Page 1

Instructions

Set / Reset Point

3A1827B

Pressure Switch

Set and reset point pressure switch used to

detect pressure changes.

Not approved for use in European explosive

atmospheres.

Models: 24K414

Equivalent: IFM Electronic GMBH PK6220

Maximum Working Pressure: 5800 psi (400 bar, 40

MPa)

Important Safety Instructions

Read all warnings and instructions in this manual

and the instructions included with your operating

system or pump. Save these instructions.

ENG

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point

symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these symbols

appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this

manual where applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding,

setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before

disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispense device, hose leaks, or

ruptured components will pierce skin. This may look like

just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point dispense device at anyone or at any

part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body,

glove, or rag.

• Follow Pressure Relief Procedure in this manual,

when you stop dispensing and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the

equipment.

• Check hoses and couplings daily. Replace worn or

damaged parts immediately.

CUS

Page 2

Pressure Relief Procedure

Relieve pressure in the system following the procedure

recommended for your operating system or pump.

Installation

NOTICE

• Electrical ratings must not be exceeded. Overload on a switch can cause switch to fail on the

first cycle.

• Never exceed pressure limits. Unit can be operated up to maximum pressure on a limited basis

(i.e., set-up, testing) but continuous operation

must be restricted to the designated adjustable

range. Excessive cycling at maximum pressure

limits could reduce sensor life.

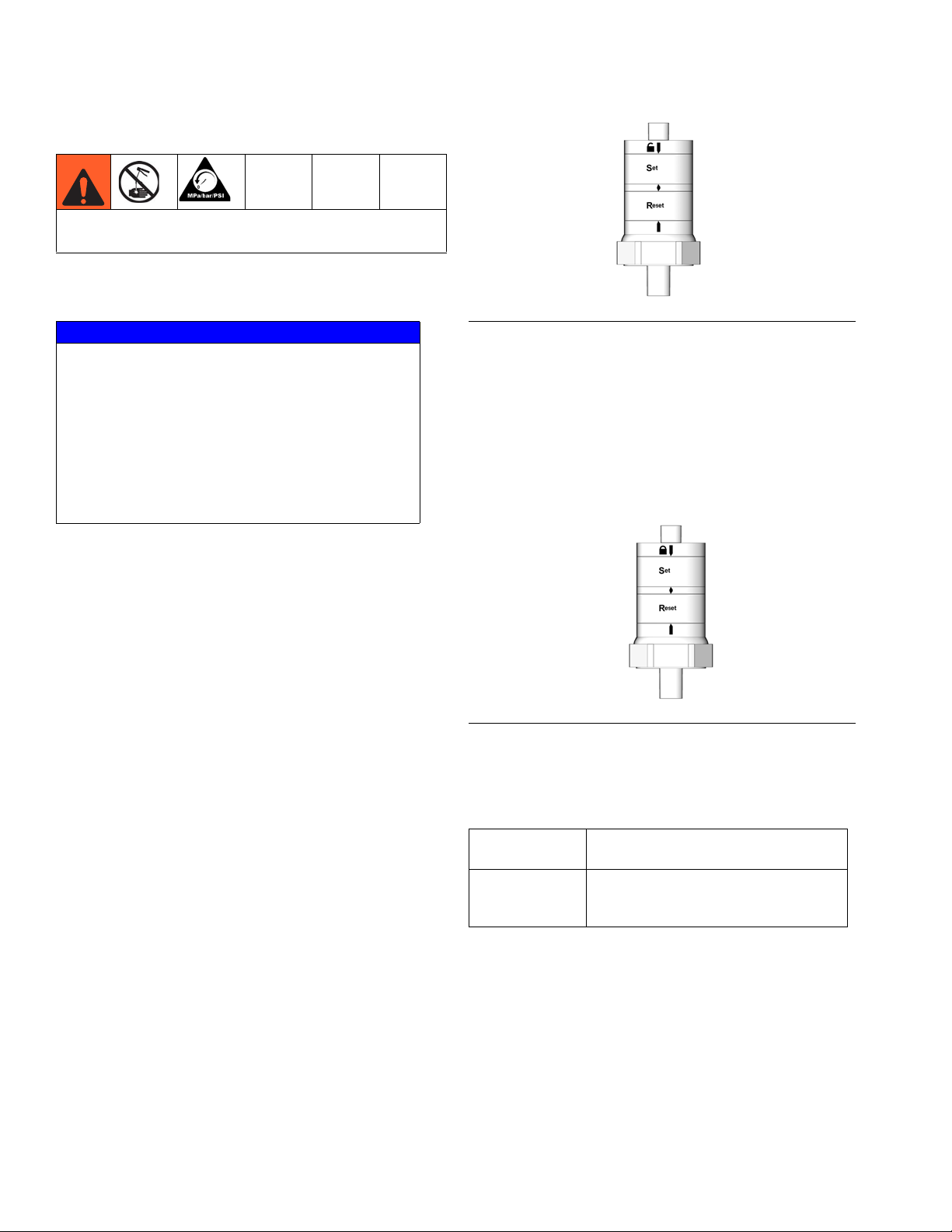

FIG. 1

2. Adjust set point to the desired pressure setting.

2500 psi (172 bar, 17.2 MPa) is the factory default

setting.

