Page 1

™

AirPro EFX

Automatic Air Spray Gun Designed for Precision Finishing

Page 2

Precision Finishing

precision

Setting the Performance Benchmark

The AirPro EFX is a complete line of air spray automatic guns with optimized

performance for the most precise spray finishing. All aspects of the AirPro EFX are

designed to meet the demands of small component precision finishing including:

• Aircaps and nozzles deliver superior, precision spray performance

• Precision uid adjustment with a micrometer-telescoping knob

• High wear components designed for abrasive materials

• Excellent uid ow rate stability and repeatability

• Compact and lightweight gun

Innovative Engineering and Design

Infused with the latest technology and performance features,

the AirPro EFX gun offers countless innovations for the fine finish market.

• 5 spray technologies including the exclusive HiTEch

• 6 nozzle sizes for ow rates as low as 10 cc per minute, up to 350 cc per minute

• 3 uid adjustment knobs for greater ow rate precision

• 2 mounting styles for manufacturing line exibility

Page 3

Breakthrough Technology

technology

Apply Superior Finishes

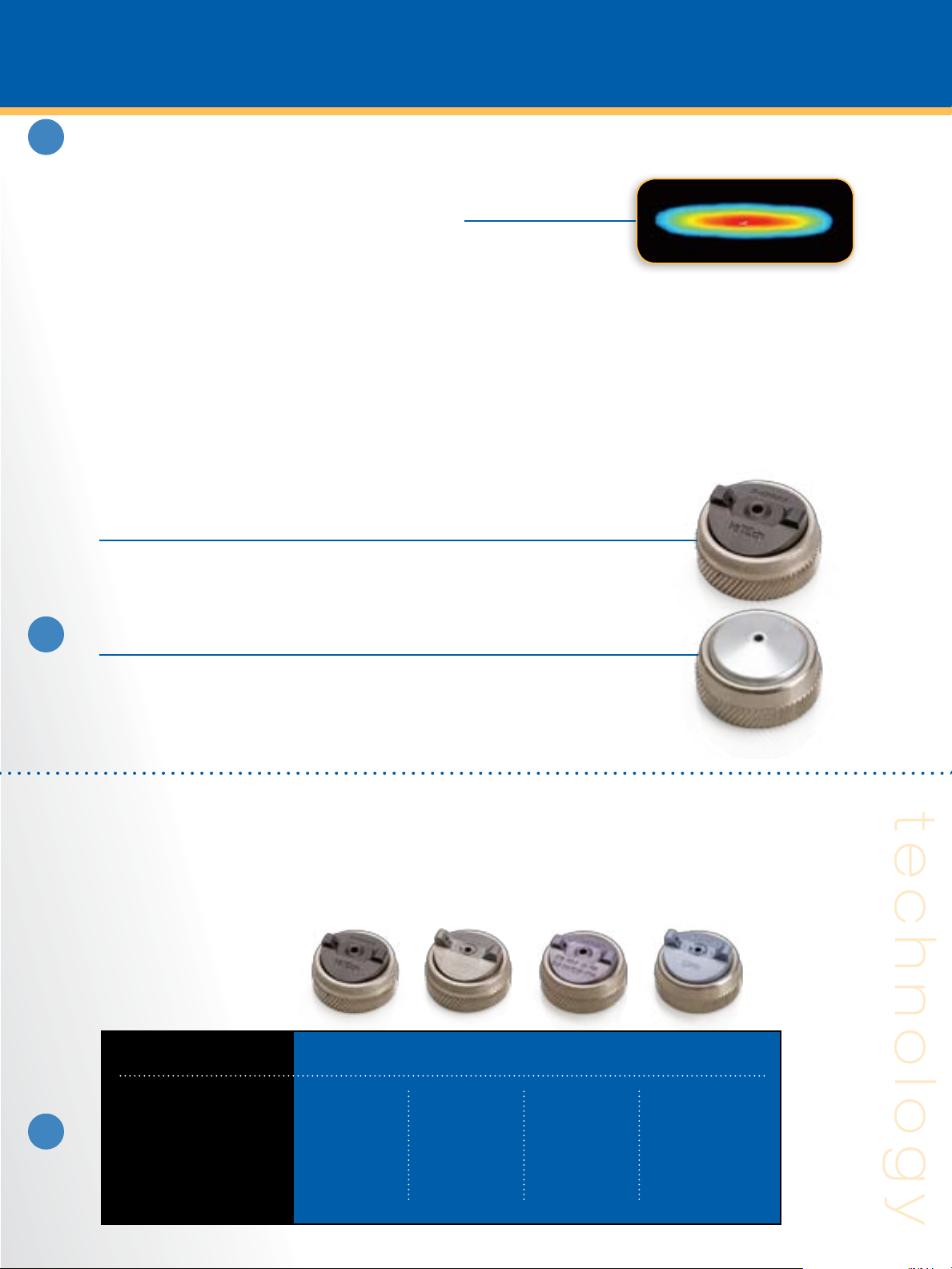

Each AirPro EFX gun is analyzed for spray pattern excellence

so you get precise coverage every time you spray.

Laser light imaging technology veries spraying benchmarks are met or exceeded

for each AirPro EFX gun – guaranteeing the following criteria:

• High quality spray pattern shape

• Enhanced atomization for outstanding nish quality

• Even material distribution through the spray pattern for optimum coverage

Advanced Aircap Technologies

HiTEch

A high transfer efciency gun with excellent atomization. Aircaps and nozzles are designed

to deliver superior nish quality while reducing overspray.

Air Brush

Delivers a round spray pattern for precise, small surface area spraying. The ability to control

pattern size decreases material usage.

Actual spray pattern

produced using laser light

sheet imaging technology

Versatile Product Line

Offered in ve air spray technologies, including air brush, Graco’s AirPro EFX automatic gun has the versatility

and exibility to accommodate a variety of spraying needs.

HiTEch LVMP HVLP CONVENTIONAL

FINISH QUALITY Best Better Good Best

TRANSFER EFFICIENCY High Medium Medium Low

FLUID FLOW Medium Medium Low High

AIR FLOW High Low High Low

Page 4

Engineered for Accuracy

configurations

