Setup and Operation

Important Safety Instructions

Read all warnings and instructions in this manual

and all related manuals before using this

equipment. Save these instructions.

3A5856A

PROVEN QUALITY. LEADING TECHNOLOGY.

HV-2000C Jet

Controller

Diaphragm-Jet™ Technology EN

For controlling non-contact dispensing of viscous material in industrial

environments. For Professional Use only.

Table of Contents

RELATED MANUALS .................................................................................................... 4

SAFETY GUIDELINES ................................................................................................... 5

1. INTRODUCTION AND SPECIFICATIONS .......................................................... 6

1.1 Advanjet HV-2000/2000C Overview ............................................................ 6

1.2 HV-2000C Controller Specifications ............................................................. 7

1.3 Technical Assistance ................................................................................... 7

1.4 HV-2000C Controller Dimensions ................................................................ 8

1.5 HV-2000C Front and Rear Features ............................................................ 9

2. INSTALLATION AND SETUP ............................................................................ 10

2.1 Physical Placement .................................................................................... 10

2.2 Pneumatic System ..................................................................................... 10

2.3 Electrical Interface ..................................................................................... 11

2.4 Input / Output Connections ........................................................................ 12

3. USING THE HV-2000C CONTROLLER FRONT PANEL .................................. 13

3.1 Jet and Fluid Pressure Regulators ............................................................. 13

3.2 Temperature Controller .............................................................................. 14

3.3 Trigger Button and LED ............................................................................. 15

3.4 LCD Display and Selection Keys ............................................................... 16

3.5 Jet Setting from the Front Panel ................................................................ 16

3.6 Special Front Panel Key Sequences .......................................................... 18

4. RS-232 COMMUNICATION ............................................................................... 19

4.1 RS-232 Connector Pins ............................................................................. 19

4.2 Changing the Default RS-232 Settings ...................................................... 20

5. ADVANJET SOFTWARE ................................................................................... 21

5.1 Installing and Starting Up the Software ...................................................... 21

5.2 Settings Menu ............................................................................................ 22

5.3 Running a Program from Software ............................................................. 25

6. TIMING RECIPES .............................................................................................. 26

6.1 Timing Recipe Parameters ......................................................................... 26

6.2 Programming Timing Recipes .................................................................... 27

6.3 DROP Mode Programming ........................................................................ 29

Dispensing one drop at a time............................................................... 29

Dispensing multiple drop sizes .............................................................. 29

6.4 LINE Mode Programming ........................................................................... 30

Method 1: Jetting a line in PULSE mode ............................................... 30

Method 2: Jetting a line in LEVEL Mode ............................................... 30

Method 3: Jetting a line during an X-Y move......................................... 31

7. ADVANJET CONTROLLER COMMANDS (ACC) ............................................. 32

7.1 The RS-232 Interface ................................................................................. 32

7.2 Command Format ...................................................................................... 32

7.3 Recipe Timing Commands ......................................................................... 33

7.4 Jetting Commands ..................................................................................... 35

7.5 Heater Commands ..................................................................................... 37

Page 2 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

Table of Contents

7.6 Output Commands ..................................................................................... 38

APPENDIX 1: FIRST DROP COMPENSATION........................................................ 39

Appendix 1-1: Background.............................................................................. 39

Appendix 1-2: Calculating First Drop Compensation ...................................... 39

Appendix 1-3: First Drop Compensation in PULSE Mode .............................. 40

Appendix 1-4: First Drop Compensation in LEVEL Mode ............................... 42

APPENDIX 2: TEMPERATURE CONTROLLER FACTORY SETTINGS ................. 43

APPENDIX 3: DIGITAL PRESSURE GAUGE .......................................................... 45

Appendix 3-1: Specifications ........................................................................... 45

Appendix 3-2: Part Names and Functions ...................................................... 46

Appendix 3-3: Connections and Input/Output Circuit ...................................... 47

Appendix 3-4: Operation Mode Selection ....................................................... 48

Appendix 3-5: Operation Mode Selection ....................................................... 49

Appendix 3-6: Adjustment ............................................................................... 50

Appendix 3-7: Other Functions and Error Indications ..................................... 51

APPENDIX 4: INPUT/OUTPUT CONNECTOR ......................................................... 52

Appendix 4-1: HD26 Pin Assignments ............................................................ 52

Appendix 4-2: Schematic for Configurable I/O DIO0-DIO31 ........................... 55

Appendix 4-3: Schematic for Buffered A/D Converter Inputs .......................... 56

Appendix 4-4: Schematic for D/A Converter Outputs ...................................... 57

Appendix 4-5: Schematic for Pressure Alarm Input/Output Circuit ................. 58

APPENDIX 5: REPLACING THE 24V DRIVER BOARD FUSE ................................ 59

GRACO STANDARD WARRANTY .............................................................................. 60

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 3 of 60

3A5855

HV-2000 Jet Setup and Operation

3A5908

Advanjet Jet Maintenance Tool Kit (JKT-2000)

3A5909

HV-2000 Maintenance and Repair

Related Manuals

Manuals are available at www.graco.com. Component manuals below are in English:

Page 4 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect only to grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

• There are no user-serviceable components under the cover. Disconnect the power cord

and contact Advanjet if there is any desire to remove the cover.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are

using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment

includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

Safety Guidelines

Hazards may arise if handled improperly by unqualified personnel. It is recommended

that operating personnel thoroughly review these operating instructions.

The following warnings are for the setup, use, grounding, maintenance, and repair of

this equipment. The exclamation point symbol alerts you to a general warning and the

hazard symbols refer to procedure-specific risks. When these symbols appear in the

body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the

body of this manual where applicable.

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 5 of 60

1. Introduction and Specifications

1.1 Advanjet HV-2000/2000C Overview

Advanjet HV-2000 non-contact jetting technology is a major leap in liquid dispensing.

The non-contact jetting is fast, allowing dispensing rates up to 300Hz. The user can

modify the drop size ± 20% from its nominal size, allowing a wide range of adjustability.

The simplicity of HV-2000 is also evident in its ease of cleaning, since all parts that

touch the fluid are easily removed.

The Advanjet HV-2000C controller provides timing signals as well as pneumatic and

electrical resources for the Advanjet HV-2000 Jet Valve.

The HV-2000C provides timing signals to drive a rapid-response solenoid valve

in the HV-2000 Jet Valve. Its internal computer remembers and executes a

variety of operational sequences. The controller can respond to actuation signals

from either a front panel switch or from an external switch.

The HV-2000C provides regulated, pressurized air for the fluid pressure and jet

pressure of the HV-2000 Jet Valve.

The HV-2000C provides electrical power to a heater element in the HV-2000 Jet

Valve, and controls the temperature of the valve’s heater by monitoring a

resistance temperature detector (RTD) sensor in the HV-2000 Jet Valve.

