Page 1

Operation,Repair,andParts

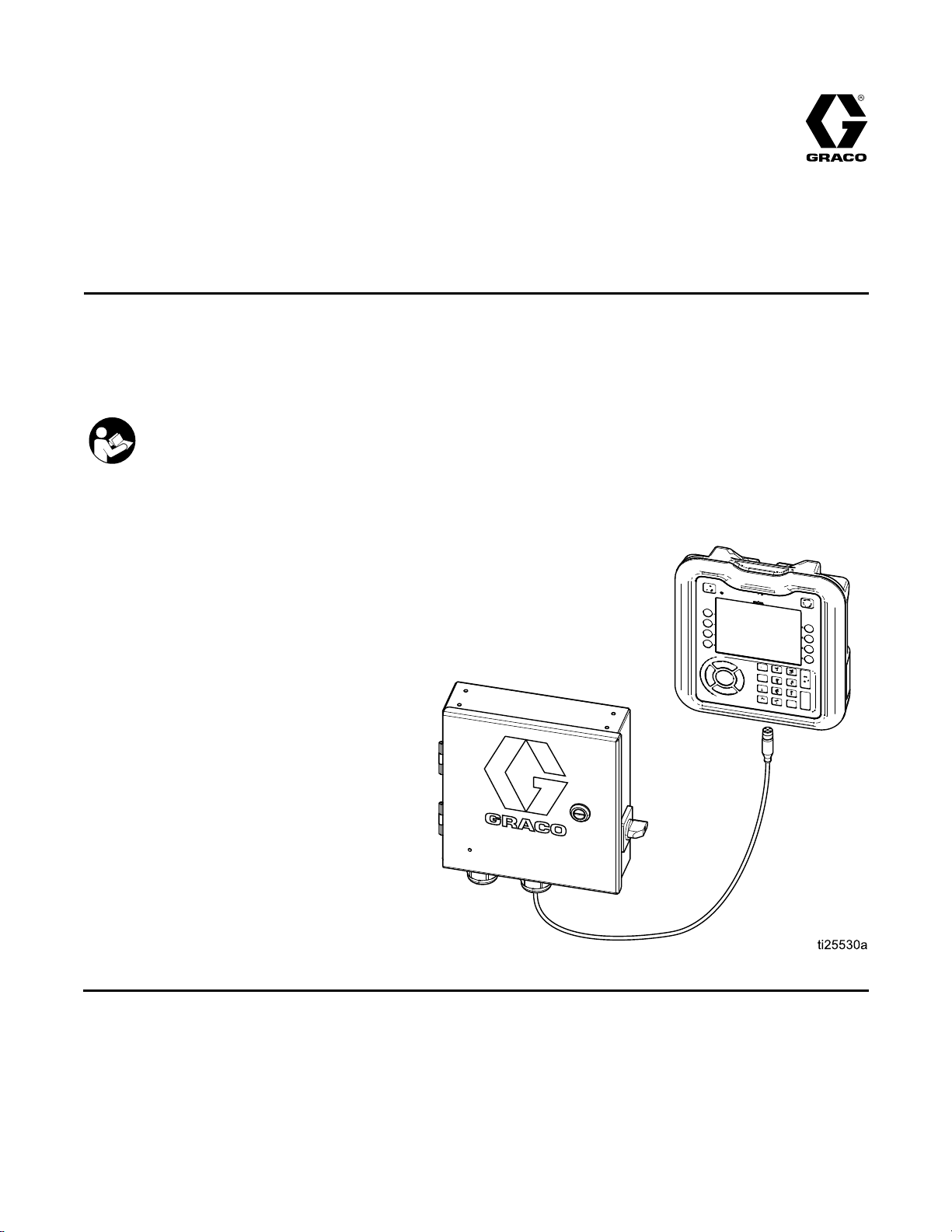

InvisiPac®

InvisiPac® InvisiPac®

To

control

To To

control control

Not

approved

Not Not

approved approved

See page 3 for model information and

Agency approvals.

uid

dispense

uid uid

dispense dispense

for

use

for for

use use

ImportantSafetyInstructions.Readallwarningsandinstructionsin

thismanualandrelatedmanuals.Savetheseinstructions.

Pattern

Pattern Pattern

valves

valves valves

explosive

in ininexplosive explosive

Controller

Controller Controller

334784A

EN

of

adhesive

of of

adhesive adhesive

atmospheres

atmospheres atmospheres

supply

supply supply

equipment.

equipment. equipment.

or

hazardous

or or

hazardous hazardous

For

professional

For For

professional professional

locations.

locations. locations.

use

only.

use use

only. only.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

AgencyApprovals...............................................3

RelatedManuals................................................3

Warnings...........................................................4

Overview............................................................7

ComponentIdentication.....................................8

Installation..........................................................9

Mounting.....................................................9

KeyToken...................................................9

ConnectAdvancedDisplayModule

(ADM)............................................9

ValveInstallation..........................................10

TriggerInstallation.......................................10

PLCInputsandOutputsInstallation

(optional)........................................11

EncoderInstallation(PC-8eonly)..................12

RunUpInstallation(PC-8eonly)...................12

ConnectElectricalCord................................13

Screens.............................................................14

ScreenMaps...............................................14

HMIInterface...............................................15

PCScreens.................................................16

AdvancedScreens.......................................27

Stitching.............................................................29

Denitions...................................................29

Setup..........................................................29

LineSpeed.........................................................30

RunUpControl...................................................31

RunUpSetup..............................................31

HighCalibrationPoint...................................31

LowCalibrationPoint...................................31

UserSettingEntry........................................31

UserSettings...............................................31

RandomLengthBeadMode.........................32

MirrorMode.................................................33

Calibration..........................................................34

GunCompensation(optional).......................34

Verication.........................................................35

Valves.........................................................35

Triggers.......................................................35

Encoder......................................................35

RunUpControl............................................35

PLCInputs..................................................35

Troubleshooting..................................................36

ErrorCodes.................................................36

Display........................................................37

Pattern........................................................37

Valve..........................................................38

Trigger........................................................38

Encoder......................................................38

RunUp........................................................39

PLCInputsandOutputs...............................39

SoftwareUpdateProcedure................................40

USBDownload...................................................41

DownloadProcedure....................................41

AccessingFiles............................................41

USBLogs....................................................41

Parts..................................................................42

Kits.............................................................44

WiringDiagram...................................................45

TechnicalData...................................................46

Notes.................................................................47

GracoStandardWarranty....................................48

2

334784A

Page 3

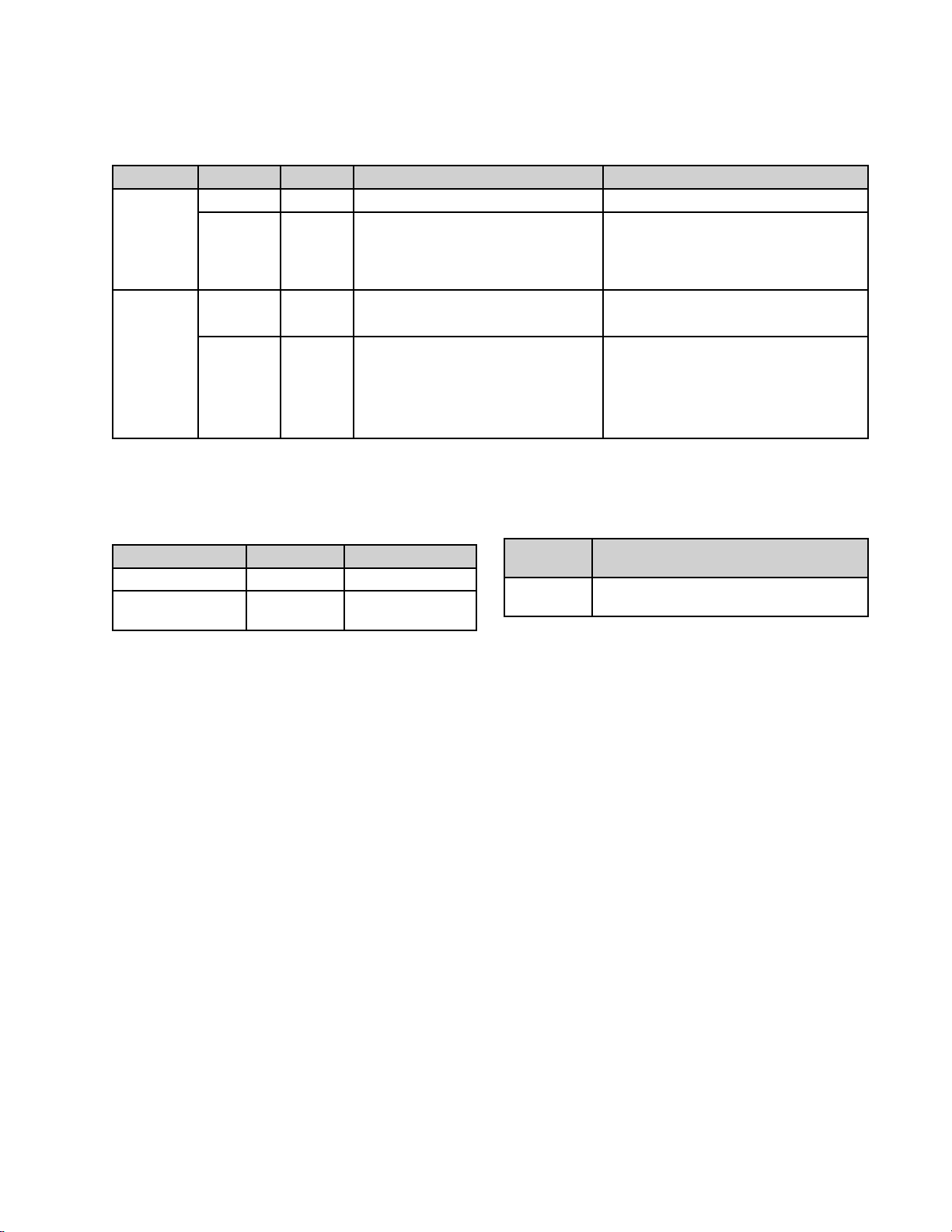

Models

Models

Models Models

Usage

Usage Usage

With

InvisiPac

Without

InvisiPac

Agency

Agency Agency

Type

Type Type

PatternController

AdvancedDisplay

Module

Part

Part Part

24X523

24X524

24X525

24X526

Approvals

Approvals Approvals

Type

Type Type

PC-8

PC-8e

PC-8

PC-8e

Description

Description Description

127971

24E451

Description

Description Description

Timeordistancemode,noencoder

Timeordistancemode,withor

withoutencoder

Runupcontrol(optional)24X626—KeyTokenforEncoder

Timeordistancemode,noencoder

Timeordistancemode,withor

withoutencoder

Runupcontrol(optional)

Related

Related Related

Manual

Contents

Contents Contents

CE,ETL,cETL

CE,ETL,cETL

Manual Manual

Number

Number Number

333347InvisiPacHM25andHM50Tank-Free™

Contents

Contents Contents

127971—PatternController

127971—PatternController

andRunup

127971—PatternController

24P860—AdvancedDisplayModule

127971—PatternController

24P860—AdvancedDisplayModule

24X626—KeyTokenforEncoder

andRunup

Manuals

Manuals Manuals

Product

Product Product

HotMeltDeliverySystem

334784A 3

Page 4

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

BURN

BURN BURN

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

HAZARD

HAZARD HAZARD

Equipmentsurfacesanduidthatisheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

immediate

immediate immediate

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

MOVING

MOVING MOVING

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

surgical

surgical surgical

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

treatment.

treatment. treatment.

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

HAZARD

HAZARD HAZARD

Pressure

Relief

Relief Relief

whenyoustopdispensingandbeforecleaning,

Procedure

Procedure Procedure

anddisconnectallpowersources.

Get

4

334784A

Page 5

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

FIRE

AND

FIRE FIRE

AND AND

MISUSE

MISUSE MISUSE

EXPLOSION

EXPLOSION EXPLOSION

HAZARD

HAZARD HAZARD

Technical

HAZARD

HAZARD HAZARD

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Procedure

Procedure Procedure

whenequipmentisnotinuse.

work

Flammablefumes,suchassolventandpaintfumes,inwork work

preventreandexplosion:

•Donotusesolvent-basedadhesivesthatcancreateanexplosiveatmospherewhen

processed.

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Useonlygroundedhoses.

Stop

•Stop Stop

•Keepaworkingreextinguisherintheworkarea.

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

operation

operation operation

equipmentuntilyouidentifyandcorrecttheproblem.

FLUID

FLUID FLUID

guidelines.

immediately

immediately immediately

FUMES

FUMES FUMES

HAZARD

HAZARD HAZARD

ifstaticsparkingoccursoryoufeelashock. ..Donotuse

Grounding

area

area area

canigniteorexplode.Tohelp

instructions.

334784A 5

Page 6

Warnings

WARNING

WARNING WARNING

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

PRESSURIZED

PRESSURIZED PRESSURIZED

Useofuidsthatareincompatiblewithaluminuminpressurizedequipmentcancauseserious

chemicalreactionandequipmentrupture.Failuretofollowthiswarningcanresultindeath,

seriousinjury,orpropertydamage.

•Donotuse1,1,1-trichloroethane,methylenechloride,otherhalogenatedhydrocarbon

solventsoruidscontainingsuchsolvents.

•Manyotheruidsmaycontainchemicalsthatcanreactwithaluminum.Contactyourmaterial

supplierforcompatibility.

PROTECTIVE

PROTECTIVE PROTECTIVE

ALUMINUM

ALUMINUM ALUMINUM

EQUIPMENT

EQUIPMENT EQUIPMENT

PARTS

PARTS PARTS

HAZARD

HAZARD HAZARD

6 334784A

Page 7

Overview

Overview

Overview Overview

InvisiPacPatternControlsystemscanbeintegratedwithInvisiPacsystemsorstandalonewithanyother

equipment.Forallinstallations,theAdvancedDisplayModule(ADM)isusedtomakeprogrammingeasy.

PC-8controllersoperateintimeordistancemodewithoutanencoder.Upto8gunsand4independent

triggersaresupported.

PC-8econtrollersincludethesamefeaturesasPC-8withtheadditionofdistancebasedcontrolusingan

encoder,andrunupcontrolusinganI/PorV/Ppressureregulator.