Light, Compact and Perfect for Robotic Applications!

The AirPro EFX air spray automatic guns are among the lightest and most compact guns in

their class. With no internal air shutoff mechanism, the AirPro EFX delivers increased reliability

and precision uid ow. The modest size and weight of this gun make it an excellent choice

for xed, reciprocating and robotic applications.

Features

1

Aircaps

Available in ve air spray technologies, •

including HiTEch and air brush

Indexing aircap provides fast, accurate •

positioning in the vertical or horizontal position

Nozzle and Needle

2

Optimized for maximum •

ow rate adjustability

Available in tungsten carbide for increased •

life with abrasive and metallic coatings

Delivers excellent ow rate •

stability and repeatability

1

3

Needle Packing

Design and material construction is durable •

for long life with abrasive materials, including

UV coatings

Three Fluid Adjustment Knob Styles

4

Air Inlet

5

Separate inlets for atomizing, fan and trigger •

air provide increased control

Quick disconnect air ttings decrease time •

needed for repairs

Two Mounting Styles

6

3

4

2

6

5

Page 5

Mounting and Fluid Adjustment Options

design

Fluid Adjustment Knobs

Ultra precision knob Indexing knob Lock ring and cap

Micrometer telescoping

knob for precision

uid adjustment with

numerical indexing for

retainable adjustment

settings

Flexible Gun Mounting

Manifold Style

Durable stainless steel uid passages•

Recirculation up to the nozzle for no dead spots•

Quick removal of the gun from the manifold for easy repair•

Manifold guarantees gun positioning even after gun repairs•

Mounting rod included for ease of installation •

Fluid adjustment in

ne ow increments

Simple thread

adjustment with

locking ring

Direct Connect Style

Hose ttings connect directly to gun•

Quick disconnect air ttings•

HiTEch gun models have stainless steel uid ttings•

Top attachment slot for consistent mounting•

Page 6

Ordering Information

Ordering Information

1. Choose Manifold or Direct Connect style gun

2. Select Spray Type (HiTEch, LVMP, HVLP, Conventional or Air Brush)

3. Select material viscosity

4. Select average ow rate

Manifold Style Guns

Part

Number Spray Type Nozzle Size

24B866 HiTEch 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Ultra Precision 24D303 24D703

24B867 HiTEch 1.0 mm (0.039 in) light-medium 20 - 200 cc/min (0.7 - 6.8 oz/min) Carbide Ultra Precision 24C221 24D703

