Page 1

GENUINE GRACO PARTS AND ACCESSORIES

Center Rebuild Kit

Husky® 1050 Diaphragm Pumps

Kits 24B621 and 24D730

Important Safety Instructions

Read all warnings and instructions in the

®

Husky

Repair/Parts manual. Save all instructions.

1

4

102

1

103

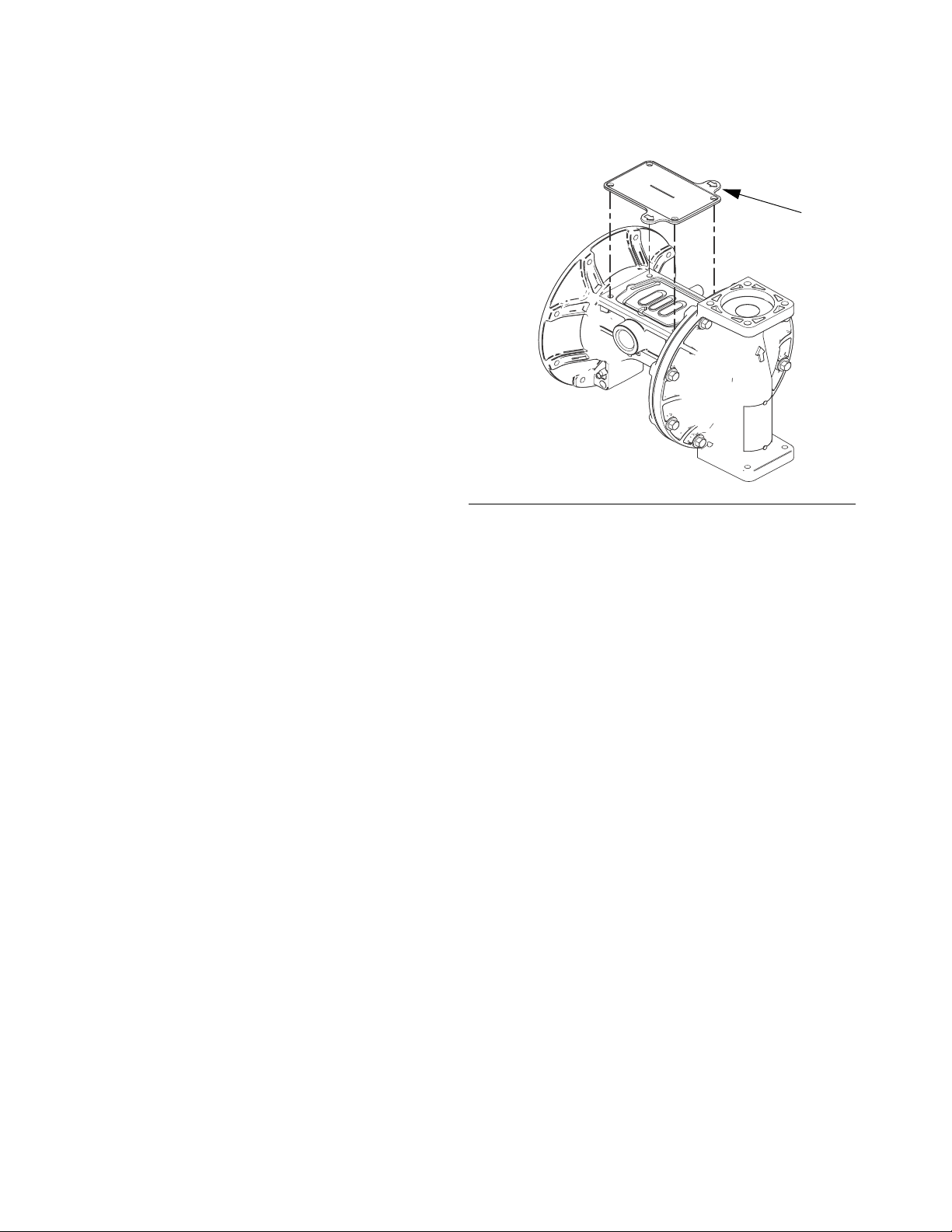

1050 Air-Operated Diaphragm Pump

105

1

106

1

2

107

109

108

Ref. Description Qty.

101 VALVE, pilot 2

102 CARTRIDGE, pilot 2

103 O-RING, cartridge 2

104 SHAFT, center 1

105 BEARING, center shaft 2

106 U-CUP, center shaft 2

107 GASKET, air valve 1

108 SCREW, M6 x 25

109 NUT (Kit 24B621, for use with plastic

110 O-RING, manifold, PTFE (not shown) 8

406806B

(for use with aluminum housings)

housings)

1

Apply lithium-based grease.

2

Lips must face out of housing.

3

Torque to 20-25 in.-lb (2.3-2.8 N•m).

4

Cartridges (102) must be installed in

housing before pilot valves (101).

ENG

4

4

4

3

1

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

406806 Rev. B 11/2009

Copyright 2009, Graco Inc. is registered to ISO 9001

101

1

4

102

103

1

1

106

1

105

1

104

2

ti14025b

See reverse for assembly instructions.

Page 2

Assembly

NOTE: Apply lithium-based grease whenever instructed

to grease.

1. Clean all parts and inspect for wear or damage.

Replace parts as needed.

2. If removed, grease and install the new pilot valve

cartridges (102) and o-rings (103). Screw in until

seated.

NOTE: Cartridges (102) must be installed before pilot

valves (101).

3. Grease and install the pilot valves (101). Torque to

20-25 in.-lb (2.3-2.8 N•m). Do not over-torque.

4. Grease and install the diaphragm shaft u-cup packings (106) so the lips face out of the housing.

5. If removed, insert the new bearings (105) into the

center housing. Use a press or a block and rubber

mallet to press-fit the bearing so it is flush with the

surface of the center housing.

6. Assemble and install the shaft (104), one of the diaphragm assemblies, and the first fluid cover. See

Reassembly in the manual or follow directions on

the sheet that accompanies all diaphragm kits.

7. To ensure proper seating and extend diaphragm life,

attach the second fluid cover with air pressure on

the pump.

a. Place the tool (supplied with diaphragms) where

the air valve gasket (107) normally goes. Arrows

(A) must face toward the fluid cover that is

already attached.

A

ti14120a

F

IG. 1. Fluid cover tool

b. Reattach the air valve.

c. Supply a minimum of 20 psi (0.14 MPa, 1.4 bar)

air pressure to the air valve. Shop air may be

used. The diaphragm will shift so the second

fluid cover will seat properly. Keep air pressure

on until the second fluid cover is attached.

d. Attach the second fluid cover (3). See Torque

Instructions in the manual.

e. Remove the air valve and the tool.

8. Align the new air valve gasket (107) on the center

housing, then attach the air valve. See Torqu e

Instructions in the manual.

9. Reassemble the ball check valves and manifolds as

explained in the manual.

2 406806B

Loading...

Loading...