Page 1

Instructions-Parts

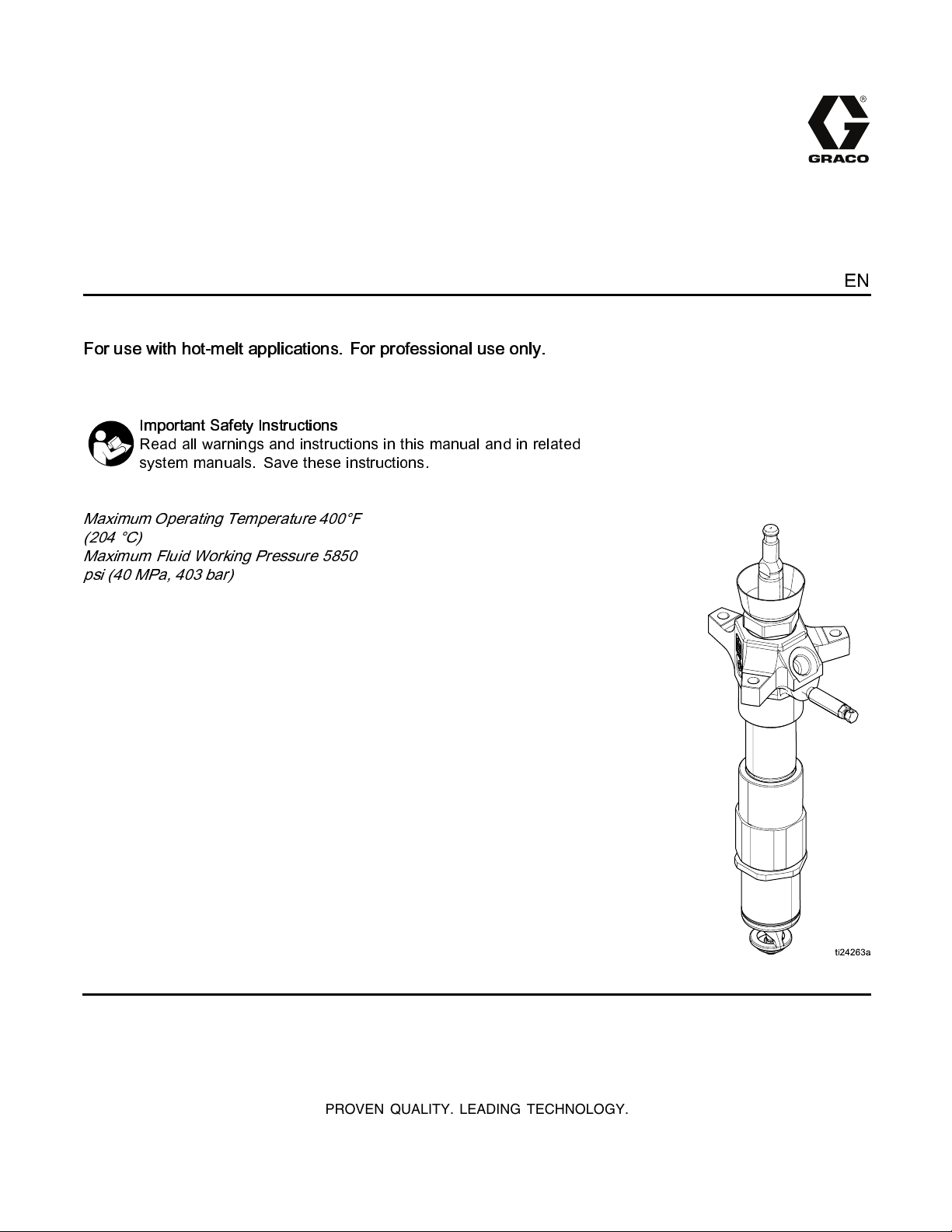

Check-Mate® 800

Displacement Pump

For use with hot-melt applications. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in related

system manuals. Save these instructions.

