Page 1

Instructions-Parts

®

Python

XL-DA25

3A6831A

Pump

Pneumatic pump for injecting chemicals at well sites. Not for use with sour gas.

For professional use only.

Not approved for use in European explosive atmosphere locations.

See page 3 for model information, including maximum working pressures.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save all instructions.

EN

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pump Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Configuration Number Matrix . . . . . . . . . . . . . . . . . 4

Pump Configuration . . . . . . . . . . . . . . . . . . . . . . 4

Lower Configuration . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Required Accessories . . . . . . . . . . . . . . . . . . . . . 7

Flush Before Using Equipment . . . . . . . . . . . . . . 7

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Mount the Pump and Connect Chemical Supply 8

Connect Pneumatic Supply . . . . . . . . . . . . . . . . . 9

Route Exhaust to Remote Location . . . . . . . . . . 9

Connect Chemical Outlet . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure Relief Procedure . . . . . . . . . . . . . . . . 11

Flush the Equipment . . . . . . . . . . . . . . . . . . . . . 11

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 12

Calibrate Chemical Dosage . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Preventive Maintenance Schedule . . . . . . . . . . 13

Tighten Threaded Connections . . . . . . . . . . . . . 13

Tighten Packings . . . . . . . . . . . . . . . . . . . . . . . 13

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair - Pump Lower . . . . . . . . . . . . . . . . . . . . . . . 15

Disconnect the Pump Lower . . . . . . . . . . . . . . . 15

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reconnect the Pump Lower . . . . . . . . . . . . . . . 18

Repair - Pneumatic Motor . . . . . . . . . . . . . . . . . . . 19

Pneumatic Valve . . . . . . . . . . . . . . . . . . . . . . . . 19

Replace Pilot Valves . . . . . . . . . . . . . . . . . . . . . 22

Repair Pneumatic Motor . . . . . . . . . . . . . . . . . . 23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Python XL-DA25 Pneumatic Pump . . . . . . . . . . 27

Pump Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pneumatic Motor Parts . . . . . . . . . . . . . . . . . . . 31

Pneumatic Valve Parts . . . . . . . . . . . . . . . . . . . 33

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . 35

Pump Lower Models . . . . . . . . . . . . . . . . . . . . . 35

Additional Kits & Accessories . . . . . . . . . . . . . . 35

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Python XL-DA25 Pump Dimensions . . . . . . . . . 36

Wall Bracket Mounting Hole Diagram . . . . . . . . 37

Pneumatic Mounting Hole Diagrams . . . . . . . . . 38

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 39

6 in. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.5 in. Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Technical Specifications . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

2 3A6831A

Page 3

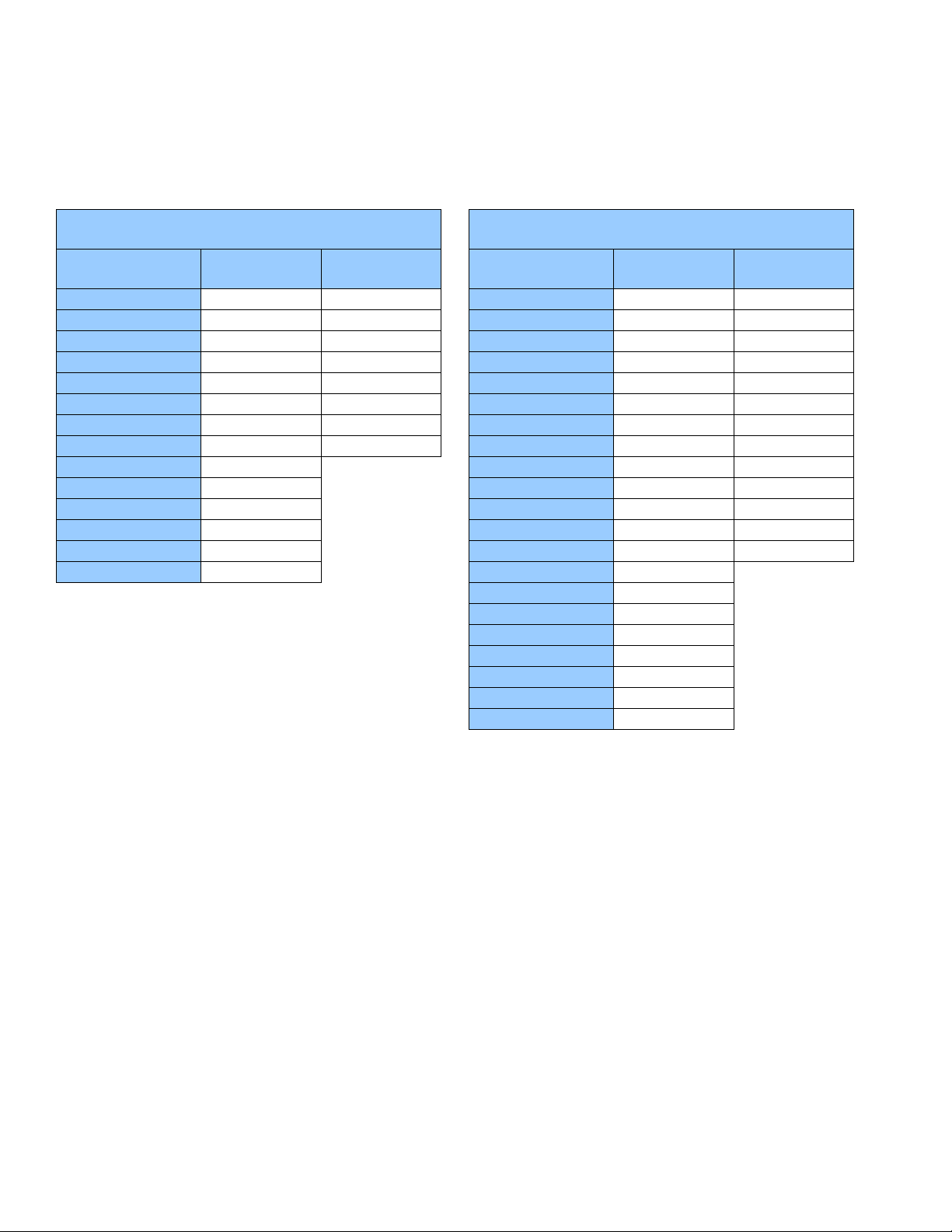

Models

Models

Pneumatic

Plunger Size

3/4 in.

1 in. 3,800 (2.6, 26)

3/4 in.

1 in. 6,100 (42.1, 421)

Motor Size

6.0 in.

7.5 in.

Maximum Working Pressure

psi (MPa, bar)

6,400 (44.1, 441)

10,000 (68.9, 689)

Maximum Pneumatic Inlet Pressure

psi (MPa, bar)

100 (0.69, 6.9)

NOTE: See the Configuration Number Matrix, page 4, to find the plunger and pneumatic motor size for your unit.

Pump Models

Part Number Configuration Code Motor Size Lower Size Lower Coating Seal Material

A22606 PCI-0600-075-113-XC-2-0

A22607 PCI-0600-075-113-XD-2-0 FFKM

A22608 PCI-0600-075-113-XE-2-0 TFE/P

A22612 PCI-0600-100-138-XC-2-0

A22613 PCI-0600-100-138-XD-2-0 FFKM

A22614 PCI-0600-100-138-XE-2-0 TFE/P

A22706 PCI-0750-075-113-XC-2-0

A22707 PCI-0750-075-113-XD-2-0 FFKM

A22708 PCI-0750-075-113-XE-2-0 TFE/P

A22712 PCI-0750-100-138-XC-2-0

A22713 PCI-0750-100-138-XD-2-0 FFKM

A22714 PCI-0750-100-138-XE-2-0 TFE/P

6.0 in.

7.5 in.

