Page 1

Wood Finishing Solutions

A full line of applicators and spray packages for wood applications

Whether you are sealing, painting, staining or adhering,

Graco’s wood finishing equipment will suit your application!

• Designed for superior performance and reliability

• Product solutions for each stage of the wood finishing process

• Deliver material while increasing efficiency and finish quality

Page 2

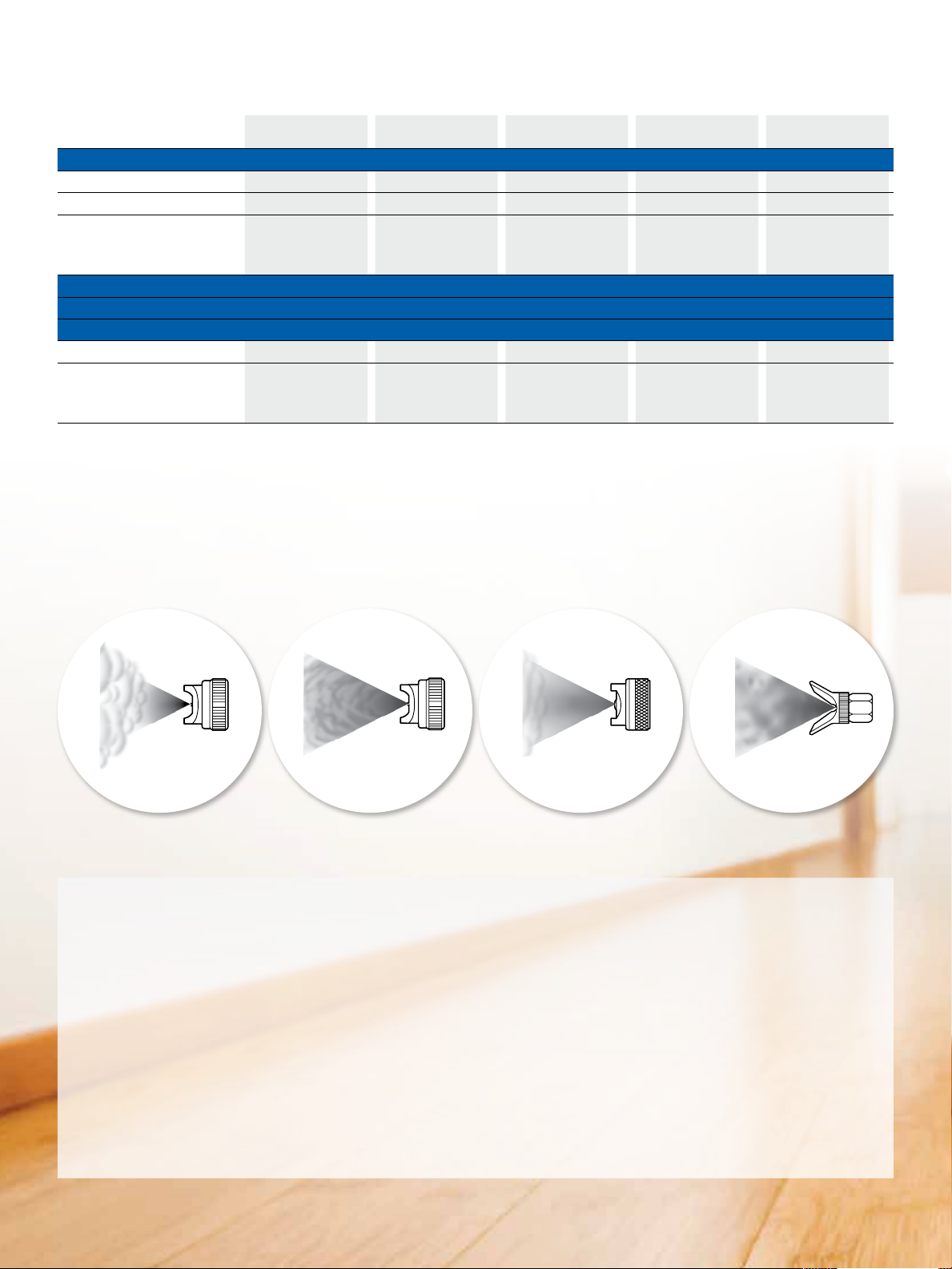

Spray Technologies

Air Spray Compliant HVLP Air-Assisted Airless

Fluids (viscosity) Low to Medium Low to Medium Low to Medium Low to High Medium to High

