Page 1

Bellows Pumps

The Newest Technology in Piston Pumps

Page 2

Merkur™ Bellows

The gentle pumping action of the

Merkur Bellows Pump, combined with

reduced sealing surfaces, provides

superior handling of shear-sensitive

materials, including UV coatings and

waterborne materials.

Applications

• Catalyzed coatings

• Varnish and lacquer

• High solid coatings

• Abrasive materials

• Solvent and waterborne materials

• Moisture-sensitive materials

• UV-cure coatings

• Flat line machine lines

• General finishing applications where open

wet cups are not preferred

Operator Control Panel

• Air controls located at operator height

for easy setting and monitoring

DataTrak

• Easy-to-set runaway protection

• Pump diagnostics for maintenance

• Resettable batch counter tracks material

usage and maintenance schedule

™

Page 3

Time (1/1000 sec)

Merkur

Competitor

1800 2000 2200 2400 2600 2800 3000

M

C

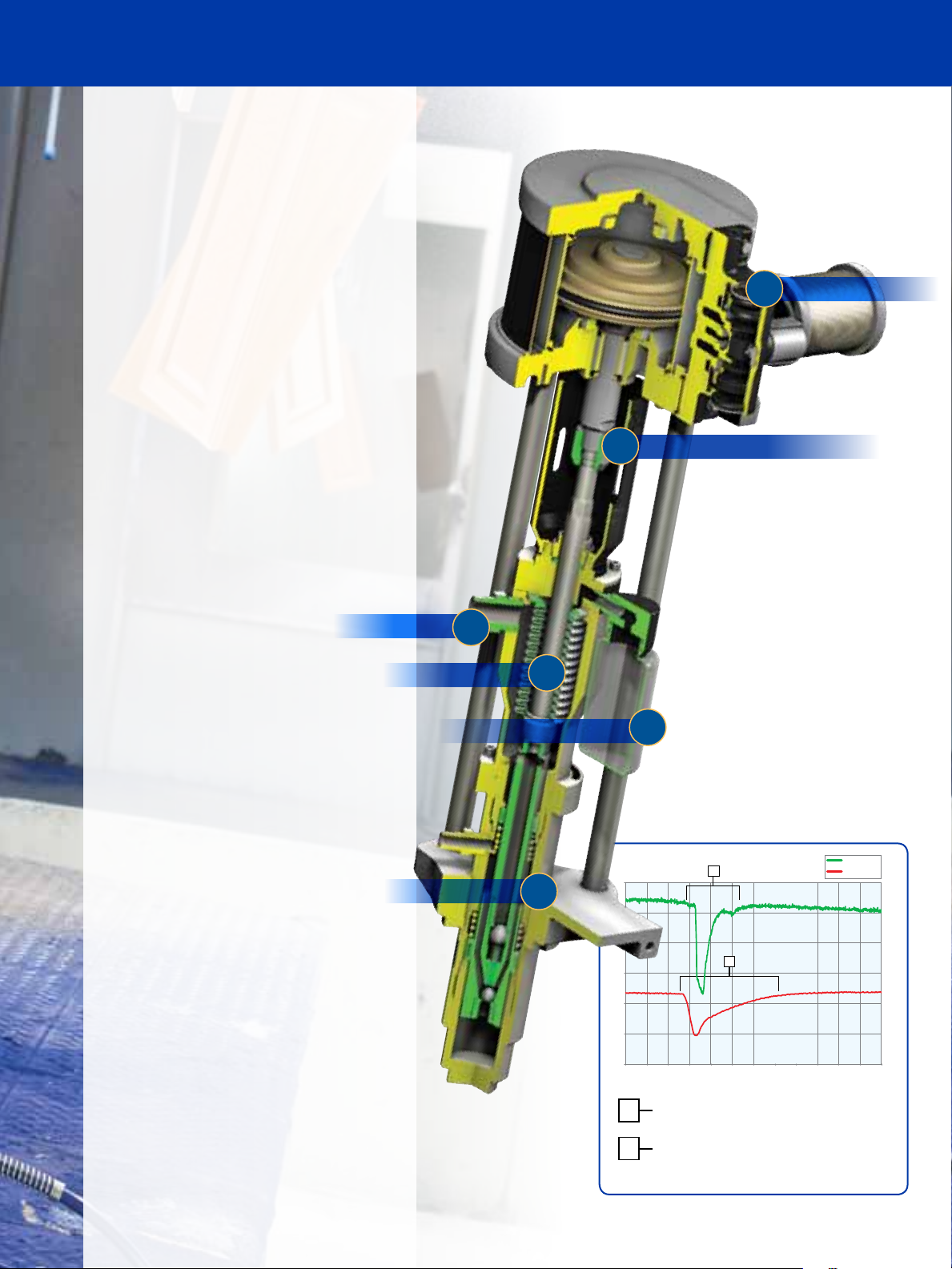

Powerful Capabilities in a Unique Piston Pump

Merkur Air Motor Technology

• Highest technology air motor on the market

• Low air consumption for increased efficiency

• Simple air motor design and minimal parts

reduces repair time

Leak Proof Pump Lower

• Easy-to-flush design allows for fast color changes

and reduced material waste

• 300 series stainless steel pump construction

provides long-lasting durability

• Fewer parts and online replacement bellows seal

means improved serviceability, lower cost of

ownership and reduced downtime

1. Air Valve

Provides smooth and rapid changeover

2. Quick Removal Coupler

Allows for easy disassembly of the pump lower

from the air motor

3. Rotatable Inlet Fitting

Inlet can be rotated 360 degrees for

easy access

4. Improved Bellows Seal Design

Eliminates throat seal leakage and lubrication

5. Overflow Chamber (Optional)

D-shaped seal and overflow chamber

contains the material within the pump

in case of bellows leakage

Inlet Fitting

3

Bellows Seal

4

Overflow Chamber

Quick Removal Coupler

2

Less Pulsation

5

for Better Results

Merkur is designed to provide