Features

Features Features

GunOutputs

TriggerInputs4

Encoder

RunUpControl2(PC-8eonly)

ProgramStorage

PLCEnable/Disable

PLCAlarmOutput

PLCProgramSelect

PasswordProtectionYes

IntegratedPowerSupply

Formoreinformation,seeTechnicalData,page46.

the

PC-8

and

of ofofthe the

PC-8 PC-8

Feature

Feature Feature

PC-8e:

and and

PC-8e: PC-8e:

Details

Details Details

8

2(PC-8eonly)

50

Yes

Yes

Yes

Yes

334784A

7

Page 8

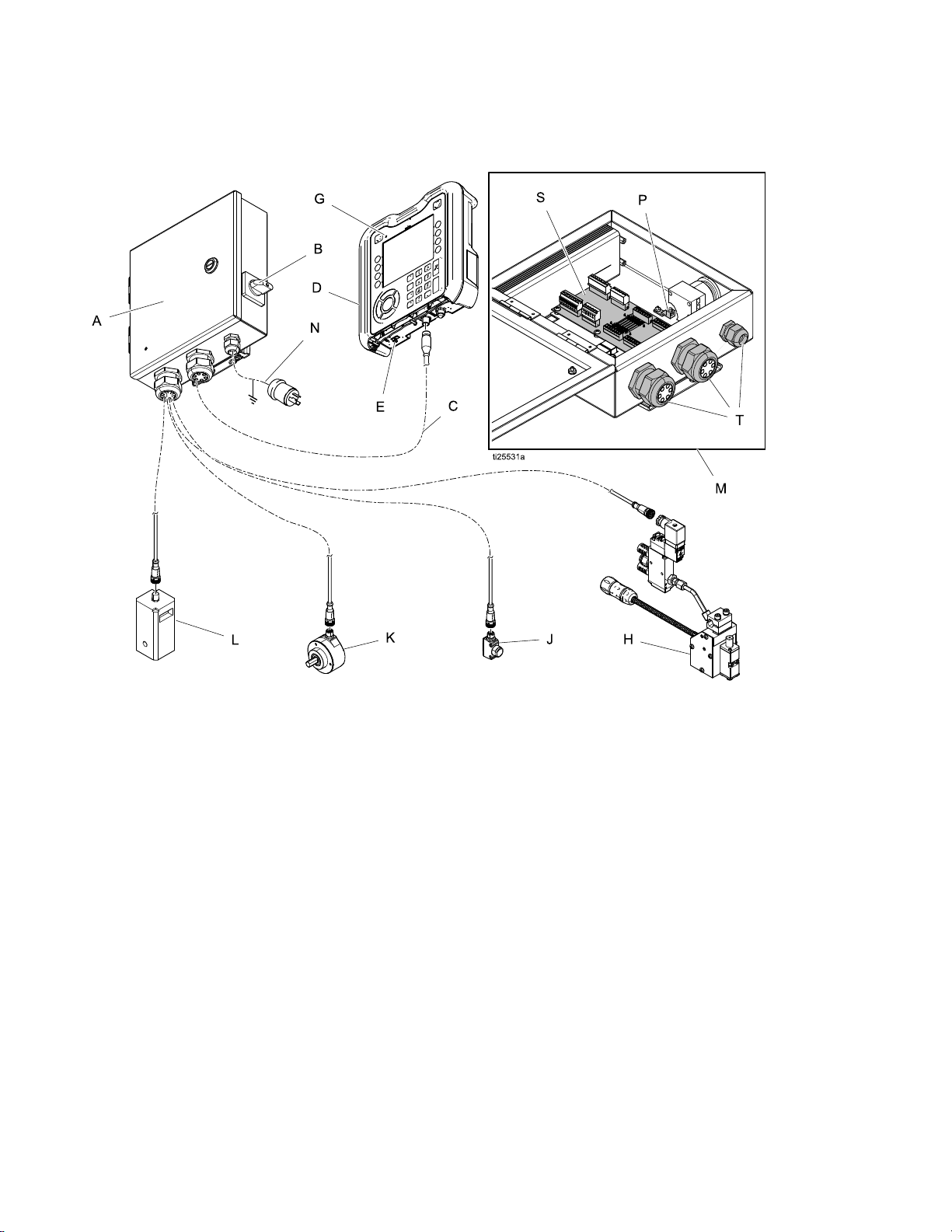

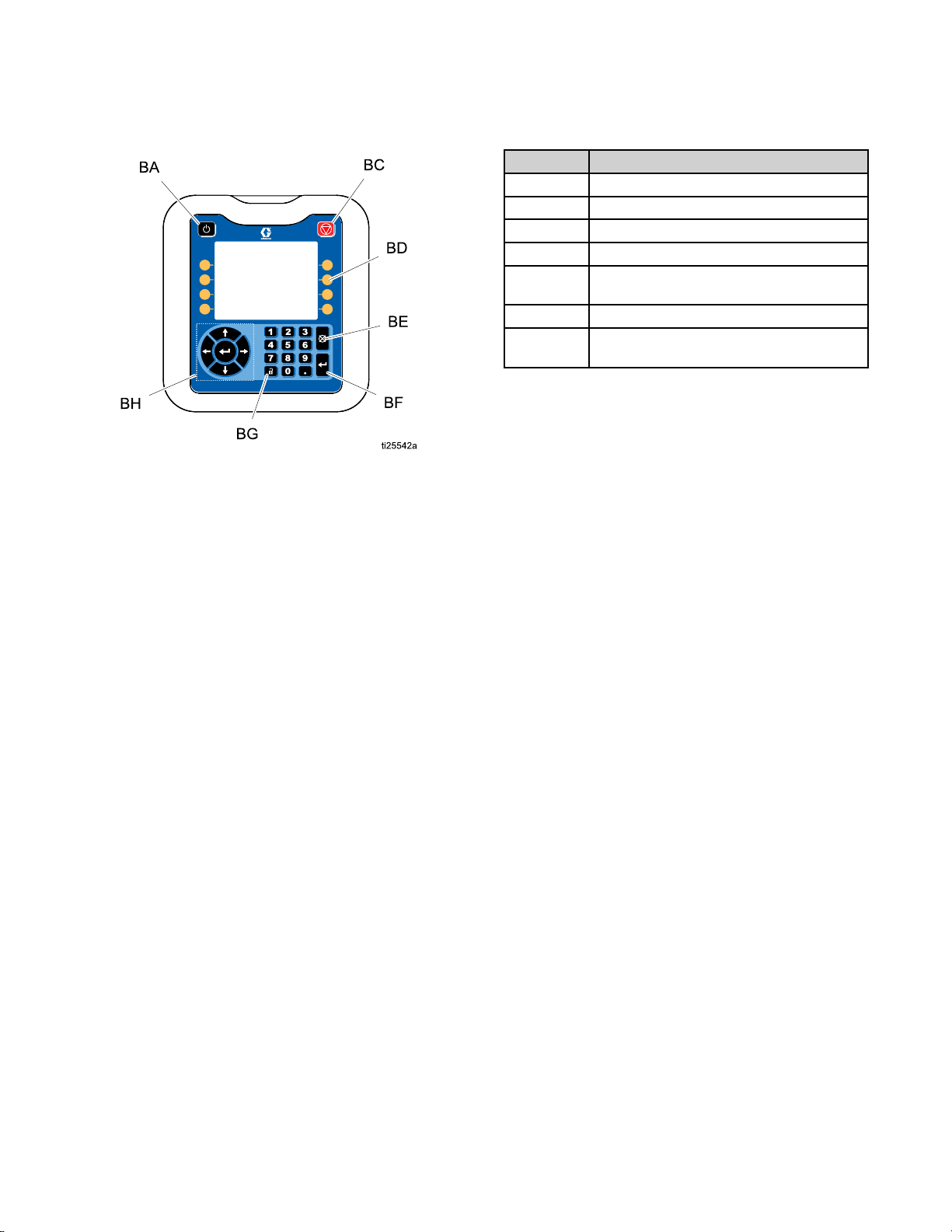

ComponentIdentication

Component

Component Component

Identication

Identication Identication

Key

Key Key

A

B

CCommunicationCable

DADM

E

G

HValve

JTrigger

PatternController

PowerSwitch

USBPort

IndicatorLight

Key

Key Key

KEncoder

LRunUp

M

N

P

SControlBoard

T

InsideViewofPatternController

PowerSupply

GroundTerminal

CordGrips(I/Ox2,power)

8 334784A

Page 9

Installation

Installation

Installation Installation

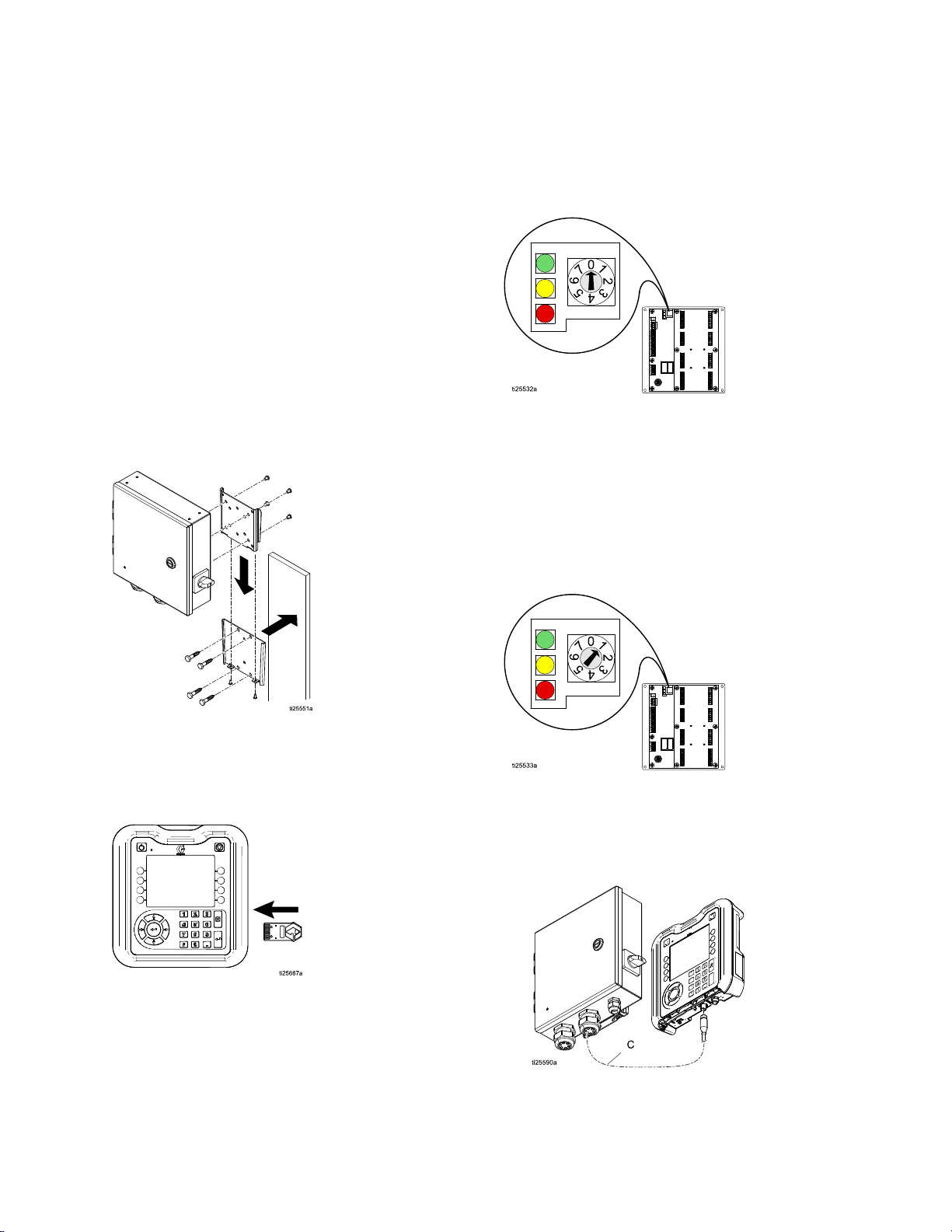

Mounting

Mounting Mounting

ThePatternControllerandADMcanbemounted

usingtheincludedVESA-compatiblebracketand

mountinghardware.

1.Unscrewthetwolowerscrewstouncouplethe

“wall”portionofthebracket.

2.Securelymountthebracketinthedesired

location.

3.Slidethecontrollerontothebracketandtighten

thetwoscrewsforpermanentfastening.

ALTERNATIVE

ALTERNATIVE ALTERNATIVE

hardwareandmountdirectlytoanysurface.

METHOD:

METHOD: METHOD:

removemounting

Connect

Connect Connect

(ADM)

(ADM) (ADM)

Integrate

Integrate Integrate

1.SetPatternControlboarddialpositionto0.

2.Unplugtheendofthecommunicationcablefrom

theADM,thenconnecttheshortcommunication

cabletotheADMandsplittertotheendof

thiscable.ConnectthePatternControllerand

InvisiPaccommunicationcablestothesplitter.

Stand

Stand Stand

Advanced

Advanced Advanced

with

InvisiPac

with with

InvisiPac InvisiPac

Alone

Alone Alone

Display

Display Display

Module

Module Module

Key

Token

Key Key

Token Token

ForPC-8emodels,installtheKeyTokenintheADM.

334784A 9

1.SetthePatternControlboarddialpositionto1.

2.MounttheADMusingtheprovidedbracket.

3.Connectthecommunicationcablebetweenthe

PatternControllerandtheADM.

