Page 1

Repair

24W996

ti25242a

24B748

24W997

24W995

GH™130/200/230/300 and

DutyMax GH/EH™230/300 Displacement Pump

For professional use only.

Not approved for use in explosive atmosphere or hazardous locations.

For portable airless spraying of architectural paints and coatings.

Models: 24B748, 24W995, 24W996, 24W997, 24W998, 24W999, 24X001

Important Safety Instructions

Read all warnings and instructions in this manual and related manuals.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

334654A

EN

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

24W998

24X00124W999

Page 2

Table of Contents

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Trigger Lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disassemble Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Assemble Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Throat Packing Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pump 24B748 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pump 24W995 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pump 24W996 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pump 24W997 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pump 24W998 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump 24W999 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pump 24X001 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2 334654A

Page 3

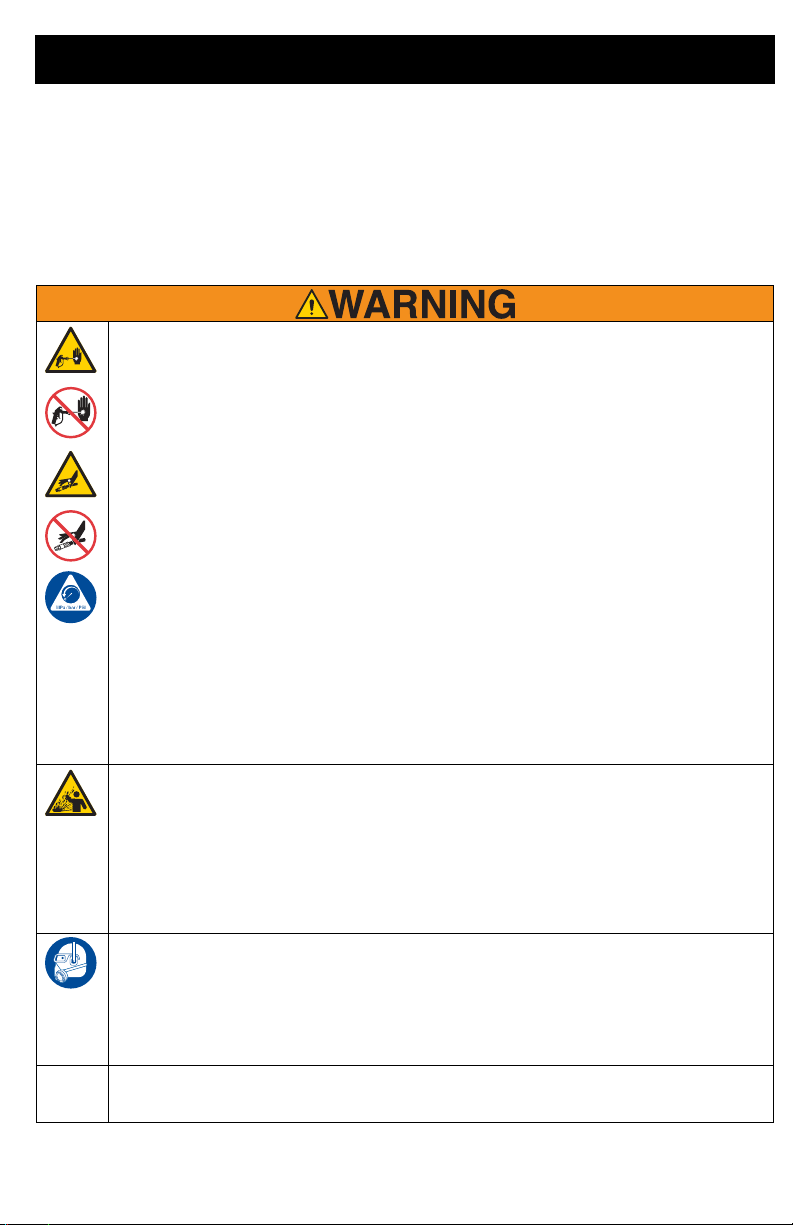

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual

where applicable.

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the

event that injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop

leaks with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the nozzle tip clogs

while spraying, follow the Pressure Relief Procedure for turning off the unit and relieving

the pressure before removing the nozzle tip to clean.

