Page 1

Operation

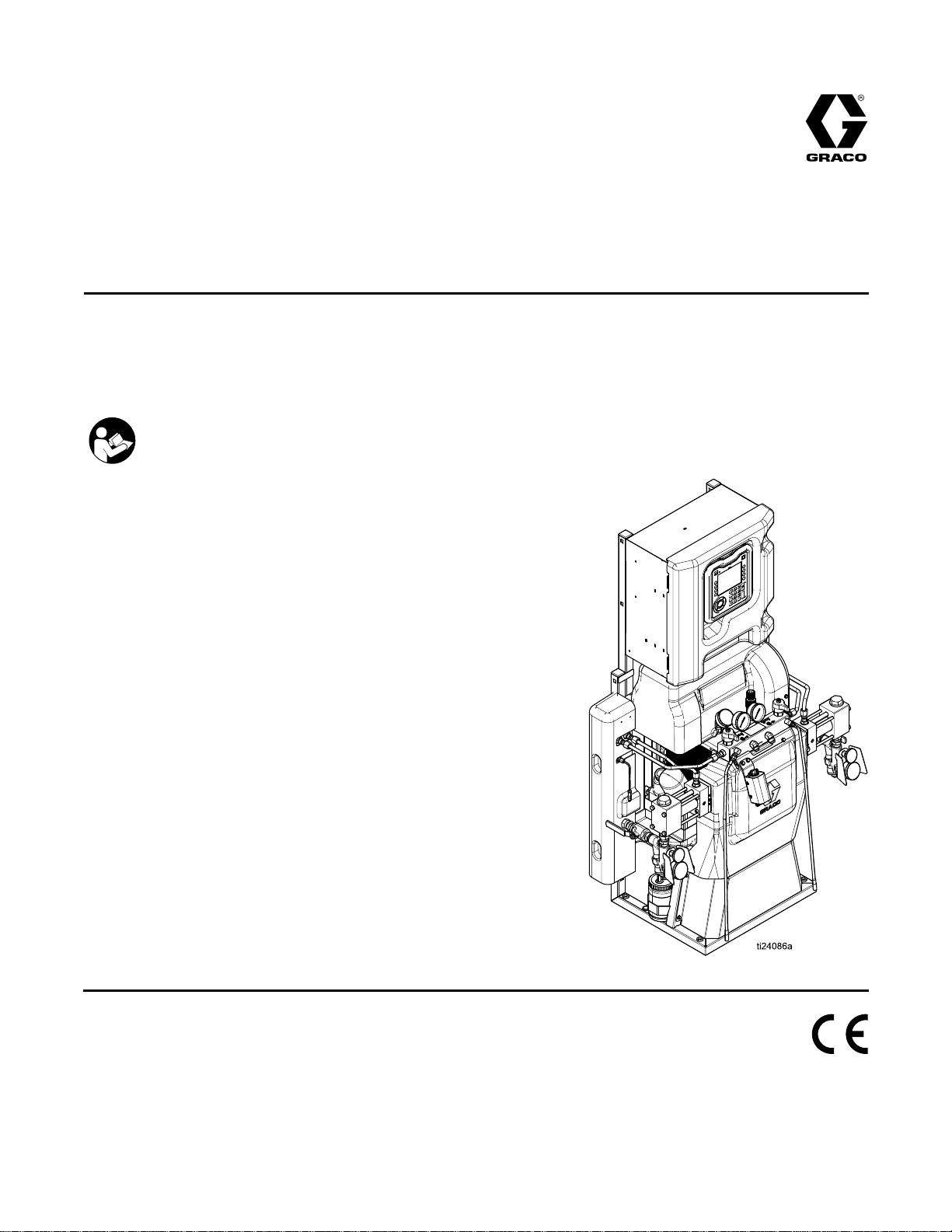

Reactor®

Reactor® Reactor®

Proportioning

Proportioning Proportioning

Hydraulic,

Hydraulic, Hydraulic,

coatings.

coatings. coatings.

Not

approved

Not Not

approved approved

For model information, see page 9.

Heated,

Heated, Heated,

Not

for

Not Not

for for

for

for for

Important

Important Important

Readallwarningsandinstructionsinthismanual.

Save

Save Save

Safety

Safety Safety

these

these these

2

2 2

Plural

Plural Plural

outdoor

outdoor outdoor

use

use use

instructions.

instructions. instructions.

Component

Component Component

use.

use. use.

explosive

in ininexplosive explosive

Instructions

Instructions Instructions

Hydraulic

Hydraulic Hydraulic

Systems

Systems Systems

Proportioner

Proportioner Proportioner

For

professional

For For

professional professional

atmospheres

atmospheres atmospheres

for

spraying

for for

spraying spraying

use

only.

use use

only. only.

or

hazardous

or or

hazardous hazardous

polyurethane

polyurethane polyurethane

locations.

locations. locations.

foam

foam foam

334945B

EN

and

polyurea

and and

polyurea polyurea

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Warnings...........................................................3

ImportantIsocyanateInformation.........................7

Models...............................................................9

Approvals...........................................................15

Accessories........................................................15

SuppliedManuals...............................................16

RelatedManuals................................................16

TypicalInstallation,withoutcirculation..................17

TypicalInstallation,withsystemuidmanifold

todrumcirculation.................................18

TypicalInstallation,withgunuidmanifoldto

drumcirculation.....................................19

ComponentIdentication.....................................20

AdvancedDisplayModule(ADM)..................22

ElectricalEnclosure......................................26

HydraulicControlModule(HCM)...................27

TemperatureControlModule(TCM)Cable

Connections...................................28

Setup.................................................................29

Grounding...................................................29

GeneralEquipmentGuidelines.....................29

ConnectPower............................................30

LubricationSystemSetup.............................31

InstallFluidTemperatureSensor..................31

InstallHeatedHosetoProportioner...............31

AdvancedDisplayModule(ADM)

Operation..............................................32

AdvancedSetupScreens.............................35

System1.....................................................36

System2.....................................................36

System3.....................................................36

Recipes.......................................................37

RunMode...................................................38

Startup...............................................................44

FluidCirculation..................................................47

CirculationThroughReactor.........................47

CirculationThroughGunManifold.................48

Spraying............................................................49

SprayAdjustments.......................................50

ManualHoseHeatMode..............................51

Standby.............................................................53

Shutdown...........................................................54

PressureReliefProcedure..................................55

Flushing.............................................................56

Maintenance......................................................57

PreventativeMaintenanceSchedule.............57

ProportionerMaintenance............................57

FlushInletStrainerScreen...........................58

PumpLubricationSystem.............................59

Errors................................................................60

ViewErrors..................................................60

TroubleshootErrors.....................................60

ErrorCodesandTroubleshooting........................61

USBData....................................................61

USBLogs....................................................61

SystemCongurationSettings......................62

CustomLanguageFile.................................63

UploadProcedure........................................63

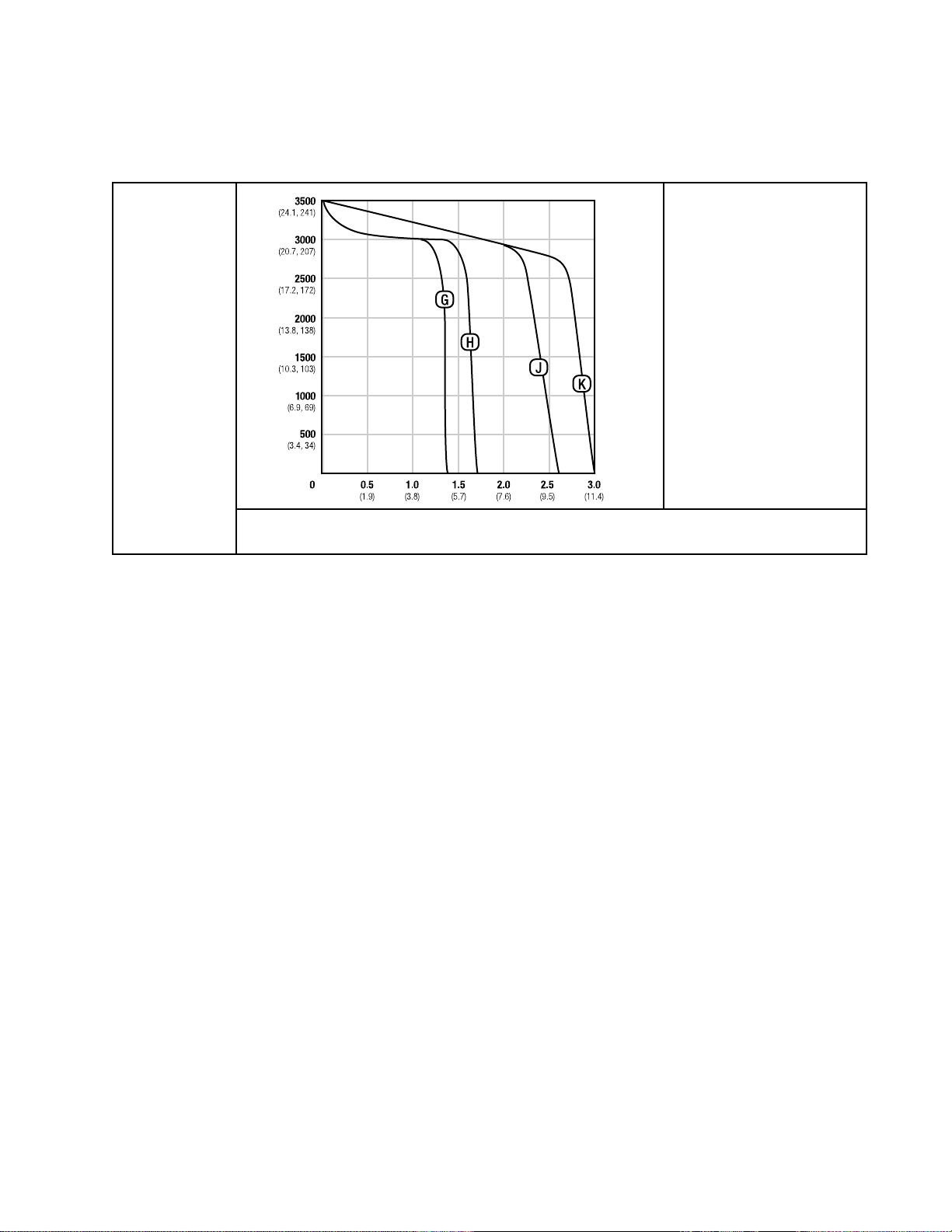

PerformanceCharts............................................64

TechnicalSpecications......................................66

Notes...............................................................68

Dimensions........................................................69

GracoExtendedWarranty...................................70

2

334945B

Page 3

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

•Donotexposetorain.Storeindoors.

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaledorswallowed.

SHOCK

SHOCK SHOCK

FLUID

FLUID FLUID

HAZARD

HAZARD HAZARD

OR

FUMES

OR OR

FUMES FUMES

Warnings

•ReadSafetyDataSheet(SDS)forhandlinginstructionsandtoknowthespecichazardsof

theuidsyouareusing,includingtheeffectsoflong-termexposure.

•Whenspraying,servicingequipment,orwhenintheworkarea,alwayskeepworkarea

wellventilatedandalwayswearappropriatepersonalprotectiveequipment.SeePersonal Personal

Protective

Protective Protective

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL

PERSONAL PERSONAL

Alwayswearappropriatepersonalprotectiveequipmentandcoverallskinwhenspraying,

servicingequipment,orwhenintheworkarea.Protectiveequipmenthelpspreventserious

injury,includinglong-termexposure;inhalationoftoxicfumes,mistsorvapors;allergicreaction;

burns;eyeinjuryandhearingloss.Thisprotectiveequipmentincludesbutisnotlimitedto:

•Aproperlyttingrespirator,whichmayincludeasupplied-airrespirator,chemically

impermeablegloves,protectiveclothingandfootcoveringsasrecommendedbytheuid

manufacturerandlocalregulatoryauthority.

•Protectiveeyewearandhearingprotection.

Equipment

Equipment Equipment

PROTECTIVE

PROTECTIVE PROTECTIVE

warningsinthismanual.

EQUIPMENT

EQUIPMENT EQUIPMENT

Personal

334945B 3

Page 4

Warnings

WARNING

WARNING WARNING

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

immediate

immediate immediate

•Engagetriggerlockwhennotspraying.

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

FIRE

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

orsolventowingthroughtheequipmentcancausestaticsparking.Tohelppreventreand

explosion:

surgical

surgical surgical

AND

EXPLOSION

AND AND

EXPLOSION EXPLOSION

HAZARD

HAZARD HAZARD

Get

treatment.

treatment. treatment.

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

HAZARD

HAZARD HAZARD

whenyoustopdispensingandbeforecleaning,

work

area

area area

canigniteorexplode.Paint

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticsparking).

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Neversprayorushsolventathighpressure.

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareanti-staticorconductive.

Stop

•Stop Stop

•Keepaworkingreextinguisherintheworkarea.

THERMAL

THERMAL THERMAL

Fluidssubjectedtoheatinconnedspaces,includinghoses,cancreatearapidriseinpressure

duetothethermalexpansion.Over-pressurizationcanresultinequipmentruptureandserious

injury.

•Openavalvetorelievetheuidexpansionduringheating.

•Replacehosesproactivelyatregularintervalsbasedonyouroperatingconditions.

operation

operation operation

equipmentuntilyouidentifyandcorrecttheproblem.

immediately

immediately immediately

EXPANSION

EXPANSION EXPANSION

ifstaticsparkingoccursoryoufeelashock. ..Donotuse

HAZARD

HAZARD HAZARD

Grounding

instructions.

4

334945B

Page 5

WARNING

WARNING WARNING

PRESSURIZED

PRESSURIZED PRESSURIZED

Useofuidsthatareincompatiblewithaluminuminpressurizedequipmentcancauseserious

chemicalreactionandequipmentrupture.Failuretofollowthiswarningcanresultindeath,

seriousinjury,orpropertydamage.

•Donotuse1,1,1-trichloroethane,methylenechloride,otherhalogenatedhydrocarbon

solventsoruidscontainingsuchsolvents.

