Page 1

SaniForce®

Equipment Catalog

Solutions for Sanitary Applications

unleash the

Page 2

SaniForce® Equipment Catalog

Table of Contents

Contents

SaniForce Pump Selection Chart ......................................2

SaniForce Drum and Bin Unloader Selection Chart

SaniForce 515, 1040,

SaniForce 1590 & 3150 High Sanitation Pumps .............11

SaniForce 1590 & 3150 3A Certified Pumps...................14

SaniForce Meat and Poultry Pumps ................................16

SaniForce Piston Pumps ................................................18

SaniForce Elevators

SaniForce Drum Unloaders.............................................23

SaniForce Bin Evacuation Systems (BES)

Hydra-Clean® Pressure Washers ....................................28

SaniForce Accesssories .................................................31

1590 & 2150 .................................6

.......................................................21

.......................25

...........4

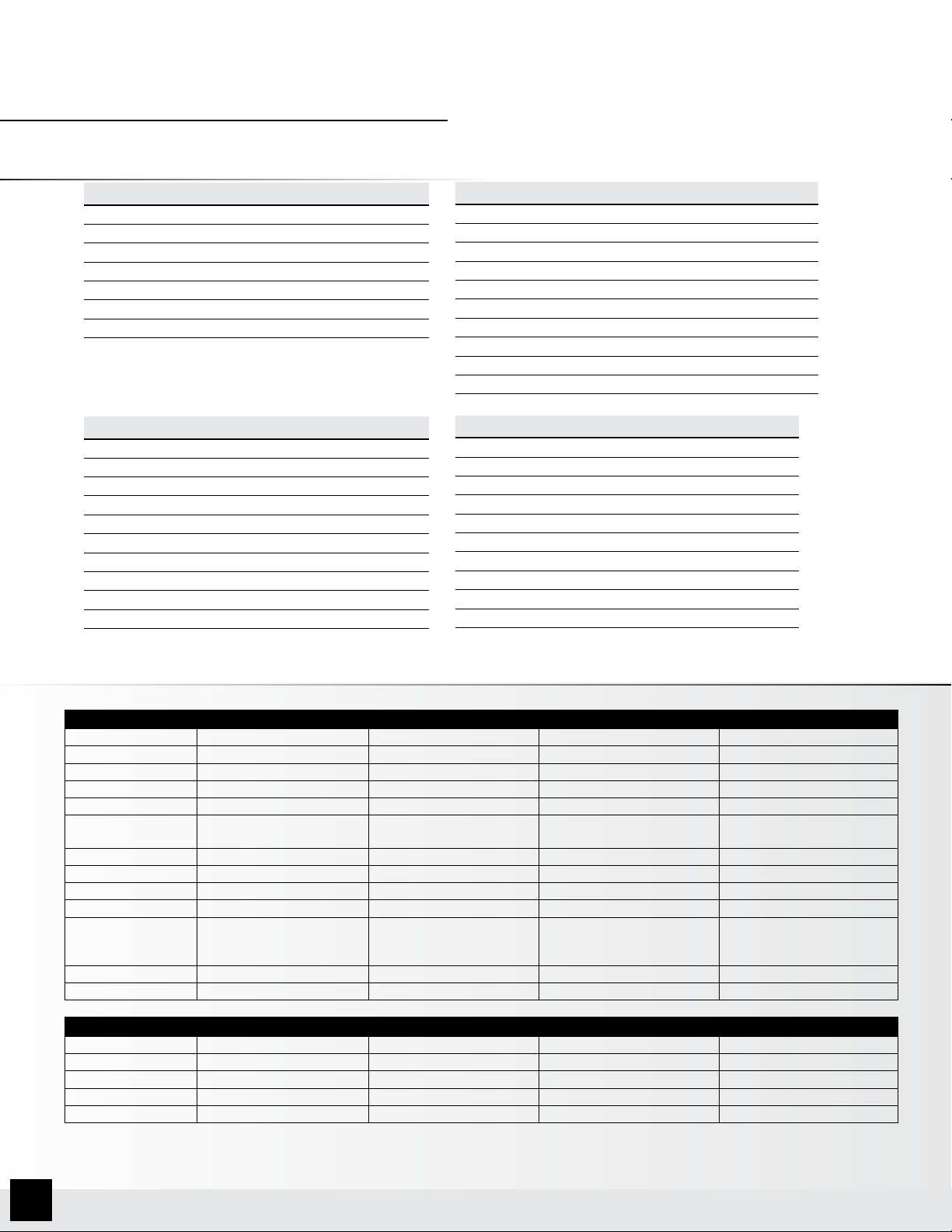

SECTION DESCRIPTION

CONTENTS

1

1

Page 3

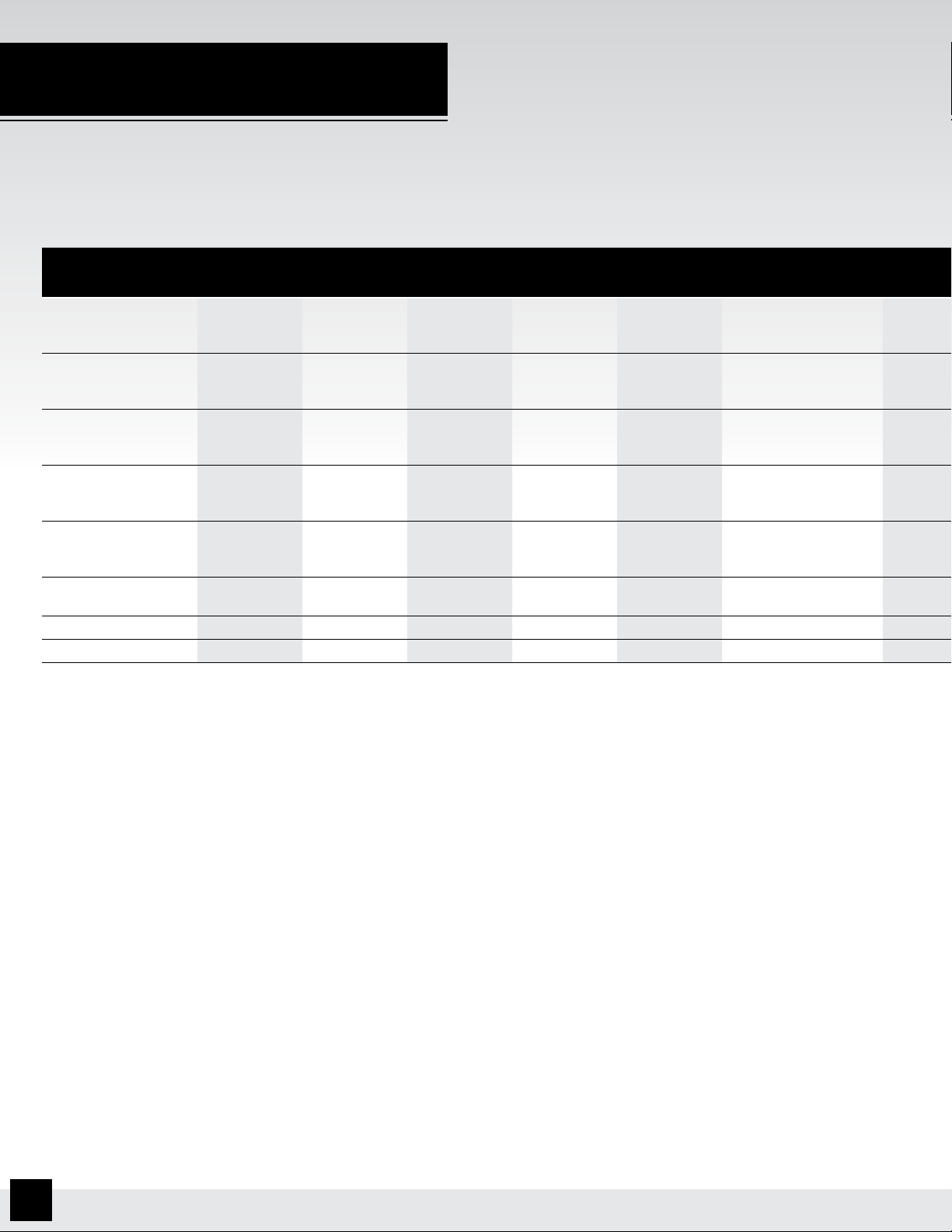

SaniForce® Pumps

Selection Chart

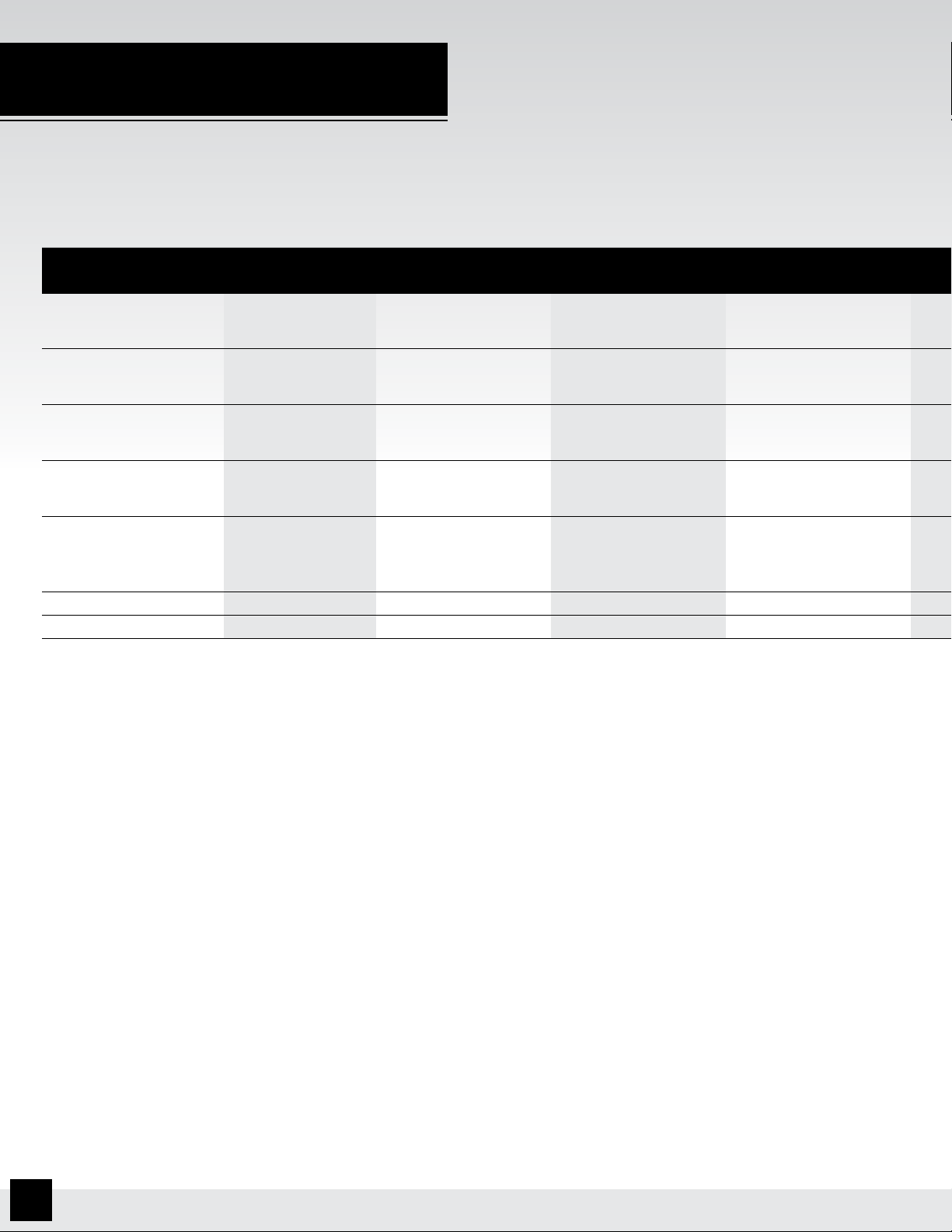

SaniForce

Model*

Max Flow Rate

Max Fluid Pressure

16 gpm

(61 lpm)

100 psi

(7 bar, 0.7 MPa)

Check Style

Suction Lift (Wet)

Max Pumpable Solids

25 ft (7.6 m) 29 ft (8.84 m) 29 ft (8.84 m) 29 ft (8.84 m) 28 ft (8.5 m) Ball = 18 ft (5.5 m)

3/32 in

(2.38 mm)

Viscosity Range

10,000 cps

Flyer

Instruction Manual

*Actual performance may vary by application

320462 320462 320462 320462 338499 338499

3A1973 311879 311879 311879 310622 310622

SaniForce

515

Ball Ball Ball Ball Ball Ball or Flapper Ball Ball Flapper Double ball Double ball or

Up to

1040

40 gpm

(151 lpm)

120 psi

(8 bar, 0.8 MPa)

1/8 in

(3.2 mm)

Up to

10,000 cps

SaniForce

1590

90 gpm

(340 lpm)

120 psi

(8 bar, 0.8 MPa)

3/16 in

(4.8 mm)

Up to

15,000 cps

SaniForce

2150

150 gpm

(568 lpm)

120 psi

(8 bar, 0.8 MPa)

1/4 in

(6.3 mm)

Up to

20,000 cps

SaniForce

1590 HS

90 gpm

(340 lpm)

120 psi

(8 bar, 0.8 MPa)

5/8 in

(15.9 mm)

Up to

15,000 cps

SaniForce

3150 HS

150 gpm

(568 lpm)

120 psi

(8 bar, 0.8 MPa)

Flapper = 10 ft (3 m)

Ball = 1 in (25.4 mm)

Flapper = 2.5 in (63.5 mm)

Up to

20,000 cps

2

SANIFORCE PUMP SELECTION CHART

Page 4

SaniForce

1590 3A

SaniForce

3150 3A

SaniForce

Meat/Poultry

SaniForce 2:1

Piston Pump

SaniForce 6:1

Piston Pump

SaniForce 5:1

Piston Pump

SaniForce 12:1

Piston Pump

90 gpm

(340 lpm)

120 psi

(8 bar, 0.8 MPa)

28 ft (8.5 m) 18 ft (5.5 m) 10 ft (3 m) N/A N/A N/A N/A

5/8 in (15.9 mm) 1 in (25.4 mm) 2.5 in (6.3 cm) 1/8 in (3.2 mm) 1/8 in (3.2 mm) 1/4 in (6.4 mm) 1/4 in (6.4 mm)

Up to

15,000 cps

338499 338499

310622 310622

150 gpm

(568 lpm)

120 psi

(8 bar, 0.8 MPa)

Up to

20,000 cps

150 gpm

(568 lpm)

120 psi

(8 bar, 0.8 MPa)

Up to

20,000 cps

338067

310622

1.5 gpm

(5.7 lpm)

250 psi

(17 bar, 1.7 MPa)

Up to

50,000 cps

338591 338591 338591 338591

3A2977 3A0733 3A0734 3A0735

4 gpm

(15 lpm)

600 psi

(41 bar, 4.1 MPa)

Priming piston

Up to

100,000 cps

14 gpm

(53 lpm)

