Page 1

Operation

®

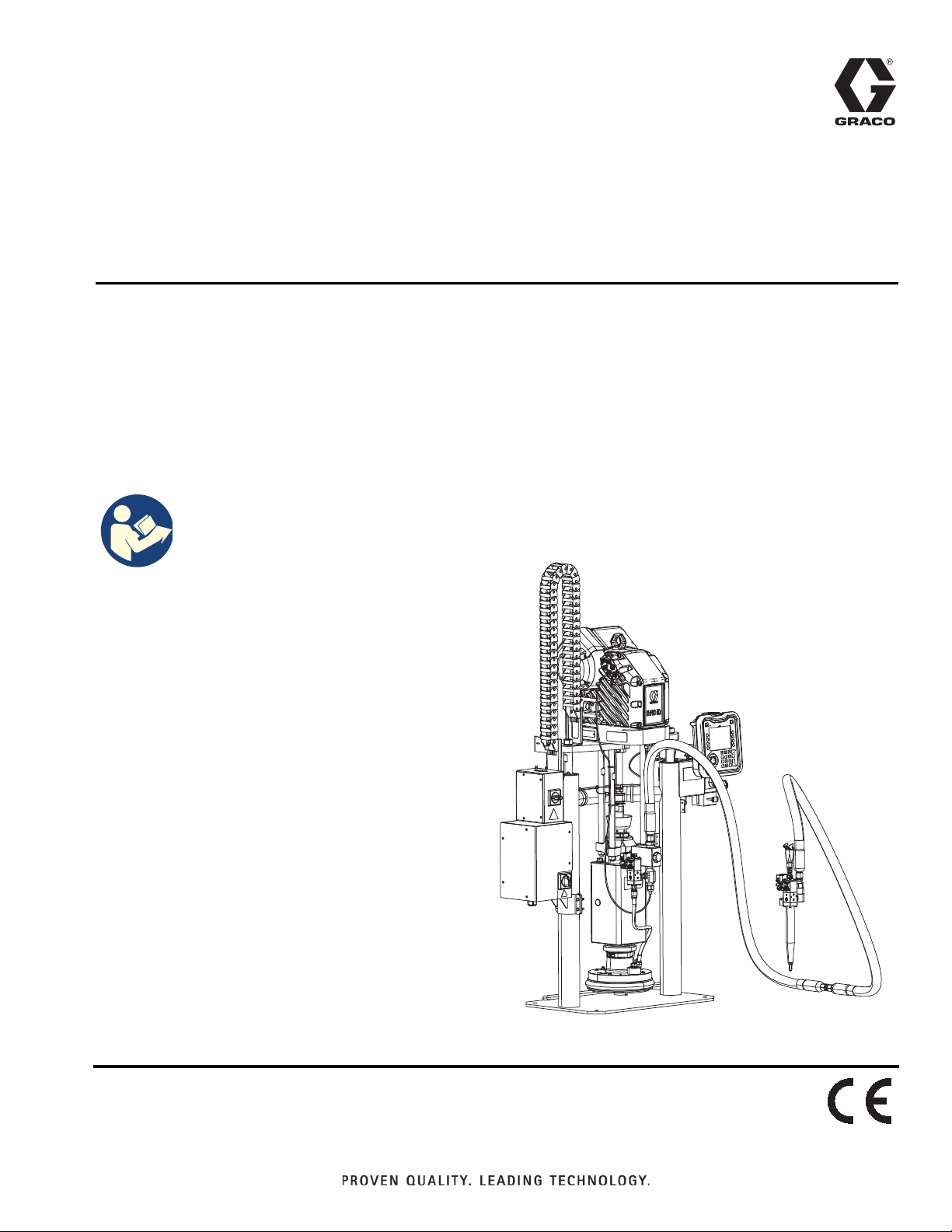

E-Flo

iQ Dispense

333587C

System

For dispensing and metering sealants, adhesives, and other medium to high viscosity

fluids. For professional use only.

Not approved for use in explosive atmospheres or hazardous (classified) locations.

See page 5 for system component information.

Important Safety Instructions

Read all warnings and instructions in this

manual and in all related manuals before

using the equipment. Save all

instructions.

EN

Page 2

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Dispense System Configurator . . . . . . . . . . . . . . . . 4

Dispense System Components. . . . . . . . . . . . . . . . 5

iQ Ram Supply Units . . . . . . . . . . . . . . . . . . . . . . 5

iQ Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . 6

Hose Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Dispense System Pressure . . . . . . . . . . . . . . . . . . . 7

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dispense System Component Identification . . . . 11

Tandem Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Supply Unit Component Identification . . . . . . . . . 13

iQ Ram Supply Unit . . . . . . . . . . . . . . . . . . . . . . 13

Power Disconnect . . . . . . . . . . . . . . . . . . . . . . . 14

Integrated Air Controls (AG) . . . . . . . . . . . . . . . 15

Integrated Air Line Accessories . . . . . . . . . . . . . 15

Advanced Display Module (ADM) . . . . . . . . . . . 16

ADM Display Details. . . . . . . . . . . . . . . . . . . . . . . . 17

ADM LED Status Descriptions . . . . . . . . . . . . . . 19

ADM Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADM Soft Keys. . . . . . . . . . . . . . . . . . . . . . . . . . 20

iQ Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System Setup Screen . . . . . . . . . . . . . . . . . . . . 23

Style Definitions . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Heat Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Advanced Setup. . . . . . . . . . . . . . . . . . . . . . . . . 31

Connect Light Tower Assembly . . . . . . . . . . . . . 33

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Flush the Pump . . . . . . . . . . . . . . . . . . . . . . . . . 34

Load Material . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Tandem Priming when Changing Drums . . . . . . 37

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Ram Run Screen . . . . . . . . . . . . . . . . . . . . . . . . 38

Tandem Run Screen . . . . . . . . . . . . . . . . . . . . . 39

Run Screen Editing Mode . . . . . . . . . . . . . . . . . 42

Heat Run Screen . . . . . . . . . . . . . . . . . . . . . . . . 42

Job Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Events and Errors . . . . . . . . . . . . . . . . . . . . . . . 45

Pressure Relief Procedure. . . . . . . . . . . . . . . . . . . 46

Shutdown the System . . . . . . . . . . . . . . . . . . . . . . 48

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Pump Maintenance Screen 1. . . . . . . . . . . . . . . 49

Pump Maintenance Screen 2. . . . . . . . . . . . . . . 50

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pump Diagnostics Screen . . . . . . . . . . . . . . . . . 51

Heat Diagnostics Screen . . . . . . . . . . . . . . . . . . 51

Pressure Diagnostics Screen . . . . . . . . . . . . . . . 52

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

View Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Troubleshoot Errors . . . . . . . . . . . . . . . . . . . . . . 53

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

USB Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Download Procedure . . . . . . . . . . . . . . . . . . . . . 64

USB Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Job Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Automation Log . . . . . . . . . . . . . . . . . . . . . . . . . 65

System Configuration Settings . . . . . . . . . . . . . . 65

Custom Language File . . . . . . . . . . . . . . . . . . . . 65

Create Custom Language Strings . . . . . . . . . . . 66

Upload Procedure. . . . . . . . . . . . . . . . . . . . . . . . 66

Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Discrete Inputs/Outputs . . . . . . . . . . . . . . . . . . . 67

Job Cycle Timing Diagram . . . . . . . . . . . . . . . . . 69

Discrete Timing Diagram . . . . . . . . . . . . . . . . . . 70

Communications Gateway Module (CGM). . . . . 71

Prime Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Depressurize Diagram . . . . . . . . . . . . . . . . . . . . 87