•Manyotheruidsmaycontainchemicalsthatcanreactwithaluminum.Contactyourmaterial

supplierforcompatibility.

PLASTIC

PLASTIC PLASTIC

Manysolventscandegradeplasticpartsandcausethemtofail,whichcouldcauseserious

injuryorpropertydamage.

•Useonlycompatiblewater-basedsolventstocleanplasticstructuralorpressure-containing

parts.

•SeeTechnical Technical

Technical

solventmanufacturer’sMSDSsandrecommendations.

ALUMINUM

ALUMINUM ALUMINUM

PARTS

PARTS PARTS

CLEANING

CLEANING CLEANING

Data

Data Data

PARTS

PARTS PARTS

SOLVENT

SOLVENT SOLVENT

inthisandallotherequipmentinstructionmanuals.Readuidand

HAZARD

HAZARD HAZARD

HAZARD

HAZARD HAZARD

Warnings

334945B 5

Page 6

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

MOVING

MOVING MOVING

MISUSE

MISUSE MISUSE

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

Technical

HAZARD

HAZARD HAZARD

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

BURN

BURN BURN

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

HAZARD

HAZARD HAZARD

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

anddisconnectallpowersources.

6 334945B

Page 7

ImportantIsocyanateInformation

Important

Important Important

Isocyanates(ISO)arecatalystsusedintwocomponentmaterials.

Isocyanate

Isocyanate Isocyanate

Sprayingordispensinguidsthatcontainisocyanatescreatespotentiallyharmfulmists,vapors,and

atomizedparticulates.

•Readandunderstandtheuidmanufacturer’swarningsandSafetyDataSheet(SDS)toknowspecic

hazardsandprecautionsrelatedtoisocyanates.

•Useofisocyanatesinvolvespotentiallyhazardousprocedures.Donotspraywiththisequipmentunless

youaretrained,qualied,andhavereadandunderstoodtheinformationinthismanualandintheuid

manufacturer’sapplicationinstructionsandSDS.

•Useofincorrectlymaintainedormis-adjustedequipmentmayresultinimproperlycuredmaterial,which

couldcauseoffgassingandoffensiveodors.Equipmentmustbecarefullymaintainedandadjusted

accordingtoinstructionsinthemanual.

•Topreventinhalationofisocyanatemists,vaporsandatomizedparticulates,everyoneintheworkarea

mustwearappropriaterespiratoryprotection.Alwayswearaproperlyttingrespirator,whichmayinclude

asupplied-airrespirator.Ventilatetheworkareaaccordingtoinstructionsintheuidmanufacturer’sSDS.

Isocyanate

Isocyanate Isocyanate

Conditions

Conditions Conditions

Information

Information Information

•Avoidallskincontactwithisocyanates.Everyoneintheworkareamustwearchemicallyimpermeable

gloves,protectiveclothingandfootcoveringsasrecommendedbytheuidmanufacturerandlocal

regulatoryauthority.Followalluidmanufacturerrecommendations,includingthoseregardinghandlingof

contaminatedclothing.Afterspraying,washhandsandfacebeforeeatingordrinking.

•Hazardfromexposuretoisocyanatescontinuesafterspraying.Anyonewithoutappropriatepersonal

protectiveequipmentmuststayoutoftheworkareaduringapplicationandafterapplicationforthetime

periodspeciedbytheuidmanufacturer.Generallythistimeperiodisatleast24hours.

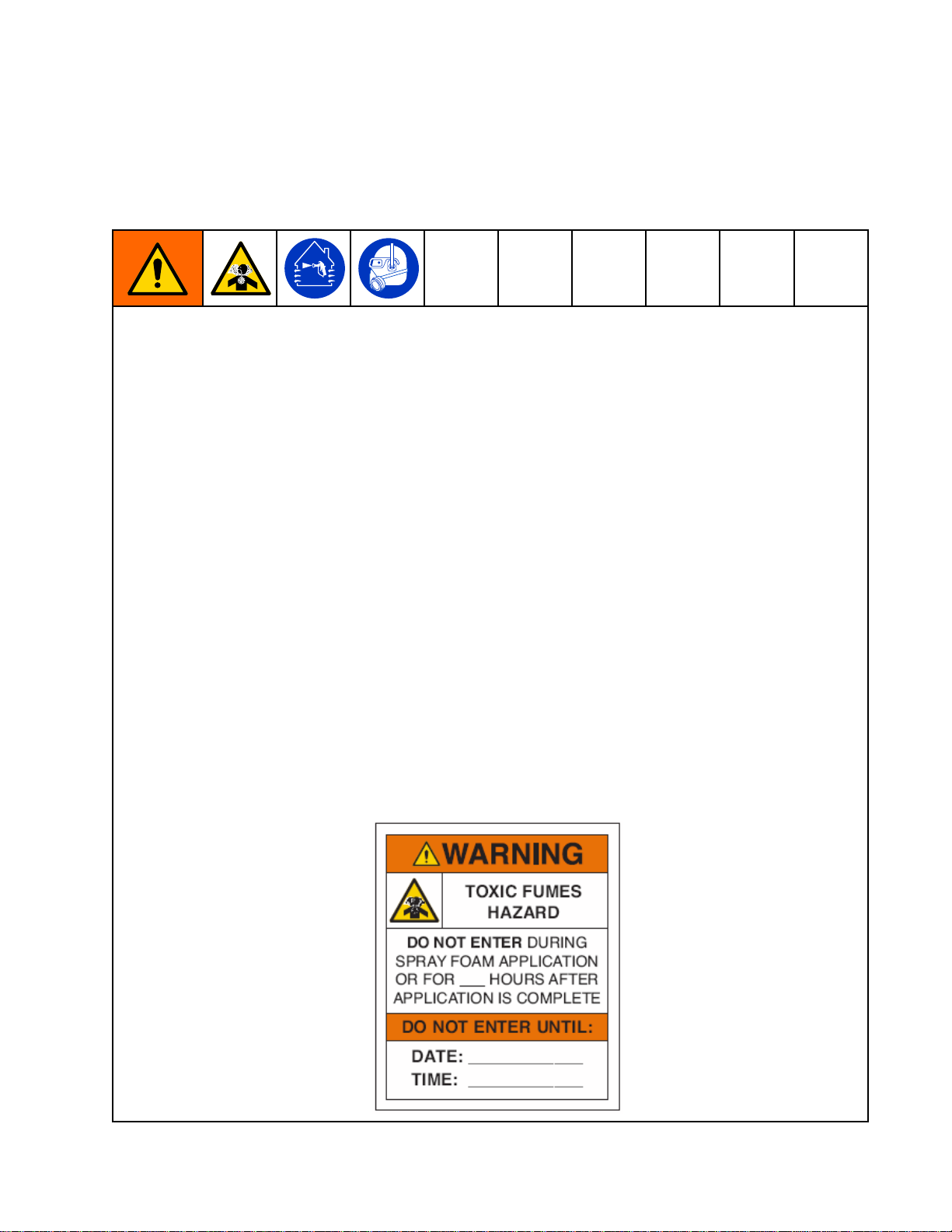

•Warnotherswhomayenterworkareaofhazardfromexposuretoisocyanates.Followthe

recommendationsoftheuidmanufacturerandlocalregulatoryauthority.Postingaplacardsuchasthe

followingoutsidetheworkareaisrecommended:

334945B

7

Page 8

ImportantIsocyanateInformation

Material

Material Material

Somematerialsmaybecomeself-ignitingifapplied

toothick.Readmaterialmanufacturer’swarnings

andSDS.

Keep

Keep Keep

Cross-contaminationcanresultincured

materialinuidlineswhichcouldcauseserious

injuryordamagetoequipment.Toprevent

cross-contamination:

Never

•Never Never

Bwettedparts.

•Neverusesolventononesideifithasbeen

contaminatedfromtheotherside.

Self

Ignition

Self Self

- --Ignition Ignition

Components

Components Components

interchangecomponentAandcomponent

A

and

A A

and and

Moisture

Moisture Moisture

Exposuretomoisture(suchashumidity)willcause

ISOtopartiallycure,formingsmall,hard,abrasive

crystalsthatbecomesuspendedintheuid.

EventuallyalmwillformonthesurfaceandtheISO

willbegintogel,increasinginviscosity.

B

Separate

B B

Separate Separate

PartiallycuredISOwillreduceperformanceand

thelifeofallwettedparts.

•Alwaysuseasealedcontainerwithadesiccant

dryerinthevent,oranitrogenatmosphere.

Never

Never Never

•KeeptheISOpumpwetcuporreservoir(if

installed)lledwithappropriatelubricant.The

lubricantcreatesabarrierbetweentheISOand

theatmosphere.

•Useonlymoisture-proofhosescompatiblewith

ISO.

•Neverusereclaimedsolvents,whichmay

containmoisture.Alwayskeepsolvent

containersclosedwhennotinuse.

Sensitivity

Sensitivity Sensitivity

storeISOinanopencontainer.

of

Isocyanates

of of

Isocyanates Isocyanates

NOTICE

NOTICE NOTICE

Changing

Changing Changing

Changingthematerialtypesusedinyour

equipmentrequiresspecialattentiontoavoid

equipmentdamageanddowntime.

•Whenchangingmaterials,ushtheequipment

multipletimestoensureitisthoroughlyclean.

•Alwayscleantheuidinletstrainersafter

ushing.

•Checkwithyourmaterialmanufacturerfor

chemicalcompatibility.

•Whenchangingbetweenepoxiesandurethanes

orpolyureas,disassembleandcleanalluid

componentsandchangehoses.Epoxiesoften

haveaminesontheB(hardener)side.Polyureas

oftenhaveaminesontheB(resin)side.

Materials

Materials Materials

NOTICE

NOTICE NOTICE

•Alwayslubricatethreadedpartswithan

appropriatelubricantwhenreassembling.

NOTE:

NOTE: NOTE:

crystallizationvariesdependingontheblendofISO,

thehumidity,andthetemperature.

Foam

Foam Foam

Agents

Agents Agents

Somefoamblowingagentswillfrothattemperatures

above90°F(33°C)whennotunderpressure,

especiallyifagitated.Toreducefrothing,minimize

preheatinginacirculationsystem.

Theamountoflmformationandrateof

Resins

Resins Resins

with

245

fa

with with

245 245

Blowing

fa fa

Blowing Blowing

8 334945B

Page 9

Models

Models

Models Models

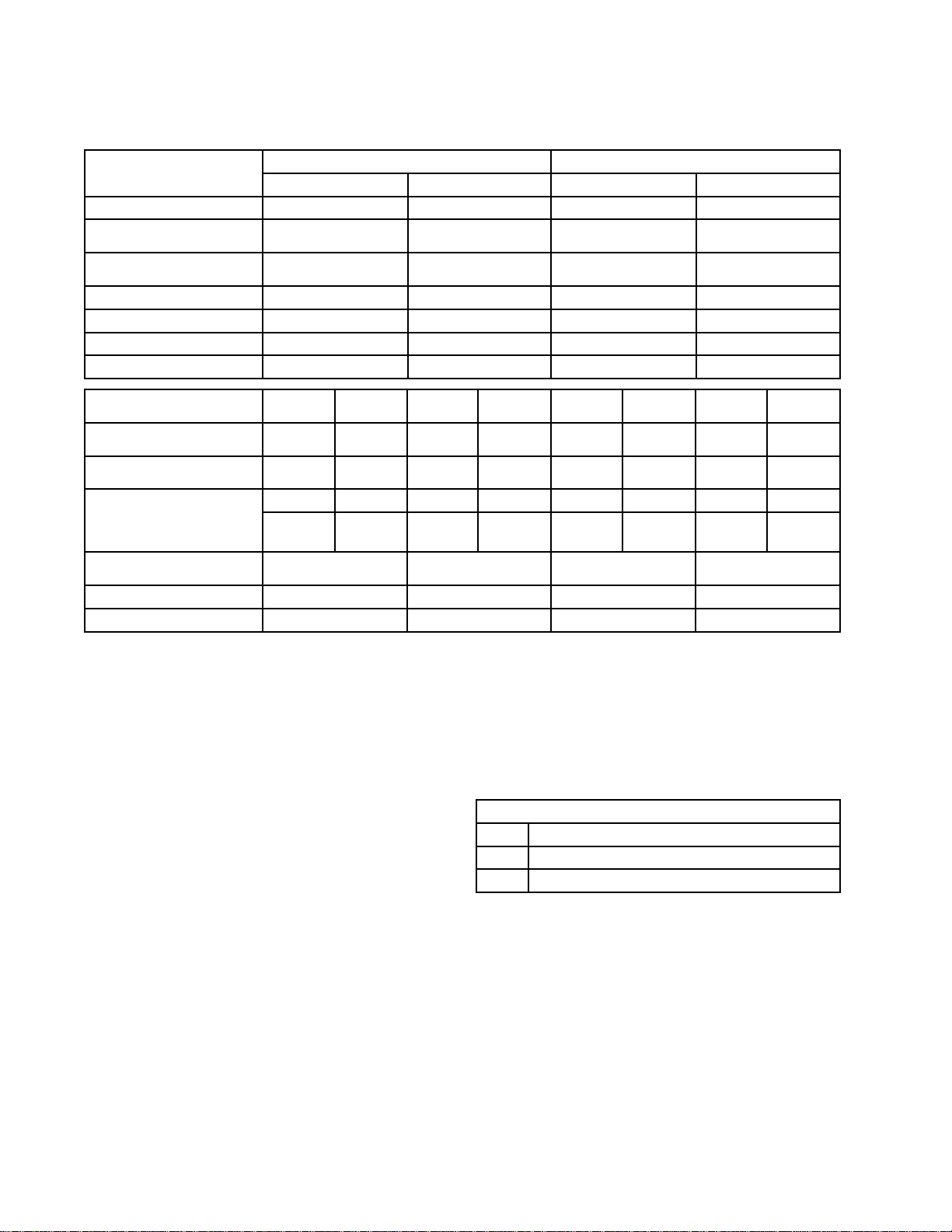

Reactor

Reactor Reactor

Model

Model Model

Proportioner

Proportioner Proportioner

Maximum

Maximum Maximum

Pressure

Pressure Pressure

Approximate

Approximate Approximate

(A+B)

gal.