a smooth, rapid changeover for

a better, more consistent finish

and less user fatigue.

1

Air Valve

6. Throat and Piston Packings

• Spring-loaded to maintain long packing

life – no adjustments needed

• Available with V-Packing seals for abrasives

or U-Cup seals for UV coatings

Packings

6

Quick changeover and recovery minimizes

M

pulsation and creates an even film thickness

C

Longer changeover and pressure spike creates

inconsistent finish

Page 4

Glutton® Bellows

Known for its robust design, the Glutton

pump features a bellows seal that

virtually eliminates the possibility of air

or moisture contaminating the fluid.

Choose the heavy-duty Glutton when

no other pump can handle the job!

Applications

• Air spray and HVLP supply

• Circulating systems

• Catalyzed coatings

• Varnish and lacquer

• High solid coatings

• Abrasive materials

• Solventborne and waterborne fluids

• Moisture sensitive materials

• UV-cure coatings

• Flatline machine lines

• General finishing applications where open

wet cups are not preferred

Page 5

Compact Design

The Heavy-Duty, Low Maintenance Solution

1. Vertical Ball Check

• Reversible seats for uniform wear and long service life

• External check allows for quick maintenance for materials

that pack or mat out easily

2. External Air Valve

• Easy installation and maintenance

3. Outlet Manifold

• Simplifies plumbing and installation

Vertical Ball Check

1

4. Pump Stand

• Included for easy mounting

5. Cylinder and Displacement Rod

• Designed to handle a broad range of coatings

6. Piston Seal

• Multiple configurations for material compatibility

7. Heavy-Duty Bellows Seal (Optional)

• Designed for longer life in abrasive applications

8. Carbide Seat Accessory

• Ideal for abrasive materials

Carbide Seat

8

External Air Valve

2

Bellows Seal

7

Outlet Manifold

3

Pump Stand

4

6

Piston Seal

Cylinder and

5

Displacement Rod

Page 6

Merkur Bellows Ordering Information

Package Description:

Pump: Package includes pump, pump only air controls. Siphon tube, hoses, and guns are not included.