System Enable - Remote Start Diagram . . . . . . 88

Acknowledge - Clear Error Diagram. . . . . . . . . . 88

Manual Crossover Diagram . . . . . . . . . . . . . . . . 89

Data Exchange Diagram . . . . . . . . . . . . . . . . . . 89

Power Reset Diagram . . . . . . . . . . . . . . . . . . . . 90

Heat CGM Timing Diagram . . . . . . . . . . . . . . . . 90

Heat Module Acknowledge-Clear Error Diagram 91

Heat Zone Acknowledge-Clear Error Diagram . . 91

Heat CGM Data Exchange Diagram . . . . . . . . . 92

Connection Details . . . . . . . . . . . . . . . . . . . . . . . 93

Gateway Setup Screens . . . . . . . . . . . . . . . . . . . 96

Integration Feedback Screens . . . . . . . . . . . . . . 99

Technical Specifications . . . . . . . . . . . . . . . . . . . 100

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . 101

End of Product Life . . . . . . . . . . . . . . . . . . . . . . 101

California Proposition 65 . . . . . . . . . . . . . . . . . . . 101

Graco Standard Warranty . . . . . . . . . . . . . . . . . . 102

2 333587C

Page 3

Related Manuals

Related manuals in English:

Manual Description

333585 iQ Dispense Valves, Instructions-Parts

333586 E-Flo iQ Dispense System, Installation-Parts

3A6321 ADM Token In-System Programming

312493 Light Tower Kit Instructions

3A1244 Graco Control Architecture Module

3A6482 APD20 Advanced Precision Driver

313138 Supply System Communications Gateway

Module Installation Kit

Related Manuals

333587C 3

Page 4

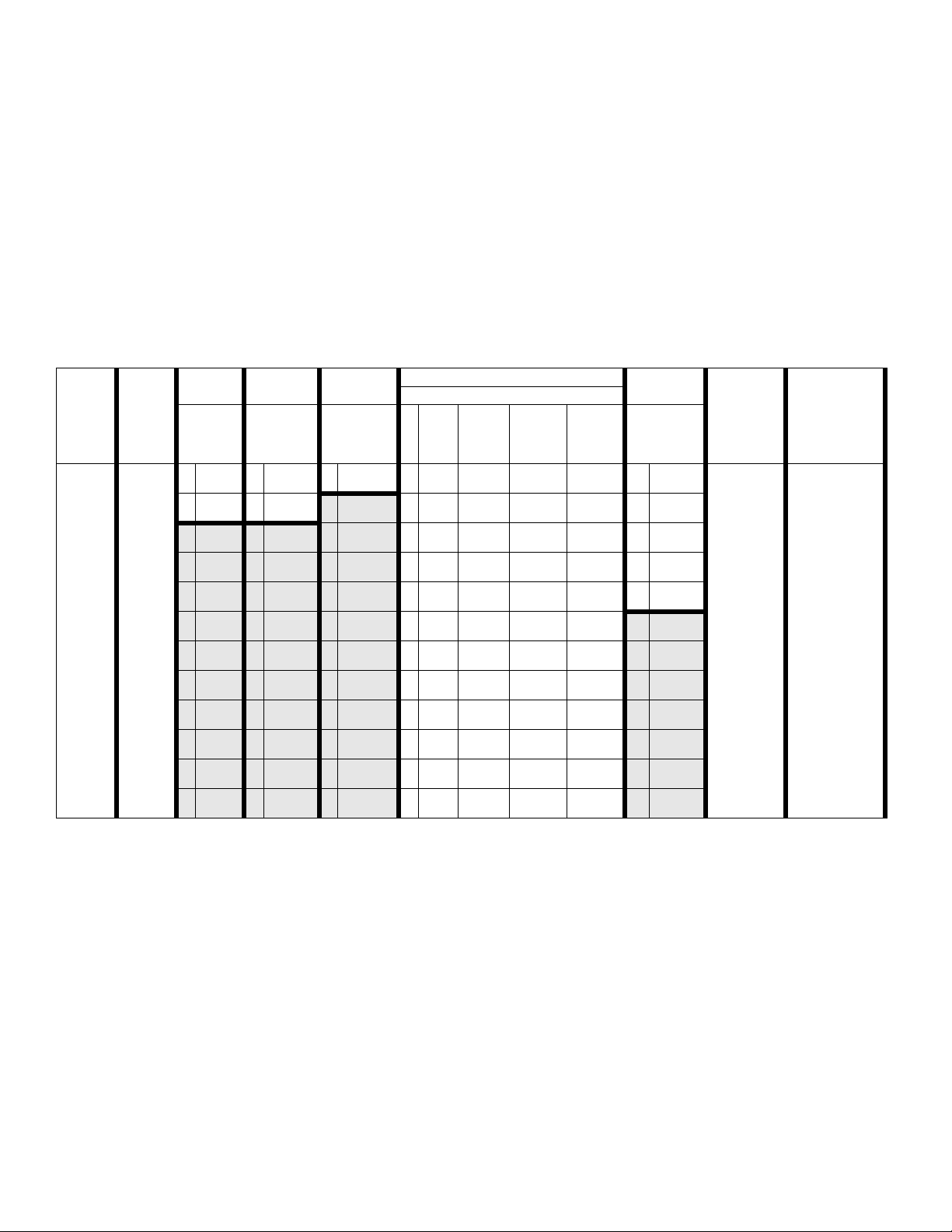

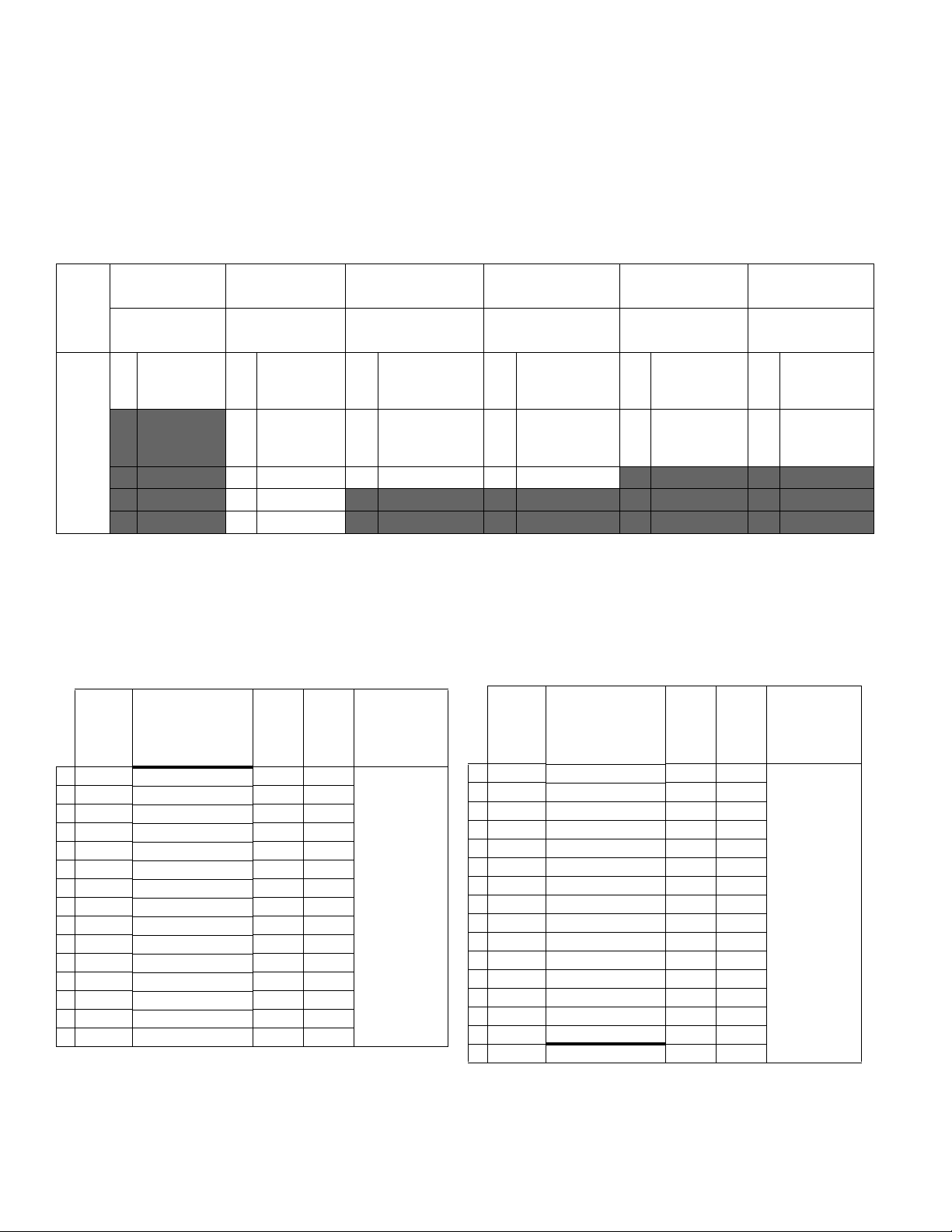

Dispense System Configurator

Dispense System Configurator

The E-Flo iQ dispense system provides the flexibility to configure a complete system to meet your specific needs.