400 psi

(28 bar, 2.8 MPa)

Double ball or

Priming piston

Up to

100,000 cps

**When mounted on drum unloader or bin evacuation system

(83 bar, 8.3 MPa)

1,000,000 cps**

8.5 gpm

(32 lpm)

1200 psi

Priming piston

Up to

SANIFORCE PUMP SELECTION CHART

3

Page 5

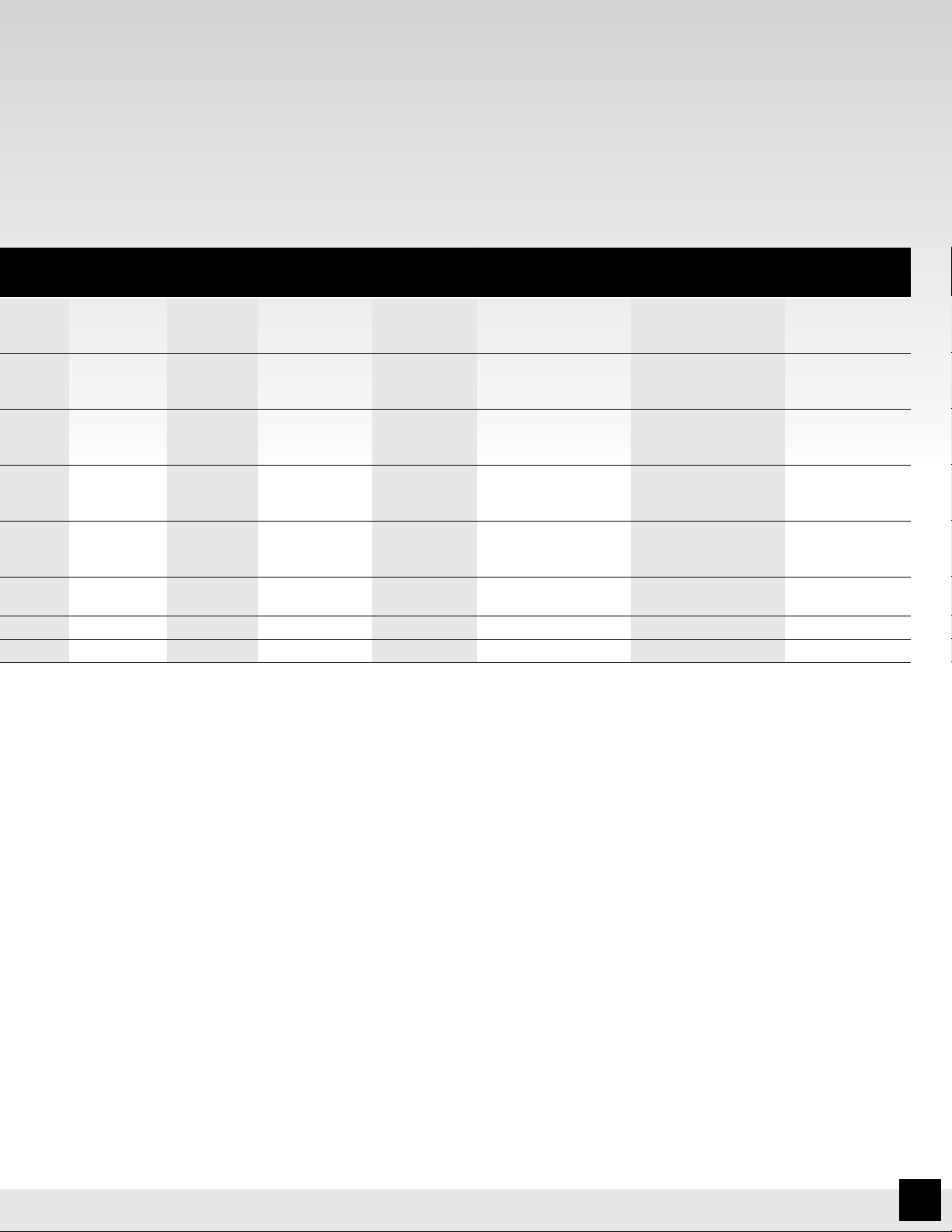

SaniForce Drum and Bin Unloaders

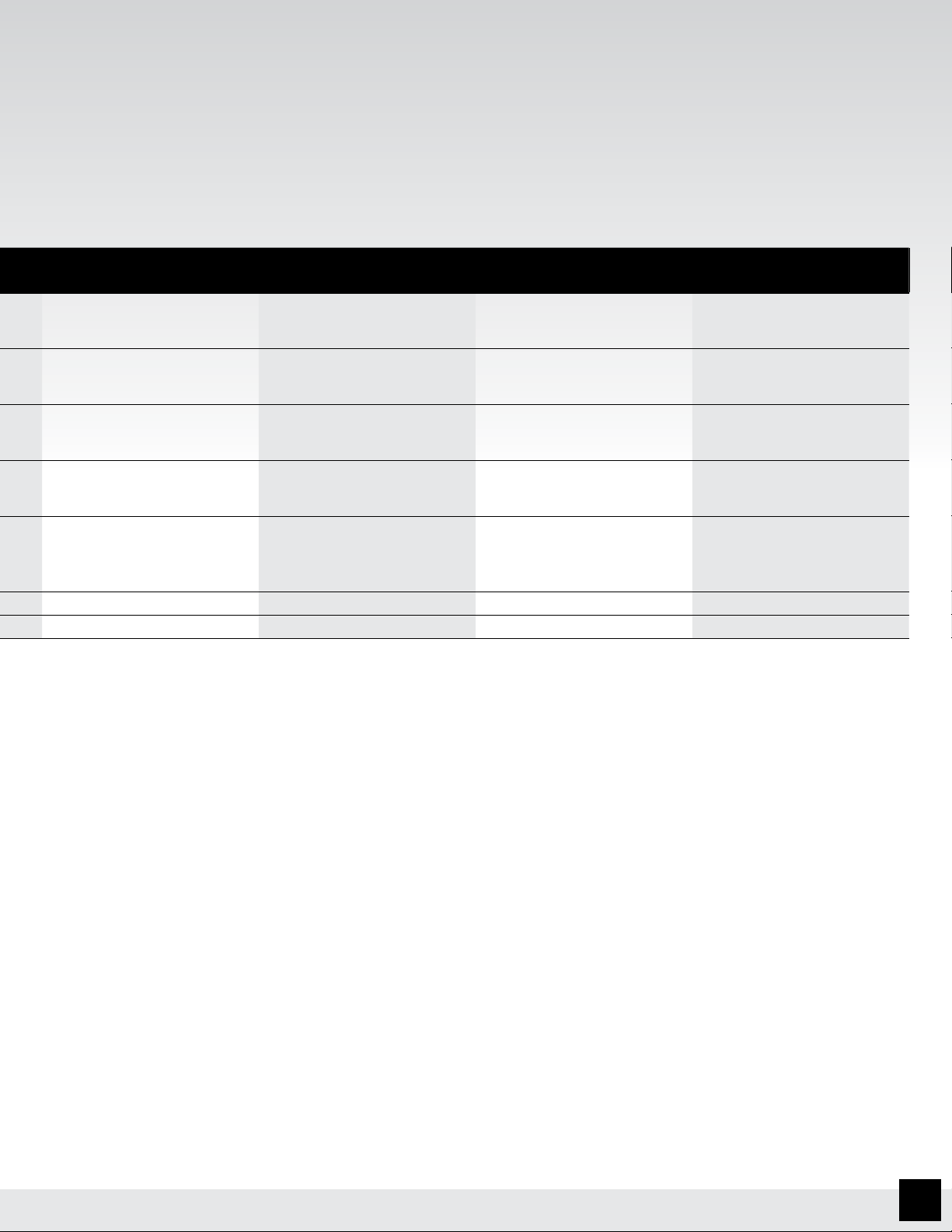

Selection Chart

Model*

Max Flow Rate

Max Fluid Pressure

Pump Style

Controls

Viscosity Range

Double Ball:

Priming Piston:

Flyer

Instruction Manual

*Actual performance may vary by application

Piston Pump

Elevators

Up to

14 gpm (53 lpm)

400 psi

(28 bar, 2.8 MPa)

Double ball Double ball or

Manual Manual Manual Manual Manual Manual Manual and Electronic Manual and Electronic

Up to 75,000 cps Up to 75,000 cps

345058 338590 338590 338590

333406 3A0591 3A0591 3A0591

SaniForce 6:1

Drum Unloader

Up to

4.0 gpm (15 lpm)

600 psi

(41 bar, 4.1 MPa)

priming piston

Up to 125,000 cps

SaniForce 5:1

Drum Unloader

Up to

14 gpm (53 lpm)

400 psi

(28 bar, 2.8 MPa)

Double ball or

priming piston

Up to 200,000 cps

+ 1,000,000 cps + 1,000,000 cps

SaniForce 12:1

Drum Unloader

Up to

8.5 gpm (32 lpm)

1200 psi

(83 bar, 8.3 MPa)

Priming piston Ball or flapper Ball Double ball or

4

SANIFORCE DRUM AND BIN UNLOADER SELECTION CHART

Page 6

SaniForce 3150 HS

Drum Unloader

SaniForce 2150

Drum Unloader

SaniForce

BES

SaniForce

3150 BES

Up to

150 gpm (568 lpm)

120 psi

(8 bar, 0.8 MPa)

Up to 100,000 cps Up to 100,000 cps + 1,000,000 cps Up to 100,000 cps

338590 338590 338589 338589

3A0591 3A0591 311163 311163

Up to

150 gpm (568 lpm)

120 psi

(8 bar, 0.8 MPa)

Up to

56 gpm (212 lpm)

1200 psi

(83 bar, 8.3 MPa)

priming piston

Up to

300 gpm (1,135 lpm)

120 psi

(8 bar, 0.8 MPa)

Ball or flapper

SANIFORCE DRUM AND BIN UNLOADER SELECTION CHART

5

Page 7

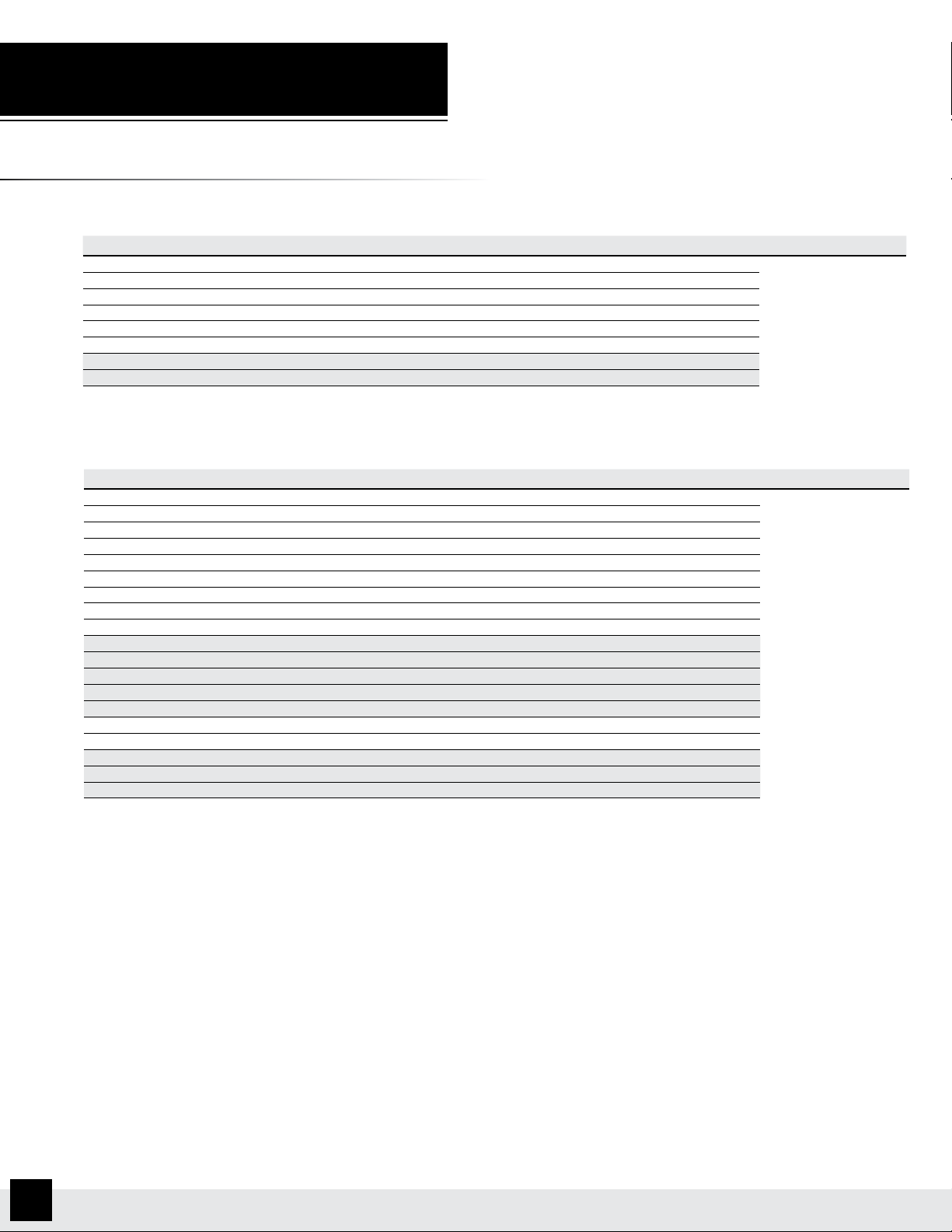

SaniForce 515, 1040, 1590 & 2150

Air-Operated Diaphragm Pumps

Ordering Information

SaniForce 515 - 1.0 in (25.4 mm) Sanitary Connection

Part Number Manifold ID Center Section Seats O-rings Balls Diaphragms Connection

FD5111 0.96 in (24.3 mm) Poly SST PTFE PTFE PTFE Sanitary Clamp

FD5113 0.96 in (24.3 mm) Poly SST PTFE PTFE Overmolded PTFE Sanitary Clamp

FD5122 0.96 in (24.3 mm) Poly SST PTFE Santoprene Santoprene Sanitary Clamp

FD5611 0.96 in (24.3 mm) Poly SST EPDM PTFE PTFE Sanitary Clamp

FD5613 0.96 in (24.3 mm) Poly SST EPDM PTFE Overmolded PTFE Sanitary Clamp

FD5622 0.96 in (24.3 mm) Poly SST EPDM Santoprene Santoprene Sanitary Clamp

FD6111 0.96 in (24.3 mm) Poly SST PTFE PTFE PTFE DIN

FD6113 0.96 in (24.3 mm) Poly SST PTFE PTFE Overmolded DIN

SaniForce 1040 - 1.5 in (38.1 mm) Sanitary Connection

Part Number Manifold ID Center Section Seats O-rings Balls Diaphragms Connections