Page 6 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

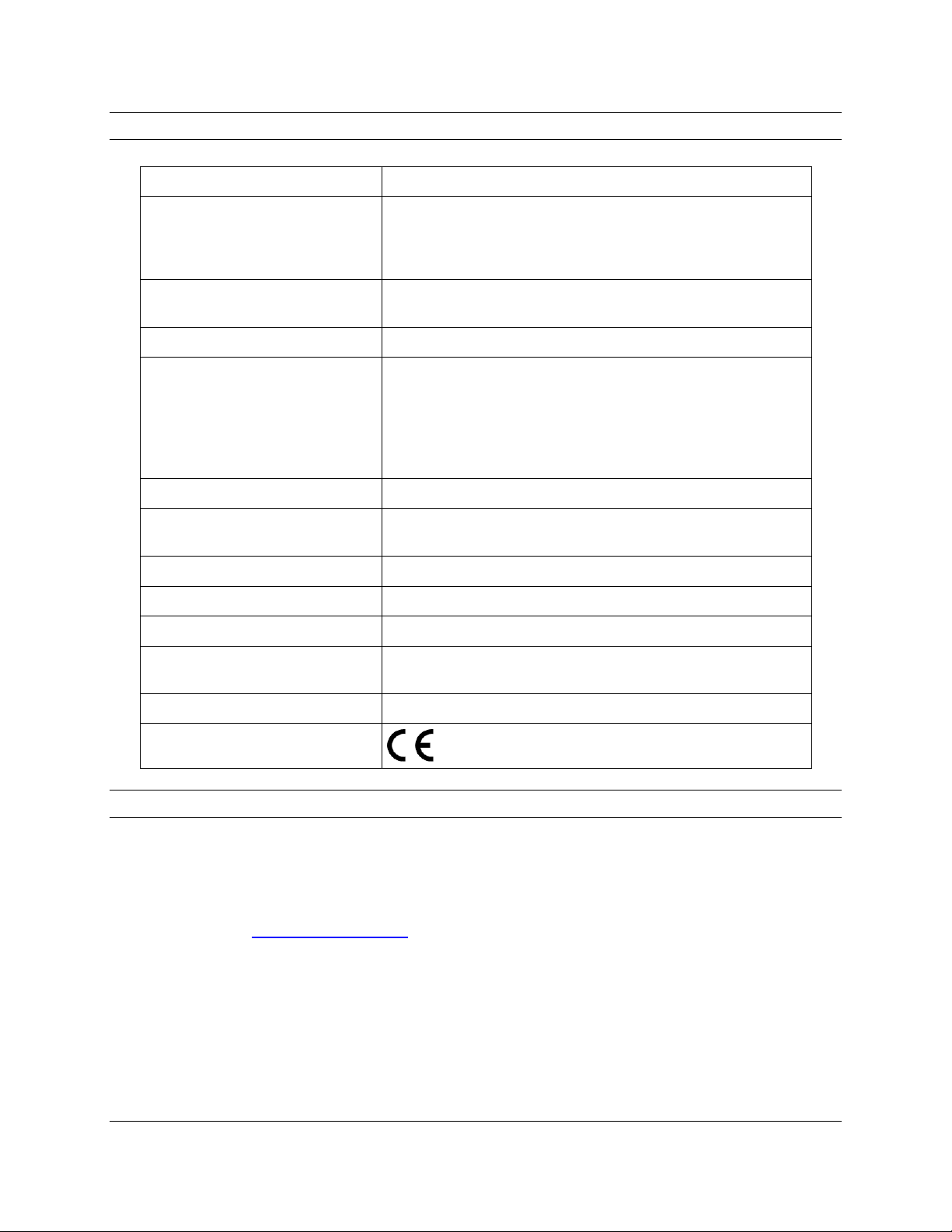

PARAMETER

SPECIFICATION

Size

Width: 254.0 mm (10.00 in)

Height: 152.5 mm (6.00 in)

Depth: 341.4 mm (13.44 in)

Weight: 3200 g (7.05 lbs)

Drop Parameters

Refill time and Dwell (0.1 msec resolution)

Number of drops (programmable from 1 to 1M)

Recipes

6 independent recipes, manual or remote triggers

Nozzle Heater

Heating to 70 C Max

± 1.0 C @ 50 C

PID control using platinum RTD, Auto tuning

24 VDC, 5.7 W, 100 Ω

Programmable shutoff timer

2 alarms for process control

First Drop Compensation

2 levels with programmable time interval

Interface

RS-232 Serial Port

LCD Display with Keypad

Input/Output

TTL level triggers

Operating Temperature

15 °C to 50 °C (59 °F to 122 °F)

Input Pressure

0.6 MPa (90 psi) - maximum

Input Power

100 – 240 VAC, 50/60 Hz, 115 W

Fuse: 5x20 mm, Fast-acting, 1.6 amp, 250 VAC

Advanjet Software

Windows XP, Vista, Windows 7 and Windows 8

Approvals

1.2 HV-2000C Controller Specifications

1.3 Technical Assistance

For technical assistance:

Phone: +1 760-294-3392

Web: www.advanjet.com

E-mail: info@advanjet.com

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 7 of 60

Note: Units are in millimeters [inches]

1.4 HV-2000C Controller Dimensions

Page 8 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

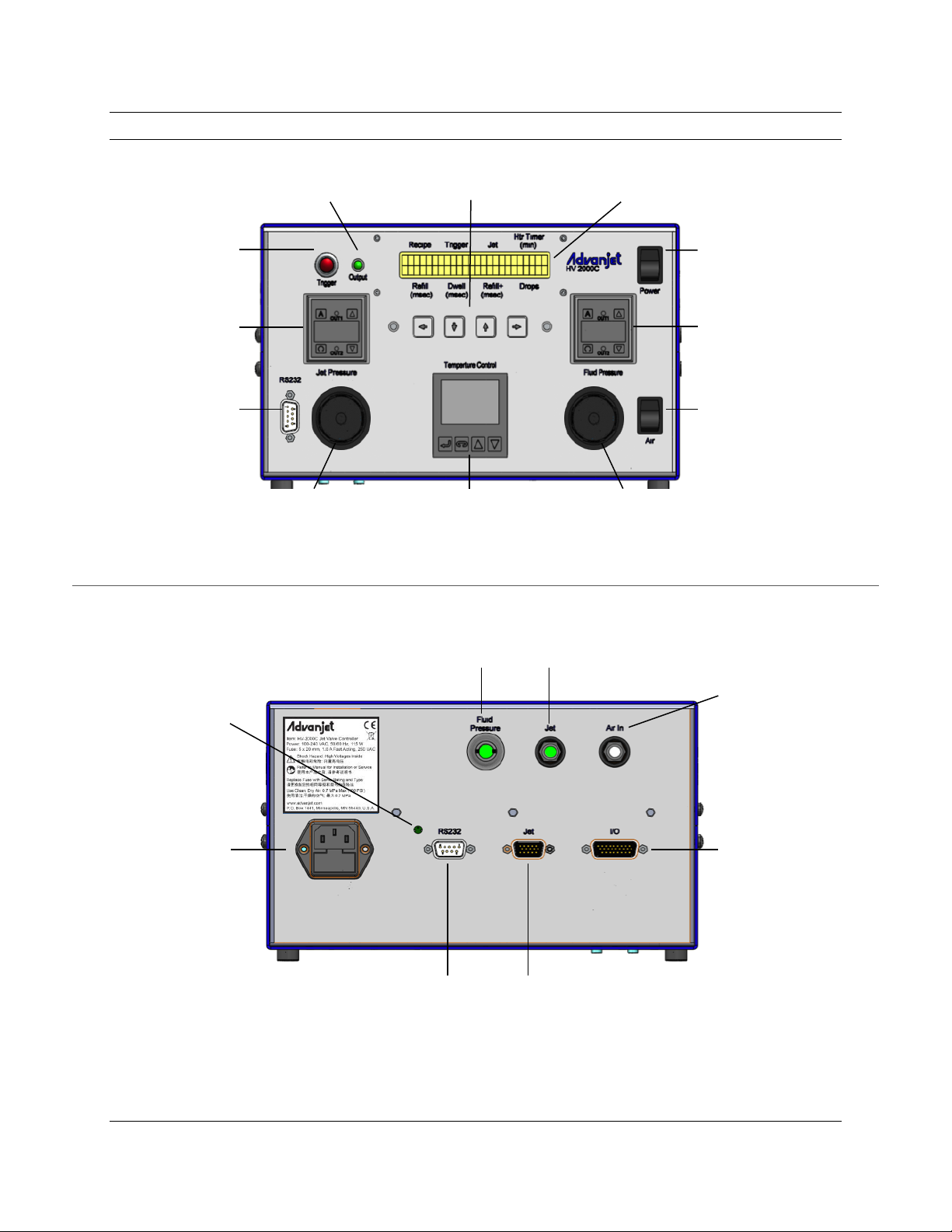

AC CONNECTOR

CORD.

