray Pattern Dirty or damaged air cap or

fluid nozzle.

Wrong

Heavy top

or bottom

Spray Pattern Fan pressure too high for vis-

cosity of material being

sprayed.

Wrong

Split pattern

Rotate air cap (5) 180°.

If pattern follows air cap, problem is in air cap. Clean and

inspect. If pattern is not corrected, replace air cap.

If pattern does not follow the air

cap, the problem is with the

fluid nozzle (4). Clean and

inspect the nozzle. If the pattern is not corrected, replace

nozzle.

Reduce fan air pressure and

increase material viscosity.

Spray Pattern Dirty or distorted air horn

holes.

Clean and inspect air cap (5). If

pattern is not corrected,

replace air cap.

Wrong

22 313869B

Page 23

Troubleshooting

Problem Cause Solution

Gun spitting. Air getting into paint stream. Check if fluid source is empty

and fill.

Tighten fluid nozzle (4).

Check fluid nozzle o-ring (3) for

damage.

Check fluid nozzle (4) for damage.

Will not spray. Fluid control valve (11) turned

too far clockwise.

Adjust fluid control valve (11)

counterclockwise.

Fluid source empty. Refill.

Excessive air blowing back. Loose fluid nozzle (4). Tighten fluid nozzle (4).

Damaged fluid nozzle seal (3). Replace seal (3).

Gun fluid pressure is too high

with gun triggered (cannot

Using needle/nozzle kit with

too small orifice.

Use needle/nozzle kit with

larger orifice.

achieve desired flow rate).

Using a low fluid pressure set-

ting, the fluid flow is too high,

Using needle/nozzle kit with

too large orifice.

Use needle/nozzle kit with

smaller orifice.

making it necessary to restrict

needle travel to reduce fluid

flow.

Fluid system will not operate at

low enough pressure [below

10 psi (70 kPa, 0.7 bar)].

Fluid flow is fluttering while

spraying.

There is no fluid regulator, or

air regulator is not sensitive

enough at low pressure.

Add low pressure fluid regula-

tor, or add more sensitive low

pressure air regulator.

Fluid source empty. Refill.

313869B 23

Page 24

Service

Service

screws (16) and remove the gun from

the manifold.

NOTE: Numbers in parenthesis in the text refer

to the reference numbers in the figures and in

the parts list.

Disassembly

1. Follow the Pressure Relief Procedure,

page 18.

2. Remove gun for service:

a. With Manifold: Use the 4 mm allen

wrench supplied to unscrew the two

1

Torque to 155-165 in-lb (18-19 N•m).

2

Torque to 80 in-lb (9.0 N•m).

b. Without Manifold: Disconnect the air

and fluid hoses. Remove the gun from

the mounting arm.

3. Remove the air cap retaining ring (21) and

air cap (5).

4. Remove the fluid adjustment knob (11) and

spring (10).

5. Pull the piston (7) and fluid needle (6) out

of the back of the gun.

11

10

7

6

2

2

1

4

21

5

FIG. 17

24 313869B

ti14946a

Page 25

Service

6. Use a 1/16 hex wrench to loosen the fluid

needle set screw (7a). Remove the needle

(6) from the piston (7).

7. Check the fluid needle (6) for damage or

excessive wear. Replace the needle if necessary.

NOTICE

The needle and tip are permanently

bonded. To prevent damage to the needle,

do not try to separate.

8. Use the 10 mm hex nut driver to remove

the fluid packing nut (2).

9. Use the 10 mm wrench to remove the

nozzle (4).

Reassembly

1. Lightly grease the new nozzle (4), which

includes o-ring (3). Use the 10 mm wrench

to install the nozzle. Torque to 155-165 in-lb

(18-19 N•m).

2. Install the new air cap assembly (5,

includes air cap, o-ring, washer, and alignment pin) and the retaining ring (21).

7

1

7a

1

Torque to 4.5 to 5.5 in-lb (0.5 to 0.6 N•m).

FIG. 18

6

ti14944a

NOTICE

To avoid damage, the nozzle (4) must be

installed before the needle (6).

5. Grease the needle shaft and piston o-ring.

Push the needle/piston assembly into the

gun as far as possible. Insert spring (10).

6. Turn counterclockwise to fully open the fluid

adjustment knob (11). Install the knob

hand-tight.

