Page 1

INSTRUCTIONS-PARTS

LIST.

308-201

This

manual

WARNINGS

READ

AND

contains

AND

RETAIN

IMPORTANT

INSTRUCTIONS

FOR

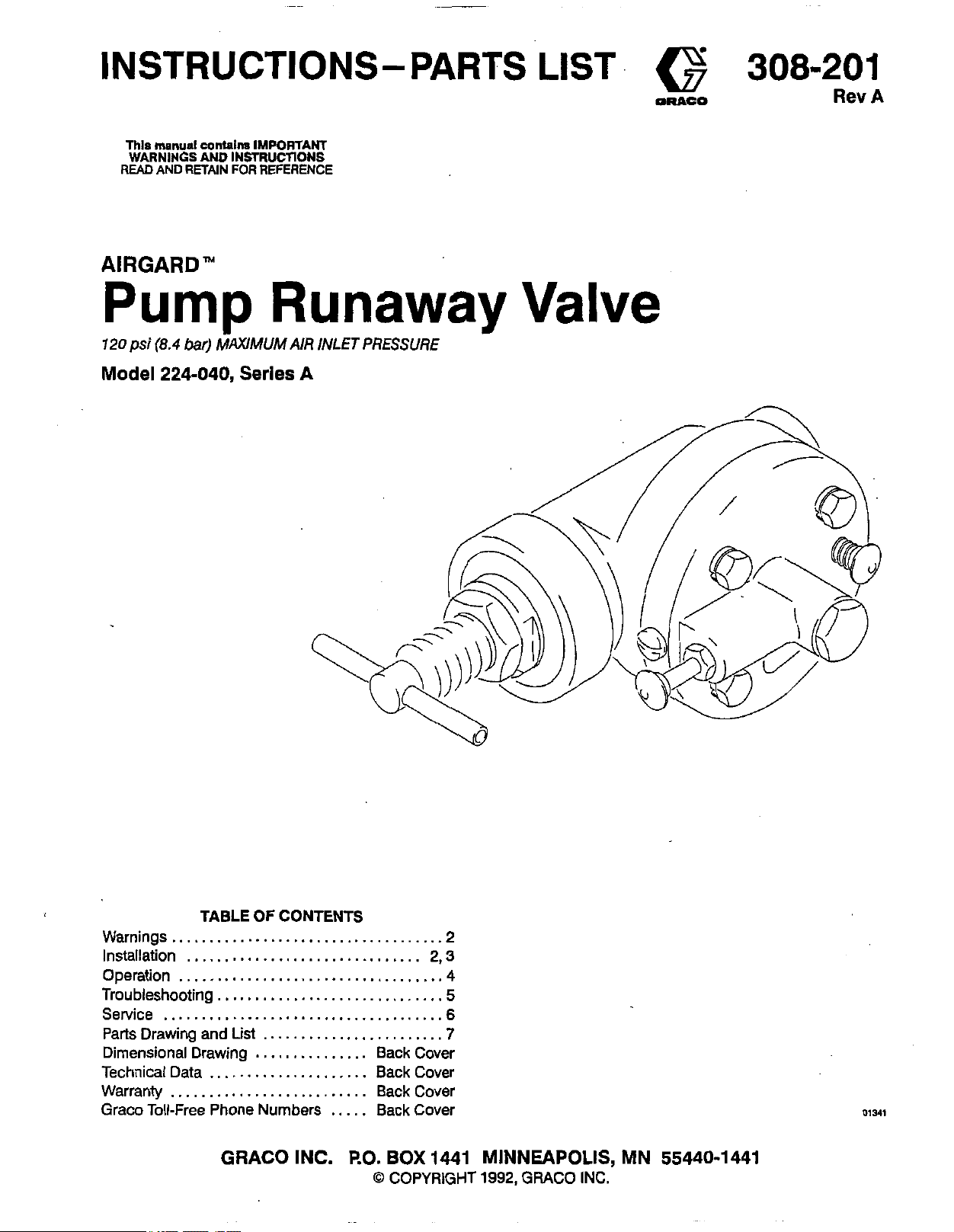

AIRGARD"

Pump

120

psi

(8.4

bar)

kXlMUM

Model

224-040,

Series

REFERENCE

Runaway

AIR

INLET

PRESSURE

A

w

0-

Valve

Rev

A

TABLE

Warnings.. .................................