LCD CONTRAST

SCREWDRIVER

JET PRESSURE OUTLET

CONNECT WITH A 6-MM Ø HOSE

FLUID PRESSURE OUTLET

PROVIDES FLUID DELIVERY AIR PRESSURE;

CONNECT TO THE FLUID SYRINGE WITH A 4-MM Ø HOSE

JET CONNECTOR

SYSTEM TO CONNECT WITH THE HV-2000 JET

RS-232 INTERFACE

CONNECTS THE HV-2000C TO A

PC RUNNING THE ADVANJET SOFTWARE WITH A

CONVERTER CABLE WITH CORRESPONDING DRIVER

AIR INLET

6-MM Ø HOSE

I/O CONNECTOR

CABLE

JET

ACTUATION PRESSURE

TRIGGER BUTTON

(ONCE)

RS-232 PORT

TO A PC VIA SERIAL

DB9-TO-USB CABLE

KEYPAD

CHANGES PARAMETER VALUES

LCD DISPLAY

PARAMETERS

TRIGGER LED

DISPENSING

TEMPERATURE

NOZZLE TEMPERATURE

JET PRESSURE

ACTUATION PRESSURE

FLUID PRESSURE

DELIVERY PRESSURE

POWER SWITCH

AIR SWITCH

DELIVERY PRESSURE

FLUID

DELIVERY PRESSURE

Figure 1-1: HV-2000C Front Panel

Figure 1-2: HV-2000C Rear Panel

1.5 HV-2000C Front and Rear Features

EXECUTES THE

DISPENSING RECIPE

ON LCD DISPLAY

PRESSURE GAUGE

DISPLAYS JET

CONNECTS HV-2000C

ILLUMINATES WHEN

CONTROLLER

REGULATES JET

MOVES LCD DISPLAY CURSOR,

CONTROLLER

REGULATES DISPENSING

SHOWS PROGRAM

TURNS THE

HV-2000C

MAIN POWER

ON/OFF

PRESSURE GAUGE

DISPLAYS FLUID

PROVIDES

QUICK ON/OFF

CONTROL OF FLUID

CONTROLLER

REGULATES FLUID

ADJUSTS THE

CONTRAST LEVEL

ON THE LCD

DISPLAY; ROTATE

THE SWITCH WITH

A SMALL

WITH FUSE

100 TO 240 VAC.

REQUIRED FUSE:

5X20 MM, FAST-

ACTING, 1 AMP,

250 VAC. OPERATE

IN OTHER

COUNTRIES USING

LOCAL POWER

SERIAL DB9-TO-USB CABLE OR A USB-TO-RS-232C

PROVIDES JET DISPENSER AIR PRESSURE;

CONNECTS TO

THE SOURCE

PRESSURE WITH A

TRIGGERS THE

DISPENSING

RECIPES AND

OUTPUTS, BUSY

FLAG, AND ERROR

SIGNALS FROM

THE HEATER

CONTROLLER AND

PRESSURE

GAUGES; USES A

STANDARD

5-FOOT 26-PIN

SENDS OUTPUT TRIGGER SIGNALS FOR THE DISPENSING

JET AND HEATER SETTINGS

**MUST USE THE ADVANJET CABLE SUPPLIED WITH THE

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 9 of 60

NOTICE

It is imperative that the air supplied to the HV-2000 is clean and dry

and free from debris and water. A 40-micron filter, a water separator,

and an overpressure relief valve set at around 120 psi (0.83 MPa)

are highly recommended. If the air is not clean and dry, serious

damage can occur to the solenoid valves. The air supply pressure

should be between 70 and 100 psi (0.48 and 0.70 MPa).

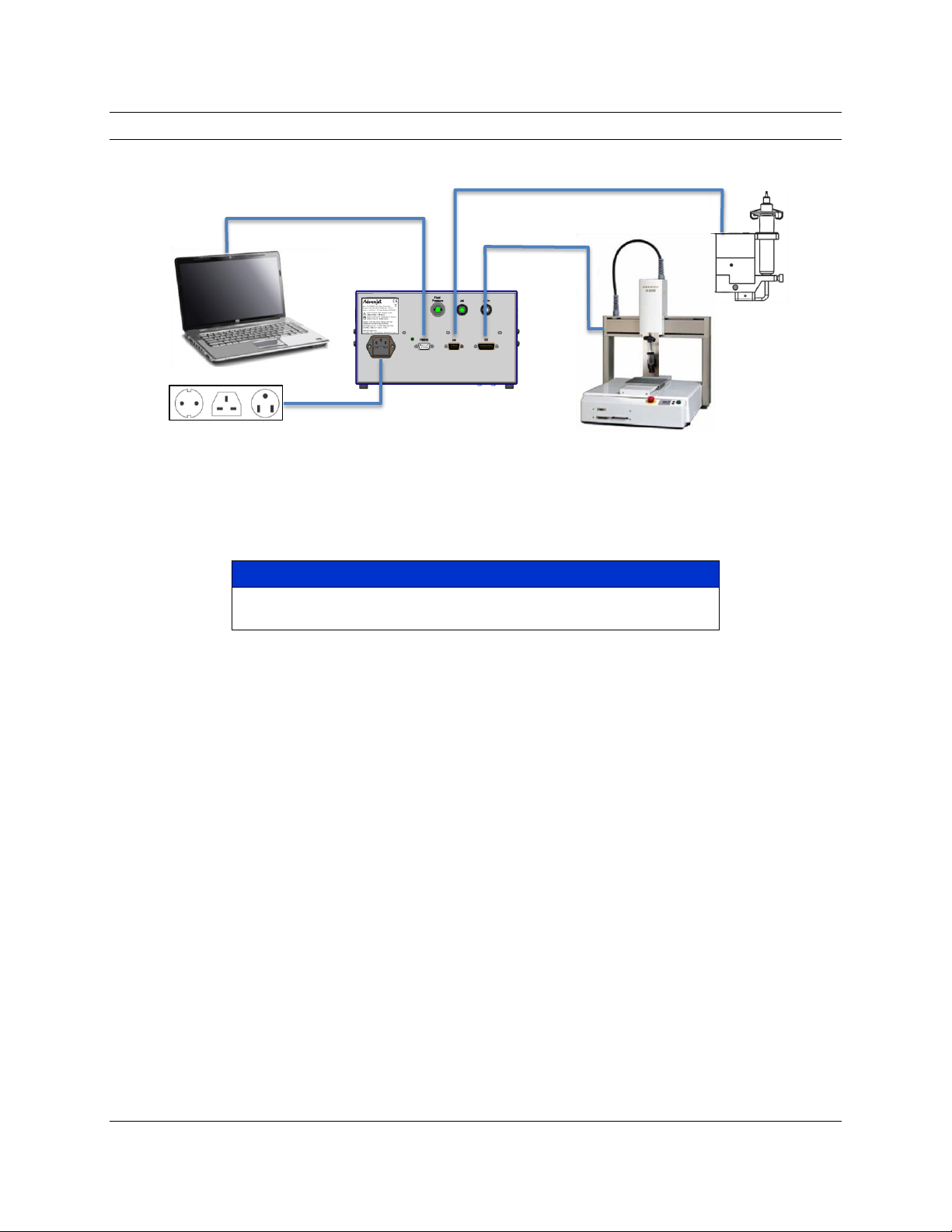

Figure 2-1: HV-2000C Pneumatic Connections

FLUID PRESSURE

4-MM OD TUBE [LOCKING BAYONET]

JET PRESSURE

6-MM OD TUBE [SLIP CONNECT COUPLER]

AIR IN

6-MM OD TUBE

2. Installation and Setup

2.1 Physical Placement

The HV-2000C controller should be placed in a location where the front panel controls

can be viewed and accessed. The ventilation holes on the sides should not be blocked.