3. Adjust the reset point to the desired pressure setting. 500 psi (35 bar, 3.5 MPa) is the factory default

setting.

4. Rotate the top portion of the switch to align the lock

symbol with the two white arrows (F

IG. 2).

1. Disconnect power to pump.

2. Disconnect cable from switch.

3. If replacing a pressure switch on an existing installation, relieve pressure.

4. Locate unit where shock, vibration and ambient temperature fluctuations are minimal. Do not mount in

ambient temperature areas exceeding 160°F

(71°C).

• Unit may be mounted in any position. However,

if installation location results in frequent exposure to liquid it is recommended that the unit be

mounted vertically with the pressure connection

down.

5. Screw switch into manifold. Always use a wrench on

pressure connection wrench flats.

6. Test unit before use.

Adjustments

1. Rotate the top portion of switch (with the lock and

unlock symbols) to align the unlock symbol with the

two white arrows (F

IG. 1).

F

IG. 2

5. Recheck set point and reset point and install switch

according to installation instructions.

Status LED’s

Steady Green

LED

Yellow LED turns

off and on

Power is supplied to pressure switch.

When you reach pressure, yellow LED

lights. When pressure drops below reset

value, yellow LED turns off.

2 3A1827B

Page 3

Troubleshooting

Problem Cause Solution

Troubleshooting

In an injector installation only, pressure switch activates before all injectors fire

Another pressure switch or pressure

gauge on the system reads different

than the pressure switch

After all injectors have reset, the

pressure switch does not deactivate

The pressure switch seems to be

operating backwards

Pressure switch is installed at the

wrong location

Pressure switch is not set to a high

enough reset point

Pressure switch is installed at the

wrong location

Pressure switch is not set to a high

enough reset point

The Reset point is set too low

Normally Open and Normally Closed

outputs not completing connection

Verify pressure switch is correctly

installed - downstream from a bank of

injectors

Verify pressure switch is set sufficiently high at a level above the firing

point of the injectors and within the

margin for error.

Verify pressure switch is correctly

installed - downstream from a bank of

injectors

Verify pressure switch is set sufficiently high at a level above the firing

point of the injectors and within the

margin for error.

Turn the reset point to a higher setting. Then verify the system is functioning correctly.

Check the Normally Open and Normally Closed outputs and make sure

the proper connection is made.

Adjust connection as needed.

1. Attempt to lower the pressure

switch set point to verify the

switch is not sensing any pressure.

Power is supplied to the pressure

switch but the switch is no longer

sensing pressure

3A1827B 3

Grease soap has accumulated in the

sensing orifice.

2. After verifing the pressure switch

is not sensing pressure, remove

the switch from the port.

3. Using a non-metalic tool, clean

out the sensing orifice.

4. Reinstall the switch in the port.

5. Retest.

Page 4

Technical Data

)

Electrical Design DC PNP

Output Normally open /

closed complimentary

Operating Voltage 9.6 - 32 VDC

Ambient Temperature Range -13° to 176°F (-25° to 80°C)

Storage Temperature -40° to 212°F (-40° to 100°C)

Current Rating 500 mA

Voltage Drop <2.0 V

Current Consumption <25 mA

Set Point Range 290 - 5800 psi (20 - 400 bar;

2.07 - 40 MPa)

Reset Point Range 175 - 5685 psi (12 - 392 bar;

1.2 - 39 MPa)

Switch point accuracy < +

Repeatability < + 0.5% Full range

Termination Type 1/4 NPT

Connection M12

Display

Power Indicator LED green

Switching Status Indicator LED yellow

Wetted Parts stainless steel 316L/1.4404

Weight 3.2 oz (0.092 kg)

Enclosure (Ingression Protection) IP67

2.5% Full range

Dimensions

1.18 in. (3 mm

1.06 in. (27 mm)

2.77 in.

(70.4 mm)

1.18 in. (3 mm)

Wiring Diagram

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original Insructions. This manual contains English. MM 3A1827

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2011, Graco Inc. is registered to ISO 9001

www.graco.com

6/2011

Loading...

Loading...