Page 1

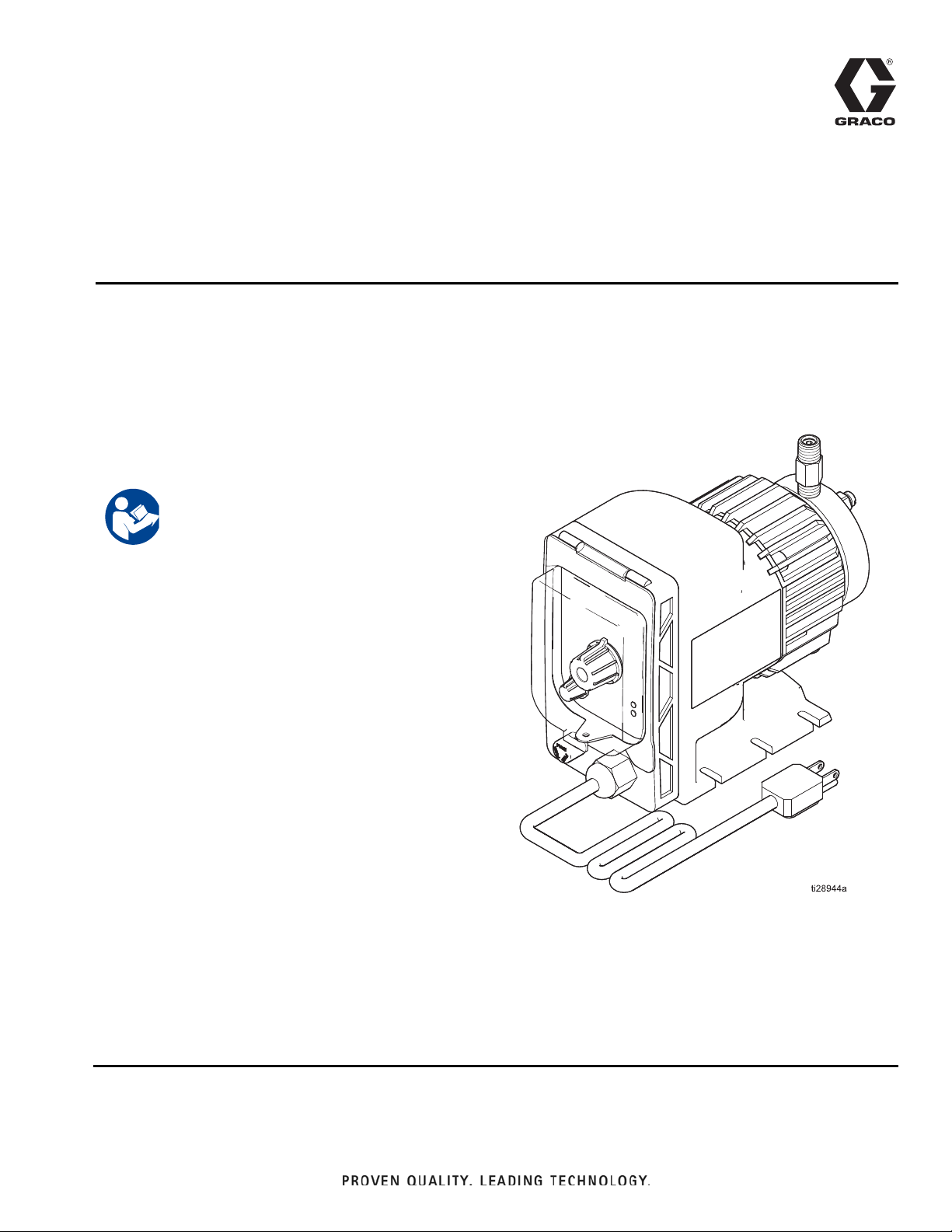

Instructions-Parts

Mongoose

Chemical Metering

3A4131H

Pump

Electric metering pump for injecting chemicals at well sites. For professional use only.

Not approved for use in explosive atmospheres or hazardous locations.

See page 2 for model information, including maximum working

pressures.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save all instructions.

EN

Page 2

3008494

Conforms to UL STD 778

Certified to CSA C22.2 No. 108

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Flush Before Using Equipment . . . . . . . . . . . . . . 5

Location Requirements . . . . . . . . . . . . . . . . . . . . 5

Plumbing Requirements for Stainless Steel /

Plastic Fluid Sections . . . . . . . . . . . . . . . . . . 5

Component Identification . . . . . . . . . . . . . . . . . . 6

Mounting and Chemical Supply Connection . . . . 7

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stainless Steel Fluid End Repairs . . . . . . . . . . . 13

Plastic Fluid End Repairs . . . . . . . . . . . . . . . . . 14

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mongoose Metering Pump . . . . . . . . . . . . . . . . 17

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 19

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 22

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 9

Flush the Equipment . . . . . . . . . . . . . . . . . . . . . . 9

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjust Feed Rate . . . . . . . . . . . . . . . . . . . . . . . 10