(A+B) (A+B)

gal. gal.

Max

Flow

Max Max

Flow Flow

Total

System

Total Total

System System

Congurable

Congurable Congurable

Full

Load

Full Full

Load Load

Fusion

Fusion Fusion

®AP AP

(Gun Part No.)

Fusion

Fusion Fusion

®CS CS

(Gun Part No.)

Probler

Probler Probler

(Gun Part No.)

Heated

50

(15

50 50

ft ftft(15 (15

24K240(scuffguard)

24Y240(Xtreme-wrap)

Heated

Heated Heated

10

10 10

ft ftft(3 (3(3m) m)

Graco

Insite

Graco Graco

Insite Insite

Fluid

Inlet

Fluid Fluid

Inlet Inlet

30

2 22H HH- --30 30

★17H03117H03217H13117H132

Fluid

Working

Fluid Fluid

Working Working

psi

(MPa,

psi psi

(MPa, (MPa,

Output

Output Output

(liter)

(liter) (liter)

Rate

lb/min

Rate Rate

lb/min lb/min

Load

Load Load

Voltage

Voltage Voltage

Peak

Current*

Peak Peak

Current* Current*

AP

Package

Package Package

CS

Package

Package Package

P2

Package

P2 P2

Package Package

Hose

Hose Hose

m)

m) m)

Whip

Hose

Whip Whip

Hose Hose

m)

Sensors

Sensors Sensors

and

and and

bar)

bar) bar)

per

Cycle

per per

Cycle Cycle

(kg/min)

(kg/min) (kg/min)

(Watts)

† ††(Watts) (Watts)

Phase

Phase Phase

6

6

6

(2)

(2) (2)

30

H HH- --30 30

10

kW

10 10

kW kW

2000(14,140)2000(14,140)2000(14,140)2000(14,140)

0.073(0.28)0.073(0.28)0.073(0.28)0.073(0.28)

28(12.7)28(12.7)28(12.7)28(12.7)

17,96023,26017,96023,260

230

1Ø

79463510059357946351005935

APH031

(246102)

CSH031

(CS02RD)

P2H031

(GCP2R2)

24K24024K24024K24024K24024Y24024Y24024Y24024Y240 Heated Heated

Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5

246050246050246050246050

Elite

Elite Elite

30

Model

H HH- --30 30

Model Model

15

kW

15 15

kW kW

230

3Ø∆

380

3ØY

AHH031

(246102)

CHH031

(CS02RD)

PHH031

(GCP2R2)

230

1Ø

APH032

(246102)

CSH032

(CS02RD)

P2H032

(GCP2R2)

230

3Ø∆

380

3ØY

AHH032

(246102)

CHH032

(CS02RD)

PHH032

(GCP2R2)

kW

10 1010kW kW

230

1Ø

APH131

(246102)

CSH131

(CS02RD)

P2H131

(GCP2R2)

✓✓

✓✓

30

Elite

H HH- --30 30

230

3Ø∆

380

3ØY

AHH131

(246102)

CHH131

(CS02RD)

PHH131

(GCP2R2)

Model

Elite Elite

Model Model

kW

15 1515kW kW

230

1Ø

APH132

(246102)

CSH132

(CS02RD)

P2H132

(GCP2R2)

230

3Ø∆

380

3ØY

AHH132

(246102)

CHH132

(CS02RD)

PHH132

(GCP2R2)

*

Fullloadampswithalldevicesoperatingat

* *

maximumcapabilities.Fuserequirements

atvariousowratesandmixchambersizes

maybeless.

=

Totalsystemwattsusedbysystem,basedon

maximumheatedhoselengthforeachunit.

•H–30series:310ft(94.5m)maximum

heatedhoselength,includingwhiphose.

★

SeeApprovals,page15.

6

Packagesincludegun,heatedhose,and

whiphose.Elitepackagesalsoinclude

GracoInSiteanduidinletsensors.AllElite

hoseandgunsystempackagesinclude

Xtreme-Wrap™50ft(15m)heatedhose.

Forpartnumbers,seeAccessories,page15.

Voltage

Voltage Voltage

Ø

∆

Congurations

Congurations Congurations

Key

Key Key

PHASE

DELTA

YWYE

334945B 9

Page 10

Models

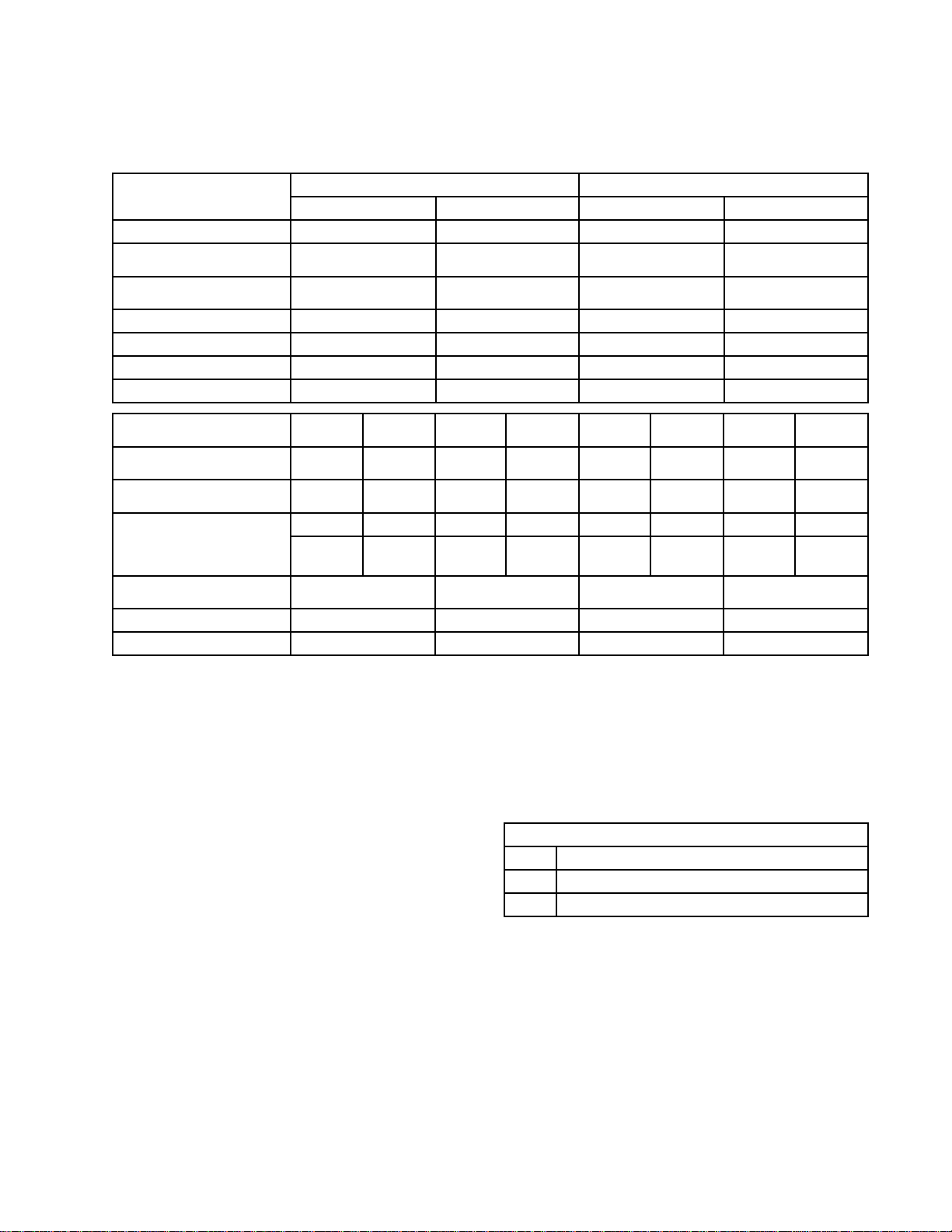

Reactor

Reactor Reactor

Model

Model Model

Proportioner

Proportioner Proportioner

Maximum

Maximum Maximum

Pressure

Pressure Pressure

Approximate

Approximate Approximate

(A+B)

gal.

(A+B) (A+B)

gal. gal.

Max

Flow

Max Max

Flow Flow

Total

System

Total Total

System System

Voltage

Voltage Voltage

Full

Load

Full Full

Load Load

Fusion

Fusion Fusion

®AP AP

(Gun Part No.)

Fusion

Fusion Fusion

®CS CS

(Gun Part No.)

Probler

Probler Probler

(Gun Part No.)

Heated

(15

50 5050ft ftft(15 (15

24K240(scuffguard)

24Y240(Xtreme-wrap)

Heated

Heated Heated

10 1010ft ftft(3 (3(3m) m)

Graco

Insite

Graco Graco

Insite Insite

Fluid

Inlet

Fluid Fluid

Inlet Inlet

H

40

2 22H H

★17H04317H04417H14317H144

Fluid

Working

Fluid Fluid

Working Working

psi

(MPa,

psi psi

(MPa, (MPa,

Output

Output Output

(liter)

(liter) (liter)

Rate

lb/min

Rate Rate

lb/min lb/min

Load

Load Load

Phase

Phase Phase

Peak

Current*

Peak Peak

Current* Current*

AP

Package

Package Package

CS

Package

Package Package

P2

Package

P2 P2

Package Package

Hose

Hose Hose

m)

m) m)

Whip

Hose

Whip Whip

Hose Hose

m)

Sensors

Sensors Sensors

and

- --40 40

and and

bar)

bar) bar)

per

Cycle

per per

Cycle Cycle

(kg/min)

(kg/min) (kg/min)

(Watts)

† ††(Watts) (Watts)

6

6

6

(2)

(2) (2)

40

H HH- --40 40

15

kW

15 15

kW kW

2000(14,140)2000(14,140)2000(14,140)2000(14,140)

0.063(0.24)0.063(0.24)0.063(0.24)0.063(0.24)

45(20)45(20)45(20)45(20)

26,60031,70026,60031,700

2303Ø∆2303Ø∆2303Ø∆2303Ø∆

71957195

APH043

(246102)

CSH043

(CS02RD)

P2H043

(GCP2R2)

24K24024K24024K24024K24024Y24024Y24024Y24024Y240 Heated Heated

Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5

246050246050246050246050

Elite

Elite Elite

40

Model

H HH- --40 40

Model Model

20

kW

20 20

kW kW

AHH043

(246102)

CHH043

(CS02RD)

PHH043

(GCP2R2)

APH044

(246102)

CSH044

(CS02RD)

P2H044

(GCP2R2)

AHH044

(246102)

CHH044

(CS02RD)

PHH044

(GCP2R2)

kW

15 1515kW kW

APH143

(246102)

CSH143

(CS02RD)

P2H143

(GCP2R2)

✓✓

✓✓

40

Elite

H HH- --40 40

AHH143

(246102)

CHH143

(CS02RD)

PHH143

(GCP2R2)

Model

Elite Elite

Model Model

kW

20 2020kW kW

APH144

(246102)

CSH144

(CS02RD)

P2H144

(GCP2R2)

AHH144

(246102)

CHH144

(CS02RD)

PHH144

(GCP2R2)

*

Fullloadampswithalldevicesoperatingat

* *

maximumcapabilities.Fuserequirements

atvariousowratesandmixchambersizes

maybeless.

=

Totalsystemwattsusedbysystem,basedon

maximumheatedhoselengthforeachunit.

•H–40series:410ft(125m)maximum

heatedhoselength,includingwhiphose.

★

SeeApprovals,page15.

6

Packagesincludegun,heatedhose,and

whiphose.Elitepackagesalsoinclude

GracoInSiteanduidinletsensors.AllElite

hoseandgunsystempackagesinclude

Xtreme-Wrap™50ft(15m)heatedhose.

Forpartnumbers,seeAccessories,page15.

Voltage

Voltage Voltage

Ø

∆

Congurations

Congurations Congurations

Key

Key Key

PHASE

DELTA

YWYE

10 334945B

Page 11

Models

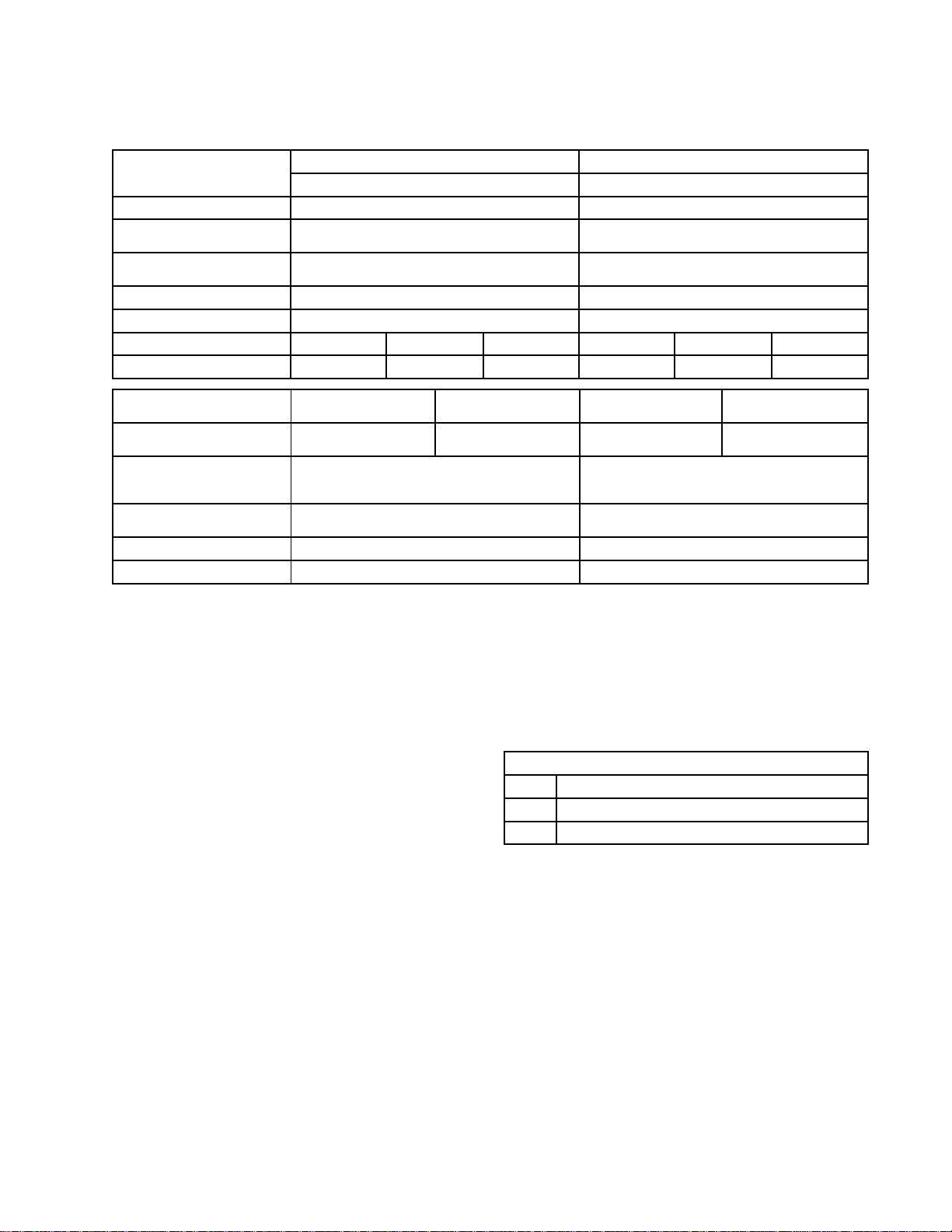

Reactor

Reactor Reactor

(Continued)

(Continued) (Continued)

Model

Model Model

Proportioner

Proportioner Proportioner

Maximum

Maximum Maximum

Pressure

Pressure Pressure

Approximate

Approximate Approximate

(A+B)

gal.