• Equipment maintains pressure after power is shut off. Do not leave the equipment

energized or under pressure while unattended. Follow the Pressure Relief Procedure

when the equipment is unattended or not in use, and before servicing, cleaning, or

removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories

that are rated a minimum of 3300 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning

properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the

controls.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact your

material supplier for compatibility.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects

or other reproductive harm. Wash hands after handling.

334654A 3

Page 4

Repair

ti24612a

ti24851a

OI

I

O

t

ti18812a

Repair

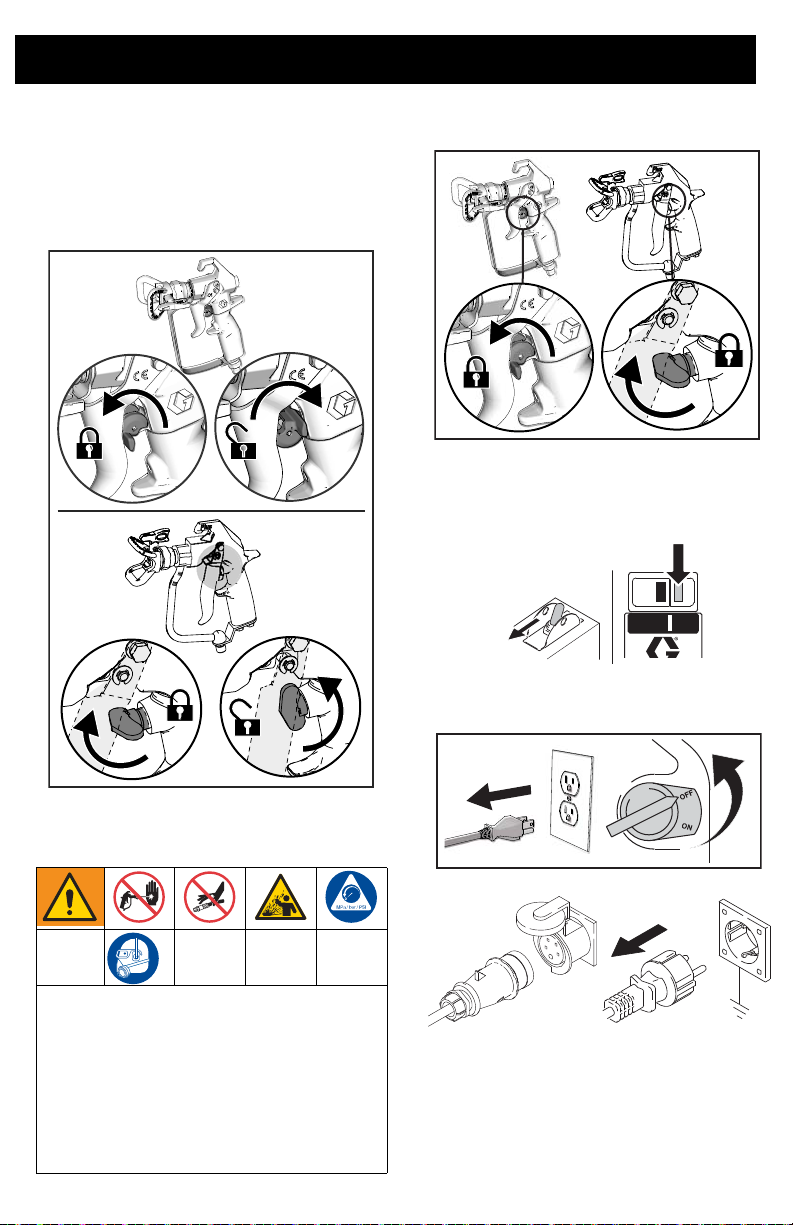

Trigger Lock

Always engage the trigger lock when sprayer

is stopped to prevent the gun from being

triggered accidentally by hand or if dropped

or bumped.

1. Engage trigger lock.

2. If applicable, turn electric motor ON/OFF

switch to OFF position. Wait 7 seconds

for power to dissipate.

3. Unplug power cord or shut engine off.

Pressure Relief Procedure

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection, splashed fluid

and moving parts, follow the Pressure

Relief Procedure whenever sprayer is

stopped and before sprayer is cleaned or

checked, and before equipment is

serviced.

