Page 1

®

Merkur

High Performance Fine Finish Packages

Page 2

Advanced Technology. Superior Performance.

The new and improved Merkur® packages are designed to outperform and outlast other pumps in their class.

With more models and configurations to choose from, you get the precise pressure and output you need for all

of your finishing applications.

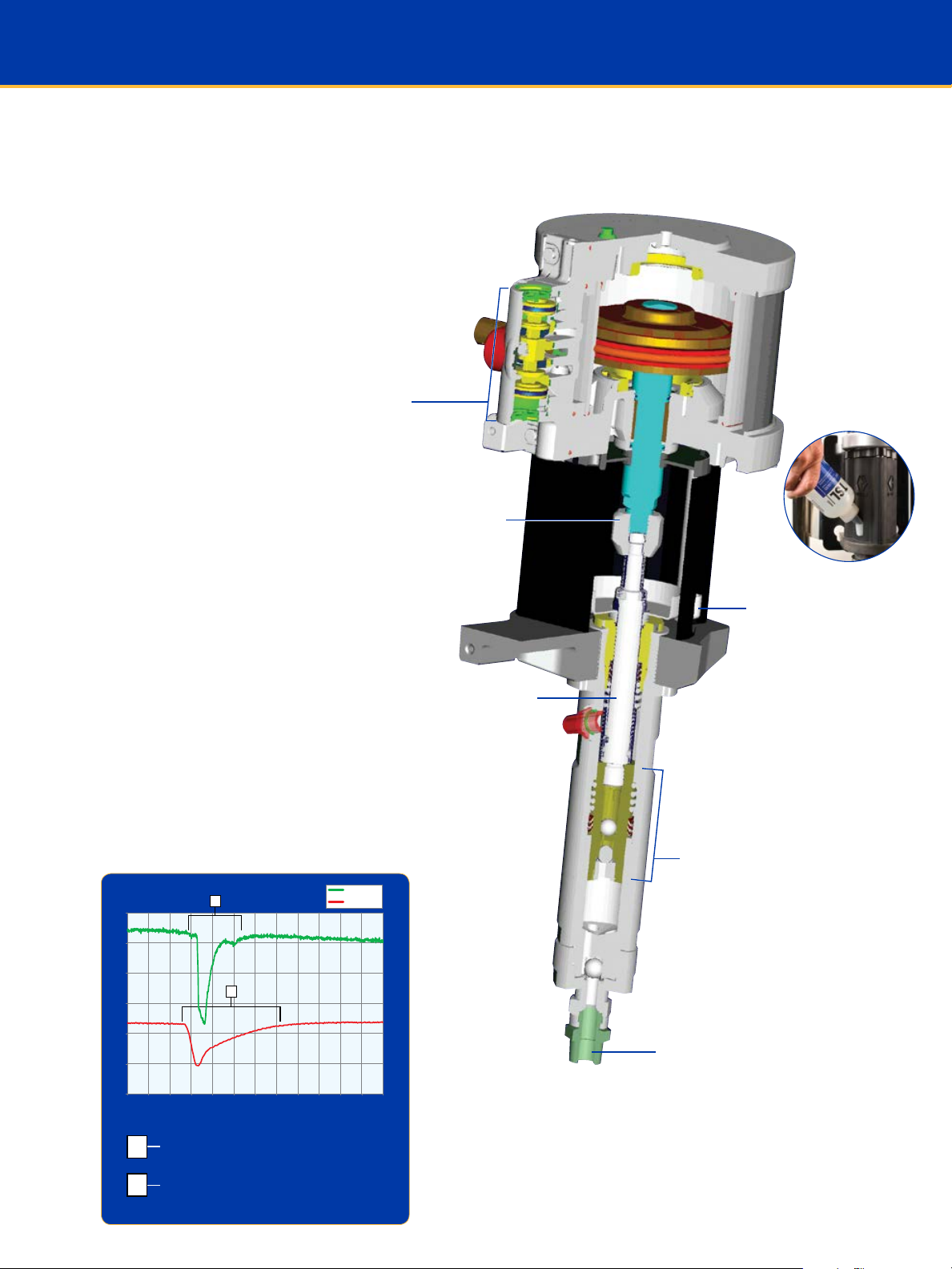

Air Motor

• Highest technology air motor on the market

• Low air consumption for increased efficiency

• Muffler provides low operating noise levels

• External valve access allows for easy

servicing and online replacement to

minimize downtime

Operator Control Panel

• Air controls located at operator height for

easy setting and monitoring

Throat Seal and Rod Enclosure

• Protects pumped material and wet cup from

contamination but can be easily removed to

monitor and service

DataTrak

Monitor and protect your pump with DataTrak*,

the market’s first integrated local monitoring

system!

• Easy to set runaway protection, where you

set the cycle rate limit

• Pump diagnostics help advise when to

maintain the pump

• Resettable batch counter tracks material

usage and maintenance schedule

*Patent pending

™

Page 3

Pump Lower

Time (1/1000 sec)

Merkur

Competitor

1800 2000 2200 2400 2600 2800 3000

M

C

• Easy-to-flush design allows for fast color

changes and reduced solvent usage

• 300 Series stainless steel pump construction

provides long-lasting durability

• Designed for improved serviceability with fewer

parts and lower cost of ownership

Air Valve

Provides smooth

and rapid

changeover

Quick Removal Coupler

Allows for easy disassembly

of the pump lower from

the air motor

Long-Lasting Durability

Throat Seal Liquid (TSL)

Level Indicator

Extended wet cup for

external filling and

monitoring of TSL™ levels

