Page 1

™

Pro Xp

Electrostatic Spray Guns That Deliver Expert Performance

Page 2

Experienced Painters Rely on

Expert Performance

Pro Xp

We took our trademark, high performing Electrostatic

Spray Guns and made them better. They are smaller,

lighter and designed to maximize your profits.

And with more models to choose from, you’ll get the

same performance you’ve come to expect from Graco

– now with greater spraying flexibility for your ever

changing production needs.

22

Page 3

Stand Out Above the Rest

With state-of-the-art technology and consistently better finishes

With excellent finish quality, aircaps and spray tips that are designed

to deliver an even higher quality finish, the Pro Xp is a real stand out!

Plus, every gun is tested and delivered with a certificate indicating the

spray pattern, mechanical performance and electrical performance

meet Graco’s requirements and your expectations.

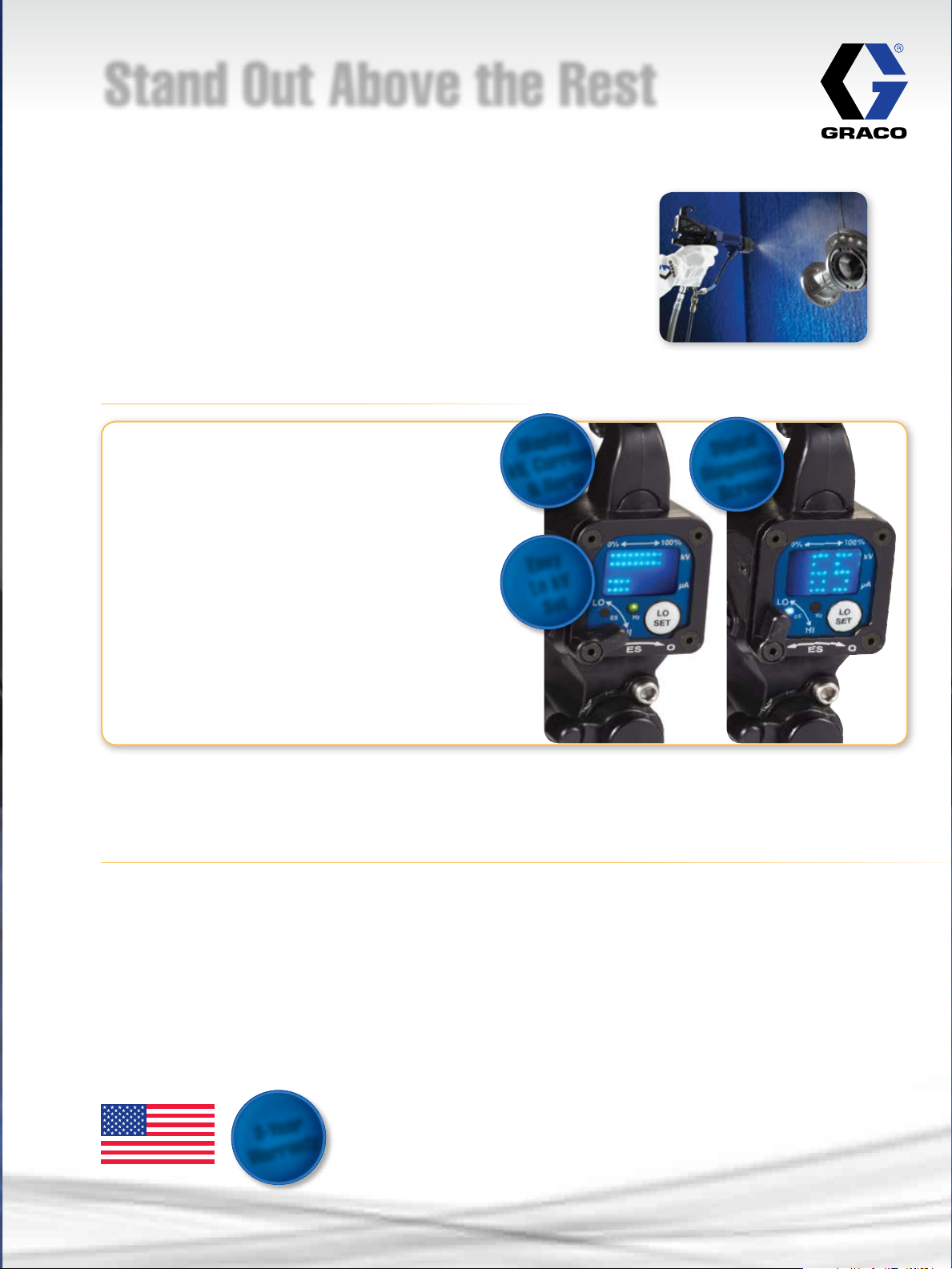

Smart Controls

Analyze Spray Performance

Bar graph shows kV and current, while alternator speed

indicator displays electrostatic performance.

