Page 1

Instructions

3A1898B

TC-130 Lubricators

Electronically controlled, single point lubricator that provides lubrication to roller and slide

bearings, shaft seals and chains located in areas with considerable temperature variations

or where intrinsic safety is a requirement. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

87 psi (0.6 MPa, 6 bar) Maximum Working Pressure

EN

Lubricator

Part No.

24J98 1

24J98 2

24J98 3

24J98 4

24J98 5

24J98 6

24J98 7

24J98 8

Replacement

Canister

24M684 Multi EP-2

24M685 Construction

24M686 Bearing

24M687 Milling

24M688 Food Grade H1

24M689 Synthetic Industrial

24M690 Ultra Spindle

24M691 Multi EP-1

Application

Intrinsically safe apparatus, suitable for installation in Class I, II and III, Division 1, Groups A, B, C,

D, E, F and G hazardous (classified) locations and Class I, Zone 1, AEx ia, IIC, and Class II, Zone

21, T-class is T4 at -20°C<

Ta < +60°C.

0359

I M1 Ex ia I Ma

II 2 G Ex ia IIC T4 Gb

II 2 D Ex ia IIIC T135°C Db

ZELM 11 ATEX 0468X

-20°C<

Ta < +60°C

EX ia I Ma

EX ia IIC T4 Gb

Ex ia IIIC T135°C Db

IECEx ZLM 11.0007 X

Page 2

WARNINGWARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer

to procedure-specific risks. When these symbols appear in the body of this manual, refer back to

these Warnings. Product-specific hazard symbols and warnings not covered in this section may

appear throughout the body of this manual where applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper

fluid, be aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and

gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are pres-

ent.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

Special Conditions for Safe Use

Equipment must comply with the following conditions when operated in a potentially explosive

atmosphere or hazardous location.

• Do not clean lubrication canister with a dry cloth. Possibility of electrostatic charge exists.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applica-

ble guidelines.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the equipment, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow the Pressure Relief Procedure before cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

2 3A1898B

Page 3

EQUIPMENT MISUSE HAZARD

WARNINGWARNINGWARNING

WARNING

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request MSDS from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in

use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Do not puncture, open or take lubricator apart.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot

surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, hearing

loss, inhalation of toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manu-

facturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth

defects or other reproductive harm. Wash hands after handling.