4 334654A

ti7529a

ti24853a

Page 5

Repair

ti22700a

ti24608a

4. Disengage trigger lock.

5. Hold a metal part of the gun firmly to a

grounded metal pail. Trigger the gun to

relieve pressure.

Solvent and oil-based fluids: follow

local code. Use only conductive metal

pails, placed on a grounded surface

such as concrete.

Do not place pail on a non-conductive

surface such as paper or cardboard

which interrupts grounding continuity.

6. Engage trigger lock.

7. Open any fluid drain valves in system.

Leave drain valves open until ready to

spray again.

ti24585a

334654A 5

Page 6

Repair

ti25168a

ti25169a

ti25170a

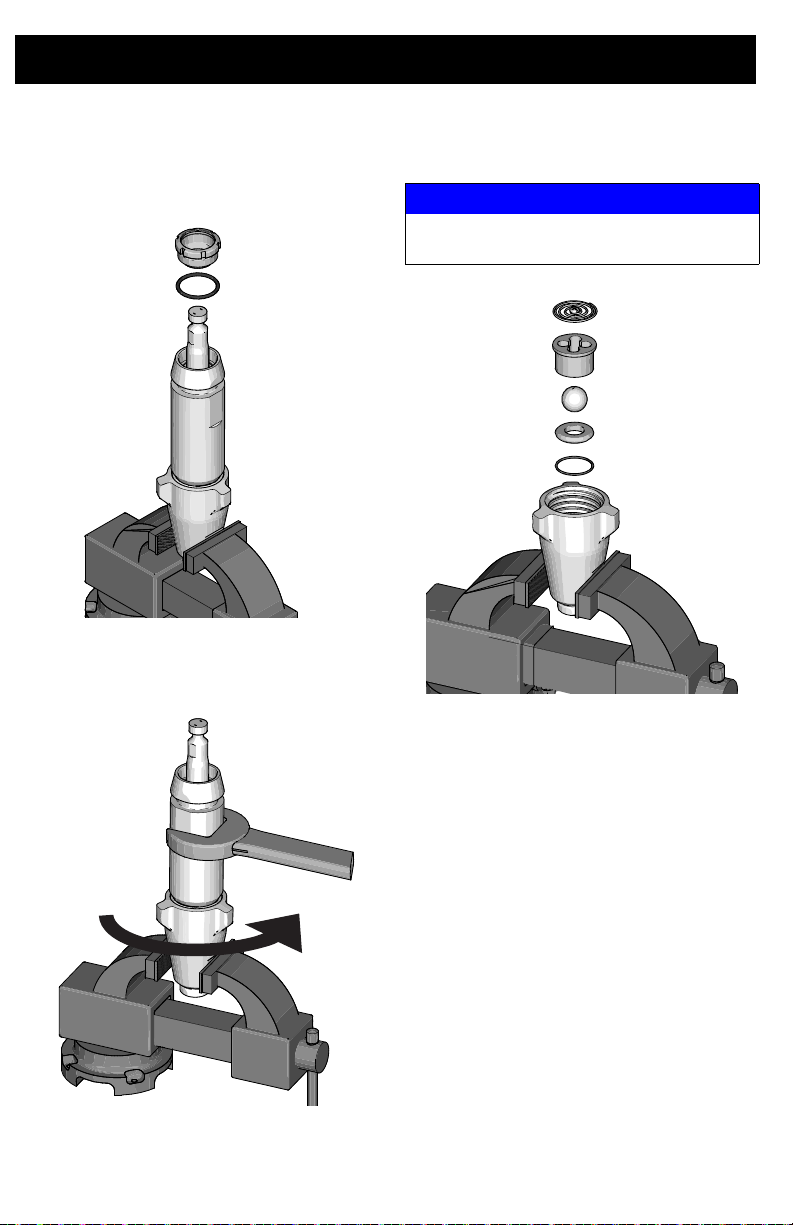

Disassemble Pump

1. Remove packing nut and throat

adjustment spacer.

2. Unscrew cylinder from intake valve.

3. Disassemble intake valve. Clean and

inspect. O-ring may require a pick for

removal.

NOTICE

If using a pick to remove the O-ring use care

to avoid damage to the machined surfaces.