NOTE: If you have an ultra-precision fluid

adjustment knob, loosen the set screw to

adjust the position of the hash markings for

convenient reading.

NOTE: Be sure to move the alignment pin if

you want a horizontal spray pattern. See Posi-

tion Air Cap, page 16.

3. Use the 10 mm hex nut driver to install new

fluid packing nut (2, includes o-ring).

Torque to 80 in-lb (9.0 N•m).

ti14947a

Set screw

4. Insert the new needle (6) in the piston (7).

FIG. 19

Apply medium-strength thread sealant to

the setscrew (7a). Use the 1/16 hex wrench

to torque the setscrew to 4.5 to 5.5 in-lb

(0.5 to 0.6 N•m).

313869B 25

Page 26

Parts

Parts

Guns with Manifold

5a

5c

5b

5d

18

7

7b

1

16

6

2

7a

Ultra-precision knob

3

4

Indexing

knob

Lock ring

20

13

20

13

15

14

10

11

and cap

21

Guns without Manifold

4

5d

5a

5b

5c

21

15

12

19

1

3

17

7a

2

7b

6

15

ti14447a

11

10

7

ti14945a

14

ti14448a

26 313869B

Page 27

Parts

Parts in Common Additional Parts for Models with Manifold

Ref. Part Description Qty.

1 ----- BODY 1

2 24C205 FLUID PACKING ASSEMBLY 1

3 111457 O-RING (included with Part 4) 1

4 See Table NOZZLE, fluid (includes Part 3) 1

5 See Table AIR CAP ASSEMBLY (includes

Parts 5a-5d)

5a ----- AIR CAP 1

5b✓ ----- O-RING 1

5c✓ ----- WASHER, UMHWPE 1

5d ----- PIN, alignment 1

6 See Table NEEDLE assembly 1

7 24C202 PISTON, needle stop (includes

Parts 7a and 7b)

7a ----- SCREW, set, 6-32 UNC x 1/16 in. 1

7b ----- O-RING 1

10 24C207 SPRING, compression 1

11

24D065

24C204

24C203

14 120538 FITTING, tube, air line,

15

24C213

24D046

21 289079 RETAINING RING, assembly

23 114141 TOOL, wrench, hex, 1/16, not

24 107157 TOOL, wrench, allen, 4 mm, not

26 101821 TOOL, wrench, allen, 3/16, not

31 24C210 TOOL, wrench, metric, not shown 1

32 24C209 TOOL, nut driver, hex, 10 mm,

33 100139 PLUG, pipe, not shown, shipped

KNOB, fluid adjustment

Ultra-Precision

Indexing

Lock ring and cap

1/8 npt x 6 mm

FITTING, tube, fluid line,

1/8 npt x 6 mm

Nylon

Stainless steel

(includes 5b and 5c)

shown

shown

shown (Models without manifold)

not shown

loose (Models without

manifold)

Ref. Part Description Qty.

12 24C215 MANIFOLD, gun (includes Parts

13, 14, 15, 19, and 20)

13 106456† O-RING, PTFE, white 2

16 24C206 SCREW, mounting 2

17 24C208 ROD, mounting (includes Part 18) 1

18 ----- SCREW, cap, hex head 1

19 24C212 SCREW, set socket, M8 2

20 112319† O-RING, FX75, black 3

25 24C211 PLUG, manifold, not shown,

shipped loose

----- Not sold separately.

1

✓ Included in Air Cap Seal Kit 289791. See Repair Kits,

page 28.

† Included in Manifold O-Ring Kit 24D827. See Repair

Kits, page 28.

1

3

2

1

1

1

1

1

1

1

1

313869B 27

Page 28

Repair Kits

Repair Kits

Gun Part Number

With

Spray Type

Conventional 24B857 24B877

Conventional 24B858 24B878

Conventional 24B859 24B879

Conventional 24B860 24B880

Conventional 24B861* ----HVLP 24B862 ----HVLP 24B863 24B881

HVLP 24B864 24B882

HVLP 24B865 24B883

HiTEch 24B866 24B884

HiTEch 24B867* 24B885*

HiTEch 24B868* 24B886*

LV MP 24B869 24B887

LV MP 24B870 24B888

LV MP 24B871 24B889

LV MP 24B872 24B890

LV MP 24B873 24B891

LV MP 24B874* ----Air Brush 24B875 24B892

Manifold

Without

Manifold

Item 5

Air Cap

(Includes seals

and alignment

pin)