Maximum Operating Temperature 400°F

(204 °C)

Maximum Fluid Working Pressure 5850

psi (40 MPa, 403 bar)

334127A

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Models............................................................... 2

Related Manuals ................................................ 2

Warnings ........................................................... 3

Component Identification..................................... 6

Installation.......................................................... 7

Grounding ................................................... 7

Connect to a Graco Air Motor ....................... 7

Pressure Relief Procedure .................................. 8

Pump Startup, Adjustment, and Shutdown

Instructions ........................................... 8

Models

Part

24W152

24W153 5 G al lo n (20

24W150

24W151

Drum Size Seal material

5 G al lo n (20

Liter)

Liter)

55 Gallon (200

Liter)

55 Gallon (200

Liter)

Carbon Filled

PTFE

Glass Filled

PTFE

Carbon Filled

PTFE

Glass Filled

PTFE

Repair................................................................ 9

Required Tools ............................................ 9

Disconnect the Pump................................... 9

Replace Throat Packings.............................. 10

Replace Priming Piston ................................11

Replace Intake Valve ................................... 12

Repair Piston ............................................... 14

Parts.................................................................. 16

Technical Specifications...................................... 20

Notes ............................................................... 21

Graco Standard Warranty....................................22

Related Manuals

Manuals are available at www.graco.com

Component manuals in English:

334128

334131

334132 NXT®Air Motor Tie Rod Kit,

Throat Seal Repa ir Kit,

Instructions-Parts

Bulldog

Rod Kit, Instructions-Parts

Instructions-Parts

®

and Senator®Air Motor Tie

2

334127A

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific

risks. When these symbols appear in the body of this manual or on warning labels, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce

skin. This may look like just a cut, but it is a serious injury that can result in amputation.

immediate surgical treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Followthe

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or dam aged parts immediately.

Pressure Relief Procedure

when you stop dispensing and before cleaning,

Get

MOVING PARTS HAZARD

Moving parts can pinch, cut or amp utate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized eq uipment can start without warning. Before checking, moving, or servicing

equipment, follow the

Pressure Relief Procedure

and disconnect all power sources.

334127A 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in

prevent fire and explosion:

• Use equipment only in well v entilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work are a. See

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

•

Stop operation immediately

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid

severe burns:

• Do not touch hot fluid or equipm ent.

EQUIPMENT MISUSE HAZARD

if static sparking occurs or you feel a shock.Do not use

Grounding

work area

instructions.

canigniteorexplode.Tohelp

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applic able safety regulations.

Technical Data

Pressure Relief Procedure

in all equipment manuals.

when equi pment is not in use.

4

334127A

Page 5

Warnings

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protectiv e eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