Less Pulsation for Better Results

Merkur is designed to provide a smooth, rapid changeover

for a better, more consistent finish and less user fatigue.

Quick changeover and recovery minimizes

M

pulsation and creates an even film thickness

C

Longer changeover and pressure spike creates

inconsistent finish

Cylinder and Displacement Rod

Designed to handle a broad

range of coatings

Throat and Piston Packings

Self-adjusting and spring-loaded

so no adjustments are needed to

maintain long packing life

360° Inlet Fitting

Makes it easy to access the pail

from almost any location

Page 4

0510 15 20 25 30 35 40 45 50

0.00

0.40

(1.5)

0.80

(3.0)

1.20

(4.5)

1.60

(6.0)

2.00

(7.5)

2.40

(9.0)

2.80

(10.5)

Pressure Ratio

Merkur Pump

Fluid Flow at 60 cpm in gpm (lpm)

The right flows at the right pressures to fit all of your

spraying needs.

With four air motor sizes and 13 different models to choose from, Merkur fine finish packages are designed

to improve productivity, reduce costs, lower emissions and provide consistent, high quality finishes for all

of your demanding applications.

•

Merkur

10:1

•

•

•

Merkur

15:1

•

Merkur

15:1

Merkur

15:1

Merkur

18:1

•

Merkur

•

24:1

Merkur

23:1

•

Merkur

28:1

Merkur

•

30:1

Merkur

•

30:1

•

Merkur

36:1

•

•

Merkur

45:1

Merkur

48:1

Page 5

Making the Right Choice for your Application

Combine a Merkur pump with a variety of guns and accessories, and you’ll be on your way

to selecting the package that’s right for you!

Select a Spray Technology

Air-Assist Gun

Select a Mounting Configuration

G15™/G40™

XTR™

Airless Gun

Pro Xp™

Air-Assist Electrostatic

Cart Mount Wall Mount Stand Mount

Determine the Accessories that are right for you!

Suction Hose

Hopper Heater Filter

Page 6

Ordering Information

Air-Assist Packages

Merkur

Assembly

Part No.