AA: Air-Assisted Airless package includes pump, pump and gun air controls, G15 or G40 guns, fluid hose, gun fluid hose,

gun air hose, 5 gallon (19 l) pail suction hose and tube

AL: Airless™ package includes pump, pump air controls, XTR™ gun, fluid hose, gun fluid hose, 5 gallon (19 l) pail suction hose and tube

ES: Electrostatic package includes pump, pump and gun air controls, PRO AA Xs4 Smart Gun, fluid hose, gun fluid hose,

gun air hose, 5 gallon (19 l) pail suction hose and tube

Ratio 5:1 12:1 15:1 15:1 23:1 24:1 25:1 35:1

Pump Volume per Cycle 150 cc 100 cc 50 cc 150 cc 100 cc 150 cc 50 cc 100 cc

Air Motor Displacement 400 cc 700 cc 400 cc 1200 cc 1200 cc 1800 cc 700 cc 1800 cc

Maximum Fluid Outlet Pressure

Maximum Air Inlet Pressure

Fluid Flow @ 60 cpm

Air Consumption @ 100 psi

(7 bar) @ 20 cpm

Fluid Inlet Size 1" npt(m) 3/4" npt(m) 3/4" npt(m) 1" npt(m) 3/4" npt(m) 1" npt(m) 3/4" npt(m) 3/4" npt(m)

Fluid Outlet Size 3/4" npt(m) 3/8" npt(m) 3/8" npt(m) 3/4" npt(m) 3/8" npt(m) 3/4" npt(m) 3/8" npt(m) 3/8" npt(m)

Air Inlet (Air Controls) 3/8" npt(f) 3/8" npt(f) 3/8" npt(f) 3/8" npt(f) 3/8" npt(f) 3/8" npt(f) 3/8" npt(f) 3/8" npt(f)

500 psi

(35 bar)

100 psi

(7 bar)

2.4 gpm

(9.0 lpm)

6 scfm

(0.17 m3/min)

1200 psi

(83 bar)

100 psi

(7 bar)

1.6 gpm

(6.0 lpm)

9 scfm

(0.17 m3/min)

1500 psi

(103 bar)

100 psi

(7 bar)

0.8 gpm

(3.0 lpm)

6 scfm

(0.17 m3/min)

1500 psi

(103 bar)

100 psi

(7 bar)

2.4 gpm

(9.0 lpm)

17 scfm

(0.48 m3/min)

2300 psi

(158 bar)

100 psi

(7 bar)

1.6 gpm

(6.0 lpm)

17 scfm

(0.48 m3/min)

2400 psi

(165 bar)

100 psi

(7 bar)

2.4 gpm

(9.0 lpm)

26 scfm

(0.74 m3/min)

2500 psi

(172 bar)

100 psi

(7 bar)

0.8 gpm

(3.0 lpm)

9 scfm

(0.17 m3/min)

3500 psi

(241 bar)

100 psi

(7 bar)

1.6 gpm

(6.0 lpm)

26 scfm

(0.74 m3/min)

Seal

Mount

Package

Drain

Valves

Fluid

Filter

DataTrak

• G05B01 G12B01 G15B01 G15B51 G23B01 G24B01 G25B01 G35B01

• • G05B02 G12B02 G15B02 G15B52 G23B02 G24B02 G25B02 G35B02

Pump

Wall

• • G15B03 G15B53 G23B03 G24B03 G25B03 G35B03

• • • G15B04 G15B54 G23B04 G24B04 G25B04 G35B04

AA

• G05B03 G12B03 G15B05 G15B55 G23B05 G24B05 G25B05 G35B05

• • G05B04 G12B04 G15B06 G15B56 G23B06 G24B06 G25B06 G35B06

V-Packing

U-Cup

Note: Graco recommends 20 cpm or less for intermittent pumping applications and 12 cpm or less for continuous pumping applications.

