Page 1

ProMix® 2KS and 3KS

Two- and Three-Component Electronic Proportioning System

Page 2

Increase Efficiency

and Productivity!

Graco’s Electronic Proportioners

ProMix® 2KS offers precise and reliable electronic

proportioning for a broad range of solventborne,

waterborne and acid catalyzed materials.

From entry level to upgraded applications, the

ProMix 2KS provides flexibility and increased

efficiency – including optimized flushing

sequences and an optional third purge

valve to properly manage waterborne

urethanes for manual and automatic operation.

Upgrade to ProMix 3KS

ProMix 3KS offers precision mixing of three

component materials and accurately reduces

your material to the correct spray viscosity as

conditions change.

ProMix 2KS Features

• Manual and automatic configurations

• Intrinsically safe fluid panels allow for integration into

hazardous areas*

• Single or multi-color and catalysts

• Accurate ratio assurance for superior finish quality

• Simple programming allows fast set up and efficient

process control

• Advanced web interface provides consolidated

system management and reporting

Key Materials

• Solventborne epoxies and polyurethanes

• Waterborne epoxies and polyurethanes

• Acid catalyzed materials

Why Electronic Proportioning?

• Offers the highest degree of ratio assurance

• Provides critical process variable feedback

• Built-in system safeguards

• Effective color change solution

• Efficient material tracking and reporting

2

*All accessories and installations need to meet local, state and national codes

Page 3

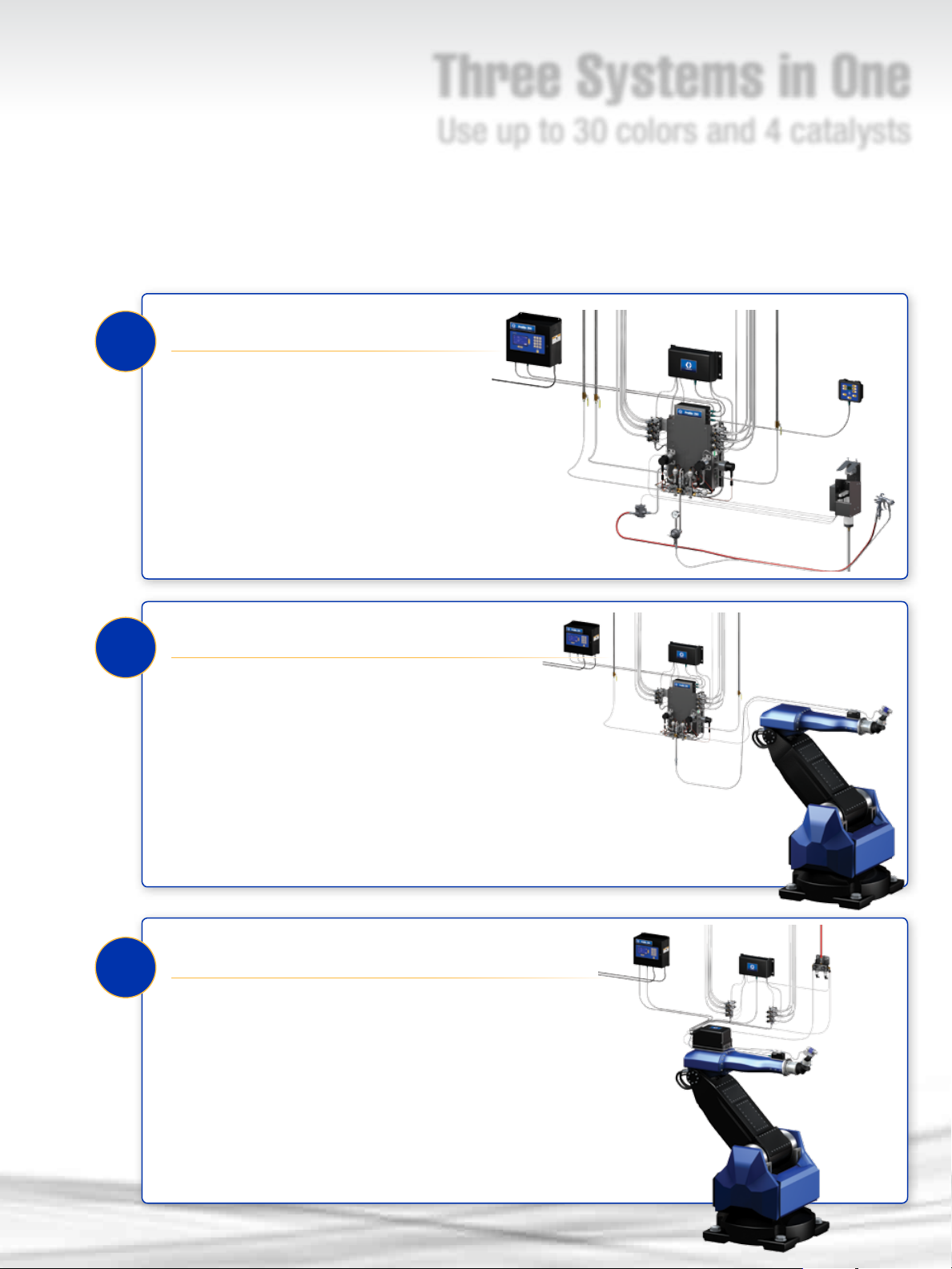

Three Systems in One

Use up to 30 colors and 4 catalysts

ProMix 2KS is available in a variety of system level configurations. Each one includes an EasyKey™ display

along with a Smart Fluid Panel. Color and catalyst change is easily integrated with a plug-and-play control

module and valves.

1

2

Manual Wall Panel

Manual systems benefit from an additional

Remote Operator Station that allows fingertip

control inside the spray booth.

Automatic Wall Panel

Optional flow control is cleanly integrated without incorporating

a mixed material line meter. Pressure and flow loops provide

fast step changes with superior closed loop control.

3

Automatic RoboMix Panel

This fluid panel can be easily integrated near the spray