3A1898B 3

Page 4

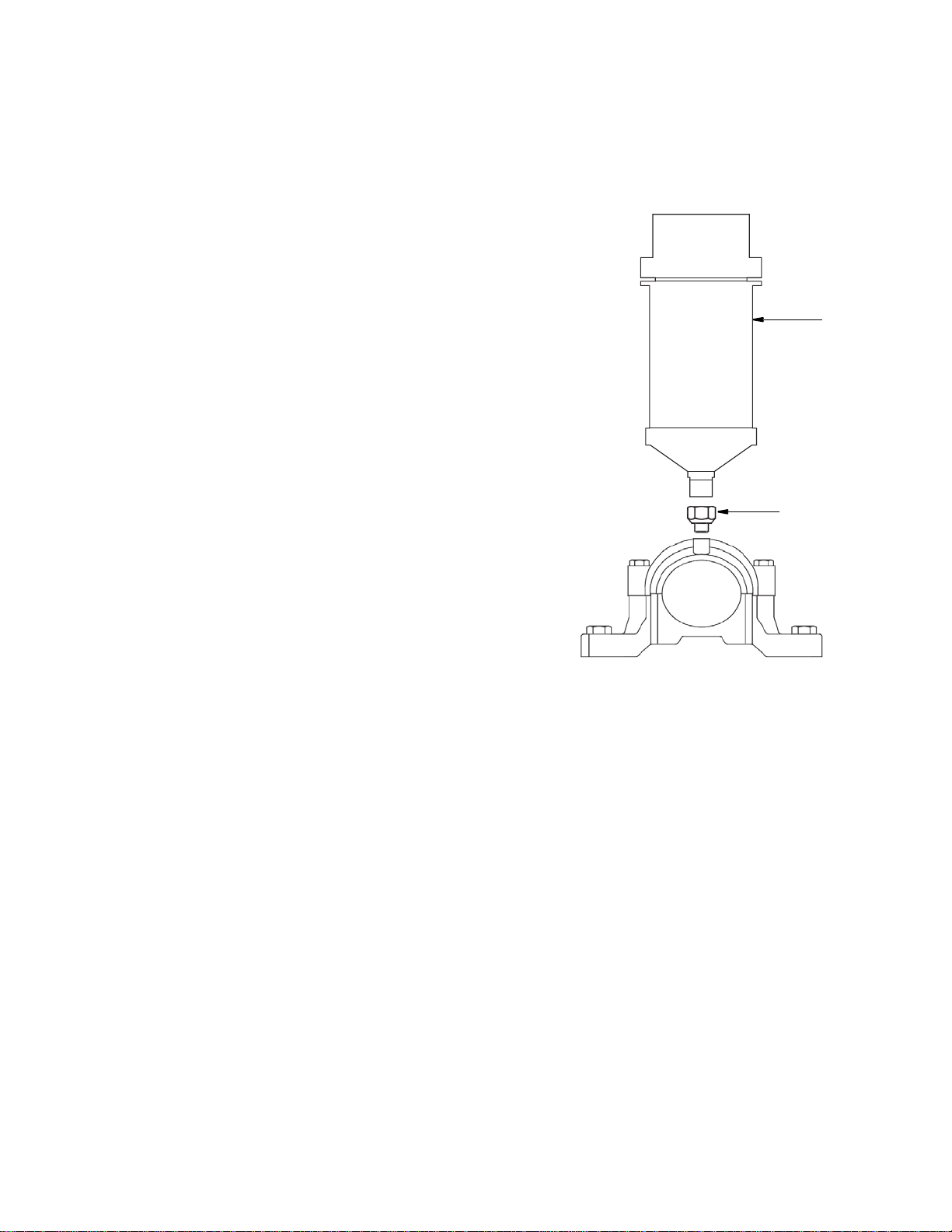

Component Identification

A

B

C

A

C

D

B

Pressure Relief Procedure

1. Cover lubrication point (A) and lubricator

(B) with a heavy rag to absorb any fluid that

may leak out while loosening the lubricator.

2. Carefully unscrew lubrication canister from

the lubrication point (A).

A Lubrication Point

B Lubrication Canister

C Electronic Control Cover

Component Identification

FIG. 1

APlug

B Lubrication Canister

NOTE: Canister cannot be refilled.

4 3A1898B

C Reusable Electronic Control

D Protective Cover

Page 5

Installation and Setup

Installation and Setup

Determining Correct Mounting Method

NOTE:

• Direct mounting should be used for lubrica-

tion points that are easily accessible.

• Remote mounting is recommended if you

answer YES to any of the questions below.

1. Is the ambient temperature at the lubrication point higher than +60°C (140°F)?

2. Is it necessary to remove protective

screens, walls or other types of protection

in order to reach the lubrication point?

3. Is the lubrication point exposed to high

vibrations?

4. Is it difficult to access the lubrication point

during operation of the machine?

5. Is the lubrication point exposed to any of

the following:

• corrosive chemicals?

• high temperatures?

• falling materials?

Installation Guidelines

Do not puncture, open or take canister apart.

Opening or breaking the canister will expose

users to the fluid and gases contained inside.

• Before installing the lubricator, the lubrica-

tion points and any extensions must be

adequately pre-lubricated with the same

lubricant contained in the lubricator. A 400

gram lubricant cartridge for grease guns is

available from Graco. See Parts, page 12

for a complete list of available lubricant cartridges.

• Install one lubricator per lubrication point.

• The grease nozzle of the lubricator has an

R 1/4 male thread. If your application has a

different thread you may need to use a

reducer.

• Do not overtighten the plastic thread of the

lubricator.

• For all metal to metal connections (i.e.,

extensions, reducers, etc.), to prevent leakage, make sure to use LOCTITE® 243* or a

similar product (semi-tight screw locking).

*Loctite

ration.

®

is a registered trademark of the Loctite Corpo-

3A1898B 5

Page 6

Installation and Setup

Electronic Control Setup

The discharge settings can be programmed for

any length of time between 1 to 12 months and

the interval may be changed at any time.

The following instructions assume this is an

existing installation and you are replacing the

lubrication cartridge. If this is a new electronic

control and a first time installation, you may

skip Steps 1- 4.

Installing the Electronic Control Cover

1. Relieve pressure,

page 4.

