Page 1

Instructions - Parts

Communications

Gateway Module

3A1704G

Installation Kit

For use with HFR™, VRM™, and VPM™ systems to provide fieldbus communications

abilities. For professional use only.

Kit 24J415

EN

Important Safety Instructions

Read all warnings and instructions in your

system manual. Save all instructions.

ti11985a

CGM with DeviceNet connector shown

Page 2

Kits

Contents

Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Available Internal Data . . . . . . . . . . . . . . . . . . . . . . 9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 26

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . 26

Kits

The following kit is the Communications

Gateway Module (CGM) hardware/software and is

required for all installations. The kit is used in conjunction with the correct fieldbus device.

CGM Part No. Description

24J415 CGM Installation Kit (Required)

Related Manuals

Manual Description

3A1974 CAN Adapter Kit, Instructions

312864 Communications Gateway Module,

Instructions - Parts

313997 HFR Operation

313998 HFR Repair - Parts

313873 VRM Operation

313874 VRM Repair - Parts

313875 VPM Operation

312764 VPM Repair - Parts

406987 GCA CAN Cables, Reference

Overview

The Communications Gateway Module (CGM) provides

a control link between the HFR, VRM, or VPM system

and a selected fieldbus. This provides the means for

remote monitoring and control by external automation

systems.

The following kits work with kit 24J415 and includes all

remaining parts necessary to install a CGM. See manual 312864 for repair parts for each assembly.

CGM Part No. Fieldbus

CGMDN0 DeviceNet

CGMEP0 EtherNet/IP

CGMPB0 PROFIBUS

CGMPN0 PROFINET

The data available by the CGM to the fieldbus depends

on which GCA based system is connected. Unique data

maps are defined for each GCA system and are available on the token provided in the kit.

See Available Internal Data on page 9 for a list of internal data from the HFR, VRM, or VPM system that can

be viewed or modified by your fieldbus master.