Page 10

Installation

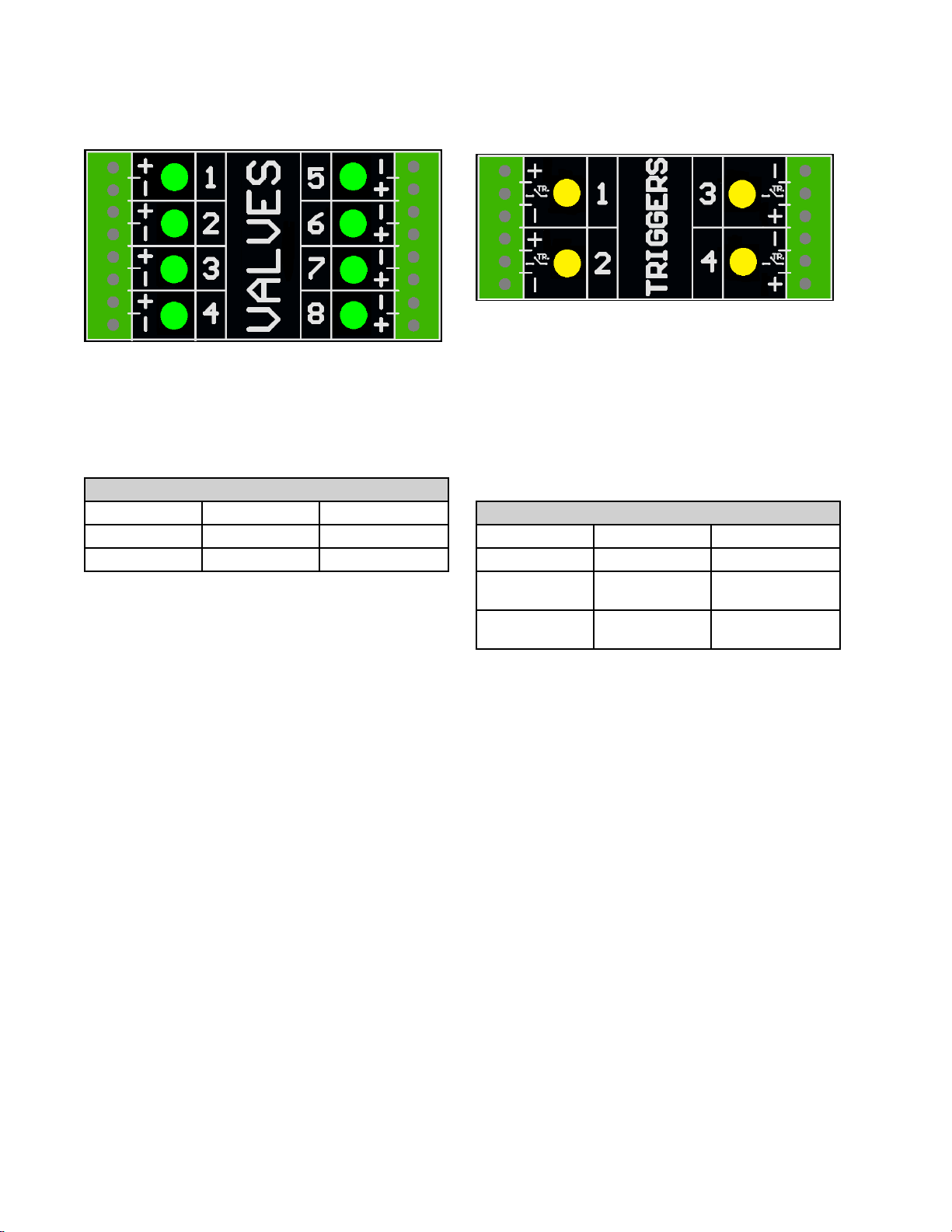

Valve

Valve Valve

1.Connectupto8valves.

Terminal

Terminal Terminal

Plus(+)24VSupply

Minus(-)

Installation

Installation Installation

NOTE:

NOTE: NOTE:

ampperoutputand6ampstotal.

NOTE:

NOTE: NOTE:

valve.

Controlvoltageis24VDCwithalimitof1

GreenLEDsindicatethestatusofeach

Standard

Standard Standard

Cable

Cable Cable

ReturnBrown/BlueM8

Trigger

Trigger Trigger

1.Connectupto4NPN,PNP,ordrycontact

triggers.

NOTE:

NOTE: NOTE:

2.ConnectthetwowiresbetweenTRandminus(-)

toinstalladrycontact.

NOTE:

NOTE: NOTE:

trigger.Polaritycanbeinvertedifneeded(see

Wiring

Wiring Wiring

Function

Function Function

Colors

Colors Colors

M8

or

M8 M8

or or

Black/BlueM12

M12

Cable

M12 M12

Cable Cable

TriggerSetup(Screen3),page23).

Terminal Terminal

Plus(+)24VSupply

TRNPN,PNP,or

Minus(-)Return(orDry

Installation

Installation Installation

Suppliedvoltage(+)is24VDC.

YellowLEDsindicatethestatusofeach

Standard

Standard Standard

Terminal

DryContact

Contact)

Wiring

Wiring Wiring

Function

Function Function

Colors

Colors Colors

M8

or

M12

M8 M8

Brown

BlackorWhite

Blue

or or

Cable

M12 M12

Cable Cable

10 334784A

Page 11

Installation

PLC

PLC PLC

Inputs

Inputs Inputs

and

Outputs

and and

Outputs Outputs

Installation

Installation Installation

(optional)

(optional) (optional)

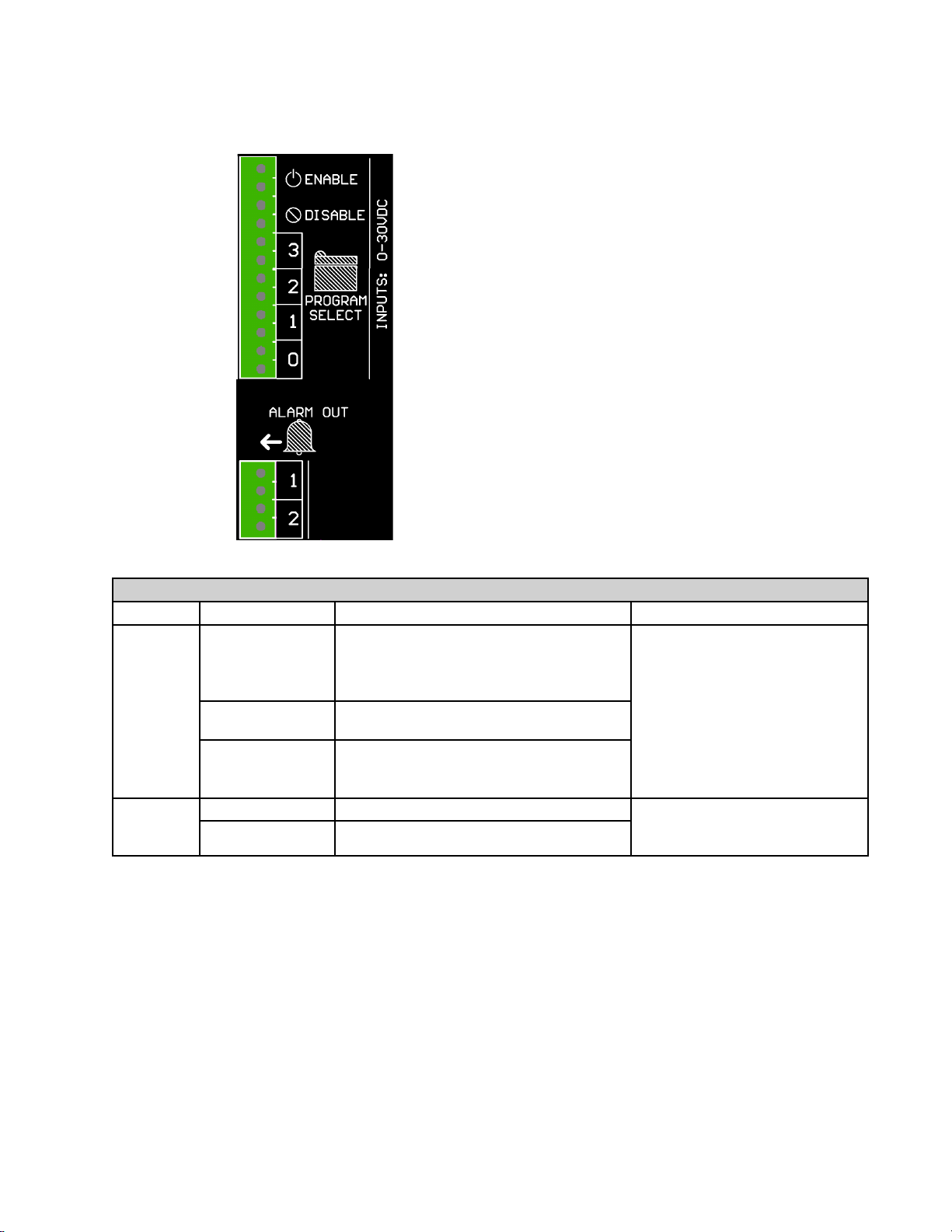

1.IntegratewithaPLCbyusingtheseinputsand

outputs.

2.Inputsarebipolarandaccepta0VDCto30VDC

signal.Eachinputiselectricallyisolated.To

connectadrycontactsignal,route24VDCto

oneterminalandconnectthegroundthroughthe

drycontacttotheotherterminal.

3.Outputsaredrycontactandopeninthecaseof

analarm.

PLC

Inputs

PLC PLC

Inputs Inputs

Type

Type Type

Input

Output

Function

Function Function

ENABLE

DISABLE

PROGRAM

SELECT

ALARM1

ALARM2

Turnsthecontrolleronandoff(rising

edgeenables,fallingedgedisables).The

controllerwillwaitforarisingedgeto

re-enableafteranalarmorpowerreset.

Disablesthecontroller.Pullhighto

disable.

Bitsselectaprogramtorun(1–15)

i.e.1010selectsprogram#10

NOTE:0000disablesPLCselection

RelayopensforactivealarmsonLine1

RelayopensforactivealarmsonLine2

and

Outputs

and and

Outputs Outputs

Description

Description Description

Bipolarinput

0–30VDC

Min.10VDCtoassert.

Sinks10mAat24VDC.

Drycontactoutput

0–24VDCor0–240VAC

2Amax

Specs

Specs Specs

334784A

11

Page 12

Installation

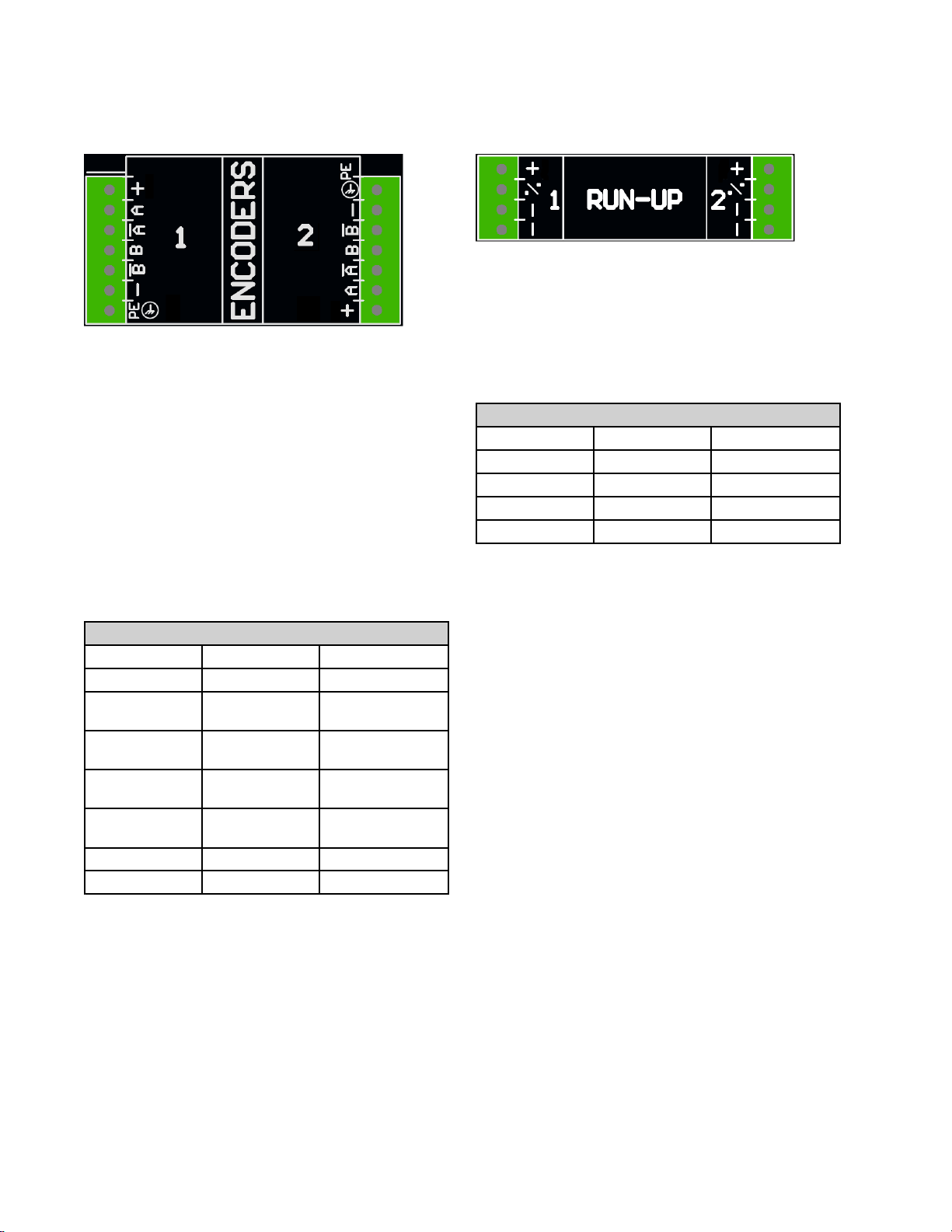

Encoder

Encoder Encoder

1.Connectuptotwoencoderstomonitorline

speed.NOTE: NOTE:

2onthescreen.

NOTE:

NOTE: NOTE:

differentiallinedriver(RS422).Scalingisentered

intheencodersetupscreenusingthelive

calibrationfeature.

NOTE:

NOTE: NOTE:

connections.Thesearenotusedanddonot

needtobeconnected.

NOTE:

NOTE: NOTE:

swappingAandA’withBandB’.Dothislineif

linespeedreadsnegativeonthedisplay.

Terminal

Terminal Terminal

Plus(+)15VSupply

APhaseAsignal

A’PhaseAsignal

BPhaseBsignal

B’PhaseBsignal

Minus(-)

PE

Installation

Installation Installation

NOTE:

Encodertypemustbequadrature

SomeencodershaveZandZ’

Encoderdirectioncanbereversedby

Graco

Graco Graco

TheseareusedforLine1orLine

Encoder

Encoder Encoder

Function

Function Function

(RS422)

return

(RS422)

return

ReturnBlue

Shield

(PC

8e

(PC (PC

- --8e 8e

Wiring

Wiring Wiring

Diagram

Diagram Diagram

Wire

Wire Wire

Red

Brown

White

Yellow

Green

Bare

only)

only) only)

Color

Color Color

Run

Up

Run Run

1.Connectuptotwo“I/P”or“V/P”run-upair

pressureregulatorstovarypumppressurebased

onlinespeed.Hardwareautomaticallydetects

whetheranI2PorV2Pisconnected.

NOTE:

NOTE: NOTE:

enteredontherun-upsetupscreen(seeRunUp

Control(Screens6–7,PC–8eonly),page26).

