Page 1

Instructions–Parts List

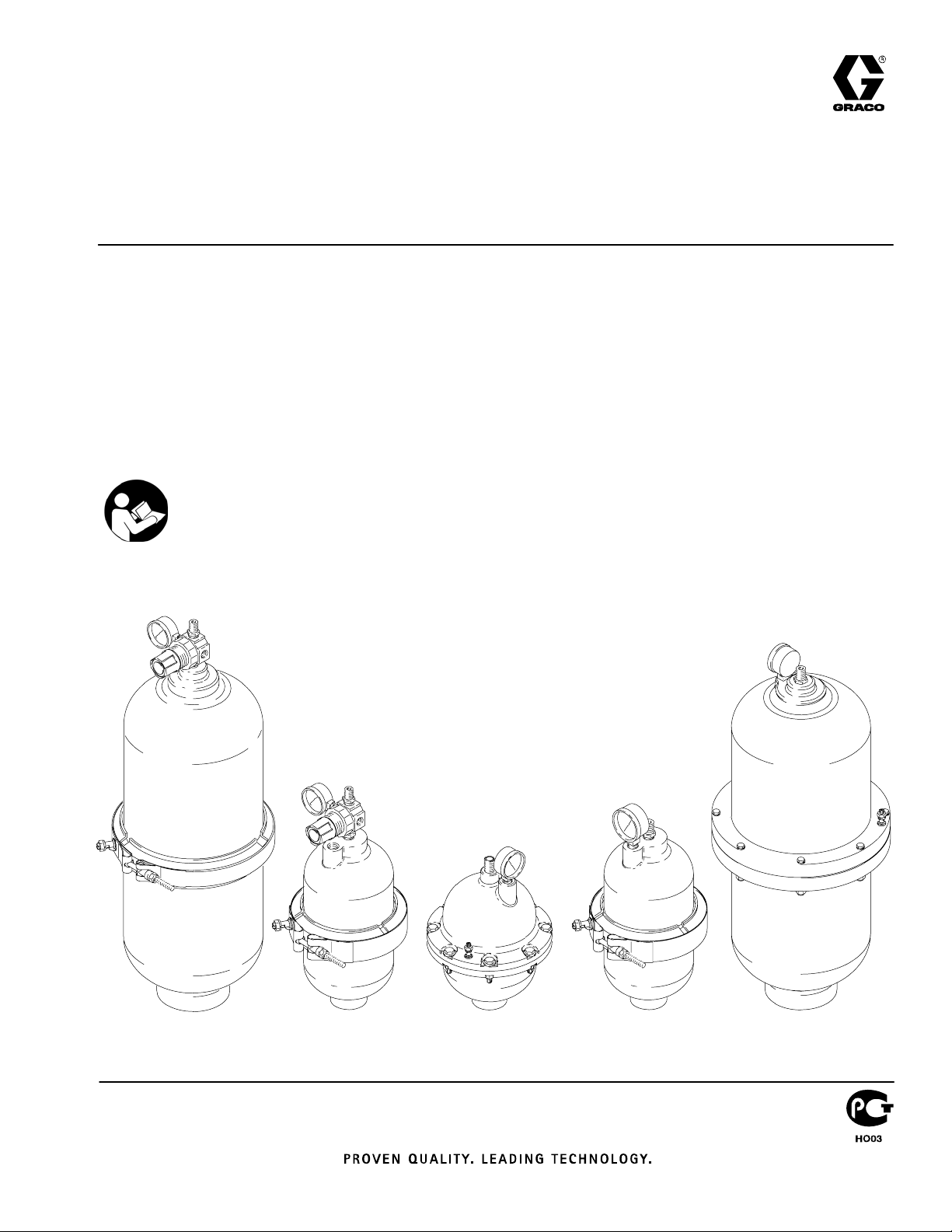

Huskyt750 and Huskyt2000

Surge Suppressors

For control of pressure fluctuations and acceleration loss,

preventing cavitation. For professional use only.

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

See the Model Numbers on page 12.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

308703G

ENG

06887

Model 239088 Model 239096Model 239095 Model 239126Model 239091

06891

06888

06892

06894

Page 2

Table of Contents

Symbols

Symbols 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model Numbers 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Matrix 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawings 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 18. . . . . . . . . . . . . . . . . . . . . .

Graco Information 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 120 psi (0.8 MPa, 8 bar) maximum working pressure and 120 psi (0.8 MPa,

8 bar) maximum incoming air pressure.

D Solvent Compatibility:

– Use fluids and solvents which are compatible with the equipment wetted parts.

– Use only compatible solvents to clean all plastic parts. Many solvents can degrade plastic

parts to the point where they could fail.

Refer to the Technical Data section of all equipment manuals. Read the fluid and solvent

manufacturer’s warnings.

D Do not use hoses to pull equipment.

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Do not operate outside the minimum and maximum operating temperature of your surge

suppressor unit. See Minimum and Maximum Operating Temperatures on page 7.

2 308703

Page 3

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

D Pipe and dispose of the exhaust air safely, away from people, animals, and food handling areas. If

the diaphragm fails, the fluid is exhausted along with the air.

D Never use an acetal pump to pump acids. Take precautions to avoid acid or acid fumes from

contacting the pump housing exterior. Stainless steel parts will be damaged by exposure to acid

spills and fumes.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Charge the surge suppressor with compressed air or nitrogen only. Do not use oxygen. Such

use could result in an explosion.

D Never pump flammable fluids with polypropylene units.

D Ground the equipment. Refer to Grounding on pages 4 and 5.

D Never use a polypropylene pump or surge suppressor with non-conductive flammable fluids as

specified by your local fire protection code. Refer to Grounding on pages 4 and 5 for additional

information. Consult your fluid supplier to determine the conductivity or resistivity of your fluid.

D If there is any static sparking or you feel an electric shock while using this equipment, stop pump-

ing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being pumped.

D Pipe and dispose of the exhaust air safely, away from all sources of ignition.

D Keep the work area free of debris, including solvent, rags, and gasoline.

D Electrically disconnect all equipment in the work area.

D Extinguish all open flames or pilot lights in the work area.

D Do not smoke in the work area.

D Do not turn on or off any light switch in the work area while operating or if fumes are present.

D Do not operate a gasoline engine in the work area.

