Page 1

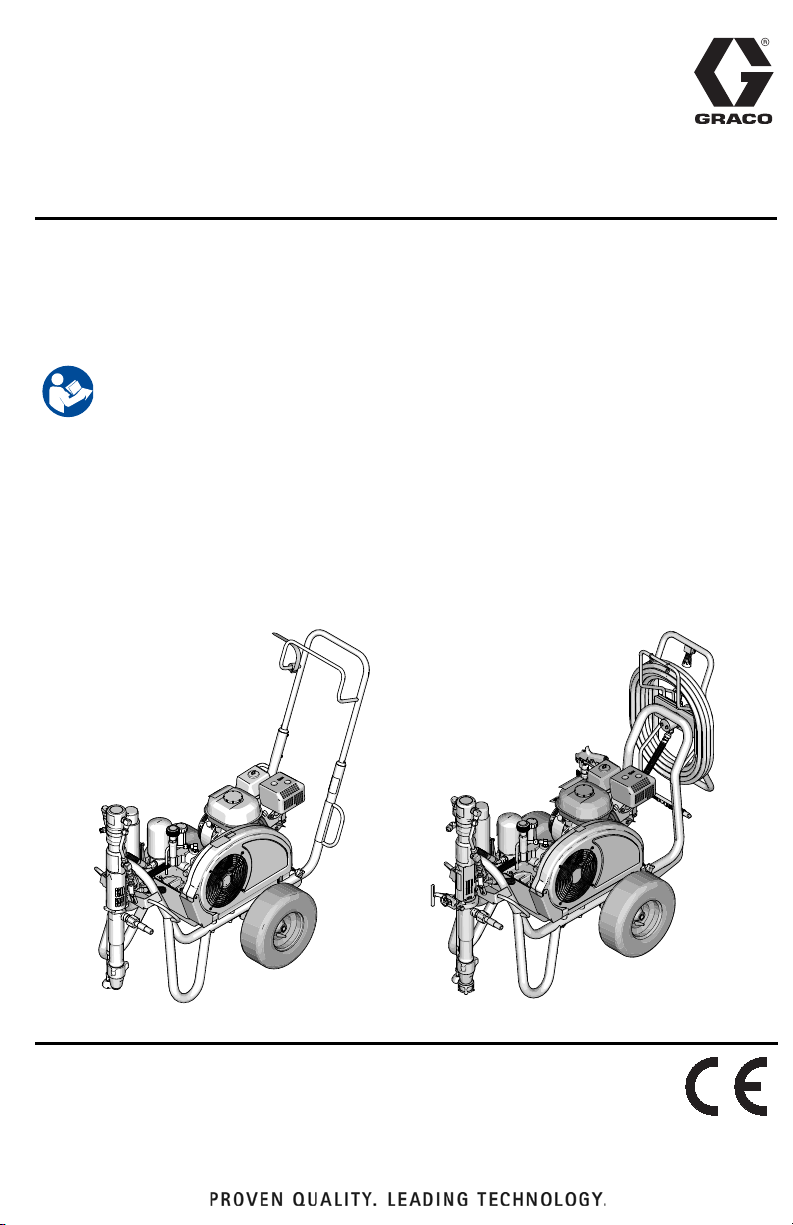

Operation, Parts

ti25305a

ti25306a

334606B

DutyMax EH/GH™230/300 Hydraulic Sprayers

For professional use only.

Not approved for use in explosive atmosphere or hazardous locations.

For portable airless spraying of architectural paints and coatings.

3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure

See page 3 for model information, including maximum working pressure and approvals.

Important Safety Instructions

Read all warnings and instructions in this manual and in related manuals.

Be familiar with the controls and the proper usage of the equipment.

Save these instructions.

Related Manuals:

308491 DutyMax GH230 Gun 334654 Pump

309495 DutyMax GH300 Gun 310812 Electric Motor

EN

Standard Series

Use only genuine Graco replacement parts.

The use of non-Graco replacement parts may void warranty.

ProContractor Series

Page 2

Table of Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electric Motor Kit Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

OEM Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electric Motor Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Gas Engine Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electric Motor/Gas Engine Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

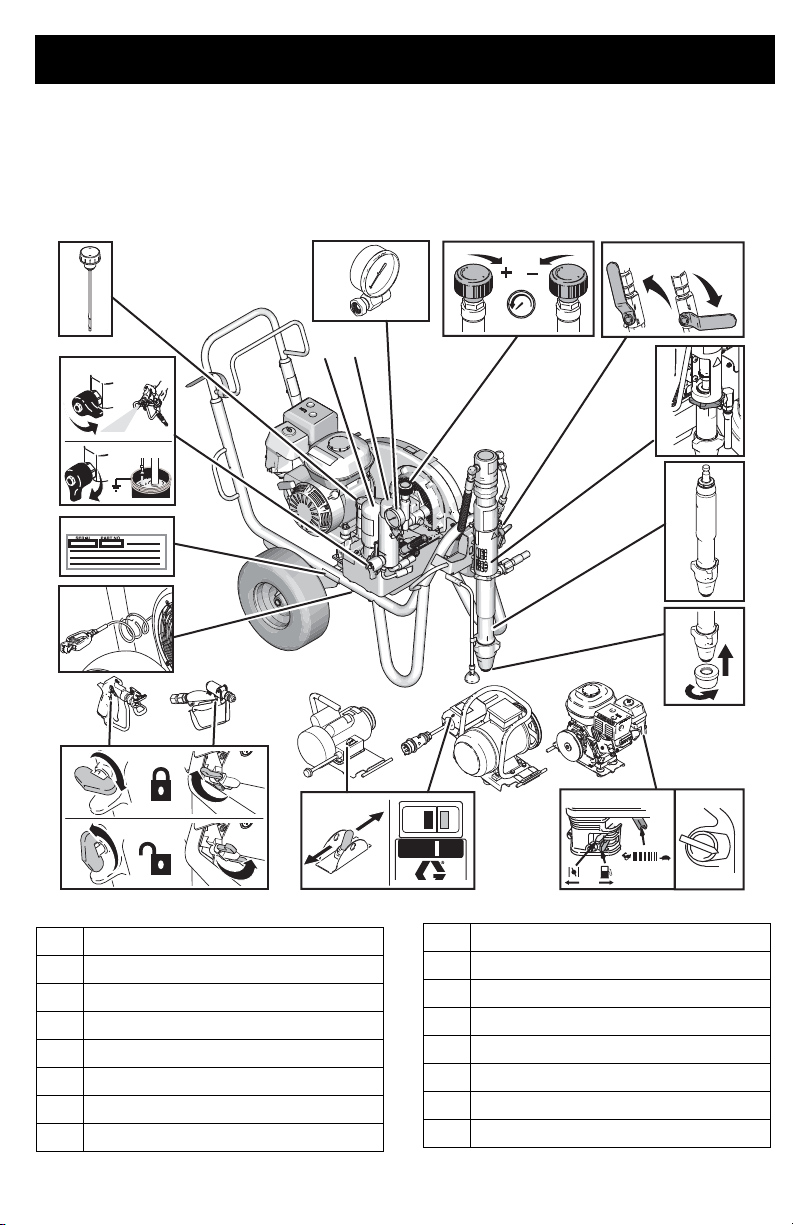

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Standard Models (EH/GH™230, 300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

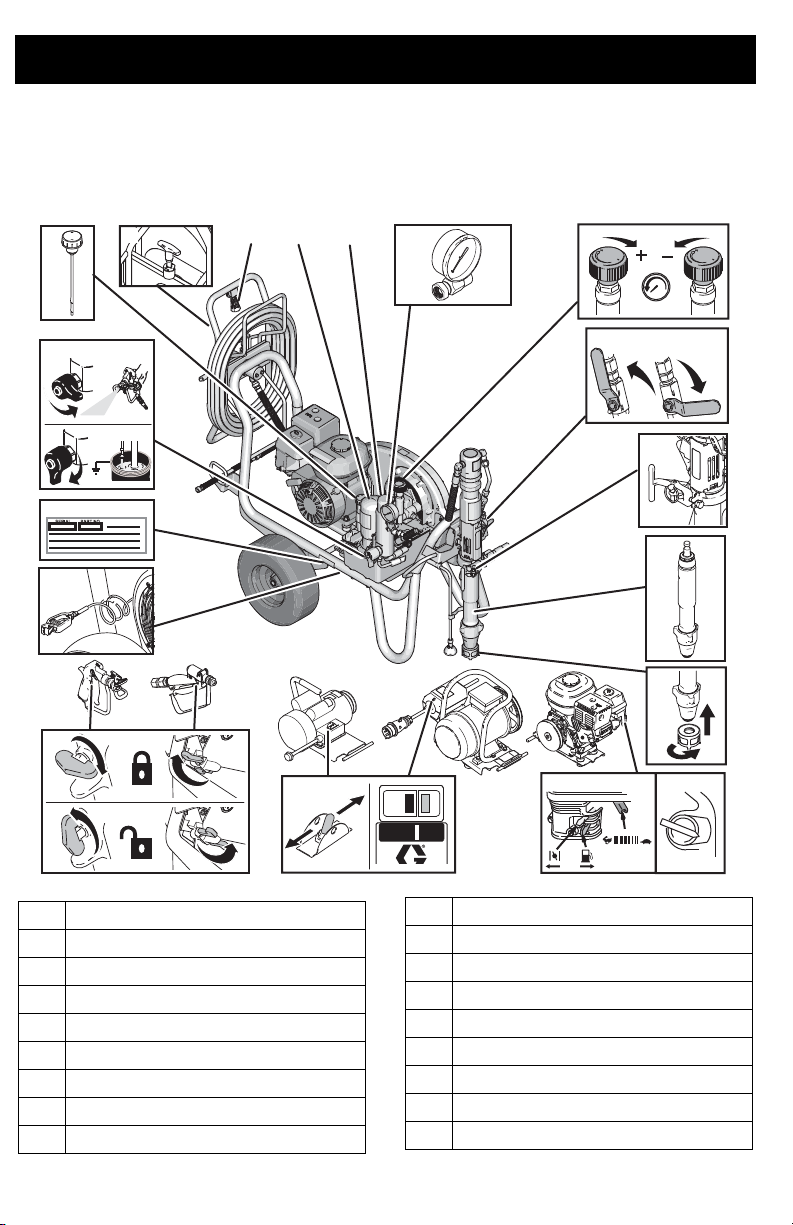

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ProContractor Models (EH/GH™230, 300) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grounding Procedure for Gas Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Grounding Procedure for Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Extension Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Grounding of Pails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Change Gas Engine or Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Complete Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Startup (Gas Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Startup (Electric Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Switch Tip™ and Guard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clear Tip Clogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Hose Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Clean Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Standard Series Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ProContractor Series Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DutyMax EH/GH™230/300 Standard Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

DutyMax EH/GH™230/300 ProContractor Series . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

ProContractor Series Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

DutyMax EH230DI Standard Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

DutyMax EH300DI Standard Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

DutyMax GH230 Standard Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

DutyMax GH300 Standard Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

DutyMax EH230DI ProContractor Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

DutyMax EH300DI ProContractor Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

DutyMax GH230 ProContractor Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

OEM Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

DutyMax GH300 ProContractor Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

2 334606B

OEM Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Page 3

Models

Models

DutyMax EH230 Direct Immersion

Model: Standard ProContractor

24W941

24W942

DutyMax GH230 Direct Immersion

Model: Standard ProContractor 120V Motor Kit 120V ETL/CSA/UL

24W943

24W944

24W945

24W962

24W963

24W964

DutyMax EH300 Direct Immersion

Model: Standard ProContractor

24W965

24W966

DutyMax GH300 Direct Immersion

Model: Standard ProContractor

24W967

24W968

Motor Kit

Electric Motor Kit Options

Kit Number Sprayer Model Description

288474 GH130 120VAC, 60Hz, 20A, ETL/CSA/UL Approved

288473 GH130 120VAC, 60Hz, 15A

248950 GH200/GH230/GH300* 120VAC, 60Hz, 20A, ETL/CSA/UL Approved

248949 GH200/GH230/GH300* 120 VAC, 60Hz, 15A

24M668 GH200/GH230/GH300* 240VAC, 50Hz, 13.4A

24M669 GH300 400VAC, 50Hz, 11.0A

*Performance is limited when using electric motor

OEM Kits

Kit Number OEM Model Description

24W297 GH130 OEM 3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure (psi)

24W298 GH200 OEM 3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure (psi)

24W299 GH230/300 OEM 3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure (psi)

334606B 3

Page 4

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this

equipment. The exclamation point symbol alerts you to a general warning and the hazard

symbols refer to procedure-specific risks. When these symbols appear in the body of this

manual or on warning labels, refer back to these Warnings. Product-specific hazard symbols

and warnings not covered in this section may appear throughout the body of this manual where

applicable.

