Page 1

INSTRUCTIONS-PARTS LIST

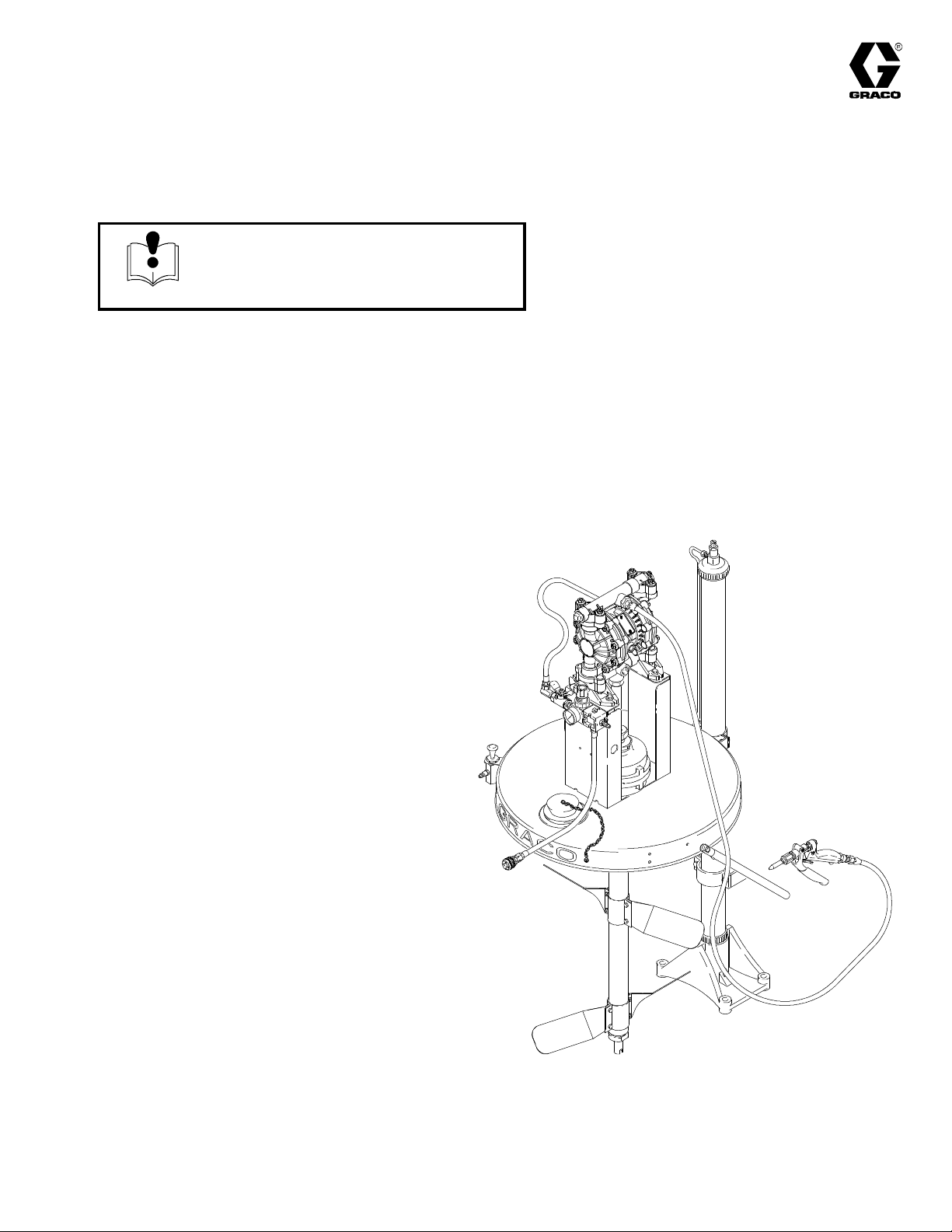

Husky 515

308666

55-Gallon Dispenser Package

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

100 psi (6.9 bar) Maximum Air Input Pressure

Model 231418, Series B

Dispense Package with Gun

Model 231419, Series B

Dispense Package

Table of Contents

Warnings 2......................................

Parts Drawings 4.................................

Parts Lists 5....................................

Installation 6.....................................

Operation 6.....................................

Service and Technical Data 7......................

Dimensional Drawing 7...........................

Warranty 8......................................

Graco Phone Number 8...........................

Rev. C

Model 231418 shown

9294A

Page 2

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

WARNING

EQUIPMENT MISUSE HAZARD

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily . Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 100 psi (7 bar) maximum working pressure.

D Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the Techni-

cal Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose hoses to temperatures above 180_ F(82_ C) or below --40_ F(--40_ C).

D Do not lift pressurized equipment.

2 308666

Page 3

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground all equipment and the equipment being dispensed to. Refer to Grounding on page 6.

D If there is any static sparking or you feel an electric shock while using this equipment, stop dis-

pensing immediately. Do not use the equipment until you identify and correct the problem.

D Do not use kerosene or other flammable solvents or combustible gases to flush the unit.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Keep the dispensing area free of debris, including solvent, rags, and gasoline.

D Do not smoke in the dispensing area.

D Extinguish all open flames and pilot lights in the dispensing area.

MOVING PARTS HAZARD

Moving parts, such as the rotating blades of the agitator, can pinch or amputate your fingers or other

body parts and can cause splashing in the eyes or on the skin.

D Keep clear of all moving parts when starting or operating the agitator.

D Always shut off the agitator and disconnect the air line before you remove the agitator from the

drum or check or repair any part of the agitator.

D Do not operate the agitator while an air line is hooked up to the elevator air fitting. Such operation

could cause the agitator blades to turn while the elevator is raised, which could result in serious

bodily injury or damage to the equipment from the hose getting tangled in the rotating agitator

blades.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled. When flushing the air motor or pump, keep your face away from the

exhaust port.

3308666

Page 4

Parts Drawing

Husky 515 55-Gallon Dispense Package with Gun, Model 231418, Series B

Includes items 1 through 54

Husky 515 55-Gallon Dispense Package, Model 231419, Series B

Includes items 1 through 26

24

23

19

18

12

16

elevator

air control

valve

25

10

11

24

1

agitator

needle

valve

6

17

27

50

restrictor

valve

1

14

13

7

8

9

51

18

52

53

54

15

20

4

4

3

3

Husky 515 Diaphragm Pump

1

21

22

2

2

(see manual 308981)

2

Drum Cover Assembly

(see manual 308466)

Siphon Kit

3

(see manual 308609)

Elevator Assembly

4

(see 306287)

Heavy-Duty SST Drum Agitator

5

(see manual 308609)

4 308666

5

5

9295A

3

3

Page 5

Parts List

Husky 515 55-Gallon Dispense Package with Gun, Model 231418, Series B

Includes items 1 through 54.

Husky 515 55-Gallon Dispense Package, Model 231419, Series B

Includes items 1 through 26.

Ref

No. Part No. Description Qty.

1 241564 PUMP, Husky 515, acetal

See manual 308981. 1

2 238283 DRUM COVER ASSEMBLY

See manual 308466. 1

3 238250 SIPHON KIT

See manual 308609. 1

4 237746 ELEV ATOR ASSEMBLY

See manual 306287. 1

5 238157 DRUM AGITAT OR, heavy duty;

SST See manual 308609. 1

6 191565 BRACKET , pump 1

7 191566 UNION, suction tube 1

8 191567 NUT, union, swivel 1

9 1 13575 O-RING, packing 1

10 1 11804 REGULATOR, air 1

1 1 111805 BLOCK, diverter 1

12 108190 GAUGE, air pressure 1

13 100086 WASHER, plain 4

Ref

No. Part No. Description Qty.

14 100022 SCREW, cap 4

15 108094 NUT, lock 4

16 1 11821 SCREW, mach, hex head 1

17 1 11280 NUT, locking 1

18 156971 NIPPLE, short 2

19 1 10223 BALL VALVE, vented 1

20 108865 SCREW, mach, pan head 1

21 100721 PLUG, pipe, headless 1

22 169971 FITTING, air line 1

23 155541 UNION, swivel; 90_ 1

24 203266 HOSE, coupled 2

25 208536 COUPLER, air line 1

27 1 10733 ELBOW, 45_, 1/4 npt 1

50 158212 BUSHING, pipe 1

51 238740 HOSE, coupled, conductive 1

52 237607 FLOW GUN, severe duty 1

53 168683 BUSHING, nozzle 1

54 161505 NOZZLE, flow gun 1

5308666

Page 6

Installation

Mounting the Elevator Base to the Floor

WARNING

You must mount the elevator base to the floor

before you operate this equipment.

1. Position the elevator where there is at least 9 feet

(2.75 meters) of overhead clearance.

2. Mark and drill holes in the floor for 0.5-in. (13 mm)

mounting bolts. See the mounting layout in the

Dimensional Drawing on page 7.

3. Level the elevator base, using shims if necessary,

and bolt the base firmly to the floor.