308703 3

Page 4

Installation

Grounding

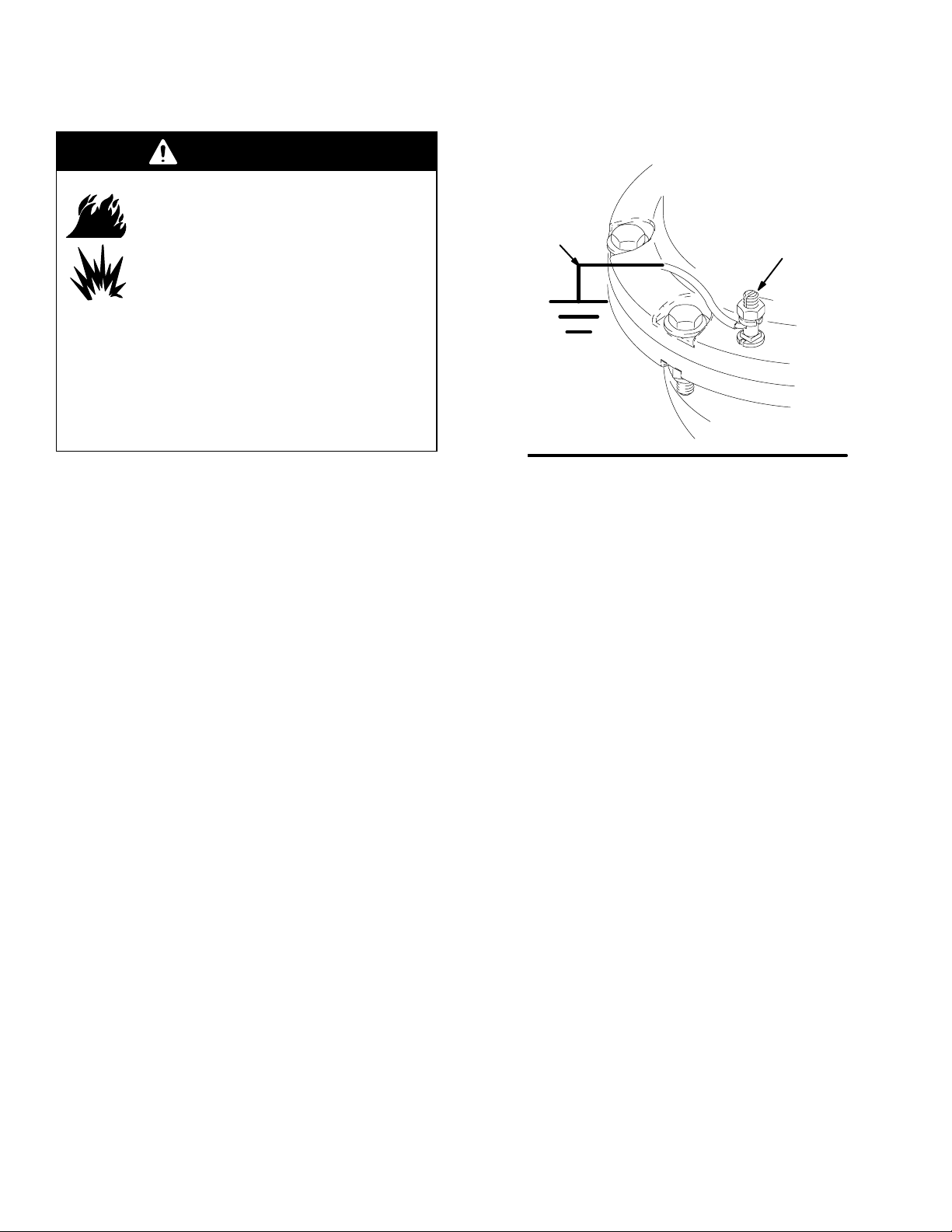

WARNING

FIRE AND EXPLOSION HAZARD

When pumping flammable fluids, the

surge suppressor must be grounded.

Before pumping, ground the system as

explained below. Also read the section

FIRE OR EXPLOSION HAZARD on

page 3.

Polypropylene surge suppressors are not

conductive. Attaching the ground wire to the

grounding lug grounds only the clamp or flange

(see Fig. 1). When pumping conductive flammable

fluids, always ground the entire fluid system by

making sure the fluid has an electrical path to a

true-earth ground.

To reduce the risk of static sparking, ground the surge

suppressor and all other equipment in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equipment. Ground all of this equipment:

D Surge suppressor: Attach a ground wire to the

grounding lug (2) as shown in Fig. 1. Connect the

clamp end of the ground wire to a true earth

ground. To order a ground wire and clamp, order

Part No. 222011.

NOTE: To connect the ground wire to the surge

suppressor, first remove the copper connector from

the non-clamp end of the ground wire and discard

it, then push the bare wire through the grounding

lug on the surge suppressor.

D Fluid supply container: Follow your local code.

23

Fig. 1

NOTE: When pumping conductive flammable fluids

with a surge suppressor, always ground the entire

fluid system. See the WARNING at left. Fig. 2

shows recommended methods of grounding fluid

containers during filling. These are only guides;

contact your Graco distributor for assistance in

grounding your system.

D Air compressor: Follow the manufacturer’s

recommendations.