2. Remove the protective plastic cover

over the electronic

control. Keep this

cover to reinstall

after setup is complete to protect the display during operation.

3. If this is an existing installation and you are

replacing the lubrication cartridge turn the

electronic control cover counter-clockwise,

to remove the cover.

4. Turn the cover

clockwise to

secure it to the

lubrication canister until a corner

of the cover

aligns with the

arrow on the

body.

Setting Up the Electronic Control

1. Repeatedly press

the SET button on

the electronic control cover until the

number of months

you are setting is

displayed on the

screen.

You are setting the length of time in months

that you want it to take to discharge the

entire 130 cc of fluid in the canister.

NOTE:

The entire volume of the lubricator will be

dispensed in the number of months displayed

• (more months = slower discharge).

• (fewer months = quicker discharge).

2. Install transparent cover over electronic

control to protect it from dust and dirt.

3. Write the installation date on the label

located on the side of the lubrication canis-

IG. 2).

ter (F

FIG. 2

6 3A1898B

Page 7

Installation and Setup

aa

bb

cc

dd

ee

ff

A

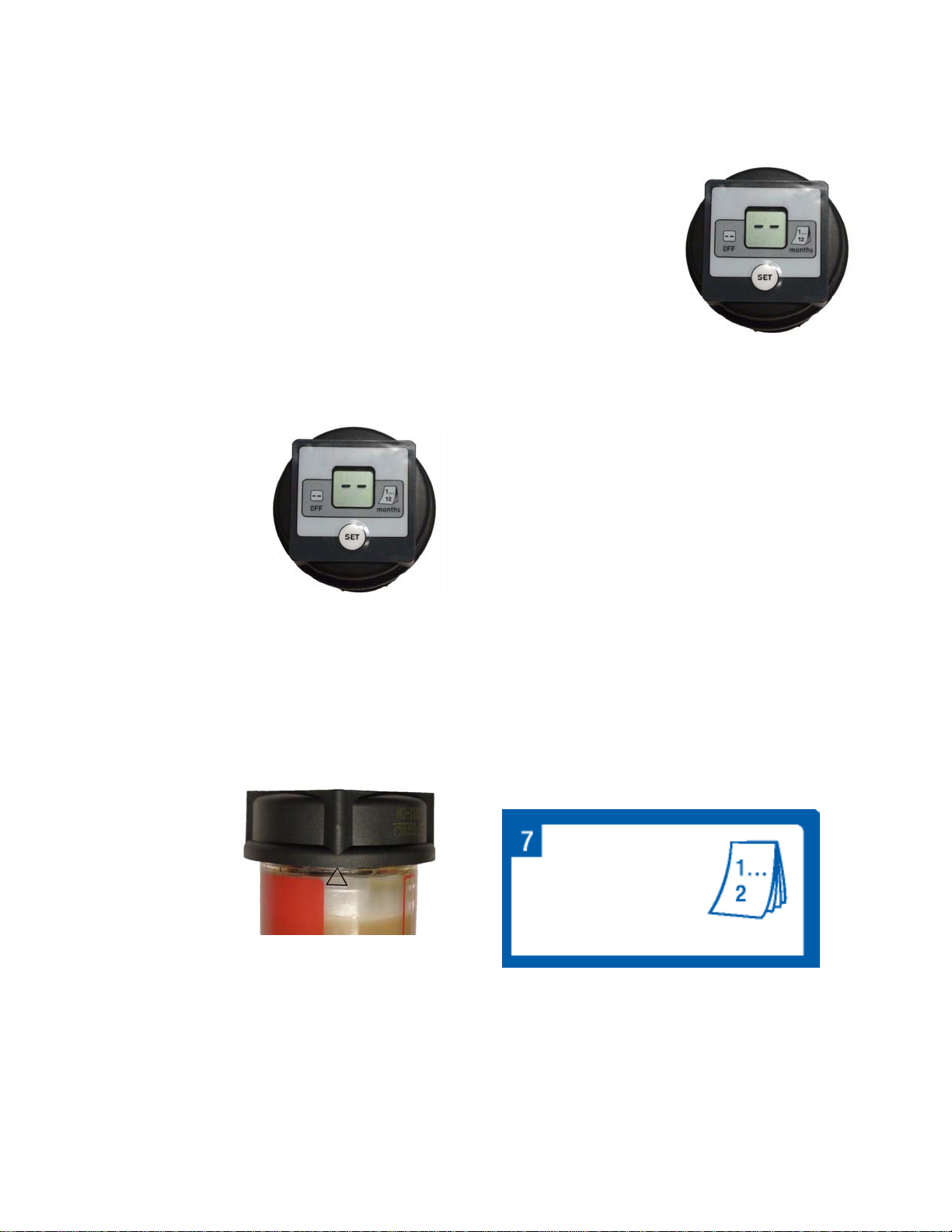

NOTE:

• If at anytime

during operation you need to

turn the unit

OFF, press the

SET button

repeatedly until

two horizontal

lines appear on

the display. This indicates the control is OFF.

• The discharge period can be

changed at anytime to suit equipment demands or planned maintenance cycles.

• The current discharge setting is

always displayed.

Graco recommends checking the counter

pressure by connecting an EM-Single Point

Lubricator to a pressure manometer (user supplied).

A pressure manometer is a simple device that

measures pressure output. To build a pressure

manometer you need a pressure gage (aa),

tee fitting (bb) and stop valve (cc). F

IG. 3

shows a correctly assembled pressure

manometer, connected to the lubricator and a

lubrication point.

FIG. 3

Preparing for Installation

Use the following procedure to check the

counter pressure of the application prior to

installation.

NOTE:

• Be sure to use a lubricant cartridge that

contains the same grease used in the

application.

• The best measurement results are

achieved during operation.

Checking the Counter Pressure

NOTE: An EM-Single Point Lubricator contain-

ing the same lubricant you are dispensing is

required to perform the Counter Pressure test

correctly. Contact Graco Customer Service or

your local Graco distributor to order this part.

aa

bb

cc

dd

ee

ff

Pressure Gage

Tee Fitting

Stop Valve

Lube Point

Lubricator

ON / OFF Switch

Counter Pressure Test Procedure

1. Clean the lubrication point to remove any

potential contaminants.

