Page 1

Instructions-Parts

Air Compressor Kit

Air compressor and receiver tank for Reactor® E-30i and E-XP2i integrated plural component

proportioning systems. For professional outdoor use only. Not for use in explosive atmospheres.

Important Safety Instructions

Read all warnings and instructions in this manual. Save these

instructions.

24K335

3A1902C

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Install Air Co

Install Air Tank ................................................... 3

Connect Air Lines ............................................... 3

mpressor......................................... 2

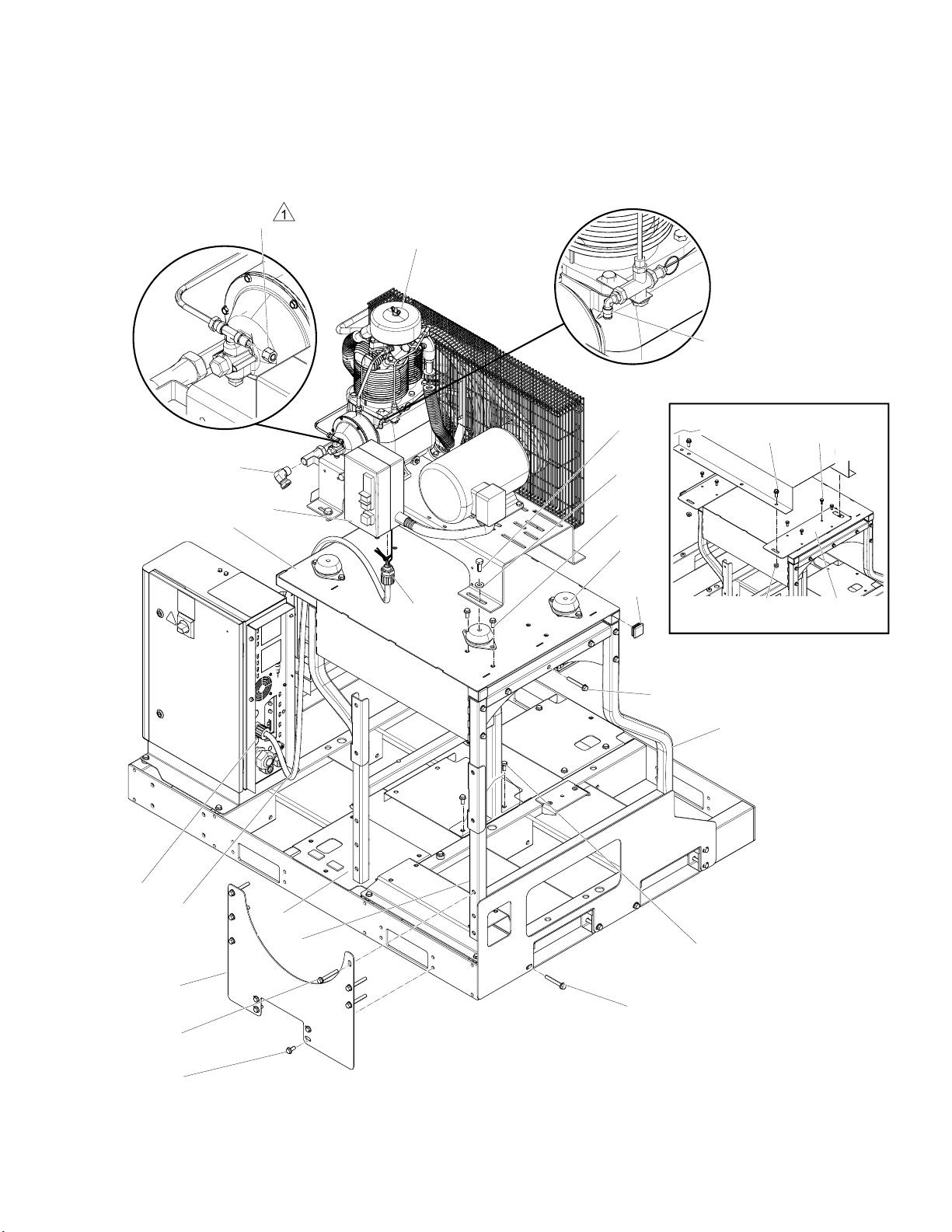

Install Air Compressor

Reference

1. Remove the battery bracket and fuel tank. See

system repair manual for instructions.