Terminal

Terminal Terminal

Plus(+)24VSupply

%Outputtorun-up

Minus(-)

Minus(-)

Installation

Up Up

Installation Installation

Pressurevs.linespeedsettingsare

Standard

Standard Standard

ReturnBlue

ReturnWhite

(PC

8e

(PC (PC

Wire

Colors

Wire Wire

Colors Colors

Function

Function Function

only)

- --8e 8e

only) only)

M12

M12 M12

Brown

Black

Cable

Cable Cable

12

334784A

Page 13

Installation

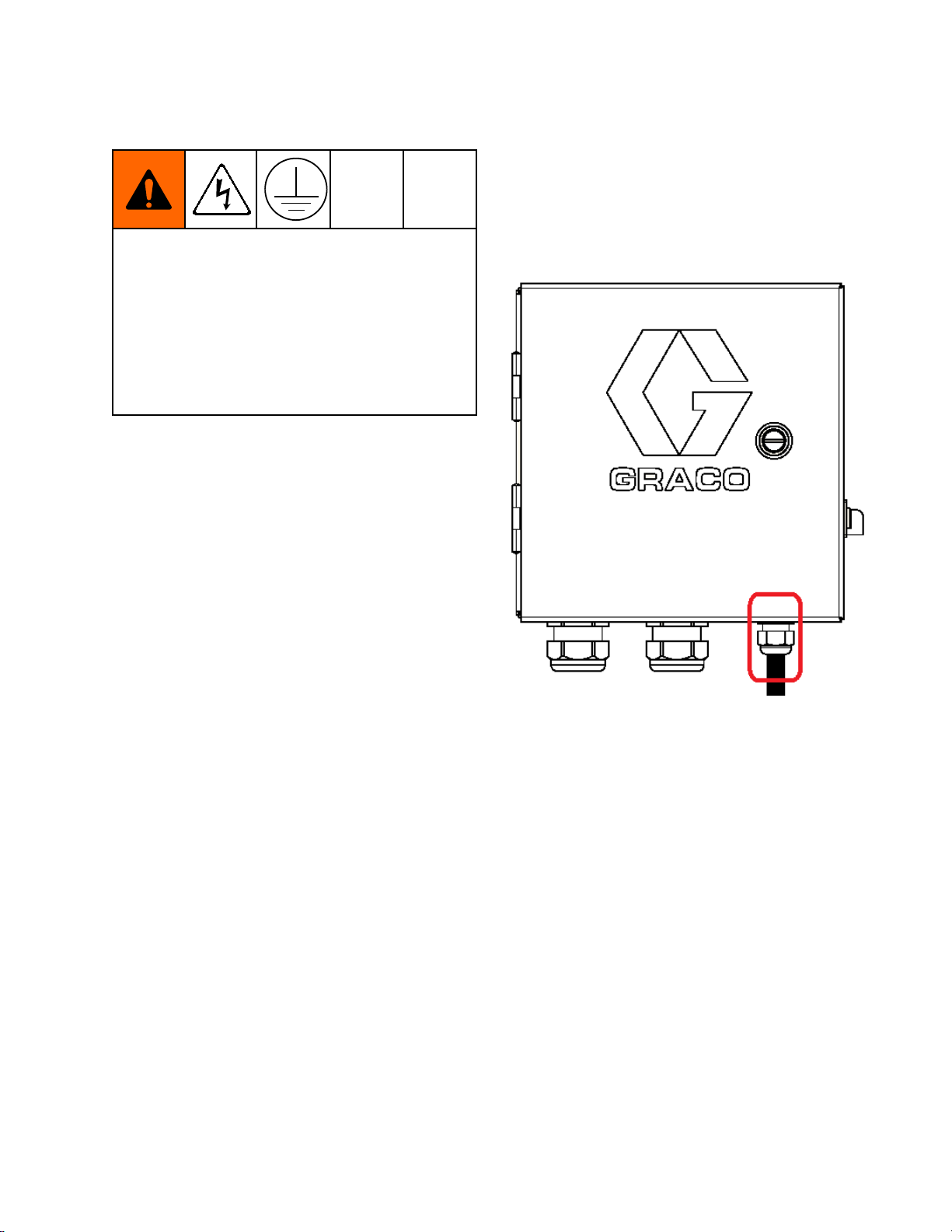

Connect

Connect Connect

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,State,andLocalsafetyandrecodes.

Theequipmentmustbegroundedtoreducethe

riskofelectricshock.Impropergroundingcan

causeelectricshock.Groundingprovidesan

escapewirefortheelectriccurrent.

TheInvisiPacsystemisequippedwithaground

terminal.Haveaqualiedelectriciangroundthe

systemusingthisterminal.

Electricalpowerentersthroughthesmallercord

gripontherightsideoftheenclosure(seebelow).

Thepowercordcanbefurthersecuredinsidethe

enclosurewiththeprovidedzip-tieandtiemount.

Electrical

Electrical Electrical

Cord

Cord Cord

1.Installpowerwires(L1/L2orL/N)intoterminals

2and4onthedisconnectswitch.Theswitch

acceptssolidorstranded12AWGand14AWG

wire.Forratings,seeTechnicalData,page46.

2.Connectearthgroundtothegroundingterminal.

3.Verifythatthecordgripsecurelytightensaround

thecord.Useawrenchtotighten,ifnecessary.

334784A 13

Page 14

Screens

Screens

Screens Screens

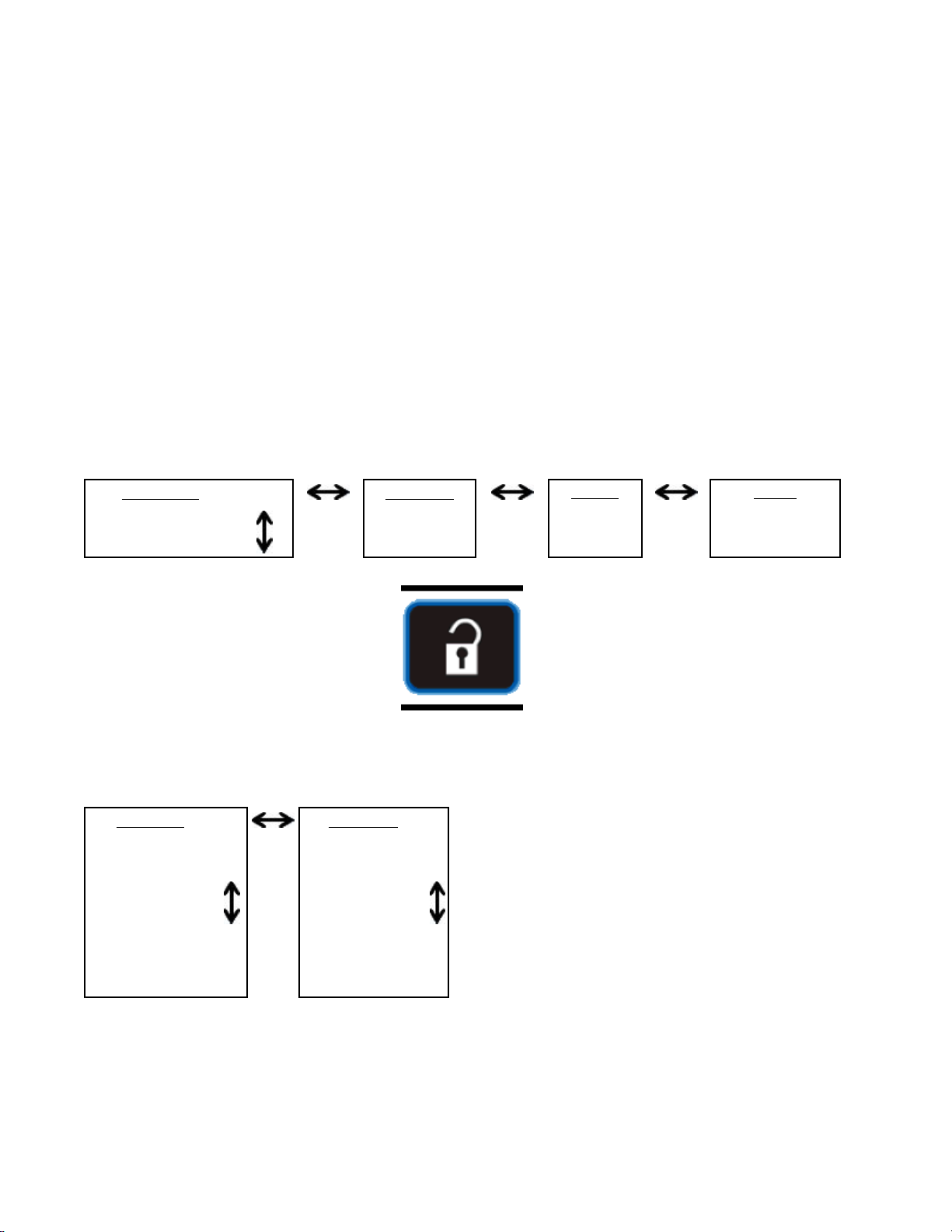

NavigatethrougheachscreentosetupthePattern

Controllerinterface.

•Runscreensincludethehomepageandpattern

denition.

•Setupscreenscontaincongurablesettingsfor

eachaccessory.

Screen

Screen Screen

NOTE:

NOTE: NOTE:

chaptersarepresentforhotmeltHMI.

Run

Run Run

1.ProgramStorage

2.PatternDenition

Setup

Setup Setup

Maps

Maps Maps

OnintegratedInvisiPacsystem,additional

Screens

Screens Screens

PC

Control

PC PC

Control Control

Screens

Screens Screens

PC

Setup

PC PC

Setup Setup

PC

Home

PC PC

Home Home

PresstoswitchbetweenRunandSetup

Advanced

Advanced Advanced

Events

Events Events

Errors

Errors Errors

1.EventMap

2.LineMode

3.TriggerSetup

4.General

5.GunSetup

6.RunUp

14

1.Display

2.Units

3.USBSettings

4.Software

334784A

Page 15

Screens

HMI

HMI HMI

Interface

Interface Interface

Key

Key Key

BA

BCStopallsystemprocesses

BD

BEAbortcurrentoperation

BFAcceptchange,acknowledgeerror,

BGTogglebetweenRunandSetupscreens

BHNavigatewithinascreenortoanew

ControllerEnable/Disable

Denedbyiconnexttosoftkey

selectitem,toggleselecteditem

screen

Function

Function Function

334784A 15

Page 16

Screens

PC

Screens

PC PC

Screens Screens

Home

Home Home

Readonlyviewofpatterncontrollerinputsandoutputs:

1.Statusofguns,triggers,andPLCsignals.

2.Productionrate

3.Materialdispensedperproduct

A AA—GunStates

B BB—TriggerStates

C CC—LineInformation

D DD—PLCSignals

Icon

Name

Icon Icon

Name Name

GunGunstatus:Active(green),Enabled(gray),Disabled(crossedout).

Trigger

LineNumber

,andunitscompleted.

.

Description

Description Description

TriggerStatus:Active(brightyellow),Inactive(darkyellow).

Linenumberforotherdisplayvaluesinrow.

LineSpeedCurrentlinespeed(orxedlinespeedsetting).

RunUpOutputPercentageofrunuppressurerangebeingoutput(PC-8eonly).

%

ProductionRate

ProductCountTotalproductscompleted.Sameascurrenttriggercyclecount.

GlueRateAmountofglueperproduct(integratedInvisiPacsystemsonly).NOTE: NOTE:

PLCEnableEnables/disablesthepatterncontrolviaPLC.

PLCDisableDisablesthesystemviaPLC.

ActiveProgram

PLCAlarmAlarmsbeinggiventothePLC(online1or2).

Numberofproductperminute.

bestresults,entertheappropriatespecicgravityvaluefortheadhesive

materialinuse(seetheInvisiPacsystemmanual).

DisplaystheactiveprogramchosenbythePLC.

16 334784A

NOTE:

For

Page 17

Screens

Program

Program Program

1.Selectprogramtoload.

2.Copyprogram,eraseprogram,orrenameprogram.

3.Purgeguns

4.Lock/unlockcontrollerformaintenance

NOTE:

NOTE: NOTE:

GeneralSetup(Screen4),page24).

A AA—EnterScreen

B BB—MaintenanceLock/Unlock

C CC—ToPurgeScreen

D DD—ActiveProgram

P PP—ScreenNumber(Screen1)

Storage

Storage Storage

Copy,erase,andrenamecapabilitiesaredisabledif“LockPatternDenition”isenabled(see

(Screen

(Screen (Screen

.

1)

1) 1)

.

Icon

Name

Icon Icon

Name Name

MaintenanceLock

MaintenanceUnlock

E EE—ExitScreen

F FF—CopySelected

G GG—EraseSelected

H HH—RenameSelected

J JJ—Press“Enter”toSelectActiveProgram

Description

Description Description

PresstodisablePatternController

PresstoenablePatternController

334784A

17

Page 18

Screens

Gun

Purge

Gun Gun

Purge Purge

1.Purgeindividualguns.

2.Purgeallgunsbypressingenter.

NOTE:

NOTE: NOTE:

NOTE:

NOTE: NOTE:

A AA—PresstoPurge

B BB—DisabledGunswillnotPurge

Onlygunswithassignedtriggerswillpurge.

Gunsmayonlybepurgedwhenthesystemisactiveorwithin5minutesofthesystembeingactive.

Icon

Name

Icon Icon

Name Name

Purge

EnterPurgeallenabledguns

Return/Cancel

Description

Description Description

Purgespecicgun

Exitscreen

18 334784A

Page 19

Screens

Pattern

Pattern Pattern

1.Enterstartpointandlengthofbeads.

2.Enableordisablestitchingforeachbead.

3.Previewthispattern.

NOTE:

NOTE: NOTE:

numberkeyforgunA.

NOTE:

NOTE: NOTE:

beads6–24.

—

A AA— —

—

B BB— —

—

C CC— —

—

D DD— —

—

E EE— —

—

P PP— —

Denition

Denition Denition

ToclonethepatternfromgunAtogunB,navigatetoanybeadongunBandpress/holdthe

Enterthescreenandscrolldowntoseevalves5–8.Addbeadsandcontinuetoscrollrighttoaccess

EnterScreen

PatternPreview

Dots=Stitched

Solid=SolidBead

CurrentProgram

StartofBead

BeadLength

ScreenNumber

(Screen2)

(Screen

(Screen (Screen

2)

2) 2)

F FF—ExitScreen

G GG—ConrmChanges

H HH—CancelChanges

J JJ—StitchBead

Icon

Icon Icon

Name

Name Name

BeadOffsetDistancefromtheedgeoftheproducttothestartofthebead

BeadLength

StitchBeadEnableordisablestitchingofthisbead.

Description

Description Description

LengthoftheBead

334784A 19

Page 20

Screens

Pattern

Pattern Pattern

Read-onlydisplayofbeadpattern.