FD1111 1.0 in (25.4 mm) SST SST PTFE PTFE PTFE Sanitary Clamp

FD1122 1.0 in (25.4 mm) SST SST PTFE Santoprene Santoprene Sanitary Clamp

FD1211 1.0 in (25.4 mm) SST SST EPDM PTFE PTFE Sanitary Clamp

FD1222 1.0 in (25.4 mm) SST SST EPDM Santoprene Santoprene Sanitary Clamp

FD1113 1.0 in (25.4 mm) SST SST PTFE PTFE Overmolded PTFE Sanitary Clamp

FD1213 1.0 in (25.4 mm) SST SST EPDM PTFE Overmolded PTFE Sanitary Clamp

FD1132 1.0 in (25.4 mm) SST SST PTFE Weighted CR Santoprene Sanitary Clamp

FD1133 1.0 in (25.4 mm) SST SST PTFE Weighted CR Overmolded PTFE Sanitary Clamp

FD1232 1.0 in (25.4 mm) SST SST EPDM Weighted CR Santoprene Sanitary Clamp

FA1111* 1.0 in (25.4 mm) AL SST PTFE PTFE PTFE Sanitary Clamp

FA1122* 1.0 in (25.4 mm) AL SST PTFE Santoprene Santoprene Sanitary Clamp

FA1132* 1.0 in (25.4 mm) AL SST PTFE Weighted CR Santoprene Sanitary Clamp

FA1133* 1.0 in (25.4 mm) AL SST PTFE Weighted CR Overmolded PTFE Sanitary Clamp

FA1222* 1.0 in (25.4 mm) AL SST EPDM Santoprene Santoprene Sanitary Clamp

FD7111 1.0 in (25.4 mm) SST SST PTFE PTFE PTFE DIN

FA7111* 1.0 in (25.4 mm) SST SST PTFE PTFE PTFE DIN

FA1231** 1.0 in (25.4 mm) AL SST EPDM Weighted CR PTFE Sanitary Clamp

FA1232** 1.0 in (25.4 mm) AL SST EPDM Weighted CR Santoprene Sanitary Clamp

FA1233** 1.0 in (25.4 mm) AL SST EPDM Weighted CR Overmolded PTFE Sanitary Clamp

*SaniForce Pump with Aluminum Center Section (aluminum air motor and 316 SST fluid section)

**Tested with water, not vegetable oil

6

AIR-OPERATED DIAPHRAGM PUMPS

Page 8

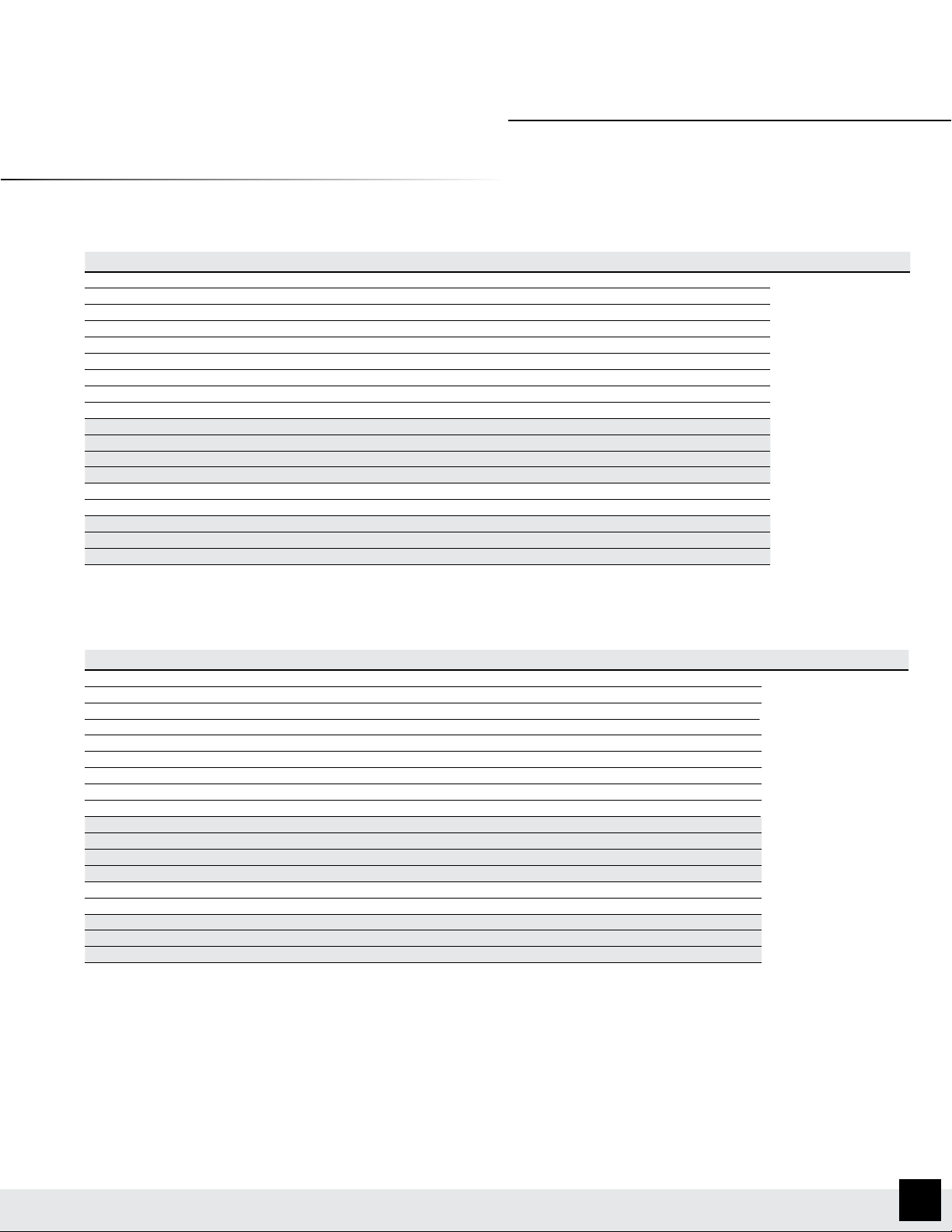

SaniForce 515, 1040, 1590 & 2150

Ordering Information

SaniForce 1590 - 2.0 in (50.8 mm) Sanitary Connection

Part Number Manifold ID Center Section Seats O-rings Balls Diaphragms Connections

FD2111 1.5 in (38.1 mm) SST SST PTFE PTFE PTFE Sanitary Clamp

FD2122 1.5 in (38.1 mm) SST SST PTFE Santoprene Santoprene Sanitary Clamp

FD2211 1.5 in (38.1 mm) SST SST EPDM PTFE PTFE Sanitary Clamp

FD2222 1.5 in (38.1 mm) SST SST EPDM Santoprene Santoprene Sanitary Clamp

FD2113 1.5 in (38.1 mm) SST SST PTFE PTFE Overmolded PTFE Sanitary Clamp

FD2213 1.5 in (38.1 mm) SST SST EPDM PTFE Overmolded PTFE Sanitary Clamp

FD2132 1.5 in (38.1 mm) SST SST PTFE Weighted CR Santoprene Sanitary Clamp

FD2133 1.5 in (38.1 mm) SST SST PTFE Weighted CR Overmolded PTFE Sanitary Clamp

FD2232 1.5 in (38.1 mm) SST SST EPDM Weighted CR Santoprene Sanitary Clamp

FA2111* 1.5 in (38.1 mm) AL SST PTFE PTFE PTFE Sanitary Clamp

FA2122* 1.5 in (38.1 mm) AL SST PTFE Santoprene Santoprene Sanitary Clamp

FA2132* 1.5 in (38.1 mm) AL SST PTFE Weighted CR Santoprene Sanitary Clamp

FA2222* 1.5 in (38.1 mm) AL SST EPDM Santoprene Santoprene Sanitary Clamp

FD8111 1.5 in (38.1 mm) SST SST PTFE PTFE PTFE DIN

FA8111* 1.5 in (38.1 mm) SST SST PTFE PTFE PTFE DIN

FA2231** 1.5 in (38.1 mm) AL SST EPDM Weighted CR PTFE Sanitary Clamp

FA2232** 1.5 in (38.1 mm) AL SST EPDM Weighted CR Santoprene Sanitary Clamp

FA2233** 1.5 in (38.1 mm) AL SST EPDM Weighted CR Overmolded PTFE Sanitary Clamp

SaniForce 2150 - 2.5 in (63.5 mm) Sanitary Connection

Part Number Manifold ID Center Section Seats O-rings Balls Diaphragms Connection

FD3111 2.0 in (50.8 mm) SST SST PTFE PTFE PTFE Sanitary Clamp

FD3122 2.0 in (50.8 mm) SST SST PTFE Santoprene Santoprene Sanitary Clamp

FD3211 2.0 in (50.8 mm) SST SST EPDM PTFE PTFE Sanitary Clamp

FD3222 2.0 in (50.8 mm) SST SST EPDM Santoprene Santoprene Sanitary Clamp

FD3113 2.0 in (50.8 mm) SST SST PTFE PTFE Overmolded PTFE Sanitary Clamp

FD3213 2.0 in (50.8 mm) SST SST EPDM PTFE Overmolded PTFE Sanitary Clamp

FD3132 2.0 in (50.8 mm) SST SST PTFE Weighted CR Santoprene Sanitary Clamp

FD3133 2.0 in (50.8 mm) SST SST PTFE Weighted CR Overmolded PTFE Sanitary Clamp

FD3232 2.0 in (50.8 mm) SST SST EPDM Weighted CR Santoprene Sanitary Clamp

FA3111* 2.0 in (50.8 mm) AL SST PTFE PTFE PTFE Sanitary Clamp

FA3122* 2.0 in (50.8 mm) AL SST PTFE Santoprene Santoprene Sanitary Clamp

FA3132* 2.0 in (50.8 mm) AL SST PTFE Weighted CR Santoprene Sanitary Clamp

FA3222* 2.0 in (50.8 mm) AL SST EPDM Santoprene Santoprene Sanitary Clamp

FD9111 2.0 in (50.8 mm) SST SST PTFE PTFE PTFE DIN

FA9111* 2.0 in (50.8 mm) AL SST PTFE PTFE PTFE DIN

FA3231** 2.0 in (50.8 mm) AL SST EPDM Weighted CR PTFE Sanitary Clamp

FA3232** 2.0 in (50.8 mm) AL SST EPDM Weighted CR Santoprene Sanitary Clamp

FA3233** 2.0 in (50.8 mm) AL SST EPDM Weighted CR Overmolded PTFE Sanitary Clamp

*SaniForce Pump with Aluminum Center Section (aluminum air motor and 316 SST fluid section)

**Tested with water, not vegetable oil

AIR-OPERATED DIAPHRAGM PUMPS

7

Page 9

SaniForce 515, 1040, 1590 & 2150

Fluid Repair Kits

515 Kits O-rings Balls Diaphragms

FK5111 PTFE PTFE PTFE

FK5113 PTFE PTFE Overmolded PTFE

FK5122 PTFE Santoprene Santoprene

FK5611 EPDM PTFE PTFE

FK5613 EPDM PTFE Overmolded PTFE

FK5622 EPDM Santoprene Santoprene

110954 PTFE – –

1040 Kits O-rings Balls Diaphragms

FK1111 PTFE PTFE PTFE

FK1122 PTFE Santoprene Santoprene

FK1133 PTFE Weighted CR Overmolded PTFE

FK1211 EPDM PTFE PTFE

FK1222 EPDM Santoprene Santoprene

FK1113 PTFE PTFE Overmolded PTFE

FK1213 EPDM PTFE Overmolded PTFE

FK1132 PTFE Weighted CR Santoprene

FK1232 EPDM Weighted CR Santoprene

253626 – – Overmolded PTFE

1590 Kits O-rings Balls Diaphragms

FK2111 PTFE PTFE PTFE

FK2122 PTFE Santoprene Santoprene

FK2133 PTFE Weighted CR Overmolded PTFE

FK2211 EPDM PTFE PTFE

FK2222 EPDM Santoprene Santoprene

FK2113 PTFE PTFE Overmolded PTFE

FK2213 EPDM PTFE Overmolded PTFE

FK2132 PTFE Weighted CR Santoprene

FK2232 EPDM Weighted CR Santoprene

253627 – – Overmolded PTFE

2150 Kits O-rings Balls Diaphragms

FK3111 PTFE PTFE PTFE

FK3122 PTFE Santoprene Santoprene

FK3133 PTFE Weighted CR Overmolded PTFE

FK3211 EPDM PTFE PTFE

FK3222 EPDM Santoprene Santoprene

FK3113 PTFE PTFE Overmolded PTFE

FK3213 EPDM PTFE Overmolded PTFE

FK3132 PTFE Weighted CR Santoprene

FK3232 EPDM Weighted CR Santoprene

253628 – – Overmolded PTFE

Technical Specifications

515 FDA 1040 FDA 1590 FDA 2150 FDA

Max. fluid working pressure 100 psi (7 bar, 0.7 MPa) 120 psi (8 bar, 0.8 MPa) 120 psi (8 bar, 0.8 MPa) 120 psi (8 bar, 0.8 MPa)

Air pressure operating range 20-100 psi (1.4-7 bar, 0.14-0.7 MPa) 20-120 psi (1.4-8 bar, 0.14-0.8 MPa) 20–120 psi (1.4–8 bar, 0.14 –0.8 MPa) 20–120 psi (1.4–8 bar, 0.14 –0.8 MPa)

Max. air consumption 28 scfm 50 scfm 130 scfm 175 scfm

Air consumption N/A 18 scfm at 70 psi/20 gpm 42 scfm at 70 psi/50 gpm 70 scfm at 70 psi/80 gpm

Max. free-flow delivery 16 gpm (61 lpm) 40 gpm (151 lpm) 90 gpm (340 lpm) 150 gpm (568 lpm)

Gallons (liters) per cycle

Max. suction lift 25 ft. (7.6 m) wet, 15 ft (4.6 m) dry 29 ft (8.83 m) wet, 16 ft (4.87 m) dry 29 ft (8.83 m) wet, 14 ft (4.27 m) dry 29 ft (8.83 m) wet, 16 ft (4.87 m) dry

Max. size pumpable solids 3/32 in (2.38 mm) 1/8 in (3.2 mm) 3/16 in (4.8 mm) 1/4 in (6.3 mm)

Air inlet size 1/4 npt(f) 0.5 in npt(f) 0.5 in npt(f) 0.5 in npt(f)

Fluid inlet/outlet size 1.0 in (25.4 mm) sanitary flange 1.5 in (38.1 mm) sanitary flange 2 in (50.8 mm) sanitary flange 2.5 in (63.5 mm) sanitary flange

Weight

FDXXXX models

FAXXXX models

Flyer

Instruction manual

0.04 (0.15) - standard diaphragms

0.03 (0.11) - overmolded diaphragms

22.6 lb (10.25 kg)

N/A

320462 320462 320462 320462

3A1973 311879 311879 311879

Maximum fluid operating temperature is based on the following maximum diaphragm, ball, and seat temperature ratings

Stainless steel 250°F (121.1°C) 250°F (121.1°C) 250°F (121.1°C) 250°F (121.1°C)

PTFE 220°F (104.4°C) 220°F (104.4°C) 220°F (104.4°C) 220°F (104.4°C)