2. Turn the B side y-strainer inlet on the Reactor

as shown.

parts illustration, Parts, page 7 .

NOTICE

Connect Power

Parts.................................................................. 7

Graco Standard Warranty.................................... 10

8. Lift side o

level bef

nuts.

9. Install f

plate ass

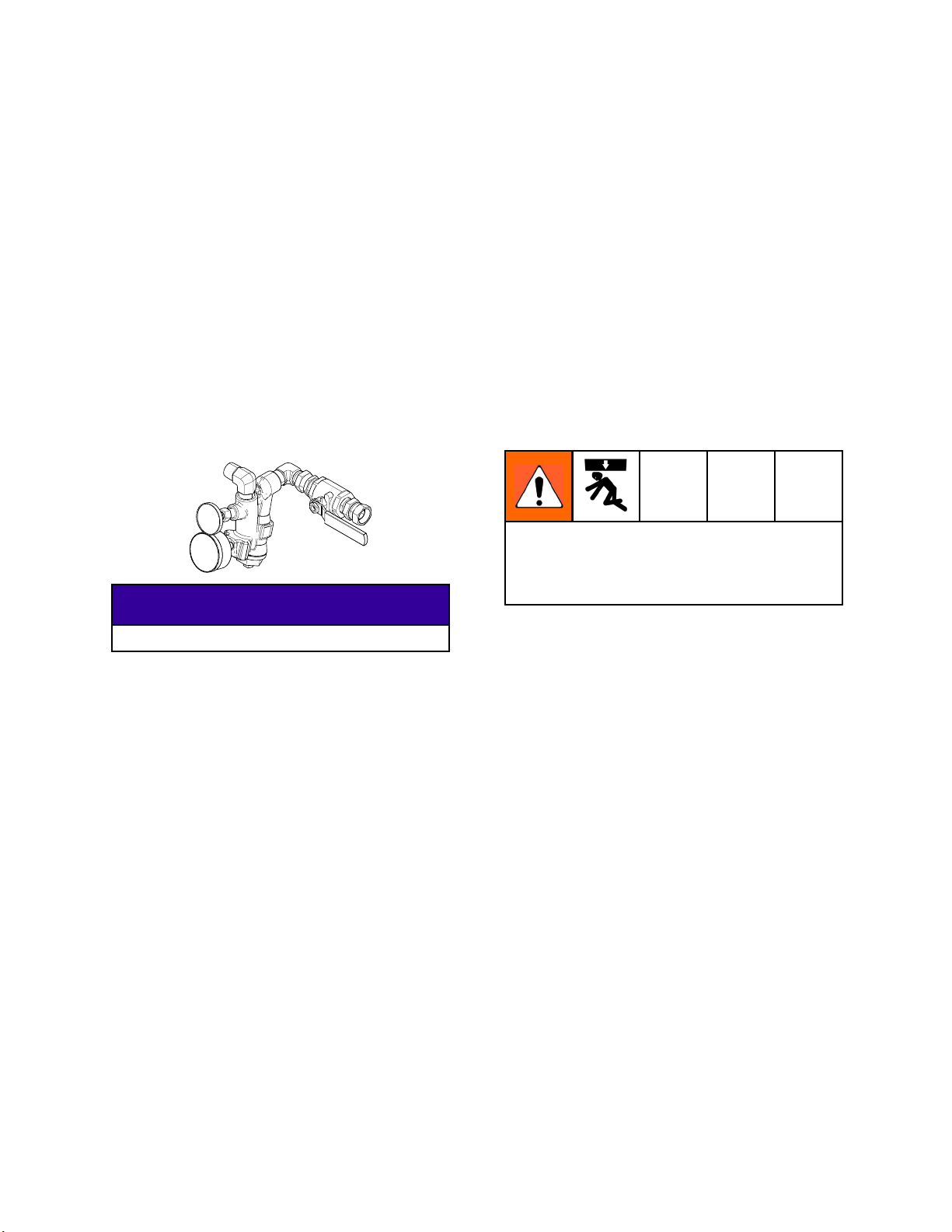

Use lifting device to prevent personal injury

when lifting the compressor. Do not overlap

lifting straps over tubing or other fragile

components.