3/4 in. Chromex

1 in. Chromex

3/4 in. Chromex

1 in. Chromex

HNBR

HNBR

HNBR

HNBR

3A6831A 3

Page 4

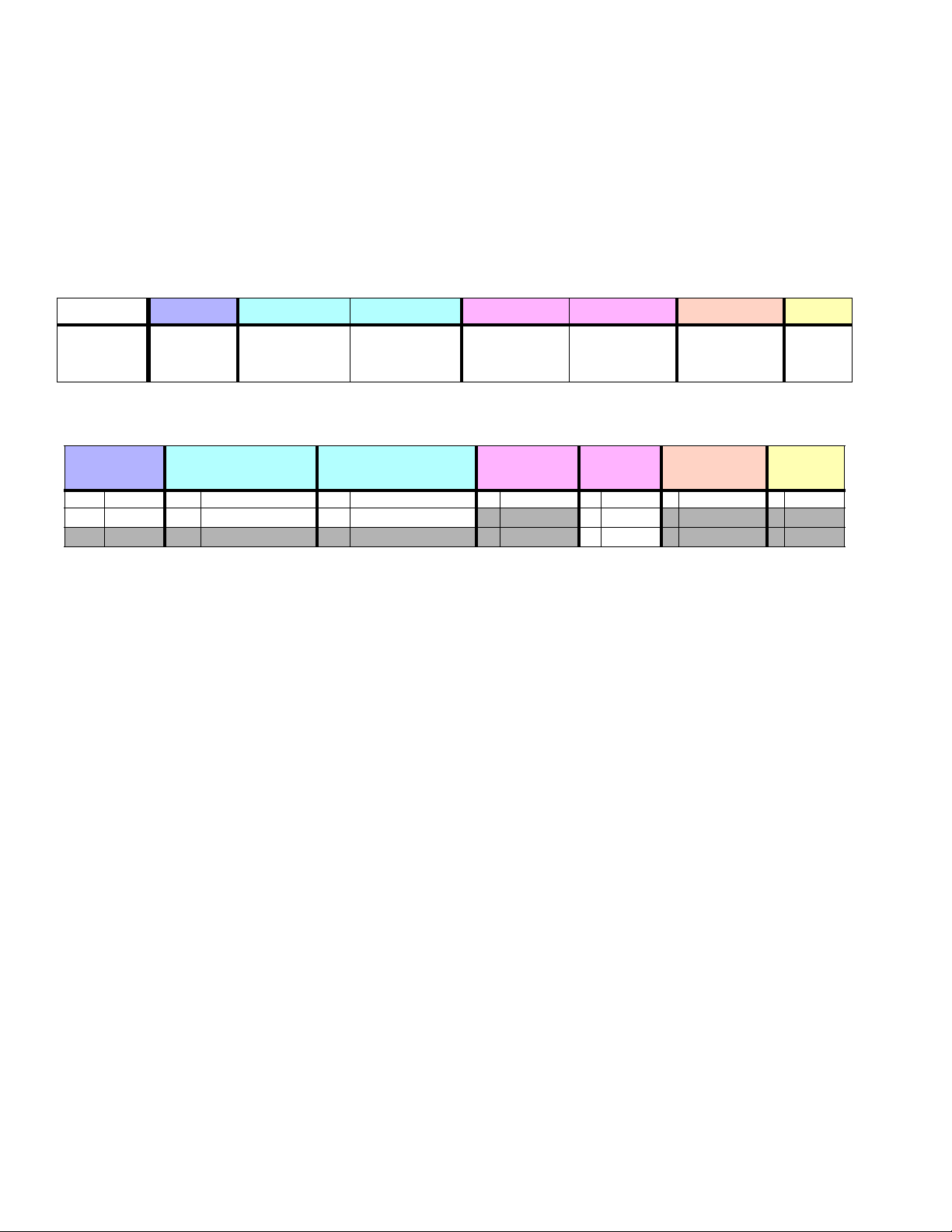

Configuration Number Matrix

Configuration Number Matrix

Check the identification plate (ID) for the 17-digit Configuration Number of your pump. Use the following matrix to

define the components of your pump.

NOTE: Not all combinations are possible.

Sample Configuration Number: PCI-0600-075-113-XC-2-0

PCI 0600 075 113 X C 2 0

Pneumatic

Chemical

Injection

Pump Configuration

Pneumatic

Motor Size

Pump Lower

Primary Seal

Size

Pump Lower

Secondary

Seal Size

Pump Lower

Coating

Seal Material Pump Stroke

Length

Qualifier

Pneumatic

Motor Size

0600 6.0 in. 075 3/4 in. diameter 113 1-1/8 in. diameter X Chromex C HNBR 2 2.5 inch 0 None

0750 7.5 in. 100 1 in. diameter 138 1-3/8 in. diameter DFFKM

Pump Lower

Primary Seal Size

Pump Lower

Secondary Seal Size

Pump Lower

Coating

Seal

Material

ETFE/P

Pump Stroke

Length

Qualifier

4 3A6831A

Page 5

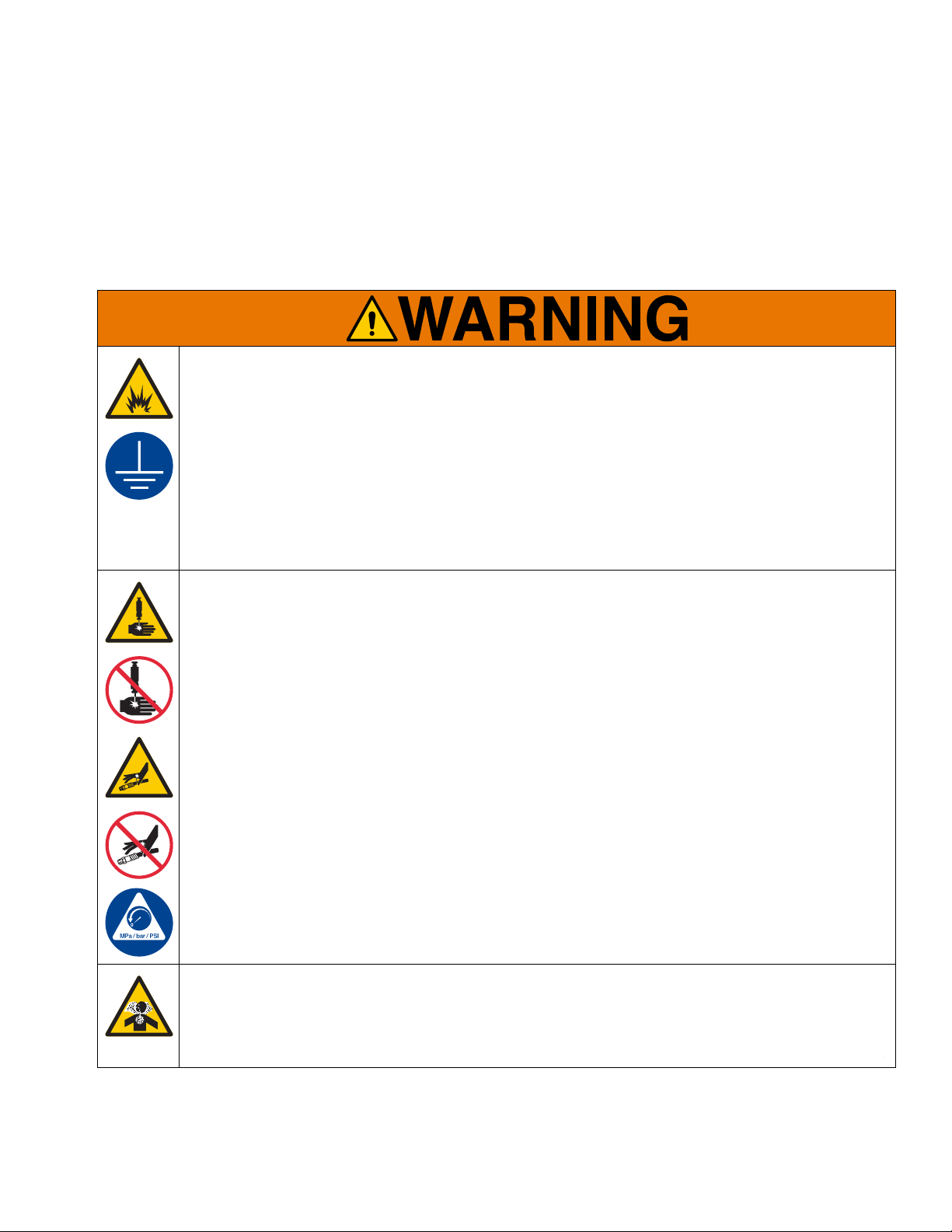

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or o n warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area be aware that flammable fumes can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extingui she r in the wor k ar ea .

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning , checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings da ily. Re pla ce worn or dam ag e d pa rt s immed ia tely.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

3A6831A 5

Page 6

Warnings

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacture r.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment regularly. Repair or replace worn or d amaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety re gu la tion s.

6 3A6831A

Page 7

Installation

If using a flammable gas to drive the motor, to reduce

the risk of fire or explosion, route the exhaust away

from all sources of ignition. See Route Exhaust to

Remote Location on page 9.

NOTE: A small amount of the exhaust is not recover-

able, and will vent to atmosphere at the pump. However, a 100% Exhaust Capture Kit, B32651, is

available.

To reduce the risk of injury from ejected ice, do not

operate the motor without a plumbed exhaust line or

muffler installed.

Installation must comply with all local codes and regulations.

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

Pump: ground through electrically conductive pneumatic and fluid lines.

Installation

Required Accessories

Install the following required accessories in the order

shown in F

Pneumatic Line

• Bleed-type master pneumatic valve (D): required

in your system to relieve air/gas trapped between it

and the pneumatic motor when the valve is closed.

• Be sure the valve is easily accessible from the

• Pump pneumatic regulator (E): to control pump

speed and outlet pressure. Locate it close to the

pump.

• Pneumatic line filter (C): removes harmful dirt and

moisture from compressed air/gas supply.

• Second bleed-type pneumatic valve (pneumatic

shutoff valve) (B): isolates pneumatic line accessories for servicing. Locate upstream from all other

pneumatic line accessories.

Fluid Line

• Fluid filter (Y-Strainer) (included in G): with a 60

mesh (250 micron) stainless steel element to filter

particles from the fluid before in reaches the pump.