NOTE: The following system network configuration files

are available at www.graco.com

• EDS file: DeviceNet or Ethernet/IP fieldbus networks

• GSD file: PROFIBUS fieldbus networks

• GSDML: PROFINET fieldbus networks

2 3A1704G

Page 3

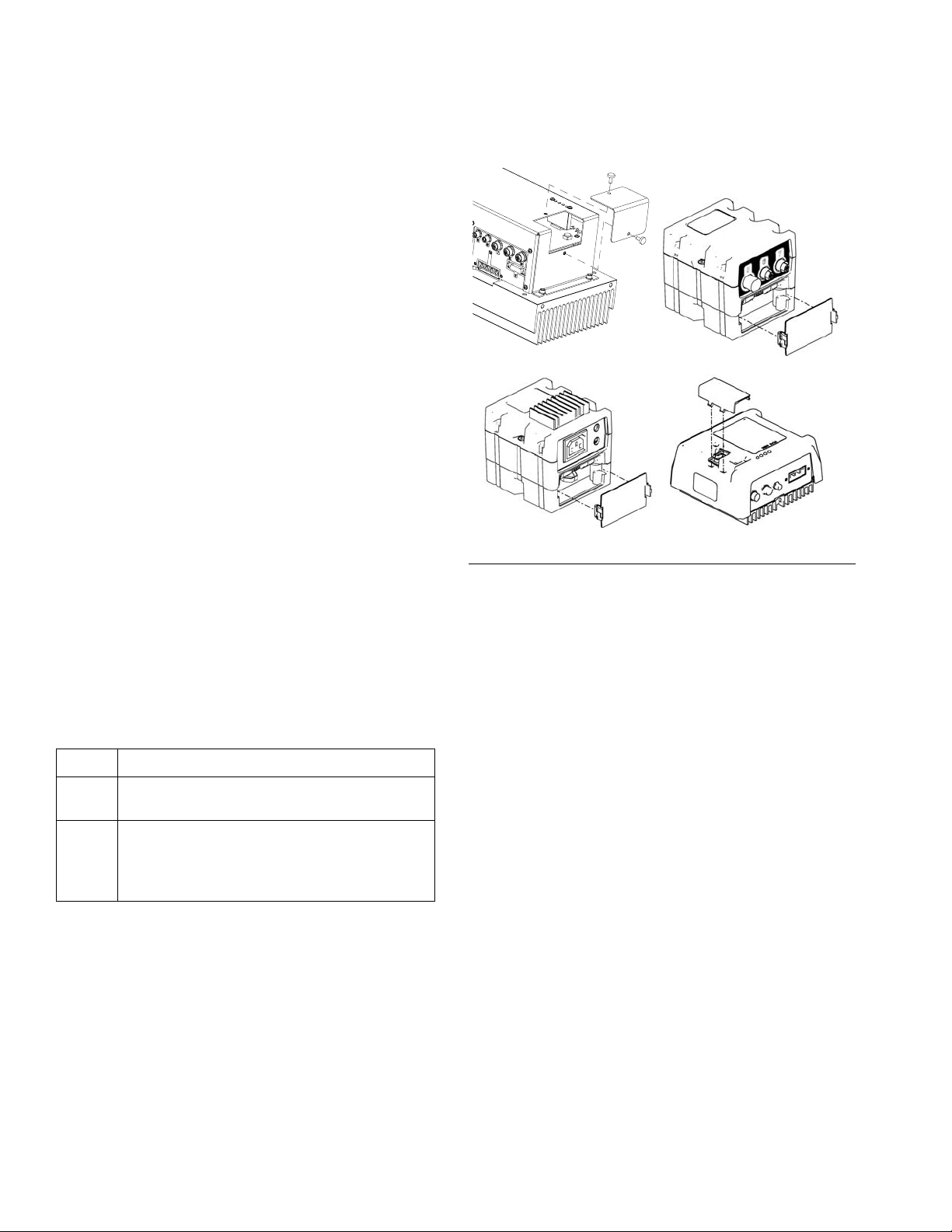

Installation

Installation

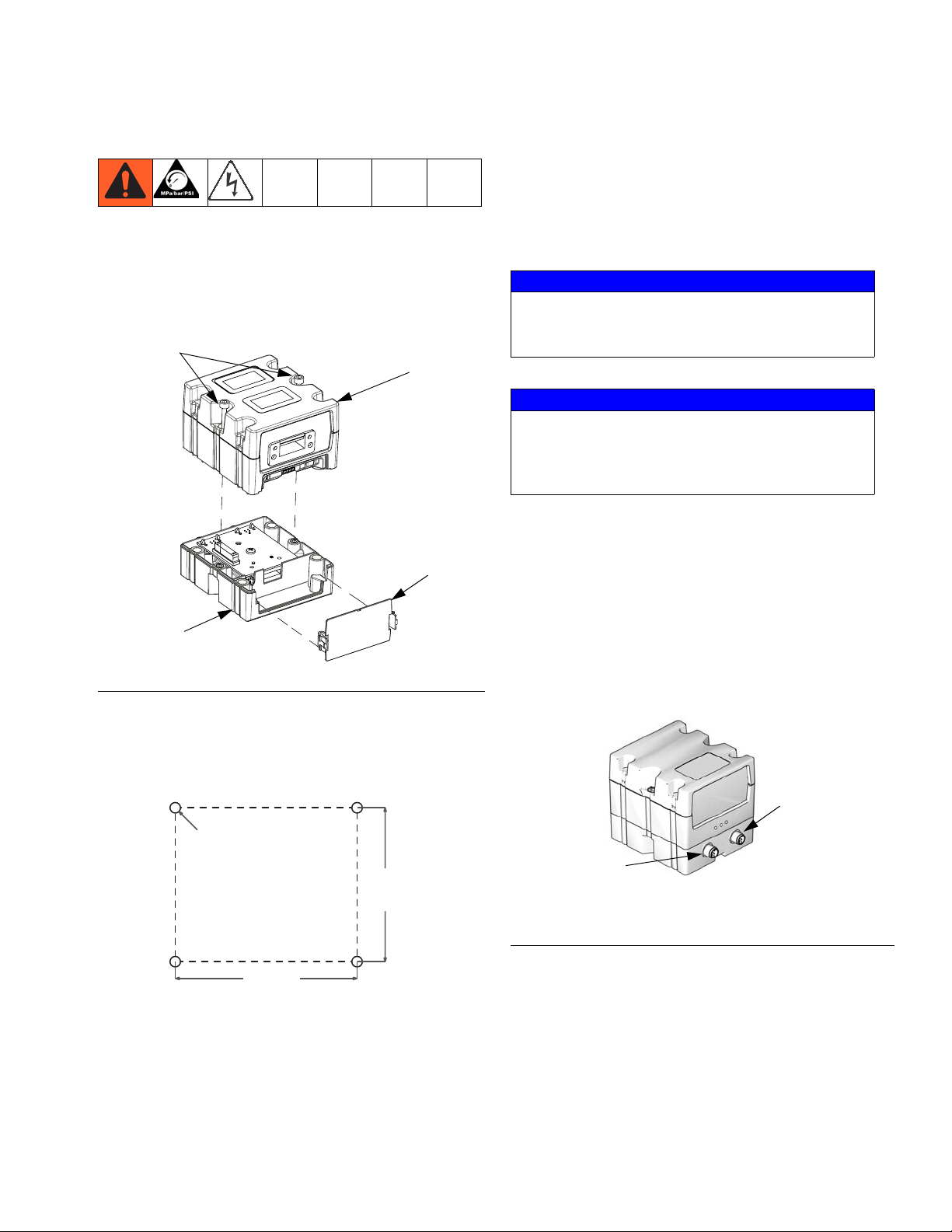

1. Install the CGM in the desired location.

a. Remove access cover (D). Loosen two screws

(C) and remove CGM (A) from base (B).

C

2. Install access cover (D).

3. Connect CAN cable from either CAN connection on

the CGM to any CAN connection found on any other

GCA device located on the machine. Attach the ferrite suppressor to CGM end of the CAN cable. For

additional extension cables, see GCA CAN Cables

Reference manual.

NOTICE

To avoid severe damage to GCA modules, ensure

the CAN cable is connected to the appropriate CAN

connection.

A

NOTICE

To avoid severe machine damage, do not connect

any CAN device to connectors 2A, 2B, or 2C on the

Motor Control Module. Connectors 2A, 2B, and 2C

are not CAN connectors.

NOTE: CAN ports are located on the base of cube

shaped GCA modules or port 6 on the High Power Tem-

D

perature Control Module.

B

FIG. 1

b. Mount base (B) in desired location with four

screws supplied in this kit. See the following

mounting dimensions.

#10-32 UNF

(M5 x 0.8)

2.75 in.

(69.9 mm)

3.25 in.

(82.6 mm)

c. Mount CGM (A) on base (B) with two

screws (C).

NOTE: If there are no free CAN ports, plug

splitter (121807) into the CAN distribution block located

in the Power Distribution Box (PDB). Connect the CAN

cable into the splitter. For more detail, refer to the CAN

Adapter Kit manual.

CAN

Connector 2

CAN

Connector 1

F

IG. 2: Cable Connections

ti11972a

3A1704G 3

Page 4

Installation

4. If used, connect the ethernet, DeviceNet, or PROFIBUS cable to the CGM as applicable. Connect the

other end of the cable to the FieldBus device.

ti11985a

F

IG. 3: Cable Connections

5. Connect cable (LC0032) to the MCM, port 2B, and a

customer provided signal device. The signal device

must have isolated, dry contacts.

6. Perform the Install or Update Data Map procedure in

CGM manual 312864.

7. See Available Internal Data on page 9 for details

on FieldBus pinout setup.

8. Perform Setup on page 5 to configure the fieldbus.

4 3A1704G

Page 5

Setup

Setup

Gateway Screens

Fieldbus Screens Page

PROFIBUS 5

PROFINET 6

DeviceNet 7

EtherNet/IP 7

The Gateway screens are used to configure the fieldbus.

These screens are shown only if a CGM is correctly

installed in your system. See Installation on page 3.

1. With the system on and enabled, press to

access the Setup screens.

2. Press the left arrow key once to navigate to the main

Gateway screen. See F

IG. 4.