gun for a shorter mixed material line, faster color changes

and less waste. Also available with flow control.

3

Page 4

3-20-2008

FP1

Simple & Efficient Operation

High-ratio assurance with easy-to-use components

EasyKey Display

Graco’s EasyKey user interface offers

simple navigation, multiple language

capabilities and a high degree of reliability.

The large LCD display screen is easy to

1

1.0:1

0.00:1

Standby

0 min

A

B

9:43

1

4

FP1

read and operate during machine set up

and process monitoring.

The independent touch pad keeps

contaminants off the screen while the

large keys allow for clear data entry.

Large

Display

LCD

Left/Right

Screen Toggle

Up/Down

Screen

Toggle

Password

Protected

System Set-Up

Remote Operator Station

Detachable

Wall Bracket

Recipe and Alarm

Code Indicator

Alarm Clear

Job Complete

Enclosure

Access Key Lock

Recipe

Select

Enter

Independent

Keypad

The remote operator station can be

mounted inside the spray booth or near

the operator for quicker response times.

The station offers easy-to-use controls for

mixing, standby, purging, reading/clearing

alarms, inputting job complete and recipe

select functions.

Mix PurgeStandby

4

Page 5

Unmatched Functionality

Wall & RoboMix Fluid Panel Features

Productive Panels

Intrinsically safe fluid panels offer increased proportioning and flushing functionality, resulting in improved process performance.

Versatile Dosing

Multiple sequential dose sizes allow the system to meet a broad range of applications without sacrificing performance and quality.

Dynamic dosing provides additional proportioning technology to meet unique applications needs.

On-Ratio Performance

Volume based dosing provides exceptional ratio accuracy across varying flow rates or gun triggering conditions. On-the-fly

monitoring and compensation enhance performance and finish quality.

Consistent Mix Quality

Optimized mix chamber hardware, along with high-speed processors and dispense valves, generate precise performance and

consistent, high quality mixed material.

Fast Color Change with Reduced Waste

New fluid manifold design reduces material volume and streamlines fluid porting for cleaner flushing. Manifold dump valves allow

simultaneous purging and loading – reducing color change time and providing better waste containment.