Merkur 10:1 1.2 gpm (4.5 lpm)

G10W05 10 1.2 (4.5) • • •

G10W06 10 1.2 (4.5) • • • •

G10W07 10 1.2 (4.5) • • • •

G10W08 10 1.2 (4.5) • • • • •

G10C07 10 1.2 (4.5) • • •

G10C08 10 1.2 (4.5) • • • •

G10C09 10 1.2 (4.5)) • • • •

G10C10 10 1.2 (4.5) • • • • •

G10C11 10 1.2 (4.5) • • •

G10C13 10 1.2 (4.5) • • • •

Merkur 15:1 0.4 gpm (1.5 lpm)

G15W05 15 0.4 (1.5) • • •

G15W06 15 0.4 (1.5) • • • •

G15W07 15 0.4 (1.5) • • • •

G15W08 15 0.4 (1.5) • • • • •

G15C07 15 0.4 (1.5) • • •

G15C08 15 0.4 (1.5) • • • •

G15C09 15 0.4 (1.5) • • • •

G15C10 15 0.4 (1.5) • • • • •

G15C11 15 0.4 (1.5) • • •

G15C12 15 0.4 (1.5) • • • •

G15C13 15 0.4 (1.5) • • • •

G15C14 15 0.4 (1.5) • • • • •

G15T03 15 0.4 (1.5) • • •

G15T04 15 0.4 (1.5) • • • •

G15T05 15 0.4 (1.5) • • •

Pump Ratio

Flow Rate at

60 cpm gpm (lpm)

Wall Mount

Cart Mount

Stand Mount

DataTrak

DataTrak - Cycle Count Only

G15 Gun

Carbide Seat

Fluid Filter

Suction Hose

Hopper (1.5 gal)

Merkur 15:1 0.8 gpm (3.0 lpm)

G15W25 15 0.8 (3.0) • • •

G15W26 15 0.8 (3.0) • • • •

G15W27 15 0.8 (3.0) • • • •

G15W28 15 0.8 (3.0) • • • • •

G15C27 15 0.8 (3.0) • • •

G15C28 15 0.8 (3.0) • • • •

G15C29 15 0.8 (3.0) • • • •

G15C30 15 0.8 (3.0) • • • • •

G15C31 15 0.8 (3.0) • • •

G15C33 15 0.8 (3.0) • • • •

G15T13 15 0.8 (3.0) • • •

G15T14 15 0.8 (3.0) • • • •

G15T15 15 0.8 (3.0) • • •

Merkur 15:1 2.4 gpm (9.0 lpm)

G15W55 15 2.4 (9.0) • • • •

G15W56 15 2.4 (9.0) • • • • •

G15C83 15 2.4 (9.0) • • • •

G15C84 15 2.4 (9.0) • • • • •

*All packages have a 25 ft (7.5 m) fluid and air hose

Air-Assist Cart Package

Page 7

Air-Assist Packages

Merkur

Assembly

Part No.

Merkur 18:1 2.0 gpm (7.5 lpm)

G18W07 18 2.0 (7.5) • • • •

G18W08 18 2.0 (7.5) • • • • •

G18W09 18 2.0 (7.5) • • • •

G18W10 18 2.0 (7.5) • • • • •

G18C05 18 2.0 (7.5) • • • •

G18C06 18 2.0 (7.5) • • • • •

G18C07 18 2.0 (7.5) • • • •

G18C08 18 2.0 (7.5) • • • • •

Merkur 23:1 1.6 gpm (6.0 lpm)

G23W09 23 1.6 (6.0) • • • •

G23W10 23 1.6 (6.0) • • • • •

G23W11 23 1.6 (6.0) • • • •

G23W12 23 1.6 (6.0) • • • • •

G23C07 23 1.6 (6.0) • • •

G23C11 23 1.6 (6.0) • • • •

G23C09 23 1.6 (6.0) • • • •

G23C12 23 1.6 (6.0) • • • • •

G23C13 23 1.6 (6.0) • • • •

G23C14 23 1.6 (6.0) • • • • •

Pump Ratio

Flow Rate at

60 cpm gpm (lpm)