Installation

Operation

Troubleshooting..

Service

Parts Drawing and List

Dimensional Drawing

Technical Data

Warranty Back Cover

Graco Toll-Free Phone Numbers Back Cover

...............................

..................................

....................................

..........................

OF

CONTENTS

...........................

.......................

...............

Back Cover

..................... Back Cover

.....

GRACO INC.

P.0.

BOX

0

COPYRIGHT

.2

2,3

.4

.5

.6

.7

1441 MINNEAPOLIS, MN 55440-1441

1992,

GRACO INC.

Page 2

OBSERVE ALL WARNINGS. Read And Understand All Instruction Manuals Before Operating Equipment.

Use Only With Compressed Air

This valve is for useonfywithcompressedair. It is not designed

for use with any other power source. NEVER use any other gas

or fluid in the runaway valve.

General Safety

Any misuse of the runaway valve, such as overpressurizing,

modifyingparts,orusingwomordamagedparts,cancausethe

valveto ruptureand result inseriousinjuryorpropertydamage.

NEVER alter or modify any part of the runaway valve; doing so

could cause it to malfunction.

CHECK all equipment regularly and repair or replace worn or

damaged parts immediately.

Moving Parts Hazard

To reduce the risk of serious injury, including pinching or am-

putationoffingersorhands, NEVERusetherunawayvalveasa

pump shutoff vaNe. The valve does not completely shut off the

airsupply,and thepumpwillcontinuetooperateslowlyafterthe

valve closes. The air motor piston (located behind the air motor

platesorshield) moveswhenairissuppliedtothemotor.NEVER

operate the pump wlth the air motor plates or shield removed.

System Pressure

NEVER exceed 120 psi (8.4 bar) MAXIMUM AIR INLET PRES-

SURE to the vaive, or the maximum air inlet pressure stated on

your pump.

DONOTexceedthemaximumworkingpressureofanycomponent or accessory used in the system.

Pressure Relief Procedure

To reduce the risk of serious injury, includin injury from

Alwayswearprotectiveeyewear,gloves,clothingandrespirator

as recommended by the fluid and solvent manufacturer.

Alwaysfollowthe Pressure Relief Procedureinyourseparate

pump manual, before checking, clearing, cleaning, flushing or

servicing any part of the system.

moving parts, alwaysfollowthisprocedurew

are servicing the runaway valve.

1. Follow the Pressure Relief Procedure in your separate pump manual.

2. Shut off the main air shutoff valve.

3,

eneveryou

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards -

particularly the General Standards, Pati1910, and the Construction Standards, Part 1926 - should be consulted.