• Up to 50:1 mix ratio for a variety of applications

• Up to 4000 psi (275.6 bar) working pressure for single

color and catalyst, supports all spray technologies

• Supports two manual spray guns and gun flush boxes

RoboMixWall Panel

• Up to 50:1 mix ratio for a variety of applications

• Up to 250 psi (17.2 bar) working pressure

• Lightweight, compact design allows easier

integration closer to the spray gun

• Can be interfaced with manual spray guns

5

Page 6

Fluid Manifold

50 cc Integrator 10 cc Integrator Dynamic Dosing

4

11

2

1

Dispense Valves

Remove high speed

cartridge style valves

without disconnecting fluid

lines for easier serviceability.

2

Manifold Flush Valves

Flush mixed material without

wasting premixed resin and

catalyst. Add a third valve to

the resin side for enhanced

flushing, especially with

waterborne materials.

5

2

3

3

4

Integration Chamber

(25 cc shown)

Accommodate a wide range of

hardware to support multiple

dose size options. Optimizes

fluid manifold for particular

application needs.

3 5

Shutoff and Sample Valves

Ensure accurate volume measurements

for meter calibrations and ratio checks

with positive shutoff and

convenient sampling.

Fluid Porting

Compact, low volume design

with no material dead spots,

provide faster flushing time

and less waste.

6

Page 7

Expanded Options

Complete Your System!

Today’s demanding applications require more than just precise and reliable proportioning from a ProMix 2KS.

Graco offers a variety of flow meter technologies and accessories that will enhance your finishing operation.

Flow Meters

• Complete line of spur gear, helical gear, and non-intrusive

Coriolis meters

• Supports a broad range of material types and

physical characteristics

G3000 meter

Coriolis meter

Intrinsically Safe Color and

Catalyst Change Module

• Provides easy and flexible installation without running

long pneumatic lines

• Accommodates future color and catalyst needs with

upgradable module

Gun Flush Box

• Automated flushing system for manual spray guns

• Eliminates manual gun triggering for more accurate

flushing and filling, and less waste

Gun Flush Box

Integrated Flow Control

• Eliminates a long pneumatic control line and

associated lag with intrinsically safe control module

• Produces quick responses and superior process control

with on-board electronics and control hardware

• Provides accurate and consistent flow control for

increased material savings

Color Change Module

Low Pressure Color Stack

Advanced Web Interface

• Perform quick and easy system configuration and recipe set up

• Offers convenient process monitoring and streamlines data

gathering and reporting

• Manages operations more efficiently by networking multiple

ProMix 2KS systems to a single PC

Communication Gateway

• Provides network integration for automatic systems

• Offers integration flexibility with multiple protocol capabilities

• Reduces installation time with quick plug-and-play set up

Integrated

Fluid Regulator Module

Advanced Web Interface screen shot

Fluid Regulator Module

External

7

Page 8

Upgrade to ProMix 3KS

Precision Mixing of Three-Component Materials

• Manual or automatic operation

• Up to 25 colors, 4 catalysts, and 4 reducers in modular color change system

• Intrinsically safe fluid panel for operation in hazardous areas*

• Optimized flushing sequences including third flush option

*All accessories and installations need to meet local, state and national codes

ProMix 3KS Example System

Step 1: Identify

Specify your base system.

Step 2: Upgrade!

Choose the ProMix 3KS Module to fit your system.

T

Three

T K Meter Color Valves 0 0

T K 0 = No Meter 0 = No Valves (single color) 0 0

K

Component

X

X

Meter

1 = G3000 1 = 2 Color LP

2 = G3000 HR 2 = 4 Color LP

3 = 1/4” Coriolis 3 = 2 Color HP

4 = S3000 4 = 4 Color HP

Color

Valves

0

0

0

0

ProMix 3KS Technical Specifications ProMix 3KS Accessories

Mix Ratio Range*

Sequential Dosing................................ 1st stage: 0.1:1 to 50:1

2nd stage: 0.1:1 to 50:1

Dynamic Dosing .................................. 1st stage: 0.1:1 to 30:1

2nd stage: 0.1:1 to 30:1

Ratio Accuracy ......................................... up to + 1% minimum (user selectable)

External Power Supply Requirements ...... 85-250Vac, 50/60 Hz. 2 amps max draw,

15 amp circuit breaker required,

8 to 14 AWG power supply wire gauge

Operating Temperature Range ................. 41 to 122°F (5 to 50°C)

