Page 1

INSTRUCTIONS-PARTS

LIST

Series

700

Turbine

100

psi

(7

bar)

Maximum

50

psi

(3.5

bar)

Maximum

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

Spray

Inlet Air Pressure

Inlet

Fluid

Gun

Pressure

G

ORACO

308-336

Rev.

A

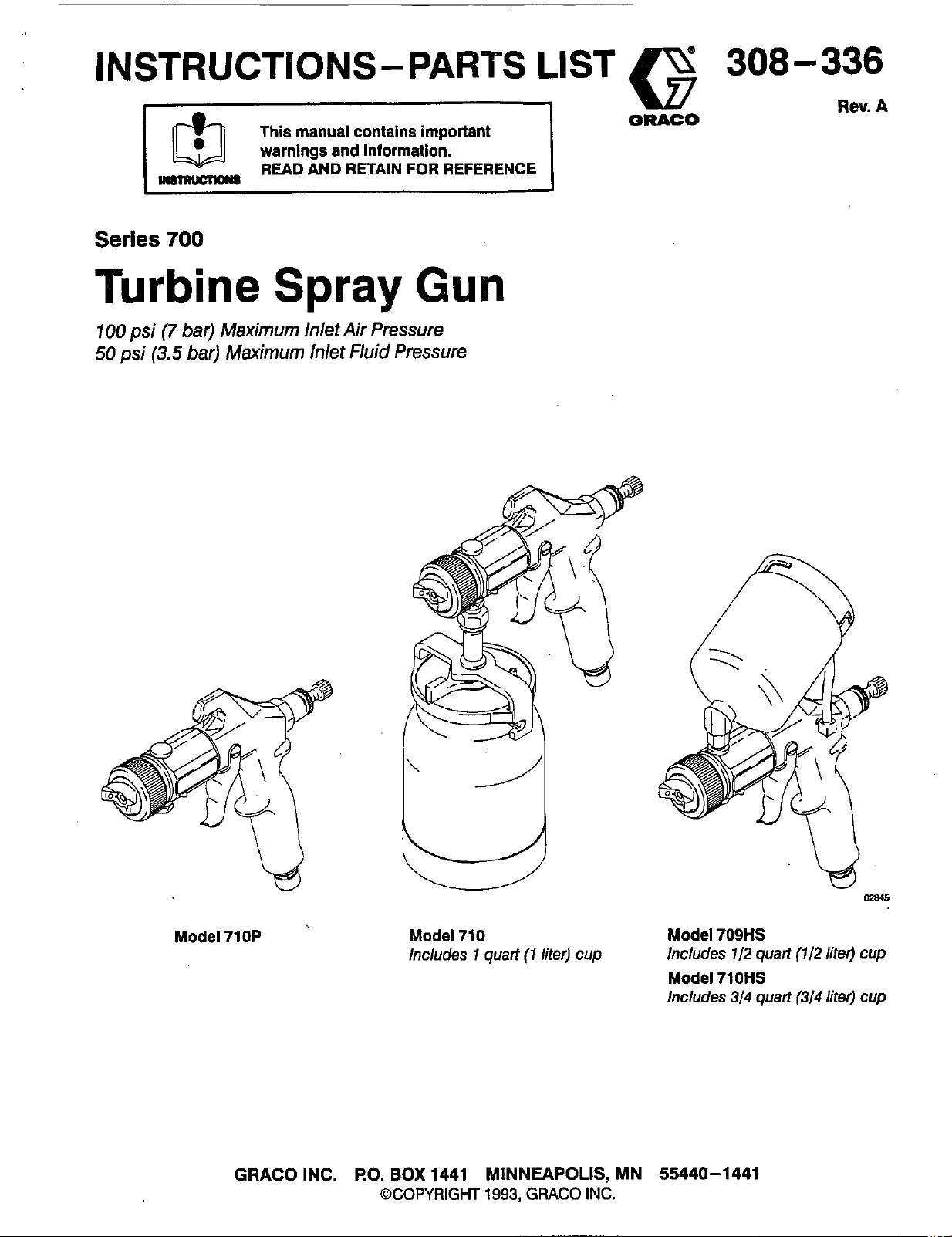

Model 710P Model 710

GRACO INC.

lncludes 1 quart (1 liter) cup

RO.

BOX

1441 MINNEAPOLIS, MN 55440-1441

@COPYRIGHT

1993,

GRACO

ma(5

Model 709HS

Includes 112 quart (112 liter) cup

Model 710HS

lncludes 314 quart (314 liter) cup

INC.

Page 2

For

Professional Use Only. Observe

Read and understand all instruction manuals before operating equipment.

All

Warnings.

EQUIPMENT MISUSE

General Safety

Any misuse of the spray equipment or accessories,

such as improper usage, over pressurizing, modifying

parts, using incompatible chemicals and fluids, or

using worn or damaged parts, can

ture and result in serious injury, fire, explosion or

property damage.

Never point the spray gun at anyone or at any part

of the body.

Never put hand or fingers over the spray nozzle. Pressure Relief

0

Never try to stop or deflect leaks with Your hand or The spray gun cups and accessory remote pressure

body. pots remain pressurized until pressure is manually

Always turn

removing the spray gun cup.

0

Check all spray equipment regularly and repair or

replace worn or damaged parts immediately.

Only use genuine Graco replacement parts when remote pressure pot cover; and whenever you stop

servicing the gun. spraying.

off

the air supply to the gun before

cause

them to rup-

System Pressure

This gun has a

psi (7 bar) and a

Maximum

HaZARD

Marimum

Maximum

(3.5 bar).

exceed the maximum pressures of

pot, or any other component or accessory used in the

system.

relieved. To reduce the risk of serious injury from

pressurized fluid or accidental spray from the gun,

always relieve pressure in the cup or pressure pot

before checking or servicing any part of the spray

system; before installing, cleaning or changing fluid

nozzles: before loosening or removing the accessory

The

accessory remote pressure pots have a

hlet Air Pressure of

Met

Fluid

Pressure of

lnlet Air Pressure of

50

psi (3.5 bar). Never

the

gun, pressure

100

50

psi

Never alter

doing

Read and follow the fluid and solvent manufacturer’s literature regarding the use of protective

eyewear, gloves, clothing, respirator and other

equipment.

Fluid Compatibility

Be sure all fluids and solvents used are chemicallv

compatible with the “Welted Parts” shown in the

Technical Data on the back cover. Always read the

fluid and solvent manufacturer’s literature before

using the fluid or solvent in this gun.

Do

not use l,l,l-trichloroethane, methylene chloride,

other halogenated hydrocarbon solvents or fluids containing such solvents in the turbine spray system,

which contains aluminum and/or galvanized-coated

parts. Such use could result in a serious chemical

reaction, with the possibility of explosion, which could

cause death, serious injury, andlor substantial prop-

erty

damage.

or

modify any part of this equipment:

so

could cause it

to

malfunction.

Spray

Gun

Cup

To

relieve pressure:

off

1. Turn

2.

Unlatch the cup cover and loosen or remove the

cup from the cover.

Accessory

To

relieve pressure:

1.

Turn

2. 2 1/2

valve ring

relieved.

2

knob (113) about one turn. Wait until pressure

completely relieved before removing the cover.

Close the knob before using the system again.

See Fig.

the air supply to the gun.

Remote

off

the air supply to the pressure pot.

Gallon Remote Pot:

Quart Remote Pot: Turn

Pressure

(206c)

4

on page

Pot

Pull

until pressure

out

the pressure relief

7.

the pressure relief

is

completely

is

2

308-336

Page 3

Tighten all fluid connections securely before each use. Handle and route hoses carefully. Do not pull on

Do

Never

use

a damaged hose. Before each use, check

the entire hose for cuts, leaks, abrasion, bulging

cover. or damaae or movement of the hose CouDlinw.

If

anyof these conditions exist, replace the hose

immediately.

.-

hoses to move equipment.

vents which are not compatible with the inner tube

and cover of the hose.

not use fluids or

sol-

FIRE

.Sparking and Flammable

Sparking can be expected

the turbine motor. Sparks could ignite fumes from from plastic drop cloths, open flames such as pilot

flammable liquid, dust particles and other flammable lights, hot objects such

substances in the spray area, and cause serious necting or disconnecting power cords or turning light

injury and property damage. Be sure to follow the pre

cautions below: of ignition.

When flammable liquid is sprayed or used for

flushing or cleaning equipment, the turbine must

be placed at least

where hazardous concentrations of flammable

vapors are likely to occur.

Use

additional air hose

the turbine is operated in a clean, dry, well venti-

lated area.

Never place the turbine inside a spray booth! Use

this equipment outdoors or in extremely well ventilated areas.

Vapors

in the normal operation

20

feet

if

Hazard

(6.1

m) away from areas

necessary to ensure that

OR

EXPLOSION

of

HAZARD

Ignition Sources

Avoid all ignition sources such as static electricity

as

cigarettes, arcs from con-

. switches on and

Grounding

To reduce the risk of static sparking, ground the tur-

bine and all other spray equipment used or located in

the spray area. Check your local electrical code for

detailed grounding instructions for your area and type

of equipment.

To

ground the turbine: Plug the power supply cord

into a properly grounded outlet. Do not remove the

grounding prong from the power cord. Do not use an

adapter. Extension cords must have three wires and

be rated for a minimum of

off.

Extinguish or remove all sources

15

amps.

IMPORTANT

United

States

Government

dards--particularly

Warnings..

Introduction

Fluid Set Selection Charts

Setup..

Shutdown

Spraying Techniques

Maintenance..

Service

....................................

...................................

.......................................

....................................

................................

......................................

safety

the General Standards,

..........................

standards

have

Part

been

1910

Table

.......................

adopted

and

the

of

2

4

4

6

11

12

13

16

under

the

Occupational

Construction

Standards,

Safety

Part

Contents

Troubleshooting..

Parts

Model710

Models

Model 71OP

Accessories

Technical Data

Warranty

709HS & 71OHS

.............................

.............................

................................

...............................

..................................

........................

and

Health

Act.

1926--should

....................

These

be

consulted.

stan-

18

20

22

24

25

Back Cover

Back Cover

308-336

3

Page 4

Introduction

The Series

coatings or finishes currently being used for automo-

tive

refinish, industrial, aerospace, marine, wood,

plastic and architectural applications.