IG. 1, using adapters as necessary.

pump and located downstream from the pneumatic regulator.

Pneumatic and fluid lines: use only electrically conductive lines.

Air compressor: follow manufacturer’s recommendations.

Fluid supply container: follow local code.

3A6831A 7

• Fluid shutoff valve (H): shuts off fluid flow.

• Pressure relief valve (J): overload protection.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid contaminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipm en t. See

Flush the Equipment, page 11.

Page 8

Installation

A

C

E

D

R

F

J

K

H

G

L

M

N

H

P

S

B

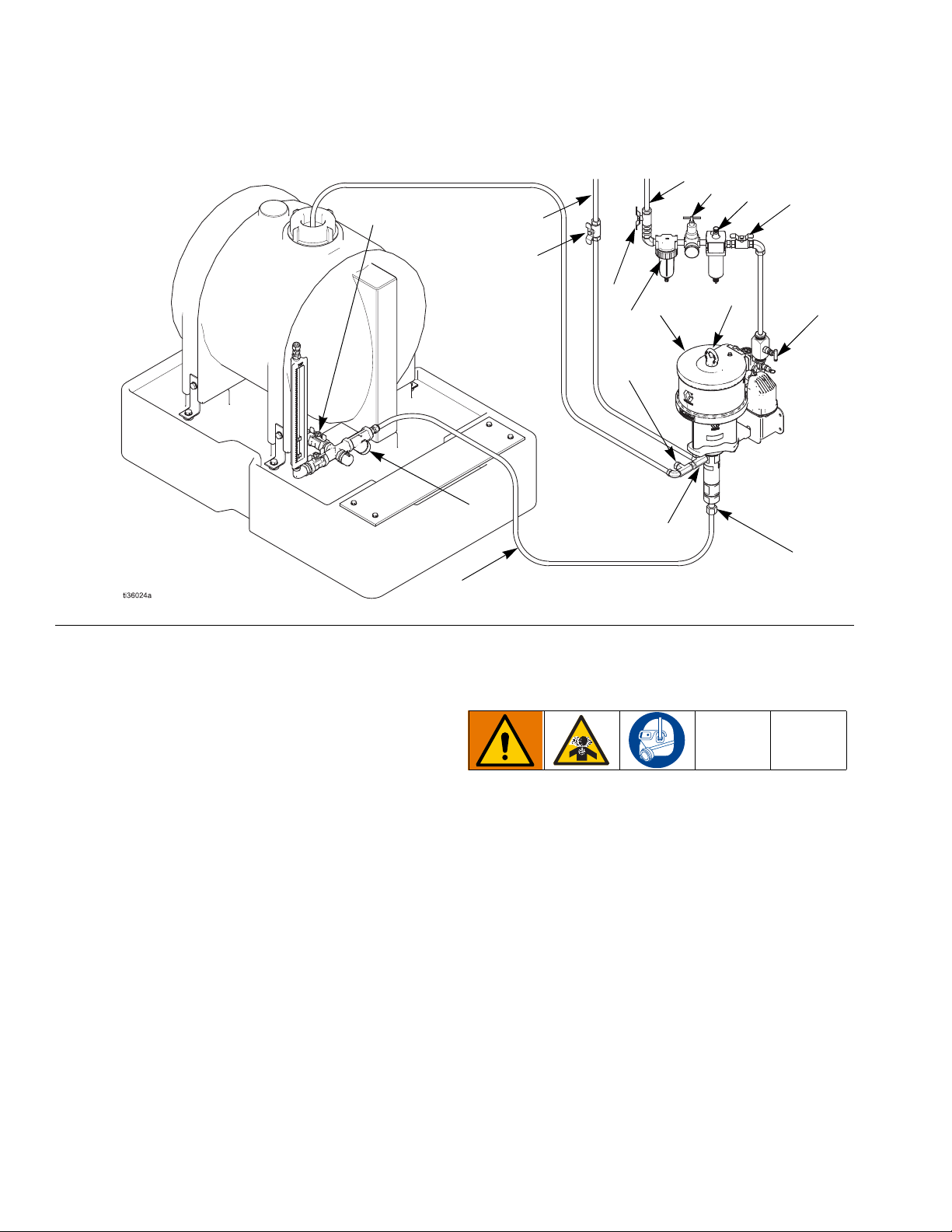

Typical Installation

FIG. 1:

FIG. 1 is an example of an installation with a Python

XL-DA25 chemical injection pump. Your installation may

differ from what is shown here. (See Required Acces-

sories, page 7.) The Python XL-DA25 pump (F) and

pneumatic needle valve (B) are the only components in

IG. 1 supplied by Graco. All other components a re sup-

F

plied by customer.

Key:

A Main Pneumatic Supply Line

B Secondary Pneumatic Bleed-Type Valve

C Pneumatic Filter

D Primary Bleed-type Master Pneumatic Valve

E Pneumatic Pressure Regulator

FPump

G Manifold Assembly (includes y-strainer and fluid shutoff

valve (H))

H Fluid Shutoff Valve (inlet & outlet)

J Fluid Pressure Relief Valve

K Fluid Inlet Line

LInlet Port

MOutlet Port

N Pneumatic Lubricator

P Fluid Outlet Line

R Speed Control Valve

S Lift Ring (for lifting the pump only)

Mount the Pump and Connect

Chemical Supply

The pump can be bolted to a wall or skid by the attached

bracket.

NOTE: The pump must always be mounted vertically.

If you have an application, or mounting configuration,

that requires installation in a manner different than

depicted in F

for assistance.

NOTE: A y-strainer (G) or chemical filter is required

before the pump inlet. This will keep any debris from the

IG. 1, please contact your Graco distributor

tank from reaching the pump seals. Fluid filter s ar e

available from Graco.

1. Mount the pump (F) and connect the fluid inlet

line (K).

8 3A6831A

Page 9

Installation

Connect Pneumatic Supply

1. Install the pneumatic regulator (E) and gauge to

control the inlet pressure. See Models on page 3 for

your model’s maximum pneumatic pressure.

NOTE: If less than 100 psi supply pressure is used, the

pump’s maximum output pressure will be decreased

proportionally.

Minimum Pneumatic Pressure can be found by first finding the table that corresponds to the plunger size (see

Minimum Pneumatic Pressures by Fluid Plunger

Size and Outlet Pressures on page 10). Next, using

the column that corresponds to the pneumatic motor

size, find the row equal to or slightly greater than the

outlet pressure of the pump. The value is the Minimum

Pneumatic Pressure required to achieve the fluid outlet

pressure.

2. Install a pneumatic line filter (C) to keep debris from

affecting pump performance and to increase pump

life.

NOTE: Keep the needle valve (B) closed at this point to

keep the pump from operating without fluid, which minimizes seal wear.

Connect Chemical Outlet

1. Connect a fluid line from the pump outlet port (M) to

the injection point.

2. Install a fluid pressure relief valve (J) on the outlet

side of the pump.

NOTE: A pressure relief valve is available from Graco

and can be connected back to the tank or directly to th e

inlet side of the pump. See Kits and Accessories on

page 35.

In the event of an injection line blockage, to reduce the

risk of skin injection and damage to the pump, ensure

the pressure relief valve is set at or below the maximum working pressure of the pump.

3. Set the pressure relief valve at or below the maximum working pressure of the pump.

3. Attach a pneumatic line to th e 1/ 4 in. fe ma le NPT

port on the needle valve (B).

Route Exhaust to Remote

Location

Replace the muffler (18) with a pneumatic line to route

exhaust to a remote location.

NOTICE

Due to the operational design of the pneumatic valve,

a small amount of the exhaust is not recoverable, a nd

will vent to atmosphere. However, a 100% Exhaust

Capture Kit, B32651, is available.