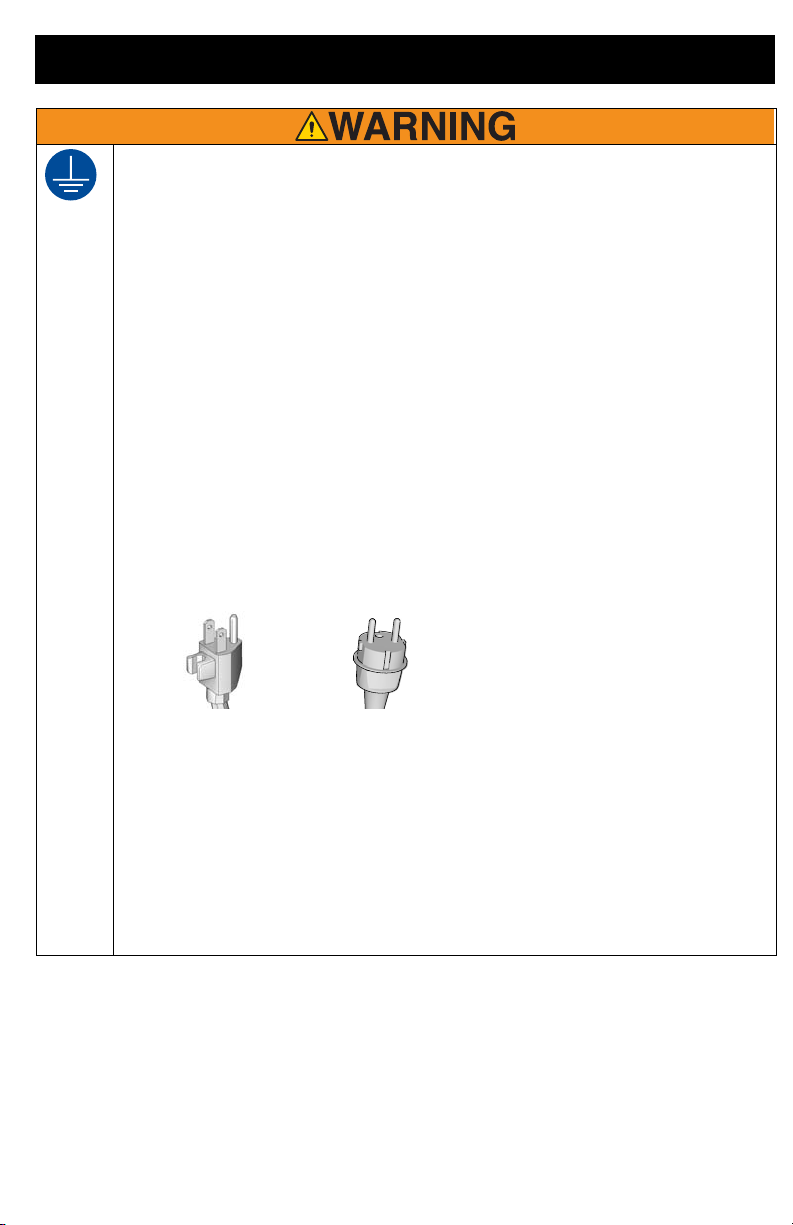

Electric Motor Warnings

HIGH VOLTAGE ELECTRIC SHOCK HAZARD

This equipment uses high voltage power. Improper contact with high voltage

equipment will cause death or serious injury.

• Turn off and disconnect power cord before servicing equipment.

• This equipment must be grounded. Connect only to grounded power source.

• Use only 3-wire extension cords for 240V and single phase models.

• Use only 5-wire extension cords for 400 AC and three phase models.

• Ensure ground prongs are intact on power and extension cords.

• Do not expose to rain. Store indoors.

4 334606B

Page 5

Warnings

120V US

230V

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding

reduces the risk of electric shock by providing an escape wire for the electric current.

This product is equipped with a cord having a grounding wire with an appropriate

grounding plug. The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric

shock.

• When repair or replacement of the cord or plug is required, do not connect the

grounding wire to either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without

yellow stripes is the grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions

are not completely understood, or when in doubt as to whether the product is

properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet

installed by a qualified electrician.

• This product is for use on a nominal 120V or 230V circuit and has a grounding

plug similar to the plugs illustrated in the figure below.

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a grounding plug and a grounding

receptacle that accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is

necessary, use 12 AWG (2.5 mm2) minimum to carry the current that the product

draws.

• An undersized cord results in a drop in line voltage and loss of power and

overheating.

334606B 5

Page 6

Warnings

Electric Motor Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or

explode. To help prevent fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources

of ignition such as cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static

electricity. Static electricity creates a risk of fire or explosion in the presence of

paint or solvent fumes. All parts of the spray system, including the pump, hose

assembly, spray gun, and objects in and around the spray area shall be properly

grounded to protect against static discharge and sparks. Use Graco conductive

or grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static

discharge. Do not use pail liners unless they are antistatic or conductive.

• Connect to a grounded outlet and use grounded extensions cords. Do not use

a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Do not spray flammable or combustible liquids in a confined area.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through

the area.

• Sprayer generates sparks. Keep pump assembly in a well ventilated area at

least 20 feet (6.1 m) from the spray area when spraying, flushing, cleaning, or

servicing. Do not spray pump assembly.

• Do not smoke in the spray area or spray where sparks or flame is present.

• Do not operate light switches, engines, or similar spark producing products in the

spray area.

• Keep area clean and free of paint or solvent containers, rags, and other

flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material

Safety Data Sheets (MSDS) and container labels provided with the paints and

solvents. Follow the paint and solvents manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

6 334606B

Page 7

Gas Engine Warnings

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Do not fill fuel tank while engine is running or hot; shut off engine and let it cool.

Fuel is flammable and can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric

lamps, and plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when

flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail

liners unless they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do

not use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

CARBON MONOXIDE HAZARD

Exhaust contains poisonous carbon monoxide, which is colorless and odorless.

Breathing carbon monoxide can cause death.

• Do not operate in an enclosed area.

Warnings

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation.

To avoid severe burns:

• Do not touch hot fluid or equipment.

334606B 7

Page 8

Warnings

Electric Motor/Gas Engine Warnings

SKIN INJECTION HAZARD

High-pressure spray is able to inject toxins into the body and cause serious bodily

injury. In the event that injection occurs, get immediate surgical treatment.

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not

try to stop leaks with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. In the case where the

nozzle tip clogs while spraying, follow the Pressure Relief Procedure for

turning off the unit and relieving the pressure before removing the nozzle tip to

clean.

• Equipment maintains pressure after power is shut off. Do not leave the

equipment energized or under pressure while unattended. Follow the Pressure

Relief Procedure when the equipment is unattended or not in use, and before

servicing, cleaning, or removing parts.

• Check hoses and parts for signs of damage. Replace any damaged hoses or

parts.

• This system is capable of producing 3300 psi (22.8 MPa, 228 bar). Use Graco

replacement parts or accessories that are rated a minimum of 3300 psi (22.8

MPa, 228 bar).

• Always engage the trigger lock when not spraying. Verify the trigger lock is

functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar

with the controls.

8 334606B

Page 9

Warnings

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when

painting.

• Do not operate or spray near children. Keep children away from equipment at

all times.

• Do not overreach or stand on an unstable support. Keep effective footing and

balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those

specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

• Do not spray with a hose shorter than 25 feet.

• Do not alter or modify equipment. Alterations or modifications may void agency

approvals and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you

are using it.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can

cause serious chemical reaction and equipment rupture. Failure to follow this

warning can result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents.

• Do not use chlorine bleach.

• Many other fluids may contain chemicals that can react with aluminum. Contact

your material supplier for compatibility.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or

servicing equipment, follow the Pressure Relief Procedure and disconnect all

power sources.

334606B 9

Page 10

Warnings

ENTANGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing

equipment, follow the Pressure Relief Procedure and disconnect all power

sources.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or

on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to

applicable guidelines.

RECOIL HAZARD

Gun may recoil when triggered. If you are not standing securely, you could fall and

be seriously injured.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent

serious injury, including eye injury, hearing loss, inhalation of toxic fumes, and

burns. Protective equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and

solvent manufacturer.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of

California to cause cancer, birth defects or other reproductive harm.

This product contains a chemical known to the State of California to cause cancer,

birth defects or other reproductive harm. Wash hands after handling.

10 334606B

Page 11

Component Identification

3.

13.

2.

7.

OFF

ON

on

off

bar/MPa

PSI

8.

OI

4.

1.

11.

9.

10.

5.

6.

14.

15.

ti25307a

12.

16.

Component Identification

Standard Models (EH/GH™230, 300)

1 Pressure Gauge

2 Pressure Control

3 Hydraulic Pump Valve

4 Threaded Pump Connection

5 Displacement Pump

6 Inlet Strainer

7 Engine On/Off Switch

8 Engine Controls

334606B 11

9 Electric Motor On/Off Switch

10 GunTrigger Lock

11 Grounding Clamp

12 Serial Number Tag

13 Prime/Drain Valve

14 Hydraulic Oil Cap / Dipstick

15 Hydraulic Oil Filter

16 Paint Filter

Page 12

Component Identification

3.

13.

2.

12.

7.

OFF

ON

on

off

bar/MPa

PSI

8.

OI

4.

1.

11.

9.

10.

5.

6.

14.

15.

16. 17.

ti25308a

18.

Component Identification

ProContractor Models (EH/GH™230, 300)

1 Pressure Gauge

2 Pressure Control

3 Hydraulic Pump Valve

4 ProConnect

5 Displacement Pump

6 Inlet Strainer

7 Engine On/Off Switch

8 Engine Controls

9 Electric Motor On/Off Switch

12 334606B

10 GunTrigger Lock

11 Grounding Clamp

12 Serial Number Tag

13 Prime/Drain Valve

14 Hydraulic Oil Cap / Dipstick

15 Hose Reel Lock

16 Hose Reel Handle

17 Hydraulic Oil Filter

18 Paint Filter

Page 13

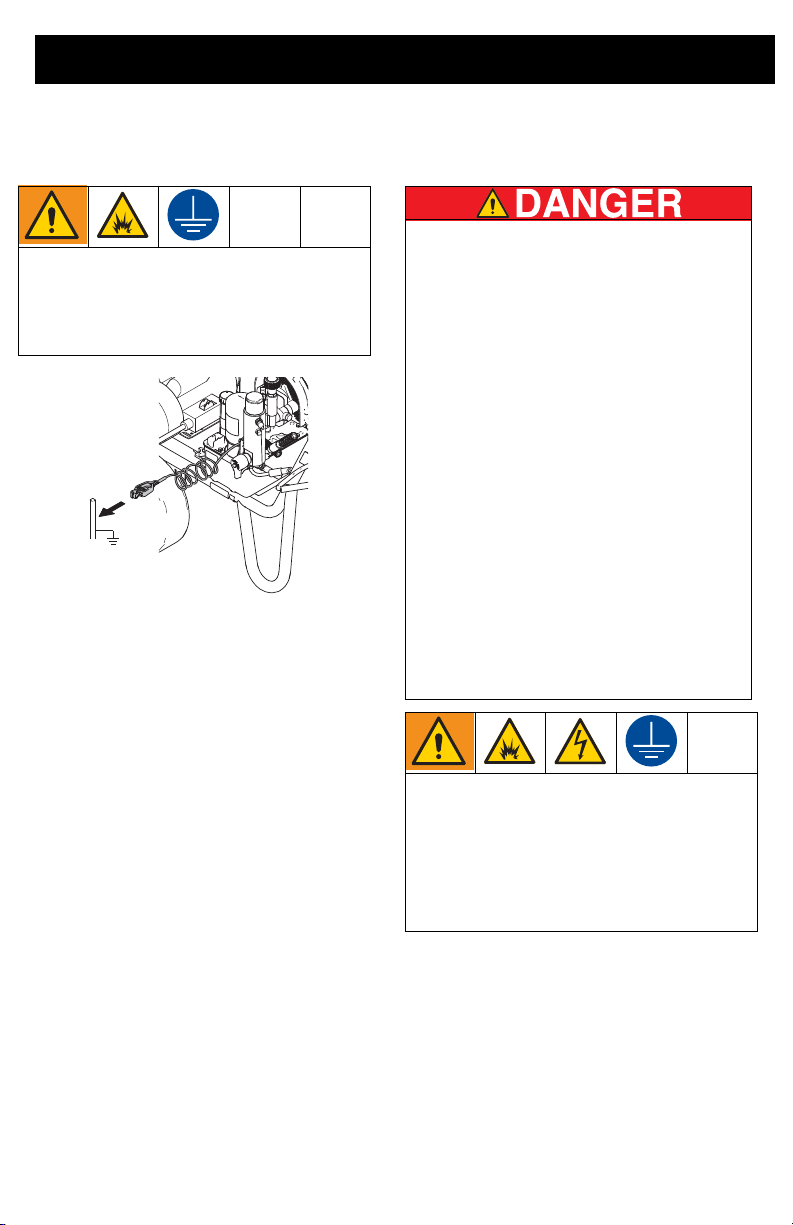

Grounding

ti18197a

Grounding Procedure for Gas Engine

The equipment must be grounded to

reduce the risk of static sparking. Static

sparking can cause fumes to ignite or

explode. Grounding provides an escape

wire for the electric current.