D Solvent pails used when flushing: Follow your local

code. Use only grounded metal pails, which are

conductive. Do not place the pail on a

non-conductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

2

4 308703

Page 5

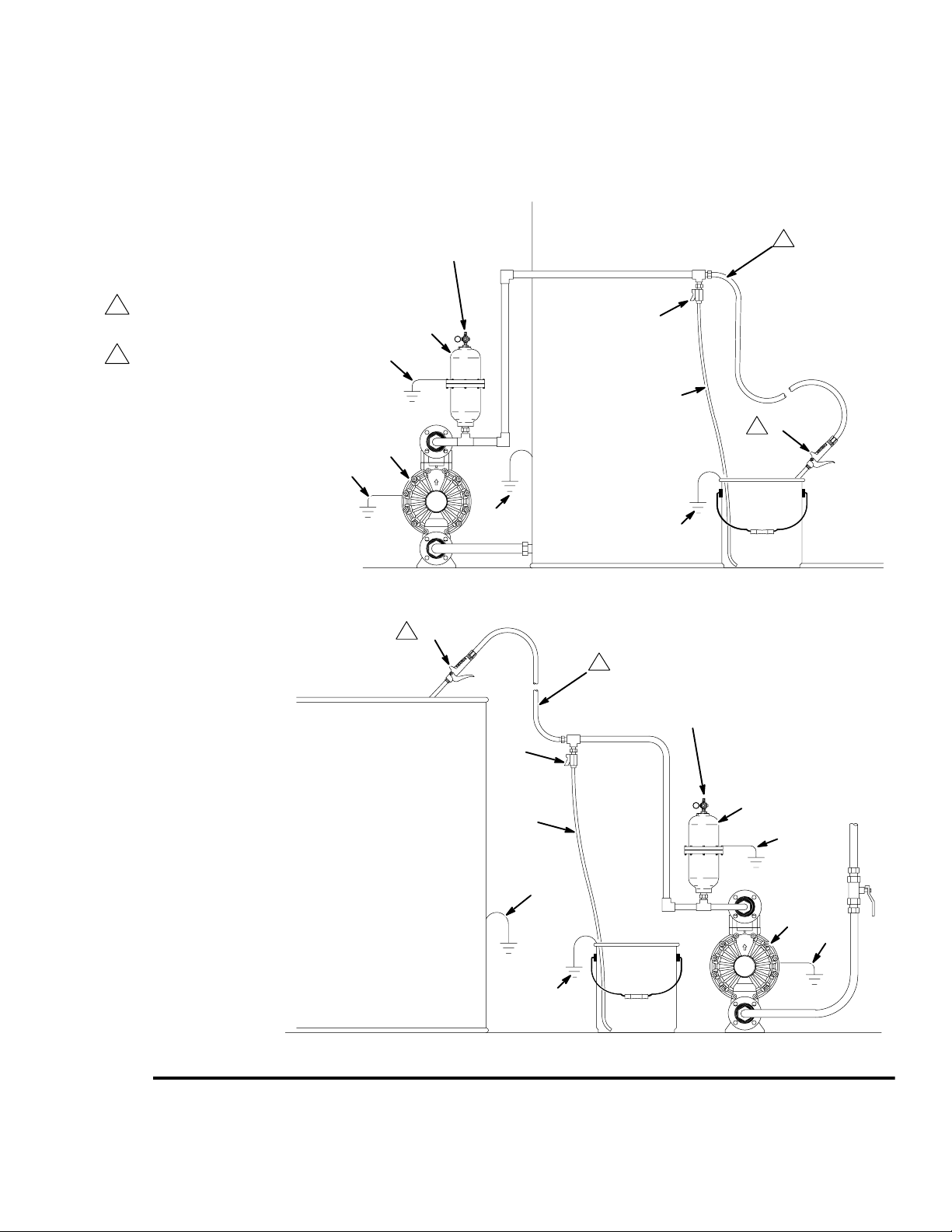

Grounding a Surge Suppressor

A Husky pump

B Husky surge suppressor

H Fluid drain valve (required)

S Dispense valve

T Fluid drain line

W Surge suppressor ground wire (required)

See page 4 for installation instructions.

Y Air motor ground wire (required)

Z Container ground wire (required)

Hose must be conductive.

1

Dispense valve nozzle must be in

2

contact with the container.

Y

Installation

air supply

connection

B

W

A

1

H

T

2

S

Z

Z

06895

2

S

1

air supply

connection

H

B

T

W

Z

A

Y

Fig. 2

Z

06896A

308703 5

Page 6

Installation

The installations in Fig. 2 are guides for selecting and installing system components. Contact your Graco distributor

for assistance in planning a system to suit your needs.

Mounting Automatic and Manual Models

Be sure the mounting surface can support the weight of the pump, surge suppressor, hoses, and accessories, and

the stress caused during operation.

D Mount the surge suppressor as close to the pump discharge as possible and upstream of equipment such as

valves, meters, filters, and so on. The surge suppressor should be installed within 10 pipe diameters of the

pump discharge.

D If you use a flexible connector from the pump to the piping system, the surge suppressor should be mounted to

the pump discharge manifold, and the flexible connector should be attached to the surge suppressor tee and

system piping.

D Because pressure is equal in all directions, the surge suppressor can be installed in any position, but the vertical

position shown in Fig. 2 is recommended for better draining. Fluids with high specific gravity or high viscosity,

settling of heavy material, and possible air entrapment further limit the mounting positions other than those

shown in Fig. 2.

NOTE: When you mount a plastic surge suppressor, do not overtighten by using a large pipe wrench near the

threads of the fluid inlet. The housing may crack if tightened too much. Hand tightening is recommended.

Connecting Automatic Models

D Connect the 1/4-in air supply hose to the 1/4 npt

connection on the top of the surge suppressor.

D The air pressure to the surge suppressor must be

greater than or equal to the pump discharge and/or

system pressure. For equal air pressure, you can

use a tee in the pump’s air supply line to run an air

line to the surge suppressor.

D For models with elastomer bladders, the tee must

be located in the pump’s air supply line before any

pump controller or instrumentation such as the

filter, regulator, or pump control valve.

D For models with PTFE bellows, the tee must be

located in the pump’s air supply line after any pump

controller or instrumentation such as the filter,

regulator, or pump control valve.

Connecting Manual Models

D Connect the 1/4-in air supply hose to the brass

one-way check valve on the top of the surge suppressor.

D The air pressure to the surge suppressor must be

greater than or equal to the pump discharge and/or

system pressure. For equal air pressure, you can

use a tee in the pump’s air supply line to run an air

line to the surge suppressor.

D The tee must be located in the pump’s air supply

line before any pump controller or instrumentation

such as the filter, regulator, or pump control valve.

6 308703

Page 7

Operation

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray from

the dispensing device, or splashing fluid, follow this

procedure whenever you

D Are instructed to relieve pressure

D Stop pumping

D Check, clean, or service any system equipment

D Install or clean fluid nozzles

1. Stop pumping, and shut off the air to the pump.

2. Relieve pressure in the surge suppressor as

follows:

D For automatic surge suppressors, remove the

air pressure gauge, and allow any residual air

pressure to escape.

D For manual surge suppressors, adjust the

regulator to relieve the air pressure by dialing

down the pressure.

