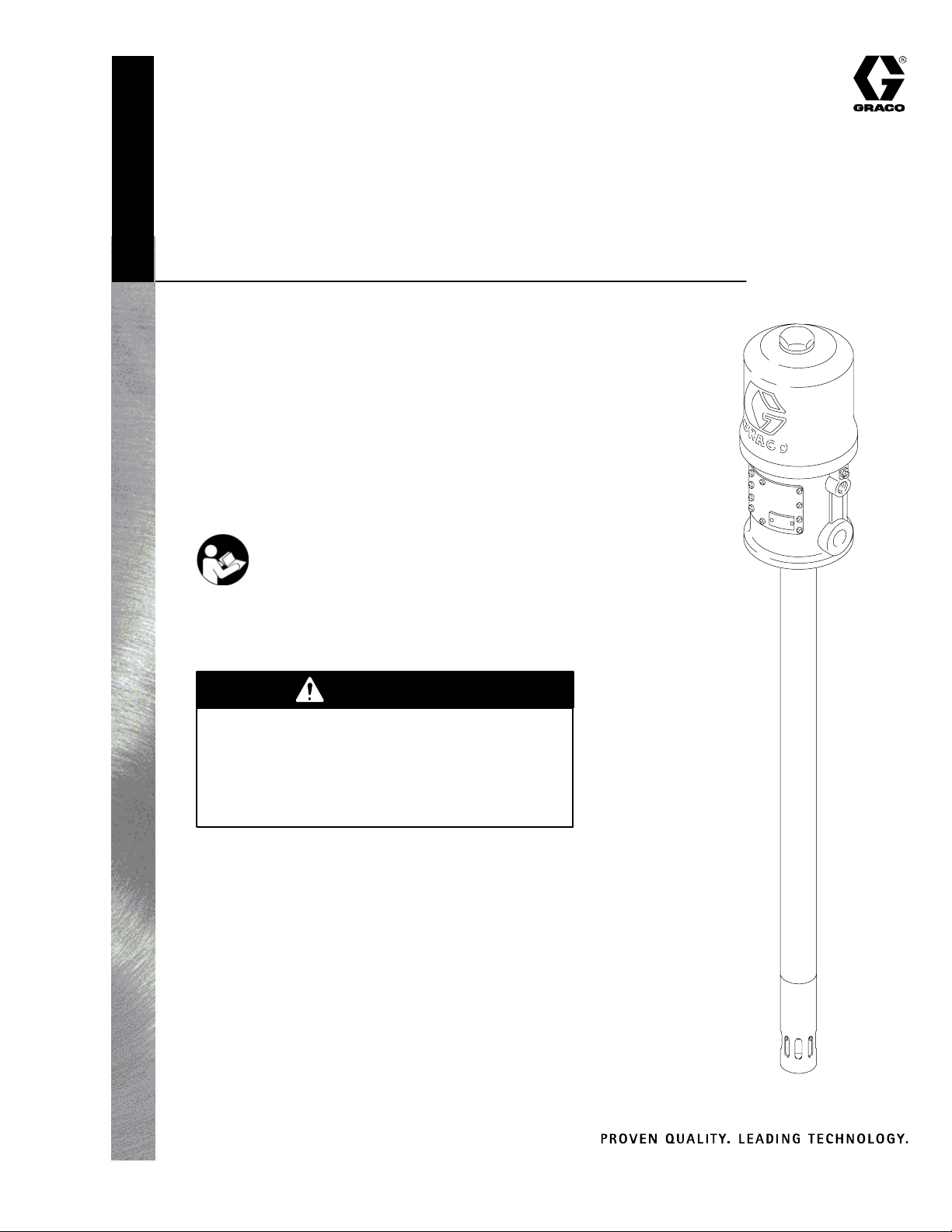

Graco 965129, 965124 User Manual

Instructions – Parts List

10:1 Fire–Ballr 425 Pump

Low–pressure, medium volume pump used to transfer grease.

1800 psi (12.4 MPa, 124 bar) Maximum Working Pressure

180 psi (1.3 MPa, 13 bar) Maximum Air Inlet Pressure

Model No. 965124, Series B, Stubby length

Model No. 965129, Series B, 400 lb (180 Kg) drum length

For Closed Drum Mounting

309407E

EN

Important Safety instructions.