2.2 Pneumatic System

Air In: Referring to Figure 2-1, connect an independently regulated and filtered main air

source to the rear of the HV-2000C controller. Use a 40-micron filter (at minimum). The

air must be clean and dry, and at a pressure of 70 to 100 psi (0.48 and 0.70 MPa).

Jet Pressure: The HV-2000 jet is supplied with a 6-mm OD air tube and terminates with

a slip connect coupler. Connect this tube to the JET connector on the rear of the

controller. Normal jet air operation is usually between 40 and 60 psi (0.28 and 0.41

MPa).

Fluid Pressure: Pressure to the dispensing fluid is supplied through a 4-mm OD tube

with a locking bayonet coupler. Connect this tube to the FLUID PRESSURE connector

on the rear of the controller.

Page 10 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

NOTICE

To prevent unintended dispensing, be sure that all power is off when

connecting or disconnecting cables from the Advanjet controller.

JET CABLE

I/O CABLE

RS-232C CABLE

POWER CORD

Figure 2-2: HV-2000C Cable Connections

2.3 Electrical Interface

Four cable connections are on the rear of the Advanjet controller: Power cord, RS-232,

Jet, and Digital I/O, as shown in Figure 2-2. To assure proper connections to the

Advanjet controller, each of the standard cables supplied by Advanjet has a distinct

connector.

Power: The power cord set includes a standard 3-wire cable (hot, neutral, ground) with

an IEC C13 straight International female connector on one end and a country-specific

plug at the other end. Advanjet is prepared to supply cord sets for the USA, for the UK

(part no. 121057), and a standard Euro connector (part no. 121056).

RS-232: The Advanjet software requires an RS-232C communication interface with the

Advanjet controller. If your computer does not have an RS-232C port, use a USB to RS232C converter cable with the drivers that come with the cable. Advanjet can supply an

RS-232C-to-USB cable and corresponding driver.

Jet: The Jet cable is a high-density HD-15 cable and should be attached directly to the

HV-2000 Jet and the controller.

I/O (for HV-2000C): The robot’s controller uses the input/output cable to trigger the

HV-2000 to fire the sequence of drops programmed into the Advanjet controller. The I/O

cable should be connected directly to the host robot’s controls. A male DB-26 connector

is required to interface with the I/O cable. The Advanjet controller has an internal

nonvolatile memory that retains the jet parameters that were downloaded into the

controller. The controller provides 6 TTL trigger lines to control jet operations. See

Section 2.4 for more details.

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 11 of 60

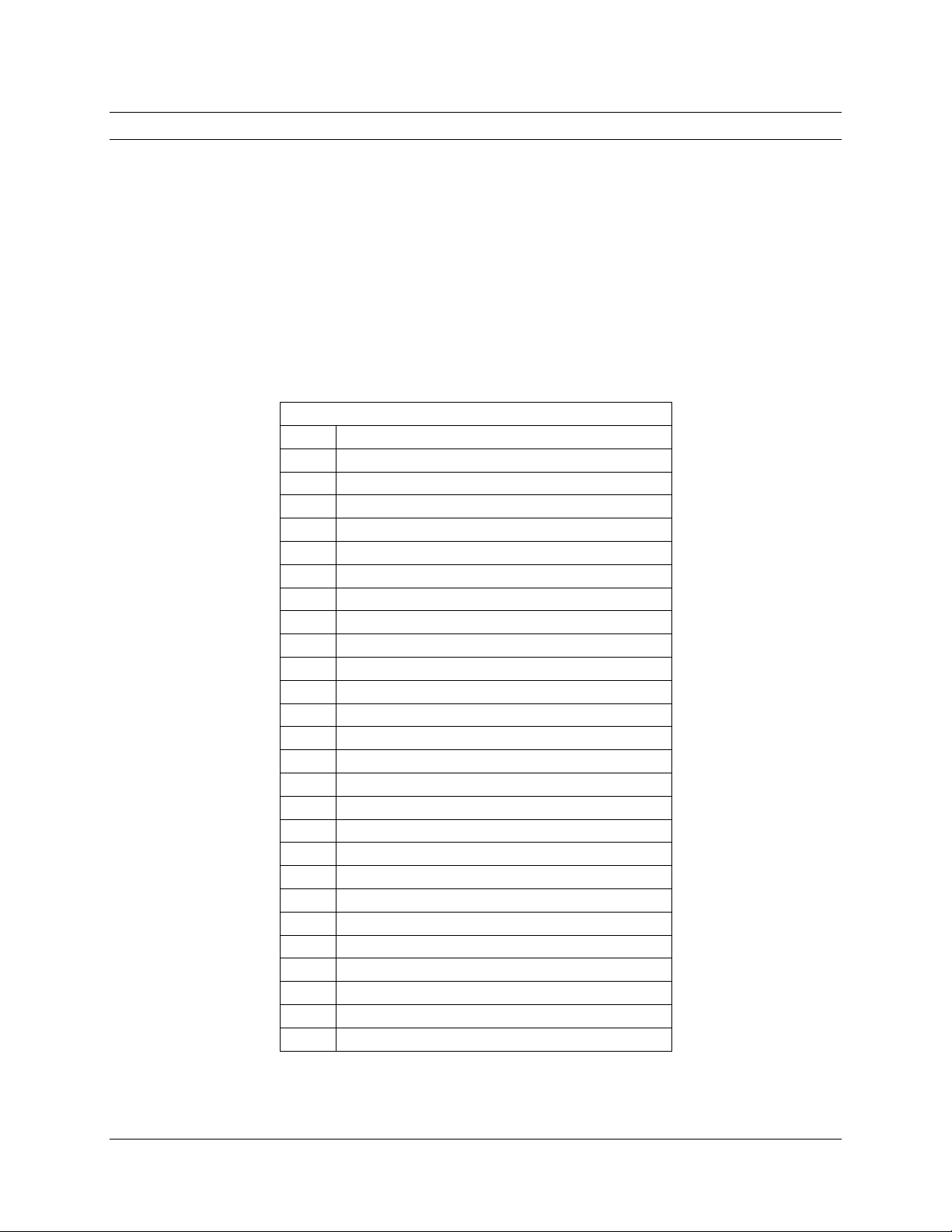

I/O PIN ASSIGNMENTS

HD26

HV-2000C

1

Recipe 1 (Input)

2

Recipe 2 (Input)

3

Recipe 3 (Input)

4

Recipe 4 (Input)

5

Recipe 5 (Input)

6

Recipe 6 (Input)

7

Busy Flag (Output)

8

External Interrupt (Input)

9

GND

10

D/A Converter Output

11

Buffered A/D Converter Inputs

12

Buffered A/D Converter Inputs

13

D/A Converter Output

14

GND

15

No connection

16

No connection

17

No connection

18

Heater Alarm Common (Output)

19

Fluid Pressure Alarm Common 2

20

Fluid Pressure Alarm 2 (Output)

21

Fluid Pressure Alarm 1 (Output)

22

Jet Pressure Alarm Common 1

23

Jet Pressure Alarm 2 (Output)

24

Jet Pressure Alarm 1 (Output)

25

Heater Alarm 1 (Output)

26

Heater Alarm 2 (Output)

2.4 Input / Output Connections

A standard, 5-foot 26-pin Input/Output cable is supplied with the HV-2000C. The table

below describes the I/O connector pin assignments. The I/O is configured for the inputs

to be pulled down to GND. When the specific input is triggered, the Advanjet controller

will activate the corresponding preprogrammed Recipe # shown.

Pins 1 through 6 are outputs from the robot to the Advanjet controller.