6 334654A

Page 7

4. Tap piston rod out of cylinder with a

ti25171a

ti8849a

hammer or flip over and tap piston rod

out against a bench.

5. Remove piston rod from sleeve.

Repair

Do not clean or wipe the piston valve

threads. Cleaning the piston valve threads

could destroy the special sealing patch and

cause the piston valve to come loose

during operation, causing a pump burst

and possible serious bodily injury.

6. Unscrew piston valve from piston rod.

334654A 7

Page 8

Repair

ti25172a

ti25173a

7. Clean and inspect parts. (The piston has

a special thread locking/sealing patch.

Do not remove the patch. The patch

allows for disassembly/assembly

procedures before it is necessary to

apply thread sealant to the threads. On

fifth assembly apply thread sealant to

threads.

8. Remove and discard throat packing and

glands from the cylinder.

8 334654A

Page 9

Assemble Pump

Leather

Packings

Blue

Brown

Blue

ti25174a

Leather

Packings

ti25175a

ti25176a

ti24892a

1. If applicable, soak leather packings in

SAE 30W oil for one hour before

assembly.

Repair

2. Install ball in piston rod. Apply thread

sealant to piston valve threads; ensure

that none gets on the ball.

3. Torque to 55 ± 3 ft-lb (75 ± 4 N•m).

334654A 9

Page 10

Repair

Leather

s

ti25178a

ti25179a

ti25180a

4. Assemble leather throat packings

soaked earlier.

Packing

ti25175a

5. Loosely install packing nut with o-ring

onto cylinder.

6. Install o-rings inside cylinder and on

sleeve. Slide sleeve into bottom of

cylinder. Replace o-ring if necessary.

7. Apply liberal amounts of grease or oil to

piston packings.

8. Grease top inch or two of piston rod that

will go through the cylinder throat

packings. Gently guide displacement

rod up through throat packings. Tap

10 334654A

bottom of piston valve as necessary with

a leather or plastic hammer.

Page 11

Repair

ti25181a

ti25182a

ti25183a

9. Grease o-ring and place on outside

diameter ring groove.

10. Clean seat thoroughly. Reassemble

intake valve with a seat, ball, and new

o-ring. Seat may be flipped over and

used on other side.

11. For GH130 torque foot valve to 110 ± 5

ft-lb (149 ± 7 N•m). For GH200/230/300

torque foot valve to 200 ± 15 ft-lb (271 ±

20 N•m).

334654A 11

Page 12

Repair

ti25184a

ti25185a

ti25186a

12. For GH130 torque packing nut to 125 ±

10 in-lbs (14 ± 1 N•m). All other GH

models torque packing nut to 140 ± 10

in-lbs (16 ± 1 N•m).

13. Storage

Throat Packing Adjustment

When pump packings begin to leak after

much use, perform Pressure Relief

Procedure, page 4, and tighten packing nut

down until leakage stops or lessens. This

allows approximately 100 gallons of

additional operation before a repacking is

required. Packing nut can be tightened

without o-ring removal.

12 334654A

Page 13

Notes

Notes

334654A 13

Page 14

Parts

1

2

20

4

5

6

7

8

9

10

24

12

14

14

16

17

18

19

26

21

27

23

22

24

3

ti25243a

12

13

28

8

2

4

1

3

1

2

3

4

Parts

Pump 24B748

Torque to 110 ± 5 ft/lbs

(149 ± 5 N•m)

Torque to 125 ± 10 in/lbs

(14 ± 1 N•m)

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

14 334654A

Page 15

Parts List

Ref. Part Description Qty.