This includes offering multiple combinations of the following components:

• iQ Ram Supply Units

• iQ Dispense Valves

• Hoses and connectors

For dispense system component information, see Dispense System Components on page 5.

First,

Second

and

Third

Digit

EQC

E-Flo iQ

System

Fourth

Digit

Revision

Fifth

Digit Sixth Digit

Seventh

Digit

Platen

Single or

Tandem

S Single H Heated Y Yes

T Tan-

dem

Heat

Option

A Ambient

Valve

Option

Eighth Digit

Ram Supply Unit Options

Size

A 3 in.

B 3 in.

C 3 in.

D 3 in.

F 3 in.

G 3 in.

H 3 in.

J 3 in.

K 6.5 in.

M 6.5 in.

N 6.5 in.

P 6.5 in.

Drum

Size

20 L

(5 Gal) CS EPDM

20 L

(5 Gal) CS

20 L

(5 Gal) CM EPDM

20 L

(5 Gal) CM

200 L

(55 Gal) CS EPDM

200 L

(55 Gal) CS

200 L

(55 Gal) CM EPDM

200 L

(55 Gal) CM

200 L

(55 Gal) CS EPDM

200 L

(55 Gal) CS

200 L

(55 Gal) CM EPDM

200 L

(55 Gal) CM

Pump

Material

Seal

Material

Neo-

prene

Neo-

prene

Neo-

prene

Neo-

prene

Neo-

prene

Neo-

prene

Ninth Digit

Fieldbus

Option

A Ether-

Net/IP

B PROF-

INET

C PROFI-

BUS

D Devi-

ceNet

N None

Digits Ten

through

Seventeen

Hose

Options for

Tandem

Hoses (Dig-

its 10-13)

and Supply

Hoses (Dig-

its 14-17)

(See Hose

Options on

page 6)

Digits

Eighteen

through

Twenty Seven

Valve Options

(See the iQ

Dispense

Valves Instruc-

tions - Parts

manual for

valve model

options)

KEY:

CS = Carbon Steel Severe Duty

CM = Carbon Steel MaxLife

®

®

4 333587C

Page 5

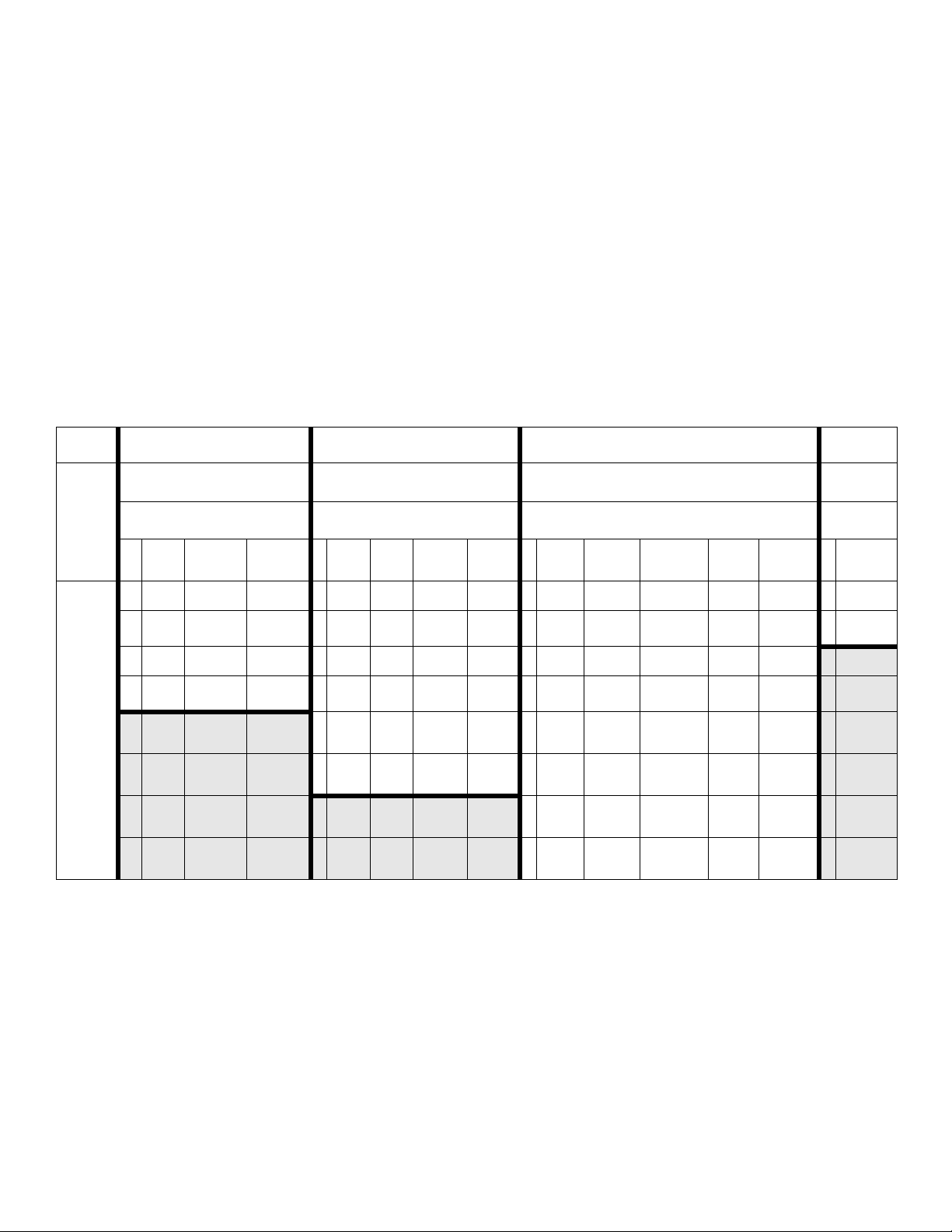

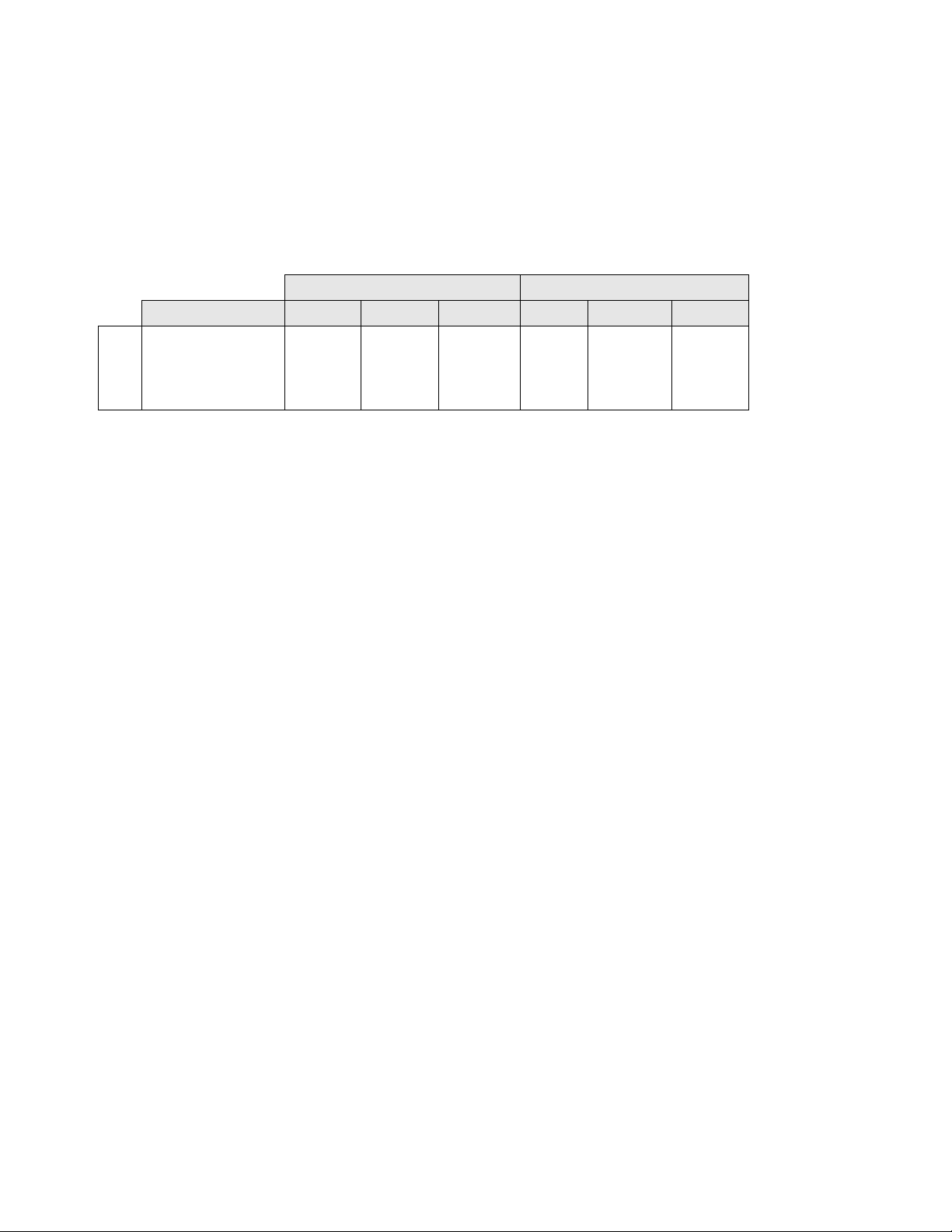

Dispense System Components

Dispense System Components

NOTE: The Heated option for the E-Flo iQ system is for warm melt applications with a maximum temperature of 70° C

(158° F).

iQ Ram Supply Units

Check the identification plate (ID) on the back of the ram post near the Power Junction Box (AJ) for the seven-digit part

number of the iQ ram supply unit. Use the following matrix to define the construction of the unit, based on the seven digits.

For example, Part No. EZC2422 represents an electric supply unit (EZ), a carbon steel Check-Mate 200 Severe Duty dis-

placement pump (C2), a 3 in. ram (4), a 5-gallon platen with a neoprene seal (2), and an ADM (2).

The digits in the following matrix do not correspond to the reference numbers in the Parts drawings and lists.

EZ C2 4

First

and

Second

Digit

EZ

(Electric

Supply

System)

Third and Fourth Digit Fifth Digit

Check-Mate Pump Options Ram Options

Pump

Size

Material

C1 200cc CS Ambient

C2 200cc CS Heated

C3 200cc CM Ambient

C4 200cc CM Heated

Heated/

Ambient

<70° C 2 D200 3 in.

<70° C 4 D60 3 in.

Name Size

1 D60 3 in.

3 D200s 6.5 in.

5 D200 3 in.

6 D200s 6.5 in.

Drum

Size Style

20 L

(5 Gal) Ambient 1

200 L

(55 Gal) Ambient 2

200 L

(55 Gal) Ambient 3

Heated

20 L

(5 Gal)

200 L

(55 Gal)

200 L

(55 Gal)

<70° C 4

Heated

<70° C 5

Heated

<70° C 6

Sixth Digit

Platen and Seal Options

Platen

(5 Gal) CST/AL Neoprene

(5 Gal) CST/AL Neoprene

(5 Gal) CST/AL EPDM

(5 Gal) CST/AL EPDM

200 L

200 L

200 L

7

200 L

8

Platen

Size

Material

20 L

20 L

20 L

20 L

(55

Gal) AL Neoprene

(55

Gal) AL Neoprene

(55

Gal) AL EPDM

(55

Gal) AL EPDM

Material Wiper

22

Seventh

Digit

Interface

Options

Seal

Single

Single

Single

Single

Double

Double

Double

Double

Heated/

Ambient Interface

Ring Ambient 2 ADM

Heated

Ring

Ring Ambient

Ring

Ring Ambient

Ring

Ring Ambient

Ring

<70° C 4No ADM

Heated

<70° C

Heated

<70° C

Heated

<70° C

KEY:

CS = Carbon Steel Severe Duty

CM = Carbon Steel MaxLife

CST/AL = Carbon Steel/Aluminum

AL = Aluminum

333587C 5

Page 6

Dispense System Components

iQ Dispense Valves

Check the identification plate on the valve for the ten-digit part number of the iQ dispense valve. Use the following

matrix to define the construction of the valve, based on the ten digits. For example, Part No. V25AB060BA

represents a valve (V) with 1/4 in. NPT inlet ports (25), NPT tip (A), ball/seat type (B), 60 mm outlet block length

(060), solenoid (B), with no heat (A).

First

Digit

Second and

Third Digit

Fourth Digit Fifth Digit

Size Tip Size Type

Sixth, Seventh,

and Eighth Digit

Outlet Block

Length

Ninth Digit Tenth Digit

Action Heat

Valve

25

1/4 in. NPT

A 1/4 in. NPT B Ball/Seat 000 NA B

Mounted

A None

Solenoid

60 mm

V

C 0.6 mm S Snuff-Back 060

D

*Remote

Solenoid

B Heated

Block

D 1.0 mm T Tip Seal 200

200 mm

F 1.3 mm

G 1.7 mm

* Remote solenoid supplied by customer.

NOTE: Refer to the iQ Dispense Valves Instructions-Parts manual for additional information about iQ Dispense

Valves. See Related Manuals on page 3

Hose Options

Working

Pressure

Temperature

Rating

4000 psi (28

MPa, 276 bar) at

-65° F - 400° F

(101° C - 204°

Part No. JIC Dash Size Length Heat

04 19M404 -10 (5/8 in, 15.9 mm) 6 ft Heated

05 19M405 -10 (5/8 in, 15.9 mm) 10 ft Heated

06 19M406 -10 (5/8 in, 15.9 mm) 15 ft Heated

07 19M407 -10 (5/8 in, 15.9 mm) 20 ft Heated

08 19M408 -10 (5/8 in, 15.9 mm) 25 ft Heated

11 19M411 -12 (3/4 in, 19.0 mm) 6 ft Heated

12 19M412 -12 (3/4 in, 19.0 mm) 10 ft Heated

13 19M413 -12 (3/4 in, 19.0 mm) 15 ft Heated

14 19M414 -12 (3/4 in, 19.0 mm) 20 ft Heated

15 19M415 -12 (3/4 in, 19.0 mm) 25 ft Heated

16 19M416 -16 (1 in, 25.4 mm) 6 ft Heated

17 19M417 -16 (1 in, 25.4 mm) 10 ft Heated

18 19M418 -16 (1 in, 25.4 mm) 15 ft Heated

19 19M419 -16 (1 in, 25.4 mm) 20 ft Heated

20 19M420 -16 (1 in, 25.4 mm) 25 ft Heated

Working

Pressure

Temperature

Rating

4000 psi (28

MPa, 276 bar) at

-65° F - 212° F

(-54° C - 100°

C)

3000 psi (21

MPa, 207 bar) at

213° F - 400° F

(101° C - 204°

C)