Nozzle

Orifice

Size

in. (mm)

Needle/Nozzle

Kit

(Includes

Items 4 and 6)

Item 4

Nozzle

(includes

o-ring)

Item 6

Needle

Assembly

(includes

tip)

0.028 (0.7) 24D177 24D174 24C191

0.035 (0.9) 24C198 24C187 24C192

0.043 (1.1) 24C199 24C188 24C193

24C182

0.051 (1.3) 24C200 24C189 24C194

0.059 (1.5) 24D178 24D175 24C195

0.020 (0.5) 24D302 24D296 24C190

0.028 (0.7) 24D179 24D176 24C191

0.043 (1.1) 24D305 24D299 24C193

24C183

0.051 (1.3) 24D306 24D300 24C194

0.028 (0.7) 24D303 24D297 24C191

0.039 (1.0) 24C221 24C219 24C220

24D703

0.059 (1.5) 24C201 24D275 24C195 24D704

0.020 (0.5) 24D277 24D259 24C190

0.028 (0.7) 24D278 24D260 24C191

0.035 (0.9) 24D279 24D261 24C192

0.043 (1.1) 24D280 24D262 24C193

24C184

0.051 (1.3) 24D281 24D263 24C194

0.059 (1.5) 24D284 24D276 24C195

0.028 (0.7) 24C197 24C186 24C191 24D705

* Needle tip and nozzle exit constructed from tungsten carbide.

Accessories

Kit 24C216, Fittings (1/4 inch)

Part Description Qty.

120388 FITTING, tube, air line,

1/8 npt x 1/4 T

111157 FITTING, tube, fluid line,

1/8 npt x 1/4 T

3

2

Kit 24D143, Robot Adapter Kit

Fanuc Paint Mate 200

Compatible with and without manifold.

Kit 24D008, Inlet Air Needle Valve

Includes needle valve and 6mm tube fittings.

Kit 24D827, Manifold O-Rings

Part Description Qty.

106456 O-RING, PTFE, white 2

112319 O-RING, FX75, black 3

HVLP Pressure Verification Kit 24C214

For use in checking air cap atomizing and fan

pattern air pressure at various supply air pressures. Not to be used for actual spraying.

Install the kit air cap on the gun. Turn on the air

to the gun and read the air pressure on the

gauge.

NOTE: To be “HVLP compliant,” the atomizing

and fan pattern air pressure must not exceed

10 psi (70 kPa, 0.7 bar).