Wall Mount

Cart Mount

DataTrak

G40 Gun

G40 RAC Gun

Fluid Filter

Suction Hose

Hopper

Heated Package

Ordering Information

Heater Voltage

Merkur 24:1 2.4 gpm (9.0 lpm)

G24W07 24 2.4 (9.0) • • • •

G24W08 24 2.4 (9.0) • • • • •

G24W09 24 2.4 (9.0) • • • •

G24W10 24 2.4 (9.0) • • • • •

G24C09 24 2.4 (9.0) • • • •

G24C10 24 2.4 (9.0) • • • • •

G24C11 24 2.4 (9.0) • • • •

G24C12 24 2.4 (9.0) • • • • •

Merkur 28:1 2.0 gpm (7.5 lpm)

G28W11 28 2.0 (7.5) • • • •

G28W12 28 2.0 (7.5) • • • • •

G28W13 28 2.0 (7.5) • • • •

G28W14 28 2.0 (7.5) • • • • •

G28W17 28 2.0 (7.5) • • • • • 120

G28W18 28 2.0 (7.5) • • • • • • 120

G28C09 28 2.0 (7.5) • • • •

G28C10 28 2.0 (7.5) • • • • •

G28C11 28 2.0 (7.5) • • • •

G28C12 28 2.0 (7.5) • • • • •

G28C15 28 2.0 (7.5) • • • • • 120

G28C16 28 2.0 (7.5) • • • • • • 120

*All packages have a 25 ft (7.5 m) fluid and air hose

Air-Assist Cart Package

Page 8

Ordering Information

Air-Assist Packages

Merkur

Assembly

Part No.

Merkur 30:1 0.4 gpm (1.5 lpm)

G30W13 30 0.4 (1.5) • • •

G30W14 30 0.4 (1.5) • • • •

G30W15 30 0.4 (1.5) • • • •

G30W16 30 0.4 (1.5) • • • • •

G30W17 30 0.4 (1.5) • • • •

G30W18 30 0.4 (1.5) • • • • •

G30C21 30 0.4 (1.5) • • •

G30C22 30 0.4 (1.5) • • • •

G30C23 30 0.4 (1.5) • • •

G30C27 30 0.4 (1.5) • • • •

G30C25 30 0.4 (1.5) • • • •

G30C26 30 0.4 (1.5) • • • • •

G30C29 30 0.4 (1.5) • • •

G30C30 30 0.4 (1.5) • • • •

G30C31 30 0.4 (1.5) • • •

G30C35 30 0.4 (1.5) • • • •

G30C33 30 0.4 (1.5) • • • •

G30C34 30 0.4 (1.5) • • • • •

G30T03 30 0.4 (1.5) • • •

G30T04 30 0.4 (1.5) • • • •

G30T05 30 0.4 (1.5) • • • •

G30T06 30 0.4 (1.5) • • • • •

G30T09 30 0.4 (1.5) • • •

G30T07 30 0.4 (1.5) • • •

G30T08 30 0.4 (1.5) • • • •

G30T11 30 0.4 (1.5) • • • •

G30T12 30 0.4 (1.5) • • • • •

Pump Ratio

Flow Rate at

60 cpm gpm (lpm)

Wall Mount

Cart Mount

Stand Mount

DataTrak

G40 Gun

G40 RAC Gun

Fluid Filter

Suction Hose

Hopper (1.5 gal)

Heated Package

Heater Voltage

Airless Wall Mount Package

Merkur 30:1 1.2 gpm (4.5 lpm)

G30W73 30 1.2 (4.5) • • • •

G30W74 30 1.2 (4.5) • • • • •

G30W75 30 1.2 (4.5) • • • •

G30W76 30 1.2 (4.5) • • • • •

G30W79 30 1.2 (4.5) • • • • • 120

G30W80 30 1.2 (4.5) • • • • • • 120

G30C65 30 1.2 (4.5) • • •

G30C67 30 1.2 (4.5) • • • •

G30C68 30 1.2 (4.5) • • • • •

G30C71 30 1.2 (4.5) • • •

G30C73 30 1.2 (4.5) • • • •

G30C74 30 1.2 (4.5) • • • • •

G30C77 30 1.2 (4.5) • • • • • 120

G30C78 30 1.2 (4.5) • • • • • • 120

Merkur 36:1 1.6 gpm (6.0 lpm)