INSTALLATION

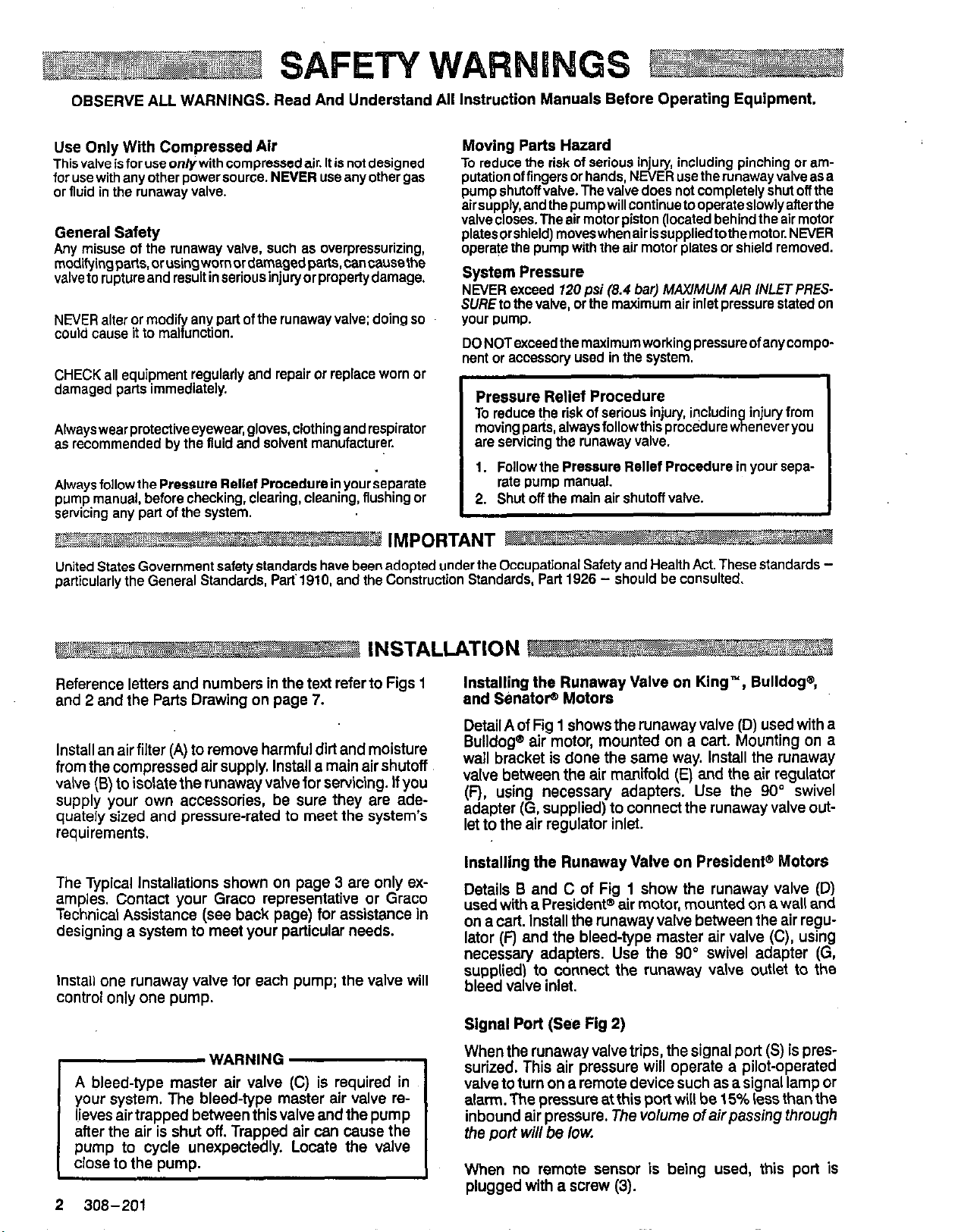

Reference letters and numbers in the text refer to Figs 1

and 2 and the Parts Drawing on page 7.

Install an air filter (A) to remove harmful dirt and moisture

from the compressed air supply. Install a main air shutoff

valve (6) to isolate the runaway valve for servicing. If you

supply your own accessories, be sure they are adequately sized and pressure-rated to meet the system’s

requirements.

The Typical Installations shown on page 3 are only examples Contact your Grace representative or Grace

Technical Assistance (see back page) for assistance in

designing a system to meet your particular needs.

install one runaway valve for each pump; the valve will

control only one pump.

WARNING

A bleed-type master air valve (C) is required in

your system. The bleed-type master air valve re-

lieves air trapped between this valve and the pump

after the air is shut off. Trapped air can cause the

pump to cycle unexpectedly. Locate the valve

close to the pump.

2 308-201

Installing the Runaway Valve on King’“, Bulldoge,

and Senatore Motors

Detail Aof Fig 1 shows the runaway valve (D) used with a

Bulldoge air motor, mounted on a cart. Mounting on a

wall bracket is done the same way. Install the runaway

valve between the air manifold (E) and the air regulator

(F), using necessary adapters. Use the 90” swivel

adapter (G, supplied) to connect the runaway valve outlet to the air regulator inlet.

lnstalltng the Runaway Valve on Presidente Motors

Details B and C of Fig 1 show the runaway valve (D)

used with a Presidente air motor, mounted on a wall and

on a cart. Install the runaway valve between the air regu-

lator (F) and the bleed-type master air valve (C), using

necessary adapters. Use the 90” swivel adapter (G,

supplied) to connect the runaway valve outlet to the

bleed valve inlet.

Signal Port (See Fig 2)

When the runaway valve trips, the signal port (S) is pres-

surized. This air pressure will operate a pilot-operated

valve to turn on a remote device such as a signal lamp or

alarm. The pressure at this port will be 15% less than the

inbound air pressure. The volume ofairpassing through

the port will be low.

When no remote sensor is being used, this port is

plugged with a screw (3).