Adjust Stroke Length . . . . . . . . . . . . . . . . . . . . . 10

Calculate Output . . . . . . . . . . . . . . . . . . . . . . . . 10

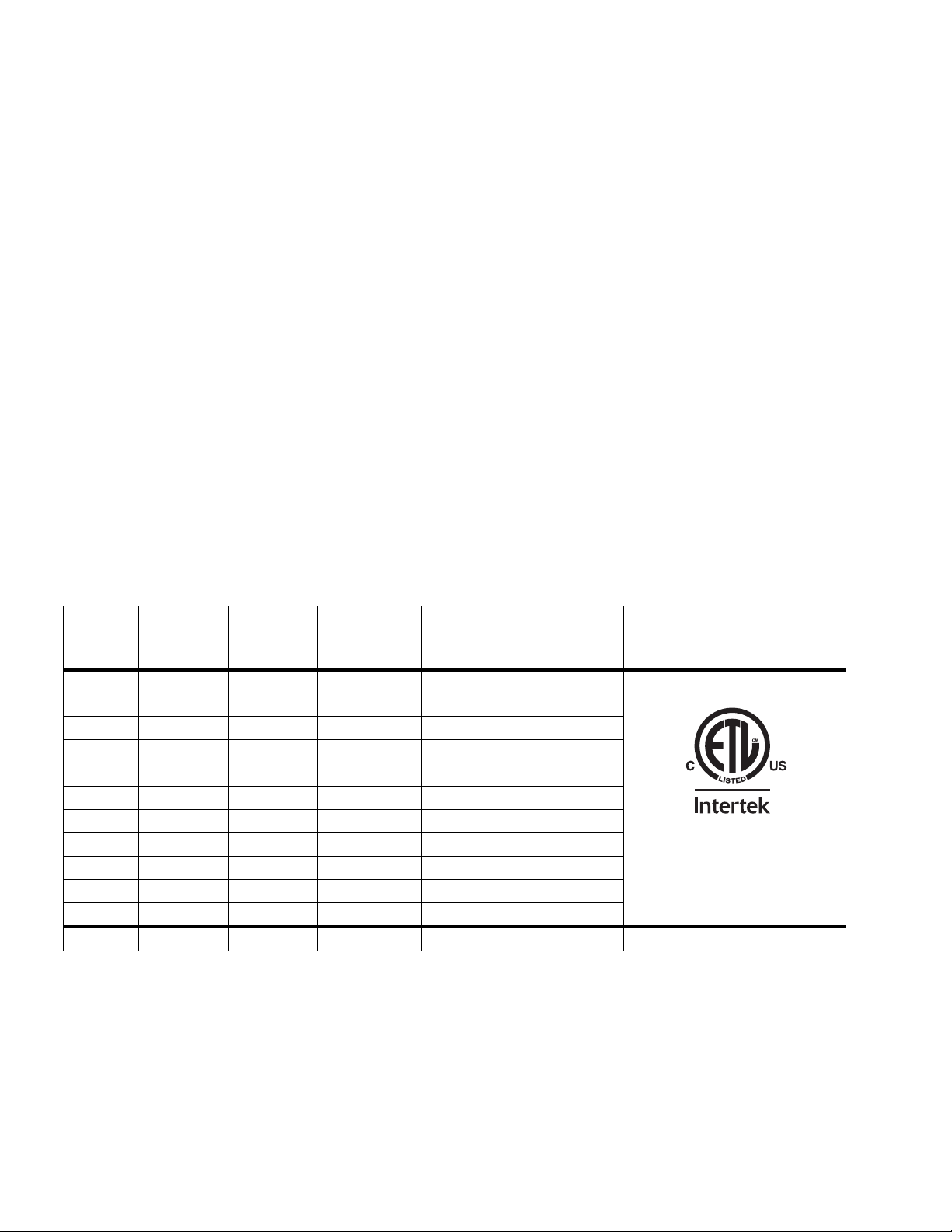

Models and Approvals

Fluid

Section

Models Voltage

A21000 120 VAC 316 SST 17 250 (1.72, 17.2)

A21001 120 VAC 316 SST 17 250 (1.72, 17.2)

A21004 230 VAC 316 SST 17 250 (1.72, 17.2)

A21008 120 VAC PVDF 17 250 (1.72, 17.2)

A21009 120 VAC PVDF 15 150 (1.03, 10.3)

A21010 120 VAC PVDF 30 110 (0.76, 7.6)

A21011 120 VAC PVDF 45 75 (0.52, 5.2)

A21012 230 VAC PVDF 17 250 (1.72, 17.2)

A21013 230 VAC PVDF 15 150 (1.03, 10.3)

A21014 230 VAC PVDF 30 110 (0.76, 7.6)

A21015 230 VAC PVDF 45 75 (0.52, 5.2)

A21016 12 VDC 316 SST

Material

Flow (GPD)

10 140 (0.97, 9.7)

Maximum Working Pressure

psi (MPa, bar)

Approvals

2 3A4131H

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or o n warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area be aware that flammable fumes can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work ar ea .

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Connect to grounded outlet protected by Class A GFCI.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on power and extension cords.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin and cause

serious injury.

• Follow the Pressure Relief Procedure when you stop spraying/dispensing and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

3A4131H 3

Page 4

Warnings

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment regularly. Repair or replace wo rn or damaged parts immediately with genuine man ufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulation s.

4 3A4131H

Page 5

Installation

3/8 in.

1/4 in.

Tubing must slip over nipple

End of the tubing

1/4 in. tubing adapter

Installation

NOTICE

It is recommended that adequate surge protection be used

in order to protect products from voltage changes in your

application.

Grounding

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

• Never remove ground wire from plug. Connect to

grounded outlet protected by Class A GFCI.

Pump: grounded through electrical cord.

Fluid lines: use only electrically conductive lines.

Fluid supply container: follow local code.

NOTICE

In order to prevent over pumping at low back pressure (less

than 50 PSI) install an inline check valve on the outlet line.

Flush Before Using Equipment

The equipment was tested with water. To avoid contaminating your fluid with water, flush the equipm en t with a

compatible solvent before using the equipm en t. See

Flush the Equipment, page 9.

Location Requirements

Select a mounting location convenient to both the chemical supply and a source of power for the pump.

NOTICE

Do not install the pump in a location where the ambient

temperature exceeds 120

will affect the output as well as the useful life of the pump.

o

F (50o C). Higher temperatures

Plumbing Requirements for Stainless Steel / Plastic Fluid Sections

The Mongoose pump uses carefully matched components to achieve a predictable metering output. This

predictability can only be maintained if all fitting sizes

remain unaltered.

All connections should be double checked to insure

against leakage. If hazardous chemicals are being

pumped, use shielding around outlet fluid lines. NOTES:

• There is an approximate 2.5 psi capability lost for

every 1 foot of vertical rise of the outlet fluid line to

the injection point.