1 288727 CYLINDER, pump 1

2 248210 SLEEVE, cylinder,

chrome

3 195894 HOUSING, intake 1

4+ 196866 SEAT, carbide 1

5+ 108526 PACKING, o-ring, ptfe 1

6+ 102972 BALL, metallic 1

7 193027 GUIDE, ball 1

8* 107098 PACKING, o-ring 2

9* 156633 PACKING, o-ring 1

10 288479 ROD, piston 1

12* 193125 PACKING, vee 8

13* 15E329 PACKING, vee 3

14* 183185 GLAND, packing,

female

16* 118504 WIPER, piston 1

17* 15J382 PACKING, vee 3

18* 24U983 VALVE, piston 1

19* 101947 BALL, bearing 1

20 193032 NUT, packing 1

21 C20987 PACKING, o-ring 1

22* 183171 PLUG 1

23* 15C998 WASHER, backup 1

24* 183178 GLAND, packing, male 2

26 15J141 PIN, pump 1

27 15Y463 FITTING, bushing 1

28 196178 ADAPTER, nipple 1

Parts

1

2

* Included in Repair Kit 288471

+ Included in Repair Kit 244199

334654A 15

Page 16

Parts

1

2

3

4

5

6

7

9

10

11

12

13

8

14

16

13

18

19

20

21

22

23

24

8

25

15

28

12

ti25244a

26

29

30

1

2

4

4

3

1

234

Parts

Pump 24W995

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Torque to 200 ± 15 ft/lbs

(271 ± 20 N•m)

Torque to 140 ± 10 in/lbs

(16 ± 1 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

16 334654A

Page 17

Parts

Parts List

Ref. Part Description Qty.

1 245413 CYLINDER, pump 1

21

248979 SLEEVE, cylinder,

249121 SLEEVE, cylinder,

3 15E655 HOUSING, intake 1

4+ 193395 SEAT, carbide 1

5*+ 107098 PACKING, o-ring 1

6*+ 107167 BALL, sst 1

7 198505 GUIDE, ball 1

8* 108822 PACKING, o-ring, ptfe 2

9* 160325 PACKING, o-ring 1

10 1

249000 ROD, piston

249119 ROD, piston, MaxLife

11* 189585 GLAND, packing, male 1

12* 198701 PACKING, vee 8

13* 198718 PACKING, vee 6

14* 15G657 GLAND, female 1

15* 189588 GLAND, packing,

16* 119636 WIPER, piston 1

18 287388 VALVE, piston 1

19* 107203 BALL, valve, check 1

20 15J792 NUT, packing 1

21* 157195 PACKING, o-ring 1

22* 112590 PLUG, throat seal 1

23* 15J800 WASHER, back-up 1

24* 15G658 GLAND, male 1

25 245256 SPRING, intake ball 1

26 197443 PIN, pump 1

28 196178 ADAPTER, nipple 1

29 116551 RING, retaining 1

30 119566 WASHER 1

chrome

MaxLife

1

female

* Included in Repair Kit 17D601

+ Included in Repair Kit 240918

334654A 17

Page 18

Parts

1

2

3

4

5

6

7

9

10

11

12

13

8

14

16

17

18

19

20

21

22

23

24

8

25

15

28

12

ti25245a

30

29

3

4

2

1

1

234

Parts

Pump 24W996

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Torque to 200 ± 15 ft/lbs

(271 ± 20 N•m)

Torque to 140 ± 40 in/lbs

(16 ± 1 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

18 334654A

Page 19

Parts List

Ref. Part Description Qty.

1 17D122 CYLINDER, pump 1

2 249121 SLEEVE, cylinder 1

3 15E655 HOUSING, intake 1

4+ 193395 SEAT, carbide 1

5*+ 107098 PACKING, o-ring 1

6*+ 107167 BALL, sst 1

7 198505 GUIDE, ball 1

8* 108822 PACKING, o-ring, ptfe 2

9* 160325 PACKING, o-ring 1

10 288469 ROD, piston 1

11* 189585 GLAND, packing, male 1

12* 198701 PACKING, vee 8

13* 198718 PACKING, vee 3

14* 15G657 GLAND, female 1

15* 189588 GLAND, packing,

female

16* 119636 WIPER, piston 1

17* 15F875 PACKING, vee 3

18 287388 VALVE, piston 1

19* 107203 BALL, valve, check 1

20 15J792 NUT, packing 1

21* 157195 PACKING, o-ring 1

22* 112590 PLUG, throat seal 1

23* 15J800 WASHER, back-up 1

24* 15G658 GLAND, male 1

25 245256 SPRING, intake ball 1

28 15J413 FITTING, pump 1

30 119566 WASHER 1

Parts

1

* Included in Repair Kit 287813

+ Included in Repair Kit 240918

NOTE: For Chromex Pump Kit order 24X018

334654A 19

Page 20

Parts

3

1

ti25246a

1

2

3

4

6

7

9

10

12

13

5

14

16

11

18

19

20

21

22

23

24

8

25

15

12

8

13

28

26

30

29

3

4

2

4

1

1

234

Parts

Pump 24W997

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Torque to 200 ± 15 ft/lbs

(271 ± 20 N•m)

Torque to 140 ± 10 in/lbs

(16 ± 1 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

20 334654A

Page 21

Parts

Parts List

Ref. Part Description Qty.