2. Remove the plug (A).

3A1898B 7

Page 8

Installation and Setup

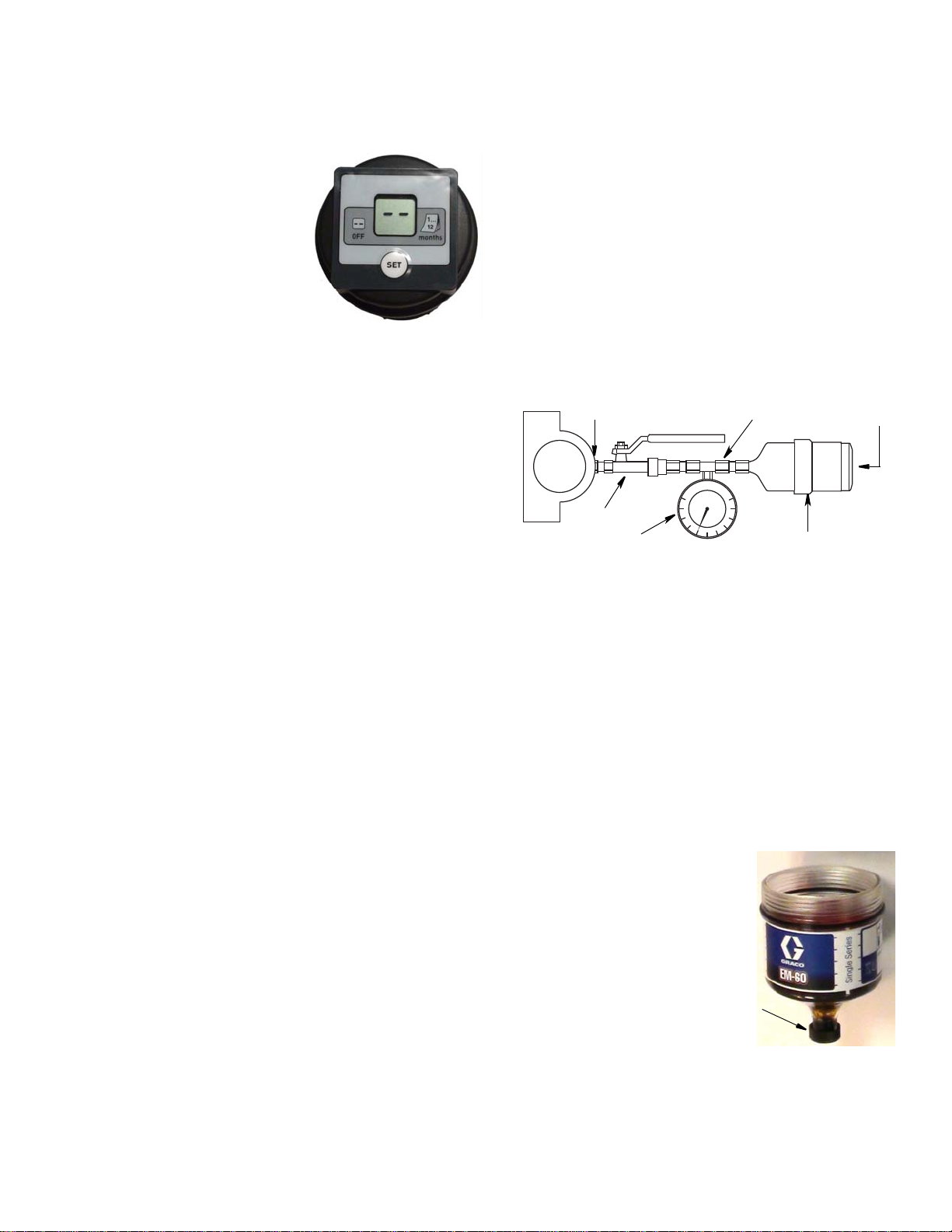

B

3. Install lubricator unit

into adapter (B).

4. Install reducers, extensions, grease line,

etc. (if necessary).

If the counter pressure does not decrease

you may need a different lubricant or size

lubricator canister. Contact Graco Customer service for assistance.

Priming / Prefilling Fittings and

Grease Lines

All accessories and grease lines must be

primed/pre filled. Without this priming/pre filling, the lubricator would first have to fill the

accessories with lubricant.

5. Screw a pressure manometer into the lubrication point (dd) (FIG. 3, page 7).

6. Ensure the stop valve (cc) of the pressure

manometer is open.

7. Attach lubricator and adapter (B) to the

pressure manometer as shown in FIG. 3

and turn the switch to “ON” (ff).

8. Run manometer for about 20 seconds.

Observe gauge and repeat this procedure

until pressure registered on gauge stays

constant.

9. To determine counter pressure, wait

approximately 5 minutes until system has

relaxed. Do one

more discharge by turning

unit OFF; then ON again until it dispenses

for no more than 5 seconds.

10.Wait approximately 5 more minutes to

make sure system does not lose pressure

and remains constant.

Example: A tube that is one meter long

requires about 28 cm

3

of lubricant. It would

take the lubricator with a 12 month setting and

an TC-130 grease canister about 3 months to

fill this 1 meter tube.

FIG. 4 illustrates one way to pre fill using a

grease gun to dispense the grease.

FIG. 4

11.Disconnect adapter (B) from manometer.

NOTICE

Do NOT disconnect lubricator from adapter

(B). Screwing anything into end of lubricator a

second time will damage self-sealing threads.

12.If counter pressure is 4 bar (58 psi) or

higher, flush lubrication point with a grease

gun.

8 3A1898B

Page 9

Installation and Setup

A

B

Remote Mounting Installations

• Installations up to 3 ft away from the lubri-

cation point can be mounted with flexible

tubes and a bracket. Refer to F

and F

IG. 7 for examples of correct remote

mounting installations.

• Remote installations require a grease line.

Graco recommends using a tube with an

inside diameter of at least 6 mm (1/4 inch).

1. Select a position for the lubricator that is

easy to access and protected from

high-pressure water jets, falling materials,

corrosive chemicals and extreme temperatures. Temperature must be below +60°C

(+140°F).

2. Prime the grease line and all accessories

with the same grease that is contained in

the lubricator.

IG. 5, FIG. 6

Direct Mounting

Reducer (optional)

3. Secure grease lines with ties or similar

means.

FIG. 5

A Lubrication Canister

B Reducer

3A1898B 9

Page 10

Installation and Setup

A

B

C

D

E

F

F

A

B

E

D

G

C

With Tube and Grease

With Tube and Oil

FIG. 6

A Lubrication Canister

B Insert for Bracket, 124088

C Mounting Bracket, 124304

D Tube connector (user supplied)*

E Nylon tube (user supplied)*

F Tube connection (User supplied)*

*Graco recommends only using tubes with an

inside diameter of at least 6 mm (1/4 inch) and

a maximum length of 1 meter (3 feet).