To ground sprayer: Attach sprayer

grounding clamp to earth ground.

Air and fluid hoses: Use only electrically

conductive hoses with a maximum of 500ft.

(150 m) combined hose length to ensure

grounding continuity. Check electrical

resistance of hoses. If total resistance to

ground exceeds 29 megaohms, replace hose

immediately.

Spray gun: Ground through connection to a

properly grounded fluid hose and pump.

Grounding

Grounding Procedure for Electric Motor

HIGH VOLTAGE ELECTRIC SHOCK

HAZARD

This equipment uses high voltage power.

Improper contact with high voltage

equipment will cause death or serious

injury.

• Turn off and disconnect power cord

before servicing equipment.

• This equipment must be grounded.

Connect only to grounded power

source.

• Use only 3-wire extension cords for

240V and single phase models

• Use only 5-wire extension cords for

400 AC and three phase models.

• Ensure ground prongs are intact on

power and extension cords.

• Do not expose to rain. Store indoors.

• All electrical wiring must be done by a

qualified electrician and comply with

all local codes and regulations.

The equipment must be grounded to

reduce the risk of static sparking and

electric shock. An electric or static spark

can cause fumes to ignite or explode. An

improper ground can cause electric

shock. A good ground provides an escape

wire for the electric current.

The sprayer cord includes a grounding wire

with an appropriate grounding contact.

If using the electric motor, plug must be

plugged into an actual outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

Do not modify the plug provided; if it does not

fit the outlet, have the proper outlet installed

by a qualified electrician.

334606B 13

Page 14

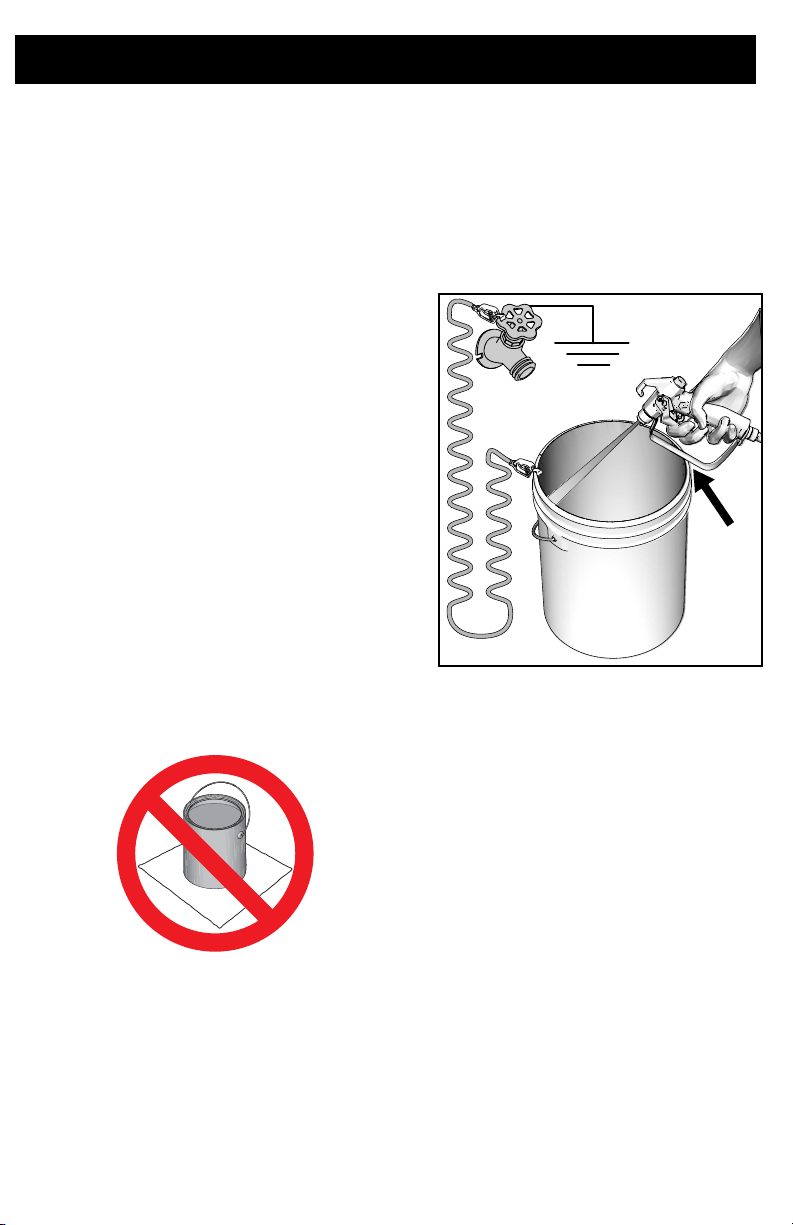

Grounding

ti25360a

Power Requirements

• 110-120V units require 100-120 VAC,

50/60 Hz, 15A, 1 phase.

• 230V units require 230 VAC, 50/60 Hz,

16A, 1 phase

• 380-400V units require 400 VAC, 50 Hz,

16A, 3 phase, 3P+N+E, 6H power

connection

• To operate the EH300DI (24W965)

sprayer, the generator needs to be sized

for 15 kW output (minimum).

Extension Cords

Use an extension cord with an undamaged

ground contact. If an extension cord is

necessary, use a 3-wire, 12 AWG (2.5 mm²)

minimum.

NOTE: Smaller gauge or longer extension

cords may reduce sprayer performance.

Grounding of Pails

Solvent pails used when flushing: Follow

local code. Use only conductive metal pails,

placed on a grounded surface. Do not place

the pail on a non-conductive surface, such as

paper or cardboard, which interrupts

grounding continuity.

Always ground a metal pail: connect a

ground wire to the pail. Clamp one end to the

pail and the other end to a true earth ground

such as a water pipe.

To maintain ground continuity when

sprayer is flushed or pressure is relieved:

hold metal part of spray gun firmly to the side

of a grounded metal pail then trigger the gun.

ti24585a

Circuit Protection

Connect sprayers only to circuits which have

the properly sized circuit breaker and/or

fuses (for unit power requirements see

Technical Data,

pages 60-63).

14 334606B

Page 15

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid, such as skin injection, splashing fluid

and moving parts, follow the Pressure

Relief Procedure when you stop

spraying and before cleaning, checking,

or servicing the equipment.

1. Engage trigger lock.

2. Turn gas engine or electric motor

ON/OFF switch to OFF. Unplug power

cord to electric motor.

3. Move pump valve to OFF and turn

pressure control knob fully

counterclockwise to lowest setting.

4. Disengage trigger lock. Hold metal part

of gun firmly to side of grounded metal

pail, and trigger gun to relieve pressure.

5. Engage gun trigger lock.

6. Turn prime valve down to DRAIN

position. Leave prime valve down until

ready to spray again.

7. If you suspect the spray tip or hose is

clogged or that pressure has not been

fully relieved:

a. VERY SLOWLY loosen tip guard

retaining nut or hose end coupling to

relieve pressure gradually.

b. Loosen nut or coupling completely.

c. Clear hose or tip obstruction.