(A+B) (A+B)

gal. gal.

Max

Flow

Max Max

Flow Flow

Total

System

Total Total

System System

Voltage

Voltage Voltage

Full

Load

Full Full

Load Load

Fusion

Fusion Fusion

®AP AP

(Gun Part No.)

Fusion

Fusion Fusion

®CS CS

(Gun Part No.)

Probler

Probler Probler

(Gun Part No.)

Heated

50

(15

50 50

ft ftft(15 (15

24K240(scuffguard)

24Y240(Xtreme-wrap)

Heated

Heated Heated

10

10 10

ft ftft(3 (3(3m) m)

Graco

Insite

Graco Graco

Insite Insite

Fluid

Inlet

Fluid Fluid

Inlet Inlet

2

40

2 2

H HH- --40 40

★17H04517H04617H14517H146

Fluid

Working

Fluid Fluid

Working Working

psi

(MPa,

psi psi

(MPa, (MPa,

Output

Output Output

(liter)

(liter) (liter)

Rate

lb/min

Rate Rate

lb/min lb/min

Load

Load Load

† ††(Watts) (Watts)

Phase

Phase Phase

Peak

Current*

Peak Peak

Current* Current*

AP

Package

Package Package

CS

Package

Package Package

P2

Package

P2 P2

Package Package

Hose

Hose Hose

m)

m) m)

Whip

Hose

Whip Whip

Hose Hose

m)

Sensors

Sensors Sensors

(2)

(2) (2)

and

and and

bar)

bar) bar)

per

Cycle

per per

Cycle Cycle

(kg/min)

(kg/min) (kg/min)

(Watts)

6

6

6

40

H HH- --40 40

15

kW

15 15

kW kW

2000(14,140)2000(14,140)2000(14,140)2000(14,140)

0.063(0.24)0.063(0.24)0.063(0.24)0.063(0.24)

45(20)45(20)45(20)45(20)

26,60031,70026,60031,700

3803Ø∆3803Ø∆3803Ø∆3803Ø∆

41524152

APH045

(246102)

CSH045

(CS02RD)

P2H045

(GCP2R2)

24K24024K24024K24024K24024Y24024Y24024Y24024Y240 Heated Heated

Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5

246050246050246050246050

Elite

Elite Elite

40

Model

H HH- --40 40

Model Model

20

kW

20 20

kW kW

AHH045

(246102)

CHH045

(CS02RD)

PHH045

(GCP2R2)

APH046

(246102)

CSH046

(CS02RD)

P2H046

(GCP2R2)

AHH046

(246102)

CHH046

(CS02RD)

PHH046

(GCP2R2)

kW

15 1515kW kW

APH145

(246102)

CSH145

(CS02RD)

P2H145

(GCP2R2)

✓✓

✓✓

40

Elite

H HH- --40 40

AHH145

(246102)

CHH145

(CS02RD)

PHH145

(GCP2R2)

Model

Elite Elite

Model Model

kW

20 2020kW kW

APH146

(246102)

CSH146

(CS02RD)

P2H146

(GCP2R2)

AHH146

(246102)

CHH146

(CS02RD)

PHH146

(GCP2R2)

*

Fullloadampswithalldevicesoperatingat

* *

maximumcapabilities.Fuserequirements

atvariousowratesandmixchambersizes

maybeless.

=

Totalsystemwattsusedbysystem,basedon

maximumheatedhoselengthforeachunit.

•H–40series:410ft(125m)maximum

heatedhoselength,includingwhiphose.

★

SeeApprovals,page15.

6

Packagesincludegun,heatedhose,and

whiphose.Elitepackagesalsoinclude

GracoInSiteanduidinletsensors.AllElite

hoseandgunsystempackagesinclude

Xtreme-Wrap™50ft(15m)heatedhose.

Forpartnumbers,seeAccessories,page15.

Voltage

Voltage Voltage

Ø

∆

Congurations

Congurations Congurations

Key

Key Key

PHASE

DELTA

YWYE

334945B

11

Page 12

Models

Reactor

Reactor Reactor

Model

Model Model

Proportioner

Proportioner Proportioner

Maximum

Maximum Maximum

Pressure

Pressure Pressure

Approximate

Approximate Approximate

(A+B)

gal.

(A+B) (A+B)

gal. gal.

Max

Flow

Max Max

Flow Flow

Total

System

Total Total

System System

Congurable

Congurable Congurable

Full

Load

Full Full

Load Load

Fusion

Fusion Fusion

®AP AP

(Gun Part No.)

Fusion

Fusion Fusion

®CS CS

(Gun Part No.)

Probler

Probler Probler

(Gun Part No.)

Heated

(15

50 5050ft ftft(15 (15

24K240(scuffguard)

24Y240(Xtreme-wrap)

Heated

Heated Heated

10 1010ft ftft(3 (3(3m) m)

Graco

Insite

Graco Graco

Insite Insite

Fluid

Inlet

Fluid Fluid

Inlet Inlet

H

50

2 22H H

★17H05317H05617H15317H156

Fluid

Working

Fluid Fluid

Working Working

psi

(MPa,

psi psi

(MPa, (MPa,

Output

Output Output

(liter)

(liter) (liter)

Rate

lb/min

Rate Rate

lb/min lb/min

Load

Load Load

Voltage

Voltage Voltage

Peak

Current*

Peak Peak

Current* Current*

AP

Package

Package Package

CS

Package

Package Package

P2

Package

P2 P2

Package Package

Hose

Hose Hose

m)

m) m)

Whip

Hose

Whip Whip

Hose Hose

m)

Sensors

Sensors Sensors

and

- --50 50

and and

bar)

bar) bar)

per

Cycle

per per

Cycle Cycle

(kg/min)

(kg/min) (kg/min)

(Watts)

† ††(Watts) (Watts)

Phase

Phase Phase

6

6

6

(2)

(2) (2)

50

H HH- --50 50

20

kW

20 20

kW kW

2000(14,140)2000(14,140)2000(14,140)2000(14,140)

0.073(0.28)0.073(0.28)0.073(0.280.073(0.28

52(24)52(24)52(24)52(24)

31,70031,70031,70031,700

2303Ø∆3803ØY2303Ø∆3803ØY

95529552

APH053

(246102)

CSH053

(CS02RD)

P2H053

(GCP2R2)

24K24024K24024K24024K24024Y24024Y24024Y24024Y240 Heated Heated

Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5

246050246050246050246050

Elite

Elite Elite

50

Model

H HH- --50 50

Model Model

20

kW

20 20

kW kW

AHH053

(246102)

CHH053

(CS02RD)

PHH053

(GCP2R2)

APH056

(246102)

CSH056

(CS02RD)

P2H056

(GCP2R2)

AHH056

(246102)

CHH056

(CS02RD)

PHH056

(GCP2R2)

kW

20 2020kW kW

APH153

(246102)

CSH153

(CS02RD)

P2H153

(GCP2R2)

✓✓

✓✓

50

Elite

H HH- --50 50

AHH153

(246102)

CHH153

(CS02RD)

PHH153

(GCP2R2)

Model

Elite Elite

Model Model

kW

20 2020kW kW

APH156

(246102)

CSH156

(CS02RD)

P2H156

(GCP2R2)

AHH156

(246102)

CHH156

(CS02RD)

PHH156

(GCP2R2)

*

Fullloadampswithalldevicesoperatingat

* *

maximumcapabilities.Fuserequirements

atvariousowratesandmixchambersizes

maybeless.

=

Totalsystemwattsusedbysystem,basedon

maximumheatedhoselengthforeachunit.

•H–50series:410ft(125m)maximum

heatedhoselength,includingwhiphose.

★

SeeApprovals,page15.

6

Packagesincludegun,heatedhose,and

whiphose.Elitepackagesalsoinclude

GracoInSiteanduidinletsensors.AllElite

hoseandgunsystempackagesinclude

Xtreme-Wrap™50ft(15m)heatedhose.

Forpartnumbers,seeAccessories,page15.

Voltage

Voltage Voltage

Ø

∆

Congurations

Congurations Congurations

Key

Key Key

PHASE

DELTA

YWYE

12

334945B

Page 13

Models

Reactor

Reactor Reactor

Model

Model Model

Proportioner

Proportioner Proportioner

Maximum

Maximum Maximum

Pressure

Pressure Pressure

Approximate

Approximate Approximate

(A+B)

(A+B) (A+B)

Max

Max Max

Total

Total Total

Congurable

Congurable Congurable

Full

Full Full

Fusion

Fusion Fusion

(Gun Part No.)

Probler

Probler Probler

(Gun Part No.)

Heated

Heated Heated

50

50 50

Heated

Heated Heated

10

10 10

Graco

Graco Graco

Fluid

Fluid Fluid

XP2

2 22H HH- --XP2 XP2

★17H06217H162

Fluid

Working

Fluid Fluid

Working Working

psi

(MPa,

psi psi

gal.

(liter)

gal. gal.

(liter) (liter)

Flow

Rate

Flow Flow

Rate Rate

System

System System

Load

Peak

Load Load

Peak Peak

AP

®AP AP

P2

Package

P2 P2

Package Package

Hose

Hose Hose

(15

m)

ft ftft(15 (15

m) m)

Whip

Whip Whip

m)

ft ftft(3 (3(3m) m)

Insite

Insite Insite

Inlet

Sensors

Inlet Inlet

Sensors Sensors

bar)

(MPa, (MPa,

bar) bar)

Output

per

Output Output

per per

lb/min

lb/min lb/min

Load

(Watts)

Load Load

† ††(Watts) (Watts)

Voltage

Phase

Voltage Voltage

Phase Phase

Current*

Current* Current*

Package

Package Package

6

Hose

Hose Hose

(2)

(2) (2)

and

and and

15

15 15

3500(24.1,241)3500(24.1,241)

Cycle

Cycle Cycle

0.042(0.16)0.042(0.16)

(kg/min)

(kg/min) (kg/min)

6

1.5(5.7)1.5(5.7)

23,26023,260

2301Ø2303Ø∆2303ØY2301Ø2303Ø∆2303ØY

10059351005935

APH062

(246101)

P2H062

(GCP2R1)

24K241

(scuffguard)

246055246055

XP2

H HH- --XP2 XP2

kW

kW kW

Elite

Elite Elite

XP2

Model

H HH- --XP2 XP2

Model Model

15kW

15kW 15kW

AHH062

(246101)

PHH062

(246101)

APH162

(246101)

P2H162

(GCP2R1)

24Y241

(Xtreme-wrap)

✓

✓

XP2

Elite

H HH- --XP2 XP2

Model

Elite Elite

Model Model

AHH162

(246101)

PHH162

(246101)

*

Fullloadampswithalldevicesoperatingat

* *

maximumcapabilities.Fuserequirements

atvariousowratesandmixchambersizes

maybeless.

=

Totalsystemwattsusedbysystem,basedon

maximumheatedhoselengthforeachunit.

•H–XP2series:310ft(94.5m)maximum

heatedhoselength,includingwhiphose.

★

SeeApprovals,page15.

6

Packagesincludegun,heatedhose,and

whiphose.Elitepackagesalsoinclude

GracoInSiteanduidinletsensors.AllElite

hoseandgunsystempackagesinclude

Xtreme-Wrap™50ft(15m)heatedhose.

Forpartnumbers,seeAccessories,page15.

Voltage

Voltage Voltage

Ø

∆

Congurations

Congurations Congurations

Key

Key Key

PHASE

DELTA

YWYE

334945B 13

Page 14

Models

Reactor

Reactor Reactor

Model

Model Model

Proportioner

Proportioner Proportioner

Maximum

Maximum Maximum

Pressure

Pressure Pressure

Approximate

Approximate Approximate

(A+B)

gal.

(A+B) (A+B)

gal. gal.

Max

Flow

Max Max

Flow Flow

Total

System

Total Total

System System

Congurable

Congurable Congurable

Full

Load

Full Full

Load Load

Fusion

Fusion Fusion

®AP AP

(Gun Part No.)

Probler

Probler Probler

(Gun Part No.)