28 313869B

Page 29

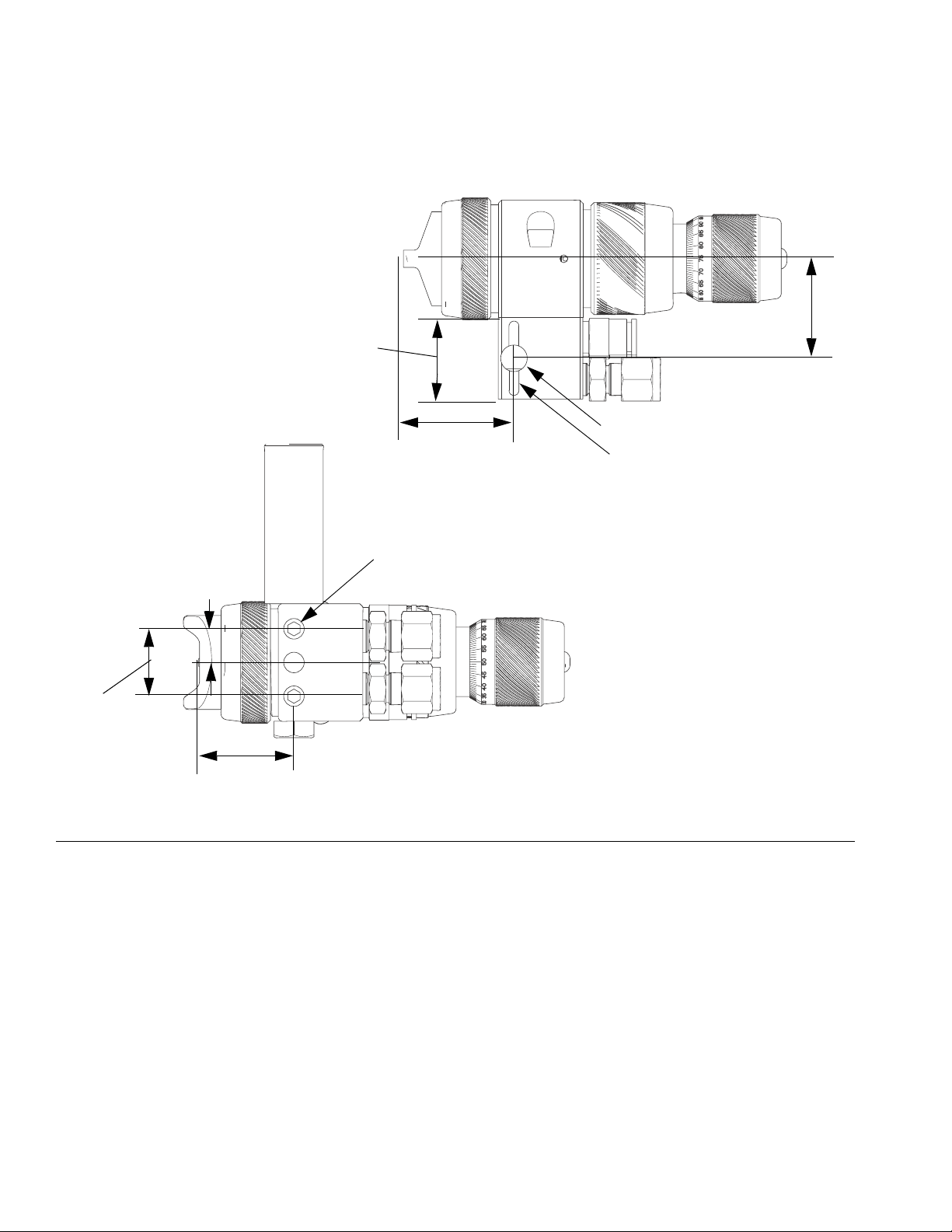

Dimensions

Guns with Manifold

Dimensions

1.3 in.

(33.0 mm)

FIG. 20

4.9 in. (124.5 mm) with Ultra-Precision knob

4.1 in. (104.1 mm) with indexing knob

3.5 in. (88.9 mm) with lock ring and cap

1.4 in.

(35.6 mm)

0.75 in. (19.1 mm)

mounting hole

2.6 in.

(66.1 mm)

TI14440A

1.6 in.

(40.7 mm)

3.8 in.

(96.5 mm)

TI14436A

Guns without Manifold

4.9 in. (124.5 mm) with Ultra-Precision knob

4.1 in. (104.1 mm) with indexing knob

3.5 in. (88.9 mm) with lock ring and cap

2.2 in.

(55.9 mm)

TI14442A

3.5 in.

(88.9 mm)

TI14437A

1.6 in.

(40.6 mm)

FIG. 21

313869B 29

Page 30

Mounting Hole Layouts

Mounting Hole Layouts

Guns with Manifold

0.95 in

(24.1 mm)

ti14700a

1.27 in

(32.3 mm)

0.86 in.

(21.8 mm)

FIG. 22

0.43 in.

(10.9 mm)

1.22 in.

(31.0 mm)

1.4 in

(35.6 mm)

3 x M8 x 1.25

0.34 in. (8.6 mm) thru

0.13 in. (3.3 mm) slot

ti14441a

30 313869B

Page 31

Guns without Manifold

0.95 in.

(24.1 mm)

Mounting Hole Layouts

1.76 in.

(44.7 mm)

M8 x 1.25 T

0.35 in. (8.9 mm) deep

0.13 slot

(3.3 mm)

FIG. 23

ti14701a

313869B 31

Page 32

Technical Data

Technical Data

Maximum working fluid pressure . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum working air pressure . . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Maximum HVLP Inbound Air Pressure. . . . . . . . . . . . . . . . See chart on page 8.

Maximum Working Fluid Temperature . . . . . . . . . . . . . . . . 120° F (49° C)

Minimum Air Cylinder Actuation Pressure . . . . . . . . . . . . . 50 psi (0.34 MPa, 3.4 bar)

Weight

with manifold. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with no manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted Parts

Models 24B857-24B860, 24B862-24B865,

24B869-24B873, 24B875 . . . . . . . . . . . . . . . . . . . . . . .