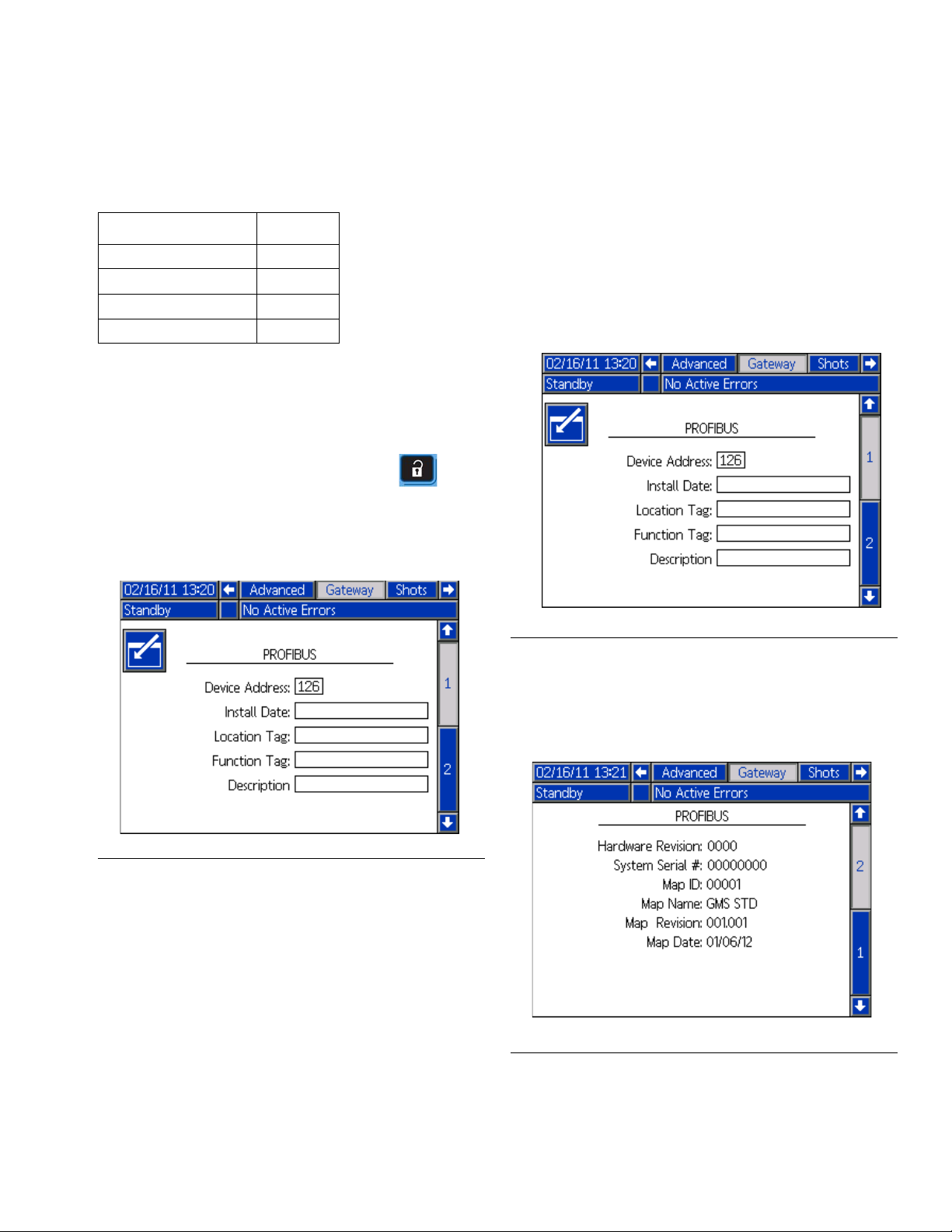

PROFIBUS Fieldbus Screens

These screens are shown only if you have a PROFIBUS

Fieldbus CGM installed. See Kits on page 2.

Screen 1

This screen enables the user to set the device address,

install date, location tag, function tag, and description.

FIG. 5: PROFIBUS Fieldbus Screen 1

F

IG. 4: Example Fieldbus Screen

Screen 2

This screen displays the hardware revision, system

serial number, and data map identification information.

IG. 6: PROFIBUS Fieldbus Screen 2

F

3A1704G 5

Page 6

Setup

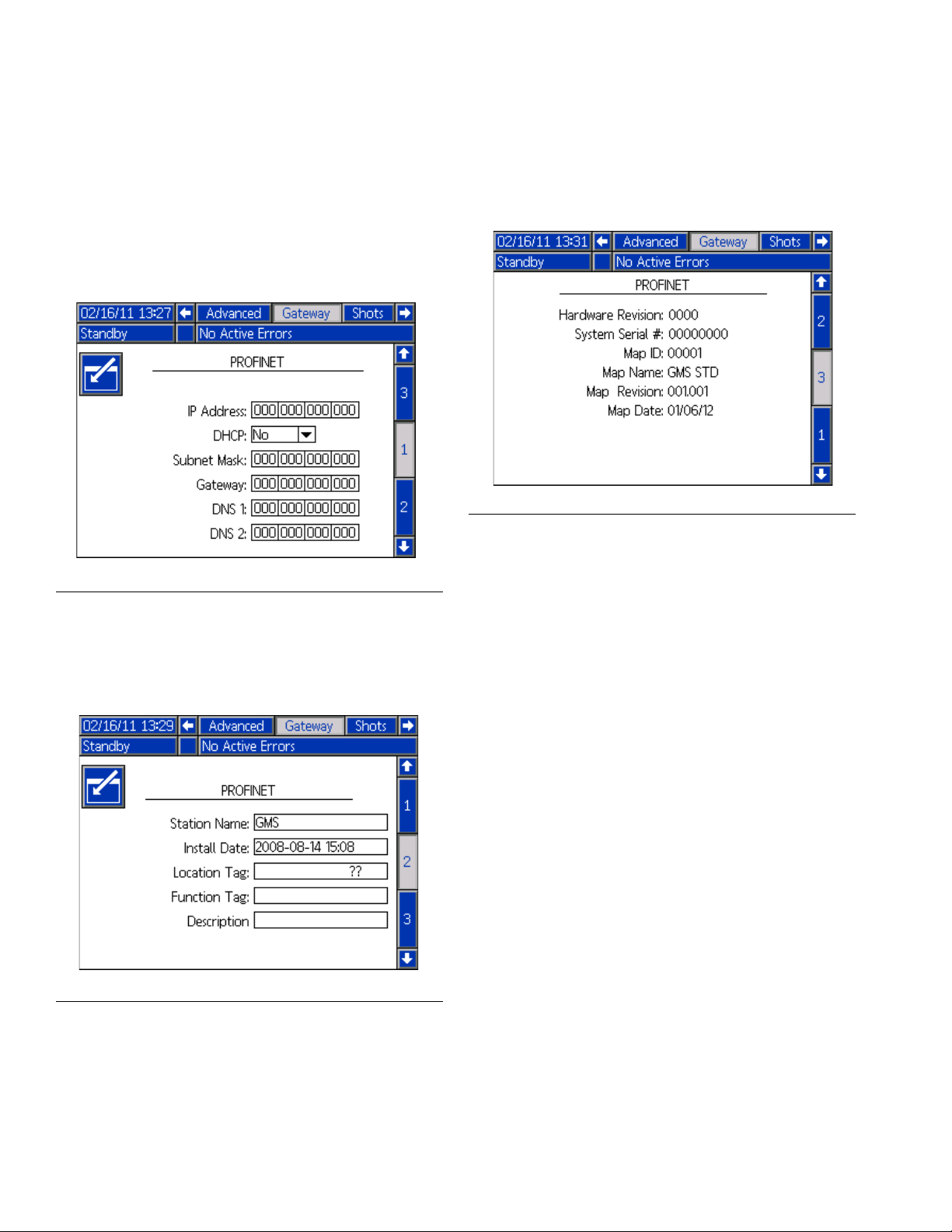

PROFINET Fieldbus Screens

These screens are shown only if you have a PROFINET

Fieldbus CGM installed. See Kits on page 2.

Screen 1

This screen enables the user to set the IP address,

DHCP settings, subnet mask, gateway, and DNS information.

F

IG. 7: PROFINET Fieldbus Screen 1

Screen 3

This screen displays the hardware revision, system

serial number, and data map identification information.