A AA—EndpointofLastBead

B BB—ExitPreview

—GunNumber

—TriggerNumber

NOTE:

NOTE: NOTE:

NOTE:

NOTE: NOTE:

gundoesnothaveatriggerselected(see

EventMap(Screen1),page21).

Preview

Preview Preview

Dottedpatternshowsstitching.Theactualnumberofstitchedbeadsisnotrepresented.

Areddottedpatternindicatesthatthe

20 334784A

Page 21

Screens

Event

Event Event

Entercongurationsettingsforthispattern:

1.Assigntriggertoeachgun.

2.Inputgun-to-triggeroffset.

3.Enterminimumproductlength(iffalsetriggerpickupisaconcern).

4.Enablepatternmirroring.

5.Enterstitchpercentageandinterval.

A AA—EnterScreen

B BB—GunNumber

C CC—TriggerforGun

D DD—GuntoTriggerOffset

E EE—MinimumProductLength

F FF—CurrentProgram

G GG—StitchInterval

H HH—StitchSavings

J JJ—MirrorPattern

P PP—ScreenNumber(Screen1)

Map

(Screen

Map Map

(Screen (Screen

1)

1) 1)

Icon

Name

Icon Icon

Name Name

TriggerTriggerassociatedwiththisgun

Gun-to-TriggerOffset

MinimumProduct

Length

MirrorBeadPattern

StitchSavingsPercentageofgluesavedbystitching.Setto0todisablestitching.

StitchIntervalThedistancebetweenthestartofeachstitch.

Description

Description Description

Thephysicaldistanceortimebetweenthetriggerandthegun.

Blockstriggersfromactivatingasecondpatternwithintheminimumproduct

length

Mirrorsbeadsfromtheleadingedgeoftheboxtothetrailingedgeofthebox.

NOTE:

NOTE: NOTE:

halfthelengthofthebox(seeMirrorMode,page33).

NOTE:

NOTE: NOTE:

Stitching,page29).

Ifmirrormodeisselected,theGun-to-TriggerOffsetmustbeatleast

Stitchingmustalsobeenabled/disabledforeachbead(see

334784A

21

Page 22

Screens

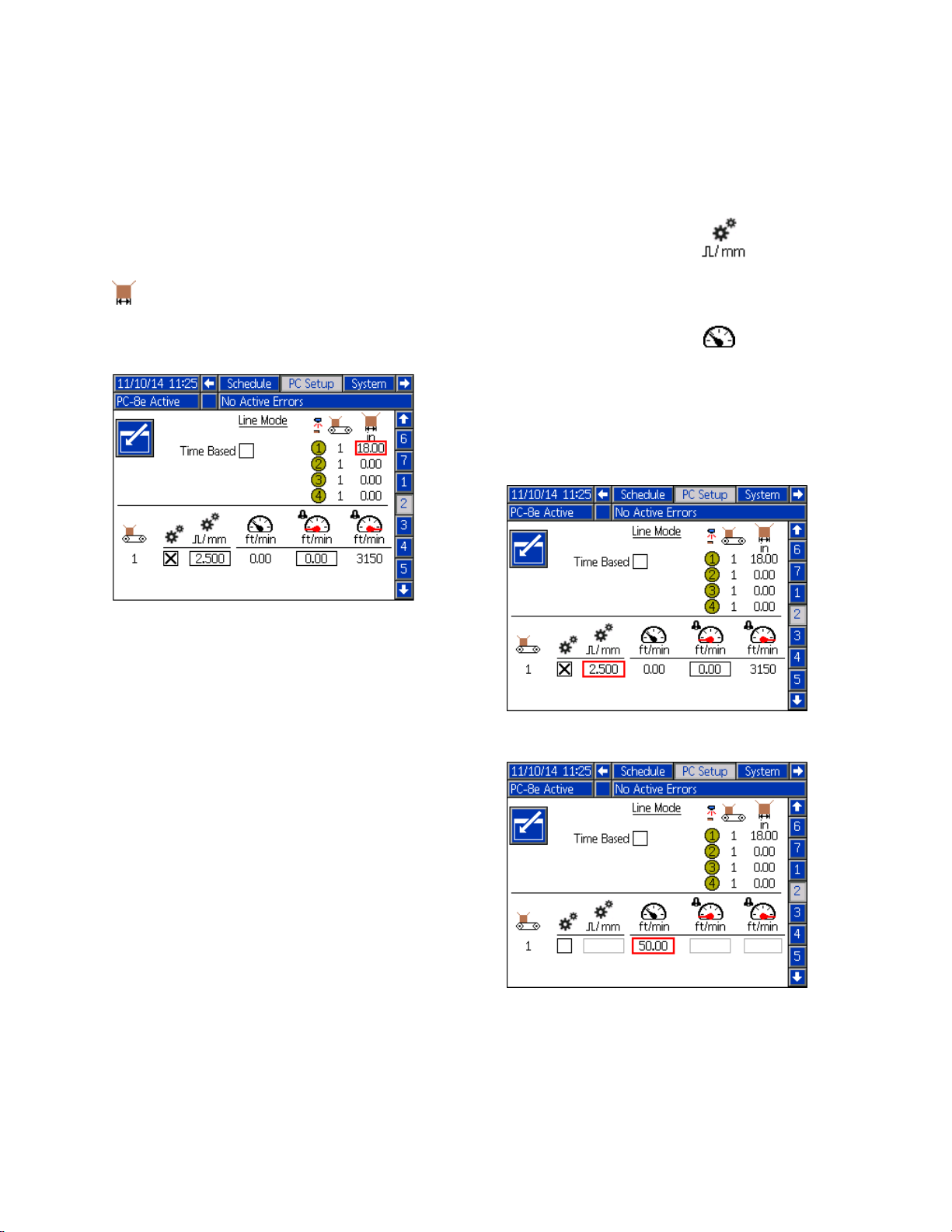

Line

Mode

Line Line

Mode Mode

(Screen

(Screen (Screen

2)

2) 2)

b.Adjustlinespeedsetting

untillengthof

1.Selectmode:

a.Timebased.

b.Distancemodewithoutencoder(usesxed

linespeed).

c.Distancemodewithencoder.

2.Fortimemode,therearenoadditionalsettings.

3.Fordistancemodewithoutencoder:

a.Passoneproductbythetriggeratnormal

speed.

NOTE:

NOTE: NOTE:

nottrippingthetriggerproperly.

A AA—EnterScreen

B BB—LastBoxLength

P PP—ScreenNumber(Screen2)

Seetriggersetupsectionifproductis

lastproductiscorrect.

4.Fordistancemodewithencoder.

a.Verifypositivelinespeedwhenlineismoving

forward.Ifspeedisnegative,swapAandA’

withBandB’wiresattheencoderconnector

onthePatternController.

b.Passoneproductbythetrigger.

c.Adjustencoderpulsespermm

lengthoflastproduct

until

iscorrect.

Icon

Name

Icon Icon

Name Name

Time

Based

TimeModeSelectIntimemode,programssettingsareinunitsofmilliseconds

LineNumber

LengthofLastProductLengthofthelastproductseenbyatriggerontheline.

Encoder

EncoderPulsesper

mm

LowLineSpeedAlarmOutputswillnotrewhenthelineisbelowthisspeed.

HighLineSpeed

Alarm

LineSpeed•Ifencoderenabled:viewcurrentlinespeed

Description

Description Description

Linenumberforothersettings/valuesinarow

NOTE:

NOTE: NOTE:

Selectifencoderistobeused

Pulsesencodergeneratespermmoflinetravel.

NOTE:

NOTE: NOTE:

NOTE:

NOTE: NOTE:

Read-only:Maximumlinespeedallowed.

NOTE:

NOTE: NOTE:

•Ifencoderdisable:enterxedlinespeed

Valueadjustsforchangesinencoder/speedsettings.

500pprencoder,200mmwheel=2.5pulses/mm.

Avalueof0disablesthisalarm.

Thevalueiscalculatedfromencoderpulsespermm.

22

334784A

Page 23

Screens

Trigger

Trigger Trigger

1.SelectTriggerPolarity

2.SelectTriggerLineNumber

A AA—EnterScreen

B BB—TriggerPolarity

C CC—Line1or2

D DD—ResetSelectedCounter

E EE—LifetimeTriggerCount

F FF—ResettableTriggerCount

P PP—ScreenNumber(Screen3)

Setup

Setup Setup

a.Triggershouldshowbrightyellowwhen

productispresentanddarkyellowforno

product.

b.Ifpolarityisbackwards,usethedrop-down

a.Ifproductrunspastalltriggersatthesame

speed,selectline1.

toinvertthedetection.

(Screen

(Screen (Screen

3)

3) 3)

b.Wheretwolinespeedsettingsarerequired,

selectline1fortriggerssensingfromtherst

:

3.TriggerCycleCounters:

(PC-8eonly):

linespeedandline2forthesecond.

a.Viewcurrentandlifetimecyclecountsof

eachtrigger.

b.Presssoftkey

countofselectedtrigger.

toresetcurrentcycle

Icon

Name

Icon Icon

Name Name

TriggerPolarity

SelectLineSelectwhichlinethetriggerissensingon(PC-8eonly)

ResetCounter

Description

Description Description

Togglepolaritytoinvertstateoftriggersignal

Resettriggercyclecount

334784A 23

Page 24

Screens

General

General General

1.LockPatternDenition(optional)—Protects

2.EnablePressureCompensation(optional,PC-8e

Setup

Setup Setup

patternfromaccidentalchanges.Operatormust

enterapasswordtochangepatterns,andcopy,

delete,orrenameprograms.

NOTE:

NOTE: NOTE:

ifRunScreensarealsolocked(see

AdvancedScreens,page27).

only):

•Usedtomaintainconsistentglueoutputwith

variablelinespeed.

•Withrun-upkitinstalled,thisfeatureadjusts

pumppressureaccordingtotheoutput

vs.speedcurve.Forrun-upsettings,see

RunUpInstallation(PC-8eonly),page12.

(Screen

(Screen (Screen

Thissettingwillonlytakeeffect

4)

4) 4)

3.EnableModulatedBead(optional,PC-8eonly):

•Usedtomaintainconsistentglueoutputwith

variablelinespeed.

•Adjustsoutputbystitchingbeadsaccordingto

theoutputvs.speedcurve.

•WhenPressureCompensationisenabled,

modulatedbeadbecomesactivebelowthe

minimumoutputpercentage.

•WhenPressureCompensationisdisabled,

modulatedbeadfollowstheoutputvs.

speedcurve.Forrun-upsettings,see

RunUpInstallation(PC-8eonly),page12.

A AA—EnterScreen

P PP—ScreenNumber(Screen4)

24

334784A

Page 25

Screens

Gun

Setup

Gun Gun

Setup Setup

1.GunCompensation:

(Screen

(Screen (Screen

5)

5) 5)

•Viewcurrentandlifetimecyclecountsofeach

gun.

•Entergunopencompensation.

•Entergunclosecompensation.

2.GunCycleCounters:

A AA—EnterScreen

B BB—GunOpenCompensation

C CC—GunCloseCompensation

D DD—LifetimeGunCycles

E EE—ResettableGunCycles

P PP—ScreenNumber(Screen5)

Icon

Name

Icon Icon

Name Name

OpenCompensationMechanicaldelaybetweenelectricalsignaltogunandphysicalopeningofgun

CloseCompensationMechanicaldelaybetweenelectricalsignaltogunandphysicalclosingofgun

ResetCounter

Description

Description Description

Resetguncyclecount

•Presssoftkey

counterofselectedgun.

toresetcurrentcycle

334784A 25

Page 26

Screens

Run

Up

Run Run

•Enterrunupoutputsettings

A AA—EnterScreen

B BB—MinimumOutput

C CC—MaximumOutput

D DD—HighCalibrationPoint

E EE—LowCalibrationPoint

P PP—ScreenNumber(Screen6)

Icon

Icon Icon

Control

Up Up

Control Control

Name

Name Name

OutputPressure

Percentage

LineSpeed

(Screens

(Screens (Screens

6–7,

PC–8e

6–7, 6–7,

PC–8e PC–8e

Description

Description Description

Enterminimumandmaximumpressureforrunupcontrol.

Entercorrespondingpressurepointsforenteredlinespeedpointstosetrun

upcurve.

UpperandLowerlinespeedpoints

only)

only) only)

RunUpPressureto

LineSpeedCurve

Curveissetbytwopointswhicharedenedbytheuser.Upperandlower

limitsdeneboundsoverwhichrun-upwillfunctionlinearly.

26 334784A

Page 27

Screens

Advanced

Advanced Advanced

Advanced

Advanced Advanced

Generaldisplaysettingsincludinglanguage,time,

andpasswordprotection.

Name

Name Name

Language

DateFormat

DateEnterthedisplaydate

TimeEnterthedisplaytime

PasswordEnterthepasswordtorestrict

ScreenSaverEnterthetime-outforthedisplay

SilentModeIfselected,disablesthedisplay

LockRun

Screens

Screens

Screens Screens

—

Display

— —

Display Display

Description

Description Description

Selectthedisplaylanguage

Selectthedisplaydateformat

accesstoSetupscreens.NOTE: NOTE:

Avalueof“0000”doesnotrequire

apasswordforaccesstosetup

screens.

screensaver.NOTE: NOTE:

disablesthescreensaver.

beepfunctionality.

Ifselected,operatorswillnotbe

abletochangemostrunscreen

settings.NOTE: NOTE:

thissettingtohaveanyeffect,a

passwordotherthan“0000”must

beenteredabove.

NOTE:

NOTE:

Inorderfor

NOTE:

Avalueof“0”

Advanced

Advanced Advanced

Selectthesystemunitstobeusedonthedisplay.

Name

Name Name

Temperature

MassUnits

SpecicGravityEnterthematerialspecicgravity

DistanceUnits

—

Units

— —

Units Units

Description

Description Description

Selectthesystemtemperature

units(integratedsystemsonly)

Selectthesystemmassunits

(integratedsystemsonly)

forhigherprecisionadhesive

consumption(integratedsystems

only)

Selectthesystemdistanceunits.

NOTE:

NOTE: NOTE:

patterncontroldistancevalues

exceptwhentimebasedmodeis

selectedon

(distanceunitsbecometimeunits

ofmilliseconds).

Thissettingappliestoall

PC Setup – Line Mode

334784A

27

Page 28

Screens

Advanced

Advanced Advanced

SelectUSBdownloadsettings.

Name

Name Name

DisableUSB

Downloads/

Uploads

DisableUSBLog

Errors

DownloadDepth

—

USB

— —

Downloads

USB USB

Downloads Downloads

DisablesUSBportfrom

transmittingdatato/fromaUSB

drive

DisablesUSBlogadvisory

Setsthelengthofthedatalogs

tobedownloaded(affectsthe

downloadtime)

Settings

Settings Settings

Description

Description Description

Advanced

Advanced Advanced

Readonlydisplayofsystemsoftware.