• Do not attempt to reduce tubing size; this may

reduce performance of unit.

Stainless Steel Fluid Section Models

Inlet and outlet valves are both 1/4 in. NPT fittings.

NOTE: Apply PTFE tape to threads on NPT fittings.

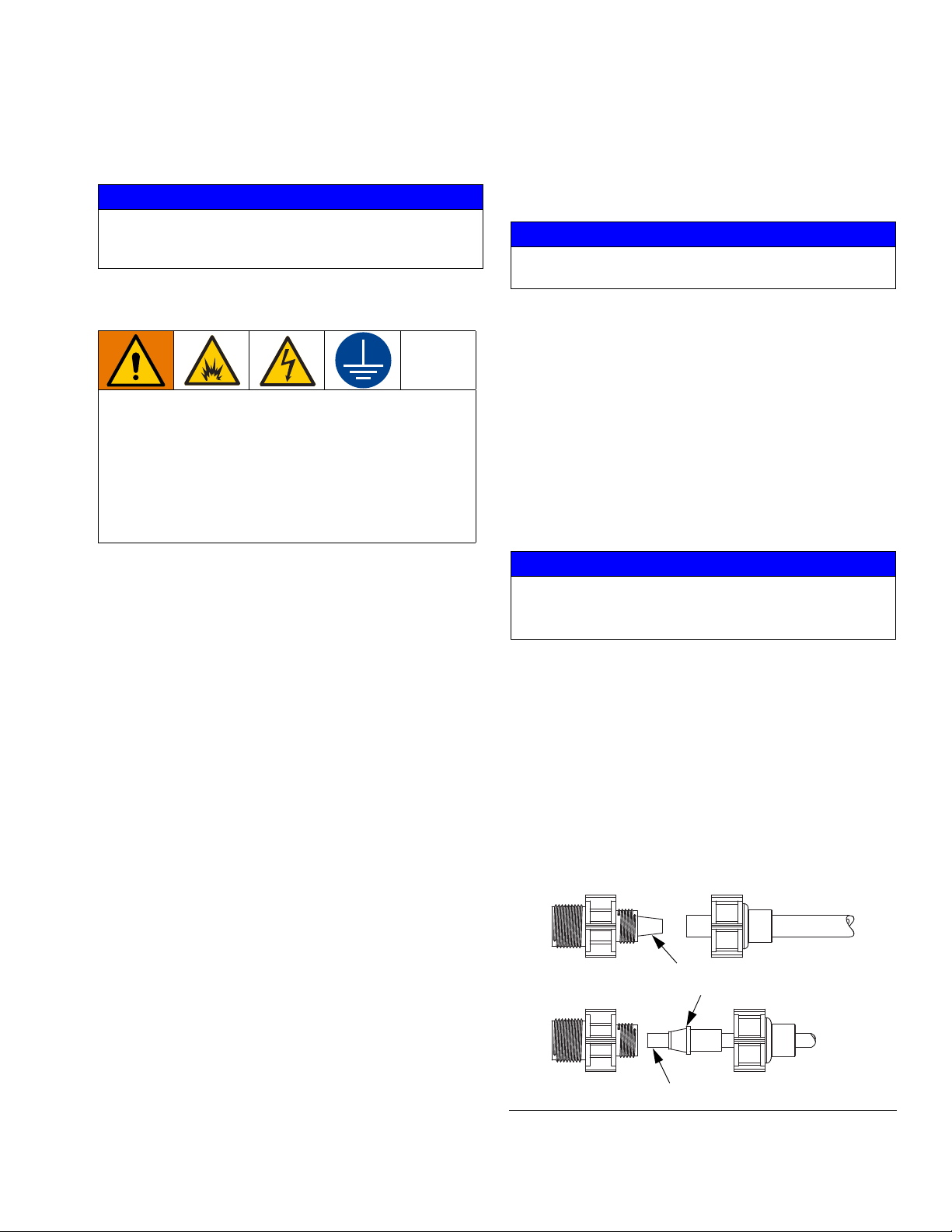

Plastic Fluid Section Models

Inlet and outlet valves use 3/8 in. or 1/4 in. tubing connectors, and 3/8 in. or 1/4 in. tubing. See F

IG. 1.

NOTE: The prime/bleed valve on the plastic fluid section

includes a 1/16 in. clear poly tubing. This tubing is to be

used only with the prime/bleed valve and is not intended

for pressurized use. Do not use with the inlet and outlet

valves.

Tighten connectors no more than a 1/4 turn after the

connection feels snug. Hand tighten only. Do not overtighten.

NOTE: Do not apply PTFE tape to threads.