Noise Level

Sound pressure level ........................... below 70 dBA

Sound power level ............................... below 85 dBA

Wetted Parts ............................................ 303 SST, 17-4 SST, PTFE, perfluoroelastomer,

tungsten carbide with nickel binder

Weight

3KS Wall fluid panel............................. 32.6 lb (14.8 kg)

Power/Barrier Assy .............................. 15.2 lb (6.9 kg)

*Ratio ranges are dependent on flow rate, dose size and meter resolution

8

Cables

123277 6 ft Yellow Color Change/Booth Control

123280 50 ft Yellow Color Change/Booth Control

123273 10 ft Green CAN Cable

123274 25 ft Green CAN Cable

123271 50 ft Red Power Cable

123272 100 ft Red Power Cable

Miscellaneous Kits

16A732 3K Floor Stand Extension

Extends 15V950 2KS floor stand for 3KS

use

Page 9

ProMix 2KS

Technical Specifications

Maximum working air pressure ............................................... 100 psig (7 bar)

Air supply ........................................................75 to 100 psig (5 to 7 bar)

Air filtration

Air logic (Graco supplied) ..................................................... 5 micron

Air purge (user supplied) ............................................ 30 micron clean/dry

Air for atomizing (user supplied) .............................. minimum of 30 micron clean/dry

Mix ratio range

Sequential dosing........................................................ 0.1:1 to 50:1

Dynamic dosing ......................................................... 0.1:1 to 30:1

Ratio accuracy........................................... up to ±1% minimum (user selectable)

Fluids handled .............................. one or two component: solvent and waterborne paints;

polyurethanes; epoxies; acid catalyzed varnishes; moisture sensitive isocyanates

Fluid filtration ............................................................. 100 mesh min

Flow meters:

METER TYPE MAX PRESSURE FLOW RANGE VISCOSITY

G250 Spur Gear 250 psi (17.2 bar) 75-3800 cc/min 20-3000 cps

G250HR Spur Gear 250 psi (17.2 bar) 38-1900 cc/min 20-3000 cps

G3000 Spur Gear 4000 psi (275 bar) 75-3800 cc/min 20-3000 cps

G3000HR Spur Gear 4000 psi (275 bar) 38-1900 cc/min 20-3000 cps

HG6000 Helical Gear 6000 psi (413 bar) 50-7500 cc/min 30-100,000 cps

1/4” Coriolis Single Tube 2300 psi (158 bar) 20-3800 cc/min* 0.1-3000 cps

3/8” Coriolis Single Tube 2300 psi (158 bar) 50-3800 cc/min* 0.1-3000 cps

S3000 (Solvent Meter) Spur Gear 3000 psi (206 bar) 50-2000 cc/min 0.5-1000 cps**

*Ratio and K-factor dependent

**No filled materials

Component working pressure

Wall fluid panel (no meters) ........................................... 4000 psig (275 bar)

RoboMix fluid panel (G250 meters)...................................... 250 psig (17.2 bar)

Flow control regulator ................................................. 200 psig (13 bar)

Low pressure color change valves ...................................... 300 psig (20.6 bar)

High pressure color change valves .................................... 3000 psig (206.7 bar)

External power supply requirements ................... 85-250 Vac, 50/60 Hz. 2 amps maximum draw,

15 amp maximum circuit breaker required,

8 to 14 AWG power supply wire gauge

Operating temperature range........................................... 41 to 122°F (5 to 50°C)

Noise level

Sound pressure level .................................................... below 70 dBA

Sound power level ...................................................... below 85 dBA

Wetted parts ...................................... 303 SST, 17-4 SST, PTFE, perfluoroelastomer,

tungsten carbide with nickle binder

Weight

EasyKey display ...................................................... 21.75 lb (9.8 kg)

Remote operator station ................................................ 0.95 lb (0.43 kg)

Wall fluid panel (no meters) ............................................... 50 lb (22.7 kg)

RoboMix fluid panel (G250 meters included)................................. 31.6 lb (14.3 kg)

Flow control regulator ..................................................... 4 lb (1.8 kg)

Approved for hazardous locations ......................... US and Canada - class 1 Div 1 Group D T3

Europe - Zone 0 Ex ia IIA T3/ATEX II2G T3

Environmental condition rating...................indoor use, pollution degree (2), installation category II

9

Page 10

ProMix 2KS

Ordering Information

M

Manual

X

Interface

Manual Wall Panel

Interface

M

D = EasyKey with

LCD Display

*Order additional low pressure valves or other high pressure valve configurations as kits (see accessories).