24B868 HiTEch 1.5 mm (0.059 in) medium 45 - 450 cc/min (1.5 - 15.2 oz/min) Carbide Ultra Precision 24C201 24D704

24B869 LVMP 0.5 mm (0.020 in) light 5 - 50 cc/min (0.2 - 1.7 oz/min) SST Ultra Precision 24D277 24C184

24B870 LVMP 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Ultra Precision 24D278 24C184

24B871 LVMP 0.9 mm (0.035 in) light-medium 15 - 150 cc/min (0.5 - 5.1 oz/min) SST Ultra Precision 24D279 24C184

24B872 LVMP 1.1 mm (0.043 in) light-medium 25 - 250 cc/min (0.8 - 8.5 oz/min) SST Ultra Precision 24D280 24C184

24B873 LVMP 1.3 mm (0.051 in) medium 35 - 350 cc/min (1.2 - 11.8 oz/min) SST Ultra Precision 24D281 24C184

24B874 LVMP 1.5 mm (0.059 in) medium 45 - 450 cc/min (1.5 - 15.2 oz/min) Carbide Ultra Precision 24D284 24C184

24B862 HVLP 0.5 mm (0.020 in) light 5 - 50 cc/min (0.2 - 1.7 oz/min) SST Indexing 24D302 24C183

24B863 HVLP 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Indexing 24D303 24C183

24B864 HVLP 1.1 mm (0.043 in) light-medium 25 - 250 cc/min (0.8 - 8.5 oz/min) SST Indexing 24D305 24C183

24B865 HVLP 1.3 mm (0.051 in) medium 35 - 350 cc/min (1.2 - 11.8 oz/min) SST Indexing 24D306 24C183

24B857 Conventional 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Indexing 24C197 24C182

24B858 Conventional 0.9 mm (0.035 in) light-medium 15 - 150 cc/min (0.5 - 5.1 oz/min) SST Indexing 24C198 24C182

24B859 Conventional 1.1 mm (0.043 in) light-medium 25 - 250 cc/min (0.8 - 8.5 oz/min) SST Indexing 24C199 24C182

24B860 Conventional 1.3 mm (0.051 in) medium 35 - 350 cc/min (1.2 - 11.8 oz/min) SST Indexing 24C200 24C182

24B861 Conventional 1.5 mm (0.059 in) medium 45 - 450 cc/min (1.5 - 15.2 oz/min) Carbide Indexing 24C201 24C182

24B875 Air Brush 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Indexing 24C197 24D705

Material

Viscosity* Flow

Needle Tip/

Nozzle Material

Fluid Adjustment

Knob

Needle/Nozzle

Kit Part No.

Air Cap with

Pin Part No.

Direct Connect Style Guns

Part

Number Spray Type Nozzle Size

24B884 HiTEch 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Ultra Precision 24D303 24D703

24B885 HiTEch 1.0 mm (0.039 in) light-medium 20 - 200 cc/min (0.7 - 6.8 oz/min) Carbide Ultra Precision 24C221 24D703

24B886 HiTEch 1.5 mm (0.059 in) medium 45 - 450 cc/min (1.5 - 15.2 oz/min) Carbide Ultra Precision 24C201 24D704

24B887 LVMP 0.5 mm (0.020 in) light 5 - 50 cc/min (0.2 - 1.7 oz/min) SST Indexing 24D277 24C184

24B888 LVMP 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Indexing 24D278 24C184

24B889 LVMP 0.9 mm (0.035 in) light-medium 15 - 150 cc/min (0.5 - 5.1 oz/min) SST Indexing 24D279 24C184

24B890 LVMP 1.1 mm (0.043 in) light-medium 25 - 250 cc/min (0.8 - 8.5 oz/min) SST Indexing 24D280 24C184

24B891 LVMP 1.3 mm (0.051 in) medium 35 - 350 cc/min (1.2 - 11.8 oz/min) SST Indexing 24D281 24C184

24B881 HVLP 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Indexing 24D303 24C183

24B882 HVLP 1.1 mm (0.043 in) light-medium 25 - 250 cc/min (0.8 - 8.5 oz/min) SST Indexing 24D305 24C183

24B883 HVLP 1.3 mm (0.051 in) medium 35 - 350 cc/min (1.2 - 11.8 oz/min) SST Indexing 24D306 24C183