1 245932 CYLINDER, pump 1

21

248980 SLEEVE, cylinder,

287817 SLEEVE, cylinder,

3 15E655 HOUSING, intake 1

4+ 193395 SEAT, carbide 1

5*+ 107098 PACKING, o-ring 1

6*+ 107167 BALL, sst 1

7 198505 GUIDE, ball 1

8* 108822 PACKING, o-ring, ptfe 2

9* 160325 PACKING, o-ring 1

10 1

249001 ROD, piston

287816 ROD, piston, MaxLife

11* 189585 GLAND, packing, male 1

12* 198701 PACKING, vee 8

13* 198718 PACKING, vee 6

14* 15G657 GLAND, female 1

15* 189588 GLAND, packing,

16* 119636 WIPER, piston 1

18 287388 VALVE, piston 1

19* 107203 BALL, valve, check 1

20 15J792 NUT, packing 1

21* 157195 PACKING, o-ring 1

22* 112590 PLUG, throat seal 1

23* 15J800 WASHER, back-up 1

24* 15G658 GLAND, male 1

25 245256 SPRING, intake ball 1

26 197443 PIN, pump 1

28 196178 ADAPTER, nipple 1

29 116551 RING, retaining 1

30 119566 WASHER 1

chrome

MaxLife

1

female

* Included in Repair Kit 17D601

+ Included in Repair Kit 240918

334654A 21

Page 22

Parts

1

2

3

4

5

6

7

9

10

11

12

13

8

14

16

17

18

19

20

21

22

23

24

8

25

15

28

ti25247a

12

30

3

4

2

1

1

2

3

4

Parts

Pump 24W998

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Torque to 200 ± 15 ft/lbs

(271 ± 20 N•m)

Torque to 140 ± 10 in/lbs

(16 ± 1 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

22 334654A

Page 23

Parts List

Ref. Part Description Qty.

1 17D123 CYLINDER, pump 1

2 287817 SLEEVE, cylinder,

chrome

3 15E655 HOUSING, intake 1

4+ 193395 SEAT, carbide 1

5*+ 107098 PACKING, o-ring 1

6*+ 107167 BALL, sst 1

7 198505 GUIDE, ball 1

8* 108822 PACKING, o-ring, ptfe 2

9* 160325 PACKING, o-ring 1

10 288470 ROD, piston 1

11* 189585 GLAND, packing, male 1

12* 198701 PACKING, vee 8

13* 198718 PACKING, vee 3

14* 15G657 GLAND, female 1

15* 189588 GLAND, packing,

female

16* 119636 WIPER, piston 1

17* 15F875 PACKING, vee 3

18 287388 VALVE, piston 1

19* 107203 BALL, valve, check 1

20 15J792 NUT, packing 1

21* 157195 PACKING, o-ring 1

22* 112590 PLUG, throat seal 1

23* 15J800 WASHER, back-up 1

24* 15G658 GLAND, male 1

25 245256 SPRING, intake ball 1

28 15J413 FITTING, pump 1

30 119566 WASHER 1

Parts

1

1

* Included in Repair Kit 287813

+ Included in Repair Kit 240918

NOTE: For Chromex Pump Replacement Kit

order 24X019

334654A 23

Page 24

Parts

1

2

3

4

5

6

9

11

12

13

14

15

16

29

18

19

20

21

22

23

24

8

10

7

ti25248a

26

12

13

8

25

3

4

4

2

1

1

234

Parts

Pump 24W999

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Torque to 200 ± 15 ft/lbs

(271 ± 20 N•m)

Torque to 140 ± 10 in/lbs

(16 ± 1 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

24 334654A

Page 25

Parts

Parts List

Ref. Part Description Qty.