Adapt to Your Voltage Needs

Adjust quickly between low or high kV. Change the low setting

in 5 kV increments with the push of a button.

Eliminate Guesswork

Diagnostic mode assists troubleshooting with a digital display

of actual voltage, current and hertz.

Quick Smart Display Changeout

Remove cartridge quickly and easily when ready to replace.

Built-in

Dependability

Stay Running Longer

Durable components give you extra

peace of mind knowing that you’ll spend

less time fixing and more time spraying.

Increase

Productivity

Reduce Muscle Strain

Smaller and lighter gun body is wellbalanced making it easier to spray

at a steady rate all day.

Display

kV, Current

& Hertz

Easy

Lo kV

Set

Digital

Diagnostic

Screen

Maximize

Your Profits

Spray More with Less

40 kV Booster gun gives you the

transfer efficiency of a 60 kV gun,

in a smaller, more compact size.

Lower Cost of Ownership

3-Year Warranty, ease of repair

and durable components reduce

ownership cost.

3-Year

Warranty

Made in the USA

Reduce Operator Fatigue

No more heavy power cords to slow you

down. The power supply is built into the

gun for added efficiency.

Increase Operator Comfort

Ergonomic handle is designed to fit

comfortably in sprayer’s hand.

Save Money

Higher transfer efficiency equals less

waste – saving you money on material.

Save on Energy Costs

New aircaps use less air and

help lower your energy bill.

3

3

Page 4

WB100™

Air Spray Waterborne

Isolation System

Paired with a Pro Xp WB Spray

Gun, this portable cabinet isolates

waterborne coatings.

Smart Controls

Available in 60 kV

& 85 kV Models

Alternator Speed Indicator

Indicator changes color with electrostatic

performance

Triton®

Air-Operated Diaphragm

Spray Packages

Air Spray Packages combine a

Pro Xp Air Spray gun with our Triton

air-operated diaphragm pump to deliver

high quality finishes.

Control Knobs

Convenient, easy to access and large knobs

allow for easier gun adjustment

Atomizing Air Control

Adjust air from full to minimal to fit your

spraying needs

Optional low profile version available

Ergonomic Handle

Smooth, curved handle fits nicely

in your hand for comfortable spraying

Light Trigger Pull

Reduces muscle strain and operator fatigue

Air Inlet Swivel

Increases maneuverability

4 4

Page 5

Internal Power Supply

Reduce operator fatigue with no

heavy cords to slow you down

Pro Xp Air Spray

Smaller, Lighter & Superior Quality Spray

Get consistent, high quality finishes every time you spray!

All models are up to 1 in (2.5 cm) shorter and 4 oz

High Wear Components

Unique design for abrasive materials.

Nozzle and electrode allow for longer

life with abrasive and metallic coatings.

Standard on High Conductivity guns

(110 g) lighter – the smallest profile gun with

an internal power supply on the market!

Available in 40, 60 & 85 kV

when you need a little more power

kV Booster Gun

Get the transfer efficiency of a

60 kV gun, in a smaller, more

compact size of a 40 kV gun.

when you need a bell-shaped pattern

Round Spray

For parts that require a slow velocity,

bell-shaped spray pattern. Available in

60 kV model, but kit fits all air spray guns.

when you have a low resistivity material

High Conductivity Gun

Longer fluid tube allows for spraying

lower resistivity material. Available in

40, 60 & 85 kV.

5

Page 6

Pro Xp Air-Assist

Smaller, Lighter & Superior Quality Spray

Get a more consistent, high quality finish every time you spray! Plus,

the 60 kV gun is the smallest and lightest air-assist gun on the market.