Minimum and Maximum Operating

Temperatures

Find the minimum and maximum operating temperatures for your surge suppressor unit in the list below.

These temperature limits are stated at zero gauge

pressure.

Automatic Husky 750

239095 10_ to 180_ F (–12_ to 82_ C)

239096 32_ to 175_ F (0_ to 79_ C)

239121 40_ to 175_ F (4_ to 79_ C)

239122 32_ to 175_ F (0_ to 79_ C)

239123 40_ to 220_ F (4_ to 104_ C)

239124 –10_ to 350_ F (–23_ to 176_ C)

Automatic Husky 2000

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed.

D Read TOXIC FLUID HAZARD on page 3.

D Use fluids and solvents which are compatible

with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

WARNING

FIRE AND EXPLOSION HAZARD

Charge the surge suppressor with

compressed air or nitrogen only. Do not

use oxygen.

Never pump flammable fluids with

polypropylene units.

Charging the surge suppressor with oxygen or

pumping flammable fluids with polypropylene units

could cause a fire or an explosion.

239092 32_ to 175_ F (0_ to 79_ C)

239093 32_ to 175_ F (0_ to 79_ C)

239126 40_ to 175_ F (4_ to 79_ C)

239127 32_ to 175_ F (0_ to 79_ C)

239128 40_ to 175_ F (4_ to 79_ C)

Manual Husky 750

239090 10_ to 180_ F (–12_ to 82_ C)

239091 32_ to 175_ F (0_ to 79_ C)

239129 40_ to 175_ F (4_ to 79_ C)

239130 32_ to 175_ F (0_ to 79_ C)

239131 40_ to 220_ F (4_ to 104_ C)

239132 –10_ to 350_ F (–23_ to 176_ C)

Manual Husky 2000

239087 32_ to 175_ F (0_ to 79_ C)

239088 32_ to 175_ F (0_ to 79_ C)

239134 40_ to 175_ F (4_ to 79_ C)

239135 32_ to 175_ F (0_ to 79_ C)

239136 40_ to 175_ F (4_ to 79_ C)

308703 7

Page 8

Operation

Charging and Startup

For optimum performance, surge suppressors should be charged to a pressure 2 to 10 psi (0.01 to 0.07 MPa,

0.1 to 0.7 bar) lower than system pressure.

Automatic Models

CAUTION

Automatic surge suppressors must have the air

supply connected before you start pumping. Failure

to do so could result in the internal air valve

puncturing or rupturing the bladder.

The air pressure gauge (1) (See Parts Drawings on

pages 14 and 15) on automatic surge suppressors

remains at zero pressure even after the air line is

connected, because the surge suppressor only allows

air into the air chamber when it is required to dampen

pulsation. After the air supply line is attached to the

one-way check valve (8) and air is available, you can

start the pump. No further adjustments are necessary.

NOTE: Automatic surge suppressors are not recommended for use as suction stabilizers at the pump inlet

or as a surge suppressor at a quick-closing valve.

Adjustable surge suppressors should be used for such

applications.

Manual Models

CAUTION

Manual surge suppressors must be charged before

you start pumping. Failure to do so could result in

the internal air valve puncturing or rupturing the

bladder.

Before you start the pump, charge the surge suppressor with air line pressure.

1. Start the pump to generate system pressure.

2. As pressure increases to approach working pressure, gradually decrease the regulated air supply

pressure into the surge suppressor by adjusting

the regulator (4) (See Parts Drawings on pages

14 and 15).

3. Wait for up to one minute to allow the system to

respond to the adjustment before you make any

further adjustments. Generally, pulsation is most

effectively minimized when the air supply to the

surge suppressor is regulated to 2 to 10 psi (0.01

to 0.07 MPa, 0.1 to 0.7 bar) lower than system

pressure.