G36W13 36 1.6 (6.0) • • • •

G36W14 36 1.6 (6.0) • • • • •

G36W15 36 1.6 (6.0) • • • •

G36W16 36 1.6 (6.0) • • • • •

G36C09 36 1.6 (6.0) • • • •

G36C10 36 1.6 (6.0) • • • • •

G36C11 36 1.6 (6.0) • • • •

G36C12 36 1.6 (6.0) • • • • •

*All packages have a 25 ft (7.5 m) fluid and air hose

Air-Assist Stand Package

Page 9

Ordering Information

Air-Assist Packages

Merkur

Assembly

Part No.

Merkur 45:1 0.8 gpm (3.0 lpm)

G45W13 45 0.8 (3.0) • • • •

G45W14 45 0.8 (3.0) • • • • •

G45W15 45 0.8 (3.0) • • • •

G45W16 45 0.8 (3.0) • • • • •

G45C15 45 0.8 (3.0) • • • •

G45C16 45 0.8 (3.0) • • • • •

G45C17 45 0.8 (3.0) • • • •

G45C18 45 0.8 (3.0) • • • • •

Merkur 48:1 1.2 gpm (4.5 lpm)

G48W13 48 1.2 (4.5) • • • •

G48W14 48 1.2 (4.5) • • • • •

G48W15 48 1.2 (4.5) • • • •

G48W16 48 1.2 (4.5) • • • • •

G48C11 48 1.2 (4.5) • • • •

G48C12 48 1.2 (4.5) • • • • •

G48C13 48 1.2 (4.5) • • • •

G48C14 48 1.2 (4.5) • • • • •

*All packages have a 25 ft (7.5 m) fluid and air hose

Pump Ratio

Flow Rate at

60 cpm gpm (lpm)

Wall Mount

Cart Mount

DataTrak

G40 Gun

G40 RAC Gun

Fluid Filter

Airless Packages

Merkur

Assembly

Suction Hose

Part No.

Merkur 23:1 1.6 gpm (6.0 lpm)

G23W07 23 1.6 (6.0) • • • •

G23W08 23 1.6 (6.0) • • • • •

G23C03 23 1.6 (6.0) • • • •

G23C04 23 1.6 (6.0) • • • • •

Merkur 24:1 2.4 gpm (9.0 lpm)

G24W05 24 2.4 (9.0) • • • •

G24W06 24 2.4 (9.0) • • • • •

G24C03 24 2.4 (9.0) • • • •

G24C04 24 2.4 (9.0) • • • • •

Merkur 28:1 2.0 gpm (7.5 lpm)

G28W05 28 2.0 (7.5) • • • •

G28W06 28 2.0 (7.5) • • • • •

G28W07 28 2.0 (7.5) • • • • • 120

G28W08 28 2.0 (7.5) • • • • • • 120

G28C03 28 2.0 (7.5) • • • •

G28C04 28 2.0 (7.5) • • • • •

G28C05 28 2.0 (7.5) • • • • • 120

G28C06 28 2.0 (7.5) • • • • • • 120

Pump Ratio

Flow Rate at

60 cpm gpm (lpm)

Wall Mount

Cart Mount

DataTrak

XTR Gun

Fluid Filter

Suction Hose

Hopper

Heated Package

Heater Voltage

Merkur 30:1 0.4 gpm (1.5 lpm)

G30W07 30 0.4 (1.5) • • • •

G30W08 30 0.4 (1.5) • • • • •

G30C07 30 0.4 (1.5) • • •

G30C08 30 0.4 (1.5) • • • •

G30C09 30 0.4 (1.5) • • • •

G30C10 30 0.4 (1.5) • • • • •

G30C11 30 0.4 (1.5) • • •

G30C15 30 0.4 (1.5) • • • •

Merkur 30:1 1.2 gpm (4.5 lpm)