Available in 60 & 85 kV

AEM & AEF Tip Lines

AEM Tip - Delivers a high quality finish

for a variety of applications

AEF Tip - Designed with a pre-orifice

which helps atomize paints for fine

finish applications

More Efficient Aircap

Increase transfer efficiency up to 10%

Improve spray performance and cleanliness

One-piece aircap is indexed for accurate

positioning

Fluid Filter

Integrated filter reduces clogging

by keeping debris out of the tip

6

6

Page 7

Smart Controls

Available in 60 kV

& 85 kV Models

Alternator Speed Indicator

Indicator changes color with electrostatic

performance

Merkur®

Air-Assist Fine Finish

Spray Packages

This complete finishing system improves

productivity, reduces costs and provides

consistent, high quality finishes when paired

with a Pro Xp Air-Assist gun.

Control Knobs

Convenient, easy to access and

large knobs allow for easier gun adjustment

Internal Power Supply

Reduce operator fatigue with no

heavy cords to slow you down

Fan Adjust Pattern Control

Reduce overspray by changing the fan

pattern width according to the size of parts

Ergonomic Handle

Smooth, curved handle fits nicely in your

hand for comfortable spraying

WB3000™

Air-Assist Waterborne

Isolation System

Paired with the Pro Xp WB Air-Assist

gun, this portable isolation cabinet with

Merkur ES 30:1 is designed to spray

waterborne materials at high pressures.

7

Page 8

Return on Investment

Calculate Your Savings

ROI Calculator

Use these ROI calculators to see how

much you can save when you replace

conventional air-assist and HVLP

guns with Pro Xp Electrostatic Guns.

The Transfer Efficiency chart below shows how

your savings increase as you move up the Pro Xp

product line.

% Transfer Efficiency

Pro Xp85 AA

Pro Xp60 AA

Pro Xp85

Pro Xp60

40 kV Booster

Pro Xp40

Conventional AA

Conventional HVLP

0% 100%

% Paint Applied to Part

% Paint Wasted

Example

Facility

Paint price per gallon $50.00

Gallons sprayed per day

Business days per month

One Month Material Cost $5,000.00

x x

x x

(Multiply to get total) (Multiply to get total)

20

Pro Xp Air Spray Material Savings

Compared to Conventional HVLP

Pro Xp85 50%

Pro Xp40 kV Booster 40%

Pro Xp60 40%

Pro Xp40 30%

One Month Material Savings

Paint price per gallon $50.00

Gallons sprayed per day

Business days per month

One Month Material Cost $5,000.00

$2,500.00

Example

Facility

x x

x x

(Multiply to get total) (Multiply to get total)

20

Pro Xp Air-Assist Material Savings

Compared to Conventional Air-Assist

Pro Xp85 55%

Pro Xp60 45%

Your

Facility

5

Your

Facility

5

Compared to Conventional HVLP

Pro Xp85 60%

Pro Xp60 50%

One Month Material Savings

88

$2,750.00

Page 9

Ordering Information

Air Spray Gun Models

Part Number Power Supply kV Recommended Coating Type Display Type Nozzle Size

L85T10 85 Standard Standard 1.5 mm (0.055 in)

L85M10 85 Standard Smart 1.5 mm (0.055 in)

L85T16 85 High Conductivity Standard 1.5 mm (0.055 in)

L85M16 85 High Conductivity Smart 1.5 mm (0.055 in)

L60T10 60 Standard Standard 1.5 mm (0.055 in)

L60T12 60 Standard Standard 1.2 mm (0.047 in)

L60M10 60 Standard Smart 1.5 mm (0.055 in)

L60M12 60 Standard Smart 1.2 mm (0.047 in)

L60T16 60 High Conductivity Standard 1.5 mm (0.055 in)

L60M16 60 High Conductivity Smart 1.5 mm (0.055 in)

L60T17 60 Waterborne Standard 1.5 mm (0.055 in)

L60M17 60 Waterborne Smart 1.5 mm (0.055 in)

L60T11 60 Standard Standard Round Spray

L40T10 40 Standard Standard 1.5 mm (0.055 in)

L40T16 40 High Conductivity Standard 1.5 mm (0.055 in)

All gun models include aircap part number 24N477.

High Conductivity gun models include a High Conductivity Fluid Tube, High Wear Nozzle and High Wear Electrode.