334127A 5

Page 6

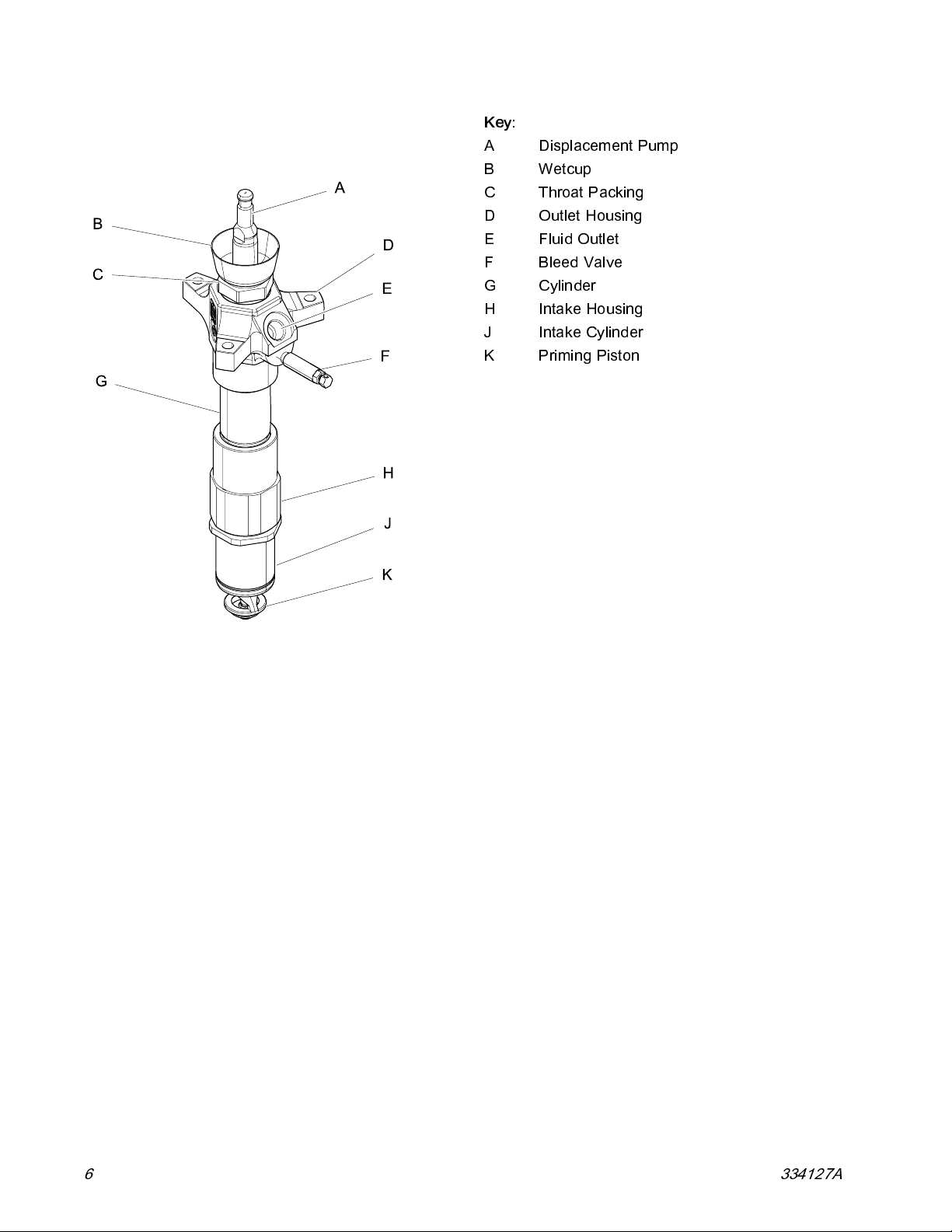

Component Identification

Component Identification

Key:

A Displacement Pump

BWetcup

C

D

E

FBleedValve

G Cylinder

H Intake Housing

J

KPrimingPiston

Throat Packing

Outlet Housing

Fluid Outlet

Intake Cylinder

6 334127A

Page 7

Installation

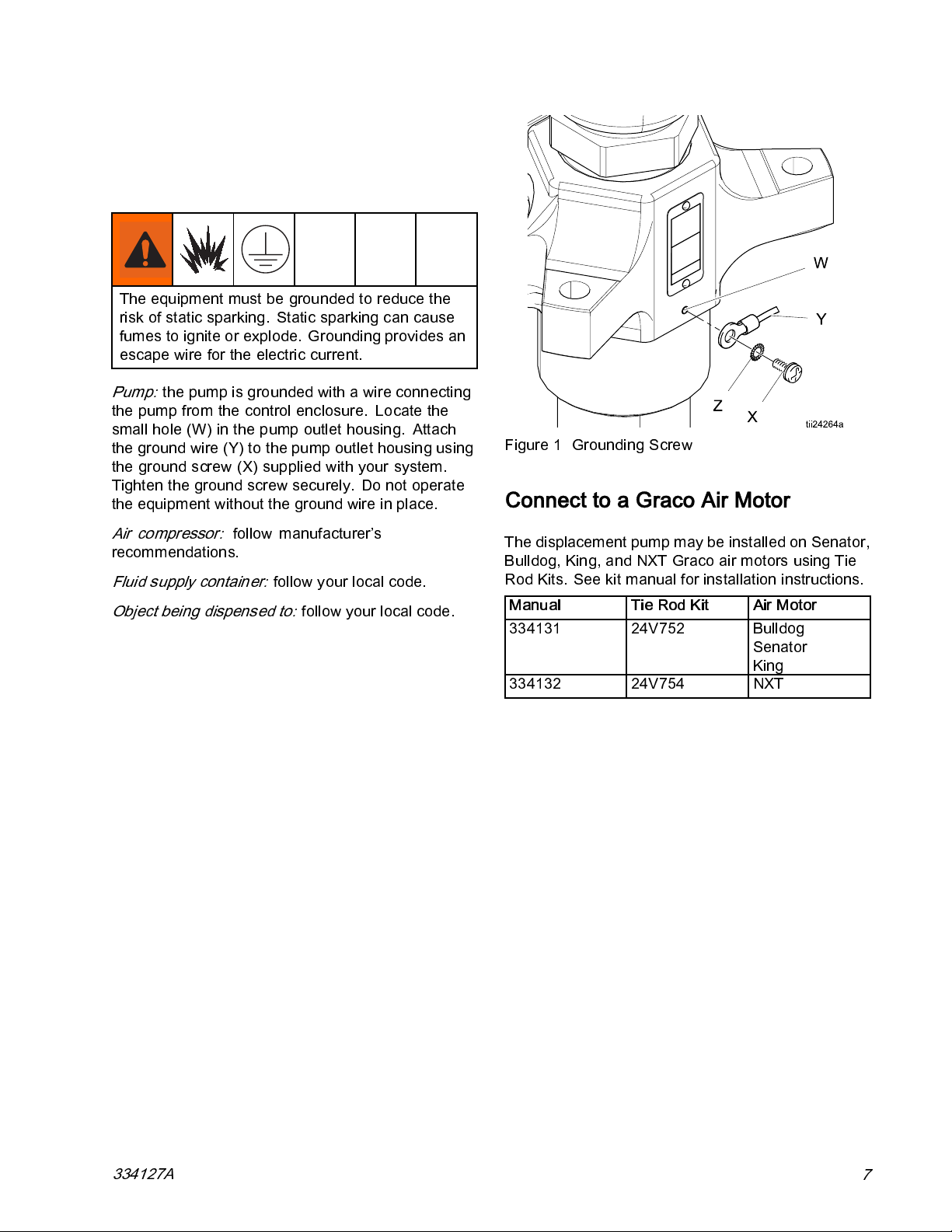

Grounding

The equipment must be grounded to reduce the

risk of static sparking. Static sparking can cause

fumes to i gn ite or explode. Grounding provides an

escape wire for the el ectric current.

Installation

Pump:

the pump from the control enclosure. Locate the

small hole (W) in the pump outlet housing. Attach

the ground wire (Y) to the pump outlet housing using

the ground screw (X) supplied with your system.

Tighten the ground screw securely. Do not operate

the equipment without the ground wire in place.

Air compressor:

recommendations.

Fluid supply container:

Object being dispensed to:

the pump is grounded with a wire connecting

follow manufacturer’s

follow your local code.

follow your local code.

Figure 1 Grounding Screw

Connect to a Graco Air Motor

The displacement pump may be installed on Senator,

Bulldog, King, and NXT Graco air motors using Tie

Rod Kits. See kit manual for installation instructions.

Manual Tie Rod Kit Air Motor

334131 24V752 Bulldog

Senator

King

334132 24V754 NXT

334127A

7

Page 8

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is manually relieved. To help preve nt serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure when you stop spraying

and before cleaning, checking, or servicing

equipment.

Heated fluid can cause severe burns and can

cause equipment surfaces to become very

hot. Wear protective gloves and clothing when

operating this equipment in a heated system. Allow

the equipment to cool thoroughly before servicing.

1. Lock the gun/valve trigger safety.

2. Close all air bleed valves (required in your

system) to shut off the air supply to the pump.

3. Unlock the gun/valve trigger safety.

4. Hold a metal part of the gun/valve firmly to the

side of a grounded metal pail, and trigger the

gun/valve to relieve pressure.

5. Lock the gun/valve trigger safety.

6. Open the pump bleeder valve (required in your

system), having a container ready to catch the

drainage.

7. Leave the pump bleeder valve open until you are

ready to spray/dispense again.

If you suspect that the spray tip/nozzle or hose is

completely clogged, or that pressure has not been

fully relieved after following the steps above, very

slowly loosen the tip retaining nut or hose end

coupling and relieve pressure gradually, then loo sen

completely. Now clear the tip/nozzle or hose.

Pump Startup,

Adjustment, and

Shutdown Instructions

See your separate system manual instructions.

8 334127A

Page 9

Repair

Repair

Required Tools

• Torque wrench

• Bench vise, with soft jaws

• Rubber malle t

•Hammer

• O-ring pic k

• 13mm(1/2in.)dia.brassrod

• Set of socket wrenches

• Set of adjustable wrenches

•Pipewrench

• Screwdriver

• Heat gun

•Gloves

• Thread lubricant

• Thread sealant

Note

Theprimingpistoncanbeserviced

without disconnecting the displacement

pump from the motor. see

Replace Priming Piston, page 11.