This spray gun typically utilizes

inbound air pressure to produce high quality paint

finishes. The gun produces a cone of air that carries

700

Turbine Spray Gun can spray most and directs the paint from the gun to the surface,

5

psi

(0.35

bar)

Fluid

Set

Selection

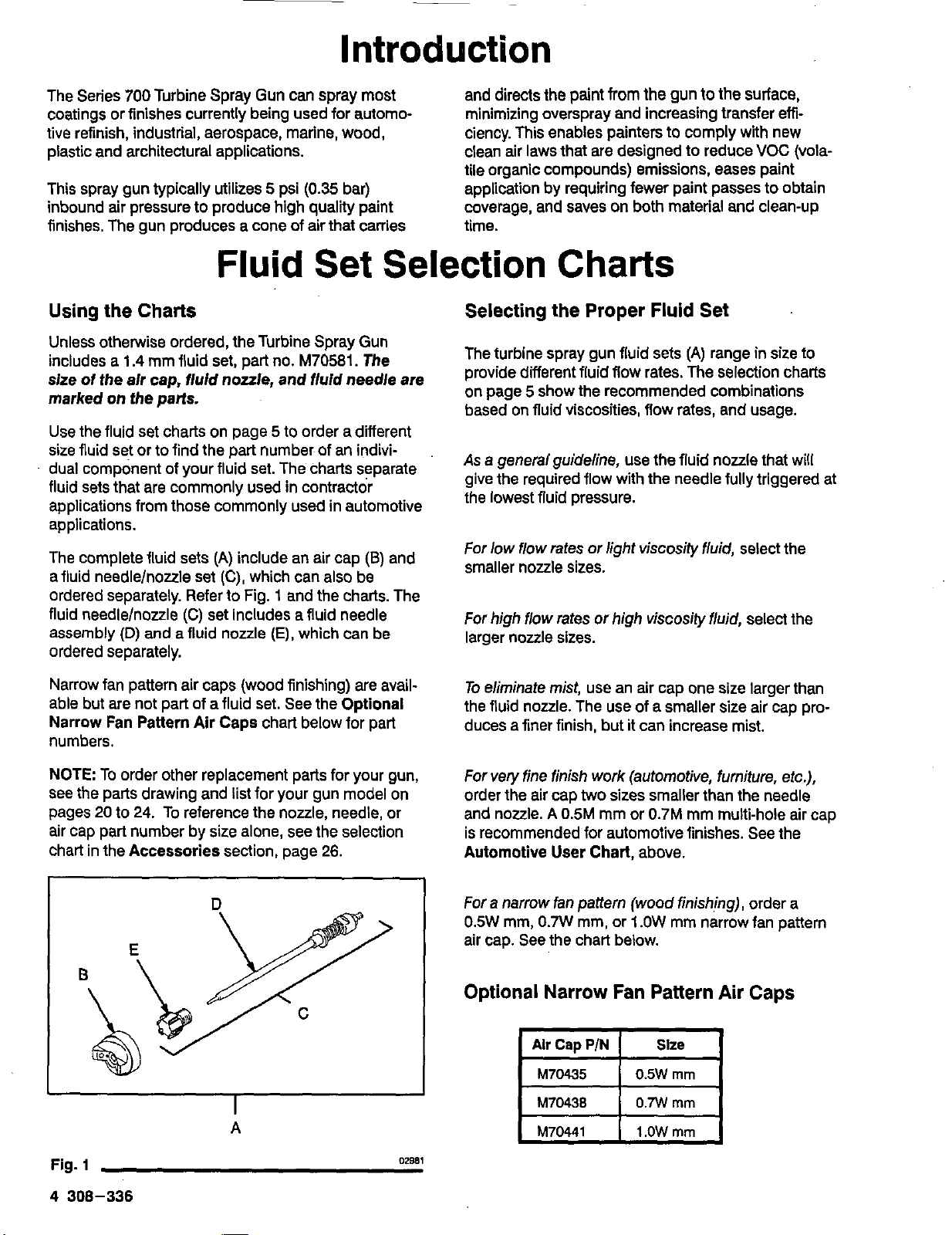

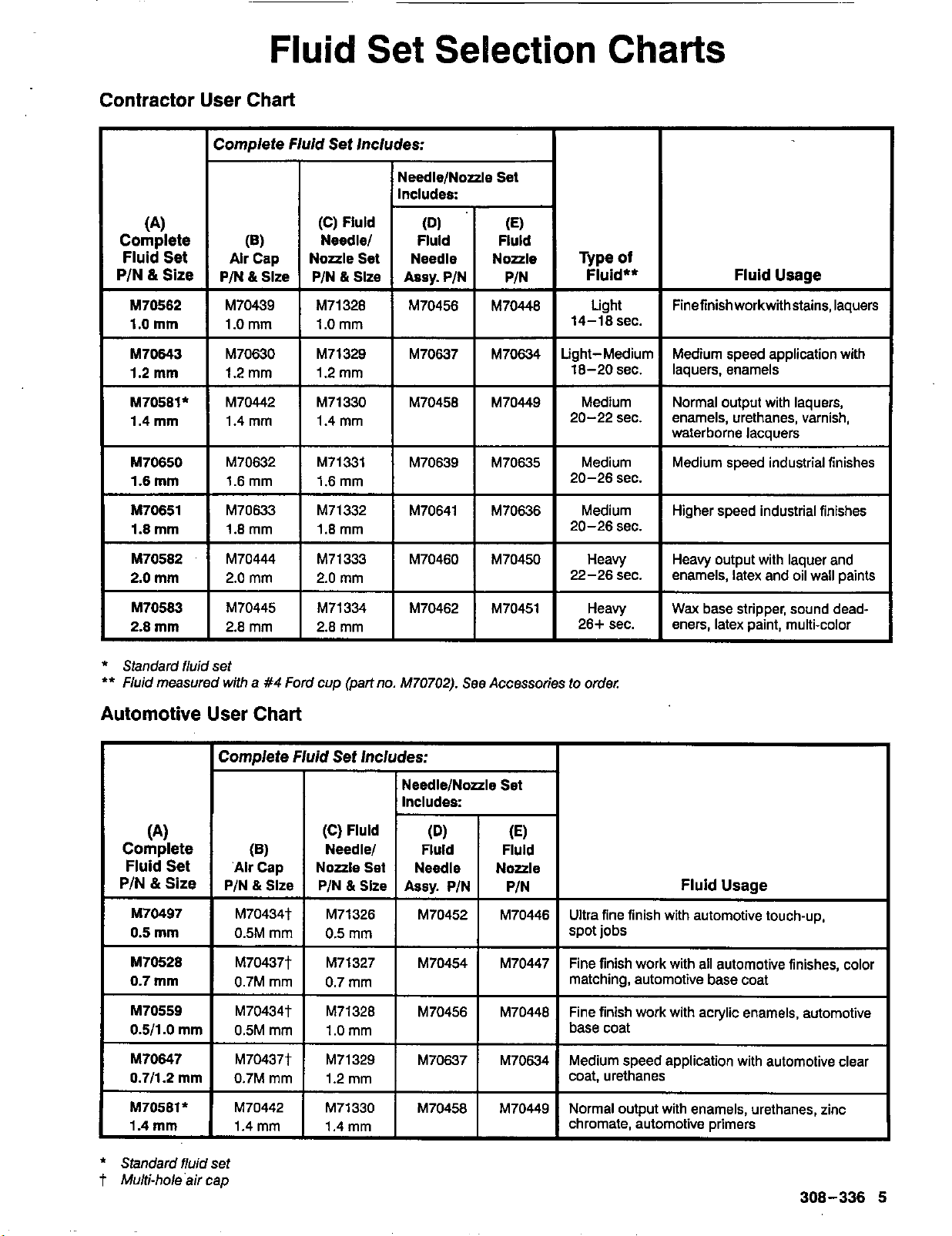

Using the Charts

Unless otherwise ordered, the Turbine Spray Gun

1.4

includes a

size

of

the a/r cap, fluid nozzle, and fluid needle are

marked on the parts.

Use

the fluid set charts on page 5 to order a different

size

fluid set or to find the part number of an individual component of your fluid set. The charts separate

fluid sets that are commonly used in contractor

applications from those commonly used in automotive

applications.

The complete fluid sets

afluid needlelnozzle set

ordered separately. Refer to Fig.

fluid needlelnoule

assembly

ordered separately.

mm fluid set, part no.

(A)

(C),

(C)

set includes a fluid needle

(D)

and

a

fluid nozzle

include an air cap

which can also be

M70581.

1

and the charts. The

(E),

which can be

The

(a)

and

minimizing overspray and increasing transfer emciency. This enables painters to comply with new

VOC

clean air laws that are designed to reduce

tile organic compounds) emissions, eases paint

application by requiring fewer paint passes to obtain

coverage, and saves on both material and clean-up

time.

(vola-

Charts

Selecting the Proper Fluid Set

The turbine spray gun fluid sets

provide different fluid flow rates. The selection charts

on page

based on fluid viscosities, flow rates, and usage.

As

give the required flow with the needle fully triggered at

the lowest fluid pressure.

For low flow rates

smaller nozzle sizes.

For

larger nozzle sizes.

5

show the recommended combinations

a general guideline, use the fluid nozzle that will

or

light viscosily fluid, select the

high

flow rates

or

high viscosity fluid, select the

(A)

range in size to

Narrow fan pattern air caps (wood finishing) are avail-

set.

able but are not part of afluid

Narrow Fan Pattern Air Caps chart below for part

numbers.

NOTE To order other replacement parts for your gun,

see the parts drawing and list for your gun model on

pages

20

to

24.

To reference the nozzle, needle, or

air cap part number by

chart in the Accessories section, page

size

A

See the Optional

alone, see the selection

26.

To

eliminate mist, use an air cap one size larger than

the fluid nozzle. The use of a smaller size air cap pro-

duces a finer finish, but it can increase mist.

For very fine finish work (automotive, furniture, etc.),

order the air cap

and nozzle.

is recommended for automotive finishes. See the

Automotive User

For a narrow

0.5W

mm,

air cap. See the chart below.

two

sizes smaller than the needle

A

0.5M

mm or

Chart,

fan

pattern (wood finishing), order a

0.7W

mm, or

0.7M

mm multi-hole air cap

above.

1

.OW

mm narrow fan pattern

Optional Narrow Fan Pattern Air Caps

Alr

Cap

M70435

~

M70438

M70441

P/N

Slze

0.5W

0.7W

1

.OW

rnm

mm

mm

Fig.