Pro Xp Air Spray

Air Spray with kV Booster Gun Models

Part Number Power Supply kV Recommended Coating Type Display Type Nozzle Size

L40T14 40 Standard Standard 1.5 mm (0.055 in)

L40T15 40 High Conductivity Standard 1.5 mm (0.055 in)

Aircap Selection Chart

Part Number (color)

24N477 (black) Round end 15-17 (381-432) Light to medium (20–70 cp) Up to 15 oz/min (450 cc/min)

24N438 (black) Round end 15-17 (381-432) Light to medium (20–70 cp) Up to 15 oz/min (450 cc/min)

24N279 (black) Round end 14-16 (356-406) Medium to heavy (70–260 cp), and

24N376 (black), 24N276 (blue)

24N277 (red), 24N278 (green)

24N274 (black) Tapered end 12-14 (305-356) Light to medium (20–70 cp) Up to 15 oz/min (450 cc/min)

24N275 (black) Tapered end 14-16 (356-406) Light to medium (20–70 cp), and

24N439 (black) Tapered end 11–13 (279–330) For use with 2.0 mm nozzles.

24N453 (black) Round end 14-16 (356-406) Light to medium (20-70 cp) Up to 15 oz/min (450 cc/min)

• Distance to target: 10 in (254 mm)

• Inlet air pressure: 50 psi (3.4 bar, 34 kPa)

Pattern

Shape

Tapered end 17-19 (432- 483) Light to medium (20–70 cp) Up to 15 oz/min (450 cc/min)

Nozzle Selection Chart

Fluid Nozzle for Standard Materials

Part Number Color Orifice Size - mm (inch)

24N619 Black 0.55 (0.022)

24N613 Black 0.75 (0.029)

24N614 Black 1.0 (0.042)

24N615 Black 1.2 (0.047)

24N616 Black 1.5 (0.055)

24N617 Black 1.8 (0.070)

24N618 Black 2.0 (0.080)

Length

in (cm)

• Fan air: adjusted for maximum width

• Fluid flow rate: 10 oz/min (300 cc/min)

Recommended Fluid Viscosity

cp at 70ºF (21ºC)

high solids (360+cp)

high solids (360+cp), aerospace coatings

Medium to heavy (70–260 cp), and

high solids (360+cp)

High Wear Fluid Nozzle for Abrasive Materials

Part Number Color Orifice Size - mm (inch)

24N620 Blue 0.75 (0.029)

24N621 Blue 1.0 (0.042)

24N622 Blue 1.2 (0.047)

24N623 Blue 1.5 (0.055)

24N624 Blue 1.8 (0.070)

24N625 Blue 2.0 (0.080)

Recommended

Production Rates

Up to 15 oz/min (450 cc/min)

Up to 25 oz/min (750 cc/min)

Up to 20 oz/min (600 cc/min)

9

Page 10

Ordering Information

Pro Xp Air-Assist

Air-Assist Gun Models

Part Number Power Supply kV Recommended Coating Type Display Type

H85T10 85 Standard Standard

H85M10 85 Standard Smart

H60T10 60 Standard Standard

H60M10 60 Standard Smart

H60T18 60 Waterborne Standard

H60M18 60 Waterborne Smart

All gun models include AEM or AEF tip of choice.

AEM Spray Tips

Recommended for high finish quality applications at low and medium pressures.

Order desired tip, Part No. AEMxxx, where xxx = 3-digit number from the matrix below.

Fluid Output

Orifice Size

inch (mm)