334606B 15

Page 16

Setup

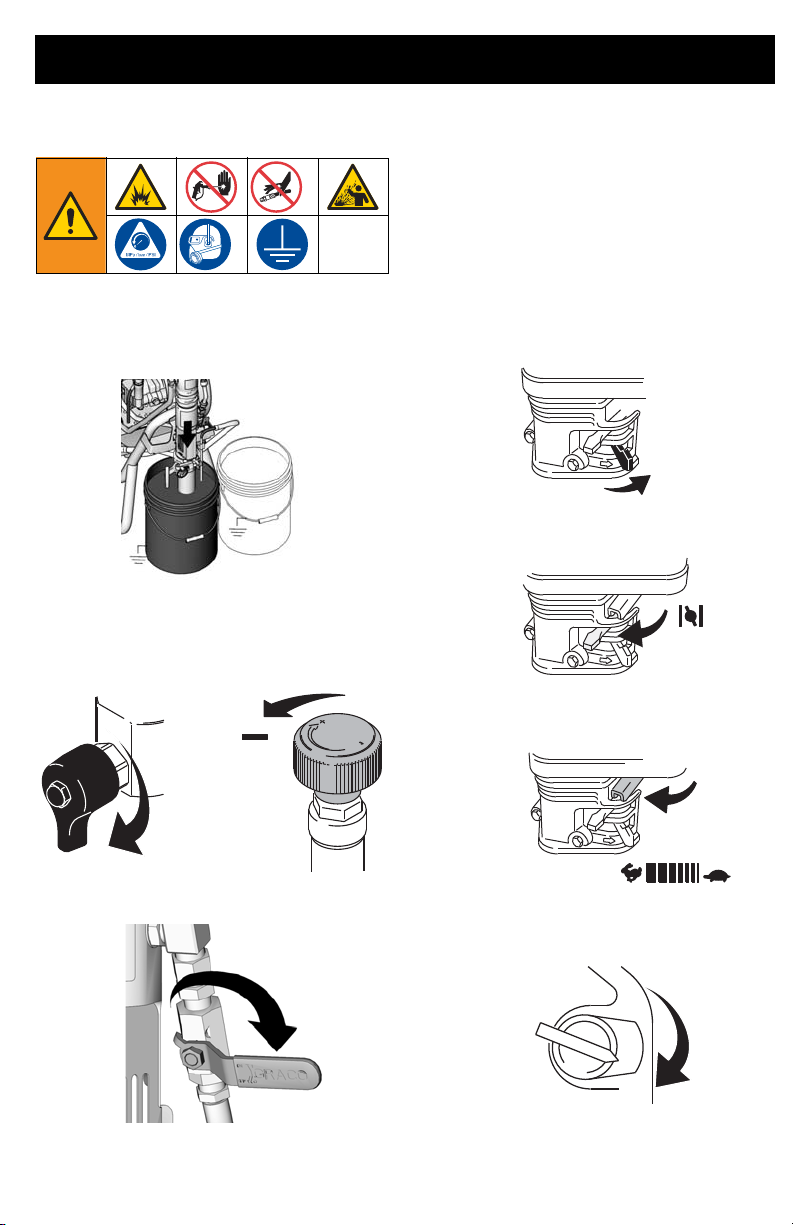

WLE

ti18812a

ti7529a

OI

OFF

ON

ti18193a

ti5387a

ti5389a

ti5382a

ti5384a

ti18192a

Setup

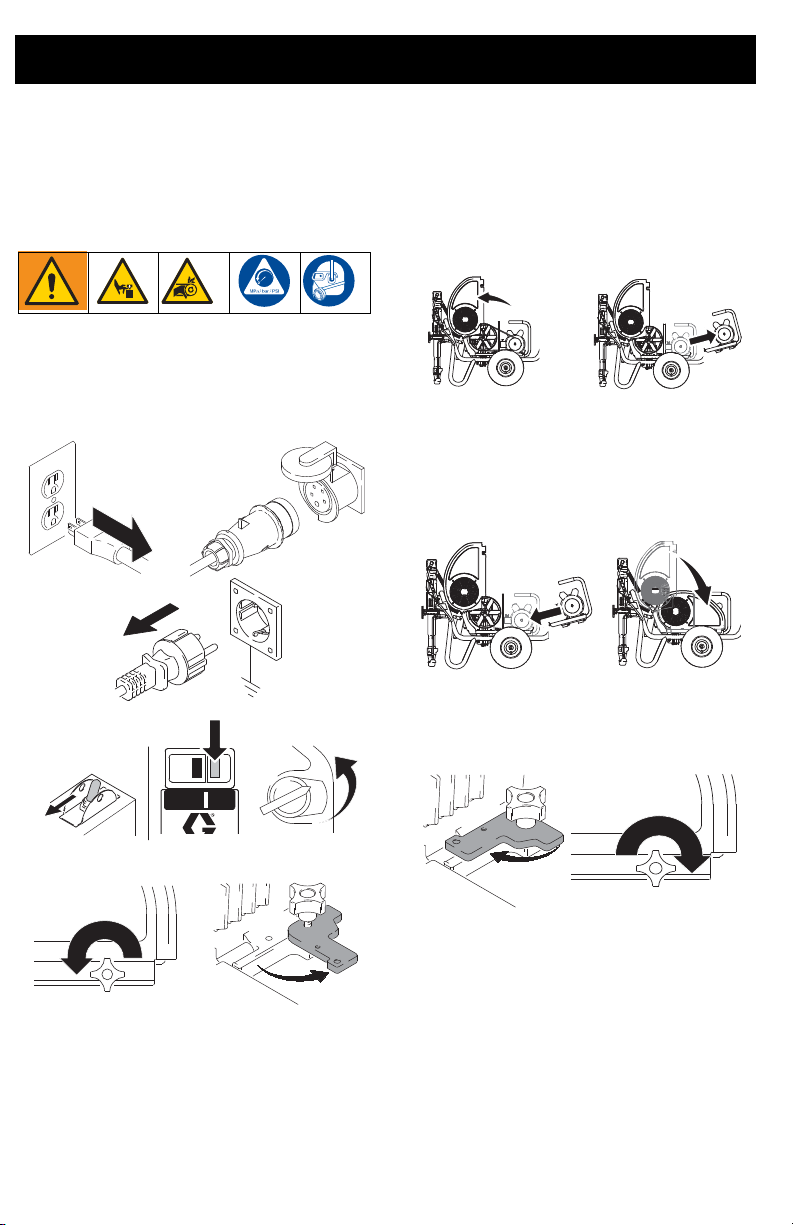

Change Gas Engine or Electric Motor

1 Turn motor OFF and unplug or turn

engine switch OFF. Loosen belt guard

knob and motor clamp. Perform

Pressure Relief Procedure, page 15.

2 Lift belt guard. Remove belt. Tilt

engine/motor and remove

engine/motor.

3 Tilt engine/motor. Install engine/motor.

Install belt. Lower belt guard.

4 Swivel motor clamp. Tighten motor

clamp and belt guard knob.

I

O

16 334606B

ti25161a

Page 17

Setup

WLD

ti22698a

ti18418b

ti8692a

ti18418a

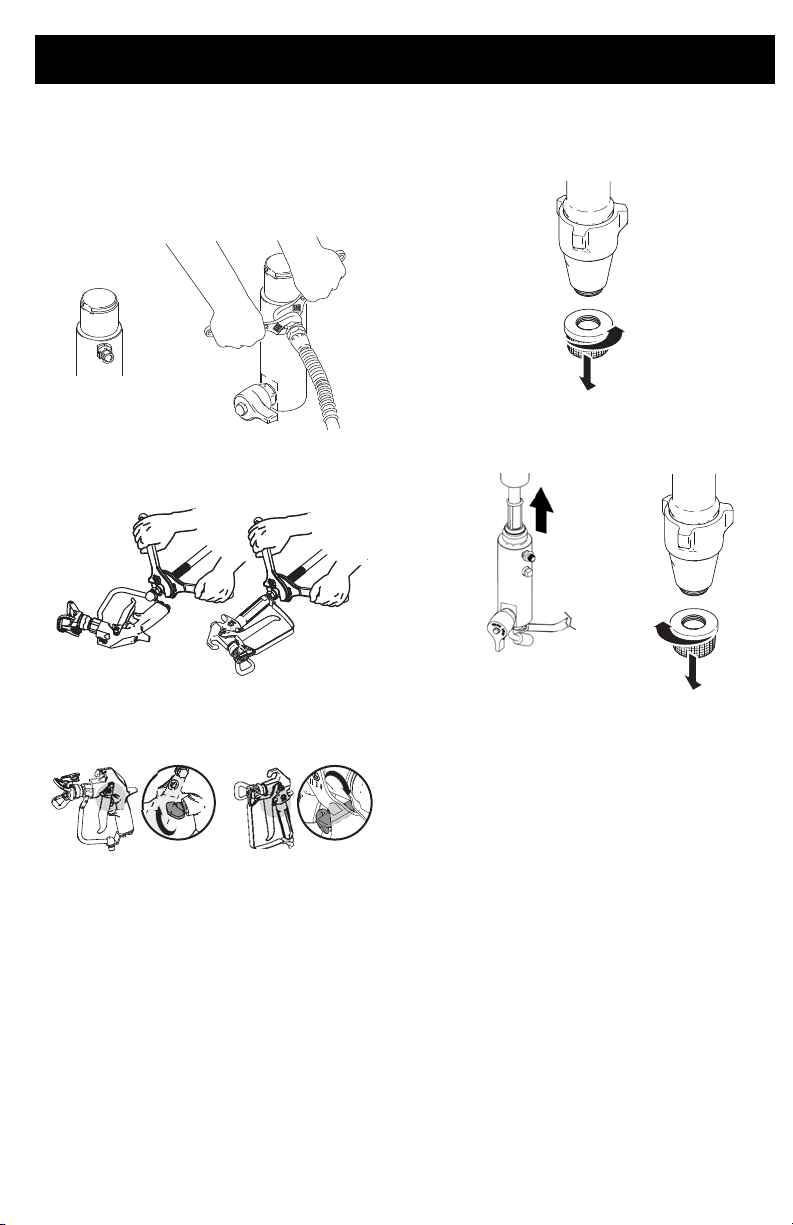

Complete Setup

1. All sprayers except ProContractor:

Connect appropriate Graco

high-pressure hose to sprayer.

2. Install hose to spray gun and tighten

securely.

5. Standard Series: Screw inlet strainer to

bottom of suction hose and hand tighten

securely.

6. When spraying texture, remove inlet

strainer and filter bowl screen.

3. Engage gun trigger lock.

ti22700a

4. Remove Tip Guard.

334606B 17

Page 18

Setup

Safe Range (cold)

ti5243a

ti18197a

$SSUR[LPDWH

)LOO/HYHO

WLD

FROG

WLD

ti5242a

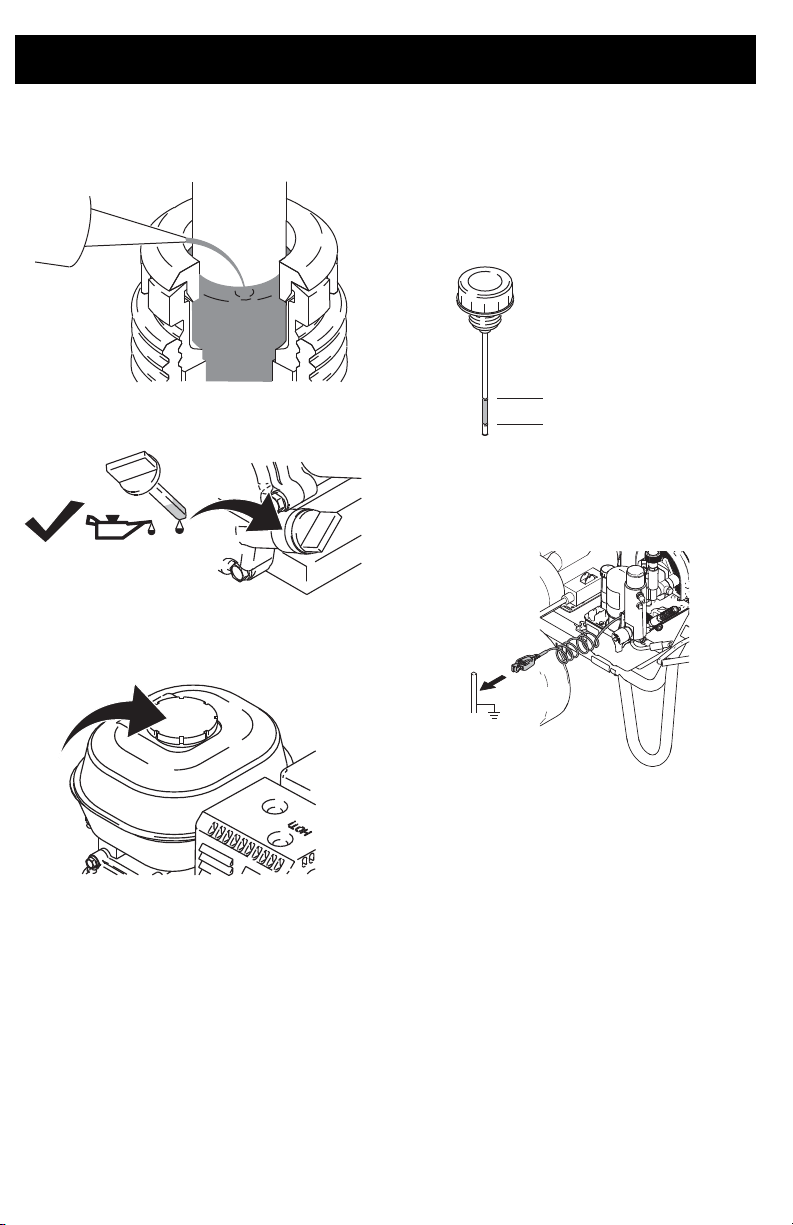

7. Fill throat packing nut with TSL to

prevent premature packing wear. Do this

each time you spray.

8. Check engine oil level.

9. Fill fuel tank.

10. Check hydraulic oil level. Add only Graco

Hydraulic Oil, ISO Grade 46, 169236 (5

gallon/18.9 liter) or 207428 (1 gallon/3.8

liter). Hydraulic tank capacity is 1.25

gallon (4.75 liters).

11. Attach sprayer grounding clamp to earth

ground.