FIG. 9: PROFINET Fieldbus Screen 3

Screen 2

This screen enables the user to set the station name,

install date, location tag, function tag, and description.

IG. 8: PROFINET Fieldbus Screen 2

F

6 3A1704G

Page 7

Setup

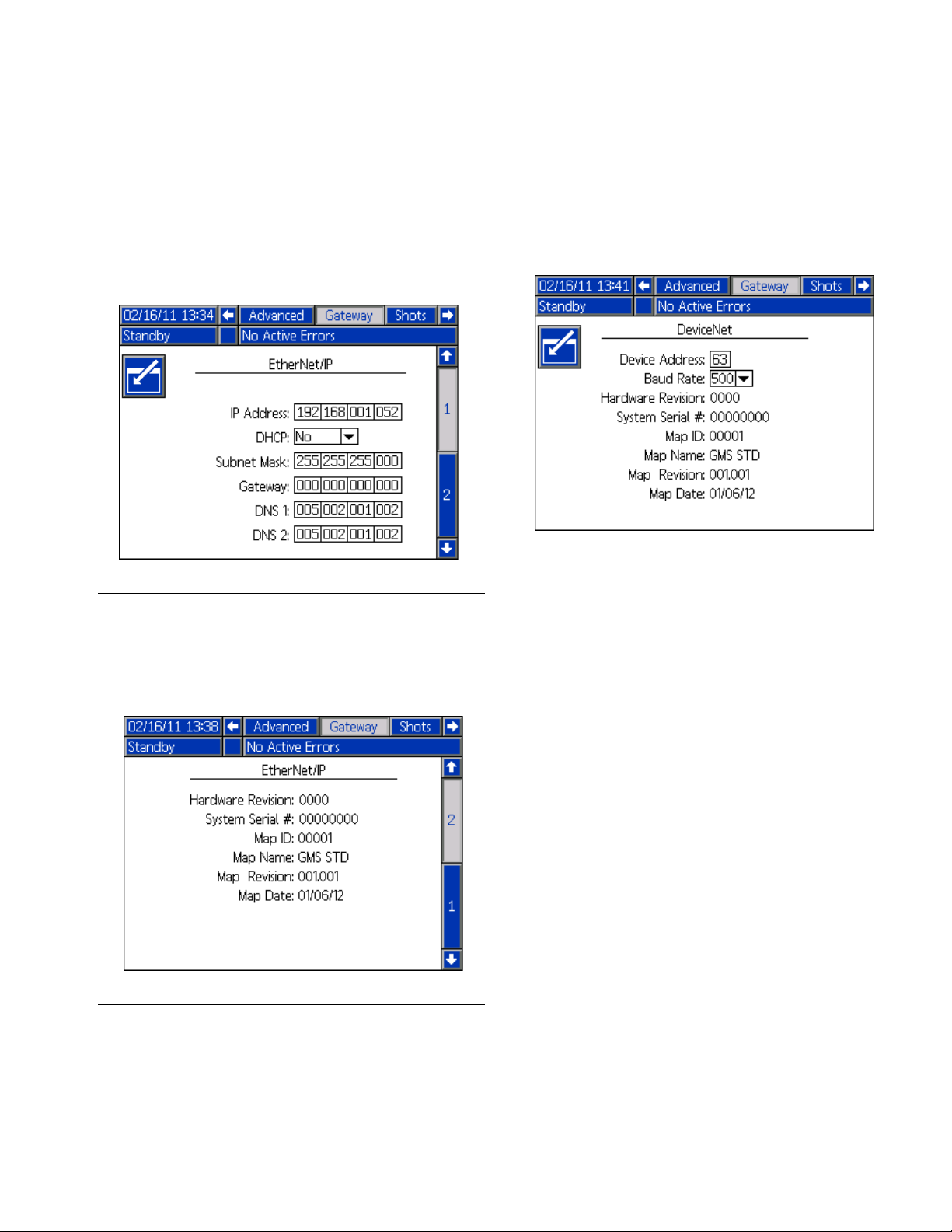

EtherNet/IP Fieldbus Screens

These screens are shown only if you have a EtherNet/IP

Fieldbus CGM installed. See Kits on page 2.

Screen 1

This screen enables the user to set the IP address,

DHCP settings, subnet mask, gateway, and DNS information.

DeviceNet Fieldbus Screen

This screen is shown only if you have a DeviceNet Fieldbus CGM installed. See Kits on page 2.

This screen enables the user to set the device address

and baud rate, and to view the hardware revision, system serial number, data map identification information.

FIG. 12: DeviceNet Fieldbus Screen

F

IG. 10: EtherNet/IP Fieldbus Screen 1

Screen 2

This screen displays the hardware revision, system

serial number, and data map identification information.

IG. 11: EtherNet/IP Fieldbus Screen 2

F

3A1704G 7

Page 8

Maintenance

Maintenance

Install Upgrade Tokens

NOTE: The Motor Control Module, Fluid Control Mod-

ule, and Temperature Control Module connection to the

system is temporarily disabled during the installation of

upgrade tokens.

To install software upgrades:

1. Use correct software token stated in the table. See

Graco Control Architecture

manual for instructions.

NOTE: Upgrade all modules in the system to the

software version on the token, even if you are

replacing only one or two modules. Different software versions may not be compatible.

All data in the module (System Settings, USB Logs,

Recipes, Maintenance Counters) may be reset to

factory default settings. Download all settings and

user preferences to a USB before the upgrade, for

ease of restoring them following the upgrade.

See manuals for locations of specific GCA components.

The software version history for each system can be

viewed in the technical support section at

www.graco.com.

Token Application

16H821 HFR:

- Communication Gateway Module

16G365 VPM:

- Communication Gateway Module

VRM:

- Communication Gateway Module

™

Module Programming

r_257396_3b9905_04b

ti12358a1

FIG. 13: Remove Access Cover

ti12334a1

ti12354a1

8 3A1704G

Page 9

Available Internal Data

The following internal data with this system can be viewed and modified by your fieldbus master.

NOTE: Refer to appropriate system manual for machine operation instructions.

CGM Input

System

Status

In

Units

(Bit Number | Name)

0 | Heartbeat 1-2 Needs to fol-

1 | Status of Dispense 1= Dispense

2 | Dispense Valve

(1 = Open)

Byte

from PLC

Output

low the CGM

Output.

0 = Close Disp e n s e V a l v e

Out

Byte

CGM Output

to PLC Input Descriptions

1-2 Square wave

toggles every

3 sec.

A c t i v e ,

0 = Dispense

not active

0 = Dispense

V a l v e C l o s e d ,

CGM initiates a square wave that

toggles every 3 sec. The PLC must

follow the heartbeat. If the heart

beat is lost from the PLC or CGM

then the system will shutdown. If the

PLC does not detect the heartbeat

then the PLC should cycle the PLC

output bit HI/LO in attempt to establish the heartbeat from the CGM. If

no heartbeat is detected then a disconnected cable or major error may

exist in the CGM.