1. Flush the pump, if possible. Stop the pump at the

bottom of its stroke, to prevent fluid from drying

on the exposed displacement rod.

2. Relieve the pressure. See

Pressure Relief Procedure, page 8 .

3. Allow the pump to cool if being used in a heated

system.

Note

It may be necessary to use a heat gun to

ease disassembly of some parts.

4. Disconnect the air and fluid hoses.

5. Disconnect the pump from the heated platen.

6. Disconnect the displacement pump from the

motor as explained in your separate system

manual.

Disconnect the Pump

Heated fluid can cause severe burns and can

cause equipment surfaces to become very

hot. Wear protective gloves and clothing when

operating this equipment in a heated system. Allow

the equipment to cool thoroughly before servicing.

334127A 9

Page 10

Repair

Replace Throat Packings

Note

The throat packings are available as a

preassembled kit.

Pump Part No.

24W152 24V752

24W153 24V753

24W150 24V752

24W151 24V753

1. Relieve the pressure. See

Pressure Relief Procedure, page 8 .

2. See Fig. 2. Unscrew the packing nut (2) using a

pipe wrench. Remove the o-ring (27) and washer

(26) from the bottom of the packing housing (25)

or from the outlet housing (3).

Throat Seal Repair

Kit

6. If necessary, use an arbor press to install o-ring

(27) in packing housing (25).

7. Screw the packing nut (2) and packing housing

(25) into the outlet housing (3). Torque to 150 ±

30 ft-lb (203 ± 41 N•m).

3. Place the flats of the packing nut (2) in a vise.

Unscrew the packing housing (25) and discard it

and the packings. Remove the washer (24), seal

(23), and backup washer (22) from the packi ng

nut.

4. The throat repair kit is preassembled. Screw the

kit into the packing nut (2), making sure that th e

backup washer (22), seal (23), and washer (24)

are properly positioned on top of the packing

housing (25), with the lips of the seal facing

down. Torque the packing housing (25) to 225

±10 ft-lb (305 ± 14 N•m).

5. Before installing packing housing into pump,

generously lubricate seals with high temperature

grease supplied with repair kit.

Figure 2 Throat Packings

Torque to 225 ± 10 ft-lb (305 ± 14 N•m).

1

Torque to 150 ± 30 ft-lb (203 ± 41 N•m).

2

Lips of u-cup packing must face down.

3

10 334127A

Page 11

Repair

Replace Priming Piston

Pump Part No. Repair Kit

24W152 237910

24W153 237910

24W150 237909

24W151 237909

1. Stop the pump on the downstroke, with the flats

of the priming piston rod (17) exposed below

the intake cylinder (18). It is not necessary to

disconnect the displacement pump from the

motor, but you may have to disconnect it from

the heated platen.

2. Relieve the pressure. See

Pressure Relief Procedure, page 8 .

3. Hold the flats of the priming piston rod (17) with

an adjustable wrench, and use a second wrench

to unscrew the priming piston seat (21) from the

rod. Slidetheprimingpiston(20)offtherod.

Inspect the inner and outer surfaces of the piston

(20) for scoring, wear, or other damage.

4. Slide the priming piston (20) onto the rod (17)

until it stops. Hold the rod (17) steady wit h a

wrench on the flats, and screw th e seat (21) onto

the rod with another wrench. Torque to 60 ± 3

ft-lb(81±4N•m).

Figure 3 Priming Piston

334127A

Torque to 60 ± 3 ft-lb (81 ± 4 N•m).

1

ue to 390 ± 45 ft-lb (529 ± 61 N•m).

Torq

2

Torque to 150 ± 30 ft-lb (203 ± 41 N•m).

3

11

Page 12

Repair

Replace Intake Valve

Note

The intake valve (V) is available as a

preassembled, pre–lubricated kit. The kit

includes the valve and all seals and packings,

and also includes the intake valve seat (15)

and seal (16). See Fig. 5.

Pump Part No. Repair Kit

24W152 253546

24W153 237907

24W150 253546

24W151 237907

1. Relieve the pressure. See

Pressure Relief Procedure, page 8 .