3A6831A 9

Page 10

Installation

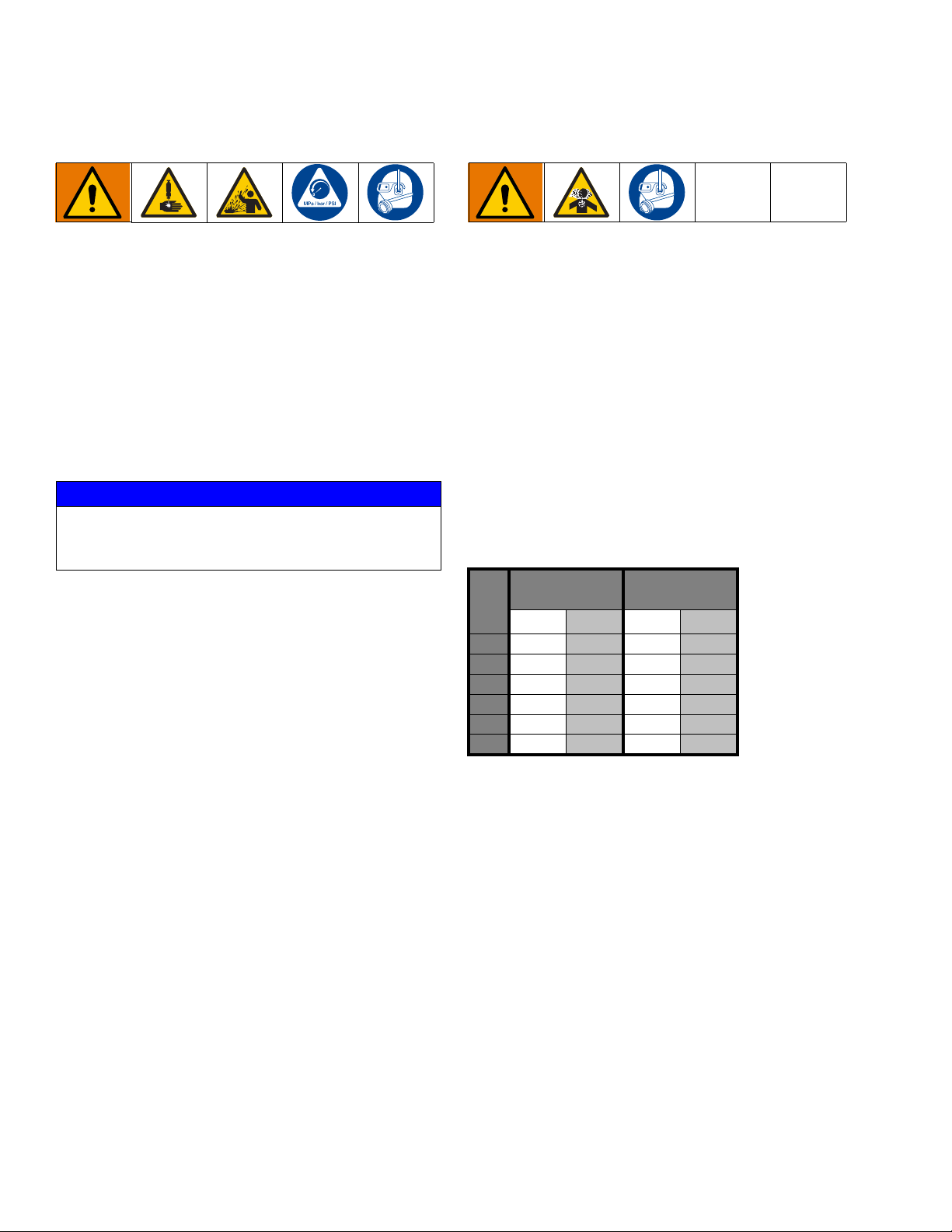

Minimum Pneumatic Pressures by Fluid Plunger Size and Outlet Pressures

Actual running pressure must be set in field to avoid stalling. See Performance Charts, starting on page 39, for maximum flows at any given pressure.

0600 (6.0 in) Pneumatic Motor Minimum Gas Pressure

psi (MPa, bar)

Outlet Pressure psi

(MPa, bar)

0 (0, 0) 15.0 (0.1, 1.0) 15.0 (0.1, 1.0)

500 (3.4, 34.5) 15.0 (0.1, 1.0) 15.0 (0.1, 1.0)

1000 (6.9, 68.9) 15.6 (0.1, 1.1) 26.3 (0.2, 1.8)

1500 (10.3, 103.4) 23.4 (0.2, 1.6) 39.5 (0.3, 2.7)

2000 (13.8, 137.9) 31.3 (0.2, 2.2) 52.6 (0.4, 3.6)

2500 (17.2, 172.4) 39.1 (0.3, 2.7) 65.8 (0.5, 4.5)

3000 (20.7, 206.8) 46.9 (0.3, 3.2) 79.0 (0.5, 5.4)

3500 (24.1, 241.3) 54.7 (0.4, 3.8) 92.1 (0.6, 6.4)

4000 (27.6, 275.8) 62.5 (0.4, 4.3)

4500 (31.0, 310.3) 70.3 (0.5, 4.8)

5000 (34.5, 344.7) 78.1 (0.5, 5.4)

5500 (37.9, 379.2) 85.9 (0.6, 5.9)

6000 (41.4, 413.7) 93.8 (0.6, 6.5)

6400 (44.1, 441.3) 100.0 (0.7, 6.9)

3/4 Inch

Fluid Plunger

1 Inch

Fluid Plunger

0750 (7.5 in) Pneumatic Motor Minimum Gas Pressure

psi (MPa, bar)

Outlet Pressure psi

(MPa, bar)

0 (0, 0) 15.0 (0.1, 1.0) 15.0 (0.1, 1.0)

500 (3.4, 34.5) 15.0 (0.1, 1.0) 15.0 (0.1, 1.0)

1000 (6.9, 68.9) 15.0 (0.1, 1.0) 16.4 (0.1, 1.1)

1500 (10.3, 103.4) 15.0 (0.1, 1.0) 24.6 (0.2, 1.7)

2000 (13.8, 137.9) 20.0 (0.1, 1.4) 32.8 (0.2, 2.3)

2500 (17.2, 172.4) 25.0 (0.2, 1.7) 41.0 (0.3, 2.8)

3000 (20.7, 206.8) 30.0 (0.2, 2.1) 49.2 (0.3, 3.4)

3500 (24.1, 241.3) 35.0 (0.2, 2.4) 57.4 (0.4, 4.0)

4000 (27.6, 275.8) 40.0 (0.3, 2.8) 65.6 (0.5, 4.5)

4500 (31.0, 310.3) 45.0 (0.3, 3.1) 73.8 (0.5, 5.1)

5000 (34.5, 344.7) 50.0 (0.3, 3.4) 82.0 (0.6, 5.7)

5500 (37.9, 379.2) 55.0 (0.4, 3.8) 90.2 (0.6, 6.2)

6000 (41.4, 413.7) 60.0 (0.4, 4.1) 98.4 (0.7, 6.8)

6500 (44.8, 448.2) 65.0 (0.4, 4.5)

7000 (48.3, 482.6) 70.0 (0.5, 4.8)

7500 (51.7, 517.1) 75.0 (0.5, 5.2)

8000 (55.2, 551.6) 80.0 (0.6, 5.5)

8500 (58.6, 586.1) 85.0 (0.6, 5.9)

9000 (62.1, 620.5) 90.0 (0.6, 6.2)

9500 (65.5, 655.0) 95.0 (0.7, 6.6)

10,000 (68.9, 689.5) 100.0 (0.7, 6.9)

3/4 Inch

Fluid Plunger

1 Inch

Fluid Plunger

For applications where the exhaust is ported to

a pressurized location, compute the difference

between the inlet and outlet pressures to get

the pneumatic pressure to be used in the

above tables. Minimum pressure differential is

15 psi (0.1 MPa, 1.0 bar).

10 3A6831A

Page 11

Operation

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection and splashing

fluid, follow the Pressure Relief Procedure when

you stop dispensing and before cleaning, checking, or

servicing the equipment.

NOTE: Always discharge fluid into an approved container or location.

1. Shut off all fluid and pneumatic lines (A, K, & P)

using the two fluid shutoff valves (H) and the pneumatic needle valve (B).

2. Slowly loosen the fluid lines to (K & P) at the pump

outlets (L & M) to bleed off any residual pressure.

3. Disconnect the fluid lines (K & P) from pump outlets

(L & M).

Flush the Equipment

To avoid fire and explosion, always ground equipment

and waste container. To avoid static sparking and

injury from splashing, always flush at the lowest possible pressure.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

1. Follow the Pressure Relief Procedure.

2. Connect the inlet port to the flushing fluid supply

source.

3. Connect the outlet port to the waste reservoir.

4. Run the pump until the dispensed fluid is predominately flushing fluid.

5. Follow the Pressure Relief Procedure.

3A6831A 11

Page 12

Operation

Prime the Pump

1. Verify all connections and fluid lines are tight.

NOTE: The pressure regulator (E) and inlet pneumatic

needle valve (B) both effect the pump cycle rate. After

inlet pressure is set, the needle valve can serve as a

speed control.

2. Adjust pneumatic regulator (E) to desired pressure.

3. Open bleed-type pn eu m at ic valv e (D) . Slowly turn

pump needle valve (B) counter-clockwise, increasing air/gas flow to the pump.

NOTICE

Pump runaway may occur if the needle valve (B) is

opened too far for pressure settings, causing damage

to the packing sets (102 and 107).

4. Keep the pump cycle rate less than 1 cycle every 3

seconds only while priming the pump.

Calibrate Chemical Dosage

1. Set the pump to an estimated setting of the flow

rate.

2. Follow the instructions provided with your calibration

gauge.

3. Adjust the cycle rate with the inlet pneumatic needle

valve (B) and/or the pressure regulator (E).

4. Repeat the steps 2 and 3 to verify your changes.

Repeat as necessary until the desired flow rate is

achieved.

Baseline Chemical Dosage Settings

See Performance Charts, starting on page 39, for maximum flows at any given pressure.

Plunger Pumps

CPM

10

20

30

40

50

60

3/4 in. Fluid

GPD LPD GPD LPD

180 680 269 1017

359 1360 537 2033

539 2041 806 3050

719 2721 1074 4066

899 3401 1343 5083

1078 4081 1611 6100

1 in. Fluid

Plunger Pumps

NOTE: Maximum cycle rate is 60 CPM (cycles per min-

ute), and the minimum cycle rate is 10 CPM. All values

are at 0 psi back pressure. Cycle rates over 60 may

cause excess wear and premature seal failure.