Finish Quality Class A Decorative Class A Decorative Class A Decorative Decorative Coating Medium to Coarse

Max Spray Rate 20 oz/min 15 oz/min 10 oz/min 35 oz/min > 40 oz/min

Transfer Efficiency*

ASTM D-5009

EN 13966

Typical Fluid Pressure** 5 - 20 psi 5 - 15 psi 4 - 10 psi 300 - 1500 psi 1000 - 2500 psi

Typical Atomizing Pressure** 10 - 60 psi 5 - 35 psi 5 - 30 psi 5 - 30 psi 0 psi

SCFM Requirements*** 13 scfm 11 scfm 15 scfm 4 scfm 0 scfm

Graco Applicator AirPro

Graco Fluid Transfer Technology

* Using ASTM standard - 50% is the maximum transfer efficiency due to conveyor methods of spraying. EN standard sprays on a flat panel.

**Pressure measured at the gun inlet under flow conditions. For best results, use the lowest fluid and air pressure for the job by determining flow rate and viscosity.

*** SCFM requirements are shown for gun only, and are averages. Pump air consumption is approximately 1.5 scfm for diaphragm pumps, and 2-5 scfm for piston pumps.

Note: typical air compressor sizing is 1 HP per 4 scfm.

(test standards)

17 - 25%

60 - 70%

™

Cup Guns

Pressure Pots

®

Triton

25 - 32%

70 - 78%

AirPro AirPro G15 or G40 XTR

Cup Guns

Pressure Pots

Triton

25 - 32%

70 - 78%

Cup Guns

Pressure Pots

Triton

30 - 40%

75 - 85%

Merkur

Merkur ES

®

27 - 35%

70 - 80%

™

Merkur

Merkur ES

SPRAY TECHNOLOGIES

Air Spray

AirPro Spray Pattern

HVLP/Compliant

AirPro Spray Pattern

DEFINITIONS

AIR SPRAY/CONVENTIONAL

The most widely used finishing method. Referred to as an

automotive finish or Class A finish. Easy to use, flexible and

provides the finest finish quality and the lowest transfer efficiency.

COMPLIANT

A controlled air spray technology that reduces bounceback

and overspray. The finish quality is compatible to air spray, air

consumption is lower than HVLP and the spray rates are higher

than HVLP.

HVLP

A controlled, compliant air spray technology that reduces bounceback and overspray. Finish quality is comparable to air spray,

however atomization is generally coarser and spray rates are lower.

AA Series Spray Pattern

Air Assist

Airless

XTR Spray Pattern

AIR ASSIST

Combines the hydraulic atomization of airless with the atomization

of air spray. Ideal for many finishing and coating applications, air

assist offers high production levels and a relatively smooth finish perfect for wood furniture topcoats or fabricated metal parts.

AIRLESS

Directs fluid under high pressure through a controlled orifice to

accomplish airless atomization. Ideal for quickly applying high

volumes of coatings to large surfaces. Most often used to apply

protective, rather than decorative coatings.

Page 3

Stain Applications

NGR and non-dye stains should be applied at low pressures due to the viscosity of the materials. Below are recommendations

for low pressure equipment which will apply material with the consistency required to best enhance the wood’s color.