Page 3

TYPICAL INSTALLATIONS

KEY

A Air Line Filter

B

C

D

E

F

Q

RECOMMENDED ADAPTERS

Main Air Shutoff Valve

Bleed-Type Master

(required, for pump)

Pump Runaway Valve

Air Manifold

Air Regulator

Runaway Valve Swivel (supplied)

Air

Valve

DETAIL

175-013

157-191 Reducer: 314 npt

160427 Swivel Adapter;

B

(WALL-MOUNTED DETAIL C (CART-MOUNTED

MAIN AIR

B

LIN

PRESIDENT AIR MOTOR)

Nipple: 314 npt

314 npt(m)

x

112

x

314 npsm(f)

npt

/

Fig 1

c

308-201

01267

3

Page 4

CAUSES

Pump runaway refers to a rapid acceleration in pump

speed, which can result in serious damage to the pump

parts caused by overheating and scoring. Conditions

which can cause pump runaway are:

The fluid supply container is empty, or the fluid supply

has been interrupted.

The pump is cavitating, which means that it has lost its

prime because an air pocket has formed around the

pump intake. This happens most frequently with highly viscous fluids.

Afluid hose downstream from the pump has ruptured,

resulting in an increased pump cycle rate.

NOTE:

When in a runaway condition, the pump requires much

more air than during normal operation. The runaway

valve senses this rapid increase in the volume of air being .used and greatly reduces the air flow, slowing the

pump to a crawl.

NOTE:

ADJUSTING THE VALVE

1.

2.

3.

OF

A RUNAWAY PUMP

The runaway valve may also trip if changes to

the system result in an increased cycle rate. For

if

example,

drops, you should readjust the valve to account

for the increased cycle.rate.

The sudden surge of air when starting the pump

may cause the valve to trip. Turn on the air slowly, or readjust the valve.

Loosen the adjustment locknut (24). See Fig 2.

Check that the T-handle (2)

counterclockwise.

Open the dispensing valve or trigger the spray gun.

you increase the number of gun

is

turned all the way

NOTE A faint hissing sound from the runaway valve

normal. The valve vents a small amount of air

from the poppet vent

5.

Adjust the pump to the desired regulated air pres-

sure and cycle rate.

6.

Turn the T-handle

valve trips. Press and hold the RESETvalve

will feel pressure on the RESET valve. Turn the handie (2) counterclockwise (approximately

turns) until pressure on the RESET valve decreases.

Release the RESET valve.

NOTE:

7.

8.

TESTING THE VALVE

To test the runaway valve, press the TEST valve

runaway valve should trip. Start the pump by pressing

the RESET valve

RESETTING THE VALVE

1.

2. If the air was shut

3.

At low pressure or a slow cycle rate, perform

step

6, then turn theT-handle (2) clockwise un-

til

you feel a slight pressure pushing on the RESET valve

counterclockwise distance

take several tries to achieve the proper setting.

Tighten the locknut (24).

Test the runaway valve as described in the following

paragraph.

Determine the condition that caused the runaway

valve to trip. Correct the condition.

den surge of air will cause the runaway valve to trip.

Press the RESET valve

conds. The pump should restart.

(2)

(R).

(R)

and holding it

off,

(H)

during operation.

clockwise until the runaway

(Turn it approximately half the

in

step

6.)

This may

in

for 5 seconds.

turn it back on slowly. A sud-

(R)

and hold it in.for 5 se-

(R);

1

0.

you

to

The

is

5

4.

Slowly open the main air shutoff valve

Fig

4

regulator

(C).

2

308-201

(F),

See Fig

2

and the bleed-type master air valve

1.

(B),

the air

NOTE:

In some installations, particularly where there is

low air volume, it may be necessary to turn off

the air supply to reset the valve.

01263

Page 5

I

PROBLEM

I

CAUSE

TROUBLESHOOTING

I

SOLUTION

CHART

Valve does not slow down

It

pump when

pump runs away

should;

Valve is not adjusted properly. Readjust valve and test.

Ruptured diaphragm. (If diaphragm is rup-

tured,

Decreased air pressure

speed

Poppet valve

of

Constant blast

vent when air supply is

turned on.

Valve shuts down for no

apparent reason

air from

Poppet valve

Increased air pressure has caused pump

speed

Interrupted or exhausted fluid supply. Check fluid supply and ensure that

Valve is not adjusted properly.

Decreased pump outlet pressure.

Air supply was turned on

,

Air leaking around

the

TEST

bunon will have no

to decrease.