12 3A6831A

Page 13

Maintenance

Preventive Maintenance

Schedule

The operating conditions of your particular pump determines how often maintenance is required. Establish a

preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your pump.

Tighten Threaded Connections

Check that all threaded connections are tight at routine

intervals.

Tighten Packings

Maintenance

The packings included in your pump have the ability to

be adjusted to stop leaks that develop when the seals

are worn. If a leak develops in the pump’s fluid section,

tighten the packing nut clockwise by 1/16 of a turn, or

lower, until the leak is eliminated. The life of the packing

can be affected by over-tightening the packings. If the

packing nut needs to be tightened repeatedly after short

intervals, replace the packing.

Storage

If the pump is going to be stored for long periods, it is

recommended that the pump be flushed with a

light-weight oil or rust prohibiter to protect pump components. Store the pump with protective fluid inside whenever possible.

3A6831A 13

Page 14

Troubleshooting

Troubleshooting

1. Follow Pressure Relief Procedure, page 11,

before checking or repairing pump.

2. Check all possible problems and causes before disassembling pump.

Problem Cause Solution

Air bubbles in fluid. Fluid inlet line is loose. Tighten.

Fluid leaking. Loose fittings. Tighten fittings.

Worn seals. Adjust packing (if leak persists, replace

packing).

Pump stroking, but no fluid moving. Air in pump. Prime pump.

Worn or damaged check valve seals. Rebuild top and bottom poppets.

Pneumatic motor will not run. Damaged pneumatic valve (217). Replace or service pneumatic valve (217).

See page 19.

Damaged pilot valve (219). Replace pilot valves (219).

See page 22.

Air continuously exhausting around

pneumatic motor plunger.

Air continuously exhausting from muffler. Damaged pneumatic valve plate (305) or

Pneumatic motor “bounces” at top of

stroke.

Pneumatic motor “bounces” at bottom of

stroke.

Icing inside motor. Pneumatic motor operating at high

Damaged u-cups (203). Replace plunger u-cups (203).

See page 25.

Replace or service pneumatic valve (217).

cup (312).

Damaged bottom pilot valve (219). Replace bottom pilot valve (219). See

Damaged top pilot valve (219). Re place top pilot valve (219).

pressure or high cycle rate.

See page 19.

page 22.

See page 22.

Reduce pressure, cycle rate, or duty cycle

of motor.

Reduce dew point of compressed air in

moisture coalescing filter.

Pump fails to operate. Restricted line or inadequate air/gas

supply; closed or clogged valves.

Obstructed fluid line; fluid line ID is too

small.

Pump operates but does not prime. Held open or worn check valves or

packings.

Pump operates, but output is low on both

strokes.

Pump operates, but output is low on

downstroke.

Erratic or accelerated pump speed. Exhausted fluid supply. Refill and prime.

Fluid being pumped is visible on the packing nut.

14 3A6831A

Restricted line or inadequate air/gas

supply; closed or clogged valves.

Obstructed fluid line; fluid line ID is too

small.

Worn packings in pump. Replace packings. See page 16.

Held open or worn check valves or

packings.

Held open or worn check valves or

packings.

Worn packings. Tighten packing nut.

Clear line or increase air/gas supply.

Check that the valves are open.

Open, clear*; use line with larger ID.

Clear valve; replace packings.

See page 16.

Clear line or increase air/gas supply.

Check that the valves are open.

Open, clear*; use line with larger ID.

Clear valve; replace packings.

See page 16.

Clear valve, replace packings.

See page 16.

Replace packings. See page 16.

Page 15

Repair - Pump Lower

15

16

11

206

11

10

Before servicing or repairing your pump, verify that

pressure is relieved according to the Pressure Relief

Procedure, page 11, and that all fluid and pneumatic

lines are properly shut off, or sealed with compat ible

valves and disconnected.

• Always use Genuine Graco Parts an d Acce ss or ies,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure rated for your system.

Disconnect the Pump Lower

Repair - Pump Lower

5. Hold the drip shield (4) out of the way if it is blocking

the pneumatic motor plunger (206). Hold the flats of

the pneumatic motor plunger (206) with a wrench.

Use another wrench to loosen the coupler nut (11).

Threads are very sharp. Use a rag to protect hands

when turning or carrying the pump.

1. Stop the pump in the middle of the stroke.

2. Follow the Pressure Relief Procedure, page 11.

3. Disconnect the fluid lines.

4. Loosen the screw (16) and remove the tie rod shield

(15). The drip shield (4) may slide down the tie ro ds

once the rod shield is removed.

FIG. 3

6. Lower the coupler nut (11) enough to remove the

coupling collars (10), and then remove the coupler

nut (11).

FIG. 4

FIG. 2

3A6831A 15

Page 16

Repair - Pump Lower

9

119

206

118

118

116

114

115

117

109

113

101

7. Use a hammer and brass rod to loosen the jam

nut (119). Unscrew the jam nut as far as possible.

FIG. 5

8. Unscrew the pump lower (9) by hand and place on

work bench.

Pump Repair

1. Remove the lower fluid cylinder (113) and cylinder

cap (117) assembly from the primary fluid cylinder

(101).

FIG. 6

2. Remove the cylinder cap (117) from the lower fluid

cylinder (113).

3. Remove the plunger (109).

4. Remove the cylinder cap check valve retainer (116)

and cylinder cap check valve poppet (114).

16 3A6831A

Page 17

Repair - Pump Lower

109

107

108

110

111

112

Primary

Seal Stack (102)

Secondary

Seal Stack (107)

103

108

106

105

103

102

101

119

FIG. 7

5. Remove the plunger check valve seat (112) and

plunger check valve poppet (110).

6. Remove the o-rings (118) from the lower fluid cylinder (113).

7. Remove the bearing (108) and secondary seal

stack (107) from the fluid cylinder (101).

8. Remove the packing nut (106), shim (105), bearing

(103) and primary seal stack (102) from the fluid cylinder (101).

FIG. 8

9. Install the new primary seal stacking (102) including

bearing (103). Use grease during installation.

10. Install the packing nut (106) with pipe sealant until

finger tight.

FIG. 9

11. Install the new secondary seal stack (107), including

bearing (108). Use grease during installation.

3A6831A 17

Page 18

Repair - Pump Lower

11

10

109

206

6

5

109

11

206

12. Install two new o-rings (118) on the lower fluid cylin der (113). Orientation does not matter for this part.

13. Apply anti-seize to both lower fluid cylinder (113)

threads and install into the fluid cylinder (101).

Torque to 100 ft-lb.

14. Inspect and replace the plunger o-ring (111), as

required, and insert the plunger poppet (110) into

the plunger (109) in the direction shown. Apply

medium strength (blue) thread locker to the check

seat (112). Torque to the following values depending on the size of your pump lower:

Pump Lower Size Torque

075 40 ft-lb (54 N•m)

100 90 ft-lb (122 N•m)

15. Apply petroleum-based lubricant to the fluid p lunger

(109) and install into the fluid cylinder (101).

16. Inspect and replace the cylinder o-ring (115), as

required, and insert the cylinder poppet (114) into

the cylinder cap (117) in the direction shown. Install

the check retainer (116). Torque to 10 ft-lb

(14 N•m).

17. Install the cylinder cap (117) onto the lower fluid cylinder (113). Torque to 100 ft-lb (136 N•m).

18. Install the packing nut shim (105) and torque the

packing nut (106) to 20 ft-lb (27 N•m).

Reconnect the Pump Lower

1. Tilt the pneumatic motor (1) onto its back, then hand

turn the pump lower (9) into the adapter plate (6).

Set the pump upright again.

FIG. 10

3. Put the coupling collars (10) into the coupler nut

(11) so the large flanges point upward.

4. Gently let the pneumatic motor plunger (206) drop

onto the fluid plunger (109). Hand tighten the coupler nut (11).

5. Screw the pump lower (9) into the adapter nut (5)

until the cylinder top is flush with the top of the

adapter plate (6).

2. Hold the pneumatic motor plunger (109) up with one

hand. With your other hand, put th e coupler nut ( 11)

on the plunger.

18 3A6831A

FIG. 11

6. Align the fluid outlet as shown and tighten the jam

nut.

7. Hold the flats of the motor plunger (206) with a

wrench. Use another wrench to tighten the coupler

nut (11). Torque the coupler nut (11) to 75-80 ft-lbs

(102-108 N•m).

8. Hold the drip shield (4) out of the way and replace

the tie rod shield (15).

Page 19

Repair - Pneumatic Motor

Repair - Pneumatic Motor

Replace Seals or Rebuild Pneumatic Valve

Inspect and replace seals and worn parts while disassembling and reassembling the pneumatic valve on the

next following pages.

Pneumatic Valve

Replace Complete Pneumatic Valve

1. Stop the pump. Follow Pressure Relief Procedure,

page 11.

2. Disconnect the pneumatic line to the motor.

3. See the figure on page 31. Remove four screws

(218). Remove the pneumatic valve (217) an d ga sket (216*).