1 17D124 CYLINDER, pump 1

21

248980 SLEEVE, cylinder,

287817 SLEEVE, cylinder,

3 15A303 HOUSING, intake 1

4+ 15J038 SEAT, carbide 1

5*+ 107098 PACKING, o-ring 1

6*+ 118602 BALL, ceramic 1

7 193391 GUIDE, ball 1

8* 108822 PACKING, o-ring, ptfe 2

9* 160325 PACKING, o-ring 1

10 17D121 ROD, piston 1

11* 189585 GLAND, packing, male 1

12* 198701 PACKING, vee 8

13* 198718 PACKING, vee 6

14* 15G657 GLAND, female 1

15* 189588 GLAND, packing,

16* 119636 WIPER, piston 1

18 287388 VALVE, piston 1

19* 118601 BALL, ceramic 1

20 15J792 NUT, packing 1

21* 157195 PACKING, o-ring 1

22* 112590 PLUG, throat seal 1

23* 15F183 WASHER, back-up 1

24* 15G658 GLAND, male 1

25+ 24E027 SPRING, intake ball 1

26 197443 PIN, pump 1

29 116551 RING, retaining 1

chrome

MaxLife

1

female

* Included in Repair Kit 24N012

+ Included in Repair Kit 24N013

334654A 25

Page 26

Parts

1

2

3

4

5

6

9

11

12

13

14

15

16

17

18

19

20

21

22

23

24

8

10

7

ti25249a

25

8

12

3

4

1

2

1

234

Parts

Pump 24X001

Torque to 55 ± 3 ft/lbs

(75 ± 4 N•m)

Torque to 200 ± 10 ft/lbs

(271 ± 20 N•m)

Torque to 140 ± 10 in/lbs

(16 ± 1 N•m)

Soak in SAE 30W oil for 1 hour

prior to assembly

26 334654A

Page 27

Parts List

Ref. Part Description Qty.

1 17D125 CYLINDER, pump 1

2 287817 SLEEVE, cylinder 1

3 15A303 HOUSING, intake 1

4+ 15J038 SEAT, carbide 1

5*+ 107098 PACKING, o-ring 1

6*+ 118602 BALL, ceramic 1

7 193391 GUIDE, ball 8

8* 108822 PACKING, o-ring, ptfe 2

9* 160325 PACKING, o-ring 1

10 288821 ROD, piston 1

11* 189585 GLAND, packing, male 1

12* 198701 PACKING, vee 8

13* 198718 PACKING, vee 3

14* 15G657 GLAND, female 1

15* 189588 GLAND, packing,

female

16* 119636 WIPER, piston 1

17* 15F875 PACKING, vee 3

18 287388 VALVE, piston 1

19* 118601 BALL, ceramic 1

20 15J792 NUT, packing 1

21* 157195 PACKING, o-ring 1

22* 112590 PLUG, throat seal 1

23* 15F183 WASHER, back-up 1

24* 15G658 GLAND, male 1

25+ 24E027 SPRING, intake ball 1

Parts

1

* Included in Repair Kit 24X096

+ Included in Repair Kit 24N013

334654A 27

Page 28

Technical Specifications

Technical Specifications

Displacement Pumps

Maximum fluid working pressure 3300 psi

25 bar, 22.8 MPa

Inlet/Outlet Sizes

Fluid inlet size 1-5/16 UN (m) models 24W995, 24W996, 24W997,

Fluid outlet size 3/8 npt (f)

Wetted materials on all models stainless steel, PTFE, leather, nylon, zinc-plated carbon

24W998

1-11 1/2 NPSM (M) models 24W999, 24X001

3/4-14 npt (m) model 24B748

steel, tungsten carbide, brass, fluorelastomer, acetal,

polyethylene, ceramic

28 334654A

Page 29

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing

its name to be free from defects in material and workmanship on the date of sale to the original purchaser

for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will,

for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or

improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts.

Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco

equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or

materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential

damages for lost profits, lost sales, injury to person or property, or any other incidental or consequential

loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED

BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose,

etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with

reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

334654A 29

Page 30

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the

nearest distributor.

All written and visual data contained in this document reflects the latest product information available at

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 334654

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

the time of publication.

Graco Headquarters: Minneapolis

www.graco.com

Revision A, December 2014

Loading...

Loading...