Manual systems only include dump valves when color and catalyst change are selected.

A & B Meter

0 = No Meter

1 = G3000 A & B

2 = G3000HR A & B

3 = 1/4” Coriolis A & G3000 B

4 = G3000 A & 1/4” Coriolis B

5 = 1/4” Coriolis A & G3000HR B

6 = G3000HR A & 1/4” Coriolis B

7 = 1/4” Coriolis A & 1/4” Coriolis B

Color Valves*

0 = No Valves (Single Color)

1 = 2 Colors LP

2 = 4 Colors LP

3 = 7 Colors LP

4 = 12 Colors LP

5 = 2 Colors HP

6 = 4 Colors HP

A

Automatic

X

Interface

Automatic Wall Panel

Interface

A

D = EasyKey with

LCD Display

A & B Meter

0 = No Meter

1 = G3000 A & B

2 = G3000HR A & B

3 = 1/4” Coriolis A & G3000 B

4 = G3000 A & 1/4” Coriolis B

5 = 1/4” Coriolis A & G3000HR B

6 = G3000HR A & 1/4” Coriolis B

7 = 1/4” Coriolis A & 1/4” Coriolis B

Color Valves*

0 = No Valves (Single Color)

1 = 2 Colors LP

2 = 4 Colors LP

3 = 7 Colors LP

4 = 12 Colors LP

X

X

A & B

Meter

A & B

Meter

Color

Valves

Catalyst Valves

0 = No Valves (Single Catalyst)

1 = 2 Catalysts LP

2 = 4 Catalysts LP

3 = 2 Catalysts HP

X

X

Color

Valves

Catalyst Valves

0 = No Valves (Single Catalyst)

1 = 2 Catalysts LP

2 = 4 Catalysts LP

X

Catalyst

Valves

X

Catalyst

Valves

X

Applicator

Handling

Applicator Handling

1 = 1 AFS

2 = 2 AFS

3 = 1 AFS with 1 GFB

4 = 2 AFS with 2 GFB

X

Flow

Control

Flow Control**

N = No***

Y = Yes

*Order additional low pressure valves or other high pressure valve configurations as kits (see accessories).

**Automatic systems with flow control include the integrated fluid regulator module.

***If an external regulator module is desired, order N = No for flow control and order control module, cable and fluid regulator separately.

R

Automatic RoboMix Panel

Interface

R

D = EasyKey with

LCD Display

*Order additional low pressure valves as kits (see accessories).

**Automatic systems with flow control include the integrated fluid regulator module.

***If an external regulator module is desired, order N = No for flow control and order control module, cable and fluid regulator separately.

A & B Meter

0 = No Meter

1 = G250 A & B

2 = G250HR A & B

Color Valves*

0 = No Valves (Single Color)

1 = 2 Colors LP

2 = 4 Colors LP

3 = 7 Colors LP

4 = 12 Colors LP

Automatic

RoboMix

X

Interface

Catalyst Valves

0 = No Valves (Single Catalyst)

1 = 2 Catalysts LP

2 = 4 Catalysts LP

X

A & B

Meter

X

Color

Valves

Catalyst

Valves

LP = low pressure; HP = high pressure; AFS = air flow switch; GFB = gun flush box

10

X

Flow Control**

N = No***

Y = Yes

X

Flow

Control

Page 11

ProMix 2KS

Accessories

Meter Kits

Contains one flow meter, cable and hardware

15V804 G3000 Flow Meter

15V827 G3000HR Flow Meter

15V820 HG6000 Flow Meter

24M261 1/4" Coriolis Flow Meter

258151 3/8" Coriolis Flow Meter

16D329 S3000 (Solvent) Flow Meter

Low Pressure Color Change Kits

Contains color valves and solenoid control module.

Order dump valves separately.