Pump

• • G15B07 G15B57 G23B07 G24B07 G25B07 G35B07

• • • G15B08 G15B58 G23B08 G24B08 G25B08 G35B08

AA

Cart

• • G23B35 G24B35 G25B33 G35B35

AL

• • • G23B36 G24B36 G25B34 G35B36

• • G15B83 G23B33 G24B33 G35B33

ES

• • • G15B84 G23B34 G24B34 G35B34

• G05B09 G12B09 G15B17 G15B67 G23B17 G24B17 G25B17 G35B17

• • G05B10 G12B10 G15B18 G15B68 G23B18 G24B18 G25B18 G35B18

Pump

Wall

• • G15B19 G15B69 G23B19 G24B19 G25B19 G35B19

• • • G15B20 G15B70 G23B20 G24B20 G25B20 G35B20

AA

• G05B11 G12B11 G15B21 G15B71 G23B21 G24B21 G25B21 G35B21

• • G05B12 G12B12 G15B22 G15B72 G23B22 G24B22 G25B22 G35B22

Pump

Cart

• • G15B23 G15B73 G23B23 G24B23 G25B23 G35B23

• • • G15B24 G15B74 G23B24 G24B24 G25B24 G35B24

AA

G05B05 G12B05 G15B09 G15B59 G23B09 G24B09 G25B09 G35B09

• G05B06 G12B06 G15B10 G15B60 G23B10 G24B10 G25B10 G35B10

G15B11 G15B61 G23B11 G24B11 G25B11 G35B11

• G15B12 G15B62 G23B12 G24B12 G25B12 G35B12

G05B07 G12B07 G15B13 G15B63 G23B13 G24B13 G25B13 G35B13

• G05B08 G12B08 G15B14 G15B64 G23B14 G24B14 G25B14 G35B14

G15B15 G15B65 G23B15 G24B15 G25B15 G35B15

• G15B16 G15B66 G23B16 G24B16 G25B16 G35B16

G05B13 G12B13 G15B25 G15B75 G23B25 G24B25 G25B25 G35B25

• G05B14 G12B14 G15B26 G15B76 G23B26 G24B26 G25B26 G35B26

G15B27 G15B77 G23B27 G24B27 G25B27 G35B27

• G15B28 G15B78 G23B28 G24B28 G25B28 G35B28

G05B15 G12B15 G15B29 G15B79 G23B29 G24B29 G25B29 G35B29

• G05B16 G12B16 G15B30 G15B80 G23B30 G24B30 G25B30 G35B30

G15B31 G15B81 G23B31 G24B31 G25B31 G35B31

• G15B32 G15B82 G23B32 G24B32 G25B32 G35B32

Page 7

Merkur Bellows Accessories

Spray Guns

Refer to the spray gun brochure for additional model numbers.

All guns include tip of choice.

24C853 G15 Carbide Air-Assisted Spray Gun

24C855 G40 Air-Assisted Spray Gun

24C857 G40 RAC Air-Assisted Spray Gun

XTR501 XTR-5 Airless Spray Gun

244573 PRO Xs AA Smart Electrostatic Spray Gun

Accessories

238926 Back Pressure Regulator

102397 Fluid Gauge

3000 psi (206 bar, 20.6 MPa)

238890 Fluid Regulator

243340 Pail Cover with Agitator

Use to agitate material in a 5 gal (18.9 l) pail

222121 Fluid Regulator, Stainless Steel

Maximum working pressure: 1500 psi (103 bar, 10.3 MPa)

Regulator range: 150-1200 psi (10-28 bar, 1-8.2 MPa)

24A587 Pump Outlet Fluid Filter, Stainless Steel

60 mesh (250 micron), 5000 psi (350 bar, 25 MPa)

256425 Fluid Filter Drain Valve, Stainless Steel

5000 psi (350 bar, 35 MPa)