FIG. 1: Tubing Connections

3A4131H 5

Page 6

Installation

1

B

A

C

4

C

D

3

2

9

11

B

A

1

102

103

109

104

E

D

11

2

E

1

B

A

C

9

4

3

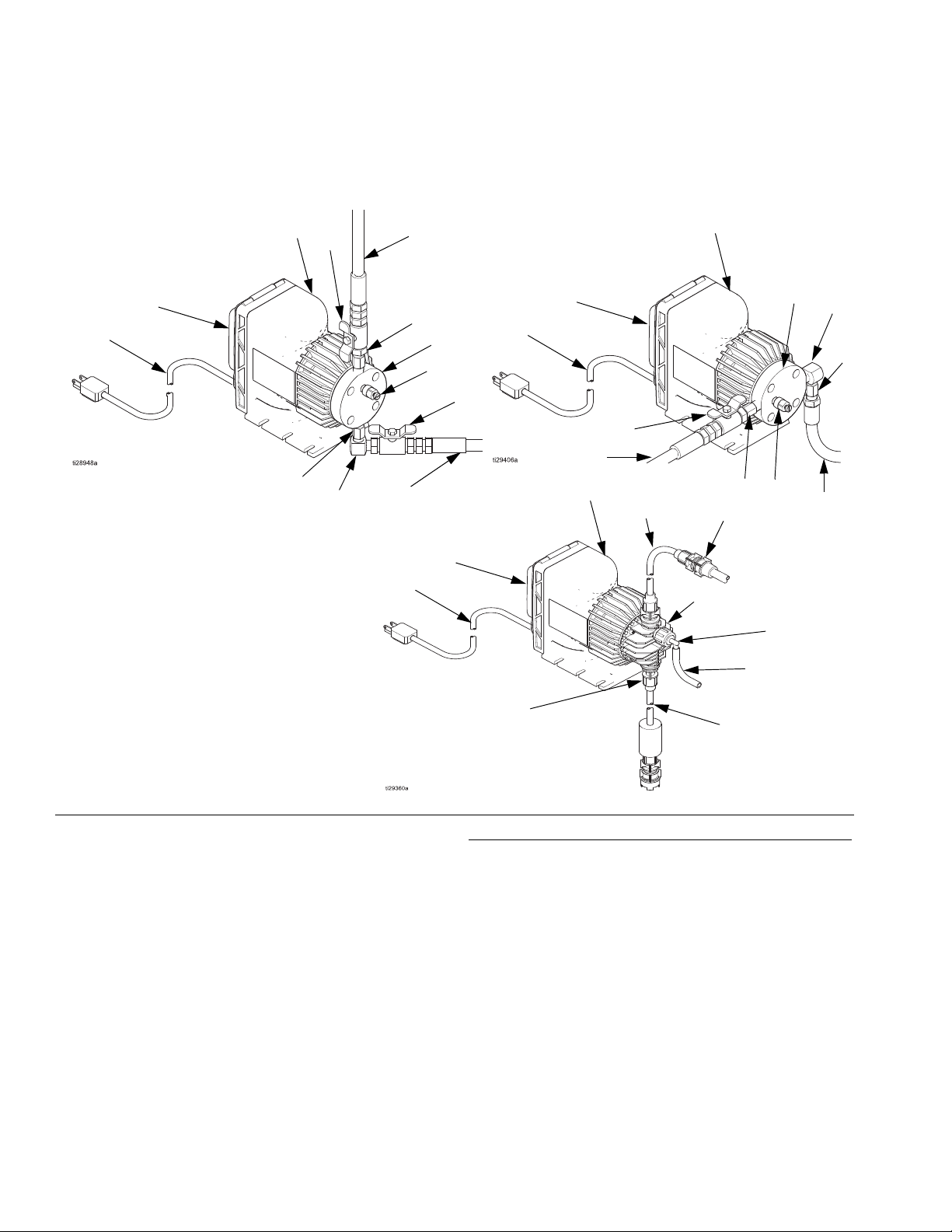

Stainless Steel Fluid End

Plastic Fluid End

(Models A21000, A21001, A21004, A21016)

(Models A21008, A21009, A21010,

A21011, A21012, A21013, A21014,

A21015)

Standard Configuration

Alternate Configuration

Clear

tubing

White

tubing

White

tubing

Component Identification

FIG. 2: Component Identification

Components Supplied by Graco

The following components are supplied by Graco:

1 Motor Assembly

2 Inlet Valve (stainless steel fluid end)

3 Outlet Valve (stainless steel fluid end)

4 Prime/Bleed Valve (stainless steel fluid end; not available

on A21001)

9 Stainless Steel Fluid End

11 Elbow Fitting (stainless steel only; not supplied with

A21001)

102 Inlet Valve Assembly (plastic fluid end, includes white tub-

6 3A4131H

ing)

103 Outlet Valve Assembly (plastic fluid end, includes white tub-

ing)

104 Prime/Bleed Valve Assembly (plastic fluid end, includes

clear poly tubing)

109 Plastic Fluid End

A Control Panel

B Power Cord

Components Supplied by Customer

The following components are required to be supplied by the

customer:

C Shutoff Valve (inlet/outlet, stainless steel fluid end)

D Inlet Fluid Line (stainless steel fluid end)

E Outlet Fluid Line (stainless steel fluid end)

Page 7

Installation

E

Use PTFE tape on

these threads only

Pipe Cross

Section

Injection

Check Valve

Do not use

PTFE tape here

Mounting and Chemical Supply

Connection

Failure of the diaphragm or a rupture in the fluid lines

may cause exposure to toxic fumes or a loss of solution in the tank. Install a fluid line shutoff valve as

close to the chemical tank as possible to minimize the

loss of, and exposure to, potentially toxic chemicals.

Flooded Suction Mounting

The fluid end (9) of the pump, shown in FIG. 2, is set up

to accommodate mounting of the pump next to the

chemical supply container (G), shown in F

NOTE: The inlet valve (2 or 102) must be kept in a vertical position for proper operation. The fluid end (9 or 109)

can be removed and rotated 90° if needed.

Suction Lift Mounting (Plastic Fluid Section

only)

IG. 4.