2. Disconnect the displacement pump. See system

manual for instructions.

3. Place the pump in a vise, with the outlet housing

(3) positioned as shown.

4. Remove priming piston (20). See

Replace Priming Piston, page 11.

5. Usingapipewrenchonthehexoftheintake

cylinder (18), unscrew it from the intake housing

(13).

Figure 4 Intake Valve

12

334127A

Page 13

Repair

6. Pull the intake seat (15) and seal (16) out the

bottom of the intake housing (13).

Note

If the seat (15) is difficult to remove,

insert a brass rod through the top of the

housing (13) and drive the seat out with

a hammer.

Figure 5

10. Lubricate the priming piston rod (17), then slide

the preassembled intake valve (V) onto the rod,

making certain that the packing nut (31) goes on

the rod first. Push the valve assembly up the

rod as far as possible. Use a rubber mallet on

theprimingpistonrod(17),todrivethevalve

assembly up to the stop (VS).

11. The intake seat (15) is reversible. Push it into

the housing (13) until it seats securely. Lubricate

the seal (16) and install in the bevel around the

bottom of the seat.

12. Screw the intake cylinder (8) into the intake

housing(13).Usingapipewrenchonthehexof

the cylinder (8), torque the cylinder to 385–400

ft-lb (522–542 N•m).

13. Replace priming piston. See

Replace Priming Piston, page 11.

14. Reconnect the displacement pump to the air

motor as explained in your separate system

manual.

7. Firmly tap the piston rod with a rubber mallet and

until the valve assembly comes free. Take care

not to drop the valve assembly (V) as it comes

free.

8. To repair the piston, cylinder, seals, and rods,

see Repair Piston, page 14.

9. Slide the intake housing (13) onto the priming

piston rod (17), making certain that the smooth

surfaceofthevalvestop(VS)isfacingdown

toward the pump intake. Screw the housing (13)

onto the cylinder (8).

Figure 6

334127A 13

Page 14

Repair

Repair Piston

Note

The piston valve is available as a

preassembled, pre–lubricated kit. The kit

includes the piston seat/guide assembly (P,

items 6, 9, 10, 11, and 12). Order Part No.

237906.

1. Follow Replace Intake Valve, page 12,to

disassemble the pump.

2. Remove outlet housing (3).

3. Using a rubber mallet, drive the displacement

rod (1) and the priming piston rod (17) out of the

cylinder (8). Inspect the outer surfaces of the

rods for damage by running a finger over the

surface.

4. Remove the seal (6) from the bottom of the

cylinder (8). See Fig. 7. Shine a light into the

cylindertoexaminetheinsidesurfaceforscoring

or damage.

or there is evidence of leaking around the top

cylinder seal (6),

outlet housing, using a pipe wrench. Remove the

top cylinder seal.

Figure 8

5. Place the flats of the displacement rod (1)

in a vise. Unscrew the piston (9) from the

displacement rod; the priming piston rod (17)

will come with it. Slide the piston seat/guide

assembly (10, 11, and 12) off the piston (9).

Only if the cylinder is damaged,

unscrew the cylinder from the

14

Figure 7

Figure 9

334127A

Page 15

Repair

6. Place the piston (9) flats in a vise and unscrew

the rod (17).

7. Place the preassembled piston seat/guide

assembly (P, items 10, 11, and 12) onto the

piston (9) so the 45 beveled seating surfaces

match.

8. Place the flats of the displacement rod (1) in a

vise. Screw the piston (9) onto the displacement

rod (1) hand tight, then torque to 250–265 ft-lb

(339–359 N•m).

Figure 10

it on the top of the cylinder. (The cylinder is

symmetrical, so either end can be the top.)

Screw the cylinder into the valve housing.

Figure 12

11. Screw the outlet housing (3) onto the cylinder.

Torque to 390±45 ft-lbs (528± 61 N•m).

12. Lubricate the displacement rod (1). Slide the rod,

piston assembly, and priming piston rod (17) into

the cylinder (10) from the bottom, until the top of

the rod (1) protrudes from the pack ing nut (2).

9. Using an adjustable wrench on the flats of the

priming piston rod (17), screw the rod into the

piston (9). Torque to 92–101 ft-lb (125–137 N•m).

Be careful not to create burrs on the flats of the

rod.