Model 24B866. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PTFE, Stainless Steel, Ultra High

Models 24B867 and 24B868. . . . . . . . . . . . . . . . . . . . . PTFE, Stainless Steel, Ultra High

1.3 lb (575 g)

0.6 lb (275 g)

Nylon, PTFE, Stainless Steel, Ultra

High Molecular Weight Polyethylene

Molecular Weight Polyethylene

Molecular Weight Polyethylene,

tungsten carbide

Models 24B861 and 24B874. . . . . . . . . . . . . . . . . . . . . Nylon, PTFE, Stainless Steel, Ultra

High Molecular Weight Polyethylene,

Tungsten Carbide

Models 24B877-24B883, 24B887-24B892 . . . . . . . . . . Anodized Aluminum, Nylon, Stain-

less Steel, Ultra High Molecular

Weight Polyethylene

Models 24B885 and 24B886. . . . . . . . . . . . . . . . . . . . . Anodized Aluminum, Stainless Steel,

Tungsten Carbide, Ultra High Molecular Weight Polyethylene

Model 24B884. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Anodized Aluminum, Stainless Steel,

Ultra High Molecular Weight

Polyethylene

Triggering Speed

These values apply to a new gun with a 12 ft. (3.6 m), 1/4 in. (6.3 mm) OD cylinder air line and a

0.043 in. nozzle. These values will vary slightly with use and with variations in equipment.

Cylinder Air

Pressure

psi (kPa, bar)

Fluid Pressure

psi (kPa, bar)

Air Pressure

psi (kPa, bar)

msec to fully

open

msec to fully

close

50 (0.35, 3.5) 50 (0.35, 3.5) 100 (0.7, 7.0) 48 84

32 313869B

Page 33

Sound Data

Conventional

Measured at 43 psi (0.30 MPa, 3.0 bar) atomizing air and

fan air pressure

Sound Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HVLP

Measured at 15 psi (0.10 MPa, 1.0 bar) atomizing air

and fan air pressure

Sound Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HiTEch

Measured at 29 psi (0.20 MPa, 2.0 bar) atomizing air

and fan air pressure

Sound Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LVM P

Measured at 43 psi (0.30 MPa, 3.0 bar) atomizing air and

fan air pressure

Sound Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Brush

Measured at 29 psi (0.20 MPa, 2.0 bar) atomizing air and

fan air pressure

Sound Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data

87.76 dBa

81.11 dBa

78.46 dBa

71.82 dBa

85.61 dBa

79.23 dBa

86.59 dBa

79.92 dBa

73.03 dBa

66.28 dBa

Sound power measured per ISO 9614-2.

313869B 33

Page 34

Air Flow

Air Flow

See the chart to determine air consumption. Add the air consumption values shown for the atomizing air and fan air to get the total air consumption. For example, air cap 24C182 with 35 psi inlet

pressure uses 3.9 scfm atomizing air and 5.4 scfm fan air for a total of 9.3 scfm air consumption.

Air Cap

24C182

(Conv.)

24C183

(HVLP)

24D703

24D704

(HiTEch)

Atomizing

Gun/Manifold

Inlet Pressure

psi (MPa, bar)

10 (0.07, 0.7) 1.5 (0.04) 2.0 (0.06)

15 (0.10, 1.0) 2.0 (0.06) 2.7 (0.08)

20 (0.14, 1.4) 2.5 (0.07) 3.3 (0.09)

25 (0.17, 1.7) 3.0 (0.08) 4.0 (0.11)

30 (0.21, 2.1) 3.5 (0.10) 4.7 (0.13)

35 (0.24, 2.4) 3.9 (0.11) 5.4 (0.15)

40 (0.28, 2.8) 4.4 (0.12) 6.0 (0.17)

45 (0.31, 3.1) 4.9 (0.14) 6.7 (0.19)

50 (0.34, 3.4) 5.4 (0.15) 7.4 (0.21)

10 (0.07, 0.7) 2.2 (0.06) 1.9 (0.05)

15 (0.10, 1.0) 3.0 (0.08) 2.5 (0.07)

20 (0.14, 1.4) 3.8 (0.11) 3.1 (0.09)

25 (0.17, 1.7) 4.6 (0.13) 3.8 (0.11)

30 (0.21, 2.1) 5.4 (0.15) 4.4 (0.12)

35 (0.24, 2.4) 6.2 (0.18) 5.0 (0.14)

40 (0.28, 2.8) 7.0 (0.20) 5.6 (0.16)