1

4

308-336

02981

Page 5

Fluid

Contractor User Chart

I

(4

Complete

Fluid Set

&

Size

PIN

Complete

Alr

P/N & Slze

Fluid

(6)

Cap

Set

Set Includes:

(C)

Fluld

Needlel Fluld Fluld

Selection

NeedlelNozzle Set

Charts

M70562

1.0

mm

M70643

mm

1.2

M70581'

mm

1.4

M70650

mm

1.6

M70651

mm

1.8

2.0

mm

M70583

2.8

mm

*

Standard fiuid set

**

Fluid

measured with

Automotive User Chart

M70439

1.0 mm

M70630

1.2 mm

M70442

1.4 rnm

M70632 M70639 M70635

I

1.6mm

I

M70633

1.8 mm 1.8 mm

M70444 M71333

mm

a

I

I

#4

Ford cup (part no.

M71328 M70456 M70446

1.0 mm

M71329 M70637 M70634

I

1.2 mm

M71330

1.4 mm

?ilz

M71332

M71334 M70445

2.8 mm 2.8

I

M70456

I

I

M70641

I

M70460

M70702).

Light

14-18 sec.

I

I

M70449

I

I

M70636

I

M70450

M70451 M70462

See Accessories to order:

Medium Normal output with laquers,

Medium Medium speed industrial finishes

20-26 sec.

Medium Higher speed industrial finishes

20-26 sec.

Heavy

22-26 sec.

Heavy

26+ sec. eners. latex Daint. multi-color

Finefinishworkwithstains,laquers

waterborne lacauers

I

I

enamels, latex and oil wall paints

I

Heavy output with laquer and

Wax

base stripper, sound dead-

I

I

Comdete Fluid Set Includes:

I

(4

Complete

Fluid Set

&

Size

PIN

M70497 M70434t

mm

0.5

M70528

0.7

mm

M70559

.O

0.511

M70647

0.711.2

M70581*

mm

1.4

*

Standard fluid set

t

Multi-hole'air cao

~ M70437t

~ 0.7M mm

mm

mm

(6)

'Alr

Cap

PIN & Slze

0.5M mm

M70434t

0.5M mm

M70437t

0.7M mm

M70442

1.4 mm

I

(C)

Fluld

Needlel

Noale

Set

&

Slze

PIN

M71326

0.5 mm

M71327

mm

0.7

M71328 M70456

1.0 mm

1.2 mm

M71330 M70458

NeedleINoale

I

Includes:

(Dl

Fluld

Assv.

PIN

I

M70454

~~

Set

I

I

(E)

Fluld

Noale Needle

PIN

M70446 M70452

M70447

M70446

M70634

M70449

Ultra fine finish with automotive touch-up,

spot jobs

Fine finish work with all automotive finishes, color

matching, automotive base coat

Fine finish work with acrylic enamels, automotive

base coat

Medium speed application with automotive clear

coat, urethanes

Normal output with enamels, urethanes, zinc

chromate, automotive primers

Fluid Usage

~ ~~~~

308-336

5

Page 6

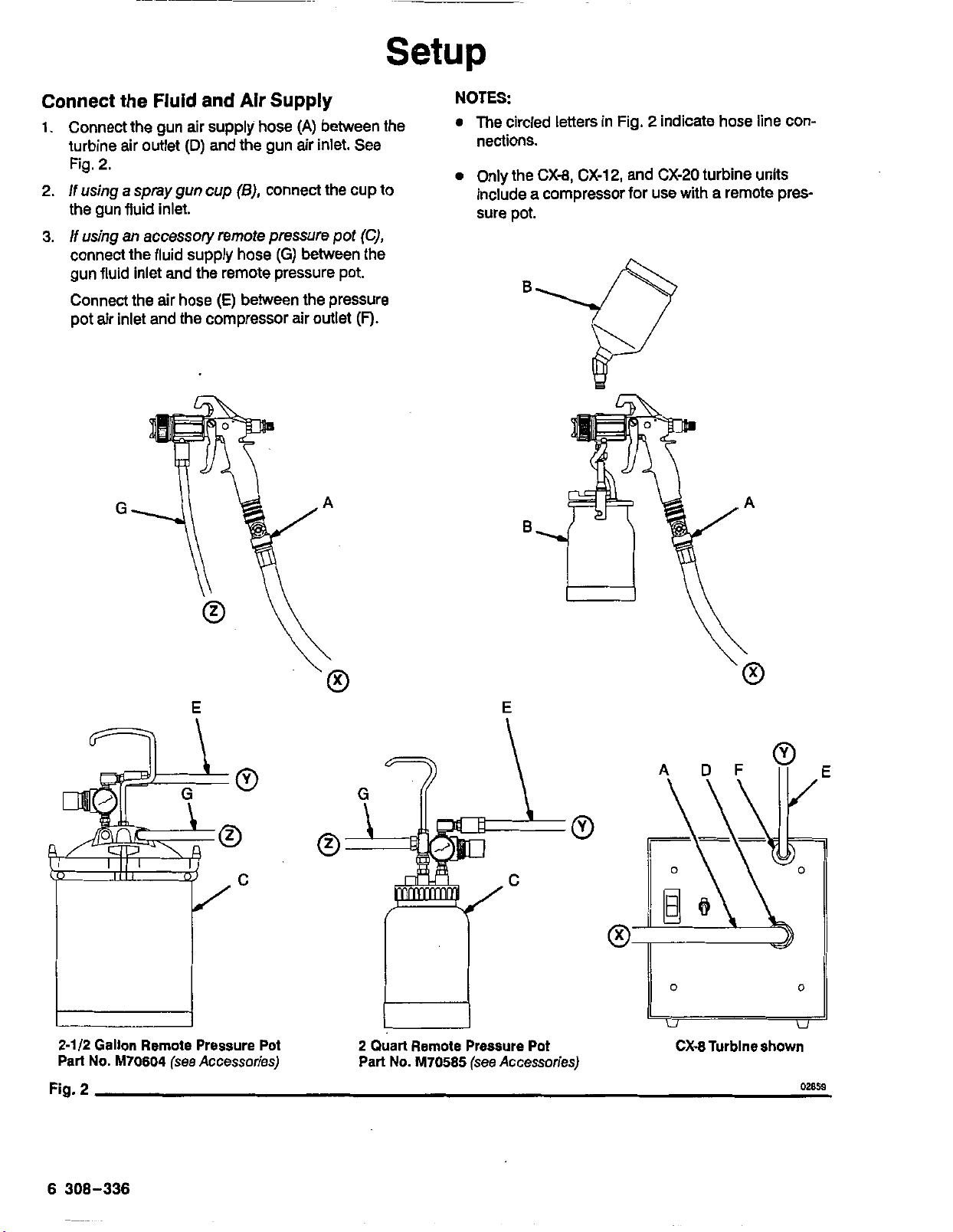

Setup

Connect the Fluid

1.

Connect the gun air supply hose

turbine air outlet

and

Air Supply

(A)

between the

(D)

and the gun air inlet. See

Fig. 2.

2.

If

using

a spray

gun

cup

(B),

connect the cup to

the gun fluid inlet.

3.

Musing

connect the fluid supply hose

an

accessory remote pressure pot (C),

(G)

between the

gun fluid inlet and the remote pressure pot.

Connect the air hose

(E)

between the pressure

pot air inlet and the compressor air outlet

(F).

E

2-112

Gallon Remote Pressure Pot

Part

No.

Fig.

M70604

2

(see

Accessories)

E

2

Quart Remote Pressure Pot

No.

Part

M70585

(see Accessories)

CX-8Turblne shown

02859

6

308-336

Page 7

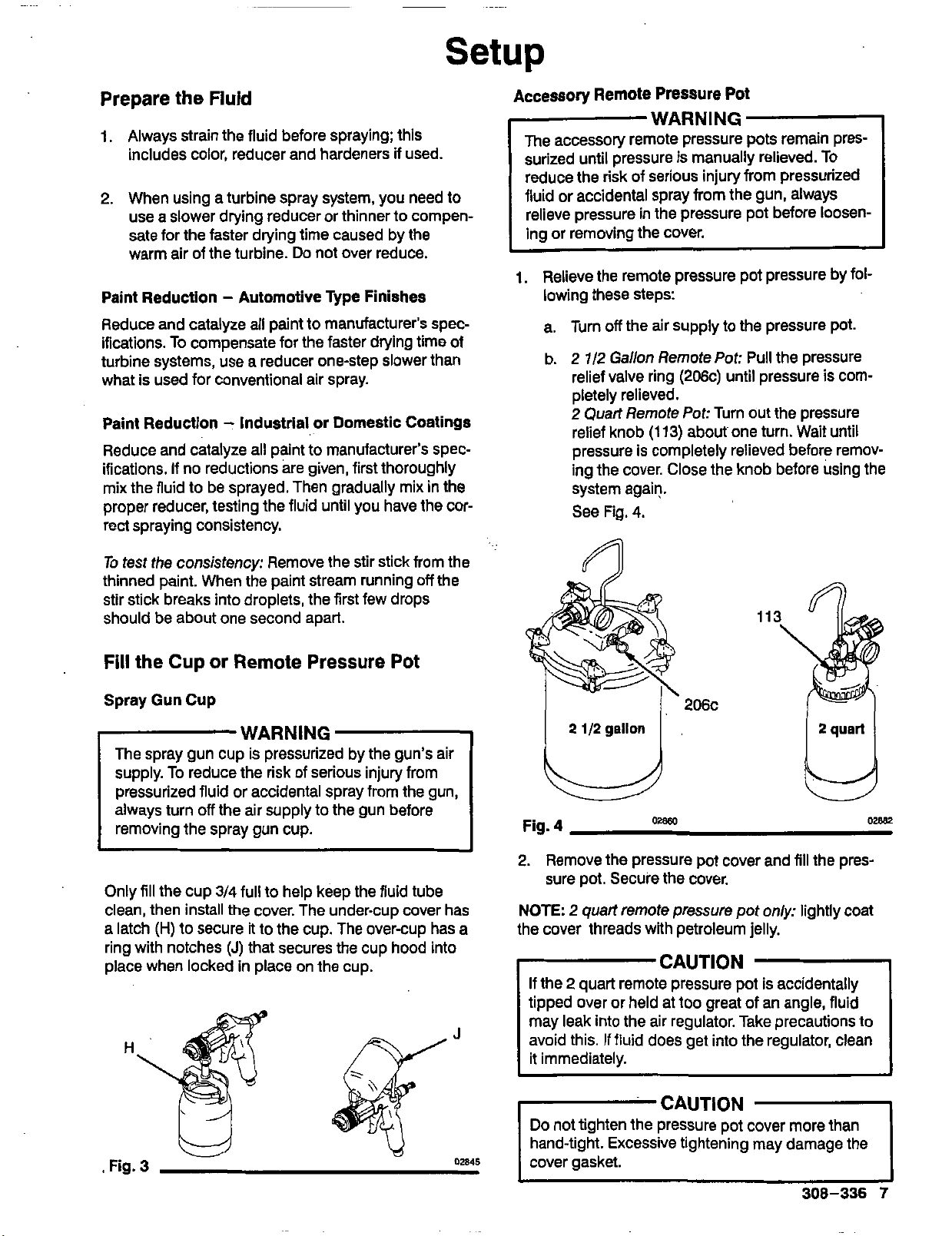

Setup

Prepare the Fluid

1.