Cable ......................................... 5

f gusset (5) to ensure top plate (3) is

ore tightening. Tighten all screws and

our isolators (8) with screws (10) on top

embly (3).

Be careful to not damage engine components.

3. Loosely assemble the front bracket (2) to pallet

using two screws (10).

4. Install the side support gusset (5) to the pallet

with four screws (10) and nuts (11) as shown. Do

not tighten the screws.

5. Install the rear bracket (1) on the pallet with five

screws (9) and nuts (11). Do not tighten the

screws.

6. Install the six screws (10) and nuts (11) through

the top of the support gusset (5). Do not tighten

the screws.

7. Assemble the top plate assembly (3) to frame

with 14 screws (9) and nuts (11). Do not tighten

the screws.

10. Lift the air compressor (7) onto the isolators (8).

Secure the air compressor to the isolators with

four screws (28), washers (29).

11. Install elbow adapter (13) in air compressor

outlet.

12. Remove plug and install elbow fitting (41) on

compressor pilot valve (see parts illustration).

13. Remove compression nut cap and install

compression nut fitting (37). Tighten finger tight

only.

14. Install end caps (32).

2

3A1902C

Page 3

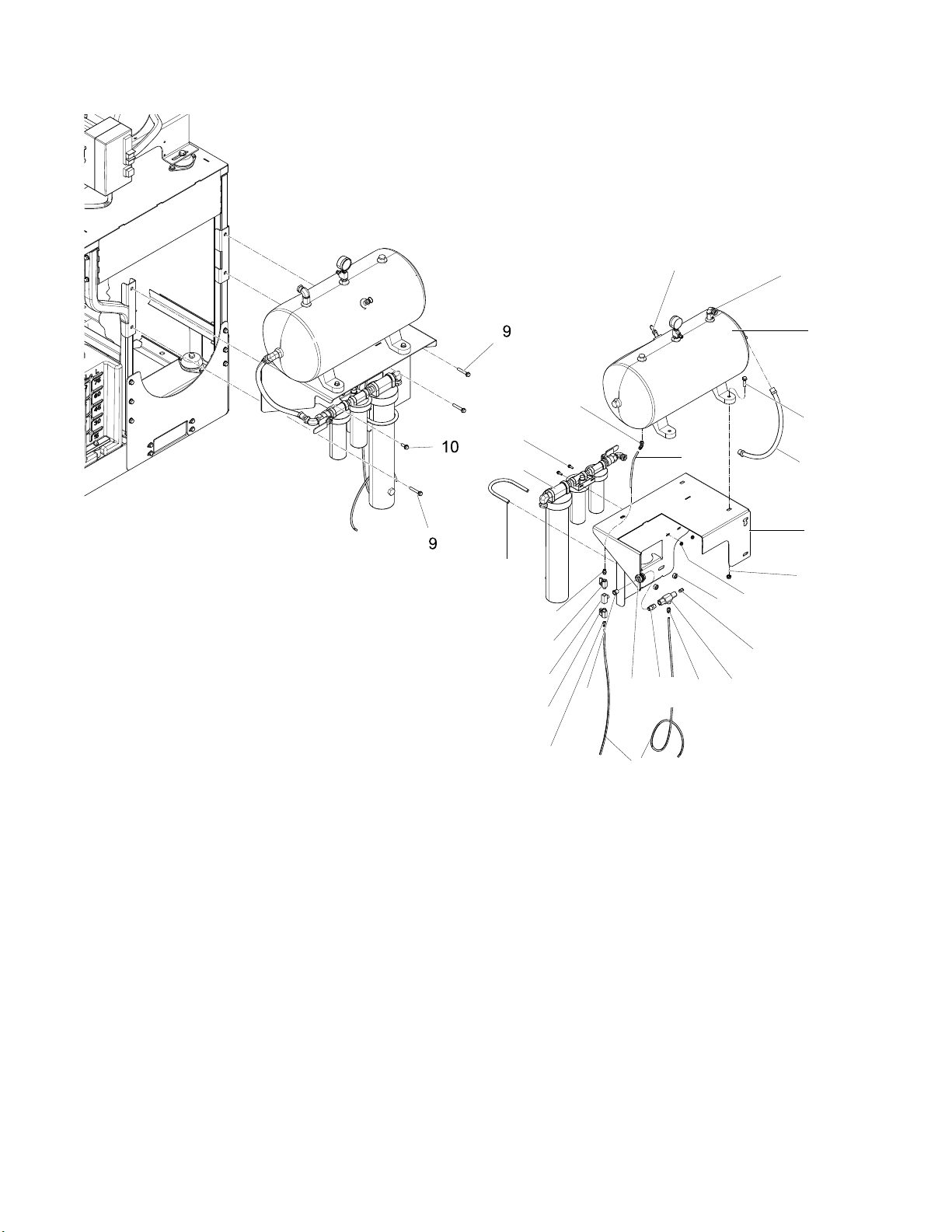

Install Air Tank

Install Air Tank

Reference parts illustration, Parts, page 8.

1. Connect nippl

connector (15

(30). Apply P

2. Install bulk

3. Install bush

and two conne

PTFE sealan

4. Install con

5. Remove desi

desiccant

Drying Sys

6. Connect ai

with screw

7. Mount tan

and nuts (

compress

screw (10

e (26), water drain valve (16),

), and connector (31) to bulkhead

TFE sealant on threads.

head assembly to bracket wall (6).

ing (47), tee (48), two ball valves (17),

ctors (15) to bulkhead (30). Apply

t on threads.

nector elbow (41) to bottom of tank (4).

ccant housing and fill with all

pellets provided. See Desiccant Air

tem manual 309921.

r dryer assembly (33) to bracket (6)

s (39), nuts (40), and clamp (38).

k (4) on bracket (6) with screws (12)

11). Mount bracket assembly to the

or frame with three screws (9), one

), and four nuts (11).