Figure 11

10. If the cylinder (8) was removed from the valve

housing (13), lubricate the seal (6) and place

Figure 13

13. Lubricate the seal (6) and install it on the bottom

of the cylinder (8).

14. Follow ReplaceIntakeValve,page12,to

assemble the pump.

334127A 15

Page 16

Parts

Parts

5 Gallon (20 Liter) Pumps

24W152, Pump with Carbon Filled Seals

24W153, Pump with Glass Filled Seals

Torque to 25 +/- 2 ft-lbs (25 +/- 2.7 N•m)

1

Torque to 390 +/- 45 ft-lbs (528 +/- 61 N•m)

2

Torque to 150 +/- 30 ft-lbs (203 +/- 40 N•m)

3

Torque to 60 +/- 3 ft-lbs (81 +/- 4 N•m)

4

Torque to 97 +/- 5 ft.-lbs (131 +/- 7 N•m)

5

16 334127A

Torque to 225 +/- 10 ft-lbs (131 +/- 13 N•m)

6

Torque to 255 +/- 16 ft-lbs (345 +/- 21 N•m)

7

Torque to 75 +/- 4 ft-lbs (101 + /- 5 N•m)

8

Apply lubricant.

9

Apply sealant to threads.

10

Page 17

24W152, Pump with Carbon Filled Seals

24W153, Pump with Glass Filled Seals

Parts

Part Description

Ref.

1 16Y958

2 237799 NUT, packing 1

3 190598

4 237908 BLEEDER VALVE KIT 1

5

190620

113040

6*

15M521

7*

8 189437

189439

9*

15M520

10*

113355

11*

189441

12*

13 190597

14 189514 VALVE, intake 1

15 189446

16 113041

17 184400

18 190608

19 113054

20

190606

21

190607

22

★

195233

ROD, displacement,

chromex, 11cm

HOUSING, outlet

FLANGE

PACKING, o-ring

BEARING, piston guide

CYLINDER, pump

SEAT, piston, sst

GUIDE, piston, 200

BEARING, piston

SEAT, piston

HOUSING, valve

SEAT, valve

PACKING, o-ring

ROD, piston

CYLINDER, intake

PACKING, o-ring

PISTON, pump

SEAT, piston

WASHER, seal back-up

Qty

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Part Description

Ref.

23

★

120286

113021

24

★

195234

★

190585 NUT, packing 1

25

26

★

195232

27

★

104537

28

113015

29

190523

30

120285

113020 PACKING, u-cup (assemb ly

31

190762 NUT, seal 1

32

184246

33

109301

34

184196

35 100508

36 189848 PLATE, designation 1

37 101754

38

▲

184090 LABEL, warning 1

39

▲

172479

PACKING, u-cup (assembly

24W152 only)

PACKING, u-cup (assembly

24W153 only)

WASHER, scraper 1.476 x

2.157

WASHER, rod scraper

PACKING, o-ring, ptfe

RING, retainer

WASHER, retainer

PACKING, u-cup (assembly

24W152 only)

24W153 only)

GLAND, packing male

PACKING, vee

GLAND, packing female

SCREW, drive

PLUG, pipe

TAG, warning

Qty

2

2

1

1

1

1

1

1

1

1

4

1

6

1

1

▲

Replacement Warning labels, signs, tags, and

cards are available at no cost.

Repair Kits

Throat

Piston * 237906

334127A

★

24W152 24W153

24V572 24V573

Repair Kits

Intake Valve

Priming Piston

24W152 24W153

253546 237907

237910

17

Page 18

Parts

55 Gallon (200 Liter) Pumps

24W150, Pump with Carbon Filled Seals

24W151, Pump with Glass Filled Seals

Torque to 25 +/- 2 ft-lbs (25 +/- 2.7 N•m)

1

Torque to 390 +/- 45 ft-lbs (528 +/- 61 N•m)

2

Torque to 150 +/- 30 ft-lbs (203 +/- 40 N•m)

3

Torque to 60 +/- 3 ft-lbs (81 +/- 4 N•m)

4

Torque to 97 +/- 5 ft.-lbs (131 +/- 7 N•m)

5

Torque to 225 +/- 10 ft-lbs (131 +/- 13 N•m)

6

Torque to 255 +/- 16 ft-lbs (345 +/- 21 N•m)

7

Torque to 75 +/- 4 ft-lbs (101 + /- 5 N•m)

8

Apply lubricant.