Name

Name Name

Module

SoftwarePart#Partnumberofsoftwareinstalled

SoftwareVersionVersionofsoftwareinstalledon

NOTE:

NOTE: NOTE:

donotmatchtheexpectedvalues,see

SoftwareUpdateProcedure,page40.

—

System

— —

System System

Nameofmoduleinsystem

onmodule

module

Ifsoftwareversionsorpartnumbers

Software

Software Software

Description

Description Description

28 334784A

Page 29

Stitching

Stitching Stitching

Tomaintainbondstrengthwhilereducingadhesiveconsumption..

Denitions

Denitions Denitions

Stitching

Sub-Bead

Sub-Bead Sub-Bead

Onedispensecycleofastitchedbead.

Stitch

Stitch Stitch

Thedistancebetweenthestartsoftwoadjacentsub-beads.

Stitch

Stitch Stitch

Thepercentageofadhesivesaved.

Anchor

Anchor Anchor

Ananchorbeadisasub-beadplacedattheendofthestitchedbeadthatguaranteesthestitchedbeadendsat

thesamelocationastheoriginal(non-stitched)bead.

—

— —

Interval

Interval Interval

Savings

Savings Savings

—

— —

—

— —

Beads

Beads Beads

Setup

Setup Setup

Inordertostitchanybead,performthefollowing

steps:

1.NavigatetoEventMap(Screen1),page21.

2.EnterthedesiredStitchInterval

Savings

Stitchingcanbedisabledbysettingthegun

StitchSavingsto“0”.

334784A 29

forthedesiredgun.NOTE: NOTE:

andStitch

NOTE:

3.NavigatetoPatternDenition(Screen2),page

19.

4.StitchindividualbeadsbyselectingtheStitch

Bead

NOTE:

NOTE: NOTE:

stitched(somecanbestitchedwhileothersare

solid).

optionwithineachbeadentrybox.

Notallbeadsforaspecicgunmustbe

Page 30

LineSpeed

Line

Line Line

1.NavigatetoLineMode(Screen2),page22.

2.Passaproductofknownlengthpastthetrigger

3.Oncetheproducthaspassedthetrigger,note

Speed

Speed Speed

inuse.

thevaluedisplayedinthe

indicator.NOTE: NOTE:

ofthepartoftheproductthatpassesbelowthe

triggerinuse,notnecessarilytheoveralllength

oftheproduct.

NOTE:

Last Product Length

Thisvalueisthelength

4.Adjustsettings:

a.Onencoder encoder

b.Onxedline line

NOTE:

NOTE: NOTE:

accordingtothechangesmadeinsettingsabove

(step2onlyneedstobeperformedonce).

encoder

Encoder Pulses per mm

ProductLengthvaluematchestheexpected

length.

adjust

Product Length

length.

Last Product Length

line

Fixed Line Speed

systems

systems systems

speed

speed speed

valuematchestheexpected

(PC-8eonly),adjust

systems

systems systems

indicatorwillupdate

untiltheLast

(bothversions),

untilthe

Last

Last Product Length

incheslong.

displayedfortriggeris18.00

Encoderpulsespermmbox.

FixedLineSpeedbox.

30 334784A

Page 31

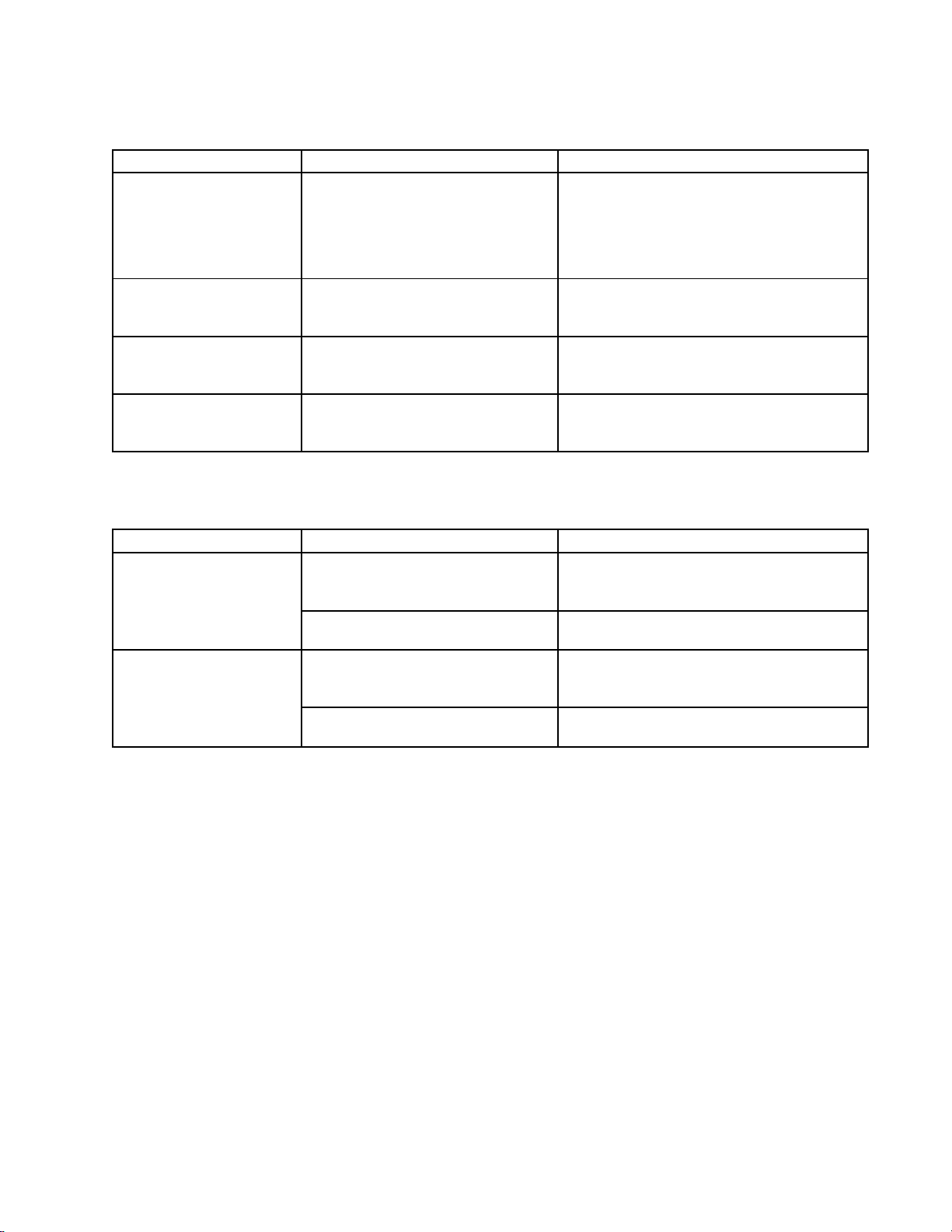

RunUpControl

Run

Run Run

Run

Run Run

1.Verifyrunupcontrollerrangeissetto100psi(10

2.NavigatetoGeneralSetup(Screen4),page24,

High

High High

1.TurnsystemONandrunlineatmaximumspeed.

2.NavigatetoLineMode(Screen2),page22,and

3.Setpressureusingthepumppressuredialand

4.NotepressuredisplayedonInvisiPacpump

5.Notepressuredisplayedonrunupcontrollerin

Up

Up Up

Up

Up Up

Vinputsignalyields100psi).NOTE: NOTE:

belowassumeinputairpressuretotheregulator

isgreaterthanorequalto100psi(simpliesrun

upprogrammingsothat%andpsivaluesare

interchangeable).

anddisablePressureCompensation.

Calibration

Calibration Calibration

noteCurrentLineSpeedinFbelow.

gaugeatthebaseoftheInvisiPacsystemuntil

thedesiredglueoutputisachieved.

pressuregaugeinG GGbelow.

B BBbelow.

Control

Control Control

Setup

Setup Setup

NOTE:

Point

Point Point

settings

User

User User

1.NavigatetoRunUpControl(Screens6–7,PC–8e

2.NavigatetoGeneralSetup(Screen4),page

User

User User

(A)

(A) (A)

(B)

(B) (B)

(C)

(C) (C)

(D)

(D) (D)

(E)

(E) (E)

(F)

(F) (F)

(G)

(G) (G)

Setting

Setting Setting

only),page26.Entersettingsinscreenshot

accordingtovaluesinsectionbelow.

24andre-enablePressureCompensation.

Settings

Settings Settings

Maximumoutput_____100

Runupcontroller

pressureathighline

speed

Runupcontroller

pressureatlowline

speed

Minimumoutput______50

Lowlinespeed

Highlinespeed

InvisiPacpump

pressureathighline

speed

Entry

Entry Entry

________

________

________

________

________

%(psi)

%(psi)

%(psi)

%(psi)

ft/minor

m/min

ft/minor

m/min

psi

Low

Low Low

1.Reducelinespeedtominimumspeedandnote

2.Reducepressureusingthedialandgaugeatthe

3.ReturnpressureonInvisiPacpumppressure

334784A 31

Calibration

Calibration Calibration

CurrentLineSpeedinE EEbelow.

baseoftheInvisiPacsystemuntilthedesired

glueoutputisachieved.Notepressuredisplayed

onregulatorinC CCbelow.

gaugetovalueinG GGbelow.

Point

Point Point

PCSetup—RunUpControlscreenwithsettings

indicatedbythelettersabove.

Page 32

RunUpControl

Random

Random Random

Forhandlingproductsofvariouslengthswithonepattern

Touserandomlengthbeadmode,performthefollowingsteps:

1.NavigatetoEventMap(Screen1),page21.

2.SelectMirrorBeadPatternforthedesired

gun.

3.VerifytheappropriateGun-TriggerOffset

fortheselectedgun.

NOTE:

NOTE: NOTE:

orequaltotheleadingmargin.

4.NavigatetoPatternDenition(Screen2),page

19.

Length

Length Length

Gun-TriggerOffsetmustbegreaterthan

Bead

Bead Bead

Mode

Mode Mode

5.Entertheleadingmargin(LM)inthebead1

offsetbox.NOTE: NOTE:

thetrailingmargin.

6.Enterthelengthofthelongestrandombead

(LRB)thatmaybeneededinthebead1length

box.

7.Enableordisablestitchingforbead1.

NOTE:

Theleadingmarginisequalto

32 334784A

Page 33

RunUpControl

Mirror

Mirror Mirror

Forsymmetricalpatterns,includingproductswith

varyinglengths.

Tousemirrormode,performthefollowingsteps:

1.NavigatetoEventMap(Screen1),page21.

Mode

Mode Mode

2.SelectMirrorBeadPattern

gun.

3.VerifyGun-TriggerOffset

gunisgreaterthanorequaltotheendofthenal

bead(nalbeadoffset+length).

4.NavigatetoPatternDenition(Screen2),page

19.

5.Enterbeadinformationforthersthalfofthe

product.

6.Enableordisablestitchingforeachbead.

forthedesired

fortheselected

334784A 33

Page 34

Calibration

Calibration

Calibration Calibration

Gun

Gun Gun

Forhighspeedlinesandprecisionapplications.

NOTE:

NOTE: NOTE:

ensuretheappropriategun-triggeroffsetvalues

havebeenenteredforeachgun-triggerpairon

EventMap(Screen1),page21.

Enteringtheappropriateguncompensationcan

ensurehigheraccuracyofbeadplacement.To

ensuretheappropriatevaluesareentered,begin

withthe

accordingtothe

Gun

Gun Gun

Compensation

Compensation Compensation

Beforeenteringguncompensationvalues,

(optional)

(optional) (optional)

Recommended Values

Calibration Routine

Compensation

Compensation Compensation

Relative

Relative Relative

Desired:

Adjustment

Adjustment Adjustment

Edge

Edge Edge

Position

Position Position

belowandadjust

Guide:

Guide: Guide:

.

Lagging

Recommended

Recommended Recommended

GM-100:5-10ms

GS-35:10–20ms

Unknown,other:10ms

Calibration

Calibration Calibration

1.NavigatetoGunSetup(Screen5),page25.

2.Dispensedesiredpattern(programcontained

withinthePatternController).

3.Measuredistancebetweendispensedpattern

(actualpositionofdispensedpatternonthe

product)anddesiredpattern.

4.AdjustOpen/Closecompensationvalues

accordingtothefollowingGun Gun

Table

Table Table

5.Repeatsteps2-3untildesiredpatternachieved.

Leading

Leading Leading

Edge

Edge Edge

Leading

Values

Values Values

Routine

Routine Routine

Gun

Compensation

Compensation Compensation

Gun

andGun Gun

Compensation

Compensation Compensation

Trailing

Trailing Trailing

Lagging

Formula

Formula Formula

Edge

Edge Edge

below.

Leading

vs.

Dispensed:

Adjustment

Gun

Compensation

Gun Gun

Compensation Compensation

Determinetheguncompensationadjustmentamountinmilliseconds.

Standard

Standard Standard

Metric

Metric Metric

Bead

Bead Bead

Compensation

Compensation Compensation

units:

units: units:

units:

units: units:

offset

distances

offset offset

distances distances

Gun

Gun Gun

(ms)

(ms) (ms)

5

5 5

10

10 10

20

20 20

Formula:

Formula: Formula:

Adjustment(ms)=

Adjustment(ms)=

inches

in inininches inches

50

50 50

15.24

15.24 15.24

0.05in.

1.27(mm)

0.1in.

2.54(mm)

0.2in.

5.08(mm)

(mm)

(mm) (mm)

ft/min

ft/min ft/min

(m/min)

(m/min) (m/min)

Increase

as

as as

a aafunction function

100

100 100

30.48

30.48 30.48

2.54(mm)

5.08(mm)

10.16(mm)

Decrease

5000xMeasuredOffsetDistance(in.)

LineSpeed(ft/min.)

60xMeasuredOffsetDistance(mm)

LineSpeed(m/min.)

function

0.1in.

0.2in.

0.4in.

ft/min

ft/min ft/min

(m/min)

(m/min) (m/min)

Gun

of ofofGun Gun

Compensation

Compensation Compensation

Line

Speed

Line Line

Speed Speed

200

ft/min

200 200

ft/min ft/min

60.96

(m/min)

60.96 60.96

(m/min) (m/min)

0.2in.

5.08(mm)

0.4in.

10.16(mm)

0.8in.

20.32(mm)

and

and and

IncreaseDecrease

Line

Line Line

500

500 500

152.4

152.4 152.4

0.5in,

12.7(mm)

1.0in.