8 308703

Page 9

Troubleshooting

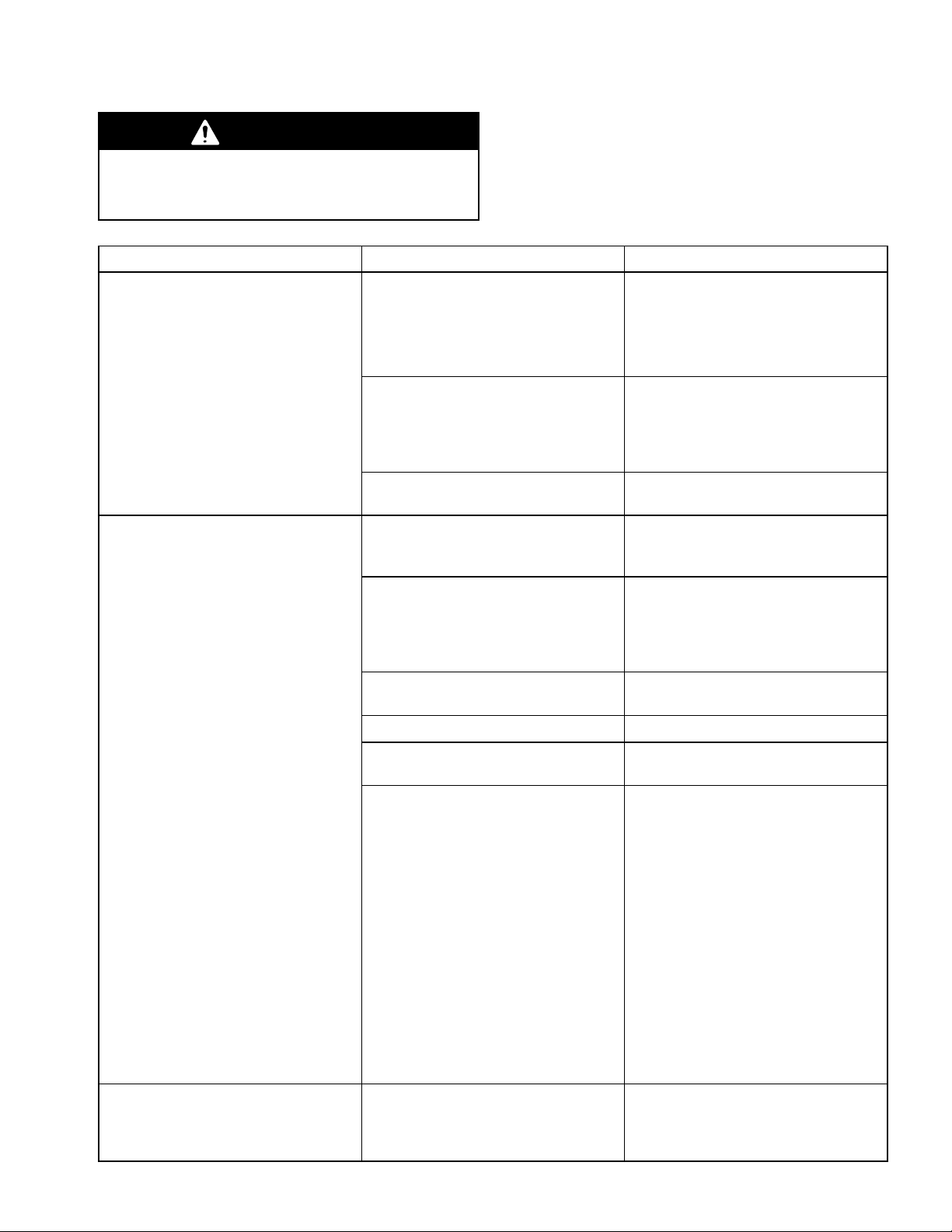

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

Relieve the pressure before checking or servicing the

equipment.

Check all possible problems and causes before disassembling the pump.

PROBLEM

Surge suppressor does not hold

pressure.

Dampening effect of surge

suppressor is not sufficient.

CAUSE SOLUTION

Manual or automatic models:

–Leaking threaded connections

–Loose flange bolts or clamp

–Failed bladder or bellows

–Blocked air line to unit

Automatic models only:

–One-way valve at air inlet is

installed backwards.

–Gauge shows no pressure,

and pump is not running.

Manual models only:

–Faulty regulator –Check regulator.

Surge suppressor installed incorrect

distance from pump

Improper pressure charge See Charging and Startup,

Surge suppressor does not hold

pressure charge.

Failed bladder or bellows See Bladder Failure, page 10.

–Check all threads for leaks.

–See Torque Table, page 11.

–See Bladder Failure, page 10.

–Use 1/4-in air line.

–Arrow should point toward surge

suppressor.

–Pressure does not register on

gauge until pump is started.

Surge suppressor should be

installed within 10 pipe diameters of

pump discharge.

page 8. Surge suppressor

pressure should be 2 to 10 psi (0.01

to 0.07 MPa, 0.1 to 0.7 bar) lower

than system pressure.

See surge suppressor does not hold

pressure in PROBLEM column.

There is leaking around surge

suppressor fluid inlet.

Surge suppressor too small for

pump

Automatic models only:

Plugged automatic valve

PTFE sealing tape or paste is

needed on threads of fluid inlet.

Install larger surge suppressor.

Remove pressure from surge

suppressor, and check automatic

valve for proper operation as

follows:

1. Leave air line attached to top

half of surge suppressor.

2. Fill top of surge suppressor

with enough water to cover

automatic valve.

There should be no bubbles.

3. Dump water out, and gently

push automatic valve.

Air should flow.

4. Replace automatic valve if

it is defective.

Apply PTFE tape or paste to

threads. Do not overtighten plastic

models. Hand tightening is

recommended.

308703 9

Page 10

Service

Bladder Failure

Normal life for bladders can be from a few months to

several years, depending upon the harshness of the

application. Below are common reasons for failed

bladders or bellows:

D Chemical attack: Check chemical compatibility

charts. Consult your Graco distributor.

D Cut bladder or bellows: Check for sharp objects

that may have been introduced into the surge

suppressor through pumped fluid.

D Insufficient compressed air charge in surge sup-

pressor during operation: See Charging and

Startup on page 8.

D Surge suppressor too small for the pump: An

undersized surge suppressor will have premature

bladder failure. Contact your Graco distributor for

assistance in ensuring that you have the correct

size surge suppressor.