Part No. JIC Dash Size Length Heat

65 17K265 -10 (5/8 in, 15.9 mm) 6 ft Ambient

66 17K266 -10 (5/8 in, 15.9 mm) 10 ft Ambient

67 17K267 -10 (5/8 in, 15.9 mm) 15 ft Ambient

68 17K268 -10 (5/8 in, 15.9 mm) 20 ft Ambient

69 17K269 -10 (5/8 in, 15.9 mm) 25 ft Ambient

72 17K272 -12 (3/4 in, 19.0 mm) 6 ft Ambient

73 17K273 -12 (3/4 in, 19.0 mm) 10 ft Ambient

74 17K274 -12 (3/4 in, 19.0 mm) 15 ft Ambient

75 17K275 -12 (3/4 in, 19.0 mm) 20 ft Ambient

76 17K276 -12 (3/4 in, 19.0 mm) 25 ft Ambient

77 17K277 -16 (1 in, 25.4 mm) 6 ft Ambient

78 17K278 -16 (1 in, 25.4 mm) 10 ft Ambient

79 17K279 -16 (1 in, 25.4 mm) 15 ft Ambient

80 17K280 -16 (1 in, 25.4 mm) 20 ft Ambient

81 17K281 -16 (1 in, 25.4 mm) 25 ft Ambient

00 No Hose N/A N/A N/A

C)

6 333587C

Page 7

Dispense System Pressure

Due to factors such as the dispense system design, the

material being pumped, and the flow rate, the dynamic

pressure will not reach the rated working (stall) pressure

of the system.

Pump Working (Stall) Pressure Max Dynamic (Run) Pressure

Lower Size psi bar MPa psi bar MPa

Dispense System Pressure

Check-Mate

200CS/CM

4,000 290 29.0 3,905 269 26.9

333587C 7

Page 8

Warnings

DANGER

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks.

When these symbols appear in the body of this manual or on warning labels, refer back to these Warnings.

Product-specific hazard symbols and warnings not covered in this section may appear throughout the body of this

manual where applicable.

SEVERE ELECTRIC SHOCK HAZARD

This equipment can be powered by more than 240 V. Contact with this voltage will cause death or

serious injury.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• This equipment must be grounded. Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

8 333587C

Page 9

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure and disconnect all power sources.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. Paint or solvent

flowing through the equipment can cause static sparking. To help prevent fire and explosion:

• Use equipment only in well-ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static sparking).

• Ground all equipment in the work area. See Grounding instructions.

• Never spray or flush solvent at high pressure.

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are anti-static or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Specifications in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Specifications in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For

complete information about your material, request Safety Data Sheets (SDSs) from distributor or

retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

333587C 9

Page 10

Warnings

WARNING

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheets (SDSs) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

10 333587C

Page 11

Dispense System Component Identification

A

B

C

D

E

H

G

J

F

*Circular

Electrical

Connection

*Square

Electrical

Connection

*Circular

Electrical

Connection

*Square

Electrical

Connection

Dispense System Component Identification

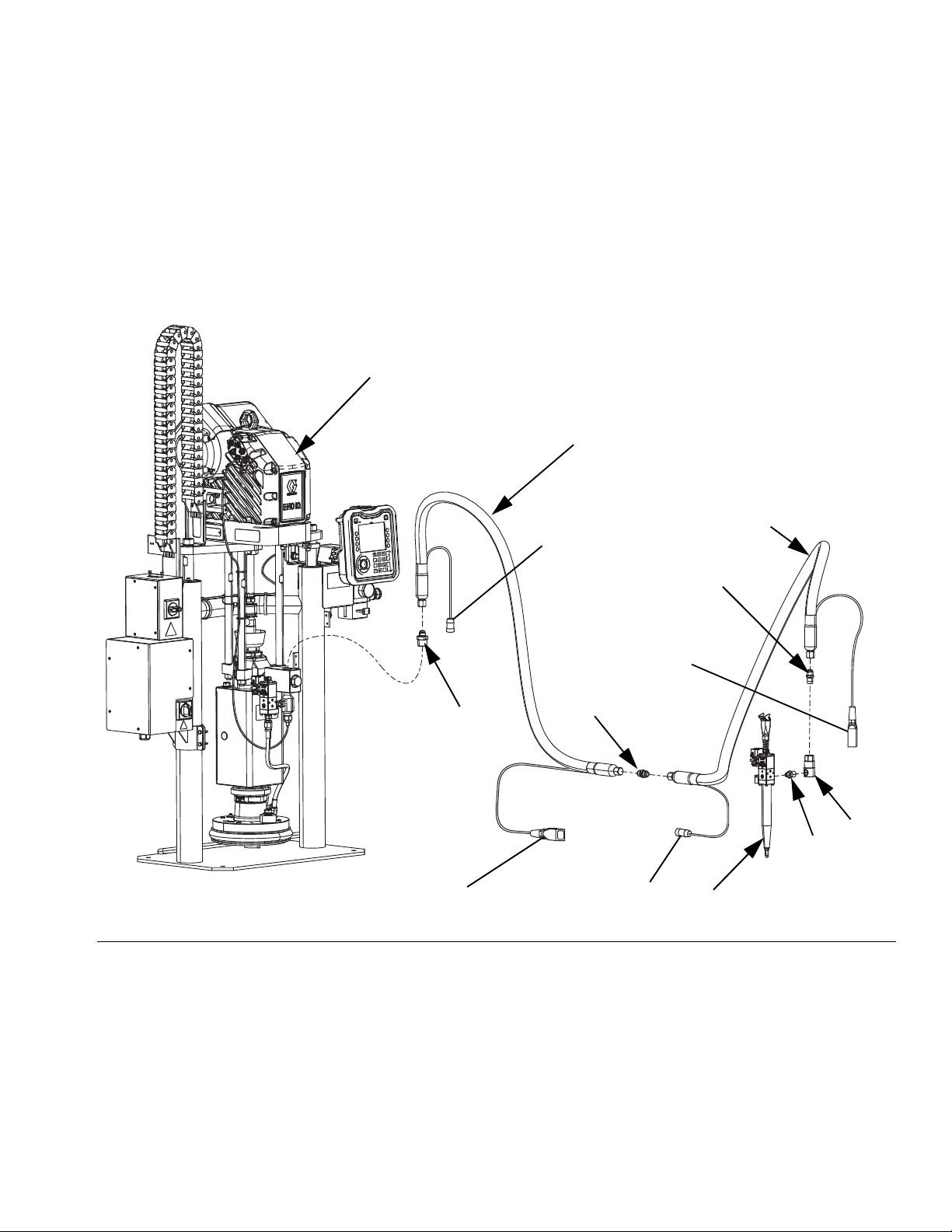

NOTE: Figure 1 shows a typical E-Flo iQ dispense

system installation with an iQ ram supply unit, hoses,

connectors, and an iQ dispense valve. Some

installations may require only one hose depending on

the needs of the system.

FIG. 1: E-Flo iQ Dispense System

Key:

A iQ Ram Supply Unit

B iQ Dispense Valve

C First Hose from Supply System

D Second Hose to iQ Dispense Valve

E Ram Supply System Fitting to First Hose

F First Hose Fitting to Second Hose

G Second Hose Fitting to Swivel

H Swivel Fitting

J Swivel to Valve Fitting

* Applies to heated hoses only.