Heated

(15

50 5050ft ftft(15 (15

24K240(scuffguard)

24Y240(Xtreme-wrap)

Heated

Heated Heated

10 1010ft ftft(3 (3(3m) m)

Graco

Insite

Graco Graco

Insite Insite

Fluid

Inlet

Fluid Fluid

Inlet Inlet

H

XP3

2 22H H

- --XP3 XP3

★17H07417H07617H17417H176

Fluid

Working

Fluid Fluid

Working Working

psi

(MPa,

psi psi

(liter)

(liter) (liter)

Rate

Rate Rate

Peak

Peak Peak

AP

P2

Package

P2 P2

Package Package

Hose

Hose Hose

m)

m) m)

Whip

Whip Whip

m)

Sensors

Sensors Sensors

bar)

(MPa, (MPa,

bar) bar)

Output

per

Output Output

per per

lb/min

lb/min lb/min

Load

(Watts)

Load Load

† ††(Watts) (Watts)

Voltage

Phase

Voltage Voltage

Phase Phase

Current*

Current* Current*

Package

Package Package

6

Hose

Hose Hose

(2)

(2) (2)

and

H

and and

20

20 20

3500(24.1,241)3500(24.1,241)3500(24.1,241)3500(24.1,241)

Cycle

Cycle Cycle

0.042(0.16)0.042(0.16)0.042(0.16)0.042(0.16)

(kg/min)

(kg/min) (kg/min)

6

2.8(10.6)2.8(10.6)2.8(10.6)2.8(10.6)

31,70031,70031,70031,700

2303Ø∆3803ØY2303Ø∆3803ØY

95529552

APH074

(246102)

P2H074

(GCP2R2)

24K24024K24024K24024K24024Y24024Y24024Y24024Y240 Heated Heated

Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5Qty:1Qty:5

246050246050246050246050

XP3

H H

- --XP3 XP3

kW

kW kW

Elite

Elite Elite

XP3

Model

H HH- --XP3 XP3

Model Model

20

kW

20 20

kW kW

APH074

(246102)

P2H074

(GCP2R2)

APH076

(246102)

P2H076

(GCP2R2)

APH076

(246102)

P2H076

(GCP2R2)

kW

20 2020kW kW

APH174

(246102)

P2H174

(GCP2R2)

✓✓

✓✓

XP3

Elite

H HH- --XP3 XP3

APH174

(246102)

P2H174

(GCP2R2)

Model

Elite Elite

Model Model

kW

20 2020kW kW

APH176

(246102)

P2H176

(GCP2R2)

APH176

(246102)

P2H176

(GCP2R2)

*

Fullloadampswithalldevicesoperatingat

* *

maximumcapabilities.Fuserequirements

atvariousowratesandmixchambersizes

maybeless.

=

Totalsystemwattsusedbysystem,basedon

maximumheatedhoselengthforeachunit.

•H–XP3series:410ft(125m)maximum

heatedhoselength,includingwhiphose.

★

SeeApprovals,page15.

6

Packagesincludegun,heatedhose,and

whiphose.Elitepackagesalsoinclude

GracoInSiteanduidinletsensors.AllElite

hoseandgunsystempackagesinclude

Xtreme-Wrap™50ft(15m)heatedhose.

Forpartnumbers,seeAccessories,page15.

Voltage

Voltage Voltage

Ø

∆

Congurations

Congurations Congurations

Key

Key Key

PHASE

DELTA

YWYE

14

334945B

Page 15

Approvals

Approvals

Approvals Approvals

Intertekapprovalsapplytoproportionerswithout

hoses.

Proportioner

Proportioner Proportioner

ConformstoANSI/ULStd.499

CertiedtoCAN/CSAStd.C22.2No.88

Approvals:

Approvals: Approvals:

9902471

9902471 9902471

Accessories

Accessories Accessories

Kit

Number

Kit Kit

Number Number

24U315

17G340CasterKit

24T280

17F837

16X521

24N449

24K207

24U174RemoteDisplayModuleKit

15V551

15M483RemoteDisplayModuleProtective

24M174

121006

Description

Description Description

AirManifold(4outlets)

GracoInSiteKit

InletSensorKit

GracoInSiteExtensioncable24.6ft

(7.5m)

50ft(15m)CANcable(forremote

displaymodule)

FluidTemperatureSensor(FTS)

withRTD

ADMProtectiveCovers(10pack)

Covers(10pack)

DrumLevelSticks

150ft(45m)CANcable(forremote

displaymodule)

24N365

RTDTestCables(toaideresistance

measurements)

334945B 15

Page 16

SuppliedManuals

Supplied

Supplied Supplied

ThefollowingmanualsareshippedwiththeReactor

2.Refertothesemanualsfordetailedequipment

information.

Manualsarealsoavailableatwww.graco.com.

Manual

Manual Manual

334945Reactor2HydraulicProportioning

334005Reactor2HydraulicProportioning

334006Reactor2HydraulicProportioning

Manuals

Manuals Manuals

Description

Description Description

SystemsOperationManual

SystemsShutdownQuickGuide

SystemsStartupQuickGuide

Related

Related Related

Thefollowingmanualsareforaccessoriesusedwith

theReactor2.

Component

Component Component

Manualsareavailableatwww.graco.com.

System

System System

333946Reactor2Repair-Parts

Displacement

Displacement Displacement

3A3085PumpRepair-Parts

Feed

Feed Feed

309572HeatedHose,Instructions-Parts

309852

309815FeedPumpKits,Instructions-Parts

309827

Spray

Spray Spray

309550

312666

313213

Accessory

Accessory Accessory

3A1905

3A3009

3A1907RemoteDisplayModuleKit,

332735

3A3010

333276

3A3084EliteKit,Instructions-Part

3A3085PumplineRepair,Instructions-Parts

Manuals

Manuals Manuals

System

System System

Gun

Gun Gun

Manuals

Manuals Manuals

Manuals

Manuals Manuals

Pump

Manual

Pump Pump

Manual Manual

Manuals

Manuals Manuals

CirculationandReturnTubeKit,

Instructions-Parts

FeedPumpAirSupplyKit,

Instructions-Parts

Manuals

Manuals Manuals

Fusion™APGun

Fusion™CSGun

Probler

Manuals

Manuals Manuals

FeedPumpShutdownKit,

Instructions-Parts

InletSensorKit,Instructions-Parts

Instructions-Parts

AirManifoldKit,Instructions-Parts

CasterKit,Instructions-Parts

GracoInSite™Kit,Instructions-Parts

®

P2Gun

in

English:

in in

English: English:

16 334945B

Page 17

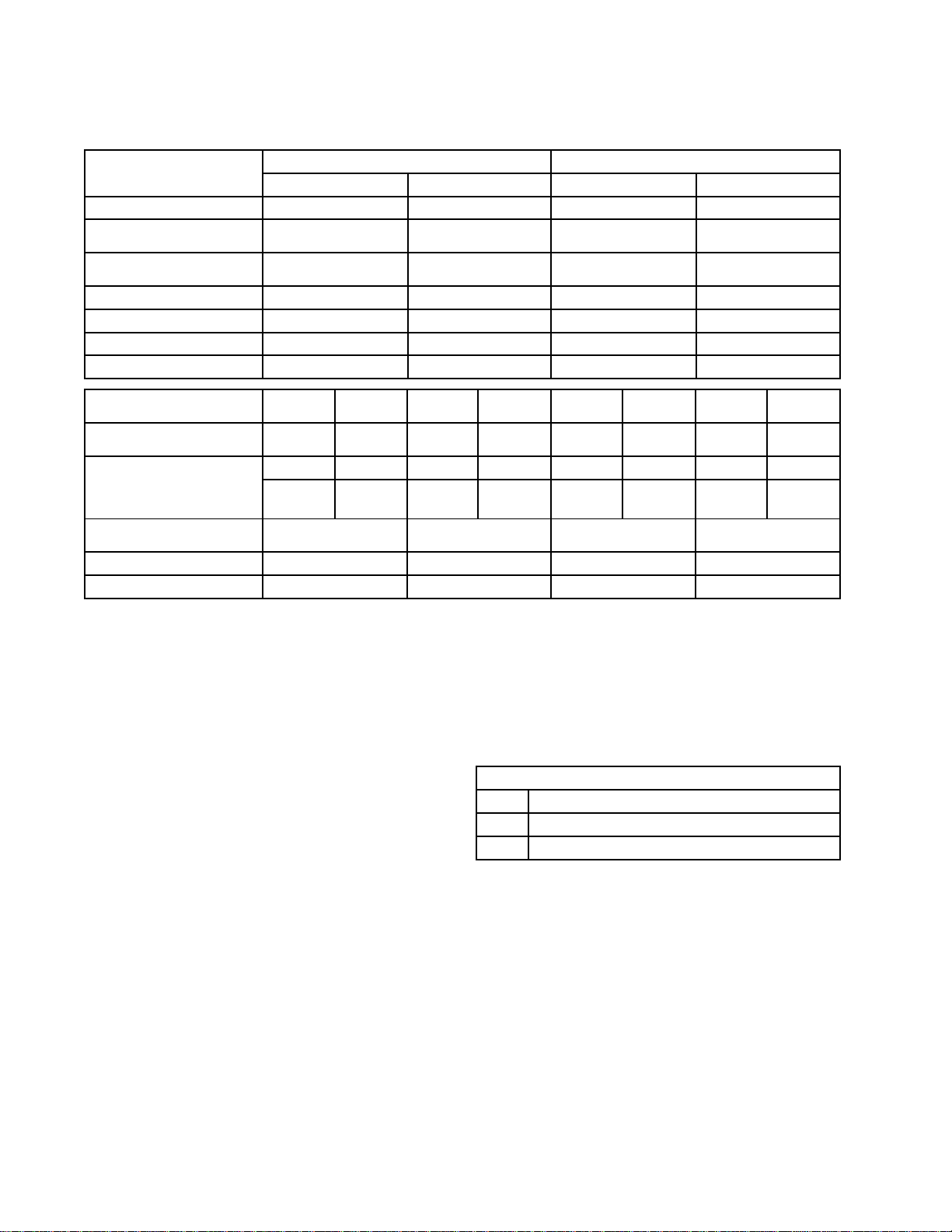

TypicalInstallation,withoutcirculation

B

G

K

M

J

G

H

K

L

J

D

S

C*

P

E

A

N

(B-RES)

(A-ISO)

F

N

Typical

Typical Typical

Installation,

Installation, Installation,

without

without without

circulation

circulation circulation

Figure1

*Shownexposedforclarity.Wrapwithtapeduringoperation.

AReactorProportioner

BHeatedHose

CFluidTemperatureSensor(FTS)

DHeatedWhipHose

E

F

GFeedPumpAirSupplyLines

H

FusionSprayGun

GunAirSupplyHose

AgitatorAirSupplyLine

J

KFeedPumps

LAgitator

MDesiccantDryer

NBleedLines

P

SRemoteDisplayModuleKit(optional)

FluidSupplyLines

GunFluidManifold(partofgun)

334945B

17

Page 18

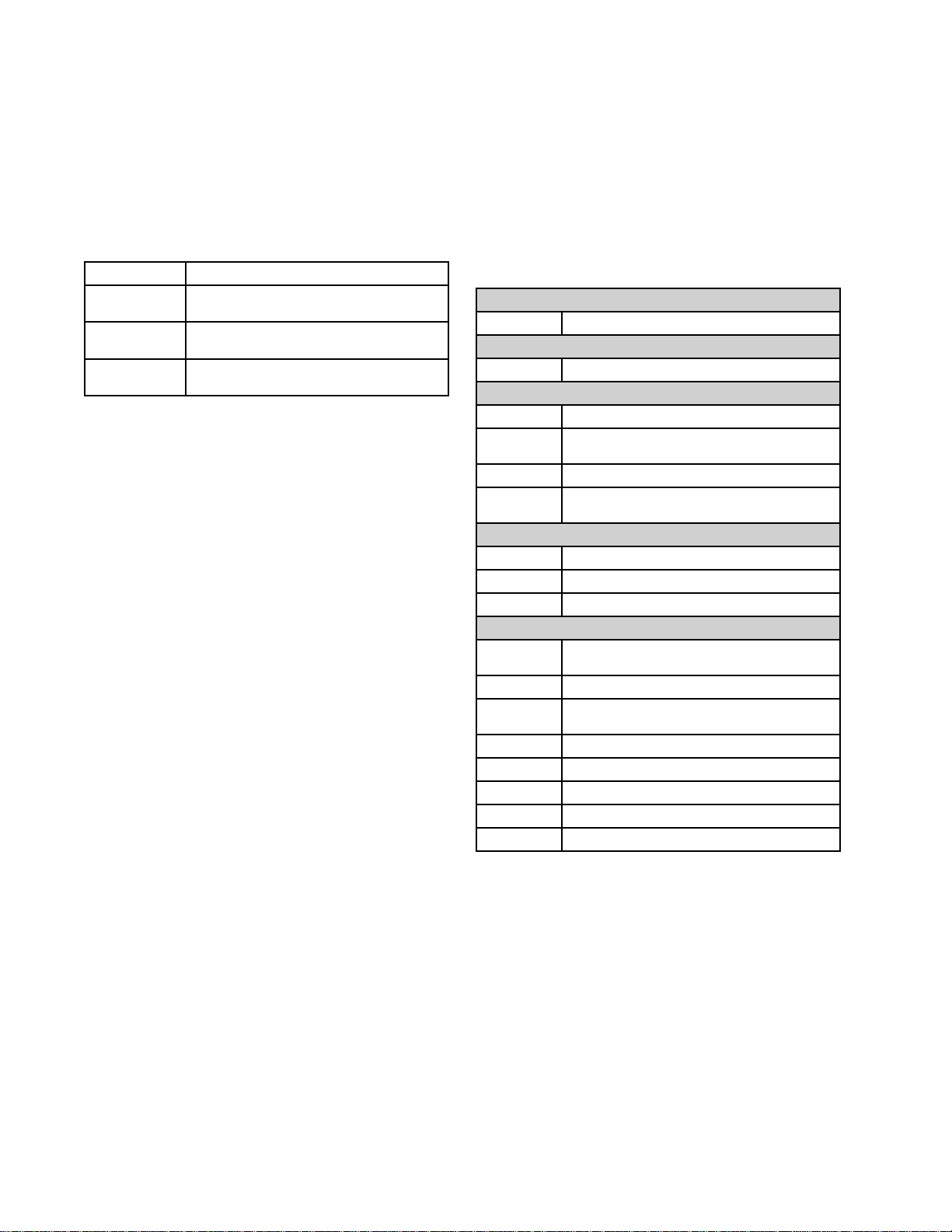

TypicalInstallation,withsystemuidmanifoldtodrumcirculation

(B-RES)

M

K

M

R

J

G

H

K

L

B

D

S

C*

P

E

R

A

(A-ISO)

G

J

F

Typical

Typical Typical

circulation

circulation circulation

Installation,

Installation, Installation,

with

with with

system

system system

uid

uid uid

manifold

manifold manifold

to

drum

to to

drum drum

Figure2

*Shownexposedforclarity.Wrapwithtapeduringoperation.