4. To repair the pneum at ic valve , go to Disassemble

the Pneumatic Valve, page 19. To install a replacement pneumatic valve (217), continue with step 5.

5. Align the new pneumatic valve gasket (216*) on

the manifold, then attach the pneumatic valve (217).

Torque screws (218) to 95-105 in-lb (11-12 N•m).

6. Reconnect the pneumatic line to the motor.

IG. 12 and the following table to identify the kits

Use F

needed for replacements:

Symbol Kit Description

† Pneumatic Valve Seal Kits. See page 34

Pneumatic Valve Repair Kits. See page 34.

Pneumatic Valve End Cap Kits. See

page 34.

Disassemble the Pneumatic Valve

1. Perform steps 1-3 under Replace Complete Pneumatic Valve, page 19.

2. See F

3. See F

IG. 12. Use a 2 mm or 5/64 in. hex key to

remove two screws (309†). Remove the valve

plate (305), cup (312), and spring (311).

IG. 12. Remove the snap ring (310) from

each end. Use the piston to push the end caps

(307) out of the ends. Remove end cap o-rings

(306†).

4. Remove the piston (302). Remove the u-cup seals

(308†) from each end, and the detent assembly

(303) and detent cam (304) from the center.

3A6831A 19

Page 20

Repair - Pneumatic Motor

1

Apply lubricant.

310

307

307

†309

305

312

311

303

302

†308

†

308

301

304

310

ti16213a

†321

†321

313

314

1

1

1

1

1

1

1

1

FIG. 12

20 3A6831A

Page 21

Repair - Pneumatic Motor

Lips face down

Lips face up

†308

†308

302

ti12754a

312

ti16283a

Magnet

Reassemble the Pneumatic Valve

1. See F

IG. 12. Lubricate detent cam (304) and

install into housing.

2. See F

IG. 13. Lubricate the u-cups (308†) and

install on the piston (302) with lips facing toward

the center of the piston.

7. Install the spring (311). Lubricate and install the

pneumatic valve cup (312), see F

IG. 14. Align the

small round magnet with the pneumatic inlet.

8. Install the valve plate (305). Tighten the screws

(309†) to hold it in place.

FIG. 14

F

3. See F

4. Lubricate and install the detent assembly (303)

5. Lubricate new o-rings (306†) and install on the

6. Install a snap ring (310) on each end to hold end

9. Perform steps 5 and 6 under Replace Complete

Pneumatic Valve, page 19.

IG. 13

IG. 12. Lubricate both ends of the piston

(302) and install it in the housing.

into the piston.

end caps (307). Install the end caps into the housing.

caps in place.

3A6831A 21

Page 22

Repair - Pneumatic Motor

15

16

15

4

3

Replace Pilot Valves

1. Stop the pump. Follow the Pressure Relief Procedure, page 11.

2. Disconnect the pneumatic line to the motor.

3. Loosen the screw (16) and remove the tie rod

shield (15).

FIG. 15

4. Slide the drip shield (4) down on the tie rods (3).

FIG. 16

5. Use a 10 mm socket wrench to remove the old pilot

valves (219) from the top (213) and bottom (201)

covers. See the figure on page 31.

6. Lubricate and install the new pilot valves (219).

Torque to 95-105 in-lb (11-12 N•m).

7. Slide the drip shield (4) to the top of the tie rods (3)

and replace the tie rod shield (15).

8. Reconnect the pneumatic line to the motor.

22 3A6831A

Page 23

Repair Pneumatic Motor

15

16

11

206

14

NOTE: Pneumatic Motor Seal Kits are available. See

Kits and Accessories, page 35, for the correct kit for

your motor. For best results, use all parts in the kit.

Disconnect the Pneumatic Motor

1. Flush the pump, if possible. (See package manual.)

Follow the Pressure Relief Procedure, page 11.

2. Disconnect the pneumatic and fluid hoses, and the

ground wire.

3. Loosen the screw (16) and remove the tie rod shield

(15). The drip shield (4) may slide down the tie ro ds

once the rod shield is removed. (See F

IG. 16.)

Repair - Pneumatic Motor

FIG. 18

FIG. 17

4. Hold the drip shield (4) out of the way if it is blocking

the pneumatic motor plunger (206). Hold the flats of

the pneumatic motor plunger (206) with a wrench.

Use another wrench to loosen the coupler nut (11).

5. Remove the tie rod nu ts (8 ).

6. Use a socket wrench to remove the mounting

screws (14).

F

IG. 19

7. Lift up on the pneumatic motor to remove it. The tie

rods (3) and drip shield (4) will remain attached.

3A6831A 23

Page 24

Repair - Pneumatic Motor

ti12749a

ti12750a

3*

43*

ti12755a

Lips face up

U-cup faces up.

Flange faces down.

Disassemble the Pneumatic Motor

1. Use a 10 mm socket wrench to remove the four

screws (218), and remove the pneumatic valve

(217) and gasket (216).

2. Remove the mufflers (18).

3. Remove the four screws (218), and remove the

manifold (215) and two gaskets (214).

4. Use a 10 mm socket wrench to remove the pilot

valves (219), and the top and bottom covers (213

and 201).

5. Remove the 17 mm tie bolts (21 0). Th e nu m be r of

bolts depends on your configuration.

Configuration

PCI-0600-xxx-xxx-xx-x-x

Reassemble the Pneumatic Motor

NOTE: For easier reassembly, start with the top

cover (213) turned over on the workbench and assemble the pneumatic motor upside-down.

1. Lubricate and install the o-ring (209) on the top

cover (213).

2. Install the upper bumper (228) on the top cover.

3. Lubricate the inside of the cylinder (211). Lower the

cylinder onto the top cover (213).

4. Lubricate and install the o-ring (208) around the piston (205).

5. Slide the piston assembly down onto the

cylinder (211). Be sure the o-ring (208) stays in

place.

6. Install the shield (212) around the cylinder (211) and

in the groove on the top cover (213).

7. Lubricate and install the new u-cup seal in the bottom of the bearing (202) in the bottom cover (201).

The u-cup must face up and the flange face down.

IG. 21.

See F

PCI-0750-xxx-xxx-xx-x-x

6. Remove the top cover (213) and the o-ring (209).

7. Remove the shield (212) from around the

cylinder (211), and remove the cylinder.

8. Slide the piston assembly straight up off the bottom

cover (201).

NOTE: There is no need to take apart the piston assembly. If any part is worn or damaged, the entire assembly

should be replaced.

9. Remove the o-ring (208) from around the piston

(205).

10. Remove the retaining ring (204), u-cup seals (203),

and the o-ring (209) from the bottom cover (201).

FIG. 20

8. Lubricate and install the new u-cup seal (203) in the

top of the bearing. Lips must face up.

9. Lubricate and install the o-ring (209) in the bottom

cover (201).

10. Install the piston bumper (228) on the bottom

cover (201).

24 3A6831A

Page 25

Repair - Pneumatic Motor

ti14544a

201

206

211

213

212

11. Carefully place the bottom cover (201) on the cylinder (211), sliding the rod (206) through the be a ring

(202). The manifold surfaces of the top and bottom

covers must align. Be sure the shield (212) is in the

groove on both the top and bottom covers.

Reconnect the Pneumatic Motor

1. Replace the motor on the mounting bracket (2).

2. Screw the tie rods (3) into the motor, with the top

hex nuts (4) attached. Torque the tie rods to 5-10

ft-lb (7-13 N•m).

NOTE: Always tighten the tie rods (3) before tightening

the top hex nuts (4).

3. Tighten the top hex nu ts (4 ) to se cur e the mou nt ing

bracket (2).

4. Slide the pump with the adapter plate (6) attached

onto the tie rods (3).

5. Install the tie rod nuts (8). Torque to 100 in-lb

(11 N•m).

6. Align the hole in the fluid plunger (109) with the hole

in the pneumatic motor plunger (206).

7. Slide the drip shield (4) to the top of the tie rods (3)

and replace the tie rod shield (15).

IG. 21

F

12. Install the tie bolts (210) hand tight.

13. Install two gaskets (214) on the manifold (215), and

install the manifold. Torque bolts to 95-105 in-lb

(11-12 N•m). (The manifold is reversible for ease of

placement of the muffler or the remote exhaust.)

14. Align the pneumatic valve gasket (216) on the manifold (215), then attach the pneumatic valve (217).

15. Tighten the bolts (210) halfway. Work in a

criss-cross pattern while tightening the tie bolts.

Check that the shield remains in the grooves on

both covers. Continue tightening the bolts in pattern

and torque to 25-30 ft-lb (34-40 N•m).

16. Lubricate and install the pilot valves (219) in the top

and bottom covers. Torque to 5-105 in-lb (11-12

N•m).

17. Reinstall the mufflers (18).

18. See Reconnect the Pneumatic Motor on page 25.

8. Reconnect the pneumatic and fluid hoses, and the

ground wire.