† 0.007 (0.178) 4.0 (0.1) 5.2 (0.15) 107 207 307 – – – – –

† 0.009 (0.229) 7.0 (0.2) 9.1 (0.27) – 209 309 409 509 609 –

† 0.011 (0.279) 10.0 (0.3) 13.0 (0.4) – 211 311 411 511 611 711 –

0.013 (0.330) 13.0 (0.4) 16.9 (0.5) – 213 313 413 513 613 713 813

0.015 (0.381) 17.0 (0.5) 22.0 (0.7) – 215 315 415 515 615 715 815

0.017 (0.432) 22.0 (0.7) 28.5 (0.85) – 217 317 417 517 617 717 –

0.019 (0.483) 28.0 (0.8) 36.3 (1.09) – – 319 419 519 619 719 –

0.021 (0.533) 35.0 (1.0) 45.4 (1.36) – – – 421 521 621 721 821

0.023 (0.584) 40.0 (1.2) 51.9 (1.56) – – – 423 523 623 723 823

0.025 (0.635) 50.0 (1.5) 64.8 (1.94) – – – 425 525 625 725 825

0.029 (0.736) 68.0 (1.9) 88.2 (2.65) – – – – – – – 829

0.031 (0.787) 78.0 (2.2) 101.1 (3.03) – – – 431 – 631 – 831

0.033 (0.838) 88.0 (2.5) 114.1 (3.42) – – – – – – – 833

0.037 (0.939) 108.0 (3.1) 140.0 (4.20) – – – – – – 737

0.039 (0.990) 118.0 (3.4) 153.0 (4.59) – – – – 539 – – –

* Tips are tested in water.

Fluid output (Q) at other pressures (P) can be calculated by this formula: Q = (0.041) (QT)

for the selected orifice size.

† These tip sizes include a 150 mesh filter.

fl oz/min (l/min)

at 600 psi

(41 bar,

4.1 MPa)

at 1000 psi

(70 bar,

7.0 MPa)

2-4

(50-100)

(100-150)

Maximum Pattern Width at 12 inches (305 mm)

4-6

6-8

(150-200)

inches (mm)

8-10

(200-250)

Spray Tip

10-12

(250-300)

√P where QT = fluid output (fl oz/min) at 600 psi from the above table

12-14

(300-350)

14-16

(350-400)

16-18

(400-450)

AEF Fine Finish Pre-Orifice Spray Tips

Recommended for high finish quality applications at low and medium pressures. AEF tips have a pre-orifice that assists in atomizing sheer thinning materials.

Order desired tip, Part No. AEFxxx, where xxx = 3-digit number from the matrix below.

Fluid Output

Orifice Size

inch (mm)

(41 bar, 4.1 MPa)

† 0.010 (0.254) 9.5 (0.28) 12.5 (0.37) 310 410 510 610 710 –

0.012 (0.305) 12.0 (0.35) 16.0 (0.47) 312 412 512 612 712 812

0.014 (0.356) 16.0 (0.47) 21.0 (0.62) 314 414 514 614 714 814

0.016 (0.406) 20.0 (0.59) 26.5 (0.78) – 416 516 616 716 –

* Tips are tested in water.

Fluid output (Q) at other pressures (P) can be calculated by this formula: Q = (0.041) (QT)

table for the selected orifice size.

† These tip sizes include a 150 mesh filter.

fl oz/min (l/min)

at 600 psi

at 1000 psi

(70 bar, 7.0 MPa)

6-8

(150-200)

Maximum Pattern Width at 12 inches (305 mm)

8-10

(200-250)

inches (mm)

10-12

(250-300)

Spray Tip

12-14

(300-350)

14-16

(350-400)

√P where QT = fluid output (fl oz/min) at 600 psi from the above

10

16-18

(400-450)

Page 11

Technical Specifications

Pro Xp Electrostatic Guns

Tech Specs by Gun Model

Pro Xp40 Pro Xp60 Pro Xp85 Pro Xp60 AA Pro Xp85 AA

Maximum Voltage Output 40 kV 60 kV 85 kV 60 kV 85 kV

Maximum Working Fluid Pressure

Maximum Working Air Pressure

Gun Weight (without hose)* 19.8 oz (560 g) 21 oz (600 g) 23.8 oz (675 g) 23 oz (660 g) 25.7 oz (728 g)

Gun Length 8.7 in (22 cm) 9.5 in (24 cm) 10.5 in (26.5 cm) 9.7 in (24.5 cm) 10.7 in (27 cm)

Recommended

paint resistivity range

Fluid Inlet 3/8 npsm(m) 3/8 npsm(m) 3/8 npsm(m) 1/4-18 npsm(m) 1/4-18 npsm(m)

Air Inlet

Instruction Manual

*Standard gun model. For other models reference the instruction manual.