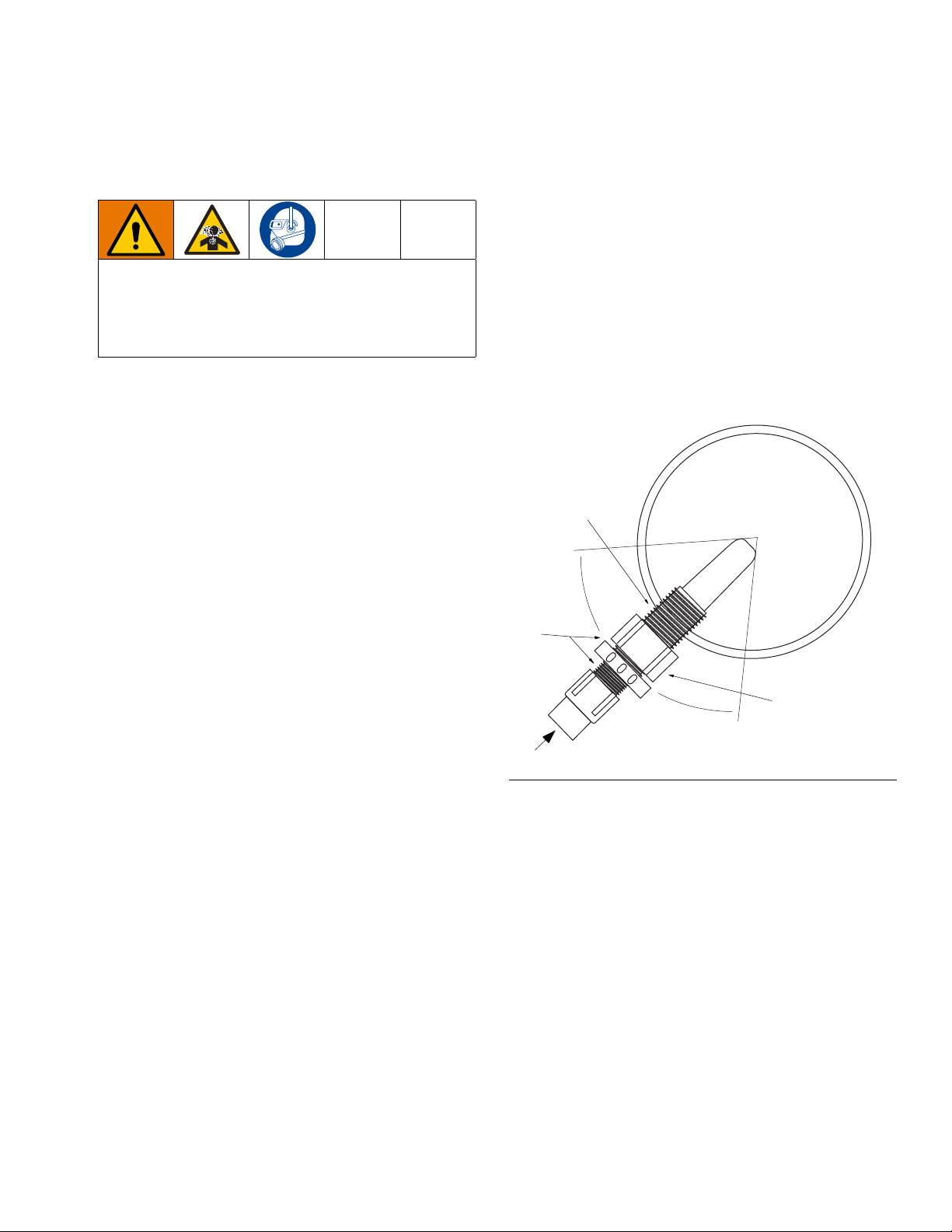

Injection Check Valve Connection (Plastic

Fluid Section only)

The injection check valve is designed to prevent a back

flow and to inject chemical into a piping system. This

valve must be mounted within 45° of vertical (see F

3).

1. Install the 1/2 in. NPT end into the piping system.

Apply PTFE tape to this end only.

2. Connect the outlet fluid line (E) from the Mongoose

pump to the to the other end of the injection check

valve.

IG.

The pump is mounted on top of a chemical supply container, shown in F

pump to the bottom of the container does not exceed

5 ft.

A weight is provided to hold the inlet fluid line (D) and

foot valve (H) in a vertical position at the bottom of the

container. Keep the inlet fluid line (D) relatively short,

and avoid high spots or bends.

NOTE: Do no allow the foot valve (H) to lie horizon ta lly

in the tank. This defeats the action of the valve and

causes the pump to lose prime.

IG. 4, so that the distance from the

FIG. 3: Injection Valve Connection

Three-Function Valve Injection Assembly

(Plastic Fluid Section only; Optional)

The optional three-function valve injection assembly

provides three functions in one injection valve asse mbly.

• Anti-siphon - which allows metering of liquids into

the inlet side of a circulating pump. It provides protection against an accidental application of suction

pressure at the fluid injection point. A PTFE coated

diaphragm provides a positive anti-siphon action.

• Back pressure - which permits metering into atmospheric discharge (such as an open container) without overpumping.

• Line check - which permits removal of outlet tubing

without release of system fluid.

3A4131H 7

Page 8

Installation

C

E

B

F

C

D

G

C

Flooded Suction Installation

Suction Lift Installation

G

H

D

E

F

No more than

5 ft. from pump

to bottom of

container

Typical Installation

FIG. 4: Typical Installation

FIG. 4 shows two examples of an installation with a Mongoose chemical metering pump. Your installation may differ

from what is shown here. The Mongoose pump (F) and the attached power cord (B) are the only components in F

4 supplied by Graco. All other components are supplied by customer.

Key:

B Power Cord

C Shutoff Valve (Inlet/Outlet)

D Inlet Fluid Line

E Outlet Fluid Line

F Mongoose Pump

G Chemical Supply Container

HFoot Valve

IG.

8 3A4131H

Page 9

Operation

Operation

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as splashing fluid, follow the

Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or servicing the

equipment.

NOTE: Always discharge fluid into an approved container or location.

1. Turn SPEED knob (H) to off and disconnect power

cord (B).

2. Shut off the inlet and outlet lines using shutoff

valves (C).

3. Slowly crack the fitting connected to the outlet check

valve to relieve downstream fluid pressure.

4. Run the pump until the dispensed fluid is predominately flushing fluid.

5. Follow the Pressure Relief Procedure.

Prime the Pump

1. Connect power (B) to the pump.

2. Set the STROKE % knob (J) to 100%. (See F

on page 10.)

3. Set the SPEED knob (H) to maximum cycles per

second.

While pump is operating, if fluid begins moving, no further priming is required.

If fluid is not moving, open prime/bleed valve (4 or 104)

approximately one turn until fluid begi ns to move. When

the inlet fluid line (D) fills, close prime/bleed valve (4 or

104).