AReactorProportioner

BHeatedHose

CFluidTemperatureSensor(FTS)

DHeatedWhipHose

E

F

GFeedPumpAirSupplyLines

H

FusionSprayGun

GunAirSupplyHose

AgitatorAirSupplyLine

J

KFeedPumps

LAgitator

MDesiccantDryer

P

RRecirculationLines

SRemoteDisplayModule(optional)

FluidSupplyLines

GunFluidManifold(partofgun)

18 334945B

Page 19

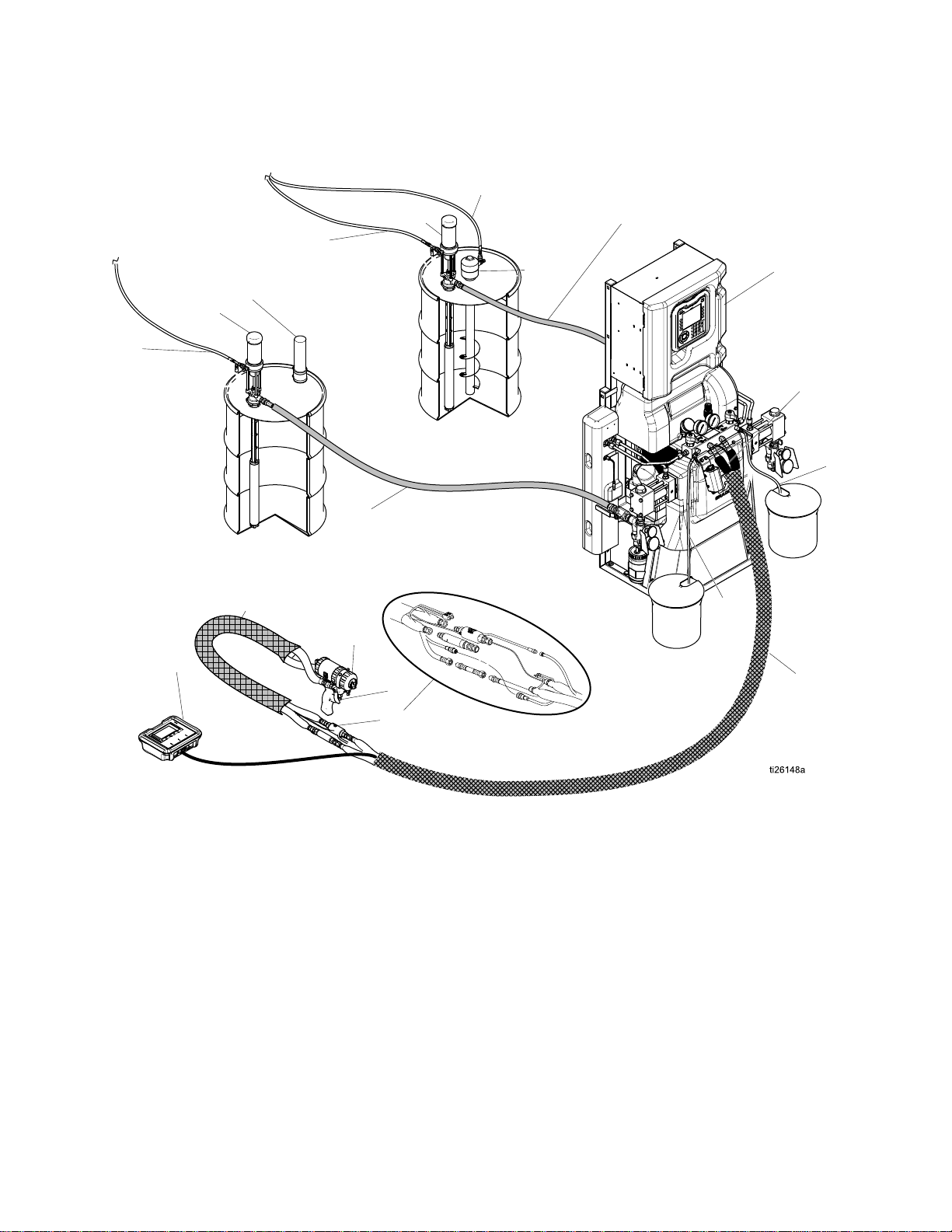

TypicalInstallation,withgunuidmanifoldtodrumcirculation

(B-RES)

M

K

M

R

J

G

H

K

L

B

J

D

S

C*

P

E

R

(A-ISO)

G

A

N

N

F

Typical

Typical Typical

circulation

circulation circulation

Installation,

Installation, Installation,

with

with with

gun

gun gun

uid

uid uid

manifold

manifold manifold

to

drum

to to

drum drum

Figure3

*Shownexposedforclarity.Wrapwithtapeduringoperation.

AReactorProportioner

BHeatedHose

CFluidTemperatureSensor(FTS)

CKCirculationBlock(accessory)

DHeatedWhipHose

F

GFeedPumpAirSupplyLines

H

GunAirSupplyHose

AgitatorAirSupplyLine

J

KFeedPumps

LAgitator

MDesiccantDryer

NBleedLines

P

RRecirculationLines

SRemoteDisplayModule(optional)

FluidSupplyLines

GunFluidManifold(partofgun)

334945B 19

Page 20

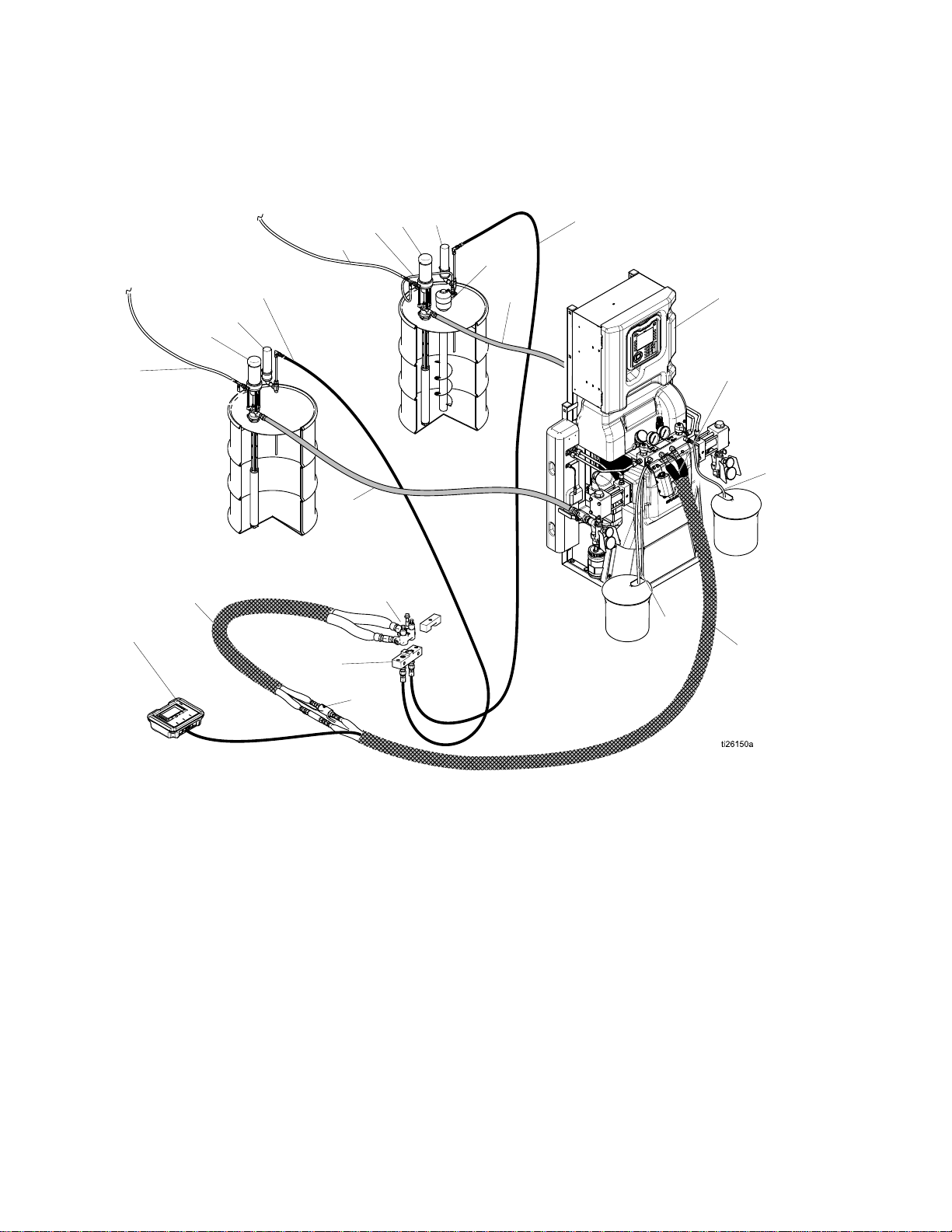

ComponentIdentication

B

D

S

C*

P

E

Component

Component Component

Identication

Identication Identication

Figure4

20 334945B

Page 21

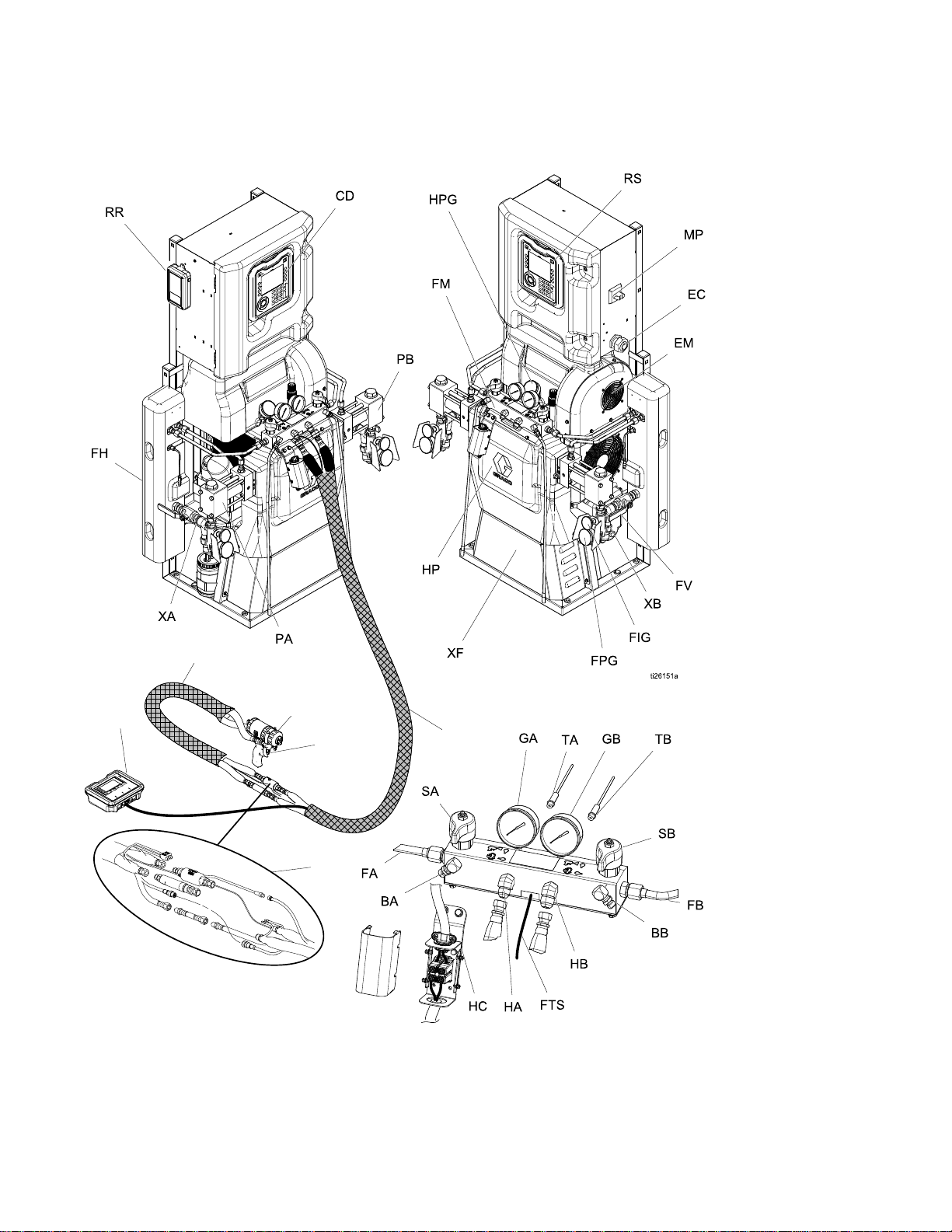

Key

Key Key

BA

BB

CDAdvancedDisplayModule(ADM)

ECElectricalCordStrainRelief

EM

FA

FB

FH

FM

FV

GAISOSidePressureGauge

GBRESSidePressureGauge

HA

HB

HC

HP

MP

PA

PB

ISOSidePressureReliefOutlet

RESSidePressureReliefOutlet

ElectricMotor(behindshroud)

ISOSideFluidManifoldInlet

RESSideFluidManifoldInlet

FluidHeater(behindshroud)

ReactorFluidManifold

FluidInletValve(RESsideshown)

ISOSideHoseConnection

RESSideHoseConnection

HeatedHoseElectricalJunctionBox

HydraulicDriver(behindshroud)

MainPowerSwitch

ISOSidePump

RESSidePump

ComponentIdentication

RR

RSRedStopButton

SAISOSidePRESSURERELIEF/SPRAY

SBRESSidePRESSURERELIEF/SPRAY

TA

TB

XA

XB

XF

FPGFluidInletValvePressureGauge

FTGFluidInletValveTemperatureGauge

FTSFTSConnection

HPGHydraulicPressureGauge

GracoInSiteCellularModule(Elitemodels

only)

Valve

Valve

ISOSidePressureTransducer(behind

gaugeGA)

RESSidePressureTransducer(behind

gaugeGB)

FluidInletSensor(ISOside,Elitemodels

only)

FluidInletSensor(RESside,Elitemodels

only)

HeatedHoseTransformer(behindcover)

334945B

21

Page 22

ComponentIdentication

Advanced

Advanced Advanced

TheADMdisplayshowsgraphicalandtext

informationrelatedtosetupandsprayoperations.