9

Apply sealant to threads.

10

18 334127A

Page 19

24W150, Pump with Carbon Filled Seals

24W151, Pump with Glass Filled Seals

Parts

Part Description

Ref

1 16Y958

2 237799 NUT, packing 1

3 190598

4 237908 BLEEDER VALVE KIT 1

113040

6*

15M521

7*

8 189437

189439

9*

15M520

10*

113355

11*

189441

12*

13 190597

14 189514 VALVE, intake 1

15 189446

16 113041

17 184400

18 190586

19 109482

20

276378

21

190241

22 195233

ROD, displacement,

chromex,11cm

HOUSING, outlet

PACKING, o-ring

BEARING, piston guide

cm200

CYLINDER, pump

SEAT, piston, sst

GUIDE, piston, 200

BEARING, piston

SEAT, piston

HOUSING, valve

SEAT, valve

PACKING, o-ring

ROD, piston

CYLINDER, intake

PACKING, o-ring

PISTON,

SEAT, piston

WASHER, seal back-up

Qty

Part Description

Ref

23

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

★

113021

120286

24

★

195234

★

190585 NUT, packing 1

25

26

★

195232

27

★

104537

28

113015

29

190523

30

113020

31

190762 NUT, seal 1

32

184246

33

109301

34

184196

35 100508

36 189848 PLATE, designation 1

37 101754

38

▲

184090 LABEL, warning, moving

39

▲

172479

PACKING, u-cup (24W151

only)

PACKING, u-cup (24W150

only)

WASHER, scraper 1.476 x

2.157

WASHER, rod scraper

PACKING, o-ring, ptfe

RING, retainer

WASHER, retainer

PACKING, u-cup

GLAND, packing male

PACKING, vee

GLAND, packing female

SCREW, drive

PLUG, pipe

parts

TAG, warning

Qty

2

2

1

1

1

1

1

1

1

4

1

6

1

2

2

▲

Replacement Warning labels, signs, tags, and

cards are available at no cost.

Repair Kits

Throat

Piston * 237906

334127A 19

★

24W150 24W151

24V572 24V573

Repair Kits

Intake Valve

Priming Piston

24W150 24W151

237907 253546

237909

Page 20

Technical Specifications

Technical Specifications

Check-Mate 800 Displacement Pump

US

Maximum fluid working pressure

Displacement pump effective area 1.24 in.

Maximum pump operating

temperature

Fluid outlet size

Wetted parts

Weight

24W152 59 lb 27 kg

24W153 59 lb 27 kg

24W150 59 lb 27 kg

24V020 59 lb 27 kg

Length

On Upstroke

On Downstroke (priming piston

exposed)

5850 psi 40 MPa, 403 bar

2

400°F 200°C

1 in. npt(f)

Carbon steel, chrome, zinc, nickel plating, alloy steel, ductile iron,

fluoroelastomer, PTFE, bronze, stainless steel (304, 316, 440, and

17–4 PH)

31.15 in 791.2 mm

33.75 in 857.2 mm

8cm

2

Metric

20 334127A

Page 21

Notes

Notes

334127A

21

Page 22

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for use.

With the exc

twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance

with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco

be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation,

operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized

Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace

free of charge any defective parts. The equipment will be returned to the original purchaser transportation

prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be

made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The

buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost

profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall be available.

Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT,

MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO.

manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of

their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of

these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco

supplying equipment hereunder, or the furnishing, performance, or use of any products or other goods sold

hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices

and legal proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be

drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en

Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de ou

en rapport, directement ou indirectement, avec les procédures concernées.

eption of any special, extended, or limited warranty published by Graco, Graco will, for a period of

These items sold, but not

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

To place an order,

Phone:

612-623-6921

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

contact your Graco Distributor or call to identify the nearest distributor.

or Toll Free:

Graco reserves the right to mak e changes at any time without notice.

Original Instructions. This manual contains English. M M 334127

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

1-800-328-0211

Graco Headquarters:

International Offices:

www.graco.com

Revision A, December 2014

Fax:

612-378-3505

Minneapolis

Belgium, China, Japan, Korea

Loading...

Loading...