Monitor Only: On Circulation systems, this indicates that a dispense

is pending or in progress (or when

pre dispense timer is active and during a dispense).On an L-head system Dispense Valve is considered

open until the end of the clean out

cycle. On other types of systems the

bit will indicate a dispense is active.

Used in diagnostics only. Not to be

used to control a dispensed shot.

Available Internal Data

1 = Open Dis-

pense Valve

3 | Ratio Check Valve

(1 = Enabled)

4 | Pump Parked

(1 = Parked)

3A1704G 9

0 = Enable Dis-

pense Valve

1 = Enable

Ratio Check

Valve

1= Begin Park 0 = Pump is

1 = Dispense

Valve Open

0 = Dispense

Valve is

enabled

1 = Ratio

Check Valve

is enabled

not Parked, 1

= Pump is

Parked

Valid for VRM/VPM, Infusion/Paste

systems only. Initiating a Dispense

cycle will dispense material out of

the Ratio Check valves when in

Ratio Check mode. When bit is OFF

the material will dispense normally

thru the Dispense valve.

Parking the pump involves moving

the Red pump to the position which

the pump shaft is least exposed to

the atmosphere. System must be in

Standby mode. Chemical will dispense out of the dispense valve.

Page 10

Available Internal Data

System

Status

5 | DV Lockout / Circulation Control

(1 = Locked out)

6 | Mix head Cleanout

(1 = Closed)

Units

CGM Input

In

Byte

from PLC

Output

1-2 0 = Unlock Dis-

pense Valve,

Non-Circulation State

1 = Lockout

Dispense Valve

, Circulation

State

0 = Open

Clean Out

Out

Byte

CGM Output

to PLC Input Descriptions

1-2 0 = Dispense

Valve is

unlocked or in

Non-Circulation State

1 = Dispense

Valve is

locked out or

in Circulation

State

0 = Clean Out

is open

Used to lock out the dispense valve

or configure to circulation mode (circulation type system) when in

standby/operator or operator/night

modes only. Only for stall to pressure systems with an electric dispense valve or any stall to pressure

dispense valve configuration (circulation type system).

Used for L-Head systems cleanout /

diagnostics only.

1 = Clean Out

is closed

0 = System

Startup OFF

1 = System

Startup ON

System Startup bit will initiate a controlled startup of the system. The

temperature conditioning zones will

be initiated when the bit is high. Low

pressure recirculation is also

enabled when the bit is set (Standby

7 | SYSTEM

STARTUP BIT

(1 = On)

Valid for Circulation

systems ONLY

1 = Close

Clean Out

0 = Stop System Startup

1 = Start System Startup

and night modes). Turning off this bit

will turn OFF the temperature conditioning zones and circulation. For

stall to pressure systems with a

manual dispense valve, setting this

bit will configure the pumps to stall

to the pressure set point. For stall to

pressure systems, set to operator

mode and set the DV Lockout / Circulation Control bit to high. Setting

this bit will start a recirculation dispense for recirculation type sys-

tems.

8 | Not Used Not Used Not Used Not Used

9 | Prime Side

(1 = Blue)

0 = RED

1 = BLUE

0 = RED

1 = BLUE

Selects which pump- Red or Blue-

to dispense from in prime mode.

Used for priming the chemical thru

the pumps and hoses. Valid for

VRM/VPM, Infusion/Paste systems

only. Initiating a Prime shot is via the

ADM or the Footswitch. Chemical

will dispense out of the Ratio check

valves if the system is not setup for

circulation.

10 3A1704G

Page 11

System

Status

Units

10 | Base Purge

(1 = On)

11 | Recirc Status

(1 = High Pressure

Recirc)

12 | Purge Alarm

(1 = Purge Active)

CGM Input

In

Byte

from PLC

Output

Out

Byte

0 = Park Pump

ON

1 =Base Purge

ON

1-2 0 = Low Pres-

1-2 0 = Low Pressure circulation ON

1 = High Pressure circulation ON

-- 0 = Purge

Available Internal Data

CGM Output

to PLC Input Descriptions

0 = Park

Pump ON

Park mode is valid for all machine

configurations. Material will dispense out of the mixer for all non cir-

1 =Base

Purge ON

culating systems. Circulating

systems can be parked without dispensing material.

Base purge is valid for VRM/VPM

systems only. Material will be dispensed out of the ratio check ports.

Valid for full circulation systems

sure circulation ON

only. Indicates status of the pump-

ing system when in circulation. If

system is in low pressure recirc the

1 = High Pres-

sure circulation ON

pumps will shift to High pressure

circ and then start the pre-dispense

time. When the pre-dispense time

expires, user can request dis-

penses. After expiration of post-dis-

pense time, the system will return to

low pressure modes. Pre and post

dispense times are settable on the

ADM system-2 sub screens.

Monitoring Only. Indicates status of

shot not

the purging routine.

Active

13 | PLC Disables dispensing

14 | CGM Control

Enabled

15 | USED INTERNALY

0 = Enable Dispensing

1 = Disable dispensing

0 = ADM has

control of the

system

1 = CGM has

control on the

system

-- --

1 = Purge

Shot Active

0 = Dispensing Enabled

1 = Dispensing Disabled

0 = CGM can

only monitor

1 = CGM can

control the

system

PLC enables / disable dispensing

from the GCA controller / footswitch

or remote start via the MCM.

Select via the PLC the control of the

system from either the CGM or the

ADM. CGM can monitor status in

either mode.

3A1704G 11

Page 12

Available Internal Data

Operating

System Mode Select 3 DISABLED

Mode

Selected

Shot

Select Shot number,

or Sequence Position

Number

Selected

Select sequence 5 In Sequence

Sequence

Conditioning / Heat

zones

Units

CGM Input

In

Byte

from PLC

Output

Mode = 1

STANDBY

Mode = 2

SHOT Mode=

3

SEQUENCE

Mode = 4

OPERATOR

Mode = 5

PRIME Mode =

6

NIGHT Mode=

7

4 In Shot Mode,

Selects the

Active Shot

number. In

Sequence

Mode, selects

the Active

Sequence

position number.

mode, selects

that active

sequence. Is

ignored in

other modes

6 Bit 0 = 1, Red

Tank heat

enable

Out

Byte

CGM Output

to PLC Input Descriptions

3 DISABLED

Mode = 1

STANDBY

Mode = 2

SHOT Mode=

3

SEQUENCE

Mode = 4

OPERATOR

Mode = 5

PRIME Mode

= 6

NIGHT

Mode= 7

4 Shot or

Sequence

number feedback

5 Sequence

selected feedback

6 Bit 0 = 1, Red

Tank heat ON

PLC selects the various modes of

the dispensing system.