G30W57 30 1.2 (4.5) • • •

G30W58 30 1.2 (4.5) • • • •

G30W59 30 1.2 (4.5) • • • •

G30W60 30 1.2 (4.5) • • • • •

G30W67 30 1.2 (4.5) • • • • • 120

G30W68 30 1.2 (4.5) • • • • • • 120

G30C55 30 1.2 (4.5) • • • •

G30C56 30 1.2 (4.5) • • • • •

G30C59 30 1.2 (4.5) • • • • • 120

G30C60 30 1.2 (4.5) • • • • • • 120

*All packages have a 25 ft (7.5 m) fluid hose

Heated Air-Assist Cart Package

Page 10

Ordering Information

Electrostatic Packages Spray Guns

All electrostatic packages include a Pro Xp Air Assist

electrostatic gun, suction hose and fluid filter

Merkur

Assembly

Part No.

Merkur 15:1 2.4 gpm (9.0 lpm)

G15W57 15 2.4 (9.0) • •

G15W58 15 2.4 (9.0) • • •

G15C85 15 2.4 (9.0) • •

G15C86 15 2.4 (9.0) • • •

Merkur 18:1 2.0 gpm (7.5 lpm)

G18W11 18 2.0 (7.5) • •

G18W12 18 2.0 (7.5) • • •

G18W13 28 2.0 (7.5) • • 120 •

G18W14 28 2.0 (7.5) • • • 120 •

G18C09 18 2.0 (7.5) • •

G18C10 18 2.0 (7.5) • • •

Merkur 23:1 1.6 gpm (6.0 lpm)

G23W13 23 1.6 (6.0) • •

G23W14 23 1.6 (6.0) • • •

G23C15 23 1.6 (6.0) • •

G23C16 23 1.6 (6.0) • • •

Pump Ratio

Flow Rate at 60 cpm

gpm (lpm)

Wall Mount

DataTrak

Cart Mount

Heated Package

Heater Voltage

Pro Xp85 kV Smart

Pro Xp85 kV Standard

Pro Xp60 kV Standard

Refer to the spray gun brochure for additional model numbers.

All guns include tip of choice.

24C853 G15 Carbide Air-Assist Spray Gun

24C855 G40 Air-Assist Spray Gun

24C857 G40 RAC Air-Assist Spray Gun

XTR504 XTR-5 Airless Spray Gun

H85M10 Pro Xp85 AA Smart Electrostatic Spray Gun

H85T10 Pro Xp85 AA Standard Electrostatic Spray Gun

H60T10 Pro Xp60 AA Standard Electrostatic Spray Gun

Accessories

256410 Hopper

1.5 gal (5 l) polyethylene

243340 Pail Cover with Agitator

Use to agitate material in a 5 gal (18.9 l) pail

222121 Fluid Regulator, Stainless Steel

Maximum working pressure: 1500 psi (103 bar, 10.3 MPa)

Regulator range: 150-1200 psi (10-28 bar, 1-8.2 MPa)

24A587 Pump Outlet Fluid Filter, Stainless Steel

60 mesh (250 micron), 5000 psi (350 bar, 25 MPa)

256425 Fluid Filter Drain Valve, Stainless Steel

5000 psi (350 bar, 35 MPa)

224458 Replacement Filter Screen Element

3-pack elements, 30 mesh, SST

224459 Replacement Filter Screen Element

3-pack elements, 60 mesh, SST

24A540 Air Control Gauge Covers

5 sheets of 10 covers

24B187 Second AA Gun Kit

Includes air regulator and gauge

Merkur 24:1 2.4 gpm (9.0 lpm)

G24W11 24 2.4 (9.0) • •

G24W12 24 2.4 (9.0) • • •

G24C13 24 2.4 (9.0) • •

G24C14 24 2.4 (9.0) • • •

Merkur 28:1 2.0 gpm (7.5 lpm)