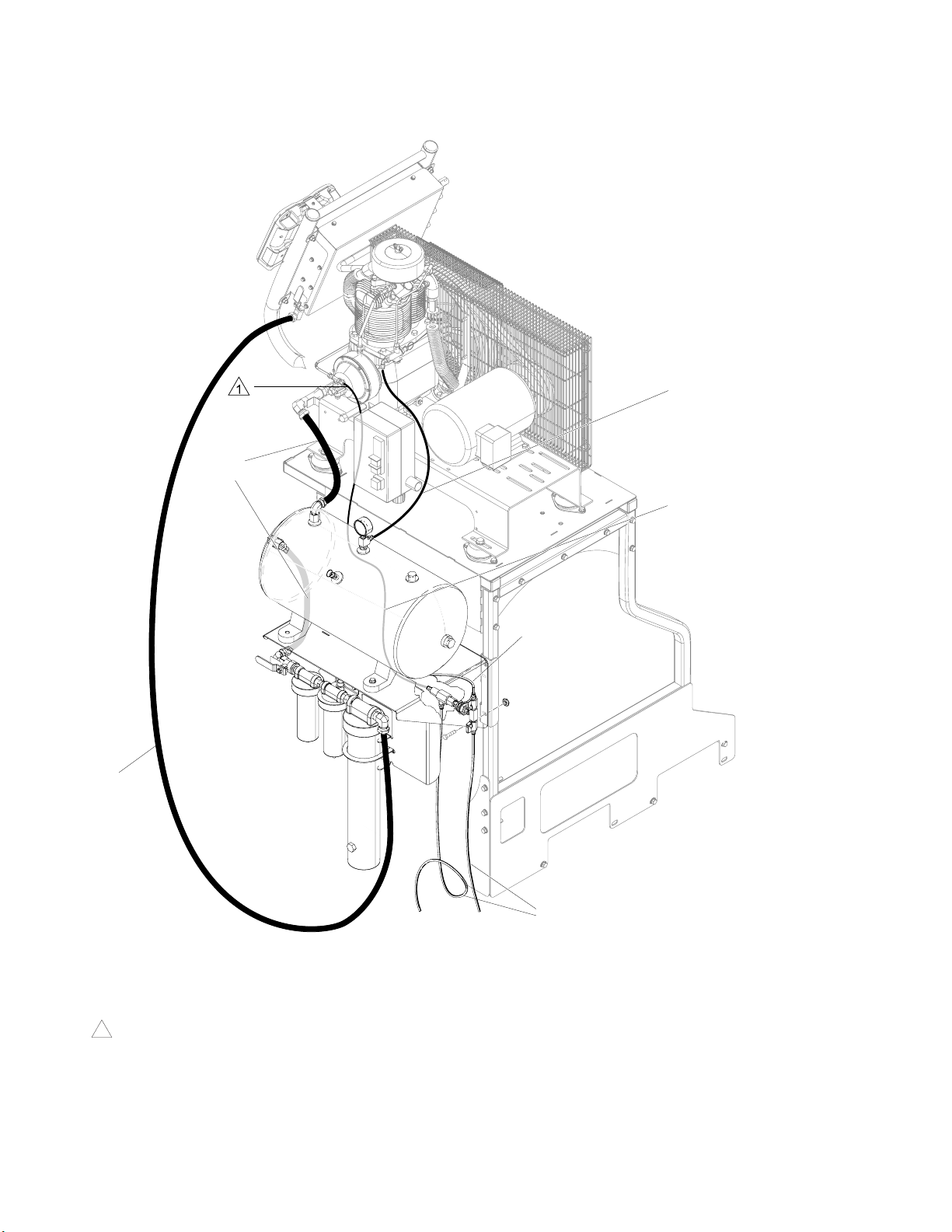

Connect Air Lines

Reference Fig

1. Cut tube (36) to the following lengths (see next

page):

a. Three – 48 in (1219 mm)

b. 9 in. (228.6 mm)

c. 25 in. (635 mm)

2. Push one end of a 48 in. (1219 mm) section fully

into compression fitting (37). Tighten 3/4 turn

past finger tight.

3. Push all tubing sections fully into push-to-connect

fittingsasshown.

4. Connect air hoses (23) and (24) as shown.

. 1, page 4.

3A1902C 3

Page 4

Connect Air Line

s

Connect all air hoses as shown.

24

24

36

25 in. (635 mm)

36

48 in.

(1219 mm)

23

Air Hose Connections

Figure 1

Tighten compression nut 3/4 turn past finger

1

tight.

36

9 in. (228.6 mm)

36

36

48 in.

(1219 mm)