Operation

WARNING

MOVING PARTS HAZARD

To reduce the risk of serious injury,

including cuts, amputation of fingers by

the agitator blades, and splashing in

the eyes or on the skin, always shut off the

agitator (disconnect the air line from the agitator)

before you raise, check, or repair the agitator.

Never operate the agitator when the elevator is

raised. See Moving Parts Hazard on page 3.

Startup

See the Parts Drawing on page 4.

Grounding

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, the mounting

cover and all electrically conductive objects or devices

in the dispensing area must be properly grounded.

Check your local electrical code for detailed grounding

instructions for your area and type of equipment.

To ground the dispenser, connect the end of the

ground wire to a true earth ground.

4. Using the needle valve on the agitator to adjust the

agitator speed, gradually increase the speed until

you can see (through the inspection port in the

drum cover) movement in the surface of the liquid,

but do not increase the agitator speed enough to

create a vortex in the surface of the liquid. If the

surface begins to vortex, decrease the agitator

speed to prevent air entrainment.

NOTE: Always maintain moderate agitator speed,

which is approximately 50 rpm of the agitator

blades. Excessive agitator speed may cause

vibration, foaming of fluid, and increased wear on

parts. Always agitate fluid thoroughly before

supplying it to the dispensing equipment, and

continue agitating fluid while the dispensing equipment is being supplied.

1. Flush the dispenser before first use.

NOTE: The pump was tested in water. To eliminate possible contamination of the fluid you are

pumping, before you use the dispenser, flush the

pump thoroughly with a solvent compatible to the

solvent you are dispensing.

2. Ensure that the needle valve on the agitator is

closed and that the dispenser ball valve (19) is

closed.

3. Connect the air supply line to the male air line

fitting (22).

6 308666

5. Use the regulator (10) and ball valve (19) to control

the pressure and operation of the pump (1).

6. Raise or lower the elevator by pulling out or pushing in the air control valve (a push-pull handle) on

the rim of the drum cover. Normal operation

requires only a few seconds for air pressure to

build up and raise the elevator or to exhaust and

lower the elevator.

NOTE: To increase the operating speed of the

elevator, loosen the hex nut on the restrictor valve,

and turn the valve needle out. To decrease the

operating speed, turn the valve needle in. The

restrictor valve is on the top of the elevator, as

shown in the Parts Drawing.

Page 7

Service and Technical Data

See the individual component instruction manuals for service instructions and technical data.

Dimensional Drawing

NOTE: See individual component instruction manualsfor dimensions

of agitator, pump, elevator, siphon kit, and drum cover.

Elevator Base

height of unit from

base to top of pump

when elevator is raised

Mounting Hole Layout

57 in.

(1448 mm)

9294A

95 in.

(2413 mm)

35.62”

33.75”

5.5 in.

(140 mm)

8.88 in.

(225.6 mm)

0.56-in.

(14.2 mm)

holes

25.9”

ti22759a

7308666

Page 8

The Graco Warranty and Disclaimers

WARRANTY

Graco warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on

the date of sale by an authorized Graco distributor to the original purchaser for use. As purchaser’s sole remedy for breach of

this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for, any malfunction, damage or wear caused by faulty installation,

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of nonGraco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility with Graco

equipment of structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any

defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor and transportation.

DISCLAIMERS AND LIMITATIONS

The terms of this warranty constitute purchaser’s sole and exclusive remedy and are in lieu of any other warranties (express or

implied), including warranty of merchantability or warranty of fitness for a particular purpose, and of any non-contractual

liabilities, including product liabilities, based on negligence or strict liability. Every form of liability for direct, special or consequential damages or loss is expressly excluded and denied. In no case shall Graco’s liability exceed the amount of the purchase

price. Any action for breach of warranty must be brought within two (2) years of the date of sale.

EQUIPMENT NOT COVERED BY GRACO WARRANTY

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose,with

respect to accessories, equipment, materials, or components sold but not manufactured by Graco. These items sold, but not

manufactured by Graco (such as electric motor, switches, hose, etc.) are subject to the warranty, if any, of their manufacturer.

Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

Graco Phone Number

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco. com/patents.

TO PLACE AN ORDER, contact your Graco distributor, or call to identify the distributor closest to you:

Phone: 6126236921 or Toll Free: 1-- 800--328--0211 Fax: 612--378--3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 308666.

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. AND SUBSIDIARIES P.O. BOX 1441 MINNEAPOLIS, MN 55440 --1441 USA

ECOPYRIGHT 1996, GRACO INC. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revision C, January 2014

8 308666

Loading...

Loading...