G28W15 28 2.0 (7.5) • •

G28W16 28 2.0 (7.5) • • •

G28W21 28 2.0 (7.5) • • 120 •

G28W22 28 2.0 (7.5) • • • 120 •

G28C13 28 2.0 (7.5) • •

G28C14 28 2.0 (7.5) • • •

G28C19 28 2.0 (7.5) • • 120 •

G28C20 28 2.0 (7.5) • • • 120 •

G28C23 28 2.0 (7.5) • •

G28C25 28 2.0 (7.5) • •

Merkur 30:1 1.2 gpm (4.5 lpm)

G30W77 30 1.2 (4.5) • •

G30W78 30 1.2 (4.5) • • •

G30W83 30 1.2 (4.5) • • 120 •

G30W84 30 1.2 (4.5) • • • 120 •

G30C75 30 1.2 (4.5) • •

G30C76 30 1.2 (4.5) • • •

G30C81 30 1.2 (4.5) • • 120 •

G30C82 30 1.2 (4.5) • • • 120 •

G30C87 30 1.2 (4.5) • •

G30C89 30 1.2 (4.5) • •

*All packages have a 25 ft (7.5 m) grounded electrostatic fluid and air hose

DataTrak

24A575 Upgrade Kit for 200 cc and 400 cc Air Motors

24A576 Upgrade Kit for 1200 cc and 1800 cc Air Motors

24A592 Upgrade Kit for DataTrak with Cycle Count Only

Suction Hoses

24A954 55 gal (208 l) Drum Suction Hose and Strainer, 3/4 in fluid inlet

24B598 55 gal (208 l) Drum Suction Hose and Strainer, 1 in fluid inlet

24B337 PTFE Lined Suction Hose for Cart Mount Pump, 3/4 in inlet

24B338 PTFE Lined Suction Hose for Cart Mount Pump, 1 in inlet

24J315 PTFE Lined Suction Hose for Wall Mount Pumps, 1/2 in inlet

24B424 PTFE Lined Suction Hose for Wall Mount Pump, 3/4 in inlet

24B425 PTFE Lined Suction Hose for Wall Mount Pump, 1 in inlet

Gun Hoses

256390 25 ft (7.5 m) Air Hose

241812 25 ft (7.5 m) Fluid Hose

3300 psig (228 bar)

24A955 50 ft (15.2 m) Bundled Air and Fluid Hose

3300 psig (228 bar)

256389 50 ft (15.2 m) Air Hose

24B562 50 ft (15.2 m) Fluid Hose

3300 psig (228 bar)

24A588 Hose Clips

Pack of 10

Page 11

Merkur Technical Specifications

Technical Specifications

Pump Ratio

Fluid Flow @ 60 cpm

Pump Volume per Cycle

Maximum Fluid Outlet Pressure

Maximum Air Inlet Pressure

Air Motor Displacement

(cc per stroke)

Air Consumption @ 100 psi

(7 bar, 0.7 MPa) @ 20 cpm

Fluid Inlet Size

Fluid Outlet Size

Air Inlet (motor)

Pump Ratio

Fluid Flow @ 60 cpm

Volume per Cycle

Maximum Fluid Outlet Pressure

Maximum Air Inlet Pressure

Air Motor Displacement

(cc per stroke)

Air Consumption @ 100 psi

(7 bar, 0.7 MPa) @ 20 cpm

Fluid Inlet Size

Fluid Outlet Size

Air Inlet (motor)

Merkur

10:1

1.2 gpm

(4.5 lpm)

2.5 oz

(75 cc)

1000 psi

(69 bar)

100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar)

400 cc 200 cc 400 cc 1200 cc 1200 cc 1200 cc 1800 cc

6 scfm

(0.17 m3/min)

3/4 npt(m) 1/2 npt(m) 3/4 npt(m) 1 npt(m) 1 npt(m) 3/4 npt(m) 1 npt(m)