Santoprene 180°F (82.2°C) 180°F (82.2°C) 180°F (82.2°C) 180°F (82.2°C)

EPDM 275°F (135°C) 275°F (135°C) 275°F (135°C) 275°F (135°C)

Polychloroprene N/A 200°F (93.3°C) 200°F (93.3°C) 200°F (93.3°C)

* Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type

0.16 (0.57)* 0.5 (1.9)* 0.97 (3.67)*

55 lb (24.9 kg)

49 lb (22.2 kg)

89 lb (40 kg)

83 lb (37.6 kg)

147 lb (66.7 kg)

141 lb (63.9 kg)

8

AIR-OPERATED DIAPHRAGM PUMPS

Page 10

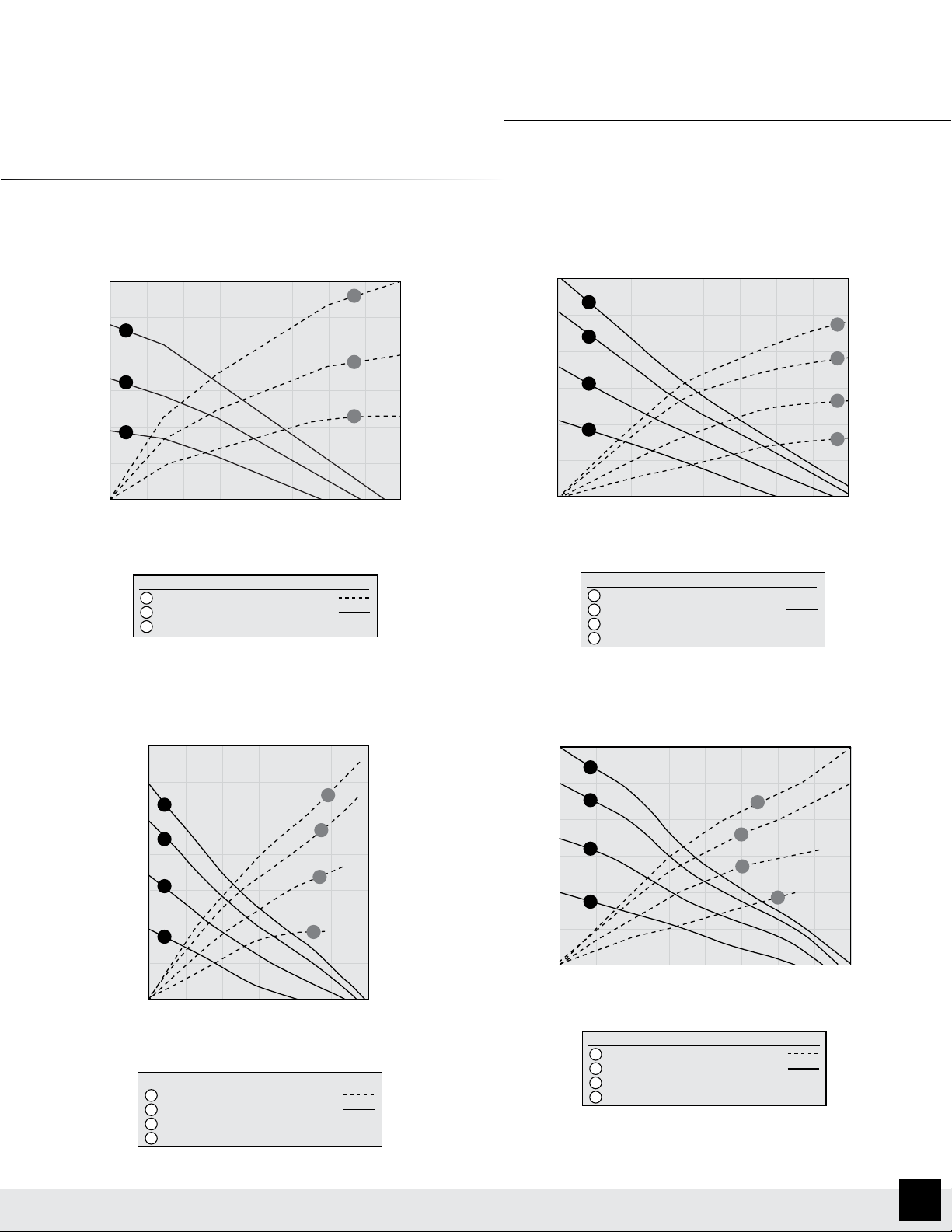

FLUID OUTLET PRESSURE

1040 Performance

AIR CONSUMPTION

scfm (m

/min)

FLUID OUTLET PRESSURE

1590 Performance

FLUID OUTLET PRESSURE

515 Performance

100

(0.7, 7)

psi (MPa, bar)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

Performance Charts

CYCLES PER MINUTE

Standard Diaphragms; Overmolded Diaphragms

46;64 91;128 137;192 182;256 228;319 273;383 319;447 364;511

A

80

B

60

40

C

20

SaniForce 515, 1040, 1590 & 2150

0 33 66 99 132 165 197 230 263

30

A

B

C

(0.84)

25

(0.70)

20

(0.56)

15

(0.42)

10

(0.28)

5

(0.14)

/min)

3

AIR CONSUMPTION scfm (m

120

(0.84, 8.4)

100

(0.7, 7)

psi (MPa, bar)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

A

B

80

C

60

40

D

20

CYCLES PER MINUTE

60

(1.7)

50

A

(1.42)

40

B

(1.13)

30

(0.85)

C

20

(0.57)

D

10

(0.28)

/min)

3

AIR CONSUMPTION scfm (m

0 2 4 6 8 10 12 14 16

140

(0.96, 9.6)

120

(0.84, 8.4)

100

(0.7, 7)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

FLUID OUTLET PRESSURE psi (MPa, bar)

(0.14, 1.4)

(7.6) (15.2) (22.7) (30.3) (37.9) (45.4) (53.0) (60.6)

FLUID FLOW gpm (lpm)

AIR PRESSURE LEGEND

= at 100 psi (7 bar, 0.7 MPa)

A

= at 70 psi (4.8 bar, 0.5 MPa)

B

= at 40 psi (2.8 bar, 0.3 MPa)

C

Air Consumption

Fluid Flow

CYCLES PER MINUTE

0 40 80 120 160 200 240

140

(3.96)

120

A

B

A

B

80

C

60

40

D

C

D

20

0 20 40 60 80 100 120

(75) (151) (227) (302) (378) (454)

(3.4)

100

(2.83)

80

(2.27)

60

(1.7)

40

(1.13)

20

(0.57)

FLUID FLOW gpm (lpm)

AIR PRESSURE LEGEND

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

Air Consumption

Fluid Flow

/min)

3

AIR CONSUMPTION scfm (m

120

(0.84, 8.4)

100

(0.7, 7)

psi (MPa, bar)

80

(0.55, 5.5)

60

(0.41, 4.1)

40

(0.28, 2.8)

20

(0.14, 1.4)

0 5 10 15 20 25 30 35 40

(19) (38) (57) (76) (95) (114) (133) (152)

FLUID FLOW gpm (lpm)

AIR PRESSURE LEGEND

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

Air Consumption

Fluid Flow

2150 Performance

0 19 39 58 78 97 117 136 155

A

B

C

D

0 20 40 60 80 100 120 140 160

(75) (151) (227) (302) (378) (454) (530) (605)

AIR PRESSURE LEGEND

A

B

C

D

CYCLES PER MINUTE

FLUID FLOW gpm (lpm)

= at 120 psi (8.4 bar, 0.84 MPa)

= at 100 psi (7 bar, 0.7 MPa)

= at 70 psi (4.8 bar, 0.5 MPa)

= at 40 psi (2.8 bar, 0.3 MPa)

A

B

C

D

Air Consumption

Fluid Flow

180

(5.1)

150

(4.25)

120

(3.4)

90

(2.54)

60

(1.7)

30

(0.85)

3

AIR-OPERATED DIAPHRAGM PUMPS

9

Page 11

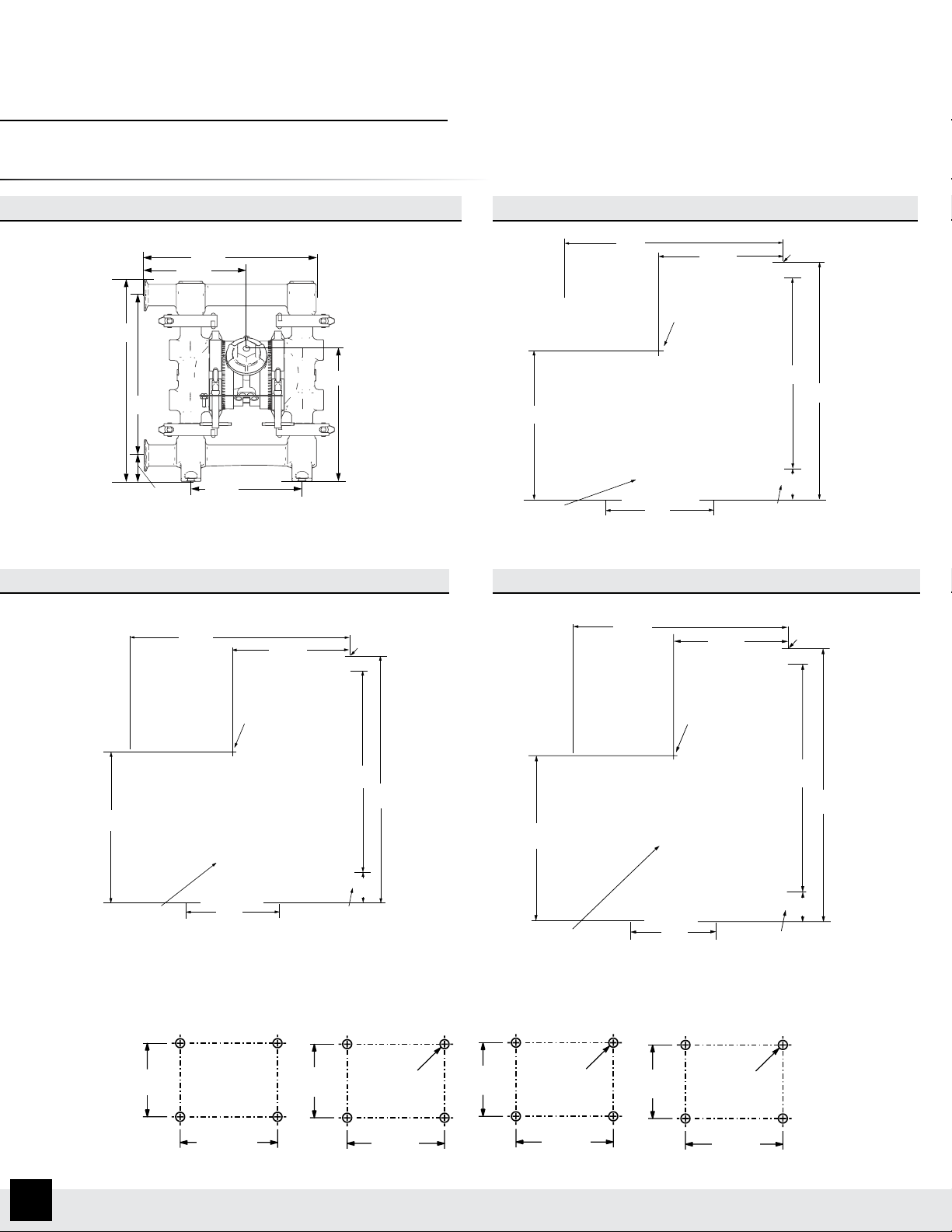

SaniForce 515, 1040, 1590 & 2150

16.3 in

1-1/2 in Outlet

10.9 in.

(323 mm)

)

(41 mm)

SaniForce 515

SaniForce 1040

SaniForce 1590

SaniForce 2150

Mounting Hole Pattern

Dimensions

SaniForce 515 SaniForce 1040

(277 mm)

6.4 in.

(163 mm)

12.7 in.

10.0 in.

(254 mm)

1.6 in.

SaniForce 1590

19.5 in

(495 mm)

7.0 in.

(178 mm)

9.8 in

(249 mm)

(213 mm

ti17653a

8.4 in.

2 in Outlet

Sanitary Flange

10.2 in

(259 mm)

Air Exhaust

(muffler included)

3/4 npt(f)

SaniForce 2150

(414 mm)

Air Inlet

1/2 npt(f)

7.4 in

(188 mm)

Overall Width = 8.2 in (208 mm)

22.0 in

(559 mm)

8.5 in

(216 mm)

10.9 in

(276 mm)

13.2 in

(335 mm)

(51 mm)

1-1/2 in Inlet

Sanitary Flange

Sanitary Flange

16.2 in

(411 mm)

2.0 in

2-1/2 in Outlet

Sanitary Flange

12.6 in

(320 mm)

(muffler included)

Air Exhaust

3/4 npt(f)

4.3 in.

(109 mm)

Air Inlet

1/2 npt(f)

7.8 in

(198 mm)

Overall Width = 10.1 in (257 mm)

Mounting Hole Pattern

7.0 in.