45 (0.31, 3.1) 7.8 (0.22) 6.3 (0.18)

50 (0.34, 3.4) 8.6 (0.24) 6.9 (0.19)

10 (0.07, 0.7) 2.2 (0.06) 1.9 (0.05)

15 (0.10, 1.0) 3.0 (0.08) 2.5 (0.07)

20 (0.14, 1.4) 3.8 (0.11) 3.1 (0.09)

25 (0.17, 1.7) 4.6 (0.13) 3.8 (0.11)

30 (0.21, 2.1) 5.4 (0.15) 4.4 (0.12)

35 (0.24, 2.4) 6.2 (0.18) 5.0 (0.14)

40 (0.28, 2.8) 7.0 (0.20) 5.6 (0.16)

45 (0.31, 3.1) 7.8 (0.22) 6.3 (0.18)

50 (0.34, 3.4) 8.6 (0.24) 6.9 (0.20)

Air Flow

SCFM

(m3/min)

Fan Pattern

Air Flow

SCFM

(m3/min)

Air Cap

24C184

(LVMP)

24D705

(Air

Brush)

Atomizing

Gun/Manifold

Inlet Pressure

psi (MPa, bar)

10 (0.07, 0.7) 1.3 (0.04) 1.9 (0.05)

15 (0.10, 1.0) 1.7 (0.05) 2.5 (0.07)

20 (0.14, 1.4) 2.2 (0.06) 3.2 (0.09)

25 (0.17, 1.7) 2.6 (0.07) 3.9 (0.11)

30 (0.21, 2.1) 3.1 (0.09) 4.6 (0.13)

35 (0.24, 2.4) 3.5 (0.10) 5.2 (0.15)

40 (0.28, 2.8) 4.0 (0.11) 5.9 (0.17)

45 (0.31, 3.1) 4.5 (0.13) 6.6 (0.19)

50 (0.34, 3.4) 4.9 (0.14) 7.2 (0.20)

10 (0.07, 0.7) 1.5 (0.04) N/A

15 (0.10, 1.0) 2.0 (0.06) N/A

20 (0.14, 1.4) 2.5 (0.07) N/A

25 (0.17, 1.7) 3.0 (0.08) N/A

30 (0.21, 2.1) 3.5 (0.10) N/A

35 (0.24, 2.4) 3.9 (0.11) N/A

40 (0.28, 2.8) 4.4 (0.12) N/A

45 (0.31, 3.1) 4.9 (0.14) N/A

50 (0.34, 3.4) 5.4 (0.15) N/A

Air Flow

SCFM

3

(m

/min)

Fan Pattern

Air Flow

SCFM

(m3/min)

34 313869B

Page 35

Air Flow

Spray Pattern Test Report

Every AirPro EFX gun must pass a spray pattern test. The test report is printed and shipped in the box with the gun.

A sample is reproduced here, with explanatory notes.

AirPro EFX

Width: the distance from

one end of the pattern to

the other along the spray

pattern major axis.

Height: The distance from

one end of the pattern to

the other along the spray

pattern minor axis.

Consistency: The calculat-

ed variation in concentra-

tion along the spray pattern

major axis.

Position: The distance be-

tween the intended spray

gun center target location

and the actual spray

pattern center location.

Curvature: The vertical

distance between the

spray pattern location and

a line formed by the

intersections of the spray

pattern end points on the

major axis.

Tilt: The angle between a

horizontal line and a line

formed by the spray

pattern major axis.

Spray Pattern Test Report

Test Number: 1234

Operator: JI

Date: 6/17/2009

Part Number: 24B857

Date Code: F09A

Spray Pattern Test Parameters

Width: Passed

Height: Passed

Consistency: Passed

Position: Passed

Curvature: Passed

Tilt: Passed

Actual spray pattern image

Notes:

x Detailed descriptions of the spray pattern test parameters can be found in instruction manual 313869.

x Spray pattern shape is dependent on the material type, material flow rate and air pressure.

Name of the technician who certified your gun.

Date on which the spray test was performed.

Certifies that the gun is within acceptable

Use this number for reference in

limits on all parameters.

Colors (if visible) represent paint

density, with red meaning most paint

particles and blue meaning fewest.

communications with Graco.

Part number of your gun.

Date code for Graco use only.

313869B 35

Page 36

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 313869

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2009, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 04/2010

Loading...

Loading...