25.4(mm)

2.0in.

50.8(mm)

Speed

Speed Speed

1000

ft/min

ft/min ft/min

(m/min)

(m/min) (m/min)

304.8

304.8 304.8

ft/min

1000 1000

ft/min ft/min

(m/min)

(m/min) (m/min)

1.0in.

25.4(mm)

2.0in.

50.8(mm)

4.0in.

101.6(mm)

34 334784A

Page 35

Verication

Verication Verication

Thissectionveriesproperinstallationofthe

InvisiPacPatternControlSystem.Forfurther

assistance,seeTroubleshooting,page36.

Encoder

Encoder Encoder

1.NavigatetoHome,page16.

2.VerifythatthelinespeeddisplayedintheCurrent

LineSpeedindicator

fordifferentlinespeeds.

ispositiveandvaries

Verication

Valves

Valves Valves

1.NavigatetoGunPurge,page18.

a.WithsystemON:attemptapurgeoneach

installedvalveandverifythatthevalveis

actuated(gluehasbeendispensedfromthe

appropriatevalve).

b.WithsystemOFF:disconnectthecable

fromthesolenoidandattemptapurge

oneachinstalledvalveandverifythatthe

signalisactuated(viatheLEDonthevalve

connector).

Triggers

Triggers Triggers

1.NavigatetoHome,page16.

2.Withoutproductinfrontofthetrigger,verifythat

thetriggerindicatorLEDisOFF.

3.Withproductinfrontofthetrigger,verifythatthe

triggerindicatorLEDisON.

3.Ifthelinespeedshowndoesnotmatchthe

known/expectedvalue,seeCalibration,page34,

tomaketheappropriateadjustments.

Run

Run Run

1.NavigatetoHome,page16.

2.TurnthesystemONandwaitforthePattern

3.Runthelineatvariousspeedsandverifythatthe

4.Ifthepercentage/pressuredisplayeddoesnot

PLC

PLC PLC

1.NavigatetoHome,page16.

Up

Control

Up Up

Control Control

ControllertobecomeACTIVE.

appropriateRunUpOutputisdisplayedonthe

screenandtheRunUpControllerisdisplayed(if

pressurereadoutisavailable).

matchtheexpectedvalue,seeRunUpControl

(Screens6–7,PC–8eonly),page26,tomakethe

appropriateadjustments.

Inputs

Inputs Inputs

2.ActuatethePLCinputremotelyandverifythat

theexpectedresultisindicatedinthePLCIO

sectionintheupperrightcornerofthedisplay.

334784A 35

Page 36

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

Error

Error Error

Whenerroroccur,press

automaticallywhentheconditionthatcauseditiscorrected.Activeerrorsscrollonthemenubar

AlarmsshutdownthePatternControllerandactivatethedrycontactPLCoutput.Advisoriesanddeviations

areinformationalonlyanddonotshutthesystemdown.

CAXPCommunication

A40P

A4XP

A4_P

K4_PHighPulseRate

Codes

Codes Codes

toacknowledgeeacherror.Afterbeingacknowledged,theerrorwillclear

Alarms

Alarms Alarms

Code

Code Code

Description

Description Description

ADMunableto

Error

OvercurrentOvercurrenton

OvercurrentOvercurrenton

OvercurrentOvercurrentonvalve

communicatewith

PatternController

accessorypowersupply

output

communicationcable

output

output“_”

Encoder“_”pulserate

exceedsmaximumlimit

(shut

the

(shut (shut

Cause

Cause Cause

system

the the

system system

down)

down) down)

Solution

Solution Solution

CheckforgreenpowerlightonthePattern

Controller

Checkcommunicationcabling

Checkaccessorycablingforshortcircuit

CheckADMCANcablingforshortcircuit

Replacedisplay(ADM)

Checkwiringforshortcircuit

Verifyvalveresistanceishigherthan24ohms

Selectencoderwithlowerpulserate

Reducelinespeedorgearingratio

Advisories

Advisories Advisories

LowLineSpeed

Description

Description Description

Code

Code Code

V1_PLowVoltagePowersupplyvoltage

V4_PHighVoltagePowersupplyvoltage

K1_P

and

Deviations

and and

Deviations Deviations

Cause

Cause Cause

below18VDC

above28VDC

PoorEncoderCoupling

online“_”

LineSpeedislessthan

lowlinespeedalarm

levelonline“_”

(do

not

shut

the

(do (do

not not

shut shut

Tocheckforoverloadedpowersupply,

measurethevoltagewithallvalvesoff,and

thenwithallvalveson(purging).

Tocheckforoverheatedpowersupply,allow

theunittocoolandrecheckvoltage.

Adjustvoltageto24Vifpossible,orreplace

thepowersupply.

Adjustvoltageto24Vifpossibleorreplacethe

powersupply.

Checktoensurepropercouplingbetween

lineandencoder.VerifyPatterncontroller

isreadingappropriatelinespeed(see

LineMode(Screen2),page22).

Increaselinespeedordecrease

lowlinespeedalarmlevel(see

LineMode(Screen2),page22).

system

the the

system system

down)

down) down)

Solution

Solution Solution

36 334784A

Page 37

Troubleshooting

Display

Display Display

Problem

Problem Problem

Displaydoesnotturnon

PatternControlScreens

notpresent

RunUpControlScreens

notpresent

Encodersettingsnot

present

Pattern

Pattern Pattern

Problem

Problem Problem

Nopatterndispensed

Cause

Cause Cause

SelectordialonPatternControl

boardsettowrongposition

Powernotturnedon

CommunicationcabledisconnectedVerifyPatternControlboardisconnected

SelectordialonPatternControl

boardsettowrongposition

SoftwareversionmismatchPerformsoftwareupdateprocess

PC-8ekeytokennotinsertedinADMObtainPC-8ekeytoken(comeswith

Cause

Cause Cause

Valvenotassociatedwithcorrect

trigger(ornotassignedtoany

trigger)

Physicalproblemwithvalve

Improperstitchsettings

IntegratedSystems:setto0

Stand-AloneSystems:setto1

CheckforgreenlightonPatternControl

boardandDisplay

toDisplay

IntegratedSystems:setto0

Stand-AloneSystems:setto1

withlatestversionofsoftware(see

SoftwareUpdateProcedure,page40).

PC-8eversionsofInvisiPacPatternControl

System)

Ensurevalvehasappropriatetrigger

selected

See“NoGlueDispensed”troubleshooting

helpwithin

Stitch Interval

Solution

Solution Solution

Solution

Solution Solution

Valve

section

tooshortor

Stitch

Patterndispensestoo

early/late

Patternmeasurement

unitsareindistance/time

Savings

Wrong/emptyprogramselectedEnsureproperprogramisselectedon

PC Control – Program Storage

ProgramStorage(Screen1),page17)

PC Control – Pattern Preview

and

PatternPreview,page20)containsapattern

PatternControllernotACTIVETurnonpatterncontroller.Stand-Alone

systemswillgoACTIVEimmediately,

whereasIntegratedsystemswillgoACTIVE

oncetheInvisiPacsystemhasgoneACTIVE

Impropergun-triggeroffsetenteredEnsureappropriate

isenteredon

(seeEventMap(Screen1),page21)

ImpropervalveOpen/Close

Compensation

Improperlinemodeselected

/entered

Performcalibrationroutinefoundin

Calibration – Gun Compensation

Calibration,page34)

Selectappropriatelinemodesettingon

Setup – Line Mode

toohigh

(see

(see

Gun - Trigger Offset

PC Setup – Event Map

(see

(see##)

334784A 37

PC

Page 38

Troubleshooting

Valve

Valve Valve

Problem

Problem Problem

Systemresetwhenguns

re

Nogluedispensed

Trigger

Trigger Trigger

Problem

Problem Problem

Triggeralwayson/off

Triggerdetectsmultiple

timesononebox

(no24VDCpresent)

Cause

Cause Cause

Currentdrawfromcombined

valvesexceedspowersupply

rating(150W)

Solenoidshorted

WrongtypeofvalveinusePatterncontrollerisonlycompatiblewith24VDC

Cause

Cause Cause

Sensoriscovered/misalignedClearanysensorobstructionsandverifysensor

Polarityisbackwards

Impropersensor

type/installation

Triggernotadjustedproperly

orartifactsontheobjectbeing

sensedcausefalsedetection

Excessivecurrentdrawnfrom

24VDCsupplyon

Ensurecurrentdrawisbelow6Atotalbetweenall

simultaneouslyringvalves.

Ensureproperwiringbetweensolenoidand

patterncontroller.Ifnoshortsfound,consider

replacingsolenoid.

solenoids(noelectricvalvesorACsolenoids)

changesstateswithobjectpresent/absent

Change

Setup

See

sensorselection/installation

Set

Event Map

Performpowercycletoresetpowerto24VDCpins Triggersensorturnedoff

Iferrorpersists,removecomponentsandpower

cycleuntilcomponentwithexcessivecurrentdraw

isdiscovered

Trigger Polarity

(seeTriggerSetup(Screen3),page23).

Installation – Trigger Installation

Minimum Product Length

(seeEventMap(Screen1),page21).

Solution

Solution Solution

Solution

Solution Solution

+/-in

PC Setup – Trigger

forproper

in

PC Setup –

Encoder

Encoder Encoder

Problem

Problem Problem

Encoderspeedvaries

signicantly

Encoderreadswrong

speed

Encoderdoesnotreadline

speed

Linespeedisxed

reversed

Encodercouplingisslipping

Encoderisimproperlyscaled

Encodermovementnot

proportionatelyscaledtopath

ofproduct

Impropersensor

type/installation

Wronglinemodeselected

Fixedlinespeedmode

selected

Cause

Cause Cause

ExchangeAandA’wireswithBandB’wires EncoderspeedisnegativeEncodertraveldirectionis

Flipencodertospintheoppositedirection

Improveencodercouplingtolinebyusingdifferent

bracket,mounting,coupling,etc.

Performcalibrationroutinefoundin

Line Speed

Remountencodertoensureratiobetweenencoder

movementandproductmovementisalwaysa

xedproportion

See

Installation – Encoder Installation

sensorselection/installation

Selectencoderlinemodesettingon

Line Mode

SelectEncoderlinemodesettingon

– Line Mode

(seeCalibration,page34).

(seeLineMode(Screen2),page22).

(seeLineMode(Screen2),page22).

Solution

Solution Solution

38 334784A

Calibration –

forproper

PC Setup –

PC Setup

Page 39

Troubleshooting

Run

Run Run

PLC

PLC PLC

Up

Up Up

Problem

Problem Problem

RunUpControllerreads0

psi

RunUpController

producesundesired

results

Inputs

Inputs Inputs

Problem

Problem Problem

InputfromPLCnotread

byPatternController

OutputfromPattern

ControllernotreadbyPLC

and

and and

Cause

Cause Cause

Integratedsystems:InvisiPac

systemisINACTIVE

Stand-Alonesystems:PCsystemis

INACTIVE

Nopressuretoinletofrunup

controller

Improperusersettingsentered

Outputpressuredesiredisgreater

thaninletpressure

Outputs

Outputs Outputs

Cause

Cause Cause

ImproperinputsignalfromPLCSeePLCInputsandOutputsInstallation

Brokenwire

ImproperinterfacetoPLCSeePLCInputsandOutputsInstallation

Brokenwire

Integratedsystems:TurnsystemON,run

upwillbeactiveoncesystemisACTIVE

(pumpwillturnon)

Stand-Alonesystems:TurnsystemON,run

upcontrollerwill

Ensurepressureisbeingsuppliedtothe

inletofrunupcontroller(checkforvalves

andshutoffsupstreamofcontroller)

Performcalibrationroutinefoundin

Calibration – Run Up Control

Calibration,page34).

Ensureenoughpressureisbeingsupplied

totheinletoftherunupcontroller(standard

calibrationroutinecallsfor100psi)

(optional),page11forpropersensor

selection/installation

CheckwiringbetweenPatternController

andPLC

(optional),page11forspecicationsand

properinstallation

CheckwiringbetweenPatternController

andPLC

Solution

Solution Solution

(see

Solution

Solution Solution

334784A 39

Page 40

SoftwareUpdateProcedure

Software

Software Software

Procedure

Procedure Procedure

WhensoftwareisupdatedontheADMthesoftware

isthenautomaticallyupdatedonallconnected

GCAcomponents.Astatusscreenisshownwhile

softwareisupdatingtoindicateprogress.

Update

Update Update

NOTE:

NOTE: NOTE:

thefollowingscreens:

First:

First: First:

Softwareischecking

whichGCAmodules

willtakethe

availableupdates.

Whenthescreenturnson,youwillsee

1.TurnsystemmainpowerswitchOFF.

2.RemoveADMfrombracket.

3.Removetokenaccesspanel.

4.InsertandpressInvisiPacsoftwareupgrade

token(partno.24R324)rmlyintoslot.

NOTE:

NOTE: NOTE:

5.InstallADMintobracket.

6.TurnsystemmainpowerswitchON.

Thereisnopreferredorientationoftoken.

NOTICE

NOTICE NOTICE

Astatusisshownwhilesoftwareisupdatingto

indicateprogress.Topreventcorruptingthe

softwareload,donotremovetokenuntilthe

statusscreendisappears.

Second:

Second: Second:

Statusofthe

updatewith

approximatetime

untilcompletion.

Third:

Third: Third:

Updatesare

complete.Icon

indicatesupdate

success/failure.

Seethefollowing

Icontable.

Icon

Icon Icon

7.Removetoken(T).

8.Replacetokenaccesspanel.

Description

Description Description

Updatesuccessful.

Updateunsuccessful.

Updatecomplete,nochanges

necessary.

Updatewassuccessful/completebut

oneormoreGCAmodulesdidnothave

aCANboot-loadersosoftwarewasnot

updatedonthatmodule.

9.Press

screens.

40 334784A

tocontinuetotheInvisiPacoperation

Page 41

USBDownload

USB

USB

USB USB

Thesystemcanstore250,000entriesinitslogs

andthesystemaddsanewentrytothelogsevery

15seconds.Thismeansthesystemstores1041

hoursofsystemoperationdata,or43daysof

around-the-clockoperation.Oncefull,thesystemwill

overwritetheoldestdata.

NOTE:

NOTE: NOTE:

than43dayswithoutdownloadingthelogs.

Download

Download Download

Uploadinganeditedsystemcongurationle

candamagethesystem.Neverputamodied

SETTINGS.TXTleintheUPLOADfolderonthe

ashdrive.

1.InsertUSBashdriveintoUSBport.