Figure5ADMFrontView

Topreventdamagetothesoftkeybuttons,donot

pressbuttonswithsharpobjectssuchaspens,

plasticcards,orngernails.

Display

Display Display

Module

Module Module

NOTICE

NOTICE NOTICE

(ADM)

(ADM) (ADM)

Table

Table Table

Key

Key Key

Startup

Startup Startup

Shutdown

Shutdown Shutdown

Key

Key Key

Indicator

Indicator Indicator

Soft

Soft Soft

Navigation

Navigation Navigation

Numeric Numeric

ADM

Keys

and

1 11: ::ADM ADM

and

and and

Stop

Stop Stop

Keys

Keys Keys

Keys

Keys Keys

Numeric

Keypad

Keypad Keypad

Keys Keys

Function

Function Function

Presstostartuporshutdownthe

system.

/

/ /

Presstostopallproportioner

processes.Thisisnotasafetyor

emergencystop.

Presstoselectthespecicscreen

oroperationshownonthedisplay

directlynexttoeachkey.

Left/Right Arrows:

•

fromscreentoscreen.

•

Up/Down Arrows:

amongeldsonascreen,items

onadropdownmenu,ormultiple

screenswithinafunction.

Usetoinputvalues.

Indicators

and and

Indicators Indicators

Usetomove

Usetomove

Usetocanceladataentryeld.

AlsousedtoreturntoHomescreen.

Cancel

Cancel Cancel

PresstoenterorexitSetupmode.

Setup

Setup Setup

Presstochooseaeldtoupdate,

tomakeaselection,tosavea

selectionorvalue,toenterascreen,

Enter

Enter Enter

22

ortoacknowledgeanevent.

334945B

Page 23

Figure6ADMBackView

CJFlatPanelMount(VESA100)

CKModelandSerialNumber

CLUSBPortandStatusLEDs

CMCANCommunicationCableConnection

CNModuleStatusLEDs

CPAccessoryCableConnection

CRTokenAccessCover

CSBackupBatteryAccessCover

ComponentIdentication

Table

Table Table

LED

LED LED

System

System System

USB

USB USB

ADM

ADM ADM

ADM

LED

2 22ADM ADM

Status

Status Status

Status

Status Status

Status

Status Status

Status

LED LED

Status Status

(CL)

(CL) (CL)

(CN)

(CN) (CN)

Descriptions

Descriptions Descriptions

Conditions

Conditions Conditions

GreenSolidRunMode,SystemOn

GreenFlashingSetupMode,SystemOn

YellowSolidRunMode,SystemOff

YellowFlashing

GreenFlashing

YellowSolidDownloadinginformationtoUSB

GreenandYellowFlashingADMisbusy,USBcannottransferinformation

GreenSolid

YellowSolidActiveCommunication

RedSteadyFlashingSoftwareuploadfromtokeninprogress

RedRandomFlashingorSolid

Description

Description Description

SetupMode,SystemOff

Datarecordinginprogress

wheninthismode

Powerappliedtomodule

Moduleerrorexists

334945B 23

Page 24

ComponentIdentication

ADM

ADM ADM

Power

Power Power

ThefollowingscreenappearswhentheADMis

poweredup.ItremainsonwhiletheADMruns

throughinitializationandestablishescommunication

withothermodulesinthesystem.

Menu

Menu Menu

Themenubarappearsatthetopofeachscreen.

(Thefollowingimageisonlyanexample.)

Display

Display Display

Bar

Bar Bar

Details

Details Details

Up

Screen

Up Up

Screen Screen

System

System System

Thecurrentsystemerrorisdisplayedinthemiddleof

themenubar.Therearefourpossibilities:

Icon

Icon Icon

NoIcon

SeeTroubleshootErrors,page60formore

information.

Status

Status Status

Thecurrentsystemstatusisdisplayedatthelower

rightofthemenubar.

Soft

Soft Soft

Iconsnexttothesoftkeysindicatewhichmodeor

actionisassociatedwitheachsoftkey.Softkeys

thatdonothaveaniconnexttothemarenotactive

inthecurrentscreen.

Topreventdamagetothesoftkeybuttons,donot

pressbuttonswithsharpobjectssuchaspens,plastic

cards,orngernails.

Errors

Errors Errors

Function

Function Function

Noinformationornoerrorhasoccurred

Advisory

Deviation

Alarm

Keys

Keys Keys

NOTICE

NOTICE NOTICE

Date

and

Date Date

Thedateandtimearealwaysdisplayedinoneof

thefollowingformats.Thetimeisalwaysdisplayed

asa24-hourclock.

•DD/MM/YYHH:MM

•YY/MM/DDHH:MM

•MM/DD/YYHH:MM

Arrows

Arrows Arrows

Theleftandrightarrowsindicatescreennavigation.

Screen

Screen Screen

Thescreenmenuindicatesthecurrentlyactive

screen,whichishighlighted.Italsoindicatesthe

associatedscreensthatareavailablebyscrollingleft

andright.

System

System System

Thecurrentsystemmodeisdisplayedatthelower

leftofthemenubar.

Time

and and

Time Time

Menu

Menu Menu

Mode

Mode Mode

Navigating

Navigating Navigating

Therearetwosetsofscreens:

Run

•Run Run

displaysystemstatusanddata.

Setup

•Setup Setup

advancedfeatures.

Press

screens.Ifthesystemhasapasswordlock,the

Passwordscreendisplays.Ifthesystemisnotlocked

(passwordissetto0000),SystemScreen1displays.

Press

Homescreen.

PresstheEntersoftkeytoactivatetheediting

functiononanyscreen.

PresstheExitsoftkey

Usetheothersoftkeystoselectthefunctionadjacent

tothem.

the

Screens

the the

Screens Screens

Screens

Screens Screens

Screens

Screens Screens

–controlsprayingoperationsand

–controlsystemparametersand

onanyRunscreentoentertheSetup

onanySetupscreentoreturntothe

toexitanyscreen.

24

334945B

Page 25

ComponentIdentication

Icons

Icons Icons

Icons

Icons Icons

Icon

Icon Icon

Function

Function Function

ComponentA

ComponentB

EstimatedSupplyMaterial

HoseTemperature

Pressure

CycleCounter(pressand

hold)

Advisory.

SeeTroubleshootErrors,

page60formoreinformation.

Deviation.

SeeTroubleshootErrors,

page60formoreinformation.

Alarm.

SeeTroubleshootErrors,

page60formoreinformation.

PumpMovingLeft

Softkeys

Softkeys Softkeys

Icon

Icon Icon

Function

Function Function

StartProportioner

StopProportioner

Turnonoroffthespeciedheatzone.

Parkpump

ResetCycleCounter

(pressandhold)

SelectRecipe

Search

MoveCursorLeftOneCharacter

MoveCursorRightOneCharacter

Togglebetweenupper-case,lower-case,and

numbersandspecialcharacters.

Backspace

Cancel

Clear

PumpMovingRight

TroubleshootSelectedError

Increasevalue

Decreasevalue

Nextscreen

Previousscreen

Returntorstscreen

334945B 25

Page 26

ComponentIdentication

Electrical

Electrical Electrical

H-40,

H-50,

H-40, H-40,

H-50, H-50,

AAATemperatureControlModule(TCM)

AABHydraulicControlModule(HCM)

AACEnclosureFan(s)

AADWiringTerminalBlocks(H-30/H-XP2only)

Enclosure

Enclosure Enclosure

H-XP3

H-XP3 H-XP3

H-30,

H-XP2

H-30, H-30,

H-XP2 H-XP2

AAEPowerSupply

AAFSacricialSurgeProtector(SSP)

AAGHoseBreaker

AAHMotorBreaker

AAJASideHeatBreaker

AAKBSideHeatBreaker

AALHoseTransformerBreaker

AAMMotorContactor

AANTB21TerminalBlock(ifequipped)

MPMainPowerSwitch

26 334945B

Page 27

ComponentIdentication

Hydraulic

Hydraulic Hydraulic

Figure7

MSModuleStatusLEDsseeLEDStatusTable

1

2

6

7

8

9

10

14

15

RS

Control

Control Control

Description

Description Description

CANCommunicationConnections

MotorOver-Temperature

APumpOutputPressure

BPumpOutputPressure

AFluidInletSensor

BFluidInletSensor

PumpPositionSwitches

GracoInsite

MotorContactorandSolenoids

RotarySwitch

Module

Module Module

™

(HCM)

(HCM) (HCM)

HCM

Rotary

HCM HCM

Rotary Rotary

0=Reactor2,H-30

1=Reactor2,H-40

2=Reactor2,H-50

3=Reactor2,H-XP2

4=Reactor2,H-XP3

Table

Table Table

3 33HCM HCM

LED

LED LED

HCM

HCM HCM

Switch

Switch Switch

HCM

Status

Status Status

Module

Module Module

(RS)

(RS) (RS)

Conditions

Conditions Conditions

GreenSolid

YellowSolid

RedSteady

Flashing

RedRandom

FlashingorSolid

Positions

Positions Positions

LED

(MS)

LED LED

Status

(MS) (MS)

Status Status

Descriptions

Descriptions Descriptions

Description

Description Description

Powerappliedto

module

Active

Communication

Softwareupload

fromtokenin

progress

Moduleerror

exists

334945B

27

Page 28

ComponentIdentication

Temperature

Temperature Temperature

Figure8

1PowerInput

2

3

4

5

6

7

8

9

10HoseTemperature

Control

Control Control

HeaterOvertemperature

CANCommunicationsConnections

PowerOutHeaterA(ISO)

PowerOutHeaterB(Res)

PowerOut(HeatedHose)

ModuleStatusLEDs

HeaterA(ISO)Temperature

HeaterB(RES)Temperature

Module

Module Module

(TCM)

(TCM) (TCM)

Cable

Cable Cable

Connections

Connections Connections

Table

Table Table

LED

LED LED

TCM

TCM TCM

TCM

4 44TCM TCM

Status Status

Module

Module Module

Status

Conditions

Conditions Conditions

GreenSolid

YellowSolid

RedSteady

Flashing

RedRandom

FlashingorSolid

LED

(7)

LED LED

Status

(7) (7)

Status Status

Descriptions

Descriptions Descriptions

Description

Description Description

Powerappliedto

module

Active

Communication

Softwareupload

fromtokenin

progress

Moduleerror

exists

28 334945B

Page 29

Setup

Setup

Setup Setup

Grounding

Grounding Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

•

Reactor:

cord.

•

Spray gun:

SeeInstallFluidTemperatureSensor.Donot

disconnectgroundwireorspraywithoutwhiphose.

Fluid supply containers:

•

•

Object being sprayed:

•

Solvent pails used when ushing:

code.Useonlymetalpails,whichareconductive,

placedonagroundedsurface.Donotplacepail

onanonconductivesurface,suchaspaperor

cardboard,whichinterruptsgroundingcontinuity.

To maintain grounding continuity when ushing or

•

relieving pressure,

rmlytothesideofagrounded

triggergun.

Systemisgroundedthroughthepower

connectwhiphosegroundwiretoFTS.

followyourlocalcode.

followyourlocalcode.

followyourlocal

holdametalpartofspraygun

metal

pail,then

General

General General

Failuretoproperlysizetheequipmentmayresult

indamage.Toavoiddamagetotheequipment,

followtheguidelineslistedbelow.

•Determinethecorrectsizegenerator.Usingthe

correctsizegeneratorandproperaircompressor

willenabletheproportionertorunatanearly

constantRPM.Failuretodosowillcausevoltage

uctuationsthatcandamageelectricalequipment.

Ensurethatthegeneratormatchesthevoltageand

phaseoftheproportioner.

Usethefollowingproceduretodeterminethecorrect

sizegenerator.

1.Listpeakwattagerequirementsofallsystem

components.

2.Addthewattagerequiredbythesystem

components.

3.Performthefollowingequation:

Totalwattsx1.25=kVA(kilovolt-amperes)

4.Selectageneratorsizethatisequaltoorgreater

thanthedeterminedkVA.

•Useproportionerpowercordsthatmeetorexceed

therequirementslistedinTable4.Failuretodoso

willcausevoltageuctuationsthatcandamage

electricalequipment,andmaycausethepower

cabletooverheat.

•Useanaircompressorwithcontinuousrunhead

unloadingdevices.Directonlineaircompressors

thatstartandstopduringajobwillcausevoltage

uctuationsthatcandamageelectricalequipment.

Equipment

Equipment Equipment

NOTICE

NOTICE NOTICE

Guidelines

Guidelines Guidelines

•Maintainandinspectthegenerator,air

compressor,andotherequipmentperthe

manufacturerrecommendationstoavoidan

unexpectedshutdown.Unexpectedequipment

shutdownwillcausevoltageuctuationsthatcan

damageelectricalequipment.

•Useawallpowersupplywithenoughcurrent

tomeetsystemrequirements.Failuretodoso

willcausevoltageuctuationsthatcandamage

electricalequipment.

334945B 29

Page 30

Setup

ti26342a_17D775

Connect

Connect Connect

NOTE:

NOTE: NOTE:

Power

Power Power

Allelectricalwiringmustbedonebya

qualiedelectricianandcomplywithalllocalcodes

andregulations.