3/8 npt(m) 3/8 npt(m) 3/8 npt(m) 3/4 npt(m) 1/2 npt(m) 3/8 npt(m) 3/4 npt(m)

1/4 npt(f) 1/4 npt(f) 1/4 npt(f) 1/2 npt(f) 1/2 npt(f) 1/2 npt(f) 1/2 npt(f)

Merkur

28:1

2.0 gpm

(7.5 lpm)

4.2 oz

(125 cc)

2800 psi

(192 bar)

100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar) 100 psi (7 bar) 90 psi (6.2 bar) 85 psi (5.8 bar)

1800 cc 400 cc 1200 cc 1800 cc 1200 cc 1800 cc

26 scfm

(0.74 m3/min)

1 npt(m) 1/2 npt(m) 3/4 npt(m) 3/4 npt(m) 3/4 npt(m) 3/4 npt(m)

1/2 npt(m) 3/8 npt(m) 3/8 npt(m) 3/8 npt(m) 3/8 npt(m) 3/8 npt(m)

1/2 npt(f) 1/4 npt(f) 1/2 npt(f) 1/2 npt(f) 1/2 npt(f) 1/2 npt(f)

Merkur

15:1

0.4 gpm

(1.5 lpm)

0.8 oz

(25 cc)

1500 psi

(103 bar)

3 scfm

(0.08 m3/min)

Merkur

30:1

0.4 gpm

(1.5 lpm)

0.8 oz

(25 cc)

3000 psi

(206 bar)

6 scfm

(0.17 m3/min)

Merkur

15:1

0.8 gpm

(3.0 lpm)

1.7 oz

(50 cc)

1500 psi

(103 bar)

6 scfm

(0.17 m3/min)

Merkur

30:1

1.2 gpm

(4.5 lpm)

2.5 oz

(75 cc)

3000 psi

(206 bar)

17 scfm

(0.48 m3/min)

Merkur

15:1

2.4 gpm

(9.0 lpm)

5 oz

(150 cc)

1500 psi

(103 bar)

17 scfm

(0.48 m3/min)

Merkur

36:1

1.6 gpm

(6.0 lpm)

3.4 oz

(100 cc)

3600 psi

(248 bar)

26 scfm

(0.74 m3/min)

Merkur

18:1

2.0 gpm

(7.5 lpm)

4.2 oz

(125 cc)

1800 psi

(124 bar)

17 scfm

(0.48 m3/min)

Merkur

45:1

0.8 gpm

(3.0 lpm)

1.7 oz

(50 cc)

4000 psi

(275 bar)

17 scfm

(0.48 m3/min)

Merkur

23:1

1.6 gpm

(6.0 lpm)

3.4 oz

(100 cc)

2300 psi

(158 bar)

17 scfm

(0.48 m3/min)

Merkur

48:1

1.2 gpm

(4.5 lpm)

2.5 oz

(75 cc)

4000 psi

(275 bar)

26 scfm

(0.74 m3/min)

Merkur

24:1

2.4 gpm

(9.0 lpm)

5 oz

(150 cc)

2400 psi

(165 bar)

26 scfm

(0.74 m3/min)

Instruction and Parts Manuals

312797 Merkur AA and Airless Spray Package

312798 Merkur Electrostatic Spray Package

313255 Merkur AA and Airless Heated Package

312794 Merkur Pumps

312792 Merkur Displacement Lower

312796 Merkur Air Motor

Page 12

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9468 8500

Fax: 61 3 9468 8599

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Room 118 1st Floor

No.2 Xin Yuan Building

No.509 Cao Bao Road

Shanghai, 200233

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 432, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2007-2013 Graco Inc. 340004 Rev. F 12/13 All written and visual data contained in this document are based on the latest product information available at the

time of publication. Graco reserves the right to make changes at any time without notice. All other brand names or marks are used for identification purposes

and are trademarks of their respective owners.

Loading...

Loading...