Standard 25 MΩ/cm to ∞ 25 MΩ/cm to ∞ 25 MΩ/cm to ∞ 3 MΩ/cm to ∞ 3 MΩ/cm to ∞

High Cond. 1 to 25 MΩ/cm 1 to 25 MΩ/cm 1 to 25 MΩ/cm – –

Waterborne

Standard 3A2494 3A2494 3A2494 3A2495 3A2495

Waterborne – 3A2496 – 3A2497 –

100 psi

(7 bar, 0.7 MPa)

100 psi

(7 bar, 0.7 MPa)

–

1/4 npsm(m)

left handed thread

100 psi

(7 bar, 0.7 MPa)

100 psi

(7 bar, 0.7 MPa)

MΩ/cm

≤ 1

1/4 npsm(m)

left handed thread

100 psi

(7 bar, 0.7 MPa)

100 psi

(7 bar, 0.7 MPa)

–

1/4 npsm(m)

left handed thread

3000 psi

(210 bar, 21 MPa)

100 psi

(7 bar, 0.7 MPa)

MΩ/cm

≤ 1

1/4 npsm(m)

left handed thread

3000 psi

(210 bar, 21 MPa)

100 psi

(7 bar, 0.7 MPa)

–

1/4 npsm(m)

left handed thread

Grounded Air Hoses (required for use)

Air Flex

Length Air Flex

6 ft (1.8 m) 244963 – 223068 235068

15 ft (4.6 m) 244964 – 223069 235069

25 ft (7.6 m) 244965 24N736 223070 235070

36 ft (11 m) 244966 24N737 223071 235071

50 ft (15 m) 244967 24N738 223072 235072

75 ft (23 m) 244968 – 223073 235073

100 ft (30.5 m) 244969 – 223074 235074

Air Flex: EPDM rubber core and cover for extra flexibility.

Air Flex with QD: Hose includes Quick Disconnect coupling, part number 112534

Standard: Modified semi-conductive polyamide core, urethane cover for added durability.

* Waterborne (required for isolated waterborne applications): Conductive SST wire braid

for grounding. Polyurethane tube and cover.

™

with QD

Standard Waterborne*

Test Equipment

Part Number Description

241079 Megohmmeter. 500 V output, 0.01-2000 megohms. Use for

722886

722860

245277 Test Fixture. High Voltage Probe and kV meter. Use to test

24R038 Test fixture adaptor to change from Pro Xs to Pro Xp

ground continuity and gun resistance tests.

Paint Resistance Meter. Use for fluid resistivity test.

Paint Probe. Use for fluid resistivity test.

These two parts must be used together.

the electrostatic voltage of the gun and the condition of the

alternator and power supply when being serviced.

Operator Accessories

Part Number Description

117823 Conductive Gloves, box of 12 (small)

117824 Conductive Gloves, box of 12 (medium)

117825 Conductive Gloves, box of 12 (large)

24N603 Gun Covers. For 40 kV and 60 kV guns. Box of 10.

24N604 Gun Covers. For 85 kV guns. Box of 10.

24N758 Display Covers. Keeps Smart display clean. Package of 5.

24N520 Comfort Grip. Snap-on grip increases handle size to reduce

operator fatigue. Medium size.

24N521 Comfort Grip. Snap-on grip increases handle size to reduce

operator fatigue. Large size.

24P170 Metal trigger to replace standard trigger.

24P171 Four-finger Trigger Kit. To convert Pro Xp air spray guns to a

four-finger trigger.

Gun Accessories

Part Number Description

24N642 Ball Swivel for gun air inlet. 1/4 npsm (left-handed thread).

24P172 Quick Adjust Knob. For quick change of fan size.

24N636 Low profile atomizing air control

24N993 High conductivity hose. 25 ft length to replace 60 kV HC

fluid tube kit.

24N318 Round Spray Kit. To convert a standard air spray gun to a

round spray aircap.

24N319 Round Spray Kit. To convert a standard air-assist spray gun

to a round spray aircap.

24N704 Electrode Replacement Needle for abrasive materials. Blue.

112534 Air quick disconnect coupling

Approvals for Pro Xp* Guns

Approved for use in Class I, Division I locations spraying

Group D Materials.

Approved for use in Group II, Category 2 locations spraying

Group IIA materials.

*Patent pending

11

Page 12

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN

55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Building 7

1029 Zhongshan Road South

Huangpu District

Shanghai 200011

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 443, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2013 Graco Inc. 345007 Rev. B 2/13 All written and visual data contained in this document are based on the latest product information available at the time

of publication. Graco reserves the right to make changes at any time without notice. All other brand names or marks are used for identification purposes and

are trademarks of their respective owners.

Loading...

Loading...