Read all warnings and instructions in this manual.

Save these instructions.

WARNING

This pump is designed to be used only in pumping

non-corrosive and non-abrasive lubricants. Any

other use of the pump can cause unsafe operating

conditions and component rupture, which can result in fluid injection or other serious injury or fire or

explosion.

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

TI2146A

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

SKIN INJECTION HAZARD

High–pressure fluid from dispense device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgi-

cal treatment.

Parts 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 18. . . . . . . . . . . . . . . . . . . . . .

Graco Information 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not point the dispensing device at anyone or any part of the body.

D Do not put your hand over the end of the fluid outlet.

D Do not stop or deflect leaks with your hand, body, glove, or rag.

D Follow the Pressure Relief Procedure on page 7 before you clean, check, or service the

equipment.

D Tighten all fluid connections before operating the equipment.

D Check the hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the pump.

D Before checking or servicing the equipment, follow the Pressure Relief Procedure on page 7 to

prevent the equipment from starting unexpectedly.

2 309407

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment and the object being dispensed to. Refer to Grounding on page 5.

D If there is any static sparking or you feel an electric shock while using this equipment, stop dis-

pensing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Keep the dispensing area free of debris, including solvent, rags, and gasoline.

D Do not smoke in the dispensing area.

D Do not turn on or off any light switch in the area while dispensing if fumes are present.

D Never use 1.1.1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state, and national guidelines.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

D The air motor exhausts any fluids added to the input air.

D Graco does not manufacture or supply the reactive chemical components that may be used in this

equipment and is not responsible for injury or property loss, damage, expense, or claims (direct or

consequential) that arise from the use of such chemical components.

3309407

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure stated on the equipment or in the Technical Data

for your equipment. Do not exceed the maximum working pressure of the lowest rated component

in your system.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Handle hoses carefully. Do not pull on hoses to move equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 66_C (150_F) or below –40_C (–40_F).

D Wear hearing protection when operating this equipment.

D Do not move or lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

4 309407

Installation

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing.

NOTE: Always use Genuine Graco Parts and

Accessories, available from your Graco distributor.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section FIRE OR EXPLOSION HAZ-

ARD on page 3.