ti18580a

4

3A1902C

Page 5

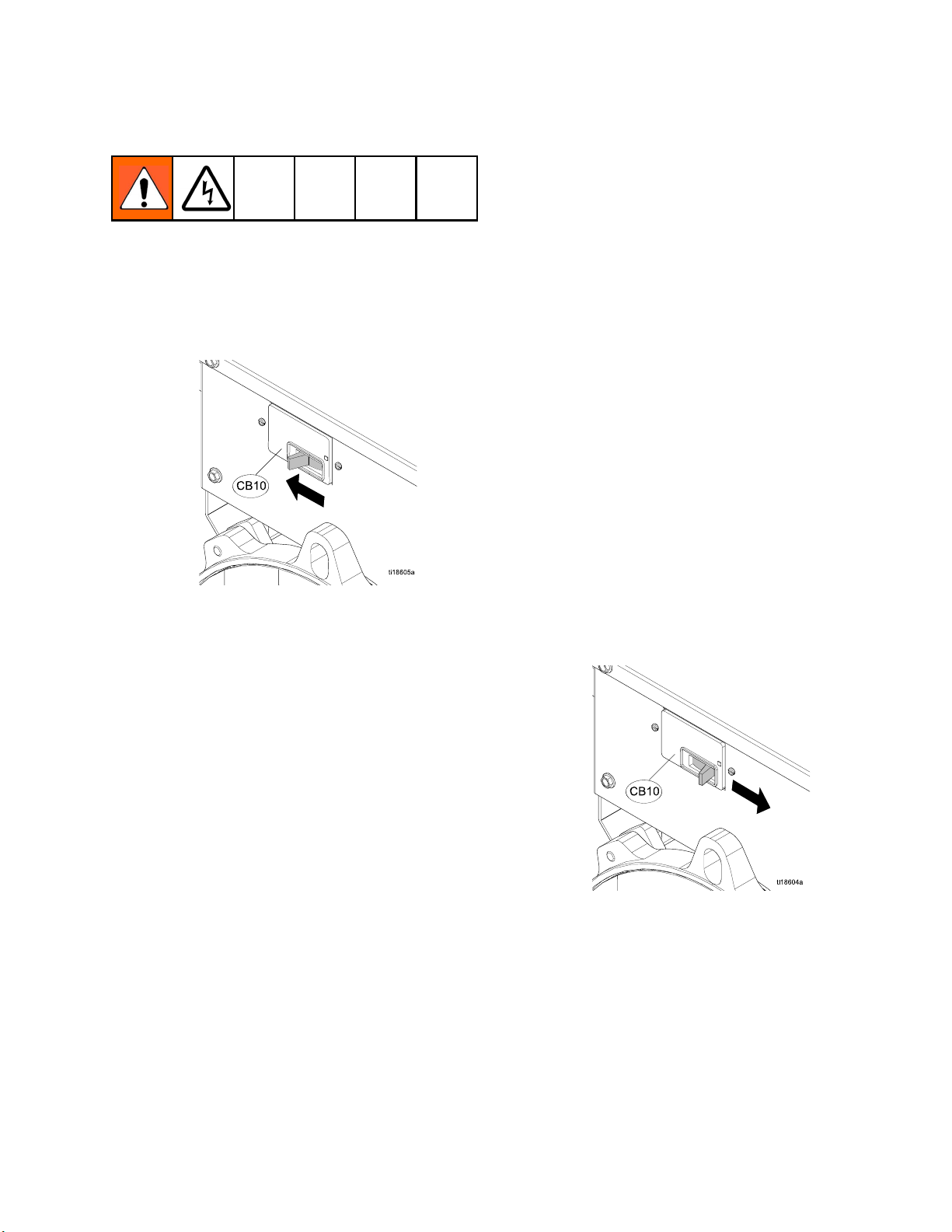

Connect Power Cable

Connect Power Ca

ble

Note

Reference wiring diagram. See

Fig. 4, page 6.

1. Turn off the 120/240 VAC alternator circuit

breaker (CB10).

Figure 2

2. Loosen screw, below the air compressor

electrical enclosure (E), 1/4 turn until the cover is

loose. Remove cover.

3. Discard washer on the cord grip (35). Install

cord grip up through the bottom of the enclosure

knockout. Tighten cord grip mounting nut inside

the enclosure.

7. Tighten the bottom nut on the cord grip (35).

8. Replace cover. See Fig. 4, page 5.

9. Loosen the bolts and remove the back panel of

the Reactor electrical enclosure.

10. Use a screw driver to punch out a knockout.

11. Discard washer from cord grip (35). Install cord

grip through back panel.

12. Loosen the nut on the cord grip (35). Insert the

free end of the power cord (34) through the cord

grip.

13. Connect the black and white wire to CB04,

see Fig. 4, page 5. Connect the green wire to

the ground bus bar, GB02 inside the Reactor

electrical enclosure.

14. Tighten nut on the cord grip (35).

15. TurnCB04on. SeeFig. 4,page5.

16. Turn on the 120/240 VAC alternator circuit