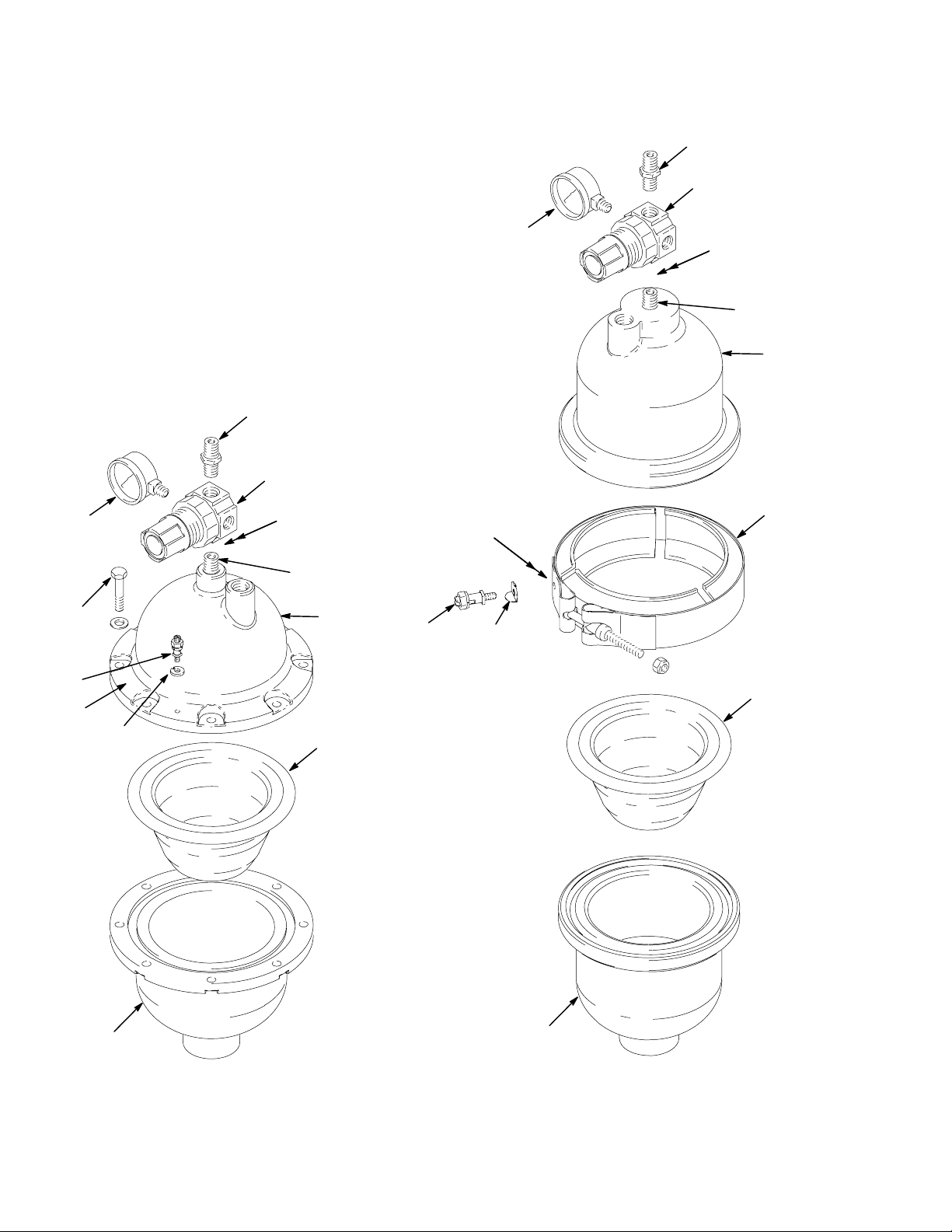

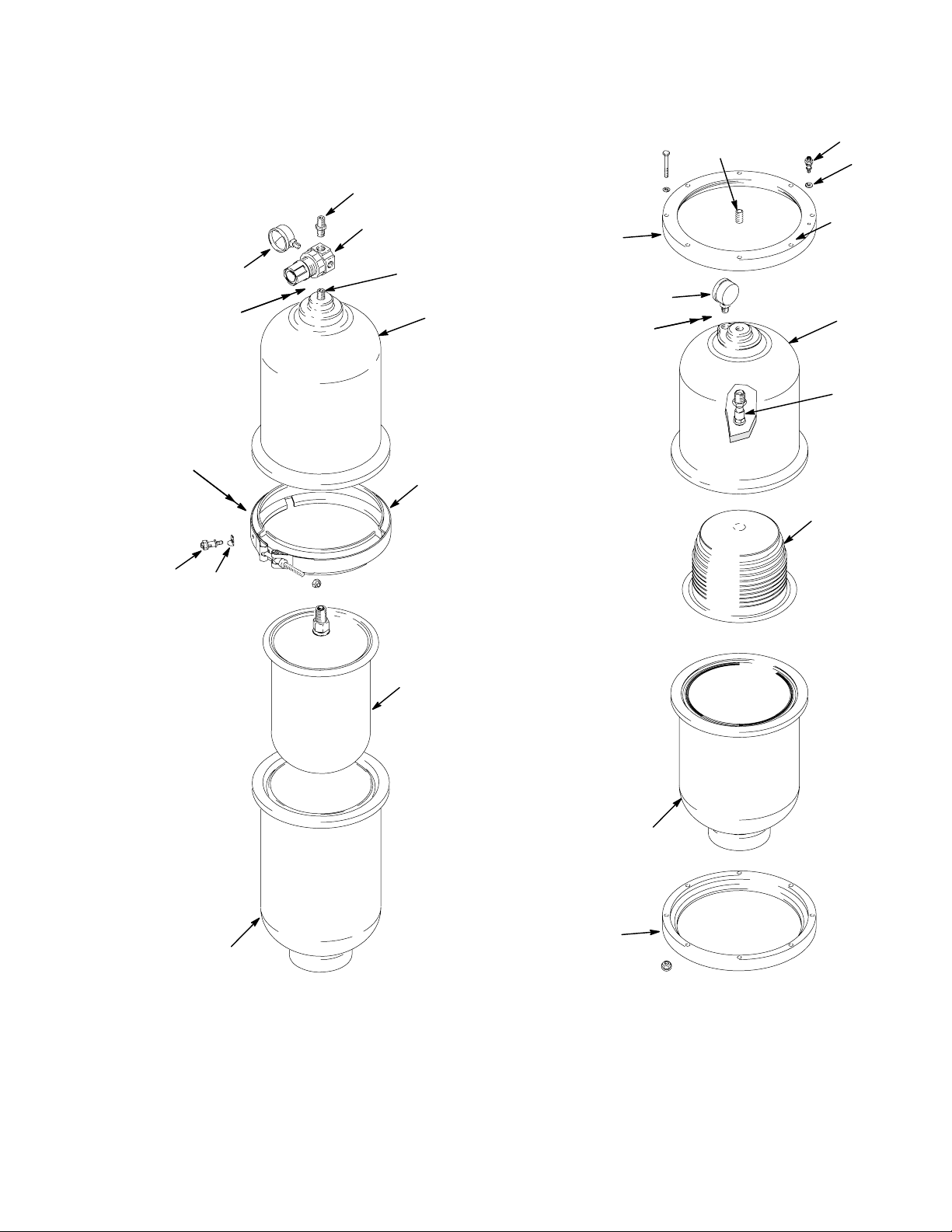

Replacing Bladder or Bellows

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 7.

2. Remove the clamp band, ring flange, or bolts.

3. Remove the top housing of the surge suppressor.

4. Remove the old bladder or bellows, and replace it

with the new bladder or bellows.

Make sure that you properly orient the parts:

D Install rubber bladders with the concave side

facing the top housing, as shown in the Parts

Drawings on page 14.

D Install PTFE bellows with the concave side

facing the bottom housing, as shown in Model

No. 239126 in the Parts Drawings on

page 15. Install the PTFE encapsulated fluoroelastomer o-rings on each side of the bellows.

5. Replace the top housing of the surge suppressor.

6. Replace the clamp band, ring flange, or bolts, and

torque according to the torque specifications in the

Torque Table on page 11.