(178 mm)

5.0 in

(127 mm)

16.9 in

(429 mm)

20.4 in

(518 mm)

2.4 in

(61 mm)

2 in Inlet

Sanitary Flange

Mounting Hole Pattern

Four 0.42 in

(10.7 mm)

diameter holes

7.4 in

(188 mm)

6.0 in

(152 mm)

15.8 in

(401 mm)

Air Exhaust

(muffler included)

3/4 npt(f)

Mounting Hole Pattern

Four 0.46 in

(11.7 mm)

diameter holes

7.8 in

(198 mm)

Air Inlet

1/2 npt(f)

8.2 in

(208 mm)

Overall Width = 12.3 in (312 mm)

6.3 in

(160 mm)

Four 0.46 in

(11.7 mm)

diameter holes

(209 mm)

2-1/2 in Inlet

Sanitary Flange

8.2 in

21.9 in

(556 mm)

(660 mm)

2.5 in

(63 mm)

26.0 in

10

10

AIR-OPERATED DIAPHRAGM PUMPS

AIR OPERATED DIAPHRAGM PUMPS

Page 12

Ordering Information

SaniForce 1590 HS Ball Pumps

SaniForce 1590 & 3150 HS

High Sanitation Diaphragm Pumps

Part

Number Type Manifold ID

SBBAAA Ball 1.9 in (48.3 mm) 2 in x 2 in Overmolded EPDM PTFE

SBBA11 Ball 1.9 in (48.3 mm) 2 in x 2 in PTFE PTFE

SABA13 Ball 1.9 in (48.3 mm) 2 in x 2 in Overmolded PTFE PTFE Includes leak detector

SBBA13 Ball 1.9 in (48.3 mm) 2 in x 2 in Overmolded PTFE PTFE

SBBA22 Ball 1.9 in (48.3 mm) 2 in x 2 in Santoprene Santoprene

SADAAA Ball 1.9 in (48.3 mm) DIN Connection Overmolded EPDM PTFE

SBDAAA Ball 1.9 in (48.3 mm) DIN Connection Overmolded EPDM PTFE

Sanitary

Connection Diaphragm Ball Material

SaniForce 1590 Kits and Accessories

Part Number Type

255058 Overmolded EPDM diaphragm kit

255059 Santoprene diaphragm kit

255060 PTFE diaphragm kit

253627 PTFE overmolded diaphragm kit

Part Number Type

112421 Santoprene ball (quantity one)

112419 PTFE ball (quantity one)

255122 Air valve repair kit 3A

15D990 Leak detector

SaniForce 3150 HS Ball Pumps

Part

Number Type Manifold ID

SA13A1 Ball 2.9 in (73.7 mm) 1.5 in x 1.5 in Overmolded PTFE/EPDM PTFE

SA23A1 Ball 2.9 in (73.7 mm) 2 in x 2 in Overmolded PTFE/EPDM PTFE

SA33A1 Ball 2.9 in (73.7 mm) 3 in x 3 in Overmolded PTFE/EPDM PTFE

SA43A1 Ball 2.9 in (73.7 mm) 4 in x 4 in Overmolded PTFE/EPDM PTFE

SA53A1 Ball 2.9 in (73.7 mm) 3 in x 2 in Overmolded PTFE/EPDM PTFE

SA3361 Ball 2.9 in (73.7 mm) 3 in x 3 in Overmolded PTFE/EPDM Santoprene

SB2AA1 Ball 2.9 in (73.7 mm) 2 in x 2 in Overmolded EPDM PTFE

SB3AA1 Ball 2.9 in (73.7 mm) 3 in x 3 in Overmolded EPDM PTFE

SB2661 Ball 2.9 in (73.7 mm) 2 in x 2 in Santoprene Santoprene

SB3661 Ball 2.9 in (73.7 mm) 3 in x 3 in Santoprene Santoprene

SB2771 Ball 2.9 in (73.7 mm) 2 in x 2 in Buna-N Buna-N

SB3771 Ball 2.9 in (73.7 mm) 3 in x 3 in Buna-N Buna-N

SB2881 Ball 2.9 in (73.7 mm) 2 in x 2 in Fluoroelastomer Fluoroelastomer

SB3881 Ball 2.9 in (73.7 mm) 3 in x 3 in Fluoroelastomer Fluoroelastomer

SA6AAA Ball 2.9 in (73.7 mm) DIN Connection Overmolded EPDM PTFE

SA73A1 Ball 2.9 in (73.7 mm) DIN Connection Overmolded PTFE/EPDM PTFE

SA7AAA Ball 2.9 in (73.7 mm) DIN Connection Overmolded EPDM PTFE

Sanitary

Connection Diaphragm Ball Material

SaniForce 3150 HS Flapper Pumps

Part

Number Type Manifold ID

SF3AF1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Overmolded EPDM

SF4AF1 Flapper 2.9 in (73.7 mm) 4 in x 4 in Overmolded EPDM

SF36F1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Santoprene

SF46F1 Flapper 2.9 in (73.7 mm) 4 in x 4 in Santoprene

SF37F1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Buna-N

SF47F1 Flapper 2.9 in (73.7 mm) 4 in x 4 in Buna-N

SF38F1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Fluoroelastomer

SF48F1 Flapper 2.9 in (73.7 mm) 4 in x 4 in Fluoroelastomer

SF7AF1 Flapper 2.9 in (73.7 mm) DIN Connection Overmolded EPDM

SF8AF1 Flapper 2.9 in (73.7 mm) DIN Connection Overmolded EPDM

Sanitary

Connection Diaphragm Material

Flapper Check Valve Ball Check Valve

AIR-OPERATED DIAPHRAGM PUMPS

11

Page 13

SaniForce 1590 & 3150 HS

Ordering Information

SaniForce 3150 HS Accessories

Part Number Type

16E975 Conversion kit: Ball to flapper, includes four flapper assemblies

15H461 3A Conversion kit: Flapper to ball, includes four housing retainers (balls need to be ordered separately)

15E285 Conversion kit: Flapper to ball, includes four housing retainers (balls need to be ordered separately)

112359 PTFE ball (order quantity four)

112361 Santoprene ball (order quantity four)

253225 Santoprene diaphragm kit

15B492 Buna-N ball (order quantity four)

253223 Buna-N diaphragm kit

15B491 F

253222 Fluoroelastomer diaphragm kit

253224 Overmolded EPDM diaphragm kit

253628 Overmolded PTFE diaphragm kit

15D990 Leak detector kit

luoroelastomer ball (order quantity four)

Technical Specifications

1590

Maximum fluid working pressure 120 psi (8 bar, 0.8 MPa)

Maximum free-flow delivery 90 gpm (340 lpm)

Maximum suction lift 28 ft (8.5 m) wet, 15 ft (4.57 m) dry

Maximum size pumpable solids 5/8 in (15.9 mm)

Air pressure operating range 20-120 psi (14-8 bar, 014-08 MPa)

Maximum air consumption 125 scfm

Air consumption at 70 psi

air inlet pressure/60 gpm

Maximum pump speed 200 cpm

*Gallons (liters) per cycle 0.5 (1.96)

**Maximum noise level at 100 psi, full flow 90 dBa

**Sound power level 103 dBa

**Noise level at 70 psi and 50 cpm 85 dBa

Air inlet size 0.5 in npt(f)

Weight 97 lb (44 kg)

Flyer

Instruction manual

Maximum fluid operating temperature is based on the following

maximum diaphragm, ball, and seat temperature ratings

PTFE (Overmolded diaphragm) 180°F (82.2°C)

PTFE (2-piece diaphragm) 220°F (104.4°C)

Santoprene 180°F (82.2°C)

3A Approved EPDM 275°F (135°C)

* Displacement per cycle may vary based on suction condition, discharge head, air pressure

and fluid type

** Noise levels measured with the pump mounted on the stand. Sound power measured

per ISO Standard 9614-1

50 scfm

338499

310622

3150

Maximum fluid working pressure 120 psi (8 bar, 0.8 MPa)

Maximum free-flow delivery* 150 gpm (568 lpm)

Maximum suction lift - ball 18 ft (5.4 m) wet, 9 ft (2.7 m) dry

Maximum suction lift - flapper 10 ft (3.0 m) wet, 5 ft (1.5 m) dry

Maximum size pumpable solids - ball 1 in (25.4 mm)

Maximum size pumpable solids - flapper 2.5 in (63.5 mm)

Air pressure operating range

Maximum air consumption 175 scfm

Air consumption at 70 psi

air inlet pressure/60 gpm

Maximum pump speed 145 cpm

*Gallons (liter) per cycle 1.03 (3.90)

**Maximum noise level at 100 psi, full flow 90 dBa

**Sound power level 103 dBa

**Noise level at 70 psi and 50 cpm 85 dBa

Fluid inlet & outlet size

(determined by part number)

Air inlet size 0.5 in npt(f)

Weight 145 lb (65 kg)

Flyer

Instruction manual

20-120 psi

(1.4 to 8.4 bar, 0.14 to 0.84 MPa)

50 scfm

Tri-clamp connections

338499

310622

Maximum diaphragm operating temperature

Santoprene 180ºF (82.2ºC)

Buna-N 180ºF (82.2ºC)

PTFE (Overmolded diaphragm) 180ºF (82.2ºC)

Fluoroelastomer 250ºF (121ºC)

3A Approved EPDM 275ºF (135ºC)

* Displacement per cycle may vary based on suction condition, discharge head, air pressure

and fluid type

** Noise levels measured with the pump mounted on the stand. Sound power measured

per ISO Standard 9614-1

12

AIR-OPERATED DIAPHRAGM PUMPS

Page 14

Performance Charts

AIR CONSUMPTION scfm (m

/min)

FLUID OUTLET PRESSURE

1590 High Sanitation Performance

AIR CONSUMPTION

scfm (m

/min)

FLUID OUTLET PRESSURE

3150 High Sanitation Performance

(490.2 mm)

SaniForce 1590 & 3150 HS

0 40 80 120 160 200 240

120

(0.84, 8.4)

psi (MPa, bar)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

A

100

(0.7, 7)

B

80

C

60

40

D

20

E

0 20 40 60 80 100 120

AIR PRESSURE LEGEND

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

= at 20 psi (1.4 bar, 0.14 MPa)

E

Dimensions

CYCLES PER MINUTE

A

B

C

D

E

(75) (151) (227) (302) (378) (454)

FLUID FLOW gpm (lpm)

Air Consumption

Fluid Flow

120

(3.96)

100

(3.4)

80

(2.83)

60

(1.7)

40

(1.13)

20

(0.57)

CYCLES PER MINUTE

0 19 39 58 78 97 117 136 155

120

(0.84, 8.4)

3

(0.7, 7)

psi (MPa, bar)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

100

80

60

40

20

A

B

C

D

0 20 40 60 80 100 120 140 160

(75) (151) (227) (302) (378) (454) (531) (606)

A

B

C

D

150

(4.2)

125

(3.5)

100

(2.8)

75

(2.1)

50

(1.4)

25

(0.7)

3

FLUID FLOW gpm (lpm)

AIR PRESSURE LEGEND

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

Air Consumption

Fluid Flow

SaniForce 1590 HS SaniForce 3150 HS

24.9 in.

(632.5 mm)

8.6 in.

(218.4 mm)

Ball Check Valve Pump

17.85 in.

(453.4 mm)

35.8 in.

(909.3 mm)

28.4 in.

(721.4 mm)

6.5 in.

(165.1 mm)

Ball Check Valve Pump

37.6 in.

(955.0 mm)

19.3 in.

AIR-OPERATED DIAPHRAGM PUMPS

13

Page 15

SaniForce 1590 & 3150 3A

3A Certified Diaphragm Pumps

Ordering Information

SaniForce 1590 3A Pumps

3A Pump with Leak Detector

Part Number Type Manifold ID Sanitary Connection Diaphragm Ball

SABAAA Ball 1.9 in (48.3 mm) 2 in x 2 in Overmolded EPDM PTFE

SaniForce 3150 3A Pumps

3A Pump with Leak Detector

Part Number Type Manifold ID Sanitary Connection Diaphragm Ball

SA1AAA Ball 2.9 in (73.7 mm) 1.5 in x 1.5 in Overmolded EPDM PTFE

SA2AAA Ball 2.9 in (73.7 mm) 2 in x 2 in Overmolded EPDM PTFE

SA3AAA Ball 2.9 in (73.7 mm) 3 in x 3 in Overmolded EPDM PTFE

SA4AAA Ball 2.9 in (73.7 mm) 4 in x 4 in Overmolded EPDM PTFE

SA5AAA Ball 2.9 in (73.7 mm) 3 in x 2 in Overmolded EPDM PTFE

3A High Sanitation Overmolded EPDM Diaphragm Kit

Part No. Description

255058 For 1.5 inch pump size, diaphragm repair kit

253224 For 2 inch pump size, diaphragm repair kit

Technical Specifications

1590 3A Certified 3150 3A Certified

Maximum fluid working pressure 120 psi (8 bar, 0.8 MPa) 120 psi (8 bar, 0.8 MPa)

Maximum free-flow delivery** 90 gpm (340 lpm) 150 gpm (568 lpm)

Maximum suction lift - ball 28 ft (8.5 m) wet, 15 ft (4.5 m) dry 18 ft (5.5 m) wet, 9 ft (2.7 m) dry

Maximum size pumpable solids - ball 5/8 in (15.8 mm) 1 in (25.4 mm)

Typical sound level at 70 psi air (4.9 bar) air @ 50 cpm 85 dBa 85 dBa

Air pressure operating range 20-120 psi (1.4 to 8.4 bar, 0.14 to 0.84 MPa) 20-120 psi (1.4 to 8.4 bar, 0.14 to 0.84 MPa)

Air inlet size 0.5 in npt(f) 0.5 in npt(f)

Fluid inlet & outlet size (determined by part number) Tri-clamp connections Tri-clamp connections

Weight 97 lb (44 kg) 145 lb (65 kg)

Flyer

Instruction manual

Maximum diaphragm operating temperature

3A Approved EPDM 275ºF (135ºC) 275ºF (135ºC)

** Flow rates are with muffler and do not vary based on diaphragm material. Displacement

per cycle may vary based on suction condition, discharge head, air pressure and fluid type.

338499 338499

310622 310622

14

AIR-OPERATED DIAPHRAGM PUMPS

Page 16

Performance Charts

AIR CONSUMPTION scfm (m

/min)

FLUID OUTLET PRESSURE

1590 3A Performance

AIR CONSUMPTION

FLUID OUTLET PRESSURE

3150 3A Performance

(632.5 mm

)

(218.4 mm

(596.9 mm)

(165.1 mm

(596.9 mm)

(721.4 mm

)

(558.8 mm)

SaniForce 1590 & 3150 3A

120

(0.84, 8.4)

100

(0.7, 7)

psi (MPa, bar)

80

(0.55, 5.5)

60

(0.41, 4.1)

40

(0.28, 2.8)

20

(0.14, 1.4)

0 40 80 120 160 200 240

A

B

C

D

E

0 20 40 60 80 100 120

(75) (151) (227) (302) (378) (454)

A

B

C

D

E

FLUID FLOW gpm (lpm)

AIR PRESSURE LEGEND

CYCLES PER MINUTE

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

= at 20 psi (1.4 bar, 0.14 MPa)

E

Air Consumption

Fluid Flow

120

(3.96)

100

(3.4)

80

(2.83)

60

(1.7)

40

(1.13)

20

(0.57)

3

(0.84, 8.4)

(0.7, 7)

psi (MPa, bar)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

0 19 39 58 78 97 117 136 155

120

100

A

B

80

C

A

B

C

60

40

D

D

20

0 20 40 60 80 100 120 140 160

(75) (151) (227) (302) (378) (454) (531) (606)

FLUID FLOW gpm (lpm)

AIR PRESSURE LEGEND

CYCLES PER MINUTE

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

Air Consumption

Fluid Flow

150

(4.2)

125

(3.5)

100

(2.8)

75

(2.1)

50

(1.4)

25

(0.7)

/min)

3

scfm (m

Dimensions

SaniForce 1590 3A SaniForce 3150 3A

24.9 in.

)

8.6 in.

)

3A Ball Check Valve Pump

35.8 in.

(909.3 mm

23.5 in.

23.6 in.

(594.4 mm)

28.4 in.

6.5 in.

3A Ball Check Valve Pump

)

)

23.5 in.

37.6 in.

(955.0 mm

22.0 in.