3A6831A 25

Page 26

Repair - Pneumatic Motor

26 3A6831A

Page 27

Parts

1

18

17

26

27

26

24

25

22

23

12

13

14

2

15

10

4

11

3

5

6

7

9

8

16

119

32

Python XL-DA25 Pneumatic Pump

PCI-0750-050-075-XC-2-0 shown

Parts

3A6831A 27

Page 28

Parts

Python XL-DA25 Pump Parts List

Ref. Part Description Qty

1 B33007 Pneumatic motor, 6.0 in.;

PCI-0600-xxx-xxx-xx-2-x

B33008 Pneumatic motor, 7.5 in.;

PCI-0750-xxx-xxx-xx-2-x

2 B33100 Wall bracket 1

3 B33101 Motor tie rod 3

4 15V028 Drip shield 1

5 -- Lower adapter nut 1

6 B33102 Pump lower adapter;

PCI-xxxx-075-113-xx-2-x

B33111 Pump lower adapter;

PCI-xxxx-100-138-xx-2-x

7 -- Lock washer, 5/8 in.; stainless

steel; (included with ref. 3)

8 -- Hex nut; (included with ref. 3) 3

9See Pump

Lower Mod-

els, pg 35

10 B33103 Coupling collar; (pack of 10) 2

11 B33104 Coupler nut 1

12 -- Flat washer; (included with ref. 2) 4

13 -- Spring lock washer; (included with

14 -- Hex head screw; (included with

15 B33105 Shield 1

16 -- Screw, M4-.7, 10 mm; stainless

17 15U426 Reducing bushing, 3/4 in. nptf - 1/2

18 24D642 Muffler, 1050 AODD; ice resistant;

22 B33106 Bushing, 1/2 in. x 1/4 in. npt, mf, 1

23 B33107 Elbow fitting, 1/4 in. nptf x 1/4 in.

24 B33108 Tee fitting, 1/4 in. nptm-nptf-nptm 1

25 B33109 Safety valve, 110 PSI 1

26 B33110 Pipe bushing fitting, 1 in. x 1/4 in.

27 131295 Needle valve 1

32 15W719 Warning Safety Label 1

119 B33173 Jam nut, 3/4 in.;

B33174 Jam nut, 1 in.;

Pump lower 1

ref. 2)

ref. 2)

steel; (included with ref. 15)

in. nptm; (pack of 1)

(pack of 1)

nptm

npt; (pack of 1)

PCI-xxxx-075-113-xx-2-x

PCI-xxxx-100-138-xx-2-x

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

1

1

1

1

3

4

4

1

2

2

1

2

1

1

28 3A6831A

Page 29

Pump Lower

101

102

103

106

105

109

107

108

118

110

111

112

113

118

117

116

115

114

104

123

Parts

3A6831A 29

Page 30

Parts

Pump Lower Parts List

PCI-xxxx-075-113-xx-2-x

Ref. Description

101 Fluid cylinder B33138 B33139 1

102 Primary seal stack See table below 1

103 Primary bearing B33136 B33137 1

104 Pellet (included with ref. 101) 1

105 Packing nut shim B3313 4 B33135 1

106 Packing nut B33132 B33133 1

107 Secondary seal stack See table below 1

108 Secondary bearing B33130 B33131 1

109 Fluid plunger B33128 B33129 1

110 Plunger poppet B33126 B33127 1

111 Plunger poppet o-ring See table below 1

112 Check seat B33124 B33125 1

113 Lower fluid cylinder B33122 B33123 1

114 Cylinder poppet B33120 B33121 1

115 Cylinder poppet o-ring See table below 1

116 Check retainer B33118 B33119 1

117 Cylinder cap B33116 B33117 1

118 O-ring packing; (pack of 10) B33114 B33115 2

119 Jam nut (shown on pg 27) B33112 B33113 1

123 Warning safety label 17G320 1

3/4 in. Part numbers

PCI-xxxx-100-138-xx-2-x

1 in. Part numbers Qty

Replacement Danger and Warning labels, tags, and cards are available at no cost.

Ref. Description Seal Material 3/4 in. 1 in.

C HNBR B33140 B33152

102 Primary Seal Stack

107 Secondary Seal Stack

111 Plunger Poppet O-ring

115 Cylinder Poppet O-ring

D FFKM B33141 B33153

E TFE/P B33142 B33154

C HNBR B33143 B33155

D FFKM B33144 B33156

E TFE/P B33145 B33157

C HNBR B33146 B33158

D FFKM B33147 B33159

E TFE/P B33148 B33160

C HNBR B33149 B33161

D FFKM B33150 B33162

E TFE/P B33151 B33163

30 3A6831A

Page 31

Pneumatic Motor Parts

201

210

242

228

209

202

203

204

206

205

208

212

209

213

237

243

219

229

230

211

214

227

216

217

218

218

219

221

215

PCI-0600, 6.0 in. (152.4 mm); PCI-0750, 7.5 in. (190.5 mm), shown

Parts

‡ These items are only available in Pneumatic Motor Kits B32251 and B32770

3A6831A 31

Page 32

Parts

Pneumatic Motor Parts List

Part number shown:

B33007 (PCI-0600): 6.0 in. (152.4 mm)

B33008 (PCI-0750): 7.5 in. (190.5 mm)

Ref. Part Description Qty

201 B33171 Lower cover; PCI-0600 1

B33172 Lower cover; PCI-0750 1

202 -- Bearing; (included with ref. 201) 1

203

204

205 24A550 Motor piston; PCI-0600 1

206 -- Piston Rod; (included with ref. 205) 1

208

209

210 B 33169 Hex cap screw; PCI-0600 4

211 15M672 Motor cylinder; PCI-0600 1

212 B33167 Bolt cover; PCI-0600 (includes

213 B33165 Upper cover; PCI-0600 1

-- U-cup packing 1

-- Retainer ring 1

16G515 Motor piston; PCI-0750 1

-- Packing o-ring; (included with ref. 205) 1

-- End cap o-ring 2

B33170 Hex cap screw; PCI-0750 6

16A516 Motor cylinder; PCI-0750 1

English warning label)

B33168 Bolt cover; PCI-0750 (includes

English warning label)

B33166 Upper cover; PCI-0750 1

Ref. Part Description Qty

214

215 24A580 Motor manifold 1

216

217 B33164 Pneumatic valve 1

218 -- Screw; M6; (included with ref. 215,

219 24A366 Pilot valve 2

221 -- Ball; (included with ref. 215, 24A580) 2

227 -- Expansion plug; (included with ref.

228 24A914 Bumper; PCI-0600 1

229 -- Upper bumper; (included with ref. 228,

1

230 -- Screw; M5; (included with ref. 228,

1

237 -- O-ring packing; (included with ref.

242

243 24E991 Hook 1

-- Manifold gasket; (included with ref.

215, 24A580)

17F429 Pneumatic valve gasket; (included

with ref. 215, 24A580)

24A580)

215, 24A580)

24A915 Bumper; PCI-0750 1

24A915)

24A915)

243)

-- Rod seal 1

2

1

8

2

1

3

1

Replacement Danger and Warning labels, tags, and cards are available at no cost.

Included in 6.0 in. Pneumatic Motor Seal Kit 24A547. See page 34.

Included in 7.5 in. Pneumatic Motor Seal Kit 24A551. See page 34.

32 3A6831A

Page 33

Pneumatic Valve Parts

310

307

307

309

305

312

311

303

302

308

308

301

304

310

ti16213a

321

321

313

314

Parts

3A6831A 33

Page 34

Parts

Pneumatic Valve Parts

Complete Pneumatic Valve Replacement Kit B33164

To replace the complete pneumatic valve, order Pneumatic Valve Replacement Kit B33164 (6 in. and 7 in.). The kit

includes items 301-312 below, and items 209 and 211 on page 32.

Pneumatic Valve Repair Kits

Pneumatic valve parts are not sold individually. The table below shows possible kit options for each part.

Pneumatic Valve

Ref. Description Qty.

301 Housing 1

302 Pneumatic valve piston 1

303 Detent piston 1

304 Detent cam 1

305 Pneumatic valve plate 1

307 Cap 2

308 U-cup packing 2

309 Screw; M3 2

310 Snap ring 2

311 Detent spring 1

312 Casting cup 1

313 Base cup 1

314 Casting cup gasket 1

321 O-ring packing 3

Replacement screws (309) are available in a pack of 10. Order Kit 24A359.

Repair Kit 24A538

Pneumatic Valve

Seal Kit 24A536

Pneumatic Valve

End Cap Kit 24A361

34 3A6831A

Page 35

Kits and Accessories

Kits and Accessories

Pump Lower Models Additional Kits & Accessories

Configuration

Part No.