Always strain the fluid before spraying; this

if

includes color, reducer and hardeners

2.

When using a turbine spray system, you need

use a slower drying reducer or thinner to compensate for the faster drying time caused by the

warm air of the turbine.

-

Paint Reduction

Reduce and catalyze all paint to manufacturer’s specifications. To compensate for the faster drying time

turbine systems, use a reducer one-step slower than

what is used for conventional air spray.

Paint Reduction

Reduce and catalyze all paint to manufacturer’s spec-

If

ifications.

mix the fluid

proper reducer, testing the fluid until you have the correct spraying consistency.

no reductions are given, first thoroughly

to

Automotive Type Finishes

-

Industrial

be sprayed. Then gradually mix in the

Do

not over reduce.

or

Domestic Coatings

used.

to

of

Accessory Remote Pressure Pot

WARNING

The accessory remote pressure pots remain pres-

surized until pressure is manually relieved. TO

reduce the risk of serious injury from pressurized

fluid or accidental spray from the gun, always

relieve pressure in the pressure pot before loosening or removing the cover.

1.

Relieve the remote pressure pot pressure by fol-

lowing these steps:

off

a. Turn

b.

2

relief valve ring (206c) until pressure is com-

pletely relieved.

2

relief knob

pressure

ing the cover. Close the knob before using the

system again.

See Fig.

the air supply to the pressure pot.

7/2 Gallon Remote

Quart Remote

(113)

is

completely relieved before remov-

4.

Pot:

Pull the pressure

Pot:

Turn out the pressure

about one turn. Wait until

To

test the consistency: Remove the stir stick from the

off

thinned paint. When the paint stream running

stir stick breaks into droplets, the first few drops

should be about one second apart.

Fill

the Cup

Spray Gun Cup

or

Remote Pressure

the

Pot

WARNING

The spray gun cup is pressurized by the gun’s air

supply. To reduce the risk of serious injury from

pressurized fluid or accidental spray from the gun,

always turn

removing the spray gun cup.

Only fill the cup

clean, then install the cover. The under-cup cover has

a latch

ring with notches

place when locked in place on the cup.

off

the air supply to the gun before

3/4

full to help keep the fluid tube

(H)

to secure it to the cup. The over-cup has a

(J)

that secures the cup hood into

Fig. 4

2.

Remove the pressure pot cover and fill the pressure pot. Secure the cover.

NOTE:

the cover threads with

2

quart remote pressure pot

petroleum jelly.

only:

lightly coat

CAUTION

If the 2

tipped

may leak into the air regulator. Take precautions to

avoid this. If fluid does get into the regulator, clean

it immediately.

quart remote pressure pot

over or held at too great of

is

accidentally

an angle, fluid

Do

not tighten the pressure pot cover more than

hand-tight. Excessive tightening may damage the

cover gasket.

308-336

7

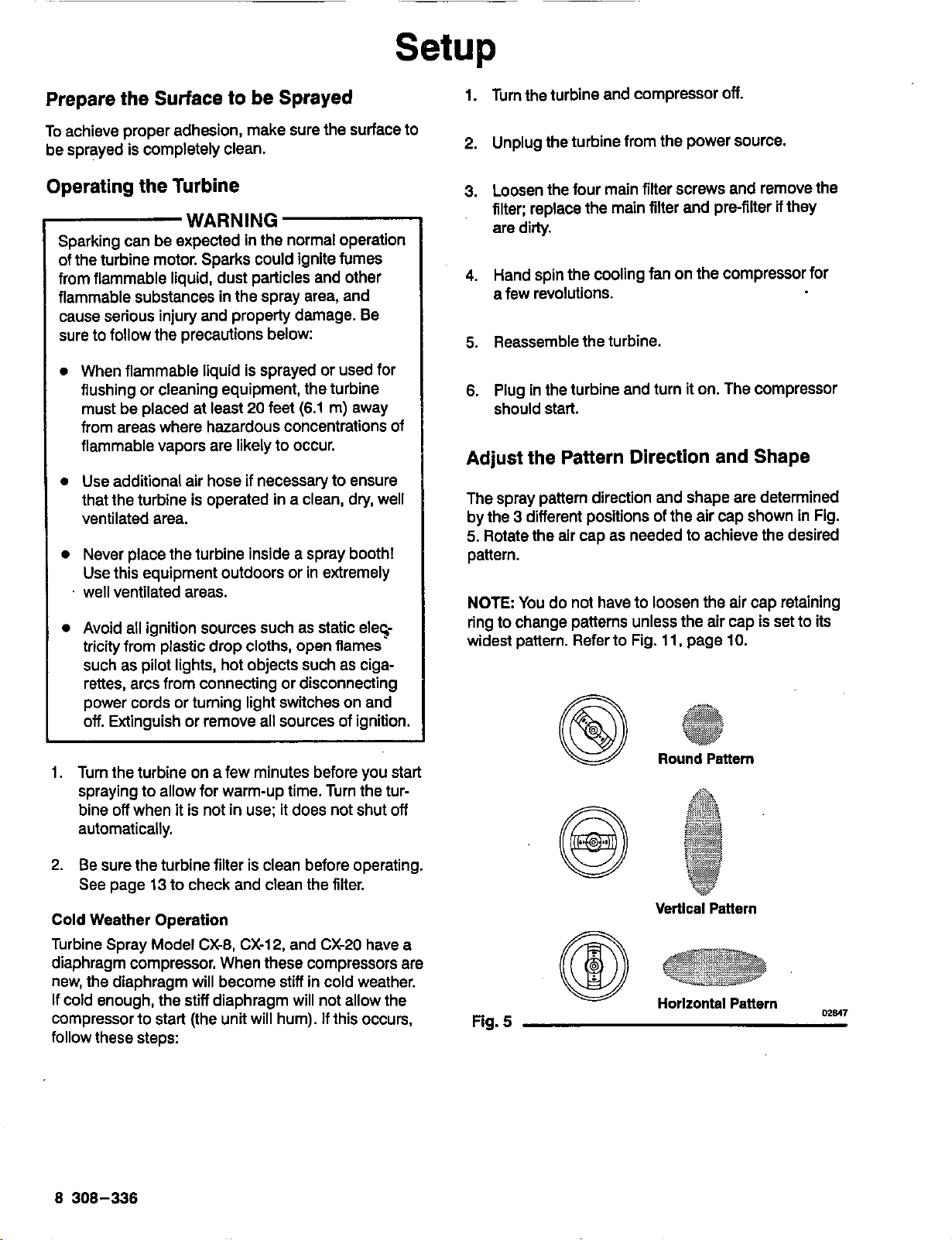

Page 8

Prepare the Surface

to

be Sprayed

Setup

1.

Turn the turbine and compressor

Off.

To achieve proper adhesion, make sure the Surface

be sprayed

is

completely clean.

to

Operating the Turbine

WARNING

Sparking can be expected in the normal operation

of the turbine motor. Sparks could ignite fumes

from flammable liquid, dust particles and other

flammable substances in the spray area, and

cause serious injury and property damage. Be

sure

to

follow the precautions below:

0

When flammable liquid

flushing or cleaning equipment, the turbine

must be placed at least 20 feet

from areas where hazardous concentrations of

flammable vapors are likely

0

Use additional air hose

that the turbine

is

ventilated area.

0

Never place the turbine inside a spray booth!

Use this equipment outdoors or in extremely

'

well ventilated areas.

0

Avoid all ignition sources such as static elestricity from plastic drop cloths, open flames

such as pilot lights, hot objects such as ciga-

rettes, arcs from connecting or disconnecting

power cords or turning light switches on and

off.

Extinguish or remove all sources of ignition.

is

sprayed or used for

(6.1

m) away

to

occur.

if

necessary

to

ensure

operated in a clean, dry, well

2. Unplug the turbine from the power source.

3.

Loosen the four main filter screws and remove the

filter; replace the main filter and prefilter

if

they

are dirty.

4.

Hand spin the cooling fan on the compressor for

a few revolutions.

5.

Reassemble the turbine.

6.

Plug in the turbine and turn

it

on. The compressor

should start.

Adjust the Pattern Direction and Shape

The spray pattern direction and shape are determined

3

by the

5.

pattern.

NOTE

ring

widest pattern. Refer

different positions of the air cap shown in Fig.

Rotate the air cap as needed

You do not have

to

change patterns unless the air cap

to

to

Fig.

to

achieve the desired

loosen the air cap retaining

11,

page

IO.

is

set

to

its

1.

Turn the turbine on a few minutes before you start

spraying

bine

to

allow for warm-up time. Turn the tur-

off

when it

is

not in use; it does not shut

off

automatically.

2. Be sure the turbine filter is clean before operating.

See

page

13

to

check and clean the filter.

Cold

Weather Operation

Turbine Spray Model CX-8, CX-12, and CX-20 have a

diaphragm compressor. When these compressors are

new, the diaphragm will become

If

cold enough, the stiff diaphragm will not allow the

to

compressor

start (the unit will hum).

stiff

in cold weather.