AIR-OPERATED DIAPHRAGM PUMPS

15

Page 17

SaniForce Meat & Poultry Pumps

Air-Operated Diaphragm Pumps

Ordering Information

Part Number Type Manifold ID Sanitary Connection Diaphragm

SFP6F1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Santoprene

SFP7F1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Buna-N

SFP8F1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Fluoroelastomer

SFPAF1 Flapper 2.9 in (73.7 mm) 3 in x 3 in Overmolded EPDM

Accessories

Part Number Description

253225 Santoprene diaphragm kit

253223 Buna-N diaphragm kit

253222 Fluoroelastomer diaphragm kit

253224 Overmolded EPDM diaphragm kit

15D990 Leak detector kit

Technical Specifications

Meat and Poultry

Maximum fluid working pressure 120 psi (8 bar, 0.8 MPa)

Maximum free-flow delivery* 150 gpm (568 lpm)

Maximum suction lift 10 ft (3.0 m) wet

Maximum size pumpable solids 2.5 in (63.5 mm)

Typical sound level at 70 psi air (4.9 bar) air @ 50 cpm 85 dBa

Air pressure operating range 20-120 psi (1.4 to 8.4 bar, 0.14 to 0.84 MPa)

Air inlet size 0.5 in npt(f)

Fluid inlet & outlet size (determined by part number) Tri-clamp connections

Weight 145 lb (65 kg)

Flyer

Instruction manual

Maximum diaphragm operating temperature

Santoprene 180ºF (82.2ºC)

Buna-N 180ºF (82.2ºC)

Fluoroelastomer 250ºF (121ºC)

EPDM 275ºF (135ºC)

* Flow rates are with muffler and do not vary based on diaphragm material. Displacement

per cycle may vary based on suction condition, discharge head, air pressure and fluid type.

338067

310622

Flapper Check Valve

16

AIR-OPERATED DIAPHRAGM PUMPS

Page 18

Performance Charts

AIR CONSUMPTION

FLUID OUTLET PRESSURE

Meat and Poultry Performance

)

)

(805.7 mm

0 19 39 58 78 97 117 136 155

120

(0.84, 8.4)

(0.7, 7)

psi (MPa, bar)

(0.55, 5.5)

(0.41, 4.1)

(0.28, 2.8)

(0.14, 1.4)

A

100

B

80

C

60

40

D

20

0 20 40 60 80 100 120 140 160

(75) (151) (227) (302) (378) (454) (531) (606)

CYCLES PER MINUTE

FLUID FLOW gpm (lpm)

SaniForce Meat and Poultry Pumps

A

B

C

D

150

(4.2)

125

(3.5)

100

(2.8)

75

(2.1)

50

(1.4)

25

(0.7)

/min)

3

scfm (m

AIR PRESSURE LEGEND

= at 120 psi (8.4 bar, 0.84 MPa)

A

= at 100 psi (7 bar, 0.7 MPa)

B

= at 70 psi (4.8 bar, 0.5 MPa)

C

= at 40 psi (2.8 bar, 0.3 MPa)

D

Air Consumption

Fluid Flow

Dimensions

SaniForce 3150 Meat and Poultry Flapper

26.28 in.

(540.5 mm

31.72 in.

)

10.44 in.

(265.2 mm

23.58 in.

19.25 in.

(489 mm)

(598.9 mm)

AIR-OPERATED DIAPHRAGM PUMPS

17

Page 19

SaniForce Piston Pumps

2:1, 6:1, 5:1 and 12:1

Ordering Information

2:1 Piston Pump

Part No. Pump Type Pump Length: Inlet to Outlet Pump Inlet Packings Weight: lb (kg)

24N300 Double Ball Long - 44.5 in (113 cm) 2 in (5.1 cm) OD UHMWPE, FKM 26 (11.8)

24N344 Double Ball Long - 44.5 in (113 cm) 2 in (5.1 cm) OD PTFE, FKM 26 (11.8)

24R046 Double Ball Standard Drum - 37.5 in (95.2 cm) 2 in (5.1 cm) OD UHMWPE, FKM 24 (10.9)

24R047 Double Ball Standard Drum - 37.5 in (95.2 cm) 2 in (5.1 cm) OD PTFE, FKM 24 (10.9)

6:1 Piston Pump

Part No. Pump Type Pump Length: Inlet to Outlet Pump Inlet Packings Weight: lb (kg)

24E840 Double Ball Drum Length - 36.4 in (92.4 cm) 2.1 in (5.3 cm) OD Buna, Nylon, Nitrile, & CR 36.9 (16.7)

24G740 Double Ball Drum Length, Ram Pkg - 36.4 in (92.4 cm) 6.0 in (15.2 cm) Tri-Clamp Buna, Nylon, Nitrile, & CR 38 (17)

24E839 Double Ball Drum Length - 36.4 in (92.4 cm) 2.1 in (5.3 cm) OD PTFE 36.9 (16.7)

24E838 Double Ball Stubby - 15.1 in (38.3 cm) 2.5 in (6.3 cm) Tri-Clamp Buna, UHMWPE & CR 28.9 (13.1)

24E837 Double Ball Stubby - 15.1 in (38.3 cm) 2.5 in (6.3 cm) Tri-Clamp PTFE 36.9 (16.7)

24E836 Priming Piston Stubby - 16.0 in (40.6 cm) 2.3 in (5.8 cm) OD Buna, Nylon, Nitrile & CR 33.8 (16.8)

24G739 Priming Piston Stubby, Ram Pkg - 16.0 in (40.6 cm) 6.0 in (15.2 cm) Tri-Clamp Buna, Nylon, Nitrile & CR 35 (16)

24F942 Double Ball Bin Length - 48.5 in (123.0 cm) 2.1 in (5.3 cm) OD Buna, Nylon, Nitrile, & CR 39.7 (18)

5:1 Piston Pump

Part No. Pump Type Pump Length: Inlet to Outlet Pump Inlet Packings Weight: lb (kg)

24F195 Double Ball Drum Length - 36.8 in (93.4 cm) 4 in (10.2 cm) OD Buna, PTFE, UHMWPE & FKM 119 (54.1)

24E833 Double Ball Stubby - 20.4 in (51.8 cm) 4 in (10.2 cm) OD Buna, PTFE, UHMWPE & FKM 91.3 (41.4)

24G742 Double Ball Stubby, Ram Pkg - 20.4 in (51.8 cm) 6 in (15.2 cm) Tri-Clamp Buna, PTFE, UHMWPE & FKM 95 (43)

24E831 Priming Piston Drum Length - 25.9 in (65.7 cm) 4 in (10.2 cm) OD Buna, PTFE, UHMWPE, CR,

24G741 Priming Piston Drum Length, Ram Pkg -

25.9 in (65.7 cm)

24F196 Double Ball Stubby with Inlet Elbow -

25.2 in (64.0 cm)

24F197 Double Ball Stubby - 19.3 in (49.0 cm) 4 in (10.2 cm) Tri-Clamp Buna, PTFE, Silicone, FKM & UHMWPE 90.6 (41.1)

6 in (15.2 cm) Tri-Clamp Buna, PTFE, UHMWPE, CR,

90º Elbow, 2.5 in (6.3 cm)

Tri-Clamp

Nylon & FKM

Nylon & FKM

Buna, FKM, PTFE & UHMWPE 93.1 (42.2)

95.3 (43.2)

99 (45)

18

18

12:1 Piston Pump

Part No. Pump Type Pump Length: Inlet to Outlet Pump Inlet Packings Weight: lb (kg)

24F625 Priming Piston Stubby, Ram Package - 16.1 in (40.8 m) 6 in (15.2 cm) Tri-Clamp Acetal, PTFE, Nitrile and UHMWPE 122 (55)

24F626* Priming Piston Stubby, Ram Package - 16.1 in (40.8 m) 6 in (15.2 cm) Tri-Clamp Acetal, PTFE, Nitrile and UHMWPE 122 (55)

OD = Outside Diameter CR = Polychloroprene *For use with viscous sticky material

Monark 5:1

Part No. Pump Type Pump Length: Inlet to Outlet Pump Inlet Packings Weight: lb (kg)

207550 Double Ball Drum Length - 36.7 in (93.3 cm) 2.1 in (5.3 cm) OD Buna, Neoprene 33 (15)

Technical Specifications

SaniForce 2:1 Piston Pump 6:1 Piston Pump 5:1 Piston Pump 12:1 Piston Pump

Fluid to air pressure ratio 2.5:1 6:1 5:1 12:1

Maximum fluid pressure 250 psi (17 bar) 600 psi (41 bar) 400 psi (28 bar) 1200 psi (83 bar)

Maximum fluid flow at 60 cpm 1.5 gpm (5.7 lpm) 4.0 gpm (15.1 lpm) 14.0 gpm (53 lpm) 8.5 gpm (32 lpm)

Air consumption at 60 cpm 6 cfm at 100 psi (7 bar) 29 cfm at 100 psi (7 bar) 75 cfm at 80 psi (5.5 bar) 116 cfm at 100 psi (7 bar)

Volume per cycle 0.041 gal (0.15 l) 0.067 gal (0.25 l) 0.23 gal (0.87 l) 0.14 gal (0.54 l)

Max. operating temp. (fluid) 180ºF (82ºC) 250ºF (121ºC) 140ºF (60ºC) 160ºF (71ºC)

Max. operating temp. (air motor) 120ºF (48.8ºC) 120ºF (48.8ºC) 120ºF (48.8ºC) 120ºF (48.8ºC)

Max. size pumpable solids 1/8 in (3.2 mm) 1/8 in (3.2 mm) 1/4 in (6.4 mm) 1/4 in (6.4 mm)

Max. air input pressure 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa) 80 psi (5.5 bar, 0.55 MPa) 100 psi (7 bar. 0.7 MPa)

Air inlet size 3/8 npt 1/2 npsm(f) 1/2 npsm(f) 1/2 npsm(f)

Fluid outlet size 1.0 in (2.5 cm) Tri-Clamp 1.5 in (3.8 cm) Tri-Clamp 2.0 in (5.1 cm) Tri-Clamp 2.0 in (5.1 cm) Tri-Clamp

Flyer 338591 338591 338591 338591

Instruction manual 3A2977 3A0733 3A0734 3A0735

SANIFORCE PISTON PUMPS

SANIFORCE PISTON PUMPS

Page 20

Performance Charts

AIR FLOW scfm (m

/min)

FLUID PRESSURE

12:1 Piston Pump Performance

AIR FLOW

FLUID PRESSURE

5:1 Piston Pump Performance

AIR FLOW scfm (m

/min)

FLUID PRESSURE

6:1 Piston Pump Performance

FLUID PRESSURE

2:1 Piston Pump Performance

SaniForce Piston Pumps

psi (bar, MPa)

450

(31, 3.1)

400

(28, 2.8)

350

(24, 2.4)

300

(21, 2.1)

250

(17, 1.7)

psi (bar, MPa)

200

(14, 1.4)

150

(10, 1.0)

100

(7, 0.7)

(3.4, 0.3)

CYCLES PER MINUTE

0 20 40 60 80 100 120

300

(21, 2.1)

250

(17, 1.7)

(13, 1.4)

(10, 1.0)

A

200

B

150

100

C

(7, 0.7)

50

(3, 0.3)

0 0.5 1 1.5 2 2.5 3

(1.9) (3.8) (5.7) (7.6) (9.5) (11.4)

FLUID FLOW gpm (lpm)

tested in No. 10 weight oil

AIR PRESSURE LEGEND

= at 100 psi (7 bar, 0.7 MPa)

A

= at 70 psi (4.8 bar, 0.5 MPa)

B

= at 40 psi (2.8 bar, 0.3 MPa)

C

Air Consumption

Fluid Flow

14

(0.39)

12

A

(0.33)

10

(0.28)

B

8

(0.23)

6

C

(0.17)

4

(0.11)

2

(0.06)

CYCLES PER MINUTE

0 8 17 25 34 42 51 60

A

B

C

50

0 2 4 6 8 10 12 14

(7.6) (15.1) (22.7) (30.3) (37.8) (45.4) (53)

FLUID FLOW gpm (lpm)

tested in No. 10 weight oil

AIR PRESSURE LEGEND

= at 80 psi (5.5 bar, 0.5 MPa)

A

= at 60 psi (4.1 bar, 0.4 MPa)

B

= at 40 psi (2.8 bar, 0.3 MPa)

C

Air Consumption

Fluid Flow

A

B

C

/min)

3

AIR FLOW scfm (m

80

(2.27)

70

(1.98)

60

(1.70)

50

(1.42)

3

40

(1.13)

30

(0.85)

20

(0.57)

10

(0.28)

/min)

scfm (m

700

(48, 4.8)

600

(41, 4.1)

500

(34, 3.4)

psi (bar, MPa)

400

(28, 2.8)

300

(21, 2.1)

200

(14, 1.4)

100

(7, 0.7)

1400

(97, 9.7)

1200

(83, 8.3)

1000

(69, 7.0)

psi (bar, MPa)

800

(55, 5.5)

600

(41, 4.1)

400

(28, 2.8)

200

(14, 1.4)

0 15 30 45 60

A

A

B

C

0 0.5 1 1.5 2 2.5 3 3.5 4

(1.9) (3.8) (5.7) (7.6) (9.5) (11.4) (13.2) (15.1)

FLUID FLOW gpm (lpm)

tested in No. 10 weight oil

AIR PRESSURE LEGEND

= at 100 psi (7 bar, 0.7 MPa)

A

= at 70 psi (4.8 bar, 0.5 MPa)

B

= at 40 psi (2.8 bar, 0.3 MPa)

C

Air Consumption

Fluid Flow

B

C

CYCLES PER MINUTE

0 10 16 23 30 36 43 49 56

CYCLES PER MINUTE

A

B

C

0 1 2 3 4 5 6 7 8

(3.8) (7.6) (11.3) (15.1) (18.9) (22.7) (26.5) (30.3)

FLUID FLOW gpm (lpm)

tested in No. 10 weight oil

AIR PRESSURE LEGEND

= at 100 psi (7 bar, 0.7 MPa)

A

= at 70 psi (4.8 bar, 0.5 MPa)

B

= at 40 psi (2.8 bar, 0.3 MPa)

C

Air Consumption

Fluid Flow

A

B

C

35

(1.0)

30

(.85)

25

(.71)

20

(.57)

15

(.42)

10

(.28)

5

(.14)

140

(3.96)

120

(3.40)

100

(2.83)

80

(2.27)

60

(1.70)

40

(1.13)

20

(.57)

3

3

SANIFORCE PISTON PUMPS

19

Page 21

SaniForce Piston Pumps

Stubby Length

Drum and Bin Length

Drum Length

Stubby Length

A

B

C

D

Dimensions

24N300 and 24N344 61.9 (157.2) 53.7 (136.4) 44.5 (113.0) 1.972 (5.0)

24R046 and 24R047 54.9 (139.4) 46.7 (118.6) 37.5 (95.2) 1.972 (5.0)

SaniForce 2:1

C

Model

in (cm)

SaniForce 5:1

SaniForce 6:1

A

B

D

A

B

in (cm)

C

in (cm)

D

in (cm)

A

B

C

ModelPump StyleAin (cm)Bin (cm)Cin (cm)

24E836

Stubby24E837

24E838

24G739

24G740

24E839

24E840

24F942

Drum

Length

Bin Length

39.2 (99.5)

60.5 (153.7)

73 (185.4)

D

D

19.5 (50)

41 (104)

53.5 (135.9)

C

15.1 (38)

36.4 (92)

48.9 (124.2)

A

B

D (OD)

in (cm)

2.1 (5.4)

2.1 (5.4)

2.1 (5.4)