333587C 11

Page 12

Dispense System Component Identification

A

B

M

D

F

G

H

J

K

L

R

C

E

N

P

*Circular

Electrical

Connection

*Square

Electrical

Connection

*Circular

Electrical

Connection

*Square

Electrical

Connection

*Circular

Electrical

Connection

S

S

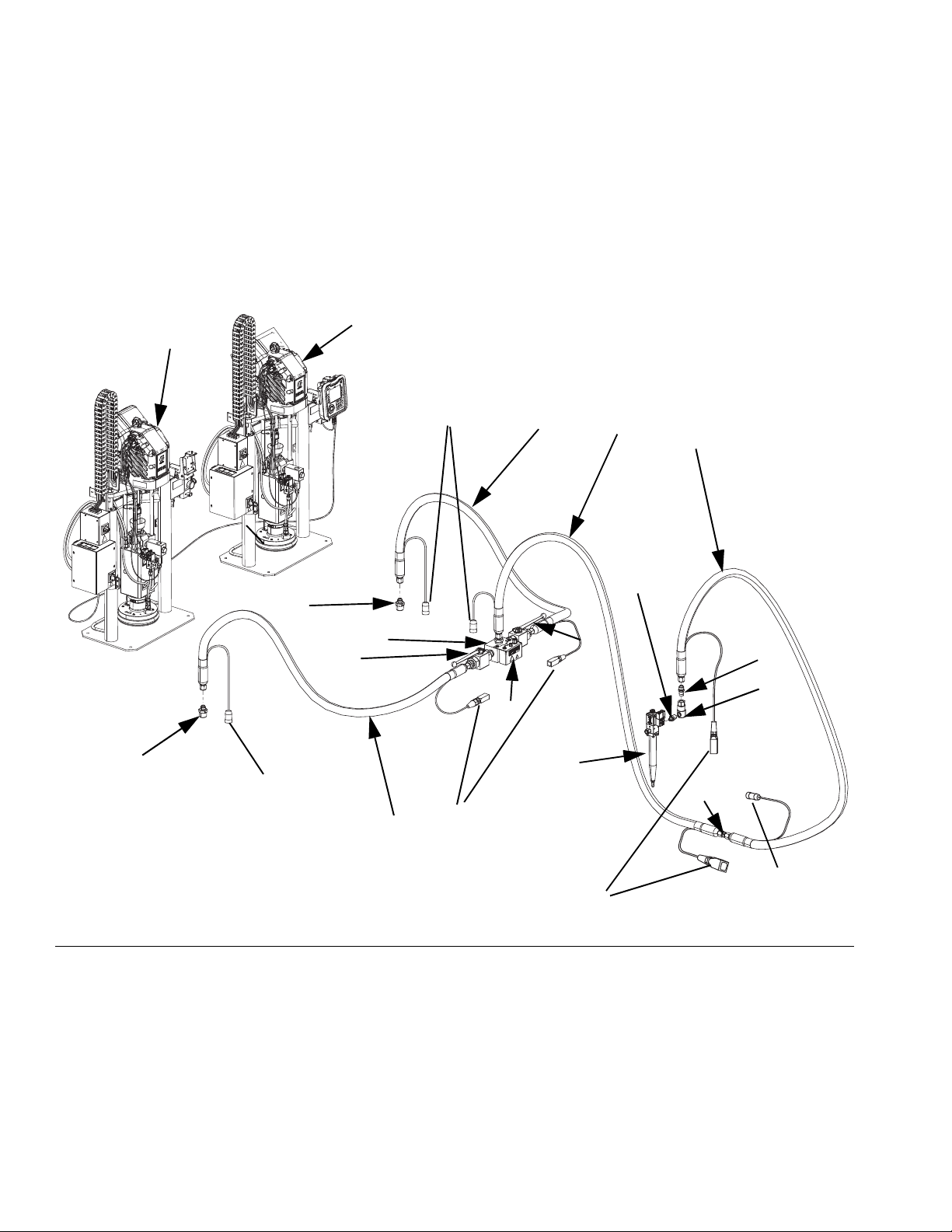

Tandem Ram

NOTE: FIG. 2 shows a typical E-Flo iQ dispense system

installation with a Tandem iQ ram supply unit, hoses,

connectors, and an iQ dispense valve. Some

installations may not require Supply Hose 2 (D) to iQ

Dispense Valve (B) depending on the needs of the

system.

FIG. 2: Tandem E-Flo iQ Dispense System

Key:

A iQ Ram Supply Unit 1

B iQ Dispense Valve

C Supply Hose 1

D Supply Hose 2

E Tandem Block Fitting to Supply Hose 1

F Supply Hose 1 Fitting to Supply Hose 2

G Supply Hose 2 Fitting to Swivel

H Swivel Fitting

J Swivel Fitting to Valve

K iQ Ram Supply Unit 2

L Tandem Hose 1

M Tandem Hose 2

N Ram Supply Unit 1 Fitting to Tandem Hose 1

P Ram Supply Unit 2 Fitting to Tandem Hose 2

R Tandem Block

S Ball Valves

* Applies to heated hoses only.

12 333587C

Page 13

Supply Unit Component Identification

AU

AT

AS

AA

ZC

AV

AF

AG

AR

AN

AM

AD

AJ

AK

*AX

AL

*ZA

AZ

AY

AC

AE

AW

ZB

Ambient System

AZ

Heated System

AZ

AK

AH

AB

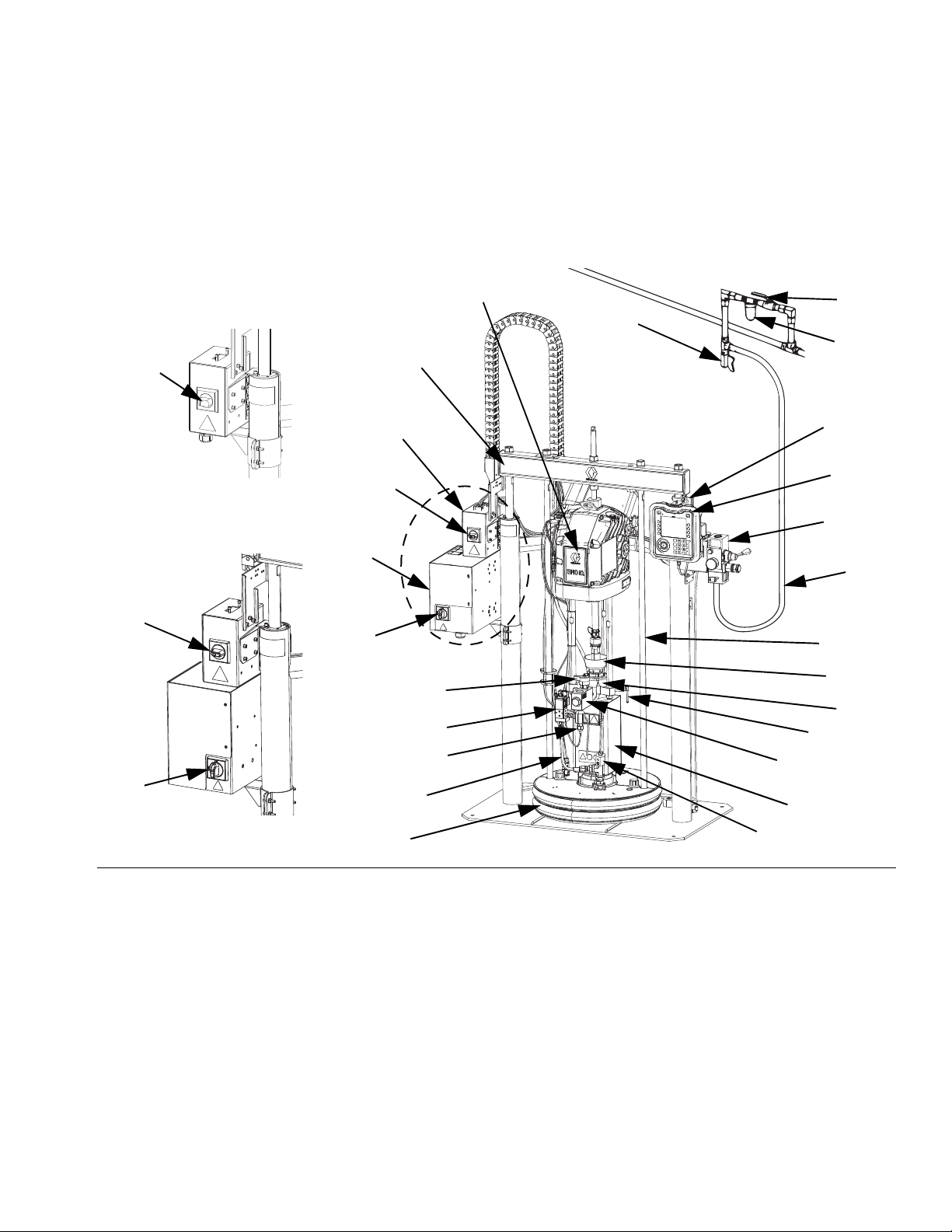

iQ Ram Supply Unit

D200 3 in. Dual Post Shown

Supply Unit Component Identification

FIG. 3: iQ Ram Supply Unit

Key:

AA Ram Assembly

AB Electric Driver

AC Displacement Pump

AD Platen

AE Fluid Check Valve

AF Advanced Display Module (ADM)

AG Integrated Air Controls (see Figure 6)

AH Platen Bleed Port

AJ Power Junction Box

AK Power Junction Box Switch

AL Platen Lift Rod

AM Pump Bleed Valve

AN Wet Cup

333587C 13

AR Air Line (not supplied)

AS Air Line Drain Valve (not supplied)

AT Air Filter (not supplied)

AU Bleed Type Air Shutoff Valve (required) (not supplied)

AV Level Sensors

AW Outlet Pressure Transducer

AX *Heat Control Box

AY Platen Valve Kit (optional)

AZ Disconnect Switch (See Power Disconnect on page 14)

ZA *Pump Heater

ZB Recirculation Hose

ZC Pump Relief Valve

* Parts on heated systems only.

Page 14

Supply Unit Component Identification

AK

AZ

Heated System

AZ

Ambient System

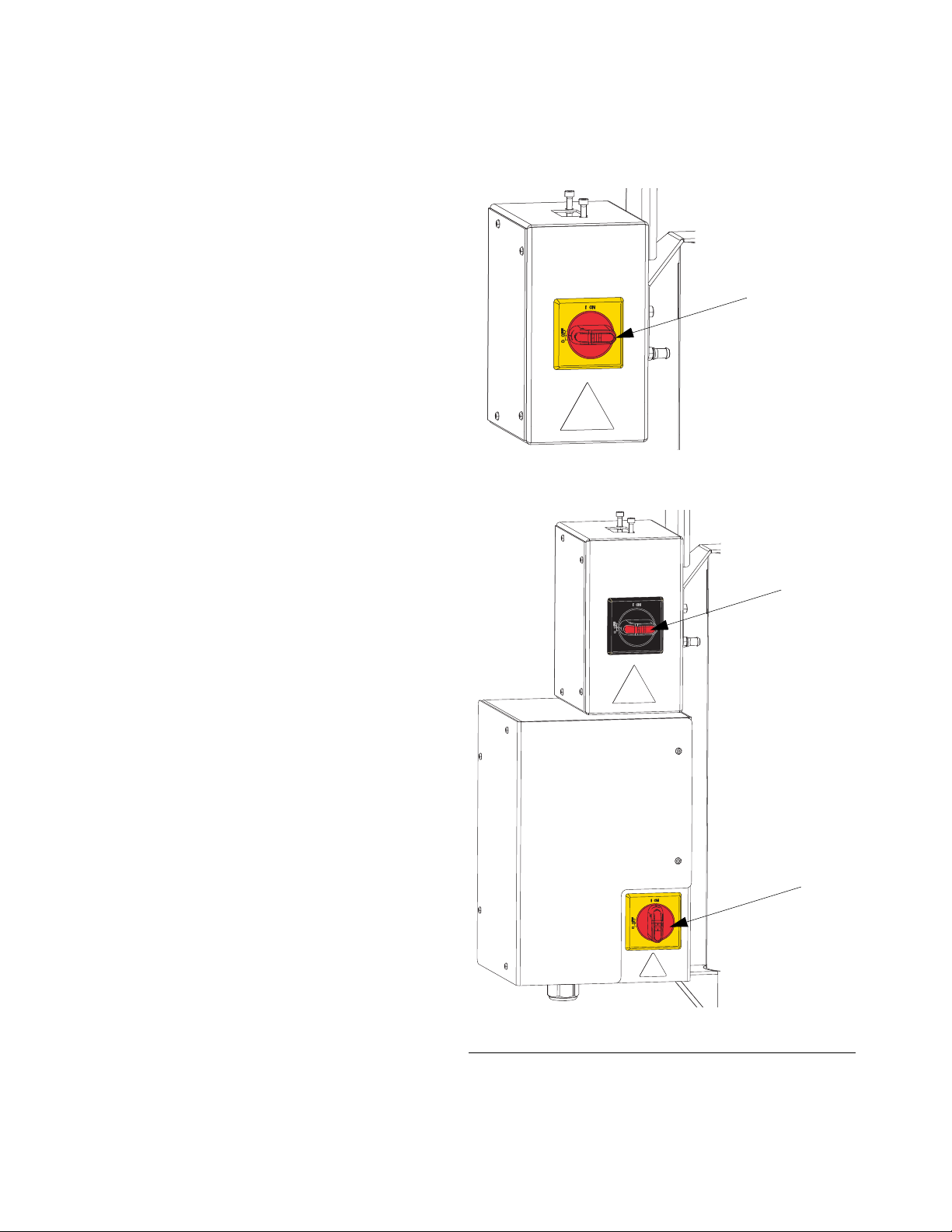

Power Disconnect

Every E-Flo iQ Dispense System has a red and yellow

Disconnect Switch which shuts off power to the entire

system. The location of the switch is different for

ambient and heated systems. See Figure 4.

On ambient systems, the Disconnect Switch (AZ) is

located on the Power Junction Box (AJ).

On heated systems, the Disconnect Switch (AZ) is

located on the Heat Control Box (AX). Heated systems

also have a red and black Power Junction Box Switch

(AK) located on the Power Junction Box (AJ). The Power

Junction Box Switch (AK) removes power to everything

EXCEPT heat. The Disconnect Switch (AZ) removes

power to the entire system, including heat.

