Page 1

Instructions

®

Dyna-Star

HP Vent

332519F

Valve Kit

Used with the Dyna-Star HP or HF Pump to reduce system pressure and allow injector to

reset. For professional use only.

Part No.: 77X540

Maximum Working Pressure: 3500 psi (241 bar, 24 MPa)

Important Safety Instructions

Read all warnings and instructions in this

manual and the Dyna-Star HP and HF Pump

instruction manual included with your unit. Save

all instructions.

EN

Page 2

Instructions

Instructions

Warnings

See the Dyna-Star HF and HP Pump Instruction manual

for additional warnings.

SKIN INJECTION HAZARD

High-pressure fluid from dispense device, hose leaks,

or ruptured components will pierce skin. This may look

like just a cut, but it is a serious injury that can result in

amputation. Get immediate surgical treatment.

Follow Pressure Relief Procedure in this manual,

when you stop dispensing and before cleaning, checking, or servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Over-pressurization can result in equipment rupture

and serious injury.

• A pressure relief valve is required at each pump

outlet.

• Follow Pressure Relief Procedure in this manual

before servicing.

Installation

Pressure Relief

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop dispensing and

before cleaning, checking, or servicing the

equipment.

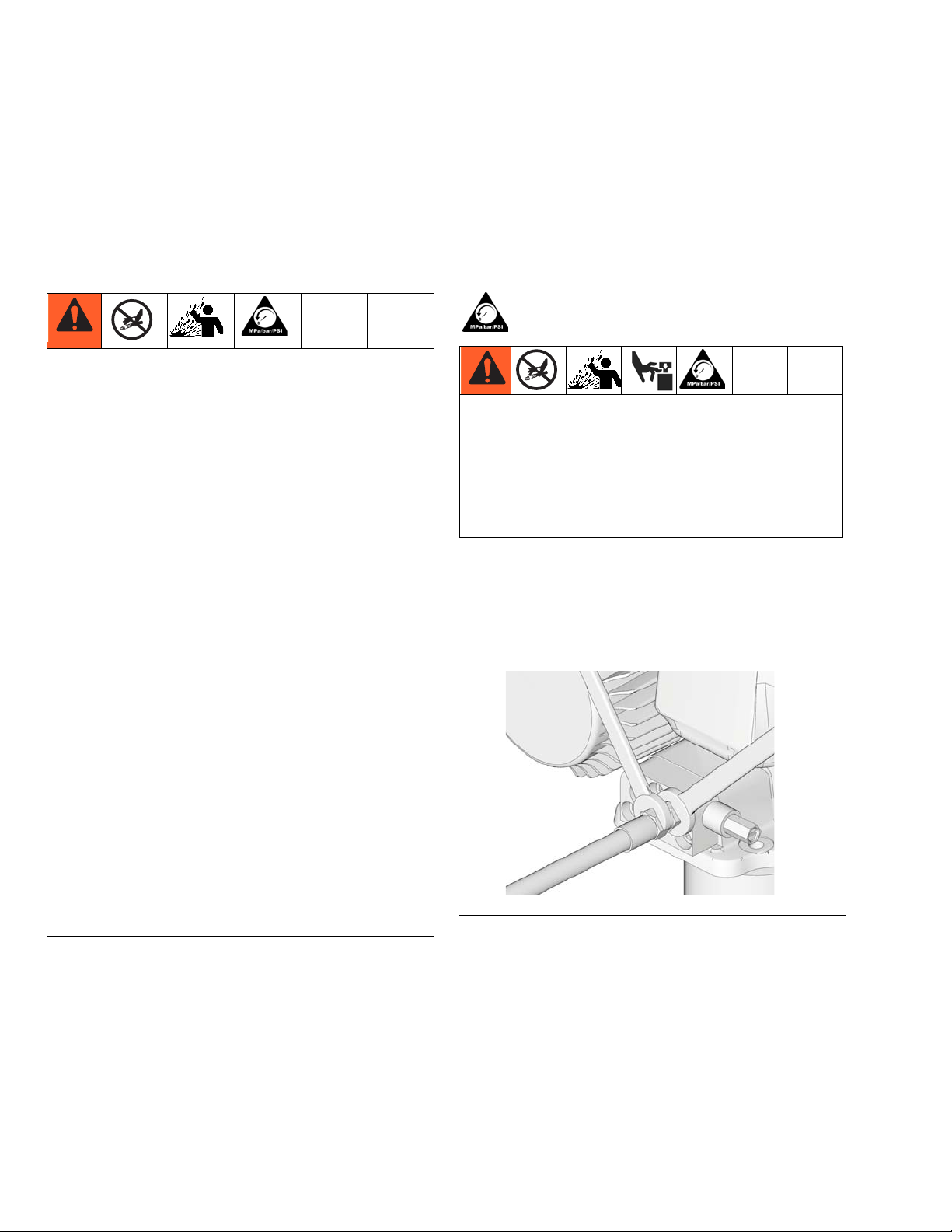

To relieve pressure in the system, use two wrenches

working in opposite directions on pump outlet fitting to

slowly loosen fitting only until fitting is loose and no

more lubricant or air is leaking from fitting as shown in

F

IG. 1.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in

pressurized equipment can cause serious chemical

reaction and equipment rupture. Failure to follow this

warning can result in death, serious injury, or property

damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents.