20

A

B

C

Model

Pump Style

24G742

Double Ball, Stubby

24E833

Double Ball, Stubby with inlet

24F196

Double Ball, Bin Length

24F197

Priming Piston, Drum Length

24G741

Priming Piston, Drum Length

24E831

Double Ball, Drum Length

24F195

SANIFORCE PISTON PUMPS

A

B

C

A

in (cm)Bin (cm)Cin (cm)

51.5 (131)

56.3 (143)

50.4 (128)

57.0 (145)

67.9 (172)

25.9 (66)

30.7 (78)

24.8 (63)

31.3 (80)

42.3 (107)

20.4 (52)

25.2 (64)

19.3 (49)

25.9 (66)

36.8 (93)

SaniForce 12:1

47.5 in

(120.7 cm)

16.1 in

(41 cm)

21.1 in

(54 cm)

Model Pump Style

24F625

24F626

Stubby Ram

Package

Page 22

Ordering Information

Saniforce Elevators

SaniForce Elevators

Pump Packages

Model Cart & Handle Stationary Base Pump Packings

24V310

24V311

24V312

24V313

24V314

24V315

24V316

24V317

24V318

24V319

24V320

24V321

24V322

24V323

24V324

24V325

x – – 24V303 305 lb (138 kg)

x – – 24V303 170 lb (77 kg)

x – – 24V307 305 lb (138 kg)

x – – 24V307 170 lb (77 kg)

x – – 24V304 305 lb (138 kg)

x – – 24V304 170 lb (77 kg)

x 2:1 UHMWPE 24V303 330 lb (150 kg)

x 2:1 PTFE 24V303 330 lb (150 kg)

x 2:1 UHMWPE 24V303 195 lb (88 kg)

x 2:1 PTFE 24V303 195 lb (88 kg)

x 6:1 Buna-N 24V307 342 lb (155 kg)

x 6:1 PTFE 24V307 342 lb (155 kg)

x 6:1 Buna-N 24V307 207 lb (94 kg)

x 6:1 PTFE 24V307 207 lb (94 kg)

x 5:1 Varied 24V304 425 lb (193 kg)

x 5:1 Varied 24V304 290 lb (132 kg)

Pump

Brackets Weight

ELEVATORS

21

Page 23

SaniForce Elevators

Mobile Model

Raised

109 in

(277 cm)

Lowered

70 in

(178 cm)

Stationary Model

Raised

100 in

(254 cm)

Lowered

61 in

(155 cm)

57.25 in

(145.4 cm)

40.375 in

(102.6 cm)

41.25 in

(104.8 cm)

12 in

(30.5 cm)

22

Technical Specifications

SaniForce Elevator 2:1 Piston Pump 6:1 Piston Pump 5:1 Piston Pump

Maximum weight capacity

Maximum ambient temp. (air motor)

Maximum fluid working pressure

Air inlet size

Maximum air inlet pressure

Sound data

Wetted parts

Flyer

Instruction manual

ELEVATORS

200 lb (91 kg) 200 lb (91 kg)) 200 lb (91 kg)

120˚F (49˚C) 120˚F (49˚C) 120˚F (49˚C))

250 psi (17 bar, 1.7 MPa) 400 psi (28 bar, 2.8 MPa) 600 psi (41 bar, 4.1 MPa)

1/2 npt(f) 1/2 npt(f) 1/2 npt(f)

100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa)

See pump manual See pump manual See pump manual

See pump manual See pump manual See pump manual

338591 338591 338591

3A2977 3A0733 3A0734

Page 24

Ordering Information

SaniForce 6:1 Drum Unloader

SaniForce Drum Unloaders

Pump Packages

Part

Number

Pump

Number Pump Type

Ram

Material

Ram

Plate No.

Inflatable

Seal No. Control Type

Weight

lb (kg)

24D776 24G739 Priming Piston SST 16G240 16G242 Exposed 353 (160)

24D780 24G739 Priming Piston CS* 16G240 16G242 Exposed 372 (169)

24D782 24G739 Priming Piston SST 16G240 16G242 Enclosed SST 367 (166)

24D788 24G740 Double Ball SST 16G240 16G242 Exposed 356 (161)

24D792 24G740 Double Ball CS* 16G240 16G242 Exposed 375 (170)

24D794 24G740 Double Ball SST 16G240 16G242 Enclosed SST 370 (168)

SaniForce 5:1 Drum Unloader

Part

Number

24D708 24G741 Priming Piston SST 16G240 16G242 Exposed 413 (187)

24D712 24G741 Priming Piston CS* 16G240 16G242 Exposed 433 (196)

24D714 24G741 Priming Piston SST 16G240 16G242 Enclosed SST 428 (194)

24D720 24G742 Double Ball SST 16G240 16G242 Exposed 417 (189)

24D724 24G742 Double Ball CS* 16G240 16G242 Exposed 437 (198)

24D726 24G742 Double Ball SST 16G240 16G242 Enclosed SST 432 (196)

Pump

Number Pump Type

Ram

Material

Ram

Plate No.

Inflatable

Seal No. Control Type

Weight

lb (kg)

SaniForce 12:1 Drum Unloader

Part

Number

24D647 24F625 Priming Piston SST 16G240 16G242 Exposed 440 (200)

24D651 24F625 Priming Piston CS* 16G240 16G242 Exposed 459 (208)

24D653 24F625 Priming Piston SST 16G240 16G242 Enclosed SST 454 (206)

24F188** 24F626 Priming Piston SST 16G240 16G242 Exposed 440 (200)

24F189** 24F626 Priming Piston CS* 16G240 16G242 Exposed 459 (208)

24F190** 24F626 Priming Piston SST 16G240 16G242 Enclosed SST 454 (206)

24U568** 24F626 Priming Piston SST 16G240 16G242 Enclosed SST 460 (209)

24F188** 24F626 Priming Piston CS* 16G240 16G242 Exposed 440 (200)

24F189** 24F626 Priming Piston SST 16G240 16G242 Enclosed SST 459 (208)

24F190**† 24F626 Priming Piston SST 17B191 16G242 Exposed 454 (206)

*CS = Painted carbon steel **For use with sticky material † = Conical shaped plate

Pump

Number Pump Type

Ram

Material

Ram

Plate No.

Inflatable

Seal No. Control Type

Weight

lb (kg)

Technical Specifications

Drum Unloaders

Max fluid pressure

Max Flow at 60 cpm 4.0 gpm (15.1 lpm) 4.0 gpm (15.1 lpm) 14 gpm (53 lpm) 14 gpm (53 lpm) 8.5 gpm (32 lpm) 60 gpm (227 lpm) 60 gpm (227 lpm)

Max Flow at 100 cpm – – – – – 100 gpm (378 lpm) 100 gpm (378 lpm)

Viscosity

Max inlet air pressure

Air inlet size (enclosed, exposed

controls)

Evacuation efficiency Up to 99% Up to 99% Up to 99% Up to 99% Up to 99% Up to 99% Up to 99%

Flyer

Instruction manual

* Flow rates based on full displacement of lower and S.G. = 1

Ball Pump

600 psi

(41 bar, 4.1 MPa)

Up to

75,000 cps

100 psi

(7 bar, 0.7 MPa)

1/2 npt(f),

3/4 npt(f)

338590 338590 338590 338590 338590 338590 338590

3A0591 3A0591 3A0591 3A0591 3A0591 3A0591 3A0591

6:1 Double

6:1 Priming

Piston

600 psi

(41 bar, 4.1 MPa)

Up to

125,000 cps

100 psi

(7 bar, 0.7 MPa)

1/2 npt(f),

3/4 npt(f)

5:1 Double

Ball Pump

400 psi

(28 bar, 2.8 MPa)

Up to

200,000 cps

80 psi

(5.5 bar, 0.6 MPa)

1/2 npt(f),

3/4 npt(f)

5:1 Priming

Piston

400 psi

(28 bar, 2.8 MPa)

Up to

750,000 cps

80 psi

(5.5 bar, 0.6 MPa)

1/2 npt(f),

3/4 npt(f)

12:1 Priming

Piston

1200 psi

(83 bar, 8.3 MPa)

Up to

1,000,000 cps

100 psi

(7 bar, 0.7 MPa)

1/2 npt(f),

3/4 npt(f)

3150 High

Sanitation

120 psi

(8.3 bar, 0.83 MPa)

Up to

100,000 cps

120 psi

(8.3 bar, 0.8 MPa)

1/2 npt(f),

3/4 npt(f)

PUMP PACKAGES

2150 High

Sanitation

120 psi

(8.3 bar, 0.83 MPa)

Up to

100,000 cps

120 psi

(8.3 bar, 0.8 MPa)

1/2 npt(f),

3/4 npt(f)

23

Page 25

SaniForce Drum Unloaders

Ordering Information

SaniForce 3150 HS Drum Unloader

Part

Number

24J364 24J389 Diaphragm SST 16D301 16E144 Exposed 428 (194) PTFE/EPDM PTFE

24J365 24J389 Diaphragm CS 16D301 16E144 Exposed 443 (201) PTFE/EPDM PTFE

24J366 24J389 Diaphragm SST 16D301 16E144 Exposed 428 (194) PTFE/EPDM PTFE

24D922 24C124 Ball SST 16G241 16G242 Exposed 428 (194) Overmolded EPDM, 3A PTFE

24D926 24C124 Ball CS* 16G241 16G242 Exposed 443 (201) Overmolded EPDM, 3A PTFE

24D928 24C124 Ball SST 16G241 16G242 Enclosed SST 442 (200) Overmolded EPDM, 3A PTFE

24D932 248273 Ball CS* 16G241 16G242 Exposed 443 (201) Santoprene Santoprene

24D936 248273 Ball SST 16G241 16G242 Enclosed SST 442 (200) Santoprene Santoprene

24D940 248273 Ball SST 16G241 16G242 Exposed 428 (194) Santoprene Santoprene

24D944 248274 Flapper SST 16G241 16G242 Exposed 428 (194) Santoprene –

24D948 248274 Flapper CS* 16G241 16G242 Exposed 443 (201) Santoprene –

24D952 248274 Flapper SST 16G241 16G242 Enclosed SST 442 (200) Santoprene –

Pump

Number

Pump

Type

Ram

Material

Ram

Plate No.

Inflatable

Seal No. Control Type

Weight

lb (kg)

Diaphragm

Material

Ball

Material

SaniForce 2150 Drum Unloader

Part

Number

24G542 24G743 Ball SST 16G241 16G242 Exposed 450 (204) Overmolded PTFE PTFE

24F191 24G743 Ball CS* 16G241 16G242 Exposed 464 (210) Overmolded PTFE PTFE

24G543 24G743 Ball SST 16G241 16G242 Enclosed SST 464 (210) Overmolded PTFE PTFE

24F192 24G744 Ball SST 16G241 16G242 Exposed 450 (204) Santoprene Weighted polychloroprene

24F193 24G744 Ball CS* 16G241 16G242 Exposed 464 (210) Santoprene Weighted polychloroprene

24F194 24G744 Ball SST 16G241 16G242 Enclosed SST 464 (210) Santoprene Weighted polychloroprene

*CS = Painted carbon steel.

Pump

Number

Pump

Type

Ram

Material

Ram

Plate No.

Inflatable

Seal No. Control Type

Weight

lb (kg)

Diaphragm

Material

Ball

Material

Dimensions

SaniForce Drum Unloader

9 ft (2.75 m)

when fully raised

38 in

(965 mm)

42 in

(1067 mm)

21 in

(534 mm)

Four 0.562 in (14 mm)

mounting holes

25 in

(635 mm)

SaniForce 3150 HS

Drum Unloader

SaniForce 2150

Drum Unloader

24

PUMP PACKAGES

Page 26

SaniForce Bin Evacuation Systems

Pump Packages

Ordering Information

SaniForce BES

Max. Working Fluid

BES Part

Number

BESAAC 400 (28, 2.8) Double Ball 2 SaniForce 5:1 Manual Buckhorn Caliber 315

BESA4C 400 (28, 2.8) Double Ball 2 SaniForce 5:1 Manual Pallecon

BESA7A 400 (28, 2.8) Double Ball 2 SaniForce 5:1 Electronic Plywood

BESA7C 400 (28, 2.8) Double Ball 2 SaniForce 5:1 Manual Plywood

BESA7F 400 (28, 2.8) Double Ball 2 SaniForce 5:1 Electronic Plywood

BESB7B 400 (28, 2.8) Double Ball 4 SaniForce 5:1 Electronic Plywood

BESB7D 400 (28, 2.8) Double Ball 4 SaniForce 5:1 Manual Plywood

BESEAC 1200 (83, 8.3) Priming Piston 2 SaniForce 12:1 Manual Buckhorn Caliber 315

BESE1A 1200 (83, 8.3) Priming Piston 2 SaniForce 12:1 Electronic Arena

BESE1C 1200 (83, 8.3) Priming Piston 2 SaniForce 12:1 Manual Arena

BESE5C 1200 (83, 8.3) Priming Piston 2 SaniForce 12:1 Manual Pallecon

BESE7C 1200 (83, 8.3) Priming Piston 2 SaniForce 12:1 Manual Plywood

BESF6B 1200 (83, 8.3) Priming Piston 4 SaniForce 12:1 Electronic Arena

BESF6D 1200 (83, 8.3) Priming Piston 4 SaniForce 12:1 Manual Arena

BESF7D 1200 (83, 8.3) Priming Piston 4 SaniForce 12:1 Manual Plywood

BESF9B 1200 (83, 8.3) Priming Piston 4 SaniForce 12:1 Electronic TNT

BESF9D 1200 (83, 8.3) Priming Piston 4 SaniForce 12:1 Manual TNT

Pressure per pump

psi (bar, MPa)

Pump

Type

Pump

Quantity Pump Description

Control

Type BIN Manuf

Note: Systems can be special ordered for bin types other than plywood, arena and pallecon. Contact your sales rep for additional information.