If

this occurs,

follow these steps:

8 308-336

Fig. 5

Round

Vertical

Pattern

Pattern

Horlzontal

Pattarn

m817

Page 9

Setup

Adjust

the

Spray

Paitern

WARMING

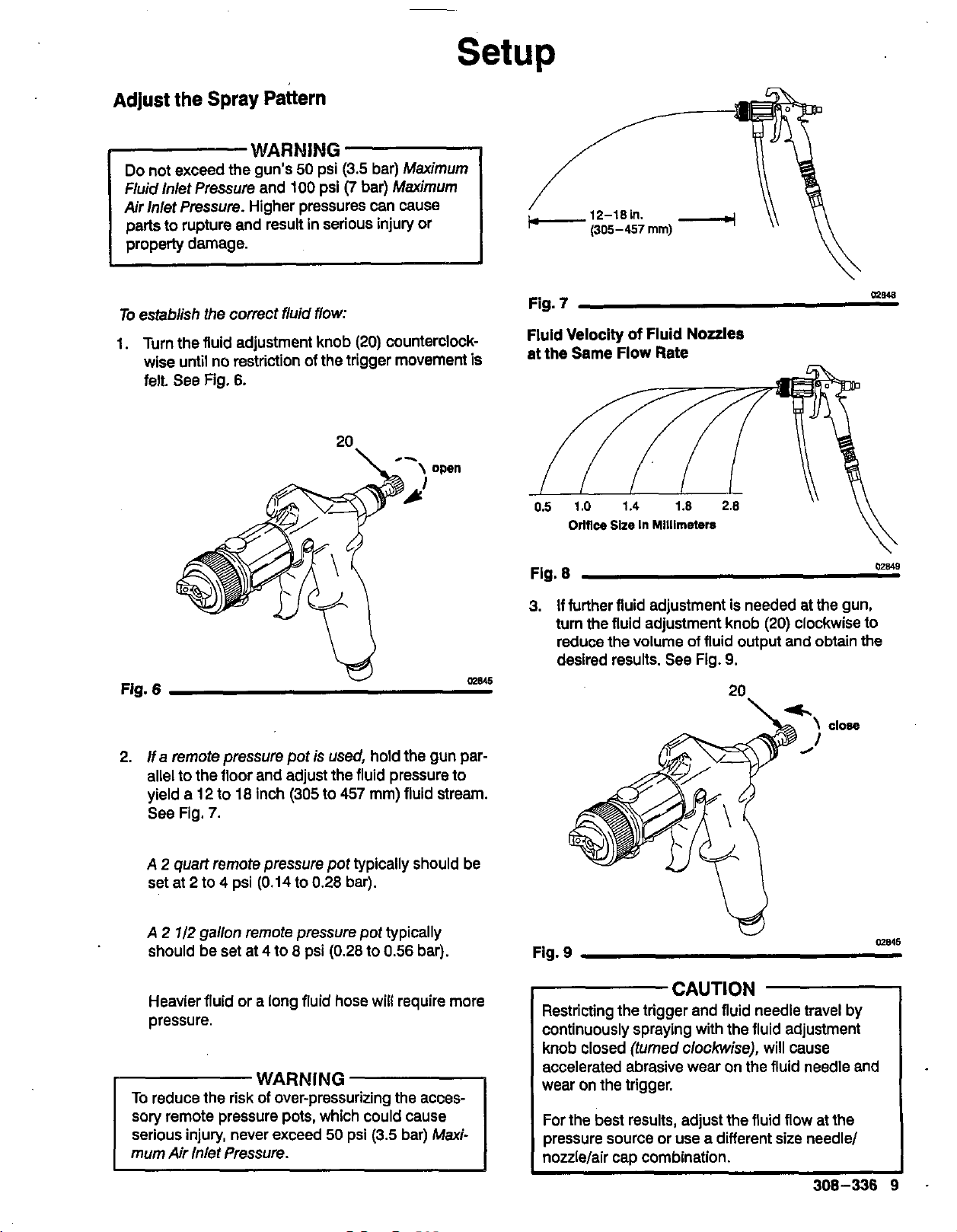

Do

not exceed the gun's

Fluid lnlet Pressure and

Air

inlet

Pressure. Higher pressures can cause

parts to rupture and result in serious injury or

properly damage.

L

To

establish the correct fluid

1.

Turn the fluid adjustment knob

wise until no restriction of the trigger movement is

felt. See Fig.

6.

50

100

psi

(3.5

psi

flow:

bar)

(7

bar)

(20)

counterclock-

Maximum

Maximum

Fig.

7

Fluid Velocity

at the Same Flow Rate

Orlflce

of

Fluid Nozzles

Size

In

Millimeters

m1u8

u

Fig.

6

2.

If a remote pressure pot

allel to the floor and adjust the fluid pressure to

yield

a

12

to

18

inch

(305

See Fig.

A

2

set at

A

2

should be set at

Heavier fluid or a long fluid hose

Dressure,

7.

quart remote pressure pot typically should be

2

to 4 psi

1/2

gallon remote pressure pot typically

(0.14

4 to

to

8

U

is

used, hold the gun par-

to

457

mm) fluid stream.

0.28

bar).

psi (0.28 to

0.56

will

require more

WARNING

To

reduce the risk of over-pressurizing the acces-

sory

remote pressure pots, which could cause

50

psi

(3.5

serious injury, never exceed

mum

Air

Inlet Pressure.

bar)

bar).

Maxi-

me45

Fig.

8

3.

if

further fluid adjustment is needed at the gun,

turn the fluid adjustment knob

reduce the volume

desired results. See Fig.

of

fluid output and obtain the

9.

(20)

clockwise to

20

U

Fig.

9

CAUTION

Restricting the trigger

continuously spraying

knob closed (turned clockwise), will cause

accelerated abrasive wear on the fluid needle and

wear on the trigger.

For the best results, adjust the fluid flow at the

pressure source or use a different

nozzlelair cap combination.

and fluid needle travel by

with the fluid adjustment

size

needle/

02849

me45

308-336

Page 10

Setup

Adjust

To

4.

5. The Air Control Valve

the Spray Pattern

establish the corfect air

Test the spray pattem and atomization while hold-

6

ing the gun about

from the test piece.

bine hose controls both the atomizing air and the

pressure in the spray gun cup (if used). See Fig.

10.

Adjust the air control valve

to 8 inches (150 to

(continued)

flow:

(M)

on the end of the tur-

as

needed.

200

mm)

M

Fig.

10

02850

Adjust

Change the pattem size by turning the air cap retaining ring in for a wide pattern or out for a narrow pattern. See Fig. 11. For a smoother finish, use a narrow

pattern. For more fluid output, use a wide pattern.

NOTE

out, the fluid flow will stop or flutter.

Normal

Spray

Pattern

Wider

Spray

Pattern

the

Pattern

If

the air cap retaining ring

Size

Is

turned

too

Air Cap

with

Fluid Nozzle

Turn

Air

Retaining Ring In

c

far

flush

Cap

NOTES

To

control over-spray mist, use only as much air as

is necessary for the fluid being sprayed. The

less

lighter the fluid, the

If

atomization

procedure above, the fluid may need

further or a different fluid set may be required.

Refer

to

set

or

page 7 to prepare the fluid.

is

unacceptable after following the

pages 4 and 5 to select the proper fluid

air required.

to

be thinned

Narrower

spray

Pattern

Fig.

11

Turn Air Cap

Retaining Ring

Out

-

02851

10

308-336

Page 11

Shutdown

WARNING

The spray gun cups and accessory remote pressure pots remain pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid or accidental spray

from the gun, always relieve pressure in the cup or

pressure pot before checking or servicing any part

of the spray sysfem; before installing, cleaning or

changing fluid nozzles: before loosening or removing the accessoly remote pressure pot cover; and

whenever you stop spraying.

1.

When spraying

to the gun.

2.

If

using a remote pressure pot, relieve

by following these steps:

a. Turn

is

finished, turn

off

the air supply to the pressure pot.

off

the air supply

its

pressure

206c

2

1/2

gallon

ULJ

Fig.

12

02860

113

MBB2

2

1/2

b.

Gallon Remote

relief valve ring (206c) until pressure

pletely relieved.

2

Quart

Remote

relief knob

pressure

ing the cover. Close the knob before using the

system again.

See Fig. 12.

(1

13)

is

completely relieved before remov-

Pot:

Pull

the pressure

is

Pot:

Turn

out

the pressure

about one turn. Wait until

com-

NOTE

will allow the fluid in the fluid hose to drain back into

the remote pressure pot.

3.

4.

Elevate the spray gun and pull the trigger.

If

using a spray gun cup, unlatch the cup cover

and loosen or remove the cup from the cover to

relieve the cup pressure.

Clean the spray gun and cup as instructed on

pages

14 and

15.

This

308-336

11

Page 12

Spraying

General Spraying Techniques

1.

Select the proper fluid set for the fluid you are

4

and

See

5.

Fig.

13.

Then adjust

Air

Cap

with

Fluid

Turn

Air

Retaining

-

spraying. See pages

2.

When fluid

fluid nozzle and air cap adjusted to the "normal

spray pattern" position.

as needed.

Normal

spray

Pattern

Wider

Spray

Pettern

is

first being applied, start with the

Flush

Nozzle

Cap

Ring

Techniques

3.

Keep the gun perpendicular

maintain a consistent distance

8

In

inches

to

sprayed. See Fig.

Always have the spray gun in motion before trig-

4.

gering

piece in a straight, smooth stroke, maintaining the

same speed and distance. Release the trigger at

the end of the stroke.

5.

To obtain an even finish, overlap previous strokes

by the same amount, generally

6.

Apply a full, wet coat whenever possible.

Automotive Spraying Techniques

(150

it.

Move the spray gun across the work-

to

to

the surface and

of

approximately

200

mm) from the object being

14.

50%

overlap.

6

Fig.

13

Turn Air Cap

Retaining

Ring

Out

-

02851

1.

When blending spots, work from the outside in.

2.

Two lengths

mended when applying automotive finish coats,

The additional hose will allow the air to cool for

better flow.

of

20

foot

(6.1

m) hose are recom-

12

308-336

~~

RIGHT

WRONG

0783

Page 13

Spraying

Techniques

Prolonged Overhead or Downward Spraying with a

For

prolonged overhead spraying, loosen the fluid

(N)

tube nut

half turn. See Fig.

(36) in the back side of the cup

will be sprayed.

36

Fig.

15

and turn the entire cup assembly one-

15.

This will position the fluid tube

so

the entire contents

Forpro/onged downwafd spraying, make sure the

fluid tube (36)

I

Flg.

Cup

16

is

positioned

as

shown in Fig. 16.

W2

Turbine Filter Maintenance

The turbine systems are lifetime lubricated. The only

maintenance required is filter cleaning and replace

ment.

The turbine main filter and pre-filter must be clean at

to

all times

and atomize the fluid. Check the filters weekly, minimum. Replace the prefilter as required.

NOTE

place a piece of paper against the air intake filter.

the air intake holds the paper in place, the filter

okay.

To

clean the main filter:

1.

Turn

2.

Loosen the four main filter screws.

provide sufficient air flow to cool the motol

To

check the filter, turn on the turbine and

off

and unplug the turbine.

If

is

3.

Remove the main filter and clean it by following

one of the following three methods:

0

Tap the filter gently on a flat surface, dirty side

down.

0

Direct compressed air

mum) through the filter panel in the opposite

direction of the arrows on the side of the filter.

0

Soak the filter for

mild detergent. Rinse the filter until it

Air dry the filter; do not use compressed air.

-

To avoid damage

tric shock, never install a damp filter in the turbine.

WARNING

to

the turbine and possible elec-

Maintenance continued on

(100

psi

[7

bar] maxi-

15

minutes in water and a

is

clean.

next

page.