IG. 5

Flush the Equipment

To avoid fire and explosion, always ground e quipment

and waste container. To avoid static sparking and

injury from splashing, always flush at the lowest possible pressure.

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted par ts.

1. Follow the Pressure Relief Procedure.

2. Connect inlet fluid line (D) to the supply source of

the flushing fluid.

3. Connect outlet fluid line (E) to a waste container.

NOTICE

Do not overtighten prime/bleed valve. Damage may occur.

3A4131H 9

Page 10

Operation

J

H

Adjust Feed Rate

The Mongoose pump allows for the exact setting of the

pump’s SPEED knob (H) on the pump’s control panel.

IG. 5.

See F

Adjust Stroke Length

The stroke length can be adjusted on the Mongoose

pump. This is a mechanical adjustment made using

STROKE % knob (J) on the control panel.

NOTICE

To avoid damage to the pump, this adjustment

should only be made while the pump is running at a

high-stroking rate.

Calculate Output

A pump’s output per minute can be determined by dividing the maximum rated gallons per day by 1440 (minutes per day).

For example, a 30 gallons per day (gpd) pump at a maximum stroke length and speed setting of 125 cycles per

minute (cpm) will pump 0.000167 gallons per stroke

(gps).

30 gpd ÷ 1440 min/day = 0.0208 gpm ÷ 125 spm =

0.000167 gal/stroke

FIG. 5: Mongoose Control Panel

NOTE: Standard cycles per minute settings available

are: 1, 2, 3, 4, 5, 6, 7, 8, 10, and increase by 5 thereafter

up to the maximum of 125.

With this value and the pump’s speed setting (cycles pe r

minute) you can calculate your pump’s output at it’s

rated pressure.

A 30 gpd pump set at 50 cycles per minute:

50 cpm x .000167 gps x 1440 min/day = 12.02 gpd

Reducing the stroke length will reduce the pump’s output again. If the example pump above had it’s str ok e

length reduced to 50% the 12.02 gallons per day ou tput

is reduced to 6.01. (Example: 12.02 gpd x 0.50 = 6.01

gpd).

A higher product viscosity will reduce the output. Pressures lower than the pump’s rating can increase the output.

10 3A4131H

Page 11

Troubleshooting

Problem Cause Solution

Troubleshooting

1. Follow Pressure Relief Procedure, page 9, before

checking pump.

Pump does not achieve or maintain

prime

Insufficient fluid Stroke adjustment set too low Check operation of STROKE %

Air trapped in inlet line Straighten inlet line to eliminate high

spots.

Worn or contaminated check valves Inspect check valves in fluid end for

cleanliness.

Excessive lift Verify the appropriate lift for the liquid

being pumped. Maximum suction lift

is 5 ft. with water or liquids of similar

specific gravity; though less with

heavier liquids, such as acids. Mount

the pump in a lower position relative

to the chemical container.

Suction fittings not properly tightened Check fittings. Overtightening may

cause restriction. Conversely, if any

leakage occurs, the pump will suck

air and fail to prime.

Split or pinch in inlet tube Inspect inlet tube through its full

length to assure there are no splits at

the connections or other restrictions.

Move objects or equipment which

impinges upon the inlet tube, or

reroute as required to assure a

smooth transition from foot valve to

pump.

Low chemical level Check fluid level in chemical supply

tank.

knob. If pump delivers too low adjustable rate, check settings. Readjust as

required.

Worn or contaminated check valves Inspect, clean, or replace as neces-

sary.

Obstruction in inlet line Check inlet line for obstructions, clog-

ging, kinks, or pinch points.

Clogged foot valve screen Clean or replace foot valve screen.

Output (system) pressure too high Relocate the injector to a lower pres-

sure part of the system.

Diaphragm worn or torn Replace diaphragm.

Blown fuse Replace fuse with like kind.

3A4131H 11

Page 12

Troubleshooting

Problem Cause Solution

Excessive fluid Excessive stroke rate Lower the stroke rate if adjustable on

your pump.

Improper stroke length Reduce stroke length.

Pump will not pump System pressure too high Check system pressure to assure

that it is within system-rated parameters of the pressure.

Diaphragm improperly installed Ensure the diaphragm is screwed

fully onto shaft.

Check valves worn or clogged Clean or replace as required.

Pump will not run Pump not turned on or plugged in Check outlet with meter to assure

that correct voltage is present, and

that power supply cord is in good

condition and plugged in.

Blown fuse Replace fuse with like kind.

Excessive noise Pump not primed Prime pump.

12 3A4131H

Page 13

Repair

Repair

Stainless Steel Fluid End

Repairs

NOTE: The following procedures apply only to models

with stainless steel fluid ends (A21000, A21001,

A21004, and A21016).

Replacing the Diaphragm

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Drain the fluid from the outlet fluid line (E).

5. Disconnect the outlet fluid line (E).

6. Remove the four fluid end screws (10) from the fluid

end (9).

7. Remove the fluid end from the motor assembly (1).

Replacing the Inlet Valve

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Close the inlet shutoff valve (C).

5. Disconnect the shutoff valve (C) from the inlet

valve (2); or elbow fitting (11), if attached.

6. Remove the elbow fitting (11), if attached. Inspect

and replace, if necessary.

7. Remove the inlet valve (2) from the fluid end (9).

Inspect the inlet valve and replace, if necessary.

8. Apply PFTE tape on the threads of the inlet

valve (2).

9. Reattach the inlet valve (2) to the fluid end (9).

NOTE: The inlet valve (2) has flow arrow that must point

towards the fluid end (9).

10. Reattach the elbow fitting (11), if used, to the inlet

valve (2).

8. Unscrew the diaphragm (7) counterclockwise from

the pump shaft.

9. Inspect the pump shaft and support ring (8) for damage.

10. Screw the new diaphragm (7) clockwise onto the

pump shaft.