B33016 075-113-XC-2

B33017 075-113-XD-2 FFKM

B33018 075-113-XE-2 TFE/P

B33022 100-138-XC-2

B33023 100-138-XD-2 FFKM

B33024 100-138-XE-2 TFE/P

Code

Lower

Size

3/4 in. Chromex

1 in. Chromex

Lower

Coating

Seal

Material

HNBR

HNBR

Part No. Description

B32045 225-750 PSI Pressure Relief Valve Kit

(Adjustable)

B32046 750-1500 PSI Pressure Relief Valve Kit

(Adjustable)

B32047 1500-2250 PSI Pressure Relief Valve Kit

(Adjustable)

B32048 2250-3000 PSI Pressure Relief Valve Kit

(Adjustable)

B32049 3000-4000 PSI Pressure Relief Valve Kit

(Adjustable)

B32050 4000-5000 PSI Pressure Relief Valve Kit

(Adjustable)

B32051 5000-6000 PSI Pressure Relief Valve Kit

(Adjustable)

HIP10RV 1000-10,000 PSI Pressure Relief Valve

Kit (Adjustable)

B32088 SST Calibration Column Kit

B32089 SST Manifold Assembly Kit

B32157 316 SST Ball Valve Kit, 3/4 in. NPT(F)

B32158 Fluid Filter 6000 PSI

B32159 Fluid Filter 10000 PSI

B32162 1/4 in. NPT(F) X 1/4 in. NPT(F) Check Kit;

10,000 PSI

3A6831A 35

Page 36

Dimensions

Dimensions

Python XL-DA25 Pump Dimensions

FIG. 22 Python Pump Dimensions

Size A B C D E

600 24.0 in.

(61.0 cm)

750 24.0 in.

(61.0 cm)

36 3A6831A

14.5 in.

(36.8 cm)

14.5 in.

(36.8 cm)

16.75 in.

(42.5 cm)

16.75 in.

(42.5 cm)

17.75 in.

(45.1 cm)

17.75 in

(45.1 cm)

8.0 in.

(20.3 cm)

8.0 in.

(20.3 cm)

Page 37

Wall Bracket Mounting Hole Diagram

2X 5.50

4X Ø .400

2.00

2.00

4X 6.936

2X 1.09

2X 8.59

4X 1.14

2.79

2.79

4X R 0.175

2X 1.000

2X 2.375

2X 11.00

Dimensions

3A6831A 37

Page 38

Dimensions

Four M8 X 1.25

optional

mounting holes

Two M8

mounting holes

Three 5/8-11

tie rod holes

5.906 in.

(150 mm)

bolt circle

ti12738a

ti12737a

3.38 in. (86 mm)

2.0 in. (50 mm)

5.250 in.

(133 mm)

4 in.

(102 mm)

Four M8 X 1.25

optional

mounting holes

Three 5/8-11

tie rod holes

5.906 in.

(150 mm)

bolt circle

Two M8

mounting holes

ti12740a

ti12739a

3.1 in. (78 mm)

5.250 in.

(133 mm)

3.1 in. (78 mm)

Pneumatic Mounting Hole Diagrams

PCI-0600 (6 in. motor)

FIG. 23

PCI-0750 (7.5 in. motor)

FIG. 24

38 3A6831A

Page 39

Performance Charts

0

0

200

(757)

400

(1514)

600

(2271)

800

(3028)

1000

(3785)

1200

(4542)

500

(34.5)

(3.45)

1000

(69.0)

(6.90)

1500

(103.4)

(10.34)

4500

(310.3)

(31.03)

0

10

20

30

40

50

60

AAB

B

C

C

D

D

E

E

2000

(137.9)

(13.79)

2500

(172.4)

(17.24)

3000

(206.8)

(20.68)

3500

(241.3)

(24.13)

4000

(275.8)

(27.58)

0

60

15

30

45

Inlet Pressure PSI (MPa, Bar)

A-15 (0.10, 1.0)

B-25 (0.17, 1.7)

C-50 (0.34, 3.4)

D-75 (0.52, 5.2)

E-100 (0.69, 6.9)

--- Fluid Flow

- - Air Flow

Flow -

GPD

(LPD)

Pressure - PSI (bar)(MPa)

Air Consumption

(SCFM)

Pump Speed

(cyc/min)

0

0

200

(757)

400

(1514)

600

(2271)

800

(3028)

1000

(3785)

1200

(4542)

1400

(5300)

1600

(6057)

1800

(6814)

500

(34.5)

(3.45)

1000

(69.0)

(6.90)

1500

(103.4)

(10.34)

0

10

20

30

40

50

60

AAB

B

C

C

D

D

E

E

2000

(137.9)

(13.79)

2500

(172.4)

(17.24)

3000

(206.8)

(20.68)

3500

(241.3)

(24.13)

0

60

15

30

45

Inlet Pressure PSI (MPa, Bar)

A-15 (0.10, 1.0)

B-25 (0.17, 1.7)

C-50 (0.34, 3.4)

D-75 (0.52, 5.2)

E-100 (0.69, 6.9)

--- Fluid Flow

- - Air Flow

Flow GPD

(LPD)

Pressure - PSI (bar)(MPa)

Air Consumption

(SCFM)

Pump Speed

(cyc/min)

6 in. Motors

3/4 in. Plunger (PCI-0600-075)

Performance Charts

FIG. 25

1 in. Plunger (PCI-0600-100)

FIG. 26

3A6831A 39

Page 40

Performance Charts

0

0

200

(757)

400

(1514)

600

(2271)

800

(3028)

1000

(3785)

1200

(4542)

1000

(69.0)

(6.90)

0

10

20

30

40

50

60

AAB

B

C

C

D

D EE

2000

(137.9)

(13.79)

3000

(206.8)

(20.68)

4000

(275.8)

(27.58)

6000

(413.7)

(41.37)

5000

(344.7)

(34.47)

7000

(482.6)

(48.26)

8000

(551.6)

(55.16)

0

60

15

30

45

Inlet Pressure PSI (MPa, Bar)

A-15 (0.10, 1.0)

B-25 (0.17, 1.7)

C-50 (0.34, 3.4)

D-75 (0.52, 5.2)

E-100 (0.69, 6.9)

--- Fluid Flow

- - Air Flow

Air Consumption

(SCFM)

Flow GPD

(LPD)

Pump Speed

(cyc/min)

Pressure - PSI (bar)(MPa)

0

0

200

(757)

400

(1514)

1000

(69.0)

(6.90)

2000

(137.9)

(13.79)

3000

(206.8)

(20.68)

4000

(275.8)

(27.58)

6000

(413.7)

(41.37)

5000

(344.7)

(34.47)

600

(2271)

800

(3028)

1000

(3785)

1200

(4542)

1400

(5300)

1600

(6057)

1800

(6814)

00

15

30

45

60

10

20

30

40

50

60

A

A

B

B

C

C

D

D

EE

Inlet Pressure PSI (MPa, Bar)

A-15 (0.10, 1.0)

B-25 (0.17, 1.7)

C-50 (0.34, 3.4)

D-75 (0.52, 5.2)

E-100 (0.69, 6.9)

--- Fluid Flow

- - Air Flow

Air Consumption

(SCFM)

Flow GPD

(LPD)

Pump Speed

(cyc/min)

Pressure - PSI (bar)(MPa)

7.5 in. Motors

3/4 in. Plunger (PCI-0750-075)

FIG. 27

1 in. Plunger (PCI-0750-100)

FIG. 28

40 3A6831A

Page 41

Technical Specifications

Technical Specifications

Python XL-DA25 Chemical Injection Pump

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . US Metric

Maximum pneumatic inlet pressure See Models on page 3.

Maximum fluid working pressure See Models on page 3.

Maximum cycle rate 60 cpm

Environmental temperature range -40°– 176°F -40°– 80°C

Noise (dBa)

6.0 in. Pneumatic Motor Sound Power* 80.1 dBA

6.0 in. Pneumatic Motor Sound Pressure** 70.2 dBA

7.5 in. Pneumatic Motor Sound Power* 78.8 dBA

7.5 in. Pneumatic Motor Sound Pressure** 68.9 dBA

Inlet/Outlet Sizes

Fluid inlet size (3/4 in. plunger) 3/4 in. npt(m)

Fluid inlet size (1 in. plunger) 1 in. npt(m)

Fluid outlet size (3/4 in. and 1 in. plungers) 1/2 in. npt(f)

Pneumatic inlet size 1/4 in. npt(f)

Exhaust fitting size 1/2 in. npt(f)

Materials of Construction

See Configuration Number Matrix on page 4 for seal mate-

Pump/Check Valve Seal Material

Wetted Parts

Weight

6.0 in. Pneumatic Motor

0.75 in. lowers (CI-0600-075-113-xx-2-x) 57.5 lbs 26.1 kg

1.00 in. lowers (CI-0600-100-138-xx-2-x) 60.5 lbs 27.4 kg

7.5 in. Pneumatic Motor

0.75 in. lowers (CI-0750-075-113-xx-2-x) 62.5 lbs 28.3 kg

1.00 in. lowers (CI-0750-100-138-xx-2-x) 65.5 lbs 28.3 kg

rial. All other packing materials are PEEK and PTFE unless

otherwise noted.

See Configuration Number Matrix on page 4 for plunger

material. All other packing materials are 316 stainless steel

unless otherwise noted.

* Sound Power at 70 psi (0.48 MPa, 4.8 bar), 20 cpm. Sound power measured per ISO-9614-2.

** Sound Pressure was test 3.28 feet (1 m) from equipment.

3A6831A 41

Page 42

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2019, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A6831

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision A,

May 2019

Loading...

Loading...