18 334606B

Page 19

Startup (Gas Models)

ti9692a

WLE

ti9686a

ti5248a

ti5249a

ti5250a

ti5262a

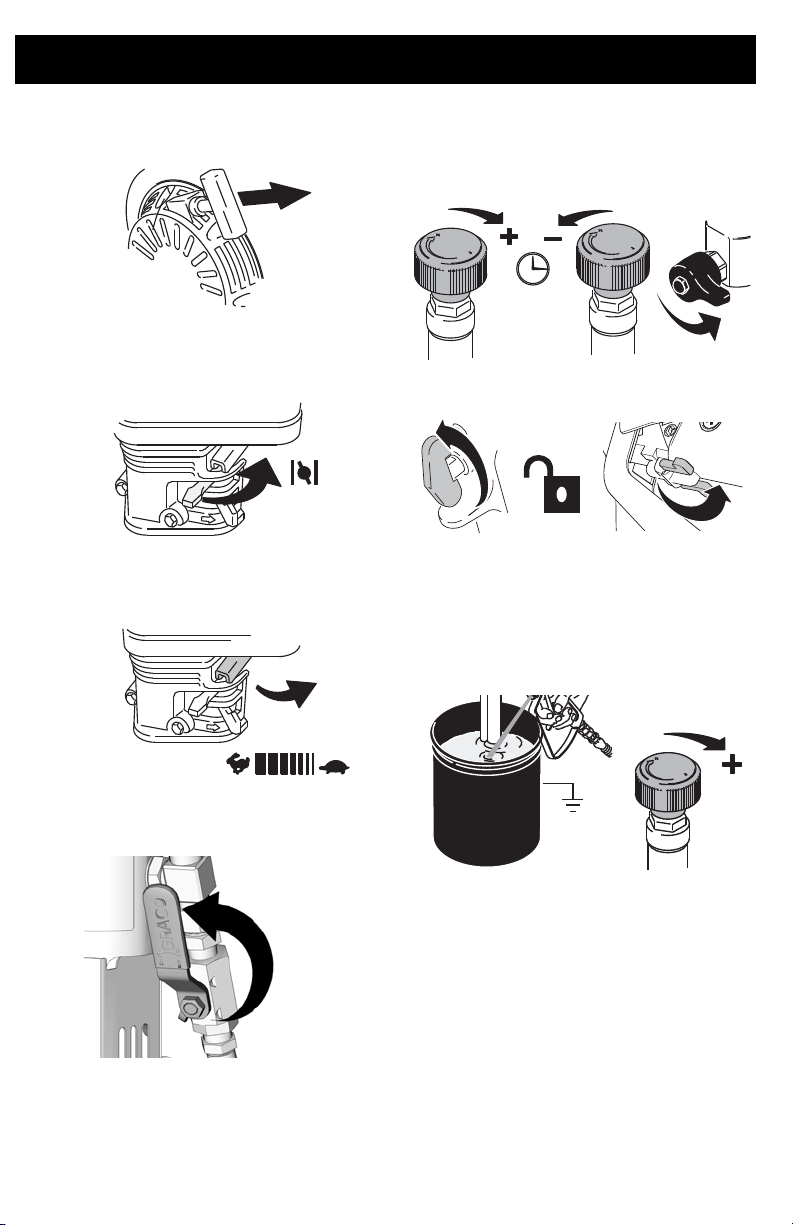

Startup (Gas Models)

1. Place displacement pump in grounded

metal pail partially filled with flushing

fluid. Attach ground wire to pail and to

earth ground.

2. Turn prime valve down to DRAIN

position. Turn pressure control

counterclockwise to lowest pressure.

4. Start engine.

a. Move fuel valve to open.

b. Move choke to closed.

c. Set throttle to fast.

3. Set hydraulic pump valve OFF.

d. Set engine switch to ON.

334606B 19

Page 20

Startup (Gas Models)

ti5263a

ti5264a

ti5251a

ti9687a

15

SEC

WLE

ti18198a

FLUSH

WLD

e. Pull starter rope.

f. After engine starts, move choke to

open.

g. Set throttle to desired setting.

5. Increase pressure enough to start

hydraulic motor stroking and allow fluid

to circulate for 15 seconds; turn pressure

down, turn prime valve horizontal.

6. Disengage spray gun trigger lock.

7. Hold gun against grounded metal

flushing pail. Trigger gun and increase

fluid pressure slowly until pump runs

smoothly. Release trigger and allow

sprayer to build pressure. Engage

trigger lock.

h. Set hydraulic pump valve ON

(hydraulic motor is now active).

20 334606B

Page 21

High-pressure spray is able to inject toxins

ti9695a

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

8. Inspect for leaks. If leaks occur, turn

sprayer OFF immediately. Perform

Pressure Relief Procedure, page 15.

Tighten leaky fittings. Repeat Startup

procedure steps 2-8. If no leaks,

continue to trigger gun until system is

thoroughly flushed.

9. Place siphon tube in paint pail.

Startup (Gas Models)

10. Trigger gun again into flushing fluid pail

until paint appears.

FLUSH

WLD

11. Assemble Tip and Guard, page 24.

334606B 21

Page 22

Startup (Electric Models)

ti9692a

WLE

ti9686a

ti18704a

ti18691a

OI

I

O

ti18419a

ti9687a

Startup (Electric Models)

1. Place displacement pump in grounded

metal pail partially filled with flushing

fluid. Attach ground wire to pail and to

earth ground.

2. Turn prime valve down. Turn pressure

control counterclockwise to lowest

pressure.

4. Plug cord into outlet.

For three phase electric motors: If red

phase sequence light is on, remove plug

from outlet and turn phase sequence

screw 180°.

5. Turn motor ON.

3. Set hydraulic pump valve OFF.

6. Set hydraulic pump valve ON (hydraulic

motor is now active).

22 334606B

Page 23

7. Increase pressure enough to start

15

SEC

WLE

ti18198a

FLUSH

WLD

ti9695a

hydraulic motor stroking and allow fluid

to circulate for 15 seconds; turn pressure

down, turn prime valve horizontal.

8. Take spray gun trigger safety OFF.

9. Hold gun against grounded metal

flushing pail. Trigger gun and increase

fluid pressure slowly until pump runs

smoothly

Startup (Electric Models)

High-pressure spray is able to inject toxins

into the body and cause serious bodily

injury. Do not stop leaks with hand or rag.

10. Inspect fittings for leaks. If leaks occur,

turn sprayer OFF immediately. Perform

Pressure Relief Procedure, page 15.

Tighten leaky fittings. Repeat Startup

procedure steps 2-8. If no leaks,

continue to trigger gun until system is

thoroughly flushed.

11. Place displacement pump in paint pail.

12. Trigger gun again into flushing fluid pail

until paint appears.

ti18248a

13. Assemble Tip and Guard, page 24.

334606B 23

Page 24

Startup (Electric Models)

ti2710a

ti13030a

ti13025a

Switch Tip™ and Guard Assembly

m

1. Perform Pressure Relief Procedure,

page 15.

2. Engage gun trigger lock. Insert Switch

Tip. Insert seat and OneSeal™.

ti13023a

3. Insert Switch Tip and face forward.

Spray

1. Spray test pattern. Increase pressure to

eliminate heavy edges. Use smaller tip

size if pressure adjustment can not

eliminate heavy edges.

2. Hold gun perpendicular, 10-12 in. (25-30

cm) from surface. Spray back and forth.

Overlap by 50%. Trigger gun after

moving and release before stopping.

ti13024a

4. Screw assembly onto gun. Tighten.

24 334606B

Page 25

Startup (Electric Models)

ti13033a

ti13034a

ti25149a

ti22744a

ti22745a

ti22746a

Clear Tip Clogs

1. Release trigger, engage trigger lock.

Rotate Switch Tip. Disengage trigger

lock. Trigger gun to clear clog.

2. Engage trigger lock. Return Switch Tip to

original position. Disengage trigger lock

and continue spraying.

1. Make sure hose is routed through hose

guide.

2. Lift and turn pivot lock 90° to unlock hose

reel. Pull on hose to remove it from hose

reel.

3. Pull reel handle down and turn clockwise

to reel in hose.

Hose Reel

(ProContractor Series only)

4. NOTE: The hose reel can be locked into

two positions: Usage and Storage.

To avoid injury, keep your head clear of

hose reel while winding up hose.

334606B 25

Page 26

Clean Up

ti8687a

21

WLD

OI

I

O

ti25161a

OFF

ON

ti5271b

PAINT

ti5272a

ti9692a

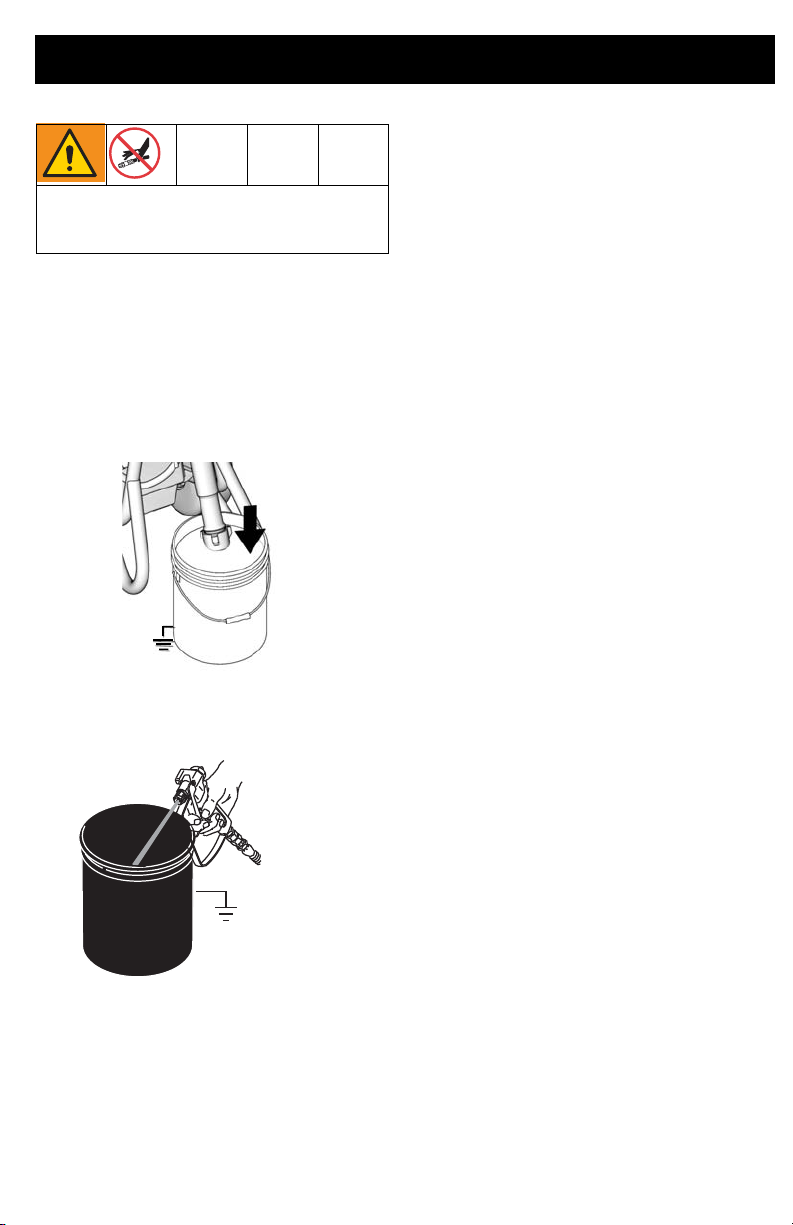

Clean Up

1. Perform Pressure Relief Procedure,

page 15.

2. Remove Guard and SwitchTip.

3. Remove displacement pump from paint

and place in flushing fluid. Use water for

water-based paint and mineral spirits for

oil based paint.

4. Turn motor switch ON or turn engine ON

and start engine. Turn hydraulic pump

valve ON. Turn prime valve forward to

SPRAY position.

5. Hold gun against pail. Disengage trigger

lock. Turn pressure control up until motor

begins to drive pump. Trigger gun until

flushing fluid appears.

26 334606B

Page 27

Clean Up

WLE

ti8692a

ti2776a

ti25424a

ti18418a

ti9694a

6. Move gun to waste pail, hold gun against

pail, trigger gun to thoroughly flush

system. Release trigger and engage

trigger lock.

7. While continuing to trigger gun, turn

prime valve down. Then release gun

trigger. Allow flushing fluid to circulate

until fluid comes out of drain tube clear.

8. Raise displacement pump above

flushing fluid and run sprayer for 15 to 30

seconds to drain fluid. Turn hydraulic

valve OFF. Turn engine OFF or turn

electric motor OFF and unplug.

9. Engage trigger lock. Remove filters from

gun and sprayer, if installed. Clean and

inspect. Reinstall filters.

ti15018a

10. Unscrew and remove inlet strainer.

Clean and replace strainer if necessary.

11. If flushing with water, flush again with

mineral spirits, or Pump Armor, to leave

a protective coating to prevent freezing

or corrosion.

12. Wipe sprayer, hose and gun with a rag

soaked in water or mineral spirits.

334606B 27

Page 28

Maintenance

Maintenance

NOTE: For detailed engine maintenance and

specifications, refer to separate Honda

Engines Owner's Manual, supplied.

DAILY: Check engine oil level and fill as

necessary.

DAILY: Check hydraulic oil level and fill as

necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun trigger lock for proper

operation.

DAILY: Check prime/drain valve for proper

operation.

DAILY: Check and fill the gas tank.

DAILY: Check that displacement pump is

tight.

DAILY: Check level of Throat Seal Liquid

(TSL) in displacement pump packing nut. Fill

nut, if necessary. Keep TSL in nut to help

prevent fluid buildup on piston rod and

premature wear of packings and pump

corrosion.