256581 2 Color

256582 4 Color

256583 7 Color

256584 12 Color

256585 2 Color and 2 Catalyst

256586 4 Color and 2 Catalyst

256587 4 Color and 4 Catalyst

256588 7 Color and 2 Catalyst

256589 7 Color and 4 Catalyst

256590 12 Color and 2 Catalyst

256591 12 Color and 4 Catalyst

256592 13-18 Colors

256593 13-24 Colors

256594 13-30 Colors

256595 0 Colors and 2 Catalysts

High Pressure Color Change Kits

Contains color valves and solenoid control module.

Order dump valves separately.

256596 2 Color

256597 4 Color

256598 7 Color

256599 12 Color

256600 2 Color and 2 Catalyst

256601 4 Color and 2 Catalyst

256602 4 Color and 4 Catalyst

256603 7 Color and 2 Catalyst

256604 7 Color and 4 Catalyst

256605 12 Color and 2 Catalyst

256606 12 Color and 4 Catalyst

256607 13-18 Colors

256608 13-24 Colors

256609 13-30 Colors

256610 0 Colors and 2 Catalysts

Valve Kits

Contains valve, solenoid and hardware

15V821 Wall Panel Dump Valve

15V354 Wall Panel 3rd Flush Valve

15V822 RoboMix Panel Dump Valve

15V202 RoboMix Panel 3rd Flush Valve

15V077 Stainless Steel Needle

High pressure valve

15V737 Lubrication Cup

High and low pressure valve - supplies

lubrication to the valve needle and seal

15U932 Carbide Seat

High pressure valve

Dosing Kits

Contains fluid manifold hardware

15V034 10 cc Sequential Dosing

15V033 25 cc Sequential Dosing

15V021 50 cc Sequential Dosing

24B618 100 cc Sequential Dosing

15U955 0 cc Dynamic Dosing

RoboMix Panel Kits

Used to interface up to two air flow switches and two

gun flush boxes to a RoboMix Panel. Order air flow

switch or gun flush box kits separately.

15V267 RoboMix Panel Ratio Check Kit

15V534 Manual Gun Interface Kit

Communication Kits

15V825 Discrete I/O Integration Board Kit

Contains inputs and outputs for controlling

automatic integration and special output

functionality. Included in automatic kits.

15W023 Communication + I/O Harness Kit

Cable and terminal strip for alarm

monitoring, remote stop input and flow

control inputs. Included in automatic kits.

15V331 Ethernet IP Gateway Assembly

15V963 DeviceNet Gateway Assembly

15V964 Profibus Gateway Assembly

Network communication assembly for

automatic integration. Contains gateway

module, power supply, and enclosure.

15V337 Advanced Web Interface with Eight Port Hub

Contains web server module, power supply,

eight port hub and enclosure

15V336 Eight Port Ethernet Hub

Contains eight port hub, power supply

and enclosure

121998 25 ft CAT V Cable

121999 50 ft CAT V Cable

15V842 100 ft CAT V Cable

15V843 200 ft CAT V Cable

Cables

15V213 100 ft Power Cable

15G710 100 ft Fiber Optic Cable

15U977 40 ft Flow Control Extension Cable

15U532 3 ft CAN Cable

15V205 6 ft CAN Cable

15V206 10 ft CAN Cable

15V207 15 ft CAN Cable

15V208 25 ft CAN Cable

15U533 50 ft CAN Cable

Miscellaneous Kits

15V826 Gun Flush Box Kit

Contains guns flush box and

control hardware

570123 Gun Flush Box Wall Mount Kit

15V823 Gun Air Shutoff Kit

Used to automatically shut off gun

atomizing air during flush and fill sequences

without a gun flush box

15T632 Air Flow Switch Kit

15V350 Remote Operator Station Kit

15V256 Manual to Automatic Conversion Kit

15X247 Auto Dump Kit

Used to incorporate an auto dump feature

without a gun flush box. Contains a dump

valve, solenoid and hardware

949122 Clear Plastic Static Mixer

15V536 Solvent Flow Switch

Used to detect solvent flow during

flush sequences

15W034 Alarm Light for Manual Systems

122193 Alarm Light for Automatic Systems

15V950 Floor Stand

Contains provisions for mounting a wall

fluid panel, EasyKey display and color

change module.