They can be TTL outputs capable of sinking 2 mA of current,

or they can also be relay contacts.

Pin 7 outputs a busy status flag from the Advanjet controller to the robot.

Pin 8 is an external interrupt used to remotely stop a dispensing program.

Pins 9 and 14 are Isolated Ground.

Pins 18-26 are alarms from the heater and pressure sensors.

Note: Refer to Appendix 4 for I/O connection details.

Page 12 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

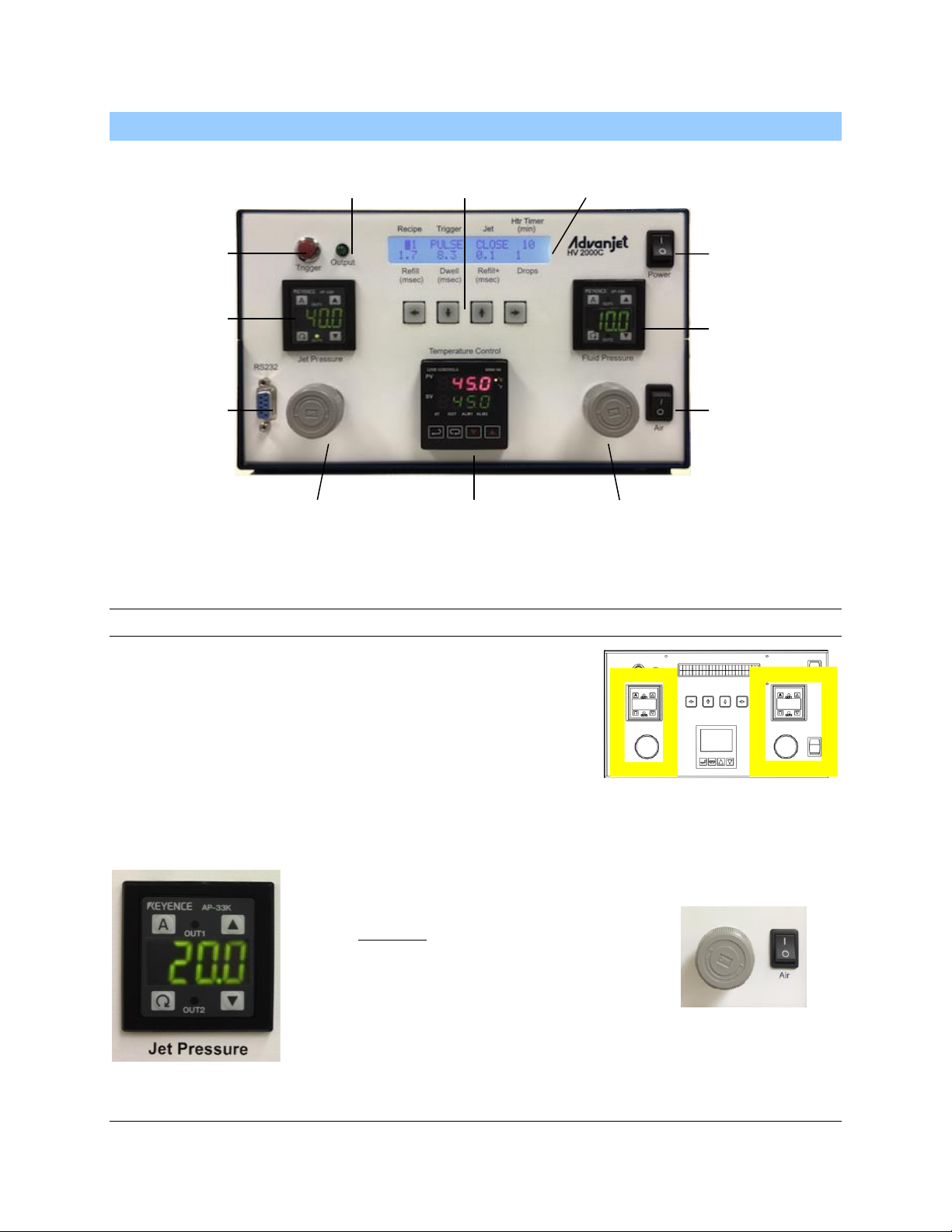

JET

TRIGGER

BUTTON

RS-232

PORT

KEYPAD

LCD DISPLAY

TRIGGER LED

TEMPERATURE

CONTROLLER

JET PRESSURE

CONTROLLER

FLUID PRESSURE

CONTROLLER

POWER

SWITCH

AIR

SWITCH

FLUID

Figure 3-2:

Figure 3-3:

Figure 3-4:

3. Using the HV-2000C Controller Front Panel

PRESSURE

GAUGE

Figure 3-1: HV-2000C Front Panel

3.1 Jet and Fluid Pressure Regulators

The HV-2000C controller has two integrated air

regulators (see Figure 3-2) that control the pressure to

the Jet and the Fluid supply. Turn the knob clockwise to

increase and counterclockwise to decrease. Digital

gauges indicate the pressure levels; the Jet Pressure

gauge is pictured below. The default pressure unit on

the HV-2000C is psi (1 psi = 0.00689 MPa). Details

from the pressure regulator manufacturer are in

Appendix 3: Digital Pressure Gauge.

The Air Switch allows the operator

to instantly turn the Fluid Pressure

ON or OFF. This is very

convenient when changing fluid or

cleaning the jet.