Technical Specifications

SaniForce BES

Part No BESAxx BESBxx BESDxx BESExx BESFxx

Max. working fluid pressure 400 psi (28 bar, 2.8 MPa) 600 psi (41 bar, 4.1 MPa) 1200 psi (83 bar, 8.3 MPa) 1200 psi (83 bar, 8.3 MPa)

Compressed air requirement 80-100 psi

Pneumatic control panel specifications

Max. inlet air pressure 80 psi (5.5 bar, 0.55 MPa) 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa) 100 psi (7 bar, 0.7 MPa)

Air inlet size 3/4 in npt(f) 3/4 in npt(f) 3/4 in npt(f) 3/4 in npt(f)

Air inlet pump 1/2 in npt(f) 1/2 in npt(f) 1/2 in npt(f) 1/2 in npt(f)

Fluid displacement (each pump) 0.23 gal/cycle (0.87 l/cycle) 0.075 gal/cycle (0.28 l/cycle 0.14 gal/cycle (0.52 l/cycle) 0.14 gal/cycle (0.52 l/cycle)

Max. flow @ 60 cpm* 28 gpm (106 lpm) 56 gpm (212 lpm) 8 pgm (30 lpm) 17 gpm (64 lpm) 34 gpm (128 lpm)

Pressure ratio 5:1 6:1 12:1 12:1

Air consumption (each pump) at

40 psi (2.8 bar, 0.28 MPa)

Pump outlet 2 in tri-clamp 2 in tri-clamp 2 in tri-clamp 2 in tri-clamp

Communication RS232 Serial RS232 Serial RS232 Serial RS232 Serial

Electrical requirements 110 VAC (60 Hz), 15A 110 VAC (60 Hz), 15A 110 VAC (60 Hz), 15A 110 VAC (60 Hz), 15A

Overall dimensions

in (m)

Flyer

Instruction manual

(5.5-7 bar, 0.55-0.7 MPa)

~2.95 scfm per gpm ~3.75 scfm per gpm ~7.5 scfm per gpm ~7.5 scfm per gpm

69 W x 60 D x 118.8 H

(1.72 W x 1.52 D x 3.0 H)

338589 338589 338589 338589

311163 311163 311163 311163

80-100 psi

(5.5-7 bar, 0.55-0.7 MPa)

69 W x 60 D x 118.8 H

(1.72 W x 1.52 D x 3.0 H)

80-100 psi

(5.5-7 bar, 0.55-0.7 MPa)

69 W x 60 D x 118.8 H

(1.72 W x 1.52 D x 3.0 H)

80-100 psi

(5.5-7 bar, 0.55-0.7 MPa)

69 W x 60 D x 118.8 H

(1.72 W x 1.52 D x 3.0 H)

* Flow rates based on full displacement of lower and S.G. = 1

Note: Graco’s BES packages are available for a variety of manufacturers’ bins and custom systems can be built upon request. Contact Graco at 1-800-543-0339 for more information.

PUMP PACKAGES

25

Page 27

SaniForce Bin Evacuation Systems

Ordering Information

SaniForce 3150 BES

Part

Number Type Bin Manuf.

BES3P3 Ball Plywood Manual 3 in (76 mm) Santoprene/ PTFE

BES3P1 Ball Plywood Electronic 3 in (76 mm) Santoprene/ PTFE

BES4P3 Flapper Plywood Manual 3 in (76 mm) Santoprene/ N/A

BES8B3 Ball Pallecon Manual 3 in (76 mm) Overmolded EPDM, 3A

BES3A1 Ball Arena Electronic 3 in (76 mm) Santoprene/ PTFE

BES4A1 Flapper Arena Electronic 3 in (76 mm) Santoprene/ N/A

Note: Contact marketing for ordering information on non-plywood bins.

**3A Approved EPDM diaphragm is available for heavy duty applications.

Control

Type Outlet Size

Diaphragm/Ball

Material**

Technical Specifications

SaniForce 3150 BES

Technical Specifications

Part No BES3xx BES4xx

Max. working fluid pressure 120 psi (8.4 bar, 0.84 MPa)

Compressed air requirement 80-120 psi (5.5-8.4 bar, 0.55-0.84 MPa)

Pneumatic control panel specifications

Max. inlet air pressure 120 psi (8.4 bar, 0.84 MPa)

Air inlet size 3/4 in npt(f)

Air inlet pump 1/2 in npt(f)

Fluid displacement (each pump) 1.03 gal/cycle (3.89 l/cycle)

Max. flow @ 145 cpm* 300 gpm (1,135 lpm)

Pressure ratio 1:1

Air consumption (each pump) at 70 psi (0.48 MPa, 4.8 bar) ~0.8 scfm per gpm

Pump outlet 3 in tri-clamp

Max. suction lift 18 ft (5.5 m) wet 10 ft (3.0 m) wet

Max. diaphragm operating temperature

(Santoprene, 3A Approved EPDM)

Typical sound level at 70 psi (4.9 bar) air @ 50 cpm 85 dBa

Weight 3,000 lb (1,360 kg)

Flyer

Instruction manual

* Flow rates are with muffler and slightly vary based on diaphragm material. Displacement per cycle may vary based on suction condition, discharge head, air pressure and fluid type.

180ºF (82.2ºC),

275ºF (135ºC)

338589

311163

26

26

SECTION DESCRIPTION

PUMP PACKAGES

Page 28

Dimensions

SaniForce BES

Front View

58.3 in

(1.48 m)

118.8 in

(3.0 m)

6.0 in

(152 mm)

SaniForce Bin Evacuation Systems

Top View

50.6 in

(1285 mm)

60.0 in

(1.52 m)

40 in

(1016 mm)

47 in

(1.19 m)

69 in

(1.72 m)

0.56 in

(14.3 mm)

4 holes per foot

Front View

58.3 in

(1.48 m)

118.8 in

(3.0 m)

60 in

(1.52 m)

Top View

50.6 in

(1.28 m)

47 in

(1.19 m)

69 in

(1.75 m)

6 in

(15.2 cm)

6 in (15.2 cm)

40 in

(1.02 m)

0.56 in

(14.3 mm)

4 holes per foot

PUMP PACKAGES

27

Page 29

Hydra-Clean Pressure Washers

High Sanitation Cleaning Packages

Ordering Information

247549 or

Package Order Number.

Package Instruction Manual 312585 312585 312585 312585 306817

Air Motor Part Number N34DN0 N65DN0 N65DN0 N65DN0 207352

Air Motor Manual 311238 311238 311238 311238 306982

Pump Lower Part number 247599 241648 687055 24B923 224344

Pump Manual 312745 311825 311825 311827 306817

Wetted Parts

Pump Std. Repair Kit 247881 222880 See Manual 24C162 224402

Optional PTFE Repair Kit N/A 222876 222846 237179 224889

Std. Discharge Hose

(3/8 x 50 ft) 4500 psi (310 bar)

Comes with M & F QD's

Std. Gun/Wand Assy 247879 247879 247879 247879 237485/207299

Std. 60 Mesh Inlet Strainer 15T284 15T284 15T284 15T284 206300

Flyer

247550

SST/PTFE/

CF-PTFE

247878 247878 247878 247878 205753

338026 338026 338026 338026 338026

247551 or

247552

SST/CF-PTFE/

UHMWPE

247553 or

247554

SST/CF-PTFE/

UHMWPE

258664 or

258665 206515

SST/CF-PTFE/

UHMWPE

SST/CR/

UHMWPE

Stainless Steel Tips

Part

Number

805538

805549

805566

805575

103921

Pressure and flow rates are tested with air pressure of 100 psi (7 bar).

Other orifice sizes and fan widths available from Graco. Contact a sales representative for more information.

Orifice

Size

0.030 in

(0.8 mm)

0.045 in

(1.1 mm)

0.065 in

(1.7 mm)

0.080 in

(2.0 mm)

0.065 in

(1.6 mm)

Fan

Angle

40º

25º

40º

0º

40º N/A N/A N/A N/A

247549 or

247550

1165 psi (80 bar)

0.6 gpm (2.3 lpm)

1137 psi (78 bar)

1.7 gpm (6.4 lpm)

1071 psi (74 bar)

3.6 gpm (13.6 lpm)

1018 psi (70 bar)

4.0 gpm (15.1 lpm)

247551 or

247552

2120 psi (146 bar)

0.8 gpm (3.0 lpm)

2020 psi (139 bar)

1.8 gpm (6.8 lpm)

1803 psi (124 bar)

3.7 gpm (14.0 lpm)

1634 psi (113 bar)

4.8 gpm (18.1 lpm)

247553 or

247554

2829 psi (195 bar)

1.0 gpm (3.8 lpm)

2553 psi (176 bar)

2.0 gpm (7.6 lpm)

2141 psi (148 bar)

4.0 gpm (15.1 lpm)

1811 psi (125 bar)

4.9 gpm (18.5 lpm)

248664 or

248665 206515

3995 psi (275 bar)

1.2 gpm (4.5 lpm)

3515 psi (242 bar)

3.3 gpm (12.5 lpm)

2924 psi (201 bar)

4.1 gpm (15.2 lpm)

2499 psi (172 bar)

5.1 gpm (19.3 lpm)

N/A

N/A

N/A

N/A

750 psi (52 bar)

2.6 gpm (9.8 lpm)

28

Hydra-Clean Wall-Mount Hydra-Clean Cart-Mount Hydra-Clean Drum-Mount

HIGH SANITATION CLEANING PACKAGES

Page 30

Accessories

Hydra-Clean Pressure Washers

Part Number Description

Guns and Wands

15T282 Optional replacement SST spray gun

15T279 32 inch SST wand

15T280 10 inch SST wand

247880 Gun SST quick disconnect connections

Part Number Description

Other

191635 10 mesh inlet strainer with 1 in npt(f) connection

15T272 Quick Coupling

For adding a second hose with gun to the outlet of

the pump

Technical Specifications

Part

Number

247549 12:1 Cart Mount 1250 (86, 8.6) 100 (7, 0.7) 8.7 (33.0) 18.6 (550) 3/4 npt(f) 1 in 3/8 in

Pump

Package

Max. Working

Pressure psi (bar,

MPa)

Max. Air Input

Pressure psi

(bar, MPa)

Fluid Flow at

60 cpm

gpm (lpm)

Vol. per

Cycle

oz (cc)

Air Inlet

Size

Fluid Inlet

Size

Fluid Outlet

Size*

247550 12:1 Wall Mount 1250 (86, 8.6) 100 (7, 0.7) 8.7 (33.0) 18.6 (550) 3/4 npt(f) 1 in 3/8 in

247551 23:1 Cart Mount 2275 (157, 15.7) 100 (7, 0.7) 9.2 (34.7) 19.6 (580) 3/4 npt(f) 1 in 3/8 in

247552 23:1 Wall Mount 2275 (157, 15.7) 100 (7, 0.7) 9.2 (34.7) 19.6 (580) 3/4 npt(f) 1 in 3/8 in

247553 30:1 Cart Mount 3065 (211, 21.1) 100 (7, 0.7) 6.8 (25.9) 14.5 (430) 3/4 npt(f) 1 in 3/8 in

247554 30:1 Wall Mount 3065 (211, 21.1) 100 (7, 0.7) 6.8 (25.9) 14.5 (430) 3/4 npt(f) 1 in 3/8 in

258664 40:1 Cart Mount 4000 (275, 27.5) 100 (7, 0.7) 4.6 (17.4) 9.8 (290) 3/4 npt(f) 1 in 3/8 in

258665 40:1 Wall Mount 4000 (275, 27.5) 100 (7, 0.7) 4.6 (17.4) 9.8 (290) 3/4 npt(f) 1 in 3/8 in

206515 10:1 Drum Mount 1800 (125, 12.5) 180 (12.5, 1.2) 3.0 (11.4) 6.4 (189) 1/2 npt(f) 1/2 in 3/4 in

*Includes two outlet ports per unit. Part number 206515 has only one outlet port.

HIGH SANITATION CLEANING PACKAGES

29

Page 31

Cart Mount Package 247549Wall Mount Package 247550

Hydra-Clean Pressure Washers

Dimensions

Hydra-Clean

17.1 in

(451 mm)

44.3 in

(1125 mm)

30.8 in

(782 mm)

50.0 in

(1270 mm)

17.1 in

(434 mm)

17.1 in

(434 mm)

Refer to manual 312585 for additional package dimensions

5.6 in

(142 mm)

25.7 in

(653 mm)

30

SECTION DESCRIPTIONHIGH SANITATION CLEANING PACKAGES

Page 32

Ordering Information

High Sanitation and Industrial PTFE Overmolded Diaphragm Repair Kits*

Part No. Description

253626 For 1 inch pump size, diaphragm repair kit

253627 For 1.5 inch pump size, diaphragm repair kit

253628 For 2 inch pump size, diaphragm repair kit

*To replace PTFE overmolded diaphragms

High Sanitation and Industrial PTFE Overmolded Diaphragm Upgrade Kits*

Part No. Description

289224 Upgrade kit for 1 inch pump

289225 Upgrade kit for 1.5 inch pump

289226 Upgrade kit for 2 inch pump

*Includes new airside diaphragm plate to upgrade current pump to PTFE overmolded diaphragms.

SaniForce 515 Drum Mount Kit

Part No. Description

262828 Kit, Drum mount SaniForce 515

110954 SaniForce 515 PTFE Seal Kit

SaniForce Accessories

SaniForce Drum Unloader Inflatable Seals

Part No. Description

16G242 FDA Polychloroprene (CR)

16M208 FDA EPDM

High Sanitation and Industrial

Upgrade Kits*

Part No. Description

24N321 Upgrade kit for 0.5 and 0.75 inch pump

289224 Upgrade kit for 1 inch pump (Husky 1040)

24B626 Upgrade kit for 1 inch pump (Husky 1050)

289225 Upgrade kit for 1.5 inch pump

289226 Upgrade kit for 2 inch pump

*Includes new airside diaphragm plate for replacement of standard bolt-through diaphragm.

3A High Sanitation Overmolded EPDM Diaphragm Kit

Part No. Description

255058 For 1.5 inch pump size, diaphragm repair kit

253224 For 2 inch pump size, diaphragm repair kit

Technical Specifications

SaniForce 1040, 1590 & 2150

Pump Repair Kits

Part No. Description

FK1113 For 1 inch pump size, with PTFE o-rings

FK1213 For 1 inch pump size, with EPDM o-rings

FK2113 For 1.5 inch pump size, with PTFE o-rings

FK2213 For 1.5 inch pump size, with EPDM o-rings

FK3113 For 2 inch pump size, with PTFE o-rings

FK3213 For 2 inch pump size, with EPDM o-rings

SaniForce 5:1 Piston Pump Repair Kits

Part No. Description

24W029 Packing kit with PTFE for high temperature fluids

17B449 PTFE seal only for high temperature fluids

Overmolded Diaphragms

Material/Construction on wetted side FDA-Compliant PTFE

Material/Construction on air side FDA-Compliant EPDM

Temperature range 14ºF to 180ºF (-10ºC to 82ºC)

Safety Complies to FDA21CFR 177.1550 (PTFE) and FDA21CFR 177.2600 (EPDM)

ACCESSORIES

31

Page 33

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special,

extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the

equipment determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance

with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco

component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance or structures,

accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the

claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned to

the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be

made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE IN

CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but

not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will

provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or the

furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence

of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite de

ou en rapport, directement ou indirectement, avec les procedures concernées.

Equipment Misuse Hazard

General Misuse: Any misuse of Graco equipment or accessories, such as over-pressurizing, modifying parts, using incompatible chemicals and

fluids, or using worn or damaged parts, can cause them to rupture. Misuse of equipment can result in fluid injection, splashing in the eyes or on

the skin, or other serious bodily injury, or fire, explosion or property damage. NEVER alter or modify any part of Graco equipment; doing so could

cause the product to malfunction. CHECK all equipment regularly and repair or replace worn or damaged parts immediately. Always wear

protective eye wear, gloves, clothing and respirator as recommended by fluid and solvent manufacturers.

System Pressure: Be sure that all equipment and accessories used are rated to withstand the applicable MAXIMUM WORKING PRESSURE.

DO NOT exceed the maximum working pressure of any component or accessory used in a system.

Fluid and Solvent Compatibility: All chemicals used in a Graco sprayer must be compatible with wetted parts. Consult your chemical supplier to

ensure compatibility. Do not use 1:1:1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such