10 308703

Page 11

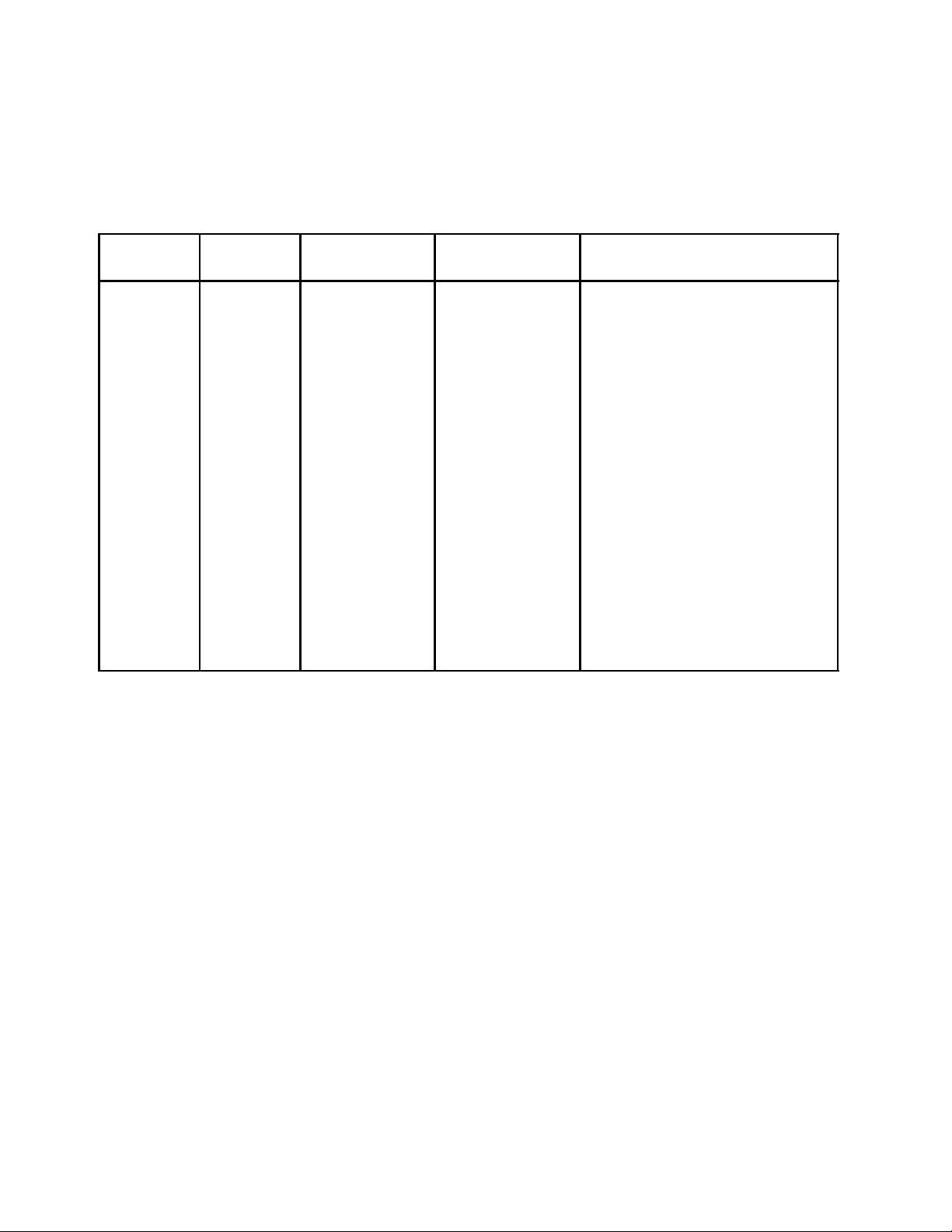

Service

Torque Table

Find the proper torque specifications for your surge suppressor unit in the table below. These are the torques to

which the clamp band, ring flange, or bolts in bolted units need to be tightened.

KEY: plastic = polypropylene or acetal

metal = stainless steel

rubber = fluoroelastomer or Buna–N

Bladder

Model

Husky 2000 rubber plastic clamp band 45 to 55 in-lb (5.1 to 6.2 N-m)

Husky 2000 rubber plastic ring flange 65 to 70 in-lb (7.3 to 7.9 N-m)

Husky 2000 PTFE plastic ring flange 90 to 105 in-lb (10.2 to 11.9 N-m)

Husky 2000 rubber metal and plastic clamp band 30 to 40 in-lb (3.4 to 4.5 N-m)

Husky 2000 rubber metal and plastic ring flange 80 to 85 in-lb (9.0 to 9.6 N-m)

Husky 2000 PTFE metal and plastic ring flange 90 to 95 in-lb (10.2 to10.7 N-m)

Husky 2000 rubber metal bolted unit 120 to 130 in-lb (13.6 to 14.7 N-m)

Husky 2000 PTFE metal bolted unit 145 to 150 in-lb (16.4 to 16.9 N-m)

Husky 750 rubber plastic clamp band 40 to 45 in-lb (4.5 to 5.1 N-m)

Husky 750 rubber plastic ring flange 50 to 55 in-lb (5.6 to 6.2 N-m)

Husky 750 PTFE plastic clamp band 80 to 85 in-lb (6.8 to 9.6 N-m)

Husky 750 PTFE plastic ring flange 85 to 90 in-lb (9.6 to 10.2 N-m)

Husky 750 rubber metal bolted unit 80 to 85 in-lb (9.0 to 9.6 N-m)

Husky 750 PTFE metal bolted unit 110 to 115 in-lb (12.4 to 13.0 N-m)