AFTER THE FIRST 20 HOURS OF

OPERATION: Drain engine oil and refill with

clean oil. Reference Honda Engines Owner's

Manual for correct oil grade.

WEEKLY: Remove engine air filter cover and

clean element. Replace element, if

necessary. If operating in an unusually dusty

environment: check filter daily and replace, if

necessary.

Replacement elements can be purchased

from your local HONDA dealer.

WEEKLY/DAILY: Remove any debris or

media from hydraulic rod.

AFTER EACH 100 HOURS OF

OPERATION: Change engine oil. Reference

Honda Engines Owner's Manual for correct

oil viscosity.

SEMI-ANNUALLY: Check belt wear.

Replace if necessary.

YEARLY OR 2000 HOURS: Replace

hydraulic oil and filter with Graco hydraulic oil

169236 (5 gallon/20 liter) or 207428 (1

gallon/3.8 liter) and filter 116909.

Replace belt.

SPARK PLUG: Use only BPR6ES (NGK) or

W20EPR-U (NIPPONDENSO) plug. Gap

plug to 0.028 to 0.031 in. (0.7 to 0.8 mm). use

spark plug wrench when installing and

removing plug.

28 334606B

Page 29

Troubleshooting

Troubleshooting

Problem Cause Solution

Gas engine pulls hard (won’t

start)

Gas engine does not start Switch OFF, low oil, no gasoline Consult engine manual

Gas engine does not work

properly

Electric motor does not start

starts slowly

334606B 29

Hydraulic pressure is too high Turn hydraulic pressure knob

Fuel shut off valve closed Open fuel shut off valve

Faulty engine Consult engine manual

Elevation Refer to Engine Repair Kit, 4.0

No power Check power source; check

Cord not connected to power

source

Switch OFF 1 phase motors: Turn on/off

Incorrect power source

Incorrect amp setting on motor

starter (3 phase motor only)

Over current switch has tripped

Hydraulic pressure is too high

counterclockwise to lowest

setting

hp - 288678 / 5.5 hp - 248943 /

6.5 hp - 248944 / 9.0 hp 248945

circuit breakers and/or fuses.

Reset/replace as required.

Connect plug to receptacle

(grounded with properly sized

circuit breaker and/or fuses).

switch to ON.

3 phase motors: Push ON

switch.

Have a certified electrician or

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

NOTE: If using the EH300DI

sprayer, the generator must be

sized for 15 kW output

minimum.

Have a certified electrician or

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

Have a certified electrician or

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

Turn hydraulic pressure knob

counter clockwise to lowest

setting.

Page 30

Troubleshooting

Problem Cause Solution

Electric motor does not work

properly

Gas engine / electric motor

operates but displacement

pump does not operate

Incorrect power source Have a certified electrician or

Low voltage to motor

3 phase motors: A phase of

three phase power has open

circuit

Faulty motor

Hydraulic pump valve is OFF

Pressure setting too low

Displacement pump outlet filter

(if used) is dirty or clogged

Tip or tip filter (if used) is

clogged

Hydraulic fluid too low Shut off sprayer. Add fluid*.

Belt is off pulley, worn or broken Replace. See Repair manual.

Hydraulic pump worn or

damaged

Dried paint seized paint pump

rod

Hydraulic motor not shifting Set pump valve OFF. Turn

For 3 Phase electric motor

only: Red phase sequence light

is ON, indicating motor rotating

in the wrong direction

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

Have a certified electrician or

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

Have a certified electrician or

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

Have a certified electrician or

authorized Graco Repair Center

evaluate and repair.

See Technical Data, pages

60-63.

Set hydraulic pump valve ON.

Increase pressure, page 20.

Clean the filter.

Remove tip and/or filter and

clean.

Bring sprayer to Graco

distributor for repair.

Service pump. See manual

334654

pressure down. Turn engine

OFF. Pry rod up or down until

hydraulic motor shifts. See

Repair manual.

Remove plug from receptacle

and rotate plug phase screw.

See Operation manual.

30 334606B

Page 31

Troubleshooting

PROBLEM CAUSE SOLUTION

Displacement pump operates,

but output is low on upstroke

Displacement pump operates

but output is low on downstroke

and/or on both strokes

Paint leaks and runs over side of

wet-cup

Excessive leakage around

hydraulic motor piston rod wiper

Fluid delivery is low Pressure setting too low Increase pressure, see

Sprayer overheats Paint build up on hydraulic

Spitting from gun Air in fluid pump or hose Check for loose connections on

Excessive hydraulic pump noise Low hydraulic fluid level Turn sprayer OFF. Add fluid*.

*Check hydraulic fluid level often. Do no allow it to become too low. Use only Graco approved hydraulic fluid, page 18.

Piston ball check not seating

properly

Piston packings worn or

damaged

Piston packings worn or

damaged

Intake valve ball check not

seating properly

Displacement pump air leak

Loose wet-cup

Throat packings worn or

damaged

Piston rod seal worn or

damaged

Displacement pump outlet filter

(if used) is dirty or clogged

Hydraulic motor is worn or

damaged

Large pressure drop in fluid

hose

components

Oil level is low Fill with oil. See Operation

Inlet to hydraulic pump

pulley/cooling fan is obstructed

Inlet to 3 phase electric motor

cooling fan is obstructed.

Fluid supply is low or empty Refill supply container.

Air in hydraulic lines Bleed lines. See Repair manual.

Service piston ball check. See

manual 334654

Replace packings. See manual

334654

Tighten packing nut or replace

packings. See manual 334654

Service intake valve ball check.

See manual 334654

Tighten wet-cup enough to stop

leakage.

Replace packings. See manual

334654

Replace these parts. See

Repair manual.

Operation manual.

Clean filter.

Bring sprayer to Graco

distributor for repair.

Use larger diameter or shorter

hose.

Clean hydraulic components.

manual.

Remove obstructions.

Remove obstructions.

siphon assembly, tighten, then

reprime pump.

334606B 31

Page 32

Standard Series Pump

ti25423a

ti2272c

ti2272b

ti2272d

Standard Series Pump

Removal

See pump manual 334654 for pump repair.

1. Flush pump.

2. Perform Pressure Relief Procedure,

page 15.

3. Remove strainer and paint hose.

4. Push retaining ring up; push out pin.

5. Loosen jam nut. Unscrew pump.

Installation

NOTICE

If pump jam nut loosens during operation,

the threads of the bearing housing and

drive train will be damaged. Tighten jam

nut as specified.

1. Screw jam nut to bottom of pump

threads. Screw pump completely into

manifold. Unscrew pump from manifold

until pump outlet aligns with hose. Hand

tighten jam nut, then tap 1/8 to 1/4 turn

with hammer.

32 334606B

Page 33

ProContractor Series Pump

ti18418b

ti8828a

ti2272e

ti2272f

If pin is loose, parts could break off and

project through the air, resulting in serious

injury or property damage. Make sure pin is

properly installed.

2. Slowly pull engine starter rope until

pump rod pin hole is aligned with

hydraulic rod hole. Push pin into hole.

Push retaining ring into groove.

3. Fill packing nut with Graco TSL.

ProContractor

Series Pump

Removal

See pump manual 334654 for pump repair.

1. Flush pump.

2. Perform Pressure Relief Procedure,

page 15.

3. Remove paint hose fitting and paint hose

from pump fitting.

334606B 33

Page 34

ProContractor Series Pump

ti8829a

ti8830a

ti8831a

ti8833a

ti8832a

ti8834a

4. Slide coupler cover up to fully expose rod

couplers.

5. Remove rod couplers.

6. Remove pin.

7. Open clamp.

8. Remove pump from unit.

Installation

1. If needed, place pump rod in adjustment

casting and pull pump to extend rod.

NOTE: Support pump with your hand before

opening t-handle.

2. Reverse removal steps to reassemble

pump.

34 334606B

Page 35

Parts

ti25305a

DutyMax EH/GH™230/300 Standard Series

Parts

334606B 35

Page 36

Parts

ti25332a

112

19

35

81

75

132

116

91

70

39

69

54

50

49

186

115

55

170

27

48

49

172

173

117

101

148

51

295

38

294

139

212

139

79

Torque to 120-130 in-lbs

(13.6-14.7 N·m)

Inflate tires to 25-35 psi

(1.7-2.5 bar)

1

2

1

1

1

2

Parts - Frame and Belt Guard

DutyMax GH™230/300 Standard Series

36 334606B

Page 37

Parts List

Ref. Part Description Qty.

19 101354 PIN, spring, straight 2

27 260212 SCREW, hex washer hd,

thd form

35 112827 BUTTON, snap 2

38 114271 STRAP, retaining 1

39 119509 WHEEL, pneumatic 2

48 867539 SCREW, cap, hex hd 2

49 100527 WASHER, plain 4

50 110838 NUT, lock 2

51 117284 GRILL, fan guard 1

54 156306 WASHER, flat 2

55 17D813 NUT, hand 2

69 116038 WASHER, wave spring 2

70 120211 RING, retaining, e-ring 2

75 15J645 WASHER 2

79 189246 LABEL, warning 1

17D947 LABEL, warning,

multi-languages

81 192027 SLEEVE, cart 2

91 194317 LABEL, warning 1

16N948 LABEL, warning, ISO 1

17D947 LABEL, warning,

multi-languages

101 17D042 LABEL, brand, side

(EH200DI)

17D044 LABEL, brand, side

(GH200DI)

17D046 LABEL, brand, side

(EH300DI)

17D048 LABEL, brand, side

(GH300DI)

112 24M397 HANDLE, cart 1

115 24M086 RAIL, belt gaurd, assy 1

116 24M085 FRAME, cart, weldment 1

117 248973 GUARD, belt assembly,

painted (includes 51, 148,

172, 173)

132 109032 SCREW, mach, pnh 4

139 16M768 LABEL, warning 2

141 15Y963 LABEL, read instructions 1

148 115477 SCREW, mach, torx pan hd4

Parts

1

1

1

1

1

1

1

1

170 102040 NUT, lock, hex 1

172 119434 SCRWE, shoulder, skt hd 1

173 116969 NUT, lock 1

212 16N398 LABEL, direction

(EH/GH300DI)

294 16D576 LABEL, made in USA 1

295 16X983 LABEL, standard series 1

Danger and Warning labels are available at no

cost.

1

334606B 37

Page 38

Parts

30

99

119a

23

175

176

190

193

174

191

192

43

133133

88

157

304

162

119

ti25479a

Torque to 26-30 in-lbs

(2.9-3.4 N·m)

Torque to 215-235 in-lbs

(24.3-26.6 N·m)

Loctite 242

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

123

4

1

4

3

2

3

2

3

Parts - Electric Motor

DutyMax EH™230DI Models

Parts List - Electric Motor (DutyMax EH

Ref. Part Description Qty.

23 110963 SCREW, cap, flange

30 114653 SCREW, cap, flange

43 16N612 PULLEY 1

44 116914 BELT, V-Gripnotch (not

88 15K616 LABEL, caution 1

99 15E585 BRACKET, mounting,

119 24M668 KIT, 3.0 hp (includes all

119a 15E669 MOTOR, electric 3 HP,

133 100002 SCREW, set 2

head

head

shown)

elec. motor

parts listed on this

page)

230V AC

38 334606B

Ref. Part Description Qty.

2

2

1

1

1

1

157 15B804 LABEL, Graco 2

162 189930 LABEL, warning 1

174 110996 NUT, hex, flange head 4

175 246214 HANDLE, conversion 1

176 111700 GRIP, handle 1

190 15F217 PLATE, isolator,

191 113817 BUMPER 4

192 100057 SCREW, cap, hex hd 4

193 111040 NUT, lock, insert,

304 117632 KEY, square 3/16 x

Danger and Warning labels are available at no

cost

™

230DI Models)

bottom

nylock, 5/16

1.25

1

4

1

Page 39

Parts - Gas Engine

30

34

43

133

106

126

23

154

99

153

154

7

24

88

119a

ti25480a

119

119a

245

246

90

Torque to 120-130 in-lbs

(13.6-14.7 N·m)

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

Loctite 242

123

2

3

1

3

1

DutyMax GH™230DI Models

Parts

Parts List - Gas Engine (DutyMax GH

Ref. Part Description Qty.