1.Turnmainpowerswitch(MP)OFF.

2.Openelectricalenclosuredoor.

NOTE:

NOTE: NOTE:

Terminaljumpersarelocatedinsidethe

electricalenclosuredoorifequipped.

3.Installsuppliedterminaljumpersinthepositions

showninimageforthepowersourceused(H-30

andH-XP2modelsonly).

4.Routepowercablethroughstrainrelief(EC)in

electricalenclosure.

5.Connectincomingpowerwiresasshownin

image.Gentlypullonallconnectionstoverify

theyareproperlysecured.

6.Verifyallitemsareconnectedproperlyasshown

inimagethencloseelectricalenclosuredoor.

Table

Table Table

Model

Model Model

H-30,10.2

kW

H-30,15.3

kW

H-XP2,

15.3kW

H-40,15.3

kW

H-40,20.4

kW

H-50,20.4

kW

H-XP3,

20.4kW

Power

5 55Power Power

Cord

Cord Cord

Input

Input Input

200-240VAC,

1Phase

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

200-240VAC,

1Phase

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

200-240VAC,

1Phase

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

200-240VAC,

3Phase,DELTA

350-415VAC,

3Phase,WYE

Requirements

Requirements Requirements

Power

Power Power

Cord

Specications*

Cord Cord

Specications* Specications*

AWG

(mm^2)

AWG AWG

(mm^2) (mm^2)

4(21.2),

2wire+ground

8(8.4),

3wire+ground

8(8.4),

4wire+ground

4(21.2),

2wire+ground

6(13.3),

3wire+ground

8(8.4),

4wire+ground

4(21.2),

2wire+ground

6(13.3),

3wire+ground

8(8.4),

4wire+ground

6(13.3),

3wire+ground

8(8.4),

4wire+ground

4(21.2),

3wire+ground

6(13.3),

4wire+ground

4(21.2),

3wire+ground

6(13.3),

4wire+ground

4(21.2),

3wire+ground

6(13.3),

4wire+ground

*Valuesareforreferenceonly.Refertoamperage

listedinModelstable(seeModels,page9)forgiven

systemandcompareagainstlatestversionoflocal

electricalcodetoselectproperpowercordsize.

NOTE:

NOTE: NOTE:

400VACsystemsarenotdesignedtooperate

from480VACpowersource.

30 334945B

Page 31

Setup

Lubrication

Lubrication Lubrication

Component

Component Component

(LR)withGracoThroatSealLiquid(TSL),part

206995(supplied).

1.Liftthelubricantreservoir(LR)outofthebracket

(RB)andremovethecontainerfromthecap.

2.Fillwithfreshlubricant.Threadthereservoironto

thecapassemblyandplaceitinthebracket(RB).

3.Pushthelargerdiametersupplytube(ST)

approximately1/3ofthewayintothereservoir.

4.Pushthesmallerdiameterreturntube(RT)into

thereservoiruntilitreachesthebottom.

NOTE:

NOTE: NOTE:

thereservoirtoensurethatisocyanatecrystals

willsettletothebottomandnotbesiphonedinto

thesupplytube(ST)andreturnedtothepump.

System

System System

(ISO)

A AA(ISO) (ISO)

Thereturn(RT)mustreachthebottomof

Pump:

Pump: Pump:

Setup

Setup Setup

FillISOlubereservoir

5.Thelubricationisreadyforoperation.Nopriming

isrequired.

Install

Install Install

TheFluidTemperatureSensor(FTS)issupplied.

InstallFTSbetweenmainhoseandwhiphose(see

RelatedManuals,page16).

Install

Install Install

1.Removecover(CV).

2.Routeheatedhosewires(HW)throughstrain

3.Reinstallcover(CV).

Fluid

Fluid Fluid

Heated

Heated Heated

relief(SR)andinstallwiresintotheopenscrew

terminalsontheterminalblock(TB).Torqueto

35in-lb(3.95N•m).

Temperature

Temperature Temperature

Hose

Hose Hose

to

to to

Sensor

Sensor Sensor

Proportioner

Proportioner Proportioner

334945B 31

Page 32

AdvancedDisplayModule(ADM)Operation

Advanced

Advanced Advanced

Whenmainpoweristurnedonbyturningthemain

powerswitch(MP)totheONposition,thepowerup

screenwillbedisplayeduntilcommunicationand

initializationiscomplete.

Thenthepowerkeyiconscreenwilldisplayuntilthe

ADMpoweron/offbutton(A)

rsttimeaftersystempower-up.

TobeginusingtheADM,themachinemustbeactive.

Toverifythemachineisactive,verifythattheSystem

StatusIndicatorLight(B)isilluminatedgreen,see

AdvancedDisplayModule(ADM),page22.Ifthe

SystemStatusIndicatorLightisnotgreen,press

theADMPowerOn/Off(A)button

StatusIndicatorLightwillilluminateyellowifthe

machineisdisabled.

Performthefollowingtaskstofullysetupyoursystem.

Display

Display Display

Module

Module Module

ispressedforthe

.TheSystem

(ADM)

(ADM) (ADM)

1.SetpressurevaluesforthePressureImbalance

Alarmtoactivate.SeeSystemScreen1,page36.

2.Enter,enable,ordisablerecipes.See

RecipesScreen,page37.

3.Setgeneralsystemsettings.See

AdvancedScreen1—General,page35.

4.Setunitsofmeasure.See

AdvancedScreen2—Units,page35.

5.SetUSBsettings.See

AdvancedScreen3—USB,page35.

6.Settargettemperaturesandpressure.See

Targets,page39.

7.SetcomponentAandcomponentBsupply

levels.SeeMaintenance,page40.

Operation

Operation Operation

32 334945B

Page 33

AdvancedDisplayModule(ADM)Operation

Setup

Setup Setup

TheADMwillstartintheRunscreensattheHomescreen.FromtheRunscreens,pressto

accesstheSetupscreens.Thesystemdefaultswithnopassword,enteredas0000.Enterthecurrent

passwordthenpress.PresstonavigatethroughtheSetupModescreens.See

SetupScreensNavigationDiagram,page45.

Set

Set Set

SetapasswordtoallowSetupscreenaccess,seeAdvancedScreen1–General,page35.Enteranynumber

from0001to9999.Toremovethepassword,enterthecurrentpasswordintheAdvancedScreen–General

screenandchangethepasswordto0000.

Mode

Mode Mode

Password

Password Password

FromtheSetupscreens,presstoreturntotheRunscreens.

334945B 33

Page 34

AdvancedDisplayModule(ADM)Operation

Setup

Screens

Setup Setup

Screens Screens

Navigation

Navigation Navigation

34 334945B

Page 35

AdvancedDisplayModule(ADM)Operation

Advanced

Advanced Advanced

Advancedsetupscreensenableuserstosetunits,adjustvalues,setformats,andviewsoftwareinformation

foreachcomponent.PresstoscrollthroughtheAdvancedsetupscreens.Onceinthe

desiredAdvancedsetupscreen,presstoaccesstheeldsandmakechanges.Whenchangesare

completepress

NOTE:

NOTE: NOTE:

throughtheAdvancedsetupscreens.

Advanced

Advanced Advanced

Usethisscreentosetthelanguage,dateformat,

currentdate,time,setupscreenspassword(0000–

fornone)or(0001to9999),andscreensaverdelay

(zeroequalsscreensaveroff).

Usersmustbeoutofeditmodetoscroll

Setup

Setup Setup

Screen

Screen Screen

toexiteditmode.

1 11— —

Screens

Screens Screens

Advanced

Advanced Advanced

—

General

General General

UsethisscreentoenableUSBdownloads/uploads,

enablealogs90%fulladvisory,enterthemaximum

numberofdaystodownloaddata,enablespecifying

daterangeofdatatodownload,andhowfrequently

USBlogsarerecorded.SeeUSBData,page61.

Screen

Screen Screen

—

USB

3 33— —

USB USB

Advanced

Advanced Advanced

Usethisscreentosetthetemperatureunits,pressure

units,volumeunits,andcycleunits(pumpcyclesor

volume).

Screen

Screen Screen

—

Units

2 22— —

Units Units

Advanced

Advanced Advanced

Thisscreendisplaysthesoftwarepartnumberand

softwareversionfortheAdvancedDisplayModule,

USBConguration,HydraulicControlModule,and

TemperatureControlModule,andRemoteDisplay

Module(optional).

Screen

Screen Screen

—

Software

4 44— —

Software Software

334945B 35

Page 36

AdvancedDisplayModule(ADM)Operation

System

System System

Usethisscreentosettheactivationpressureforthe

PressureImbalanceAlarmandDeviation,enableor

disablediagnosticscreens,setthemaximumand

minimumdrumvolume,andenabledrumalarms.

System

System System

UsethisscreentoenableManualHoseMode

andinletsensors,aswellassettingtheinlet

sensorlowpressurealarmandlowtemperature

deviation.ManualHoseModedisablesthehose

temperatureRTDsensorsothesystemcan

operateifthesensorsweretomalfunction(see

ManualHoseHeatMode,page51formore

information).Defaultsettingsare10psi(0.07MPa,

0.7bar)forlowinletpressurealarmand50˚F(10˚C)

forlowinlettemperaturedeviation.

1

1 1

2

2 2

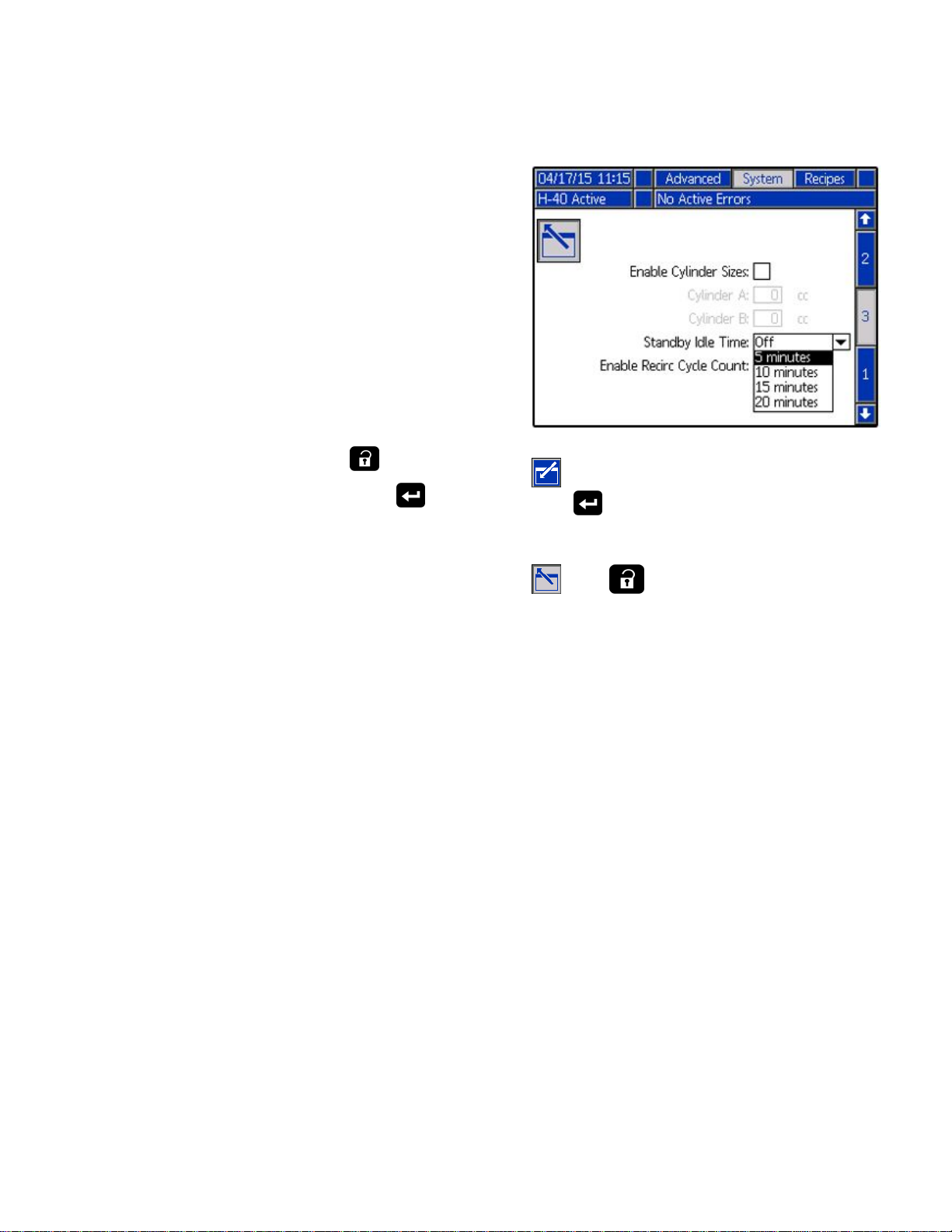

System

System System

Usethisscreentoenablealternatepumpcylinder

sizes,toturnmotorstandbymodeonandoff,and

toenablerecirculationcyclecount.Cyclesbelow

700psioutletpressurewillnotbecountedunless

enabled.

3

3 3

36 334945B

Page 37

AdvancedDisplayModule(ADM)Operation

Add

Recipes

Recipes Recipes

Recipe

Add Add

Recipe Recipe

Usethisscreentoaddrecipes,viewsavedrecipes,

andenableordisablesavedrecipes.Enabled

recipescanbeselectedattheHomeRunScreen.24

recipescanbedisplayedonthethreerecipescreens.

1.Pressandthenusetoselecta

recipeeld.Presstoenterarecipename

(maximum16characters).Presstoclearthe

oldrecipename.

2.Usetohighlightthenexteldandusethe

numberpadtoenteravalue.Press

tosave.

Enable

Enable Enable

1.Press

2.Use

or

Disable

or or

Disable Disable

andthenusetoselectthe

recipethatneedstobeenabledordisabled.

tohighlighttheenabledcheckbox.

Press

toenableordisabletherecipe.

Recipes

Recipes Recipes

334945B 37

Page 38

AdvancedDisplayModule(ADM)Operation

Run

Run Run