(11, 14, 15)

(1 1, 14, 15)

to

increase.

Defective poppet valve.

TEST

effect.)

has

caused pump

is stuck closed.

is stuck open.

too

quickly.

valve. Replace

See

page

4.

Replace the diaphragm.

Readjust valve and test.

Disassemble and clean valve. Replace O-rings. Piston is stuck.

See

page

6.

Disassemble and clean poppet valve.

Disassemble and clean poppet valve.

Readjust valve and

Readjust valve and test.

Check for properly adjusted fluid outlet pressure.

Check and repair.

Press

RESET

valve.

TEST

valve.

test.

See

See

See

See

See

page

page

6.

page

4.

page

4.

it

remains constant.

page

4.

6.

See

See

page 6.

page

6.

Valvedoesnotresetwhen

RESET

valve is pressed

1

~ Piston is stuck; no air is escaping from vent. Disassemble and clean runaway valve.

Alr blowing from poppet vent.

Valve is not adjusted properly. Readjust valve and test.

Poppet vent hole plugged.

Remove

See

I

I

Disassemble and clean poppet valve.

RESET

page

valve. Clean needle and seat area.

6.

See

page

4.

See

See

page

page

6.

6.

308-201

5

Page 6

SERVICE

TOOLS REQUIRED

.

IO mm socket wrench

.

t 1 I1 6” socket wrench

.

Adjustable wrench

.

Torque wrench

.

I” crow%-foot

.

I//;;;3 mm) brass rod, or a press

.

.

Small needle-nose pliers

.

O-ring pick

.

Thread lubricant

DISASSEMBLY (See the Parts Drawing on page 7)

NOTE: Reoair Kit 224-937 is available to service the dia-

phiagm and o-rings. For best results, use all

parts in the kit. Parts included in the kit are

marked with an asterisk (for example, 4*).

l. Follow the Pressure Relief Procedure Warning in

your separate pump manual. Shut off the main air

valve. Tighten the locknut (24) to lock the valve at its

current adjustment. Remove the runaway valve

from the air line.

2. Place the valve in a vise with the T-handle (2) facing

left and the poppet valve cap (25) facing upward.

Unscrew the adapter (34) from the valve outlet.

3. Using an adjustable wrench on the flats, unscrew

the stem guide (17) from the lower housing (22).

The adjustment screw (21) will come free with the

stem guide and connecting parts.

4. Reach into the valve outlet and push out the piston

(16). Remove the o-rings (6,36) from the piston.

NOTE: The TEST valve assembly is also press-fit lo-

gether. Do not disassemble it unless it is leaking

and the parts require replacement.

12. Clean all parts and inspect for damage. Se sure to

clean all air passages, cavities, and surfaces.

REASSEMBLY (See the Parts Drawing on page 7)

1.

Place the upper housing (23) in a vise. Install the RESET valve In the upper housing. Tighten the valve

housing (19) to secure.

2.

Install the diaphragm (27’) in the lower housing (22)

so the larger center plate of the diaphragm is facing

outward. Align the four large holes in the diaphragm

with the four threaded holes in the housing.

3.

Lubricate the dowel pin (6). Working from the inside

of the upper housing (23), insert the pin (6) into the

small center hole. Push the pin all the way in, so it is

flush with the surface of the housing.

4.

Place the lower housing (22) in a vise. Position the

upper housing (23) so the boss (marked RESET) is

oriented as shown, and the four holes are aligned

with the holes in the diaphragm (27) and lower

housing (22). Assemble the two housings using the

four screws (9) and lockwashers (I). Using a 10 mm

socket wrench, torque to 50-70 in-lb (5.6-7.9 N.m).

5.

Lubricate the o-ring (4*) and install it on the push pin

(15). Install the valve poppet (14,) on the barbed

end of the push pin. Insert these parts into the cen-

ter hole of the upper housing (23), with the poppet

(14) facing outward.

5. Insert a brass rod into the valve outlet so it contacts

the valve body (16). Tap the rod with a mallet to unseat the valve body. (This can also be done with a

press.) Push the valve body out of the housing (22).

6.

Remove the o-rings (5, 7) from the valve body (16).

Remove the gasket (13) from ih& housing (22).

7.

Using an 1 l/16” socket wrench, loosen but do not

remove the cap (25) from the upper housing (23).

a.