PRESSURE

GAUGE

Pressure Regulators and

Air Swicth

Air Switch

Jet Pressure Gauge

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 13 of 60

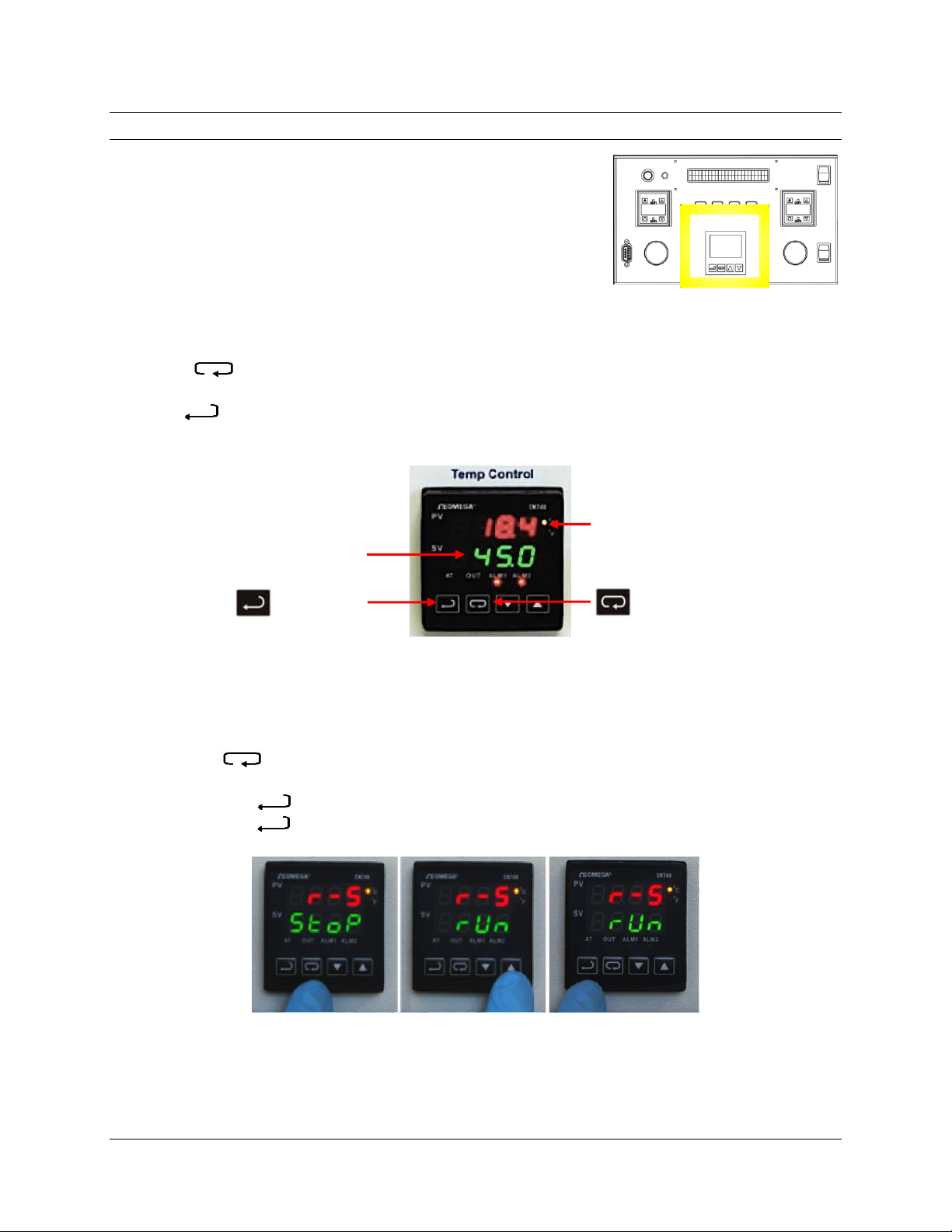

PRESENT TEMPERATURE

SET POINT TEMPERATURE

―ENTER‖ KEY

―INDEX‖ KEY

Figure 3-6: Present Value (PV) , Set Value (SV),

Figure 3-7: Turn ON the Heater

Figure 3-5:

3.2 Temperature Controller

The HV-2000C Temperature Controller regulates the

temperature of the dispensing fluid and displays the

present and set point temperatures.

The main menu displays the present temperature

value (PV) in red on the top line of the display and the

set point temperature value (SV) in green on the

bottom line of the display.

Use the (INDEX) key to cycle through the menu options on the PV line,

the keys to scroll though settings or increase or decrease temperature values,

and the (ENTER) key to save an input and exit the menu.

Temperature Controller

ENTER Key and INDEX Key

To turn ON the heater:

Press until the Run-Stop Output Control screen (r-S) is on the PV line.

Use the keys to select the rUn setting to turn ON the heater.

Press the key to save the change. Now the heater is turned ON.

Press the key again to return to the main screen display.

Page 14 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

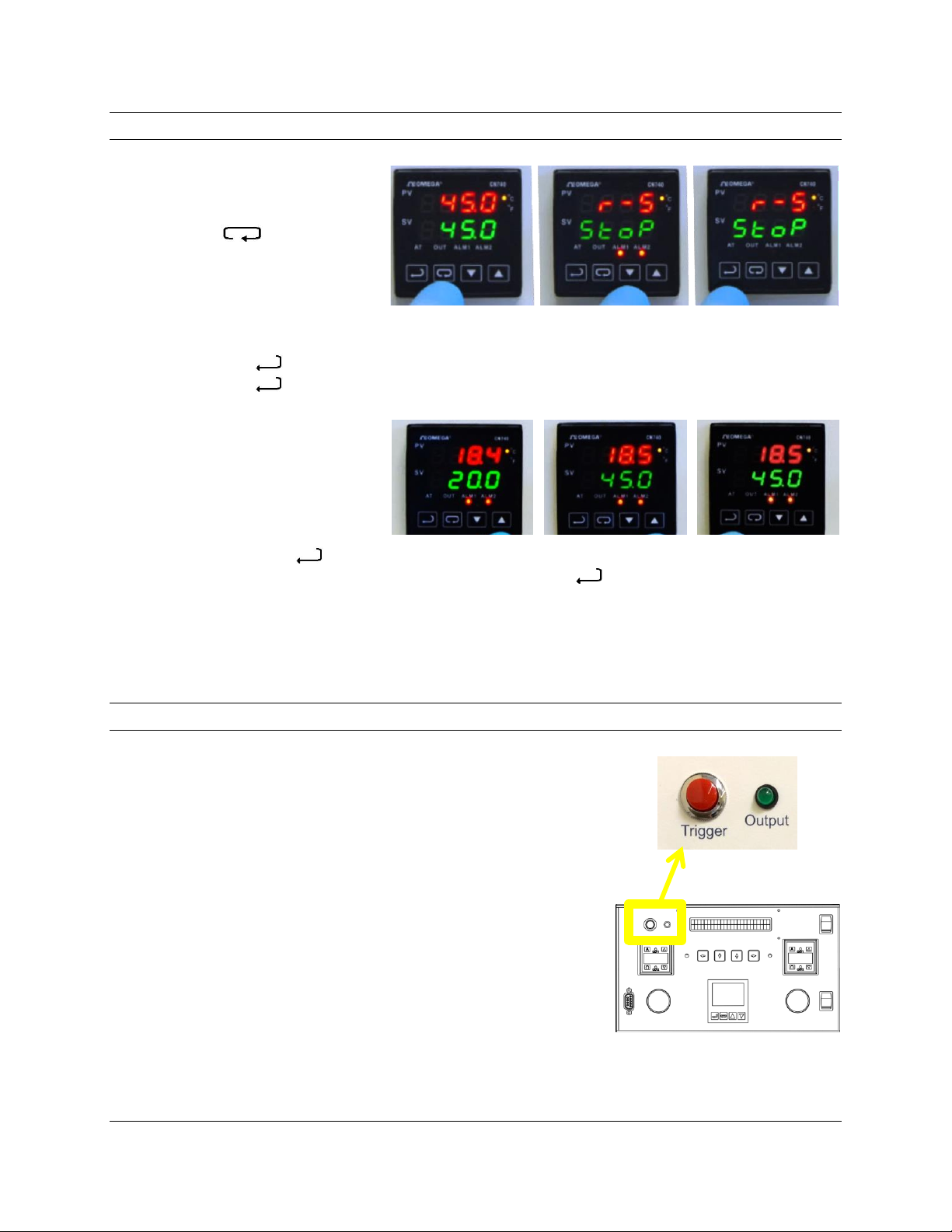

To turn OFF the heater:

Press until the

Run-Stop screen is

displayed (r-S).

Use the keys to

select the Stop setting

to turn OFF the heater.

Press the key to save the change. Now the heater is turned OFF.

Press the key again to return to the main screen display

To change the Set Value (SV)

temperature, use the keys

to increase/decrease the value.

For example, to change SV

from 20 to 45 degrees, use the

key to increase the SV value

to 45, and then press to

save the change.

Figure 3-8: Turn OFF the Heater

Figure 3-10:

Trigger Button and Output LED

3.2 Temperature Controller (Continued)

Figure 3-9: Press to increase the SV value to 45,

then press to save the change

Technical specifications of the heater can be found in Appendix 2: Temperature

Controller Factory Settings.

3.3 Trigger Button and LED

Pressing the Trigger Button immediately executes

the current recipe (recipe # and parameters)

displayed on the LCD screen. If multiple drops were

specified in the recipe, multiple drops will be

dispensed.

The Trigger Output LED is on when the Jet is firing

to verify a signal was sent to the Jet. The light is off

when the Jet is in idle state.