breaker (CB10).

4. Loosen the outside nut on the cord grip (35).

Insert the end of the power cable (34) with shorter

strip lengths through the cord grip.

5. Connect the black wire to terminal 1/L1 and the

white wire to 3/L2.

6. Loosen ground screw and connect ground wire

with existing ground wire.

Figure 3

3A1902C 5

Page 6

Connect Power Ca

ELECTRICAL ENCLOSURE BOUNDARY

CIRCUIT BREAKER

ASS’Y, 24J728

TB18

{

GND

TB17

TB16

L2

{

TB15

TB14

L1

{

TB13

ble

AIR COMPRESSOR ELECTRICAL ENCLOSURE

WHT

BLK

1/L1

2/T1 4/T2 6/T3

BLK

3/L2 5/L3

BLK

WHT

BLK

CB01 CB0 2 CB03 CB04 CB05 CB06 CB0 7 CB0 8TB12TB11

POWER CABLE, 16M827

CT02

CORD GRIP,

16M826

GRN

GB02

Ground Bar

122313

BLK

BLK

GRN

GRN

CORD GRIP,

16M826

TO AIR

COMPRESSOR

Air Compressor Wiring Diagram

Figure 4

6 3A1902C

Page 7

Parts

24K335, Complete Air Compressor Kit

37

7

Parts

41

13

3

28

29

E

35

10

8

32

9

44

45

2

10

46

35

34

5

9

10

Apply anaerobic sealant to all non-swivel pipe threads.

3A1902C

2

1

ti18539b

10

9

7

Page 8

Parts

39

33

38

15

17

48

17

41

47

30

26

4a

36

15

38

4b

4

12

24

6

11

40

31

16

ti18540b

15

Apply anaerobic sealant to all non-swivel pipe threads.