11. Replace the fluid end (9) and the four screws (10).

Tighten the screws evenly.

12. Reconnect the outlet fluid line (E).

13. Reconnect power (B).

14. Prime the Pump, page 9.

NOTE: Tighten fluid end screws (10) after the pump’s

initial week of operation.

11. Reconnect the shutoff valve (C).

12. Reconnect the power (B).

13. Prime the Pump, page 9.

3A4131H 13

Page 14

Repair

Replacing the Outlet Valve

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Close the inlet shutoff valve (C).

5. Disconnect the shutoff valve (C) from the outlet

valve (3).

6. Remove the outlet valve (3) from the fluid end (9).

Inspect and replace, if necessary.

7. Apply PTFE tape on the threads of the outlet

valve (3).

8. Reattach the inlet valve (3) to the fluid end (9).

NOTE: The outlet valve (3) has flow arrow that must

point away from the fluid end (9).

9. Reconnect the shutoff valve (C).

10. Reconnect the power (B).

11. Prime the Pump, page 9.

Replacing the Prime/Bleed Valve

Plastic Fluid End Repairs

NOTE: The following procedures apply only to models

with plastic fluid ends (A21008, A21009, A21010,

A21011, A21012, A21013, A21014, A21015).

Replacing the Diaphragm

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Drain the fluid from the outlet fluid line (E).

5. Disconnect the outlet fluid line (E).

6. Remove the four fluid end screws (110) from the

fluid end (109).

7. Remove the fluid end (109) from the motor assembly (1).

8. Unscrew the diaphragm (7) counterclockwise from

the pump shaft.

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Close the inlet shutoff valve (C).

5. Remove the prime/bleed valve (4) from the fluid end

(9). Inspect and replace, if necessary.

6. Apply PTFE tape on the threads of the prime/b le ed

valve (4).

7. Reattach the prime/bleed valve (4) to the fluid

end (9).

8. Reconnect the power (B).

9. Prime the Pump, page 9.

9. Inspect the pump shaft and support ring (8) for damage.

10. Screw the new diaphragm (7) clockwise onto the

pump shaft.

11. Replace the fluid end (109) and the four screws

(110). Tighten the screws evenly.

12. Reconnect the outlet fluid line (E).

13. Reconnect power (B).

14. Prime the Pump, page 9.

NOTE: Tighten fluid end screws (110) after the pump’s

initial week of operation.

14 3A4131H

Page 15

Repair

Ball check cartridge in this end of valve

3/8 in.

1/4 in.

Replacing the Inlet Valve

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Remove the inlet valve (102) from the from the fluid

end (109).

5. Remove the o-ring from the inlet port of the fluid

end (109).

6. Reattach the inlet valve (102) to the fluid en d (1 09 ) .

7. Reconnect the power (B).

8. Prime the Pump, page 9.

Replacing the Outlet Valve

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

Replacing the Valve Ball Check Cartridge

The following procedure is the same for all plastic valve

assemblies: inlet (102), outlet (103), foot (111), injection

(112), and three-function (113). See the Model A21008

(Plastic Fluid End) shown parts diagram on page 18.

Follow the Pressure Relief Procedure, page 9. is

explained on page 15.

The part of the valve that holds the ball check cartridge

is interchangeable among each of the valve assemblies.

The ball check cartridge is in the end away from any

connected tubing. See F

IG. 6.

4. Remove the outlet valve (103) from the from the

fluid end (109).

5. Remove the o-ring from the outlet port of the fluid

end (109).

6. Reattach the outlet valve (103) to the flui d

end (109).

7. Reconnect the power (B).

8. Prime the Pump, page 9.

FIG. 6: Location of Valve Ball Check Cartridge

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Disconnect the valve at the end away from the tubing. Verify that the ball check o-ring is still attached

to, or came out with, the ball check cartridge (114).

5. Use a hooked tool to pull out the ball check

cartridge (114). Verify that the second o-ring is not

left in the valve.

6. Discard the ball check cartridge (114) and o-rings.

7. Attach new o-rings to both ends of the new ball

check cartridge (114).

3A4131H 15

Page 16

Repair

NOTICE

To ensure the proper function of the pump and to

avoid potential damage, consider the direction of flow

before inserting the ball check cartridge (114) into the

valve. The cartridge has a hole on each end, with one

being larger than the other. The cartridge needs to be

oriented so that the flow goes in the larger hole and

out the smaller.

8. Insert the ball check cartridge (114), with o-rings,

into the end of the valve.

9. Reconnect the valve.

10. Repeat steps 4-9 for each valve ball check cartridge

(114) being replace.

11. Reconnect the power (B).

12. Prime the Pump, page 9.

Replacing the Fluid End Ball Check

Cartridges

The following procedure applies only to the two ball

check cartridges (114 and 115) in the plastic fluid end

(109). Replacing the Valve Ball Check Cartridge is

explained on page 15.

NOTICE

To ensure the proper function of the pump and to

avoid potential damage, consider the dire ction of flow

before inserting each ball check cartridge (114 and

115) into the fluid end ports. Each cartridge has a

hole on each end, with one being larger than the

other. The cartridges need to be oriented so that the

flow goes in the larger holes and out the smaller.

8. Insert the ball check cartridge (114), with o-rings,

into the inlet port of the fluid end (109).

9. Reconnect the inlet valve (102) to the inlet port on

the fluid end (109).

10. Align the priming hole on the side of the ball check

cartridge (115) with the prime/bleed valve (104)

before inserting the cartridge (115) into the outlet

port of the fluid end (109).

11. Reconnect the outlet valve (103) to the outlet port

on the fluid end (109).

12. Reconnect the power (B).

13. Prime the Pump, page 9.

Replacing the Prime/Bleed Valve

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Disconnect both the inlet valve (102) and the outlet

valve (103) at the end away from their respective

tubing.