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 15 of 60

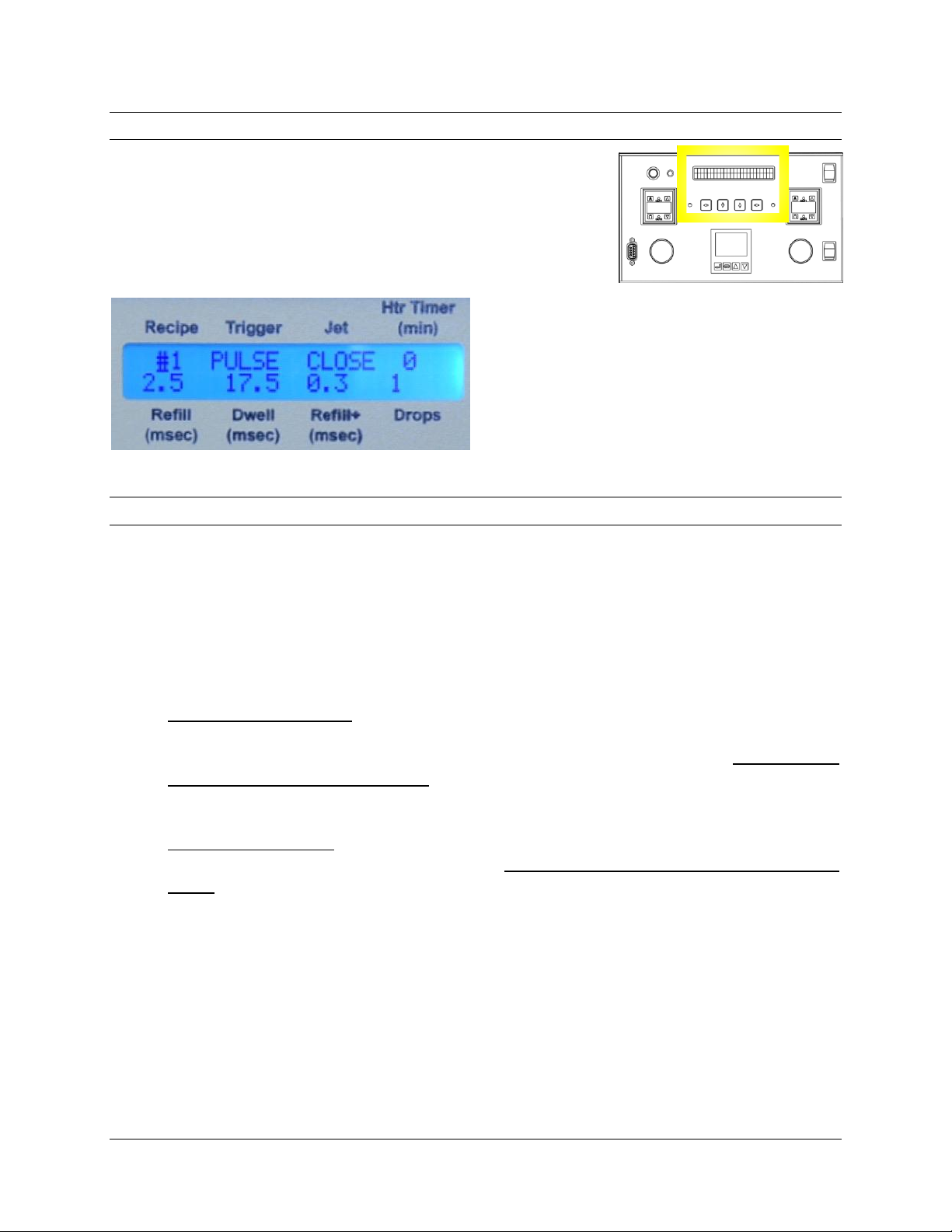

Figure 3-11:

LCD Display and Selection Keys

Figure 3-12: LCD Display with Cursor at Recipe #

3.4 LCD Display and Selection Keys

HV-2000C front panel programming and operation uses

the LCD display and input keypad, highlighted in Figure

3-11 at right. Eight basic settings can be input from the

main LCD menu. The selected setting is indicated by a

blinking cursor.

Figure 3-12 shows the cursor selecting the

Recipe #. Use the LEFT/RIGHT keys to

move the cursor and the UP/DOWN keys

to increment the values.

3.5 Jet Setting from the Front Panel

The eight jetting parameters on the LCD display can be programmed from the input

keypad.

Recipe: Select the recipe number from 1 to 6. Each recipe consists of the Trigger mode,

Refill time, Dwell time, Refill+ time (―first drop‖ adjustment), and the number of drops to

dispense. Up to 6 dispensing recipes can be programmed and saved in the controller.

Trigger: There are two Trigger modes—PULSE or LEVEL.

In the PULSE mode, the number of drops dispensed per trigger signal is

specified in the Drops setting. For example, if a recipe has set Trigger to PULSE

and Drops to 5, the jet will dispense 5 drops per Trigger signal. Pressing the

Trigger button in PULSE mode sends a Trigger signal and the jet will dispense 5

drops.

In the LEVEL mode, the jet will dispense drops nonstop until the Trigger signal

retreats—the Drops count is ignored. Pressing the Trigger button in LEVEL

mode causes LEVEL mode to be ignored, and the jet will dispense the number of

drops specified in the Drops.

Jet: Use this to CLOSE or OPEN the Jet valve.

Htr Timer (min): The Heater Off timer automatically turns off the heater after the Jet

has been idle for the specified number of minutes. This feature is useful if materials will

be adversely affected by long periods of heating. For example, some materials can be

―cured‖ by high temperature while sitting in the nozzle chamber for a long period of idle

time. If Htr Timer is set to zero, the Heater Off timer is not activated.