197902 EasyKey Paint Shields

Includes 10 disposable clear plastic shields

to cover the EasyKey display and shield it

from paint overspray

15M483 Remote Operator Station Paint Shields

Includes 10 disposable clear plastic shields

to cover the remote operator station

display and shield it from paint overspray

15W600 Wall Panel Fluid Manifold Cover

Gun Flush Box Gun Holders

198787 Graco Pro Xs2

198405 Graco Pro Xs3, Pro Xs4

196768 Graco PRO 3500, 3500hc, 4500

15T646 Graco AirPro Air Spray

196769 Graco Delta Air Spray

196770 Graco Alpha

196771 Graco Alpha Plus, Alpha Plus RAC

15G093 Graco G15

15G346 Graco G40, G40 RAC

24N528 Graco Pro Xp60 and Pro Xp80

24N529 Graco Pro Xp40

Flow Control Parts & Accessories

249849 Flow Control module,

integrated fluid regulator

24H989 Flow Control module, external fluid

regulator (fluid regulator not included)

15U977 Cable, flow control

Required for 24H989. Included with

integrated flow control (249849) when

ordered with a ProMix 2KS system.

11

Page 12

ABOUT GRACO

Founded in 1926, Graco is a world leader in fluid handling systems and components. Graco products

move, measure, control, dispense and apply a wide range of fluids and viscous materials used

in vehicle lubrication, commercial and industrial settings.

The company’s success is based on its unwavering commitment to technical excellence, world-class

manufacturing and unparalleled customer service. Working closely with qualified distributors, Graco

offers systems, products and technology that set the quality standard in a wide range of fluid handling

solutions. Graco provides equipment for spray finishing, protective coating, paint circulation, lubrication,

and dispensing sealants and adhesives, along with power application equipment for the contractor

industry. Graco’s ongoing investment in fluid management and control will continue to provide

innovative solutions to a diverse global market.

GRACO LOCATIONS

MAILING ADDRESS

P.O. Box 1441

Minneapolis, MN 55440-1441

Tel: 612-623-6000

Fax: 612-623-6777

AMERICAS

MINNESOTA

Worldwide Headquarters

Graco Inc.

88 -11th Avenue N.E.

Minneapolis, MN 55413

EUROPE

BELGIUM

European Headquarters

Graco N.V.

Industrieterrein-Oude Bunders

Slakweidestraat 31

3630 Maasmechelen,

Belgium

Tel: 32 89 770 700

Fax: 32 89 770 777

ASIA PACIFIC

AUSTRALIA

Graco Australia Pty Ltd.

Suite 17, 2 Enterprise Drive

Bundoora, Victoria 3083

Australia

Tel: 61 3 9467 8558

Fax: 61 3 9467 8559

CHINA

Graco Hong Kong Ltd.

Shanghai Representative Office

Room 118 1st Floor

No.2 Xin Yuan Building

No.509 Cao Bao Road

Shanghai, 200233

The People’s Republic of China

Tel: 86 21 649 50088

Fax: 86 21 649 50077

INDIA

Graco Hong Kong Ltd.

India Liaison Office

Room 432, Augusta Point

Regus Business Centre 53

Golf Course Road

Gurgaon, Haryana

India 122001

Tel: 91 124 435 4208

Fax: 91 124 435 4001

JAPAN

Graco K.K.

1-27-12 Hayabuchi

Tsuzuki-ku

Yokohama City, Japan 2240025

Tel: 81 45 593 7300

Fax: 81 45 593 7301

KOREA

Graco Korea Inc.

Shinhan Bank Building

4th Floor #1599

Gwanyang-Dong, Dongan-Ku,

Anyang-si, Korea 431-060

Tel: 82 31 476 9400

Fax: 82 31 476 9801

SALES/

DISTRIBUTION/

SERVICE

North America

Customer Service

800-328-0211

Fax 877-340-6427

Call today for product information or to request a demonstration.

877-84GRACO (1-877-844-7226) or visit us at www.graco.com.

Graco Inc. is registered to I.S. EN ISO 9001

©2013-2014 Graco Inc. 339996 Rev. D 02/14 All written and visual data contained in this document are based on the latest product information available at the time

of publication. Graco reserves the right to make changes at any time without notice. All other brand names or marks are used for identification purposes and are

trademarks of their respective owners.

Loading...

Loading...