308-336

13

Page 14

Maintenance

WARNING

The spray gun cups and accessory remote pres-

sure pots remain pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid or accidental spray

from the gun, always relieve pressure in the cup or

pressure pot before checking or servicing any part

of the spray system; before installing, cleaning or

changing fluid nozzles; before loosening or removing the accessory remote pressure pot cover; and

whenever you stop spraying.

6.

Relieve the pressure pot pressure, following

2.a and b, above.

7.

Disconnect the air and fluid hoses from the gun.

8.

Clean and lubricate

pages

15

and

Flushing the Spray Gun

1.

Turn

off

the air supply to the gun.

16.

the

gun

as

instructed on

and

Cup

steps

NOTES

0

Check for any fluid leakage from the gun and fluid

hoses. Tighten fittings or replace equipment as

needed.

Flush the gun before changing colors and whenever you are done spraying.

CAUTION

Clean all parts with a solvent Compatible with the

fluid being sprayed and compatible with the spray

gun and cup or accessory remote pressure pot

wetted parts. See the Technical

cover.

Data

on the back

Flushing the Spray Gun Using a Remote

Pressure Pot

1.

Turn

off

the air supply to the gun.

2.

Relieve the pressure pot pressure by following

these steps:

off

a. Turn

the air supply to the pressure pot.

2.

Unlatch the cup cover and remove the cup from

the cover.

3.

Turn the air cap to the round pattern position and

turn the air control valve

reduce the solvent mist.

@

1

Fig.

17

4.

Fill the empty cup with about

mm)

of

compatible solvent and reinstall the cup.

Be sure the cover

5.

Turn on the air to the gun.

6.

Point the gun down into a container and flush

until the solvent runs clean. See Fig.

is

secured.

so

it's half open to

See

Fig.

17.

Alr

Cap

Round

Pattern

Posltlon

1-1/2

inches

(38.1

18.

me41

2

7/2

b.

3.

Fill the pressure pot with compatible solvent.

4.

Turn the air cap to the round pattern position and

turn the air control valve

reduce

5.

Flush the spray gun, using compressor air only.

Point the gun down into a container and flush

until the solvent runs clean.

14

308-336

Gallon

relief valve ring (206c) until pressure

pletely relieved.

2

Quart

relief knob

pressure

ing the cover. Close the knob before using the

system again.

See Fig.

the

Remote Pot: Pull the pressure

is

Remote

is

12,

solvent mist. See Fig.

Pot:

Turn out the pressure

(113)

about one turn. Wait until

completely relieved before remov-

page

11.

so

it's

haif open to

17.

com-

Fig.

18

7.

Turn

off

the air to the gun.

8.

Disconnect the air supply and remove the cup

from the gun. Clean and lubricate the gun as

instructed on pages

15

and

16.

028u

Page 15

Maintenance

Clean the Spray Gun

1.

Clean the gun and cup by hand with a compatible

solvent or place them in a gun washer with the

trigger held open; cycle the washer as necessary

to clean the gun.

4.

Soak the air cap, detent plate and fluid nozzle in

solvent. Clean the air car, and fluid nozzle daily,

.~

minimum, with solvent and the brush (R), pro-.

vided. See Fig.

21.

Some applications require

more frequent cleaning. Keep all air cap holes

clean.

CAUTION

Clean air cap horn holes with a non-metallic item

to avoid permanently damaging them.

R

Fig.

19

2.

Remove the air cap retaining ring

spring

(27).

20.

3.

Trigger the gun while you remove the fluid nozzle

(19)

with

Fig.

20.

(25),

and detent plate (26). See Fig.

the

nozzle wrench

(29),

(P),

provided. See

air cap

CAUTION

Trigger the gun whenever you tighten or remove

the nozzle. This keeps the needle seat awayfrom

the nozzle seating surface and prevents the seat

from being scratched.

Me53

Fig.

21

5.

With the gun pointed down, clean the front of the

02858

gun, using the brush, and solvent.

6. Trigger the gun while you install the fluid nozzle

(19)

with the nozzle wrench

7. Install the spring (25) into the front of the gun.

8.

Install the detent plate (26) into the gun housing

with its open sockets

ent plate tab

ing. See Fig.

Install the air cap

9.

(U)

with the detent plate sockets

0

with the notch in the gun hous-

22.

(27),

(P).

See Fig. 20.

(S)

facing up; align the det-

aligning the air cap balls

(S).

See

Fig. 22.

Secure the air cap with the air cap retaining ring

(29).

NOTE

If

installed correctly, the air cap will snap into

4

definite positions, with no loose rotation between the

positions.

Fig.

20

OW

Fig.

22

10.

Lubricate the gun after cleaning

page

16.

n

%===??=

it

as instructed on

308-336

M968

15

Page 16

Service

Lubricating the Spray

After cleaning or servicing the gun, lubricate the parts

23

indicated in Fig.

cant or similar material. See page

cant.

0

All

threaded areas (A)

0

Trigger screws

0

Trigger

0

Fluid needle assembly

axle

with silicone-free spray gun lubri-

(8)

(C)

Gun

26

(D)

-

where indicated

to order lubri-

2.

Loosen the locking nut (14d) and turn the drum

(14c). See Fig.

3.

Turn the drum (14c) until the trigger has about

1/16 in.

(1.59

25.

mm) free travel before the needle

(14) is engaged and starts to move. See Fig.

4.

Lock the adjustment

5.

Make

sure

the spring

ing

(22),

then install the housing with the other

with

the locking nut (14d).

(23)

is

in place in the hous-

parts. Hand-tighten the housing.

25.

~

Fluid

Fig.

Needle

2

23

in.

(50.8

Assembly

mm)

02949.

Adjusting the Needle

The needle may need to be adjusted whenever you

change nozzle/needle sizes or to compensate for

wear.

To

adjust

the

needle:

1.

Remove the housing

gun. The fluid adjustment knob

spring (23-not shown) will come out with it. See

24.

Fig.

(22)

from the back of the

(20),

nut

(21),

om

and

Fig.

Fig.

24

25

02857

16 308-336

Page 17

Service

Adjusting

The needle packings require adjustment once a

month under normal use to ensure fluid does not leak

back through the needle packings. The needle packings must also be adjusted whenever

removed or adjusted.

To

adjust the needle packings:

1.

First flush the gun as instructed on page

2.

Remove the air cap retaining ring

(27),

26.

3.

Trigger the gun while you remove the fluid nozzle

(19)

Fig.

Trigger the gun whenever you tighten or remove

the nozzle. This keeps the needle seat away from

the nozzle seating surface and prevents the seat

from beina scratched.

ICAUTIOY

the Needle

spring

with the nozzle wrench

26.

(25),

Clean the gun as instructed on page

Packings

the

(29),

and detent plate

(P),

provided. See

needle

(26).

air cap

See Fig.

1

14.

is

15.

K

5.

Trigger the gun while you install the fluid nozzle

(19)

with the nozzle wrench

98

(P).

See Fig.

26.

Fig.

26

4.

Trigger the gun while you turn the packing

slightly clockwise with the packing wrench

provided.

packings.

The packings need very

well. If the needle binds, the packings are

tight; back the packing nut

needle should then move freely. If the packings

are over-tightened, they may be damaged and

need to be removed and replaced.

See

Fig.

27.

This will compress the

little

pressure to

off

1/16

turn. The

nut

(K),

seal

too

02854

(9)

6.

Install the spring

7.

Install the detent plate (26) into the gun housing

with its open sockets

ent plate tab

ing. See Fig.

8.

Install the air cap

(U)

with the detent plate sockets

Secure the air cap with the air cap retaining ring

(29).

NOTE

definite positions, with no loose rotation between the

positions.

If installed correctly, the air cap will snap into

Fig.

28

(25)

into the front of the gun.

(S)

facing

0

with the notch in the gun hous-

28.

(27),

aligning the air cap balls

up;

align the det-

(S).

See Fig.

308-336

28.

4

02868

17

Page 18

Troubleshooting.

Spray

Gun

Problems

PROBLEM

No or slow fluid flow, inter-

mittent spray, or fluttering

spray

CAUSE

Proper size fluid set is not being used.

Air cap is adjusted too far forward.

Gun

fluid

nozzle

blocked by dried paint,

aged.

Cup or pressure pot cover is not tight

enough or gasket is damaged.

Cup or pressure pot fluid tube

blocked by dried paint or is damaged.

Air flow to cup is blocked.

is

not tight enough, is

or

is dam-

SOLUTION

Select the proper fluid set for the fluid

being sprayed. See pages

Adjust the air cap

tion. See page

Tighten, clean or replace fluid nozzle.

lighten cover or replace gasket.

Clean or replace fluid tube.

To

check: remove the cup (leave

cover connected), trigger the gun and

check for air flow out of the cup lower

pressure tube.

freely, clean the air

to

10.

is not flowing

If

air

passage tubes.

4

and

5.

"normal" posi-

Fluid leaks at fluid nozzle

after the trigger is released

Poor spray pattern

Needle packings are not properly adjusted. Fluid

will effect fluid pressure and cause a

fluid build-up in the gun body.

Needle is not properly adjusted. Fluid

flow will be restricted if there is too

much free travel between the trigger

and needle.

Needle is not seating in the fluid

nozzle.

Air cap horn holes and/or fluid nozzle

plugged.

loss

though the packings

Clean the gun body with solvent and

the brush provided. Adjust the needle

packings as instructed on page

Adjust the needle as instructed on

page

16.

0

Check for a loose fluid nozzle or

bent nozzle or needle; tighten the

nozzle or replace parts as needed.

0

Check the needle adjustment; see

16.

page

0

Check the needle packings adjust-

ment; see page

Soak air cap and/or fluid nozzle in

vent. Clean air cap horn holes with

non-metallic item to avoid permanently damaging them. See page

17.

17.

a

sol-

15.

18

308-336

Page 19

Troubleshooting

Spray

Finish

'ROBLEM

Problems

-

)range peel finish - Paint

iurface not smooth

3lushing

-

Clear coatings

appear milky

CAUSE

Paint droplets too large.

Paint droplets drying too fast to properly flow out of gun.