5. Use a hooked tool to pull the ball check cartridges

(114 and 115) from the inlet and outlet ports,

respectively, of the fluid end (109). Verify that both

o-rings on both cartridges are removed.

6. Discard the ball check cartridges (114 and 115) and

o-rings.

7. Attach new o-rings to both ends of each new ball

check cartridge (114 and 115).

1. Follow the Pressure Relief Procedure, page 9.

2. Flush the Equipment, page 9.

3. Disconnect the power (B).

4. Remove the prime/bleed valve (104) from the fluid

end (9). Inspect and replace, if necessary.

5. Reattach the prime/bleed valve (104 ) to th e flu id

end (109).

6. Reconnect the power (B).

7. Prime the Pump, page 9.

16 3A4131H

Page 17

Parts

2

1

3

4†

7

5

8

9

10

1

1

Apply PTFE tape to threads

1

11‡

6

(opposite ref. 5)

Mongoose Metering Pump

Model A21000 (Stainless Steel Fluid End) shown

Parts

Mongoose Metering Pump Parts List (Stainless Steel Fluid End)

Ref. Part Description Qty

1 -- Motor assembly 1

2 B32279 Inlet check valve 1

3 B32280 Outlet check valve 1

4† B32191 Prime/bleed valve 1

5 -- Branding label 1

6 17M292 Warning label 1

7 B32281 Diaphragm; 75, 110 psi 1

B32282 Diaphragm; 150, 250 psi 1

8 -- Support ring 1

9 -- Fluid end 1

10 -- Fluid end screws 4

11‡ 17M529 Elbow fitting 1

3A4131H 17

Replacement Warning label is available at no cost.

† Not available with A21001.

‡ Not provided with A21001.

Page 18

Parts

1

103*

104*

7*

5

8

109*

110*

1

6

(opposite ref. 5)

102*

112

114

115

114

114

111

Apply PTFE tape only to

threads on the end of the injection

valve assembly.

1

Weight

Priming Hole

Model A21008 (Plastic Fluid End) shown

18 3A4131H

Page 19

Kits and Accessories

Mongoose Metering Pump Parts List

(Plastic Fluid End)

Ref. Part Description Qty

1 -- Motor assembly 1

5 -- Branding label 1

6 17M292 Warning label 1

7* B32281 Diaphragm; 75, 110 psi 1

B32282 Diaphragm; 150, 250 psi 1

8 -- Support ring 1

102* B32290 Inlet check valve assembly, 3/8

in. (includes tubing)

B32291 Inlet check valve assembly, 1/4

in. (includes tubing)

103* B32292 Outlet check valve assembly,

3/8 in. (includes tubing)

B32293 Outlet check valve assembly,

1/4 in. (includes tubing)

104* B32296 Prime/bleed valve assembly

(includes clear poly tubing)

109* -- Fluid end 1

110* -- Fluid end screws 4

111 B32288 Foot valve assembly, 3/8 in. 1

B32289 Foot valve assembly, 1/4 in. 1

112 B32286 Injection valve assembly, 3/8 in. 1

B32287 Injection valve assembly, 1/4 in. 1

113 B32294 Three-function valve assembly,

3/8 in. (not shown)

B32295 Three-function valve assembly,

1/4 in. (not shown)

114† B32298 Ball check cartridge assembly 5

115† B32299 Ball check cartridge assembly,

with priming hole

1

1

1

1

1

1

1

1

Kits and Accessories

Part No. Description

B32283* Pump Kit, 110 psi, 3/8 in. tubing

B32284* Pump Kit, 150 psi, 3/8 in. tubing

B32285* Pump Kit, 250 psi, 1/4 in. tubing

B32297† Ball Check Kit (six ball check cartridge

assemblies)

* Includes 7, 102, 103, 104, 109, and 110.

† Includes 114 and 115.

Replacement Warning label is available at no cost.

* Included in Pump Kits B32283, B32284, and

B32285.

† Included in Ball Check Kit B32297.

3A4131H 19

Page 20

Dimensions

Dimensions

FIG. 7: Mongoose Pump Dimensions

A B C D

10.6 in.

(26.9 cm)

20 3A4131H

7.5 in.

(19.0 cm)

5.0 in.

(12.7 cm)

4.13 in

(10.5 cm)

Page 21

Technical Data

Mongoose Chemical Metering Pump

US Metric

Maximum fluid working pressure See Models and Approvals, page 2.

Maximum cycle rate (A21011 & A21015) 160 cpm

Maximum cycle rate (all except A21011 &

A21015)

Input Voltage (A21016) 10.5 - 16.0 VDC

Input Voltage (A21000, A21001, A21008,

A21009, A21010, A21011)

Input Voltage (A21004, A21012, A21013,

A21014, A21015)

Rated Amperage .35 A

Fuse Fast Blow 3A Barrel Style 314

Environmental temperature range -40°– 120°F -40°– 50°C

Inlet/Outlet Sizes

Stainless Steel Fluid Section

Fluid inlet/outlet size (A21000, A21001,

A21004, A21016)

Prime/bleed size 1/16 in. NPT

Plastic Fluid Section

Fluid inlet/outlet size (A21008 & A21012) 1/4 in. tubing

Fluid inlet/outlet size (A21009, A21010,

A21011, A21013, A21014, A21015)

Prime/bleed size 1/16 in. clear poly tubing

Wetted Parts

Diaphragm Seal Material PTFE

Check Valve Seal Material Plastic Fluid Sec-

tion

Check Valve Seal Material Stainless Steel

Fluid Section

Weight

All models 10 lbs. 4.5 kg

95 - 135 VAC; 50/60 Hz

(100 - 120 VAC recommended)

195 - 260 VAC; 50/60 Hz

(210 - 250 VAC recommended)

125 cpm

1/4 in. NPT

3/8 in. tubing

FKM

FFKM

Technical Data

3A4131H 21

Page 22

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2016, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A4131

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision H,

June 2019

Loading...

Loading...