Material

Housing

Material

Type of Clamp Torque

308703 11

Page 12

Model Numbers

Automatic Husky 750, 3/4-in Surge Suppressors

Polypropylene Wetted Bottom Housing and Non-Wetted Top Housing

239096 with Buna–N bladder

239121 with PTFE bellows

239122 with fluoroelastomer bladder

Stainless Steel Wetted Bottom Housing and Non-Wetted Top Housing

239095 with Buna–N bladder

239123 with PTFE bellows

239124 with fluoroelastomer bladder

Automatic Husky 2000, 2-in Surge Suppressors

Stainless Steel Wetted Bottom Housing, Polypropylene Non-Wetted Top Housing

239093 with Buna–N bladder

239126 with PTFE bellows

239127 with fluoroelastomer bladder

Polypropylene Wetted Bottom Housing and Non-Wetted Top Housing

239092 with Buna–N bladder

239128 with PTFE bellows

Manual Husky 750, 3/4-in Surge Suppressors

Polypropylene Wetted Bottom Housing and Non-Wetted Top Housing

239091 with Buna–N bladder

239129 with PTFE bellows

239130 with fluoroelastomer bladder

Stainless Steel Wetted Bottom Housing and Non-Wetted Top Housing

239090 with Buna–N bladder

239131 with PTFE bellows

239132 with fluoroelastomer bladder

Manual Husky 2000, 2-in Surge Suppressors

Stainless Steel Wetted Bottom Housing, Polypropylene Non-Wetted Top Housing

239088 with Buna–N bladder

239134 with PTFE bellows

239135 with fluoroelastomer bladder

Polypropylene Wetted Bottom Housing and Non-Wetted Top Housing

239087 with Buna–N bladder

239136 with PTFE bellows

12 308703

Page 13

Parts Matrix

is 1 for every model

The X’s indicate the

Replacement Parts for Huskyt 750 and Huskyt 2000 Surge Suppressors, Series A

Parts

Automatic

NOTE: The quantity of every part in this list

.

parts that are included in each model.

Ref

No. Part No. Description

1 100960 GAUGE, air press.;200 psi

(1.4 MPa, 14 bar); 1/4 npt

2 104029 LUG, grounding X X X X X X X X X X X X X X X X X X X X X X

3 104582 WASHER, tab X X X X X X X X X X X X X X X X X X X X X X

4 110318 REGULATOR, air; 1/4 npt X X X X X X X X X X X

5 110319 GAUGE, air press., 200 psi

(1.4 MPa, 14 bar); 1/8 npt

6 113872 CLAMP, band; SST X X X X X X

7 113878 BELLOWS, PTFE with

o-ring kit

8 113879 VALVE, check X X X X X X X X X X X X X X X X X X

9 113880 CLAMP, band; SST X X X X

’

Husky 750

2

2

2

2

3

3

3

3

9

9

9

0

9

5

X X X X X X X X X X X

9

0

1

1

9

2

2

6

1

2

Surge Suppressor Models

Automatic

Husky 2000

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

9

9

9

9

9

9

9

1

1

0

0

1

1

2

2

9

9

2

3

4

2

2

3

6

7

X X X X

9

1

0

2

9

8

0

X X X X X X X X X X X

Manual

Husky 750

2

2

2

3

3

3

9

9

9

0

1

1

9

2

3

1

9

0

Manual

Husky 2000

2

2

2

2

2

2

3

3

3

3

3

3

9

9

9

9

9

1

1

0

3

3

1

8

2

7

9

0

1

1

8

3

3

8

4

5

2

3

9

1

3

6

10 113881 FLANGE, ring, with fasteners X X X X

11 113882 VALVE ASSY, automatic

for rubber bladders

13 113884 FLANGE, ring, with fasteners X X

14 113885 BLADDER, Buna–N X X X X

15 113886 BELLOWS; PTFE with

o-ring kit

16 113887 VALVE ASSY, automatic

for rubber bladders

18 113889 BLADDER; fluoroelastomer X X

19 113890 BLADDER; fluoroelastomer X X X X

20 113891 BLADDER, Buna–N X X X X

21 113923 BOLT, WASHER, NUT SET X X X X X X

22 186620 STICKER, grounding symbol X X X X X X X X X X X X X X X X X X X X X X

24 290306 LABEL, identification X X X X X X X X X X X X X X X X X X X X X X

25 290322 LABEL, warning X X X X X X X X X X X X X X X X X X X X X X

26 290323 LABEL, product X X X X X X X X X X X X

27 290324 LABEL, product X X X X X X X X X X

28 290384 LABEL, caution X X X X X X X X X X X X X X X X X X X X X X

X X X X

X X X X X X

X X X X X

Non-Replacement Parts for Huskyt 750 and Huskyt 2000 Surge Suppressors, Series A

A Top housing (See Model Numbers list on page 12 for housing material of each model)

B Bottom housing (See Model Numbers list on page 12 for housing material of each model)

C Close nipple, SST; 1/4”

308703 13

Page 14

Parts Drawings

(see Parts Matrix on page 13)

8

4

5

24, 25, 26, 28

hanging on regulator

C

A

8

4

21

22

5

2

3

24, 25, 26, 28

hanging on regulator

C

A

20

22

2

3

9

20

B

14 308703

06890

Model 239090

B

06889

Model 239091

Page 15

Parts Drawings

(see Parts Matrix on page 13)

24, 25, 27, 28

hanging on regulator

22

2

3

C

8

4

10

5

C

A

6

includes fasteners

1

24, 25, 27, 28

hanging on gauge

2

3

22

A

11

7

14

B

10

B

06886

includes fasteners

Model 239088 Model 239126

06893

308703 15

Page 16

Dimensions

Manual Husky 2000

8.5 in.

(216 mm)

239088 shown

06887

20.25 in.

(514 mm)

23.25 in.

(591 mm)

8.5 in.

(216 mm)

2 npt fluid inlet

Automatic Husky 2000

239126 shown

22.50 in.

(572 mm)

20.25 in.

(514 mm)

06894

2 npt fluid inlet

Manual Husky 750

6.0 in.

(152 mm)

3/4 npt fluid inlet

239091 shown

10.0 in.

(254 mm)

06891

13.25 in.

(337 mm)

Automatic Husky 750

6.0 in.

(152 mm)

3/4 npt fluid inlet

239096 shown

12.5 in.

(318 mm)

10.0 in.

(254 mm)

06892

16 308703

Page 17

Technical Data

Maximum air input pressure 120 psi (0.8 MPa, 8 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air line connection 1/4 npt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Inlet size

Husky 2000 models 2 npt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Husky 750 models 3/4 npt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted and non-wetted parts See the Model Numbers list on page 12.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight

Models 239091, 239096, 239121,

239122, 239129, and 239130 9 lb (4.1 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 239090, 239095, 239123, 239124, 239131, and 239132 16 lb (7.3 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 239088, 239093, 239126, 239127, 239134, and 239135 36 lb (16.3 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 239087, 239092, 239128, and 239136 18 lb (8.2 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

308703 17

Page 18

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the distributor closest to you:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 308703

18 308703

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1996, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 06/2010

Loading...

Loading...