AirPro Spray Gun

Part #: 289109

• Conventional spray

• Pressure feed

• 0.040” nozzle

Improved transfer efficiency through

reduced air consumption

Ergonomically designed for improved

operator comfort

Available in HVLP (289110) and

compliant (289111)

Finex™ Spray Gun

Part #: 289244

• Conventional spray, gravity feed

• 0.055” nozzle

• Includes 20 oz plastic cup

Superior value air spray gun

™

3M

PPS™ cup compatible

Available in HVLP (289239)

AirPro Spray Gun

Part #: 289011

• Conventional spray, gravity feed

• 0.055” nozzle

• Includes 23 oz plastic cup

Improved transfer efficiency through

reduced air consumption

Ergonomically designed for improved

operator comfort

Available in HVLP (289014) and

compliant (289017)

Mini Finex Spray Gun

Part #: 289259

• HVLP, gravity feed

• 0.047” nozzle

• Includes 4 oz plastic cup

Superior value air spray gun

™

3M

PPS™ cup compatible

Optional glaze nozzle (24F733) available

Triton Air Spray Package

Part #: 289642

• 100 psi fluid and air pressure

• AirPro HVLP spray gun

• Pail mount, stainless steel pump

Double diaphragm design for smooth

changeover and low pulsation

Quick and easy flushing reduces

material waste

Available with conventional (289644) or

compliant (289643) AirPro gun

Aluminum pump available with conventional

(289647), HVLP (289645), or compliant

(289643) AirPro gun

2.5 Gallon Pressure Tank

Part #: 223833

• Aluminum construction

• Up to 50 psi

Dual regulators provide convenient

fluid and air control

Available with single regulator (171226)

Triton Air Spray Package

Part #: 289635

• 100 psi fluid and air pressure

• AirPro HVLP spray gun

• Cart mount, stainless steel pump

Double diaphragm design for smooth

changeover and low pulsation

Quick and easy flushing reduces

material waste

Available with conventional (289637) or

compliant (289636) AirPro gun

Aluminum pump available with conventional

(289640), HVLP (289638) or compliant

(289639) AirPro gun

Pressure Cup

Part #: 239803

• Stainless steel construction

• 1 quart capacity

Dual regulators provide convenient

fluid and air control

Available with single regulator (239802)

Page 4

Top Coat Applications

Top coats and sealers are generally applied with medium pressure equipment due to the mil thickness required for a high quality

finish. Air assisted equipment will deliver optimal flow rates while maximizing transfer efficiency and increasing productivity.

G15 AA Spray Gun

Part #: 24C853

• Air-assisted

• HVLP compliant

• Up to 1500 psi

Enhanced tip design provides uniform

atomization and improved finish quality

Lightweight and low trigger pull for

improved operator comfort

Merkur ES Spray Package

Part #: 24F151

• 15:1 air-assisted pump

• G15 AA gun

• 25 ft hose set

Quick flush pump reduces material and

solvent usage

Wall mount (24F150) and stainless steel

stand (24F159) and wall (24F158) versions

also available

Merkur Spray Package

Part #: G15C09

• 15:1 air-assisted pump, 0.4 gpm

• G15 AA gun

• 25 ft hose set

Pump outlet filter improves material

cleanliness for enhanced spray performance

Easy flush pump lower allows fast color

change and reduced solvent usage

Wall mount version also available (G15W07)

5 Gallon Pail Mount Agitator

Part #: 243340

• Stainless steel agitator

• Stainless steel pail cover

• 1/4 HP air driven motor

Carbon steel 5 gallon pail cover with

stainless agitator also available (226086)

Adhesive Applications

Adhesive applications vary in requirements from a bead of material to a full spray pattern. Low pressure equipment will assist in

delivering the adhesive to the wood.

AirPro Spray Gun

Part #: 288982

• Conventional spray

• Pressure feed

• 0.051” nozzle

Unique aircap designed for spraying

adhesive

Ergonomically designed for improved

operator comfort

All written and visual data contained in this document are based on the latest product information available at the time of publication. Graco reserves the right to make changes at any time without notice.

AirPro Pressure Tank Packages

Part #: 24C828

• AirPro adhesive spray gun

• 2.5 gallon aluminum pressure pot

• 25 foot hose set

Dual regulators provide convenient

fluid and air control

Call today for product information or to request a demonstration.

877.84GRACO (1-877-844 -7226) or visit us at www.graco.com.

©2010 Graco Inc. Form No. 344795 Rev. B 11/10 Printed in the U.S.A.

All other brand names or marks are used for identification purposes and are trademarks of their respective owners.

Loading...

Loading...