CGM feedbacks the status of the

system to the PLC.

Prime mode is only available for

variable ratio systems.

Night mode is only available on

standard HFRs with full circulation

systems.

If using a manually controlled dispense valve, shot and sequence

modes are not available.

Select, via the PLC, the active shot

number when in Shot mode or the

Current Sequence position number

when in Sequence mode

Select via the PLC the active

sequence when in Sequence mode

PLC enables / disable the various

Conditioning Zones.

Setting the bit = 1 enables the Heat

Zone.

Setting the bit = 0 disables the Heat

Zone.

Feedback: 0 = zone OFF, 1 = Zone

ON

Bit 1 = 1, Blue

Tank heat

Bit 1 = 1, Blue

Tank heat ON

enable

Bit 2 = 1, Red

Inline heat

Bit 2 = 1, Red

Inline heat ON

enable

Bit 3 = 1, Blue

Inline heat

Bit 3 = 1, Blue

Inline heat ON

enable

12 3A1704G

Page 13

Tank Blue

Fill

Tank Red

Fill

Errors

Needing

Acknowledgement

CGM Input

Units

In

Byte

from PLC

Output

Bit 4 = 1, Red

Hose heat

enable

Bit 5 = 1, Blue

Hose heat

enable

Bit 6 = 1, Red

Chiller heat

enable

Bit 7 = 1, Blue

Chiller heat

enable

1 = Filling, 0 = Off 7 Tank Fill Not

Active = 0

Begin Tank Filling = 1

1 = Filling, 0 = Off 8 Tank Fill Not

Active = 0

Begin Tank Filling = 1

9-12 The PLC ASCII

Output must

match the PLC

Input ASCII

value.

Out

Byte

CGM Output

to PLC Input Descriptions

Bit 4 = 1, Red

Hose heat ON

Bit 5 = 1, Blue

Hose heat ON

Bit 6 = 1, Red

Chiller ON

Bit 7 = 1, Blue

Chiller ON

7 Tank not Fill-

ing = 0

Tank Filling =

1

8 Tank not Fill-

ing = 0

Tank Filling =

1

9-12 CGM ASCII

value of the

error currently requiring

Acknowledgement.

Available Internal Data

Initiates a fill valve open. This bit

can be used to initiate a manual fill

cycle or a auto fill cycle if the auto fill

mode is selected. The tank fill valve

will close upon reaching the high

level switch. See Byte 79 for tank

level status. If the Tank fill bit is

maintained the GCA will close the

valve when the tank is full. Auto time

out and alarm if the Hi level is not

reached within a preset time.

Initiates a fill valve open. This bit

can be used to initiate a manual fill

cycle or a auto fill cycle if the auto fill

mode is selected. The tank fill valve

will close upon reaching the high

level switch. See Byte 79 for tank

level status. If the Tank fill bit is

maintained the GCA will close the

valve when the tank is full. Auto time

out and alarm if the Hi level is not

reached within a preset time.

Errors requiring acknowledgement

are presented on first in first out

basis. The latest error is currently in

the error register in the CGM. The

PLC must send back the exact

ASCII value for the error to be

acknowledged in the CGM. If an

incorrect ASCII error code is sent

back to the CGM then the error will

not clear and the CGM register will

be overwritten with the incorrect

error. If multiple error codes exists

then the PLC must acknowledge

them in the order the errors are sent

to the PLC from the CGM. See

bytes 80-83 and 84 for errors and

status.

3A1704G 13

Page 14

Available Internal Data

Units and

Units and Operating

Operating

Info

Bit | Function

0-1 | Volume Units -- 0 0 | Gallons;

2 -3 | Weight Units -- 0 0 | grams; 0

Units

Info

CGM Input

In

Byte

from PLC

Output

Out

Byte

CGM Output

to PLC Input Descriptions

-- -- 13-14 Bit

xx | Meaning

0 1 | cc's; 1 0 |

Liter

1 | kilogram s;

1 0 | pounds

Monitoring Only. The operating units

of the machine can be read into the

PLC and used as required.

Flow rate

setpoint

Dispense

amount

setpoint

4-5 | Pressure Units -- -- 13-14 0 0 | bar; 0 1 |

psi; 1 0 | MPa

6 | Temperature -- 0 = Fahren-

heit; 1 = Celsius

7 | Flow Unit -- 0 = Volume; 1

= Weight

8 | Rate Unit -- 0 = Minute; 1

= Second

9 | Control Mode -- 0 = Pressure;

1 = Flow

10 11 | Dispense

Mode

-- 0 0 | Time; 0 1

| Volume; 1 0 |

Weight

12 | Reserved for

-- --

future use

13 | Reserved for

-- --

future use

14 | Reserved for

-- --

Future use

15 | Reserved for

-- --

future use

Depending on system

setup the units can be

by weight or volume

-- -- 15-18 Integer value

of the Flow

rate setpoint

in the dispensing system.

Depending on system

setup the units can be

by weight, volume, or

time

-- -- 19-22 Integer value

of the Dispense amount

setpoint in the

dispensing

system.

Monitoring Only. The operating units

of the machine can be read into the

PLC and used as required.

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.0001 for the requested

flow rate to be in system units

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.001 for the requested

amount to be in system units

14 3A1704G

Page 15

Ratio of

the Blue /

Red material - setpoint

Pump Red

Pressure Actual

Pump

Blue Pressure Actual

Pump

Flow Actual

Ratio of

the Blue /

Red materials

-Actual

Dispense

Amount Actual

Dispense

Duration

-Actual

Blue Inline

Temp Actual

Blue Hose

Temp Actual

Red Inline

Temp Actual

CGM Input

Units

Depending on system

setup the units can be

by weight or volume

In

Byte

-- -- 23-24 Integer value

from PLC

Output

Out

Byte

CGM Output

to PLC Input Descriptions

of the Blue /

Red Material

Ratio setpoint

in the dispensing system.

PSI, bar, or MPa -- -- 25-28 Integer value

of the actual

Red pump

pressure in

the dispensing system.

PSI, bar, or MPa -- -- 29-32 Integer value

of the actual

Blue pump

pressure in

the dispensing system.

Depending on system

setup the units can be

by weight or volume

-- -- 33-36 Integer value

of the actual

Flow rate in

the dispensing system.

Depending on system

setup the units can be

by weight or volume

-- -- 37-38 Integer value

of the actual

Material Ratio

in the dispensing system.

Depending on system

setup the units can be

by weight or volume

-- -- 39-42 Integer value

of the actual

Dispense

amount in the

dispensing

system.

mS -- -- 43-46 Actual Dura-

tion of the dispense in mS

Depending on system

setup the units can be

-- -- 47-48 Actual temperature

read in C or F

Depending on system

setup the units can be

-- -- 49-50 Actual temperature

read in C or F

Depending on system

setup the units can be

-- -- 51-52 Actual temperature

read in C or F

Available Internal Data

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.01 for the requested

material Ratio to be in system units

Blue is the value and Red is always

= 1. Blue: Red == xx.xx:1

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.0001 for the actual Red

pump pressure to be in system units

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.0001 for the actual Blue

pump pressure to be in system units

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.0001 for the actual flow

rate to be in system units

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.01 for the Actual material

Ratio to be in system units. Blue is

the value and Red is always = 1.