36

8 3A1902C

Page 9

Parts

Part Description

Ref

24M147

1*

24M146

2*

24M145

3*

424M125

4a 125967

4b 16N185

16K133

5*

24M150

6*

7

125970

8 125165

121488

9*

111192

10*

112958

11*

12 112785

13 120375 ADAPTER, elbow, 3/4–14

15 125428

16 125991 VALVE, drain, automatic 1

17 15B565 VALVE, ball 2

23 214656

24 218

26 297436

093

RACK, compressor, rear

RACK, compressor, front

RACK, compressor, top

TANK, ASM, 12 gal, air

receiver (includes 4a and

4b)

VALVE, safet

psi (1.4 MPa

VALVE, check, 1/2 m x f

GUSSET, compressor,

support, side

BRACKET, air tank/dryer

COMPRESSOR, air, 5 HP

KIT, isolator (4 pack)

SCREW, hex hd, flanged;

2.75 in. (70 mm), 3/8–16

SCREW, c

.875 in.

NUT, hex, flanged; 3/8–16

SCREW, hex hd, flanged;

1.5in. (38mm),3/8–16

NPT (f)X 1/2–14 NPS (m)

CONNECTOR, male, 1/4

NPT (f)

, coupled, 61209,10

HOSE

3m)

ft (

HOSE, coupled; 1/2–14

NPT

STRAIGHT, nipple, hex.

3/8

y relief, 200

,14bar)

ap flange hd;

(22 mm), 3/8–16

Qty

1

1

1

1

1

1

1

1

1

4

28

15

4

4

1

3

1

2

1

Part Description

Ref

28 105324

29 109570

30 16N177 BULKHEAD, brass, 3/8 1

31 115671

111218

32*

33 24M636

34 16M827

35 16M826

36 24M675 KIT, tube, nylon, rd; 1/4 in.

37 16M960 NUT, compression, with

38 126017

39 113796

40 115942

41 114109

111195

44*

112731

45*

16N1

46*

47 126109

48 126110

SCREW, cap, hex hd; 1.18

in. (30 mm), M12 x 1.75

WASHER, plain

CONNECTOR, m

OD x 1/8 NPT (f

CAP, tube, square

SYSTEM, desiccant air

dryer; see manual 309921

HARNESS, wire, 3 pole, 8/3

CORD, grip, 3/4 in.

OD,16ft(4.8m)

sleeve; 1/4 OD

BOLT,U,1/2-13,4ODpipe

SCREW, flanged, hex hd;

0.75 in. (19 mm), 1/4–20

NUT, hex

1/4–20

ELBOW, male, swivel; 1/4

OD, 1/4 NPT (f)

SCREW, cap, flange hd;

1.25 in. (31.75 mm), 1/2–13

NUT,

65

PLAT

adap

FITTING, bushing adapter,

3/8–18 NPT (m) x 1/4–18

NPT (f)

TTING, tee, male branch,

FI

4–18 NPT

1/

, flange head;

hex, flanged; 1/2–13

E, compressor,

ter

ale; 1/4

)

Qty

4

4

1

4

1

1

2

1

1

1

2

2

2

4

2

2

1

1

cluded in Compressor Frame Kit 24M258.

*

In

Parts for adapting to the mounting feet of the

optional Quincy PTL5–5B air compressor.

See Fig. 1, page 3 for Air Hose Connections.

3A1902C 9

Page 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for use.

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of

twelve mont

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance

with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco

be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation,

ation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

oper

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized

Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace

free of charge any defective parts. The equipment will be returned to the original purchaser transportation

prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be

made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The

buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost

profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall be available.

Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT,

MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but not

manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of

their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of

these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco

supplying equipment hereunder, or the furnishing, performance, or use of any products or other goods sold

hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices

and legal proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be

drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en

Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou

en rapport, directement ou indirectement, avec les procédures concernées.

hs from the date of sale, repair or replace any part of the equipment determined by Graco to be

Graco Information

For the latest information about Graco products, visit www.graco.com.

To place an order, contact your Graco Distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original Instructions. This manual contains English. MM 3A1902

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revised 28 June 2012

Loading...

Loading...