24B877 Conventional 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Lock Ring 24C197 24C182

24B878 Conventional 0.9 mm (0.035 in) light-medium 15 - 150 cc/min (0.5 - 5.1 oz/min) SST Lock Ring 24C198 24C182

24B879 Conventional 1.1 mm (0.043 in) light-medium 25 - 250 cc/min (0.8 - 8.5 oz/min) SST Lock Ring 24C199 24C182

24B880 Conventional 1.3 mm (0.051 in) medium 35 - 350 cc/min (1.2 - 11.8 oz/min) SST Lock Ring 24C200 24C182

24B892 Air Brush 0.7 mm (0.028 in) light 10 - 100 cc/min (0.3 - 3.4 oz/min) SST Indexing 24C197 24D705

* Light: 20 or less centipoise

Light-Medium: 21 - 42 centipoise

Medium: 43 - 64 centipoise

Material

Viscosity* Flow

Needle Tip/

Nozzle Material

Fluid Adjustment

Knob

Needle/Nozzle

Kit Part No.

Air Cap with

Pin Part No.

Page 7

Technical Specifications

Technical Data

Maximum working uid pressure................................................. 100 psi (7 bar, 0.7 MPa)

Maximum working air pressure .................................................. 100 psi (7 bar, 0.7 MPa)

Maximum working uid temperature ......................................................120°F (49°C)

Minimum air cylinder actuation pressure ..........................................50 psi (3.4 bar, 0.34 MPa)

Weight

Manifold style guns ...............................................................1.3 lb (575 g)

Direct Connect style guns ..........................................................0.6 lb (275 g)

Wetted Parts

Manifold style guns ...................................................Nylon, PTFE, Stainless Steel,

Ultra High Molecular Weight Polyethylene,

Tungsten Carbide

Direct Connect style guns......................................... Anodized Aluminum, Stainless Steel,

Ultra High Molecular Weight Polyethylene,

Tungsten Carbide, Nylon

Triggering Speed

These values apply to a new gun with a 12 ft (3.6 m), 1/4 in (6.3 mm) OD cylinder air line and a 1.1 m (0.043 in) nozzle.

Values will vary slightly with use and with variations in equipment.

Cylinder Air Pressure Fluid Pressure Air Pressure

50 psi (3.5 bar, 0.35 kPa) 50 psi (3.5 bar, 0.35 kPa) 100 psi (7 bar, 0.7 kPa) 48 84

MSEC

to Fully Open

Accessories

24C216 Fittings Kit, 1/4 inch

Includes 3 air ttings and 2 uid ttings

24D143 Robot Adapter Kit Fanuc Paint Mate 200

Compatible with and without manifold

24D008 Inlet Air Needle Valve

Includes needle valve and 6 mm tube tting

24C214 HVLP Pressure Verication Kit

For use in checking air cap atomizing and fan pattern air

Fluid Adjustment Knobs

24D065 Ultra-Precision Knob

Micrometer telescoping knob which is indexed for precision adjustment

24C204 Indexing Knob

Fluid adjustment in ne ow increments

24C203 Lock Ring and Cap

Simple thread adjustment with locking ring

pressure at various supply air pressures. Not to be used

for actual spraying.

MSEC

to Fully Close

Needle Assembly Identification

Part Number Needle Assembly Size # of Grooves Material

24C190 0.5 mm (0.020 in) 1 SST

24C191 0.7 mm (0.028 in) 2 SST

24C192 0.9 mm (0.035 in) 3 SST

24C220 1.0 mm (0.039 in) 0 Carbide

24C193 1.1 mm (0.043 in) 4 SST

24C194 1.3 mm (0.051 in) 5 SST

24C195 1.5 mm (0.059 in) 0 Carbide

Page 8

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9467 8558

Fax: 61 3 9467 8559

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Room 118 1st Floor

No.2 Xin Yuan Building

No.509 Cao Bao Road

Shanghai, 200233

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 432, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2010 Graco Inc. 344813 Rev. A 02/10 All written and visual data contained in this document are based on the latest product information available at the time

of publication. Graco reserves the right to make changes at any time without notice. All othe r br and name s or marks are used for identif ication purposes and

are trademark s of th eir respectiv e ow ners.

Loading...

Loading...