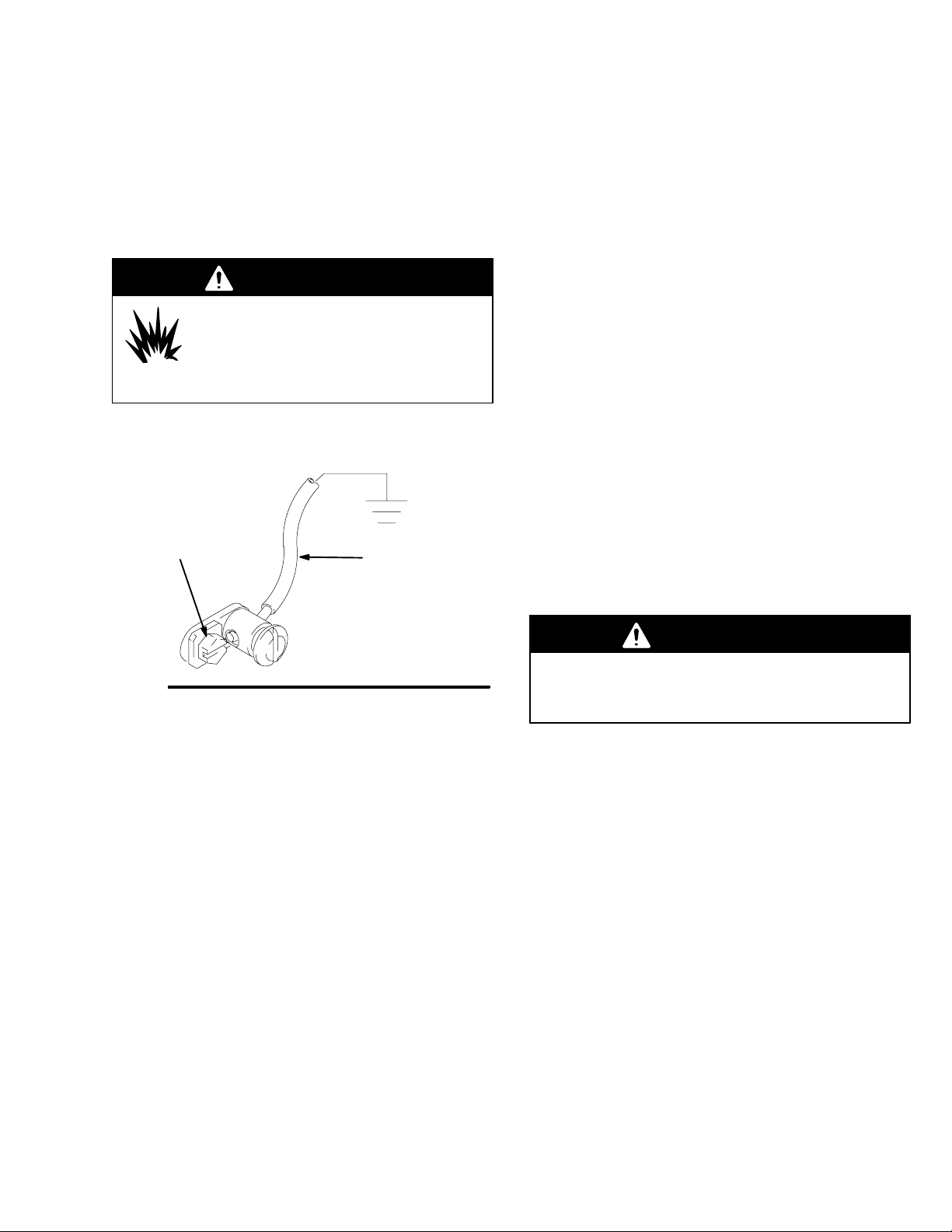

D Pump: Use a ground wire and clamp as shown

below.

Z

Y

D Dispensing valve: Ground through connection to a

properly grounded fluid hose and pump.

D Object being dispensed to: Follow your local code.

D Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the pail

on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

D To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the

dispensing gun firmly to the side of a grounded

metal pail, then trigger the gun to ground the pump.

To ground the pump, remove the ground screw (Z)

and insert through the eye of the ring terminal at end of

ground wire (Y). Fasten the ground screw back onto

the pump and tighten securely. Connect the other end

of the ground wire to a true earth ground. See Fig. 1.

To order a ground wire and clamp, order Part No.

222011.

Fig. 1

D Air and fluid hoses: Use only electrically conductive

hoses.

D Air compressor: Follow manufacturer’s

recommendations.

TI1052

Mounting the Pump

WARNING

Mount the pump securely so that it cannot move

around during operation. Failure to do so could

result in personal injury or equipment damage.

D Select a convenient location for the equipment to

ensure easy operator access to the pump air

controls, sufficient room to change supply

containers, and a secure mounting platform.

D If you are mounting the pump directly on the supply

tank, position the pump so its intake valve is no

more than 1 in. (25 mm) from the bottom of the

container. Mount the pump to the cover or other

suitable mounting device.

5309407

Installation

Mount the pump to suit the type of installation planned.

Very heavy lubricants may require an inductor plate.