Download

Download Download

Topreventlosinganydata,nevergomore

Procedure

Procedure Procedure

NOTICE

NOTICE NOTICE

NOTE:

NOTE: NOTE:

Flashdrivemustbe8GBorsmaller.

numericfoldernamematchesthe8-digitADMserial

number,whichislocatedonthebackoftheADM.

WhendownloadingfrommultipleADMs,therewillbe

onesub-folderintheGRACOfolderforeachADM.

Theloglesshouldbeopenedinaspreadsheet

program.

NOTE:

NOTE: NOTE:

minimizelesize.

USB

USB USB

Duringoperation,InvisiPacstoressystemand

performancerelatedinformationtomemoryinthe

formoflogles.InvisiPacmaintainstheevents,data,

GCA,BlackBox,andDiagnosticslogs.Followthe

Download

Download Download

Events

Events Events

Theeventlog(1-EVENT.CSV)maintainsarecordof

thelast175,000events.Eacheventrecordinthelog

lecontainsthedateandtimetheeventoccurred,

theeventtype,eventcode,andeventdescription.

Ifemailingtheles,zip(compress)themto

Logs

Logs Logs

Procedure

Procedure Procedure

Log

Log Log

toretrievelogles.

2.ThemenubarandUSBindicatorlightsindicate

thattheUSBisdownloadingles.WaitforUSB

activitytocomplete.Apop-upwillbepresentuntil

thetransferiscompleteifitisnotacknowledged.

NOTE:

NOTE: NOTE:

ashdriveisnotcompatiblewiththeADM.Trya

differentashdrive.

NOTE:

NOTE: NOTE:

dataperweek,dependingonsystemoperation.

Accessing

Accessing Accessing

AlllesdownloadedfromtheUSBareputina

DOWNLOADfolderonthestickdrive.Forexample:

“E:\GRACO\12345678\DOWNLOAD\”.The8-digit

Ifthepop-upscreendoesnotappear,the

Thesystemcanlogupto45mbofadditional

Files

Files Files

Data

Log

Data Data

Log Log

Thedatalog(2-DATA.CSV)tracksthesetpointand

actualtemperaturesevery15seconds.Thislogcan

storeupto250,000linesofdata.Thesystemstores

1041hoursofsystemoperationdata,or43daysof

around-the-clockoperation.Oncefull,thesystemwill

overwritetheoldestdata.

NOTE:

NOTE: NOTE:

than43dayswithoutdownloadingthelogs.

GCA

GCA GCA

Thislog(3-GCA.CSV)liststheinstalledGCA

modulesandtheirrespectivesoftwareversions.

Black

Black Black

Theselogs(4-BLACKB.CSV,5-DIAGN.CSV)are

designedtoprovideusefulinformationtoGracowhen

callingfortechnicalassistance.

Topreventlosinganydata,nevergomore

Log

Log Log

Box,

Diagnostic

Box, Box,

Diagnostic Diagnostic

Logs

Logs Logs

334784A

41

Page 42

Parts

Parts

Parts Parts

42

334784A

Page 43

Parts

Parts

Parts Parts

List

List List

Ref.

Ref. Ref.

Part

Part Part

1

2

3LABEL,pattern

▲4LABEL,symbol,

5

127886

6126881

7

126891NUT,bushing2

8114421

11

12

13127939

15

16

1724W293

19

20

Description

Description Description

ENCLOSURE,PC,

painted

FOAM,gasket

controller

ground

GROMMET,pattern

controller

BUSHING,strainrelief

BUSHING,strainrelief

FASTENER,hex,

standoff

TOOL,screwdriver

BLOCK,ground

WASHER,lock,ext

NUT,#8–32hex

MODULE,GCA,

patterncontrol

SCREW,machine,ph,

8x3/8in.

WASHER,lock

Qty.

Qty. Qty.

1

2

1

1

2

2

1

4

1

1

2

2

1

4

Ref.

Ref. Ref.

▲

Part

Part Part

21NUT,hex1

22

23

24

25

26BLANK,labelkit1

29116772

30119162

31128156

32128147

33128117

35127768

37TIE,cable,7.5in.1

Replacement Danger and Warning labels are

Description

Description Description

WASHER,lock

LATCH,tool,secured

LATCH,cam

SCREW,cap,hexhd

CONNECTOR,plug,

3.81mm,4position

CONNECTOR,plug,6

position

BRACKET,mounting,

slide-on

CONNECTOR,plug,

3.81mm,8position

CONNECTOR,plug,

3.81mm,12position

CABLE,can,female

1.5m

Qty.

Qty. Qty.

4

1

1

4

1

2

1

2

1

1

available at no cost.

1

334784A 43

Page 44

Parts

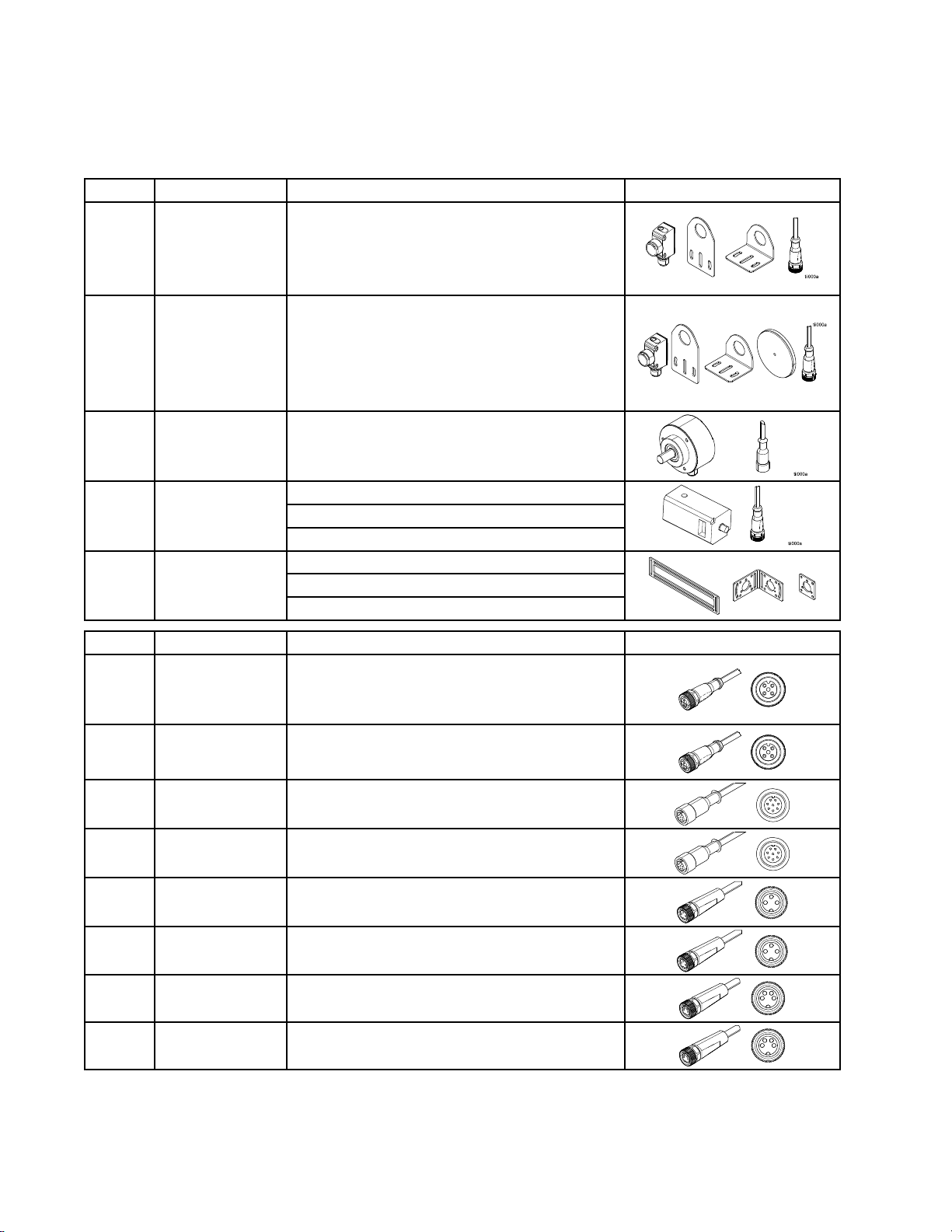

Kits

Kits Kits

Kits

List

Kits Kits

List List

Part

Part Part

24X446KIT,photoeye,

24X447KIT,photoeye,

24X448KIT,encoder,

17E020KIT,runup

24X607KIT,encoder

Description

Description Description

diffuse,18mm

polretref,18mm

1000PPR,

10mm

brackets

Contents

Contents Contents

128073-SENSOR,photoelectricdiffuse

128070-BRACKET,sensormount,angled

128071-BRACKET,sensormount,straight

128081-CABLE,M12,4-pin,5.0m

128072-SENSOR,photoelectric,polarized

128069-SENSOR,reector

128070-BRACKET,sensormount,angled

128071-BRACKET,sensormount,straight

128081-CABLE,M12,4-pin,5.0m

128074-ENCODER,incremental

128079-CABLE,M12,8-pin,10.0m

127787-REGULATOR,pressure,V2P

128081-CABLE,M12,4–pin,5.0m

_______-FITTINGS

17E017-BRACKET,90degree,encoder

17E018-BRACKET,encoder

17E037-BRACKET,mounting,encoder

Part

Part Part

24X449KIT,cable,M12,

24X453KIT,cable,M12,

24X454

24X455

24X456KIT,cable,M8,

24X457KIT,cable,M8,

24X458KIT,cable,M8,

24X459KIT,cable,M8,

Description

Description Description

4-pin,F-L,5m

4-pin,F-L,10m

KIT,cable,M12,

8-pin,F-L,5m

KIT,cable,M12,

8-pin,F-L,10m

3-pin,F-L,5m

3-pin,F-L,10m

4-pin,F-L,5m

4-pin,F-L,10m

Used

For

Used Used

For For

Standardsolenoidvalve(i.e.GS-35)

Run-upcontroller

TriggerswithM12connection(12mmnut)

Standardsolenoidvalve(i.e.GS-35)Run-up

controllerTriggerswithM12connection(12mm

nut)

Encoder

Encoder

Minisolenoidvalve(i.e.GM-100)

Minisolenoidvalve(i.e.GM-100)

TriggerswithM8connection(8mmnut)

TriggerswithM8connection(8mmnut)

44

334784A

Page 45

WiringDiagram

Wiring

Wiring Wiring

Ref.

Ref. Ref.

915U423

10127887

14

Diagram

Diagram Diagram

Part

Part Part

Description

Description Description

SWITCH,2P,25A

POWERSUPPLY,24

DC,6.3A,150W

HARNESS,ground

Qty.

Qty. Qty.

1

1

1

Ref.

Ref. Ref.

Part

Part Part

28

38

39

Description

Description Description

CONNECTOR,plug,3

position

TERMINAL,fork,#8

TERMINAL,fork,#4

Qty.

Qty. Qty.

1

2

1

334784A 45

Page 46

TechnicalData

Technical

Technical Technical

Description

Description Description

Gun

Outputs

Gun Gun

Outputs Outputs

Trigger

Trigger Trigger

Encoder

Encoder Encoder

Run

Run Run

PLC

PLC PLC

PLC

PLC PLC

PLC

PLC PLC

Integrated

Integrated Integrated

Program

Program Program

Beads

Beads Beads

Distance

Distance Distance

Time

Time Time

Enclosure

Enclosure Enclosure

Ambient

Ambient Ambient

Inputs

Inputs Inputs

Up

Control

Up Up

Control Control

Enable/Disable

Enable/Disable Enable/Disable

Program

Program Program

Alarm

Output

Alarm Alarm

Output Output

Power

Power Power

Storage

Storage Storage

Per

Output

Per Per

Output Output

Accuracy

Accuracy Accuracy

Accuracy

Accuracy Accuracy

Environmental

Environmental Environmental

Temperature

Temperature Temperature

Data

Data Data

Value

Value Value

8

4

2(PC-8eonly)Quadraturedifferentiallinedriver

2(PC-8eonly)I/P(4–20mA)orV/P(0–10V)

YES0–30VDC,min10Vtoassert

Select

Select Select

Bit

Bit Bit

Supply

Supply Supply

Rating

Rating Rating

32˚–120˚F,0˚–50˚C

4

YES0–250VAC(drycontactoutput)

YES

50

24

1mm,0.1in.

1ms

IP54Resistanttodustandsplashingwater

24VDC,1Aeach,6Amaxtotal

NPNorPNPorDryContact

Selectupto15uniqueprograms

Input:100–240VAC,50/60Hz

Output:24VDC,150W

Eachbeadcanbestitched,allowingmany

morethan24dots

Details

Details Details

46 334784A

Page 47

Notes

Notes

Notes Notes

334784A

47

Page 48

Graco

Graco Graco

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoandbearingits

nametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginalpurchaserforuse.

Withtheexceptionofanyspecial,extended,orlimitedwarrantypublishedbyGraco,Gracowill,foraperiodof

twelvemonthsfromthedateofsale,repairorreplaceanypartoftheequipmentdeterminedbyGracotobe

defective.Thiswarrantyappliesonlywhentheequipmentisinstalled,operatedandmaintainedinaccordance

withGraco’swrittenrecommendations.

Thiswarrantydoesnotcover,andGracoshallnotbeliableforgeneralwearandtear,oranymalfunction,

damageorwearcausedbyfaultyinstallation,misapplication,abrasion,corrosion,inadequateorimproper

maintenance,negligence,accident,tampering,orsubstitutionofnon-Gracocomponentparts.NorshallGraco

beliableformalfunction,damageorwearcausedbytheincompatibilityofGracoequipmentwithstructures,

accessories,equipmentormaterialsnotsuppliedbyGraco,ortheimproperdesign,manufacture,installation,

operationormaintenanceofstructures,accessories,equipmentormaterialsnotsuppliedbyGraco.

Thiswarrantyisconditionedupontheprepaidreturnoftheequipmentclaimedtobedefectivetoanauthorized

Gracodistributorforvericationoftheclaimeddefect.Iftheclaimeddefectisveried,Gracowillrepairorreplace

freeofchargeanydefectiveparts.Theequipmentwillbereturnedtotheoriginalpurchasertransportation

prepaid.Ifinspectionoftheequipmentdoesnotdiscloseanydefectinmaterialorworkmanship,repairswillbe

madeatareasonablecharge,whichchargesmayincludethecostsofparts,labor,andtransportation.

THIS

WARRANTY

THIS THIS

WARRANTY WARRANTY

INCLUDING

INCLUDING INCLUDING

FOR

FOR FOR

A AAPARTICULAR PARTICULAR

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove.The