Blue: Red == xx.xx:1

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.001 for the actual

amount to be in system units

Monitoring Only. Time base is 0.001

seconds == xxx ms.

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.1 for the actual temperature to be in system units.

3A1704G 15

Page 16

Available Internal Data

Red Hose

Temp Actual

Blue Tank

Material Actual

Red Tank

Material Actual

Blue

Chiller

Temp -

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Actual

Red

Chiller

Temp -

Depending on system

setup the units can be

read in C or F

Actual

Blue Inline

Temp - Set

point

Depending on system

setup the units can be

read in C or F

Units

CGM Input

In

Byte

from PLC

Output

Out

Byte

CGM Output

to PLC Input Descriptions

-- -- 53-54 Actual temperature

-- -- 55-56 Actual temperature

-- -- 57-58 Actual temperature

-- -- 59-60 Actual temperature

-- -- 61-62 Actual temperature

-- -- 63-64 Set point temperature

Monitoring Only. The value from the

CGM is an integer and must be multiplied by 0.1 for the set point temperature to be in system units.

Blue Hose

Temp - Set

point

Red Inline

Temp - Set

point

Red Hose

Temp - Set

point

Blue Tank

MaterialSet point

Red Tank

Material Set point

Blue

Chiller

Temp - Set

point

Red

Chiller

Temp - Set

point

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

Depending on system

setup the units can be

read in C or F

See CGM Input bytes 23-26 for

changing the temperature setpoints.

-- -- 65-66 Set point temperature

-- -- 67-68 Set point temperature

-- -- 69-70 Set point temperature

-- -- 71-72 Set point temperature

-- -- 73-74 Set point temperature

-- -- 75-76 Set point temperature

-- -- 77-78 Set point temperature

16 3A1704G

Page 17

Tank

Material

Level Status Feedback

Scrolling

Error

Units

Tank Level High = 3

Tank Level Mid = 2

Tank Level Low = 1

ASCII values of the

current errors

CGM Input

In

Byte

from PLC

Output

Out

Byte

CGM Output

to PLC Input Descriptions

-- -- 79 Bits 3-0 = Red

Tank Level

Bits 7-4 =

Blue Tank

Level

-- -- 80-83 This will contain the ASCII

characters of

the Error

Code matching the Error

in the Scrolling Error Bar

on the ADM.

Available Internal Data

Monitoring Only. The values from

the CGM:

Tank Level High = 3

Tank Level Mid = 2

Tank Level Low = 1

Monitoring Only. The ASCII value

from the CGM matches the current

Error Codes on the ADM. The errors

scroll if multiple error exists. The

errors may require acknowledgement, see Bytes 9-12. See system

manual for description of the errors.

3A1704G 17

Page 18

Available Internal Data

ADM

Feedback

Units

CGM Input

In

Byte

from PLC

Output

-- -- 84

Out

Byte

CGM Output

to PLC Input Descriptions

Monitoring Only:

Error types that need acknowledged

will be indicated first. After all errors

have been acknowledged then current error types will be indicated.

Bits 3-0 =

ADM Status

bits.

Bits 4-7 are

broken down

as follows:

Bit 4 = System

Power status

Bit 5 = Dispense System ready to

dispense

Bits 7-4 Status

Error needing Acknowledged Alarm = (0x03)

Error needing Acknowledged - Deviation = (0x02)

Error needing Acknowledged - Advisory = (0x01)

Error - Alarm = (0x0C)

Error - Deviation = (0x08)

Error - Advisory = (0x04)

System status bits available.

Bits 3 thru 0 as noted:

S y s t e m Po w e r s t a tu s 0 = O f f, 1 = O n

(Bit 0)

Dispense System ready to dispense

0 = Not Ready, 1 = Ready (Bit 1)

Bit 6 = Dispense System is ready

for external

Dispense System is ready for external requests 0 = Not Ready, 1 =

Ready (Bit 2)

requests

Bit 7= Future

Use

Dispense Valve Open (=1) Indication

18 3A1704G

Page 19

Change

Dispense

Flow Rate

or Pressure Set

point

Change

Dispense

Amount

Set point

Change

material

Ratio Set

point

Change

Temperature Conditioning

Set point

Units

Depending on system

setup the units can be

by weight, volume,

flow, or pressure

Depending on system

setup the units can be

by weight, volume, or

time

Depending on system

setup the units can be

by weight or volume

Select conditioning

zone set point to

change

MSW = Conditioning

Zone Selected

Available Internal Data

CGM Input

In

Byte

13-16 Integer value of

from PLC

Output

the requested

rate in the dispensing system.

Out

Byte

CGM Output

to PLC Input Descriptions

-- -- Changes current shot selected to a

new rate. The value outputted to the

CGM must be an integer. The PLC

value is xxx.xxx and must be multiplied by 1000 prior to being sent to

the CGM

17-20 Integer value of

the requested

Dispense

amount in the

dispensing system.

21-22 Integer value of

the requested

Material Ratio

in the dispensing system.

Blue: Red

-- -- Changes current shot selected to a

new dispense amount. The value

outputted to the CGM must be an

integer. The PLC value is xxx.xxx

and must be multiplied by 1000 prior

to being sent to the CGM

-- -- Changes current shot selected in a

variable ratio system to a new ratio.

The value outputted to the CGM

must be an integer and must be

multiplied by 100 for the requested

material Ratio. Blue is the value

and Red is always = 1. PLC input

is: Blue: Red == xx.xx:1

23-24 0 = Red Tank -- -- When changing a heat zone, select

the appropriate zone number which

will enable the CGM to write a new

temperature set point to the heat

zone selected. Only 1 heat zone

can be selected at a time.

LSW = Temperature

setpoint in 0.1 degree

increments

(example: 501 = 50.1)

MSW + LSW combined to form a

DINT from the PLC output to CGM

input.

NOTE: If the system is a standard

HFR, the LSW setpoint must be

0.1 °C, regardless if Fahrenheit

mode is selected on the ADM.

1 = Blue Tank

2 = Red Inline

3 = Blue Inline

4 = Red Hose

5 = Blue Hose

6 = Red Chiller

7 = Blue Chiller

3A1704G 19

Page 20

Available Internal Data

Change

Temperature Con-

Depending on system

setup the units can be

read in C or F

ditioning

Set point

LSW = Desired set

point in 0.1°C for standard HFR units.

Desired setpoint in

0.1 °C / 0.1°F for recirculation units.