7 100023 WASHER, flat 4

23 113664 SCREW, cap, hex hd 4

30 108842 SCREW, cap, hex hd 2

34 112717 WASHER 1

43 116908 PULLEY, 5.50 in. 1

44 119433 BELT, V-Gripnotch (not

50 110838 NUT, lock 4

88 194126 LABEL, warning 1

90 16Y720 LABEL, warning, ISO

99 15F157 BRACKET, mounting,

106 15B314 SLEEVE, motor shaft 1

shown)

engine

engine

Ref. Part Description Qty.

119 248944 KIT, gas engine 6.5 hp

119a 116298 ENGINE, 6.5 gas 1

126 117632 KEY, square, 3/16 x

1

133 100002 SCREW, set 1

153 15E888 DAMPENER, motor

154 108851 WASHER, plain 8

1

245 128099 DEFLECTOR, exhaust 1

246 128101 SCREW, tapping 2

1

Danger and Warning labels are available at no

cost

™

230DI Models)

(includes all parts listed

on this page)

1.25

mount

334606B 39

2

1

4

Page 40

Parts

99

119a

23

174

195

198

200

175

30

174

191

192

193

43

93

92

88

162

157

ti18618a

119

Torque to 26-30 in-lbs

(2.9-3.4 N·m)

Torque to 215-235 in-lbs

(24.3-26.6 N·m)

Loctite 242

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

123

4

2

3

3

4

2

3

1

Parts - Electric Motor

DutyMax EH™300DI Models

Ref. Part Description Qty.

162 189930 LABEL, caution 1

4

4

1

1

1

1

1

1

174 112958 NUT, hex, flanged 8

175 16M473 TUBE, handle,

191 113817 BUMPER 4

192 100057 SCREW, cap, hex hd 4

193 111040 NUT, lock, insert,

195 16M474 BRACKET, motor

198 24N064 STARTER, motor

200 119236 SCREW, plastite 4

Danger and Warning labels are available at no

cost

™

300DI Models)

conversion

nylock, 5/16

starter

assembly

Parts List - Electric Motor (DutyMax EH

Ref. Part Description Qty.

23 111193 SCREW, cap, flange

30 116780 SCREW, hex, hd,

43 125811 PULLEY, cast iron,

88 15K616 LABEL, caution 1

92 16N399 LABEL, motor switch

93 16N400 LABEL, red light

99 16M467 BRACKET, mounting,

119 24M669 KIT, motor (includes all

119a 24N019 MOTOR, elec., 400

40 334606B

head

flanged

8.75 in

box on-off

indicator

motor, EH300

parts listed on this

page)

VAC, 50 Hz, 7.3 hp

1

4

1

1

Page 41

Parts - Gas Engine

1547154

99

153

23

119a

245

246

9

106

126

43

133

175

34

30

176

171

88

90

ti25499a

119

Torque to 120-130 in-lbs

(13.6 -14.7 N·m)

Loctite 242

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

1

2

3

1

2

2

3

1

2

1

DutyMax GH™300DI Models

Parts

Parts List - Gas Engine (DutyMax GH

Ref. Part Description Qty.

7 100132 WASHER, flat 4

9 101566 NUT, lock 4

23 106212 SCREW, cap, hex hd 4

30 116645 SCREW, cap, hex head 1

34 100696 WASHER, wrought 1

43 119401 PULLEY 1

44 119432 BELT, V-Gripnotch (not

88 194126 LABEL, warning 1

90 16Y720 LABEL, warning, ISO

99 15E583 BRACKET, mounting,

106 15E586 SLEEVE, shaft, engine 1

119 248945 KIT, gas engine 9.0 hp

shown)

engine

engine

(includes all parts listed

on this page)

™

300DI Models)

Ref. Part Description Qty.

119a 803900 ENGINE, gasoline, 9.0

126 119484 KEY, parallel, square 1

133 100002 SCREW, set 1

153 195515 DAMPENER, motor

154 108851 WASHER, plain 8

1

171 C20010 SCREW, cap, socket

175 15E764 SPACER, shaft, engine 1

1

176 15E973 SHIELD, engine shaft 1

245 124145 DEFLECTOR, exhaust 1

1

246 128101 SCREW, tapping 3

Danger and Warning labels are available at no

cost

2

hp (Honda)

mount

head

334606B 41

1

4

4

Page 42

Parts

ti18346a

267

236

265

233

237

234

235

242

243

247

238

239

240

248

244

245

249

253

255

254

252

250

251

262

232

246

231

230

229

227

261

264

256

257

258

259

228

263

236

96

197

44

144

84

85

87

4

55

3

266

285

241

299

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

Loctite 242

Torque to 90-110 in-lbs

(10.2-12.4 N·m)

Torque to 335-395 in-lbs

(37.9-44.6 N·m)

Torque to 15-25 in-lbs

(1.7-2.8 N·m)

Loctite 277

Torque to 110-120 in-lbs

(12.4-13.6 N·m)

12345

6

7

6

3

5

1

2

2

4

7

7

3

Parts - Reservoir and Filter

42 334606B

Page 43

Parts List - Reservoir and Filter

Ref. Part Description Qty.

3 196178 FITTING, outlet

(EH/GH230DI)

183285 FITTING, outlet,

(EH/GH300DI)

4 15E476 BRACKET, retainer,

motor

44 116914 BELT, V, AX42

(EH230DI)

119433 BELT, V, AX41

(GH230DI)

125834 BELT, V, AX48

(EH300DI)

119432 BELT, V, AX44

(GH300DI)

55 15D862 NUT, hand 2

84 198585 LABEL, hydraulic fluid, GH1

85 15A464 LABEL, control 1

87 189892 LABEL, Graco 1

96 15E410 PULLEY, fan 1

144 15K440 LABEL, brand, GH/EH

cooling

197 120087 SCREW, set, 1/4 x 1/2 2

227 15J513 TANK, reservoir, blue 1

228 101754 PLUG, pipe 1

229 120604 GASKET, reservoir 1

230 116919 FILTER 1

231 15E587 TUBE, suction 1

232 154594 PACKING, o-ring 1

233 15M056 COVER, reservoir 1

234 107188 PACKING, o-ring 4

235 156401 PACKING, o-ring 1

236 119426 SCREW, mach, hex

washer hd

237 120726 CAP, breather, filter 1

238 198841 RETAINER, ball,

pressure bypass

239 100084 BALL, metallic 1

240 116967 SPRING, compression 1

Ref. Part Description Qty.

241 237686 WIRE, ground assembly

1

242 249003 PUMP, hydraulic

1

243 110792 FITTING, elbow, male,

1

244 15B438 KNOB, pressure 1

1

245 117560 SCREW, set, socket

246 245167 TUBE, hydraulic, case

1

247 120634 FITTING, elbow,

1

248 246173 FILTER, oil, spin on 1

249 15E599 HOUSING, filter 1

250 15G331 PLUG, pipe 1

251 196178 ADAPTER, nipple 1

252 244067 FILTER, fluid 1

253 16C766 TUBE, diffusion 1

254 117285 PACKING, o-ring 1

255 16C765 CAP, filter 1

1

256* 287879 VAVLE, drain, assy 1

257* 114708 SPRING, comp 1

258* 15G563 HANDLE, valve 1

259* 116424 NUT, cap 1

261* 193710 SEAL, seat, valve 1

262 117471 SCREW, mach, hex flat

263 120184 FITTING, hydraulic 1

264* 193709 SEAT, valve 1

265 121311 FITTING, elbow, 45°

266 102814 GAUGE 1

11

267 243683 UNION, swivel 1

285 116618 MAGNET 1

299 290079 LABEL, ground warning,

1

* Included in Drain Valve Kit 245103

Parts

w clamp

(EH/GH230DI)

90°

head

drain

hydraulic w/o rings

head

street

English

16Y633 LABEL, ground warning,

Chinese

1

1

1

1

1

1

4

1

1

1

334606B 43

Page 44

Parts

288

290

116 ref

288

268

269

270

271

281

278

279

289

290c

290b

290a

291

296

297

298

299

300

291

295

111

64

41

129

83

194

260

73

103

110

9

77

76

290

157

143

65

68

63

64a

68

64e

64f

64b

64d

64e

64

ti25335a

83

86

64c

2

1

1

3

4

123

4

Parts - Hydraulic Motor and Displacement Pump

Torque to 145-155 ft-lbs

(196.6-210.2 N·m)

Torque to 12-18 ft-lbs

(16.3-24.4 N·m)

Torque to 140-160 in-lbs

(15.8-18.1 N·m)

Torque to 70-80 ft-lbs

(94.9-108.5 N·m)

44 334606B

Page 45

Parts

Parts List - Hydraulic Motor and Displacement Pump

Ref. Part Description Qty.

8 15F584 LABEL, ProConnect 1

9 101566 NUT, lock 4

33 189920 STRAINER, (1-11 1/2

41 107210 SCREW 4

57 288344 CLAMP, pump 1

58 105510 WASHER, lock, spring

59 101550 SCREW, cap, sch 2

63 257908 HOSE, coupled 1

64 24M611 KIT, check valve

64a 16N461 HOUSING, seat, check

64b 16N462 HOUSING, ball, check

64c 24M725 KIT, repair, check valve

64d* O-RING 2

64e* SEAT, valve 1

64f* BALL, ceramic 1

65 109450 PACKING, o-ring 1

68* C20195 PACKING, o-ring 1

73 198542 CLIP, spring 1

76 15K642 HOSE, hydraulic, return 1

77 15K641 HOSE, hydraulic, supply 1

83

86 193394 NUT, retaining,

103 243993 HOSE, drain, Ultra

110 241920 DEFLECTOR, threaded 1

111 24W999 PUMP, displacement 1

129 15B063 LABEL, warning 1

143 17D061 LABEL, brand, front

192840 LABEL, warning 1

17D063 LABEL, brand, front

17D065 LABEL, brand, front

npsm)

(hi-collar)

(includes 64a -64f)

valve

valve

(includes 64d, 64e, 64f,

68)

GH230/300

hi-boy

(EH230DI)

(GH230DI)

(EH300DI)

Ref. Part Description Qty.

17D067 LABEL, brand, front

157 15B804 LABEL, Graco 2

1

178 156698 PACKING, o-ring 1

179 277377 COUPLER, pump 2

180 15H957 COVER, coupler 1

194 24X474 COVER, shield 1

2

260 15E243 MANIFOLD, adapter 1

268+ 117739 WIPER, rod 1

269+ 112342 BEARING, rod 1

270+ 112342 PACKING, block 1

1

271+ 117283 PACKING, o-ring 1

278+ 108014 PACKING, o-ring 1

1

279+ 178226 SEAL, piston 1

281+ 178207 BEARING, piston 1

1

288 248991 SLEEVE, hydraulic 1

289 15A726 NUT, jam 1

1

290 288737 KIT, repair, tripod

290a 106276 SCREW, cap, hex head 1

290b 155685 PACKING, o-ring 1

290c 178179 WASHER, sealing 1

291 117607 FITTING, elbow std thd 2

295 100139 PLUG, pipe 1

296 15E596 TUBE, hydraulic, supply 1

297 117609 FITTING, tee, branch,

298 117328 FITTING, nipple, straight 1

1

299 117441 VALVE, ball 1

300 116813 FITTING, nipple,

1

Danger and Warning labels are available at no

cost

Included in Hydraulic Motor Repair Kit 288760

1

1

1

(EH/GH300).

+ Included in Seal Kit 246174

* Included in Check Valve Repair Kit 24M725

(GH300DI)

(includes 129, 278, 279,

281, 282, 295)

str thd

hydraulic

1

1

1

1

334606B 45

Page 46

Parts

202a

202b

202c

202d

202e

202f

ti25337a

225f

225d

225b

225a225a

Parts

DutyMax EH/GH™230DI Sprayer - Spray Gun and Hose

Ref. Part No. Description

202a 240797 HOSE, grounded, nylon; 3/8 in.

202b 241735 HOSE, grounded, nylon; 1/4 in.

202c 241705

202d 159841 ADAPTER, 3/8 x 1/4 in. npt

202e 239663 SWIVEL, straight

202f 196178 ADAPTER, nipple

DutyMax EH/GH

Ref. Part No. Description Qty.