Using a IO mm socket wrench, remove the four

screws (9) .and lo&washers (I). Pull the upper

housing (23) away from the lower housing (22). Re-

move the diaphragm (27).

9.

Unscrew the cap (25) from the upper housing (23).

Remove the gasket (IO) from the cap. Remove the

poppet valve spring (1 I). Push down on the poppet

so the dowel pin (6) protrudes from the hole on the

inside of the housing (23).

10,

Remove the poppet (14), push pin (15), and o-ring

(1) from the upper housing (23). Working on the inside of the housing (23), grasp the dowel pin (6) with

a needle-nose pliers and pull it.out of the housing.

11.

Unscrew the valire housing (19) and pull the RESET

valve assembly out of the upper housing (23).

6.

Install the spring (Ii*) in the upper housing (23) and

seat it on the poppet (14). Install the gasket (IO*) on

the spring retainer cap (25). Apply thread sealant to

the threads of the retainer cap. Screw the cap into

the housing using an 11/16” socket wrench, and

torque to 50-70 in-lb (5.6-7.9 N.m).

7.

Install the gasket (13*) into the lower housing (22),

making sure it seats on the inside shoulder.

a.

Lubricate the two o-rings (5*, 7*). Install the larger

o-ring (5*) in the outside groove of the valve body

(I@, and the smaller o-ring (7*) in the inside groove.

Slide the valve body into the lower housing (22),

with the end holding the o-rings facing intd the

housing. Use a brass rod and mallet (or a press) to

seat the valve body securely in the housing.

9.

Install the two o-rings (6*, 36’) in the grooves of the

piston (16). Slide the piston into the valve body (16),

with the narrow end facing inward. Push the piston

into the valve body as far as it will go.

10. Turn the adjustment screw (21) all the way counterclockwise, then install it and the stem guide (17) in

the lower housing (22). Use a 1” crow’s-foot to

torque the guide to 20-30 R-lb (27-41 N.m). so its

shoulder is flush with the surface of the housing.

NOTE: The RESET valve assembly is press-fit together.

Do not disassemble it unless the needle (20) or

valve housing (19) require replacement.

6 308-201

11. Screw the adapter (34) into the valve outlet. Reinstall the runaway valve inthe air line. Adjust and test

the valve as described on page 4.

Page 7

Model 224-040, Series A

PTFE

Includes items l-36

DESCRIPTION QN

PARTS DRAWING AND LIST

: : Ei::

3 103-962

4 104-007*

104-010*

105-399*

z

7 105~400*

: 105-402 111.667

LOCKWASHER. spring; l/4”

PIN. spring, straight

SCRMI, machine, pan hd;

1032 unf-2a; 0.312” (7.9 mm) long

O-RING; bun&N

O-RING; buna-N

O-RING; nitrile

O-RING; buna-N

PIN, dowel

SCREW. cao. hex hd: M6 x 1:

20 mm lbnrj'

10 150451’

:: 156-916’ 156-920

:: 166-601’

169-216*

15 176-671

;; 166-706 166-707

:: 1 ;g::;:

:: 166-711 166710

$Z 166-714 166-713

24 167-545

;: 167-549

224-945*

:: 166-l 157626 02

34 160-327

36 111-027’

l included in Repair Kit 224-937.

GASKET: copper

SPRING, compression

PUSHBUTTON

GASKET;

POPPET valve

PIN, push

BODY, valve

;,UIDIDkstem

HOUSING. valve

NEEDLE, valve

SCREW, adjustment

HOUSING, valve, lower

HOUSING, valve, upper

NUT, {am, hex; Q/4-32 un-2b

;;“f;prina;tatner

NEEDLE, valve

O-RING

ADAPTER, swivel;

3/4 npt(m) x 3/4 npsm(fJ

O-RING; buneN

SEALANT AND

TORQUETO

5070 In-lb

j”

17

TORQUE TO

20-30 n-lb

(27-41 N.m)

\

24

/ m -AIR OUTLET

AIR INLET

308-201 7

Page 8

DIMENSIONAL DRAWING

Maximum air input pressure ............. 120 psi (8.4 bar)

Air pressure range ................ 20-120 psi (1.4-8.4 bar)

I

\

t-

rrrr

11111

Airvolume range ............ .5-250 cfm (0.14-7.0 m3/min)