Units

CGM Input

In

Byte

from PLC

Output

25-26 The tempera-

ture set points

are limited by

the temperature high and

low alarm values. There

must be a difference of at

least 10

between the

new set point

and the alarm

values or the

new set point

will be ignored.

Out

Byte

CGM Output

to PLC Input Descriptions

-- -- The value outputted to the CGM

must be an integer and must be

multiplied by 10 for the requested

zone temperature. Temperature

input into the PLC == xxx.x F or C

and must be changed to xxxx C

prior to sending to the CGM (standard HFR only). The temperature

set points are limited by the temperature high and low alarm values.

The alarm setpoints must be greater

than 10 degrees (standard HFR) or

2 degrees (recirculation unit) from

the requested setpoint. If the alarm

is closer than 10 degrees (standard

HFR) or 2 degrees (recirculation

unit) then the requested setpoint will

be ignored. Manually changing the

alarm setpoints on the ADM will be

required prior to a new setpoint

change. See Output Bytes 63 thru

78 for temperature zone feedback

from the CGM.

System

Power

System Power 27 Toggles Sys-

tem Power on

change.

LSW = Desired Set point in 0.1°

units

LSW + MSW combined to form a

DINT from the PLC output to CGM

input.

-- -- System power is ON when the ADM

is in any active mode. System

power is OFF when the power LED

is in the yellow state. To turn the

System power ON or OFF, write a

different value to the System Power

byte. Changing the value will toggle

the state from ON to OFF or OFF to

ON. See Out Byte 84 for System

Power Status

20 3A1704G

Page 21

Available Internal Data

Controlling Device

CGM Control and Night Mode

When the controlling device sets the HFR into night

mode using the CGM, the controlling device will be

responsible for turning on and off the pumps accordingly

(by setting or clearing the “SYSTEM STARTUP BIT”, or

bit 7 bytes 1-2) when the “CGM Control Enabled” bit is

set (Bit 14, bytes 1-2). Any active night mode periodic or

time of day timer will be over-ridden by the controlling

device when the corresponding timer expires within the

Advanced Display Module (ADM). If the controlling

device clears the “CGM Control Enabled” bit after setting the HFR into night mode, the night mode timers will

operate properly and condition the dispense material

accordingly.

CGM Control and Parking the Pumps

After the HFR is set to Standby mode, the controlling

device (and user by pressing the footswitch) will have

the option to park the pumps. When the pumps are

parked, the red material pump shaft will be immersed

into the red material, hence preventing exposure of the

shaft and red material on the shaft to the atmosphere.

ADM Screen Information when CGM

Control is Started or ended

When the user or controlling device sets or clears the

“CGM Control Enabled” bit, information provided on the

ADM display may or may not be current. If the user navigates away, then back to the main home run screen, the

information provided will be current.

If the system is a full circulation based system, the controller device will need to have the pumps cycling in low

pressure mode (by setting the “SYSTEM STARTUP

BIT”, or bit 7 bytes 1-2) prior to setting the “Pump

Parked” bit (bit 4, bytes 1-2). For a standard HFR, the

user will have to remove the “SYSTEM STARTUP BIT”

immediately after the pump reaches the parked position.

For a recirculation type system, the pump will remain in

the park position, and ignore an active “SYSTEM

STARTUP BIT” request. For a recirculation type system, to exit a parked state, the controlling device will

need to clear the “Pump Parked” bit, then set the “SYSTEM STARTUP BIT” from a cleared state. When this

occurs, the pumps will start cycling in the last low pressure flow rate executed.

If the system is a stall to pressure type system, the controlling device simply needs to set the “Pump Parked” bit

from an idle state, then the pumps will move to the

parked position. If the system has a manual dispense

valve, the user will need to ensure the pump pressures

are less than approximately 391 psi (2.7 MPa, 27 bar)

prior to setting the “Pump Parked” bit, and ensure either

the dispense valve is opened, or the material is diverted

out of the pressure relief valves at the material manifold.

3A1704G 21

Page 22

Available Internal Data

Timing Diagrams

The following diagrams show the signal sequence of the CGM communication.

Heart Beat Timing Diagram

Heart Beat CGM Input

Bytes /Bit

CGM HB - Normal

PLC HB - Normal

CGM HB - No HB

PLC HB - Cycle Hi / Lo

I/O

I/O

System Power Bit Diagram

System Power Bit CGM Input

Bytes /Bit

Set CGM Control

Verify CGM Control

System Power ON

Verify System Power ON

2/7

27

Shot Setup - Change Diagram

Shot Setup - Change CGM Input

Bytes /Bit

Select Shot Mode

Verify Shot Mode

Select Shot Number

Verify Shot Number

Set Flow Rate

Verify Flow Rate

Set Shot Size

Verify Shot Size

3

4

13-16

17-20

CGM Output

Bytes /Bit

I/O

I/O

CGM Output

Bytes /Bit

2/7

84/0

CGM Output

Bytes /Bit

3

4

13-16

19-22

22 3A1704G

Page 23

System Startup and Dispensing Recirculation Diagram

Power

Dispense

Dispense

Available Internal Data

OFF

End

Start

Ready

System

ON

Power

3

2/731/7

Bytes /Bit

CGM Output

2/7

Bytes /Bit

CGM Input

N/A

84/1

6/0 thru 7

3

N/A

4

2/6

2/4

1/1

1/2

1/6

4

2/6

N/A

Verify Heat Zones ON

Verify System Startup Bit

Verify CGM Control

Set CGM Control

System Startup and Dispensing

Recirculation System

System Startup Bit - Circ Only

System Heat / Startup time

Verify Shot Mode

Select Shot Mode

System Ready to Dispense

Select Shot Number

PLC Enable Dispense - 0 = Enabled

Verify Shot Number

Verify PLC Enabled Dispense

Circulation Status - 1 = Hi Press

Dispense Start - Direct to MCM

L-Head Cleanout (L-Head Only)

Dispense Valve Open

Dispense Active

3A1704G 23

Page 24

Parts

Parts

Model 24J415

17

16

6

3

7

15

3

Ref Part Description Qty

3† CGMxx0 MODULE, CGM 1

6 114984 SCREW, tapping, phillips pan head 4

7 16J526 TOKEN, map 1

12 121000 CABLE, CAN, female / female 0.5 m 1

13 121901 SUPPRESSOR, box snap, ferrite 3

15 16H821 TOKEN, GCA, upgrade, ADM32 1

16 121807 CONNECTOR, splitter 1

17 124005 BUSHING, strain relief 1

† Not included in kit. See Kits on page 2 for available

CGM modules. See the Communications Gateway

Module manual 312864 for CGM parts list.

Not shown.

24 3A1704G

Page 25

Parts

3A1704G 25

Page 26

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Toll Free: 1-800-746-1334 Fax: 330-966-3006

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2011, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 3A1704

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised March 2013

Loading...

Loading...