Cold weather spraying.

~~~ ~ ~~

Moisture condensation is trapped

the lacquer when spraying

in

in

hot, hu-

mid conditions.

SOLUTION

Maintain proper spraying distance:

see page

12.

Keep the turbine air filters clean to

allow

full

air flow. See page

Do

not use an air hose that is to0

13.

long to provide sufficient atomization pressure.

If droplets are still too large,

reduce the fluid or use a smaller

air cap.

the

Keep

object being sprayed out of

direct sunlight. When spraying in

warmer temperatures, use a slower

evaporating solvent or a retarder.

Keep the fluid and the object being

to

sprayed as close

room temperature

as possible. When sprayed on a cold

surface, most paints will become too

thick to flow properly.

Allow the turbine to warm up a few

minutes before spraying.

Store the lacquer

off

concrete

floors, at room temperature.

Apply lighter coats and ailow for

proper drying time.

Use a slower evaporating solvent

or retarder.

Do

not spray

in

windy conditions.

Fish eyes

-

Small pools on

painted surface that will not

fill

Runsandsags

~ ~~

Solvent pops or bubbles

Silicone contamination from lubricants, grease, polish, or waxes on the

surface being sprayed.

Applying too much paint per pass for

the

drying

conditions.

Sprayed surface drying before solven

gas can be released.

Clean all parts with a cleaning solvent:

use a solvent rag and a clean rag to

wipe with. Replace rags as needed. If

the problem persists, use a fish eye

eliminator.

Move the

gun

faster or decrease

the fluid.flow.

Maintain proper spraying distance:

see page

12.

Reduce the amount of thinner or

use a faster drying thinner.

Apply fluid in lighter coats to allow

for proper evaporation.

Use the recommended thinners.

Follow the solutions, above, for

Orange peel finish-paint droplets

too large.

308-336

19

Page 20

Parts

for

Model

710

NOTE:

The

(181,

and fluid

available

page 5 for

air

needle

as

complete

pari

cap

(27).

assembly

fluid sets.

numbers.

fluid noale

(14)

See

are

37

38

NOTE

Wrap

around fluid tube

hose

(36).

(34)

20

308-336

Page 21

Parts

PTFE

for

Model

710

Ref

No.

1

2*

3*

4*

5*

6

7

8*

9*

10

11*

14

14a

14b

14c

14d

19

20

21

22

23

25*

26*

Part

No.

M70373

M70410

M70388

M70389

M70392

M70384

M70401

M70381

M70380

M70391

M70386

-

M70403

M70404

M70405

M70406

-

M70467

M70466

M70465

M70407

M70378

M70377

Description

GUN BODY

ACTUATOR, needle

PIN, actuator

AXLE, trigger

GUIDE, trigger

HOLDER, nozzle

FITTING, fluid inlet

PACKING KIT. fluid:

NUT, packing

TRIGGER

SCREWIBUSHING ASSY., trigger 2

NEEDLE

page 5 for part no.: Includes

items

14a-14d

-RING, driving

*SPRING, driving ring

DRUM

=LOCKING NUT, drum

FLUID NOZZLE,

page 5 for part no.

ADJUSTMENT KNOB, fluid

NUT, adjustment

HOUSING, adjustment

SPRING, needle return

SPRING, air cap

DETENT PLATE, air cap

axle

ASSY.;

See

See

chart

chart on

Qty

on

1

1

1

1

1

1

1

1

1

1

Ref

No.

27

29

30

31

32*

33

34*

35

36

37

38

39

40

42

43

44

51

52

53

55

Part

M70375

M70400

M70721

M70430

M70394

M70395

M70426

M70413

M70415

M70417

M70422

M71151

M70420

M70424

M70423

M70419

M71117

M71118

M70612

These

which

No.

-

parts

may

Description

AIR

CAP; See chart

part no.

RETAINING RING, air cap

QUICK DISCONNECT, turbine

O-RING; quick disconnect

SET

SCREW, quick disconnect

CONNECTOR, hose

HOSE, air pressure (upper)

CONNECTOR, hose

FLUID TUBE

YOKE, cup

LEVER, cup

COVER,

ELBOW,

NUT, locking

GASKET, cup; polyethylene:

See Accessories to order 5 pack

CUP: 1 quart

HOSE, air pressure (lower)

CONNECTOR, hose

FERRULE

TOOL

brush, T-wrench,

are

included

be

purchased sepafafe/y.

cup

air

pressure

KIT;

(not shown) Includes a

in

Repair

on

(1

liter)

&

nozzle wrench

Kit

page 5 for

M70290,

1

Qty

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

308-336

21

Page 22

Parts

for

Models

709HS

81

71OHS

NOTE:

Model

Model

709HS

710HS

includes

includes 3/4 quart (3/4

1/2

quart

(1/2

liter)

liter)

cup

cup

22

308-336

10

11*

NOTE

The air cap

fluid needle assembly

complete fluid sets. See page 5 for part numbers.

(27),

fluid

(14)

noale

are available

(IS),

and

as

02886

Page 23

Parts

PTFE

for

Models

709HS

&

710HS

Ref

No.

1

2*

3*

4*

5*

6

8*

9*

10

ll*

14

14a

14b

14c

14d

19

20

21

22

23

25*

26*

27

29

Part

No.

M71114

M70410

M70388

M70389

M70392

M70384

M70381

M70380

M70391

M70386

-

M70403

M70404

M70405

M70406

-

M70467

M70466

M70465

M70407

M70378

M70377

-

M70375

Description

GUN BODY

ACTUATOR, needle

PIN, actuator

AXLE, trigger

GUIDE, trigger

HOLDER, nozzle

PACKING KIT. fluid:

NUT, packing

TRIGGER

SCREW/BUSHING ASSY, trigger

NEEDLE ASSY; See chart

page 5 for part no.: Includes

items

14a-14d

*RING, driving

*SPRING, driving ring

DRUM

LOCKING NUT, drum

FLUID NOZZLE, See chart on

page 5 for part no.

ADJUSTMENT KNOB, fluid

NUT, adjustment

HOUSING, adjustment

SPRING, needle return

SPRING, air cap

DETENT PLATE, air cap

AIR

CAP; See chart on page 5 for

part no.

RETAINING RING, air cap

axle

on

~

Qty

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Ref

No.

30

31

32*

33

34

35

36

37

30

39

40

41

42

43

44

45

46

47

55

*

Part

M70400

M70721

M70430

M70426

M71031

M71030

M71033

M71032

M71035

M71034

M71040

M71039

M71037

M71026

M71021

M71019

M71045

M70393

M71046

M70612

These parts are included

which may be purchased separately.

Description

No.

QUICK DISCONNECT, turbine

O-RING: quick disconnect

SET

SCREW, quick disconnect

SET SCREW, plug

FITTING, fluid inlet

NUT, fluid inlet

O-RING

O-RING

CUR 1/2 quart (1/2 liter);

Model

709HS only

CUR 3/4 quart (3/4 liter);

Model

NUT

FITTING

RING, cup

GASKET, cup; polyethylene:

See

COVER, cup

NUT 2

TOOL KIT; (not shown) Includes a

710HS only

Accessories to order 5 pack

HOSE, air pressure

ELBOW CONNECTOR, hose

ELBOW CONNECTOR, hose

brush, T-wrench, &nozzle wrench

in

Repair Kit

w

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

M70290,

308-336

23

Page 24

19

PTFE

Parts

for

Model

7IQP

Ref

No.

1

2'

3*

4*

5*

6

7

8*

9*

10

11*

14

14a

14b

14c

14d

19

Part

No.

M70373

M70410

M70388

M70389

M70392

M70384

M70401

M70381

M70380

M70391

M70386

-

M70403

M70404

M70405

M70406

-

7

'

Description

GUN BODY

ACTUATOR, needle

PIN, actuator

AXLE, trigger

GUIDE, trigger axle

HOLDER, nozzle

FITTING, fluid inlet

PACKING KIT, flu

NUT, packing

TRIGGER

SCREW/BUSHING ASSY, trigger 2

NEEDLE ASSY.: See chart on

5

page

items 14a- 14d

*SPRING, driving ring

FLUID NOZZLE, See chart on

page 5 for part no.

for part no.: Includes

RING, driving

DRUM

LOCKING NUT, drum

YU

10

11*

Qty

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

NOTE

The air cap

fluid needle assembly

complete fluid sets. See page

Ref

No.

20

21

22

23

25*

26*

27

29

30

31

32*

33

55

Part

No.

Description

M70467

M70466

M70465

M70407

M70378

M70377

-

M70375

M70400

M70721

M70430

M70426

M70612

These parts are included

which may be purchased separafely.

ADJUSTMENT KNOB, fluid

NUT,

adjustment

FITTING, gun

SPRING, needle return

SPRING, air cap

DETENT PLATE, air cap

AIR CAP: See chart on page 5 for

part no.

RETAINING RING,

QUICK DISCONNECT, turbine

O-RING; quick disconnect

SET

SCREW,

SET SCREW,

TOOL KIT; (notshown) Includes a

brush, T-wrench,

(27),

in

Repair

fluid nozzle

(14)

are available as

air

quick disconnect

plug

B

(W),

and

5

for part numbers.

cap

nozzle wrench

Kif

M70290,

028M

Qtv

1

1

1

1

1

1

1

1

I

1

1

1

1

24

308-336

Page 25

2

112

50

psi

2 112

Gallon

gallon

Pressure Pot

(3.5

bar) Maximum Inlet Air Pressure

(9.5 liter)

M70604

capacity,

aluminum

Accessories

2

Quart

Pressure Pot

50

psi

(3.5

bar) Maximum Inlet

2

quart

tank.

(2 liter)

capacity,

M70962

aluminum

102 119

Air

Pressure

cup.

205

204

203

202

206f

206b

206c

201

-

206a

206d

-

206

121

125

124

123

Ret.

No.

/

4

Part

No.

LX

Descrlptlon

118

103

101

105

113

111

107

104

106

108

logel

w.

'

Ret.

No.

201 M70670 PRESSURE GAUGE

202

203 M70671

204 M70805

205

206

206a M70667 *COUPLING

206b M70676 *O-RING, pressure relief valve

206c

206d M70616 *GASKET, standard; EPDM

206e

206f M70688

Part

No.

M70674

M70675

M71433

M70686

M70617 GASKET, solvent resistant; Thiokal

M70683

Descrlptlon

HEX NIPPLE, 1/4

PRESSURE REGULATOR

ELBOW, 90"

QUICK DISCONNECT, male

PRESSURE POT ASSEMBLY

Includes replaceable items 206a-20611

*

PRESSURE RELIEF VALVE

(optional-must order separately)

POT, 2 1/2 gallon (9.5 liter),

galvanized steel

.COVER

in.

02861

w.

101 M70670

102 M70727

103 M70671

104 M70731

105

106 M70733

107 M70734

108 M70735

109 M70730

110 M70729

111

112 M70628

113 M70726

114 M70725

1

115 M70724

1

116 M70723

1

117

1

118 M70675

1

119 M70805

120 M71491

1

121 M71470

1

122 M70854

1

123 M70402

1

124 M70397

125 M71412

1

126 M70399

1

1

M70895

M70728

M70722

PRESSUREGAUGE

SAFETY VALVE

PRESSURE REGULATOR

SPRING

REDUCER

BRACKET

VALVE

SCREW

2