• Many other fluids may contain chemicals that can

react with aluminum. Contact your material supplier

for compatibility.

FIG. 1

2 332519F

Page 3

Instructions

a

b

a

c

8

Vent Valve Installation

Reference numbers used in these instructions correspond to Parts included in Kit and are provided on page

5. Parts identified with an alpha character are user provided or already installed components.

To ensure the correct pressure relief valve is used and

pressure settings are correct, always use new parts

included in your Vent Valve Kit for reassembly.

1. If unit has already been in service, relieve pressure

(see Pressure Relief procedure, page 2).

2. Disconnect Dyna-Star HP or HF pump from main

power source.

3. Remove outlet tubing from port marked “0” on the

pump adapter block (a) (F

IG. 2).

5. Loosen, remove and discard the 3 socket head cap

screws (b) from the adapter block (a) (F

IG. 3).

FIG. 3

6. Remove adapter block (a) and o-rings (c) (F

IG. 3).

Discard these parts according to state and local

codes for proper disposal. These parts will not be

used for reassembly.

7. Grease o-rings (8) and install o-rings in vent valve

block as shown in F

IG. 4.

FIG. 4

FIG. 2

4. Remove plug or inlet tubing from port marked “1” on

the pump adapter block (a) (F

IG. 2).

Clean surface of the Dyna-Star pump outlet with a

clean dry cloth. Inspect pump surface for scratches or

nicks. A scratched surface can result in fluid leakage.

332519F 3

Page 4

Instructions

4

1

10

d

c

8. Install vent valve (1) to pump surface using the 3

cap screws (4) included in the kit (F

IG. 5). Hold the

vent valve tight to the surface of the pump to ensure

o-rings stay in place during installation.Torque

screws to 17-19 ft-lbs (23-26 N.m).

FIG. 5

9. Install lubrication line to vent valve pump outlet port

marked “0” (F

IG. 6).

11. Connect cable (d) to valve cartridge (c) (F

IG. 7).

FIG. 7

12. Install other end of cable (d) to solenoid control

device.

NOTE:

• Cable (d) is available from Graco. See Accesso-

ries, page 5 for a list of available cables.

• Connector termination is a Deutsch DT-04-2P.

• Solenoid inputs are not polarity dependent.

Voltage can be applied in either direction.

FIG. 6

10. In the inlet port marked “1” (F

IG. 6) install either:

• a plug (10).

• inlet plumbing necessary to attach a fill pump.

NOTE:

• For tube-in-tube pump models, the “1” inlet can

be used as a fill port.

• For models equipped with a follower plate, without a tube-in-tube, the “1” inlet deposits grease

on top of the follower plate.

• Solenoid should be activated when the pump is

running. See wiring diagrams in pump manual

for more details.

13. Reconnect pump to main power supply.

14. Test system to ensure proper operation.

4 332519F

Page 5

Parts

1

2

8

4

3

9

10

Ref Description Qty

1 MANIFOLD, electric vent valve 1

2 VALVE, cartridge, 24VDC 1

3 VALVE, pressure relief, 3500 psi 1

4 SCREW, cap, socket, M8 x 1.25 3

8O-RING 2

9 PLUG, pipe, 1/8 in. npt 1

10 PLUG, 1/4 in. npt 1

Accessories

Part No. Description

24N402 CABLE, 6 ft, vent valve, 2 pin for vent valve

control

77X529 CABLE, power injector system only. Use

with 77X528

77X528 CABLE, power extension, 15 ft (4.6m), use

with 77X529

Parts

Technical Data

.

Vent Valve for Dyna-Star HP

US Metric

Maximum working pressure* 3500 psi 24.1 MPa, 241 bar

Inlet/Outlet Sizes

Outlet (marked “0”)

Inlet (refill - marked “1”)

Pressure Relief Valve

Factory Set Pressure 4000 psi +

Reset Pressure 80% of set pressure

Relief Rate** 0.1 gallons/minute @3500 psi 0.4 liters/minute @24.1 MPa. 241 bar

Solenoid Valve

Flow** Up to gpm 0.2 gallons/minute,

Wetted materials Zinc plated steel, carbon steel, aluminum, fluoroelastomer, polyurethane

Weight 4.0 lbs 1.8 kg

IP Rating IP65K

Solenoid Coil Resistance (DC) (Ohms) @ 68°F (20°C) Initial Current Draw (Amps)

24 VDC 28.8 0.83

40 in

250 psi 27 MPa, 275 bar + 10%

3

/minute

*Dyna-Star HP Pump Models are rated for 5000 psi (34.47 MPa, 344 bar) maximum working pressure, however,

when a vent valve is installed on the HP Pump, the maximum working pressure must be reduced to 3500 psi (24.1

MPa, 241 bar).

3/8 in. npt(f)

3/8 in. npt(f)

0.65 liters/minute

**Flow capability depends on viscosity, type of fluid, temperature, etc.

332519F 5

Page 6

Dimensions

4.95 in.

2.5 in.

1.5 in.

4.0 in.

1.5 in (3.81 cm)

(12.57 cm)

(6.36 cm)

(3.81 cm)

(10.16 cm)

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 332519

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

August 2014

Loading...

Loading...