Air inlet ..................................... 314 notffl

Air outlet . . Without swivel attached: 3i4 npt(c

Weight . Wilfioutswivelaffached: 2 lb 5 oz (1.05 kg);

TECHNICAL DATA

With swivel attached: 3/4 npsm(f)

With swivel affached: 3 lb (1.36 kg)

I

314 NM(F) INLET

THE GRACO WARRANTY AND DISCLAIMERS

WARRANN

Gracowarrantsallequipmentmanufaoturedb

of sale by an authorized Grace distributor tot K ”

Gracowill,foraperiodoftwelvemonthsfromthedateofsale,repairorreplaceanypartoftheequipmentprovendefective.Thiswarranty

applies only when the equipment is installed, operated and maintained in accordance with Grace’s written recommendations.

itand bearingitsnametobefreefromdefectsinmaterialandworkmanshiponthedate

e ongmal purchaser for use. As purchaser’s sole remedy for breach of this warranty,

Thiswarrantydoesnotcover,andGracoshallnotbeliablefor,anymalfunction,damageorwearcaused byfaultyinstallation,misapplication,abrasion,corrosion,inadequateorimpropermaintenance,negligence,acciden!.tampering,orsubstitutionofnon-Gracocomponent parts. NorshallGraco beliableformalfunction,damageorwearcaused bythetncompatibrlitywithGracoequipment ofstructures,accessories,equipmentormaterialsnotsuppliedbyGraco,ortheimproperdesign,manufacture,installation,operationormaintenance of structures, accessories, equipment or materials not supplied by Graoo.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defectiveto an authorized Grace distributor for

verificationoftheclaim.Iftheclaimeddefectisver%ed,Gracowillrepairorreplacefreeofchar eanydefectivepatis.Theequipmentwiil

be returned tothe original purohasertransportatlon prepaid. If inspection ofthe equipment 3 08s not disclose any defect in material or

workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor and transportation.

DISCLAIMERS AND LIMITATIONS

THETERMSOFTnlSWARRANMCONS~PURGHASER’SSOLEANDWCLUSNEREMEDYANDAREINUEUOFANYOTHERWARRANTlES

(EXPRESS OR IMPUED). INCLUDING WARRANTYOF MERCHANTABILRYOR WARRANTYOF FITNESS FOR A PARTICULAR PURPOSE, AND OF

ANY NON-CONTRACTUAL LiABILtTIES, INCLUDING PRODUCT LIABILITIES, BASED ON NEGUGENCE OR STRICT UABIUTY. EVERY FORM OF

LIABILITY FOR DIRECT. SPECIAL OR CONSEQUENTtAL DAMAGES OR LOSS IS EXPRESSLY EXCLUDED AND DENIED. IN NO CASE SHALL

GRACO’SLlABlUNEXCEEOTHEAMOUNTOFTHEPURCHASEPRICE.ANYACTlONFORBREACHOFWARRANNMUSTBEBROUGHTWlTHlN

MI0 (2) YEARS OFTHE DATE OF SALE.

EQUIPMENT NOT COVERED BY GRACO WARRANN

GFiACO MAKES NO WARRANTY AND DISCWMS AU IMPLIED WARRANTIES OF MERCHANTABIUTYAND FITNESS FOR A PARTICULAR PUR-

POSE, WITH RESPECTTOACCESSORIES, ECUIPMENT, MATERIALS, OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These

itemssold. butnotmanufacturedbyGraco(suchaselectricmotor,switches. hose,etc.)aresubjecttothewarranty,ifany,oftheirmanu-

facturer. Graoo will provide purchaser with reasonable assistance in making any claim tor breach of these warranttes.

IMPORTANT PHONE NUMBERS

TO PLACE AN ORDER, contact your Grace distributor, or call

this number to identify the distributor closest to you:

1-800-329-0211 Toll Free

FOR TECHNICAL ASSISTANCE, service repair information or

assistance regarding the application of Grace equipment:

l-900-9439339 Toll Free

Factory Branches: Atlanta, Chicago, Dallas, Detroit, Los Angeles, Mt. Arlington (N.J.)

Subsidiary and Affiliate Companies: Canada: England; Switzerland; France; Germany; Hong Kong; Japan; Korea

GRACO INC. RO. BOX 1441 MINNEAPOLIS, MN 55440-1441

PRINTED IN U.S.A. 30820, es2

Loading...

Loading...