See page 16 for the mounting hole layout and

dimensions

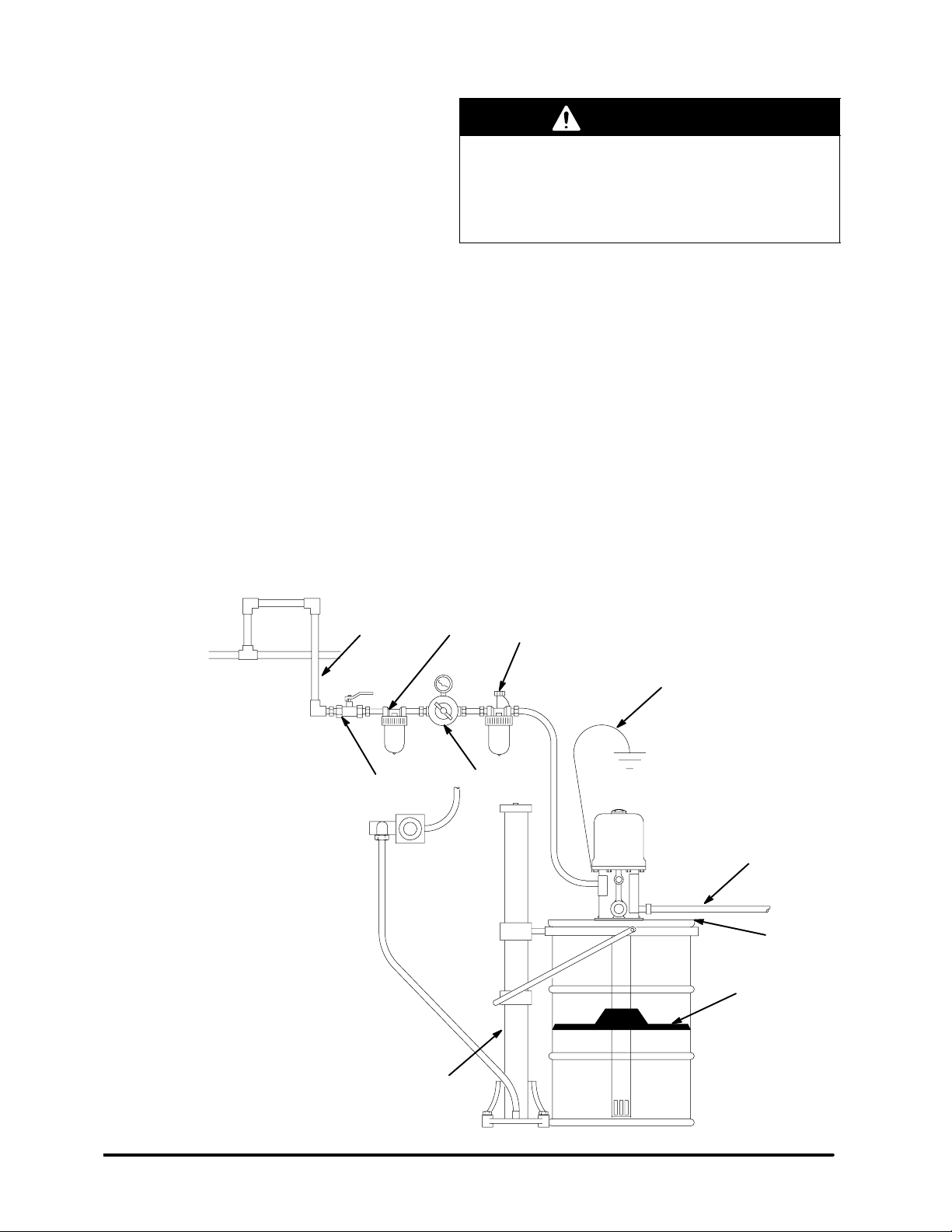

Install the air line accessories in the approximate order

shown in the Typical Installation. Install a bleed-type

master air valve (B) within easy reach of the pump,

upstream from the air regulator. Install an air filter (C)

to remove harmful dirt and moisture from your

compressed air supply. For automatic air motor

lubrication, install an air line oiler (D) close to the pump

air inlet. Install an air regulator (E) to control pump

speed.

Typical Installation

Key

A

Grounded Air Line

B

Bleed-type Master Air Valve

C

Air Filter

D

Air Line Oiler

E

Air Regulator

F

Grounded Dispensing Hose

H

Elevator Assy. 241663

J

Ground Wire

K

Follow Plate 223701

L

Drum Cover 200326

A

WARNING

A bleed-type master air valve (B) is required to

shut off and relieve air pressure that may be

trapped in the air motor. Trapped air could cause

the pump to cycle unexpectedly and cause serious

bodily injury, including amputation.

Be sure the air hose is properly sized to deliver an

adequate supply of air to the motor. Refer to the

Technical Data on page 17.

Connect a dispensing hose to the 3/4 npt(f) pump

outlet. Install an appropriate gun or dispensing valve to

the hose.

Ground the pump as explained on page 5.

C

D

J

Fig. 2

6 309407

B

E

F

L

K

H

TI2371A