quart (1.94 liter), aluminum

POT,

FLUID TUBE

COVER

GASKET, polyethylene

PRESSURE RELIEF KNOB

FITTING

FLUID OUTLET

NllT

HANDLE

PLUG, male, quick disconnect

ELBOW, 90"

HOSE, fluid; 5

1/4 in. (6.35 mm) ID

HOSE, air; 4.5

HOSE CLAMP

QUICK DISCONNECT, female

AIR CONTROL VALVE

O-RING, air valve

QUICK DISCONNECT, male

ft. (1.5 m) long;

ft. (1.4 m) long

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Accessories continued on next ?age.

308-336

25

Page 26

Accessories

NOTE For information on making selections according to the type of

Needle, Nozzle, and Complete

Listed

by

size.

Fluid

Set Chart

-

*

Fluid needlelnoule

**

Complete fluid

air cap.

Fluid

Noale

P/N

M70446

M70447

M70448

M70634

M70449

M70635

M70636

M70450

M70451

set

includes the needle and nozzle.

set

includes needle, nozzle. and standard

Fluld Needle1

Nozzle

Set*

M71326 M70497

Complete

Fluid Set

**

fluid

being sprayed,

Air Cap Chart

Listed

t

t

tt

see

pages 4 and

by

size.

Standard

Orltlce

0.5

mm

0.7 mm

1.0 mm

1.2 mm

1.4 mm

1.6 mm

1

.8

mm

2.0 mm

2.8 mm

Multl-holm

(example:

Narrow fan pattern air cap. Size

marked with a W (example: 05W).

Alr

Cap

PIN

M70434t

M70437t

M70439

M70630

M70442

M70632

M70633

M70444

M70445

air

cap.

05M).

Size

marked

5.

Narrow

Fan Air

Cap PIN

M70435tt

M7043Btt

M70441

with

tt

an

M

User Kit

Used with CX-5, CX-7, CX-9, CX-10, and CX-20.

Includes:

User Kit

Used with

Includes:

Lubricant

One

lubricant for fluid seals and wear areas.

26 308-336

M70704

Pari

No. Descrldlon

M70562 1.0 mm Fluid Set

M70582 2.0 mm Fluid

1

M70425

M70464 Fluid Strainer

M70395 Upper

-

M71449

CX-8

Pari

No.

M70439

M70444

M70448

M70450

M71425

M70460

M70456

M70377

M70376

11 1-265

4

02.

(1

Quart Under-cup

Parts

Box

and

CX-12.

DescrlDtlon

1

.O

Air

2.0

Air

1.0 Fluid Nozzle

2.0

Fluid Nozzle

5 pack of Polyethylene Gaskets for

2 quart (2 liter) pressure pot

2.0 Needle Assembly

1

.O

Needle Assembly

Detent Plate

Spring

13

gram) tube sanitaty (non-silicone)

Set

Air

Pressure

with Compartments

Cap

Cap

Gaskets

Hose

Qtv.

1

1

1

.1

3

1

Qtv.

1

1

1

1

1

1

1

1

1

#4 Ford Viscosity Cup

To

measure viscosity

Blow Gun

For dusting and drying. With quick disconnect and air

control valve.

1

Quart

FRs

on cup part no. M70423 for air tight storage

fluid.

1

Quart

1

quart

1

Quart

5

pack

iiter) under-cup.

3/4

Quart

314

quart (314 liter) over-cup with lid.

314

Quart

5

pack of polyethylene gaskets for

(314 liter) over-cup.

Cup Check Valve

To

help prevent the cup from de-pressurizing after the

air is shut

M70703

(1

liter) Cup

(1

liter) Cup and Lid Assembly

(1

liter) under-cup with air tight lid.

(1

liter) Cup Gaskets

of

polyethylene gaskets for

(314

liter) Cup and

(314

liter) Cup Gaskets

off.

M70702

of

fluid.

Lid

M70610

M71007

M70427

use

Lid

Assembly

M71027

use

of

M70427

with 1 quart

with 3/4 quart

(1

M71047

~~

Page 27

Accessories

Fluid Strainer

Install on the end

to strain the fluid and help eliminate surface

blemishes and plugged tips.

Air Hose

For use

250

psi

(1

For connection between the pressure pot and compressor.

f

x

f quick-disconnect,

Air

Hose Extension

For use wlth the 2 quart

250

psi

(1

To

extend the length of pressure pot air hose

20

ft.

(6.10

1/4

in.

(6.35

Air Hose

For use

150 psi (10.5 bar) Maximum Working Pressure

For connection between the pressure pot and compres-

3

ft.

sor.

NOTE Quick-Disconnect

M70804

Female Quick-Disconnect

For use with air hose

male quick-disconnect on the

pressure pot.

Barbed Fitting

For use with air hose

compressor.

Air Control Valve

Install on turbine hose to control the atomizing air and

the pressure in the spray gun cup.

valve O-ring, order part no.

M70464

of

the cup or pressure pot fluid tube

100

mesh screen. Coupled,

M70666

wlth

the 2 quart

7.5 bar) Maximum Working Pressure

20

ft.

(6.10

7.5 bar) Maximum Working Pressure

m)

long, coupled,

mm)

braided.

M70803

wlth

the

2 112

(0.92

m)

long, coupled,

are

needed to connect the air hose.

M70804

(2

llter) pressure

m)

long, coupled,

114

in.

M70665

(2

liter) pressure pot

gallon

M70911

M70911

M70803

M70803

M70397

M71412.

(6.35

mm)

braided.

m

x

f

quick-disconnect,

(9.5

liter) pressure pot

1/4

in.

(6.35

and Barbed Fitting

to connect to the

2 112

gallon

to connect to the

To

replace the air

pot

M70666.

mm).

(9.5

liter)

Turbine Hose

100

psi

(7

bar) Maximum Working Pressure

For connection between the turbine and spray gun.

3/4

in.

(19

mm),

spring on turbine end.

v

M71451

M71453

Turbine Hose Extension

100

psi

(7

To

extend the length of turbine hose

M71453.

Fluid Hose

For use wlth the

175 psi

For connection between the pressure pot and spray

gun.

Fluid Hose Extension

For use with the

175psi

To

318

NOTE Fluid Hose Connector

ordered with

Fluid Hose Connector

For use with fluid hose extension

318

Coupled,

Part

No.

M71462

M71464

(12.1

25

ft.

(12.1

extend the length of fluid hose

in.

(9.53

Part

No.

M71480

M71484

npsm.

20

ft.

(6.10

m)

30

ft.

(9.15

m)

bar) Maximum Working Pressure

M71451

3/4

in.

(19

mm).

Lenath

20

ft. (6.10 m)

30

ft.

(9.15

m)

M71481

2 112

gallon

bar) Maximum Working Pressure

(7.63

m)

long, coupled,

2 112

gallon

bar) Maimum

mm).

the

fluid hose extension.

Lenath

20ft.

(6.10

30

ft.

(9.15

(9.5

(9.5

Working

M70693

m)

m)

M70693

liter) pressure pot

3/8

in.

(9.53

liter) pressure

Pressure

M71481.

must be

M71480

or

or

mm).

pot

Coupled,

M71484.

308-336 27

Page 28

The

PTFE

PTFE

WARRANTY

Graco warrants all equipment manufactured by it and bearing its name

date

of

sale by an authorized Graco distributor to the original purchaser for use.

ranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defective.

This warranty applies only when the equipment is installed, operated and maintained in accordance with Gram's written recom-

mendations.

This warranty does not cover, and Graco shall not be

application, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of nonGraco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility with Graco

equipment of structures, accessories, equipment or materials not supplied by Graco, or

tion, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed

for verification

equipment will be returned to the original purchaser transportation prepaid.

defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the

labor and transportation.

DISCIAIMERS AND LIMITATIONS

The terms of this warranty constitute purchaser's sole and exclusive remedy and are in lieu of any other warranties (express or

implied), lncludlng warranty

:iabiiities, including product liabilities. based on negligence or strict liability. Every form

damages or

action for breach

of

loss

Graco Warranty and Disclaimers

to

be

free

from defects in material and workmanship on the

As

purchaser's sole remedy for breach of this war-

liable

for, any malfunction, damage or wear caused by faulty installation,

the improper design, manufacture, installa-

to

the claim.

is expressly excluded and denied. In

of

If

the claimed defect is verified, Graco will repair or replace.free of charge any defective parts. The

of

merchantablllty or warranty

warranty must be brought within two

be defective

If

inspection of the equipment does not disclose any

of

fltness for a particular purpose, and

of

no

case shall Graco's liability exceed the amount of the purchase price. Any

(2)

years of the date

of

sale.

to

an authorized Graco distributor

of

any non-contractual

liability for direct, special or consequential

costs

of

mis-

parts,

EQUIPMENT

Graco makes no warranty, and disclaims all implied warrantles

respect to accessories, equipment, materials,

manufactured by Graco (such as electric motor, switches, hose, etc.) are subject to the warranty,

Graco will provide purchaser with reasonable assistance

Maximum

Maximum

Wetted

Bare

Spray

2

Remote

2-112

Remote

NOT

COVERED

BY

GRACO WARRANTY

or

Technical Data

Inlet

Fluid

Inlet

Air

Pressure

Parts

Spray

Gun

Gun

Cups

Quart

Accessoly

Pressure

Gallon

Accessory

Pressure

is

a

registered trademark

Pressure

.........

........

Pot

Pot..

........

...........

Stainless

50

100

Steel,

Hard-coated

Aluminum, Polyethylene

....

Aluminum,

........

of

the Corporation.

Polyethylene

Galvanized

EPDM

of

merchantablllty

components sold but not manufactured by Graco. These items sold, but not

in

making any claim for breach of these warranties.

and

fltness for a particular purpose, with

Graco Phone

psi

(3.5

bar)

psi

(7

bar)

~ ~~i~~~,

TEcffN'cAL

information

Graco

equipment:

Steel,

(standard)

Numbers

Ass'sTANcE~

or

assistance

1-800-543-0339

regarding

if

any,

of

their manufacturer.

the

repair

application

Toll Free

of

Sales Offlces: Atlanta, Chicago, Dallas, Detroit,

Forelgn Offlces: Canada; England; Korea: Switzerland: France: Germany: Hang Kong; Japan

GRACO INC.

RO.

BOX

1441 MINNEAPOLIS, MN 55440-1441

PRINTED

IN

U.S.A.

Los

308-336

Angeles, Mt. Arlington (N.J.)

1/94

Loading...

Loading...