Page 16 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

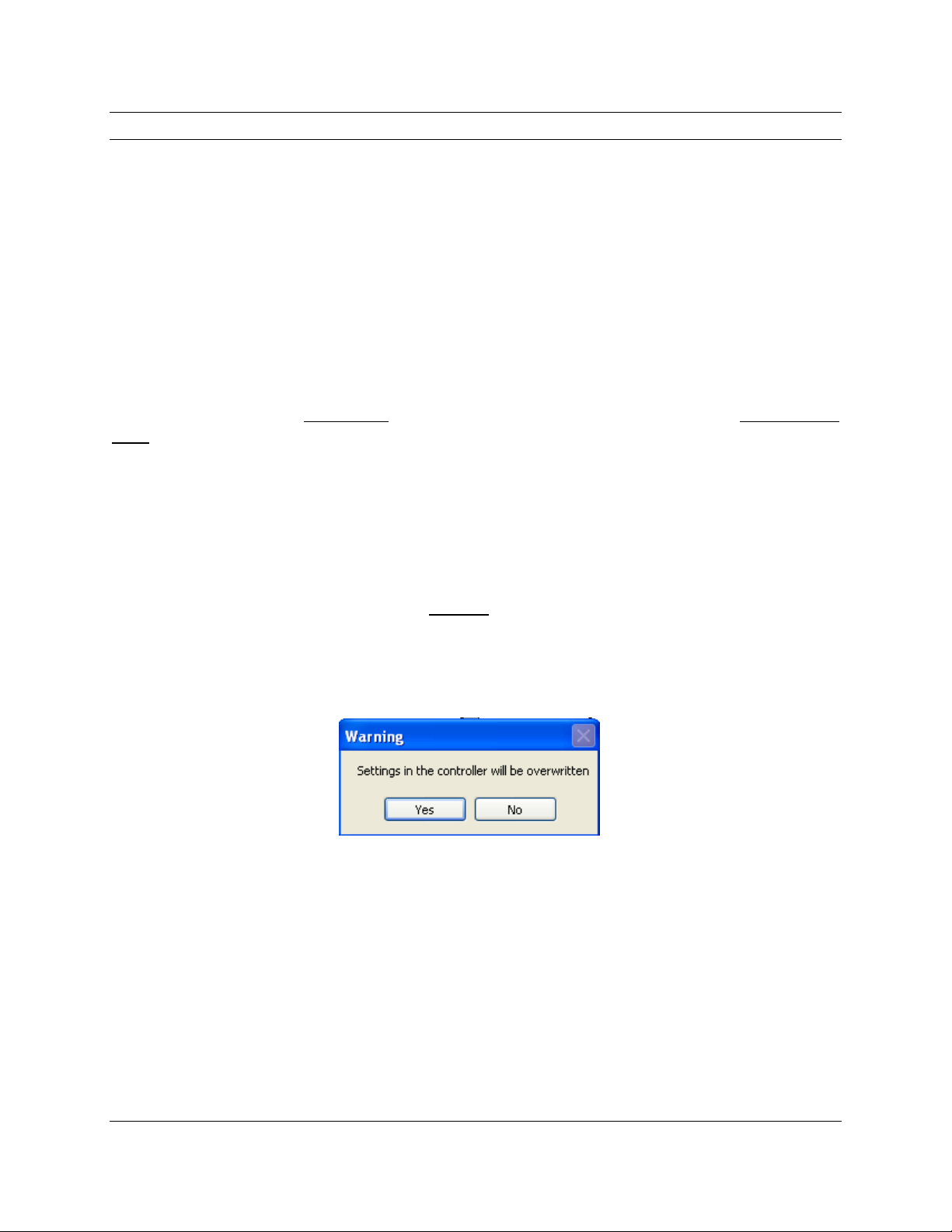

Figure 3-13: Overwrite Warning

3.5 Jet Setting from the Front Panel (Continued)

Refill (msec): Refill time is the time required for the material to flow into the nozzle after

each drop is ejected. Refill is set in msec with 0.1 msec resolution. Section 6.1 - Timing

Recipe Parameters provides a detailed explanation of Refill Time.

Dwell (msec): Dwell time is the time required for the material to flow out of the nozzle

and form a drop. Dwell is set in msec with 0.1 msec resolution. Section 6.1 - Timing

Recipe Parameters provides a detailed explanation of Dwell Time.

Refill+ (msec): Sometimes the jet requires a little extra time for the first drop to be

ejected, depending on the material or if the jet is idle for a period of time. Refill+ time is

added to Refill time to adjust the size and quality of the first drop. In PULSE mode,

Refill+ time applies to each drop; in LEVEL mode, Refill+ time applies to just the first

drop. Detailed explanations can be found in Section 6.2 – Programming Timing Recipes

(Adjust Refill Time for First Drop), and also Appendix 1: First Drop Compensation.

Drops: Specify the number of drops to be dispensed. To dispense a single drop per

trigger signal, enter 1. To dispense 10 drops per trigger signal, enter 10.

Note: If the Advanjet controller software is being used and values are changed using

the front panel display, the changes will not be transferred to the Advanjet controller

software. Also, the front panel values can be overwritten each time you start the

Advanjet software program. The warning below will be displayed. It is recommended to

write down any recipe changes made from the front panel and then enter them into the

software to synchronize.

3A5856A Advanjet HV-2000C Jet Controller Setup and Operation Page 17 of 60

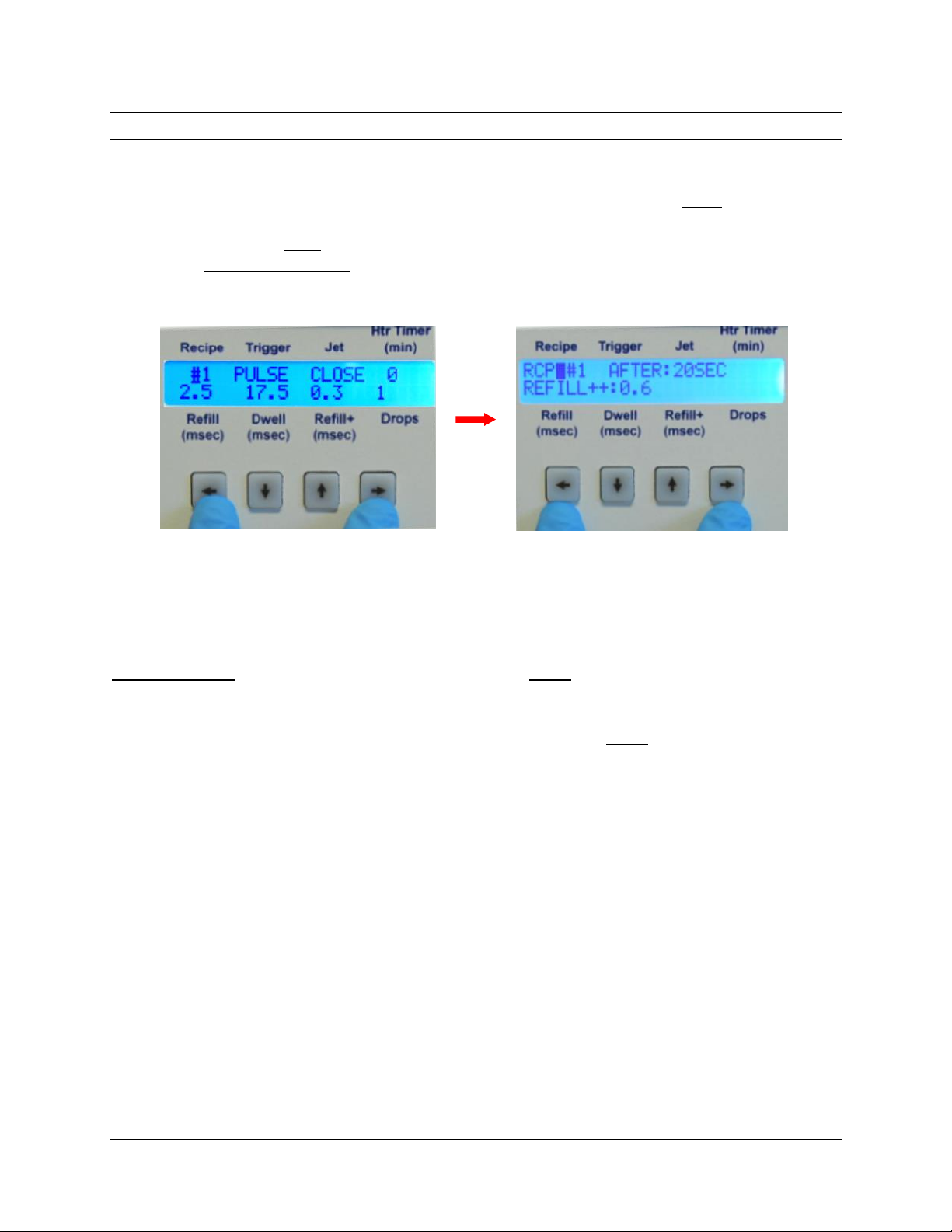

Figure 3-14: Press LEFT + RIGHT to Set the Refill++ Parameter

3.6 Special Front Panel Key Sequences

Pressing a combination of front panel keys accesses additional settings.

Refill++ time: Simultaneously pressing the LEFT and RIGHT keys once brings up the

Refill++ time menu. As another method of first drop compensation, Refill++ time is

added to Refill time after the jet is idled for a defined number of seconds. Refill++ time

applies to just the first drop in both PULSE and LEVEL modes. To access Refill++,

press LEFT + RIGHT once. The screen on the right appears:

For RCP, enter the recipe number. AFTER is the jet idle time in seconds, and

REFILL++ is the extra refill time. For a detailed explanation, see Section

6.2 - Programming Timing Recipes (Adjust Refill Time for First Drop), and also

Appendix 1: First Drop Compensation. After entering the REFILL++ settings,

simultaneously press the LEFT and RIGHT keys twice to accept the new settings and

return to the main menu.

RS-232 Settings: Simultaneously pressing LEFT+RIGHT twice brings up the RS-232

Settings menu. This setting is explained in detail in Section 4.2 - Changing the Default

RS-232 Settings. Press LEFT+RIGHT again to return to the main menu.

Page 18 of 60 Advanjet HV-2000C Jet Controller Setup and Operation 3A5856A

Loading...

Loading...