FIG. 7

A Lubrication Canister

B Insert for Bracket, 124088

C Mounting Bracket, 124304

D Tube connector (user supplied)*

E Nylon tube (user supplied)*

F Tube connection (user supplied)*

G Oil throttle, 124102

*Graco recommends only using tubes with an

inside diameter of at least 6 mm (1/4 inch) and

a maximum length of 1 meter (3 feet).

10 3A1898B

Page 11

Changing the Lubrication Canister

Changing the Lubrication

Canister

1. Relieve pressure,

page 4.

2. Unscrew the lubrication canister and

remove from

grease port.

3. Remove the protective plastic cover over the electronic control. Keep this cover to reinstall after setup

is complete to protect the display during

operation.

4. Turn the electronic control cover

counter-clockwise, to remove the cover.

Canister Disposal

1. Use a spanner wrench to separate battery

from lubrication canister.

2. Dispose of the battery and lubrication canister in approved containers, and according

to applicable local and state guidelines.

Read the MSDS to know the specific hazards of the fluids you are using.

Storage

When lubricators are not immediately installed,

they must be stored in a dry, dust free, sunlight

protected room, indoors.

Replacement Cansiters

Replacement canisters are available from

Graco. Refer to the chart below to select the

correct canister for your application.

Part No.

24M684 Multi EP-2

24M685 Construction

24M686 Bearing

24M687 Milling

24M688 Food Grade H1

24M689 Synthetic Industrial

24M690 Ultra Spindle

24M691 Multi EP-1

Application

3A1898B 11

Page 12

Troubleshooting

Troubleshooting

Malfunction Possible Cause Solution

No lubrication

Grease spurts from lubricator

when removed from service

Canister empty Replace canister

Lubricator off

See Setting Up Electronic

Control, page 6

• Manually purge point to

ensure that grease can

be freely received by

bearing.

• Reduce grease line

Resistance to grease flow too

high

length and/or increase

line diameter

Grease dispensing too fast

Wrong month setting selected

Average ambient temperature

or vibration too high for activator type

For Oil Filled Lubricators

Only: Oil throttle not installed

Eliminate restrictions caused

by small orifice fittings

Use a higher pressure lubricator for dispensing

Select a more appropriate

discharge period.

• fewer months = faster dis-

charge

• more months = slower

discharge.

See Setting Up Electronic

Control, page 6.

Remote mount lubrication

canister away from heat

source

Install oil throttle

12 3A1898B

Page 13

Malfunction Possible Cause Solution

Grease dispensing too slowly

Average ambient temperature

is below -20°C (-4°F)

Resistance to grease flow too

high

Troubleshooting

Remote mount lubricator in

area with an ambient temperature within specified

range of -20°C - +60°C (-4°F +140°F)

• Manually purge point to

ensure that grease can

be freely received by

bearing.

• Reduce grease line

length and/or increase

line diameter

Eliminate restrictions caused

by small orifice fittings

Counter pressure is too high

Set discharge to a shorter

period (fewer months). See

Setting Up the Electronic

Control, page 6

Select grease with better

pump-ability

Check lubrication point for

obstructions

3A1898B 13

Page 14

Technical Data

L

D

Technical Data

Housing Material Transparent plastic

Lubricants Grease and oil

Drive Electrochemical

Grease Nozzle Thread R1/4 male

Lubricant Volume

Length (L) 145 mm (5.71 in.)

Maximum Diameter (D) 65 mm (2.5 in.)

Weight Full = 130 g (4.6 oz)

Discharge Period 1-12 months

Temperature Range -20°C - +60°C (-4°F - +140°F)

Maximum Output Pressure 6 bar (87 psi)

Storage

Conditions Dry, dust free, do not expose to direct sunlight

Temperature +20°C (+68°F)

130 cm3 (8 in.3)

Empty = 250 g (5.3 oz)

Dimensions

14 3A1898B

Page 15

Notes

Notes

3A1898B 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 3A1898

Patent information: www.graco.com/patents

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2012, Graco Inc. is registered to ISO 9001

www.graco.com

December 2014

Loading...

Loading...