224458 Replacement Filter Screen Element

3-pack elements, 30 mesh, SST

224459 Replacement Filter Screen Element

3-pack elements, 60 mesh, SST

24A540 Air Control Gauge Covers

5 sheets of 10 covers

24B187 Second AA Gun Kit

Includes air regulator and gauge

239850 Heater 120 (v)

239851 Heater 240 (v)

24E298 Overflow Chamber Kit

DataTrak

24A575 Upgrade Kit for 400 cc Air Motors

24A576 Upgrade Kit for 700 cc, 1200 cc and 1800 cc Air Motors

24A592 Upgrade Kit for DataTrak with Cycle Count Only

Suction Hoses

24A954 55 gal (208 l) Drum Suction Hose and Strainer, 3/4 in fluid inlet

24B598 55 gal (208 l) Drum Suction Hose and Strainer, 1 in fluid inlet

24B424 PTFE Lined Suction Hose for 5 gal (19 l) Pails and Strainer, 3/4 in inlet

24B425 PTFE Lined Suction Hose for 5 gal (19 l) Pails and Strainer, 1 in inlet

Gun Hoses

256390 25 ft Air Hose

241812 25 ft Fluid Hose: 3300 psig (228 bar)

24A955 50 ft Bundled Air and Fluid Hose: 3300 psig (228 bar)

256389 50 ft Air Hose

24B562 50 ft Fluid Hose: 3300 psig (228 bar)

24A588 Hose Clips: Pack of 10

PTFE Seals

24J858* Reinforced PTFE V-Packing Kit for 50 cc Displacement Pump

24J859* Reinforced PTFE V-Packing Kit for 100 cc Displacement Pump

24J860* Reinforced PTFE V-Packing Kit for 150 cc Displacement Pump

24J850* PTFE Bellows Kit for 50 cc Diplacement Pump

24J851* PTFE Bellows Kit for 100 cc and 150 cc Displacement Pump

Instruction and Parts Manuals

312799 Merkur Bellows AA and Airless Spray Package

312798 Merkur Electrostatic Spray Package

312795 Merkur Bellows Pump Assembly

312793 Merkur Bellows Displacement Pump

312796 Merkur Air Motor

* Use with materials that cause chemical compatibility concerns with UHMWPE,

such as acid catalyst materials

Glutton Bellows Ordering Information and Accessories

Technical Specifications

Ratio Glutton 4:1

Output per cycle 355 cc

Max working pressure 400 psi (28 bar)

Max air input pressure 100 psi (7 bar)

Output at 60 cpm 5.6 gpm (21.2 lpm)

Pump inlet size 1.25 npt(f)

Pump outlet size 1 npt(f)

Pump manual 307843

Pump Construction

Material Seals Glutton 4:1

CS Nylon 237008

CS UHMWPE 220663

SST Nylon 237011

SST UHMWPE 220666

Accessories

206221 Glutton Wall Bracket

102969 Loctite® High Strength Sealant

To secure piston shafts to the piston stud.

223319 Return Tube Kit for returning circulated fluid back to a 55 gal drum

Includes SST return tube, SST bushing and SST elbow

208259 55 Gallon (200 Liter) Suction Kit

Suction hose (3/4 in ID x 6 ft (1.8 m)), elbow, bung adapter, riser tube,

3/4 in npt(f) outlet fitting.

204385 Elevator with Fixed Mounting

Use with 237949 and 237579 to raise and lower pump when changing drums

237949 Stainless Steel Drum Cover Kit (55 gal)

Includes SST drum cover, agitator gasket, access hole plug and fasteners

237579 Air Control Kit for 204385 elevator to raise and lower drum cover

222345 Air Filter/Regulator/Lubricator Kit

Replacement Parts

220656 Air Valve and Pilot Valve Repair Kit

24C134 Piston Seals and Bellows Kit – UHMWPE

24C135 Piston Seals and Bellows Kit – Nylon

220658 Piston Seal Kit – Urethane

221134 Carbide Ball and Seat Kit (2 each)

189432 Fluid Piston – SST

686499 Fluid Piston – Ceramic

Page 8

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9467 8558

Fax: 61 3 9467 8559

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Room 118 1st Floor

No.2 Xin Yuan Building

No.509 Cao Bao Road

Shanghai, 200233

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 432, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2011 Grac o Inc. 344834 Elec tronic Copy Only. All written and visual data contained in this document are based on the latest product information available

at the time of publication. Graco reserves the right to make changes at any time without notice. All othe r brand names or mark s are used f or id entifi cation

purpo ses a nd are tradem arks of th eir respective owne rs.

Loading...

Loading...