225a 159239 FITTING, nipple, pipe, rdcg 2

225b 191239 HOSE, cpld, 3/8 in. x 11 ft 10 in. 1

225d 245820

225f 278499 HOSE, cpld, 1/2 in. x 50 ft,

ID; cpld 3/8-18 npsm; 50 ft (15

m); spring guards both ends

ID; cpld 1/4 npt(m) x 1/4

npsm(f); 3 ft (0.9m); spring

guards both ends 3300 psi (227

bar, 22.7 MPa)

GUN, spray, texture, Includes

©

Tip Guard and LTX531

RAC

Spray Tip Cylinder, See 308491 for

parts

™

300DI Sprayer - Spray Gun and Hose

KIT, accessory, gun

3300 wp

Qty.

1

1

1

1

1

1

1

1

46 334606B

Page 47

Parts

ti25306a

DutyMax EH/GH™230/300 ProContractor Series

Parts

334606B 47

Page 48

Parts

ti25333a

116

91

70

39

69

54

50

49

186

115

55

170

27

48

49

172

173

117

101

148

51

5

139

212

297

139

50

50

311

23

311

79

1

1

1

2

1

2

Parts - Frame and Belt Guard

DutyMax GH™230/300 ProContractor Series

Torque to 120-130 in-lbs

(13.6-14.7 N·m)

Inflate tires to 25-35 psi

(1.7-2.5 bar)

48 334606B

Page 49

Parts List

Ref. Part Description Qty.

5 16D576 LABEL, made in USA with

19 101354 PIN, spring, straight 2

23 110963 SCREW, cap, flange

27 260212 SCREW, hex washer hd,

35 112827 BUTTON, snap 2

38 114271 STRAP, retaining 1

39 119509 WHEEL, pneumatic 2

48 867539 SCREW, cap, hex hd 2

49 100527 WASHER, plain 4

50 110838 NUT, lock 2

51 117284 GRILL, fan guard 1

54 156306 WASHER, flat 2

55 17D813 NUT, hand 2

69 116038 WASHER, wave spring 2

70 120211 RING, retaining, e-ring 2

75 15J645 WASHER 2

79 189246 LABEL, warning 1

81 192027 SLEEVE, cart 2

91 194317 LABEL, warning 1

16N948 LABEL, warning, ISO 1

17D947 LABEL, warning,

101 17D042 LABEL, brand, side

17D044 LABEL, brand, side

17D046 LABEL, brand, side

17D048 LABEL, brand, side

115 24M086 RAIL, belt gaurd, assy 1

116 17D108 FRAME, cart, weldment 1

117 248973 GUARD, belt assembly,

132 109032 SCREW, mach, pnh 4

139 16M768 LABEL, warning 2

141 15Y963 LABEL, read instructions 1

148 115477 SCREW, mach, torx pan hd4

global component

head

thd form

multi-languages

(EH230DI)

(GH230DI)

(EH300DI)

(GH300DI)

painted

Parts

1

1

1

1

1

1

1

1

1

170 102040 NUT, lock, hex 1

172 119434 SCRWE, shoulder, skt hd 1

173 116969 NUT, lock 1

212 16N398 LABEL, direction

(EH/GH300DI)

297 17D033 LABEL, ProContractor 1

311 128051 CLAMP 2

Danger and Warning labels are available at no

cost

1

334606B 49

Page 50

Parts

30

99

119a

23

175

176

190

193

174

191

192

43

133133

88

157

304

162

119

ti25479a

Torque to 26-30 in-lbs

(2.9-3.4 N·m)

Torque to 215-235 in-lbs

(24.3-26.6 N·m)

Loctite 242

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

123

4

1

4

3

2

3

2

3

Parts - Electric Motor

DutyMax EH™230DI Models

Parts List - Electric Motor (DutyMax EH

Ref. Part Description Qty.

23 110963 SCREW, cap, flange

30 114653 SCREW, cap, flange

43 15E588 PULLEY 1

44 116914 BELT, V-Gripnotch (not

88 15K616 LABEL, caution 1

99 15E585 BRACKET, mounting,

119 248946 KIT, electric motor 3.0

119a 15E669 MOTOR, electric 3 HP,

133 100002 SCREW, set 2

head

head

shown)

elec. motor

hp (includes all parts

listed on this page)

230V AC

50 334606B

2

2

1

1

1

1

Ref. Part Description Qty.

157 15B804 LABEL, Graco 2

162 189930 LABEL, warning 1

174 110996 NUT, hex, flange head 4

175 246214 HANDLE, conversion 1

176 111700 GRIP, handle 1

190 15F217 PLATE, isolator,

191 113817 BUMPER 4

192 100057 SCREW, cap, hex hd 4

193 111040 NUT, lock, insert,

304 117632 KEY, square 3/16 x

Danger and Warning labels are available at no

cost

™

230DI Models)

bottom

nylock, 5/16

1.25

1

4

1

Page 51

Parts - Gas Engine

30

34

43

133

106

126

23

154

99

153

154

7

24

88

119a

ti25480a

119

119a

245

246

90

Torque to 120-130 in-lbs

(13.6-14.7 N·m)

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

Loctite 242

123

2

3

1

3

1

DutyMax GH™230DI Models

Parts

Parts List - Gas Engine (DutyMax GH

Ref. Part Description Qty.

7 100023 WASHER, flat 4

23 113664 SCREW, cap, hex hd 4

30 108842 SCREW, cap, hex hd 2

34 112717 WASHER 1

43 116908 PULLEY, 5.50 in. 1

44 119433 BELT, V-Gripnotch (not

50 110838 NUT, lock 4

88 194126 LABEL, warning 1

90 16Y720 LABEL, warning, ISO

99 15F157 BRACKET, mounting,

106 15B314 SLEEVE, motor shaft 1

shown)

engine

engine

Ref. Part Description Qty.

119 248944 KIT, gas engine 6.5 hp

119a 116298 ENGINE, 6.5 HP gas 1

126 117632 KEY, square, 3/16 x

1

133 100002 SCREW, set 1

153 15E888 DAMPENER, motor

154 108851 WASHER, plain 8

1

245 128099 DEFLECTOR, exhaust 1

246 128101 SCREW, tapping 2

1

Danger and Warning labels are available at no

cost

™

230DI Models)

(includes all parts listed

on this page)

1.25

mount

334606B 51

2

1

4

Page 52

Parts

99

119a

23

174

195

198

200

175

30

174

191

192

193

43

93

92

88

162

157

ti18618a

119

Torque to 26-30 in-lbs

(2.9-3.4 N·m)

Torque to 215-235 in-lbs

(24.3-26.6 N·m)

Loctite 242

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

123

4

2

3

3

4

2

3

1

Parts - Electric Motor

DutyMax EH™300DI Models

Ref. Part Description Qty.

162 189930 LABEL, caution 1

4

4

1

1

1

1

1

1

174 112958 NUT, hex, flanged 8

175 16M473 TUBE, handle,

191 113817 BUMPER 4

192 100057 SCREW, cap, hex hd 4

193 111040 NUT, lock, insert,

195 16M474 BRACKET, motor

198 24N064 STARTER, motor

200 119236 SCREW, plastite 4

Danger and Warning labels are available at no

cost

™

300DI Models)

conversion

nylock, 5/16

starter

assembly

Parts List - Electric Motor (DutyMax EH

Ref. Part Description Qty.

23 111193 SCREW, cap, flange

30 116780 SCREW, hex, hd,

43 125811 PULLEY, cast iron,

88 15K616 LABEL, caution 1

92 16N399 LABEL, motor switch

93 16N400 LABEL, red light

99 16M467 BRACKET, mounting,

119 24M669 KIT, motor (includes all

119a 24N019 MOTOR, elec., 400

52 334606B

head

flanged

8.75 in

box on-off

indicator

motor, EH300

parts listed on this

page)

VAC, 50 Hz, 7.3 hp

1

4

1

1

Page 53

Parts - Gas Engine

1547154

99

153

23

119a

245

246

9

106

126

43

133

175

34

30

176

171

88

90

ti25499a

119

Torque to 120-130 in-lbs

(13.6 -14.7 N·m)

Loctite 242

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

1

2

3

1

2

2

3

1

2

1

DutyMax GH™300DI Models

Parts

Parts List - Gas Engine (DutyMax GH

Ref. Part Description Qty.

7 100132 WASHER, flat 4

9 101566 NUT, lock 4

23 106212 SCREW, cap, hex hd 4

30 116645 SCREW, cap, hex head 1

34 100696 WASHER, wrought 1

43 119401 PULLEY 1

44 119432 BELT, V-Gripnotch (not

88 194126 LABEL, warning 1

90 16Y720 LABEL, warning, ISO

99 15E583 BRACKET, mounting,

106 15E586 SLEEVE, shaft, engine 1

119 248945 KIT, gas engine 9.0 hp

shown)

engine

engine

(includes all parts listed

on this page)

™

300DI Models)

Ref. Part Description Qty.

119a 803900 ENGINE, gasoline, 9.0

126 119484 KEY, parallel, square 1

133 100002 SCREW, set 1

153 195515 DAMPENER, motor

154 108851 WASHER, plain 8

1

171 C20010 SCREW, cap, socket

175 15E764 SPACER, shaft, engine 1

1

176 15E973 SHIELD, engine shaft 1

245 124145 DEFLECTOR, exhaust 1

1

246 128101 SCREW, tapping 3

Danger and Warning labels are available at no

cost

2

hp (Honda)

mount

head

334606B 53

1

4

4

Page 54

Parts

267

ti25481a

241

236

265

233

237

234

235

242

243

247

238

239

240

248

244

245

249

253

255

254

252

250

251

262

232

246

231

230

229

227

261

264

256

257

258

259

228

263

236

96

197

44

144

84

85

87

4

55

3

266

285

286

299

3

6

2

5

2

4

3

7

1

2

34567

Parts - Reservoir and Filter

Torque to 58-62 in-lbs

(6.6-7.0 N·m)

Loctite 242

Torque to 90-110 in-lbs

(10.2-12.4 N·m)

Torque to 335-395 in-lbs

(37.9-44.6 N·m)

Torque to 15-25 in-lbs

(1.7-2.8 N·m)

Loctite 277

Torque to 110-120 in-lbs

(12.4-13.6 N·m)

1

54 334606B

Page 55

Parts List - Reservoir and Filter

Ref. Part Description Qty.

3 161889 FITTING, outlet 1

4 15E476 BRACKET, retainer,

motor

44 116914 BELT, V, AX42

(EH230DI)

119433 BELT, V, AX41

(GH230DI)

125834 BELT, V, AX48

(EH300DI)

119432 BELT, V, AX44

(GH300DI)

55 17D813 NUT, hand 2

84 198585 LABEL, hydraulic fluid, GH1

85 15A464 LABEL, control 1

87 189892 LABEL, Graco 1

96 15E410 PULLEY, fan 1

144 15K440 LABEL, brand, GH/EH

cooling

197 120087 SCREW, set, 1/4 x 1/2 2

227 15J513 TANK, reservoir, blue 1

228 101754 PLUG, pipe 1

229 120604 GASKET, reservoir 1

230 116919 FILTER 1

231 15E587 TUBE, suction 1

232 154594 PACKING, o-ring 1

233 15M056 COVER, reservoir 1

234 107188 PACKING, o-ring 4

235 156401 PACKING, o-ring 1

236 119426 SCREW, mach, hex

washer hd

237 120726 CAP, breather, filter 1

238 198841 RETAINER, ball,

pressure bypass

239 100084 BALL, metallic 1

240 116967 SPRING, compression 1

241 237686 WIRE, ground assembly

w clamp

242 249003 PUMP, hydraulic 1

243 110792 FITTING, elbow, male,

90°

244 15B438 KNOB, pressure 1

Ref. Part Description Qty.

245 117560 SCREW, set, socket

1

246 245167 TUBE, hydraulic, case

1

247 120634 FITTING, elbow,

248 246173 FILTER, oil, spin on 1

249 15E599 HOUSING, filter 1

1

250 15G331 PLUG, pipe 1

251 196178 ADAPTER, nipple 1

1

252 244067 FILTER, fluid 1

253 16C766 TUBE, diffusion 1

254 117285 PACKING, o-ring 1

255 16C765 CAP, filter 1

256* 287879 VAVLE, drain, assy 1

257* 114708 SPRING, comp 1

258* 15G563 HANDLE, valve 1

259* 116424 NUT, cap 1

1