F

IG

. 4. Power Disconnect

14 333587C

Page 15

Supply Unit Component Identification

BA

BB

BC

BE

BD

BD

1/4 NPT

Plug

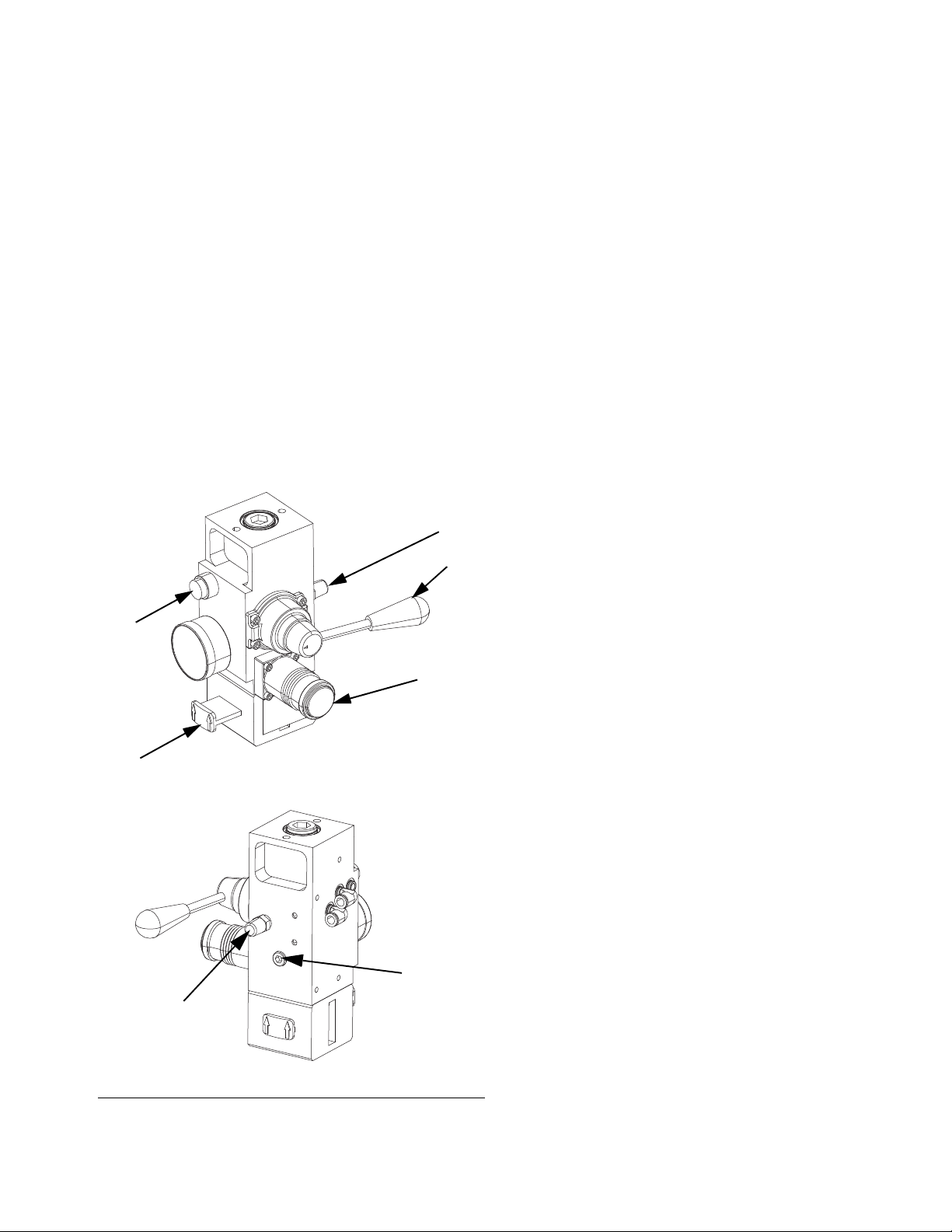

Integrated Air Controls (AG)

The integrated air controls include:

• Main Air Slider Valve (BA): turns air on and off to

the system. When closed, the valve relieves pres-

sure downstream.

• Ram Air Regulator (BB): controls Ram up and

down pressure and blowoff pressure.

• Ram Director Valve (BC): controls Ram direction.

• Exhaust Port with Muffler (BD)

• Blowoff Button (BE): turns air on and off to push

the Platen (D) out of an empty drum.

Integrated Air Line Accessories

See Figure 3.

• Air Line Drain Valve (AS): removes condensed

water from the air line. Not supplied.

• Air Line Filter (AT): removes harmful dirt and mois-

ture from the compressed air supply. Not supplied.

• Second Bleed-type Air Valve (AU) (required): iso-

lates Air Line accessories for servicing. Locate

upstream from all other Air Line accessories. Not

supplied.

F

IG

. 5. Integrated Air Control Module

333587C 15

Page 16

Supply Unit Component Identification

CA

CB

CC

CD

CE

CF

CG

CH

CP

CK

CN

CM

CL

CJ

CR

CS

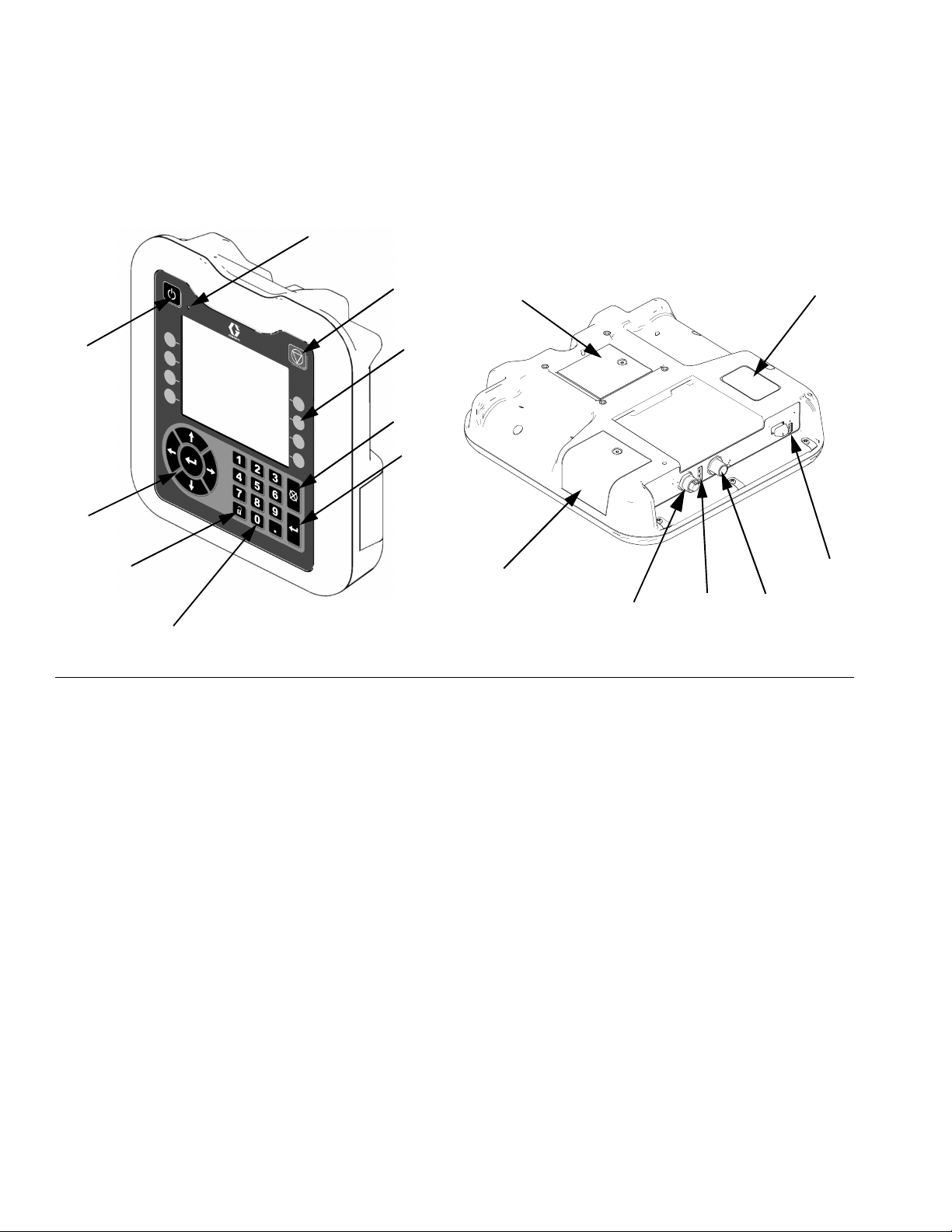

Advanced Display Module (ADM)

Front and Rear Views

FIG. 6: ADM Component Identification

Key:

CA Startup/Shutdown

Starts up or shuts down the system. Toggles

between Active and Inactive system.

CB System Status Indicator LED

CC Pump Soft Stop

Stops all pump processes and disables the pump.

Also stops all heating processes and disables the

heat. This is not a safety or emergency stop.

CD Soft Keys

Defined by the icon on the screen next to the soft

key. Performs the specific operation for that icon

when pressed.

CE Cancel

Cancels a selection or number entry while in the

process of entering a number or making a selection.

Cancels the pump processes. Exits a screen

without saving changes.

CF Enter

Select to update a field, accept a selection or value,

acknowledge an event, enter a screen, and toggle

selected items.

CG Lock/Setup

Toggles between Run screens and the iQ Menu.

CH Directional Keypad

Navigate within a screen or to a new screen.

CJ Numeric Keypad

Input numeric values.

CK Part Number Identification Label

CL USB Interface

CM CAN Cable Connection

Power and communication.

CN Module Status LEDs

Visual indicators to show the status of the ADM.

CP Token Access Cover

Access cover for blue software token.

CR Battery Access Cover

CS Light Tower Connection

NOTE: If using a Tandem system, the AMD is only

included with the iQ Ram Supply Unit 1 (A)

16 333587C

Page 17

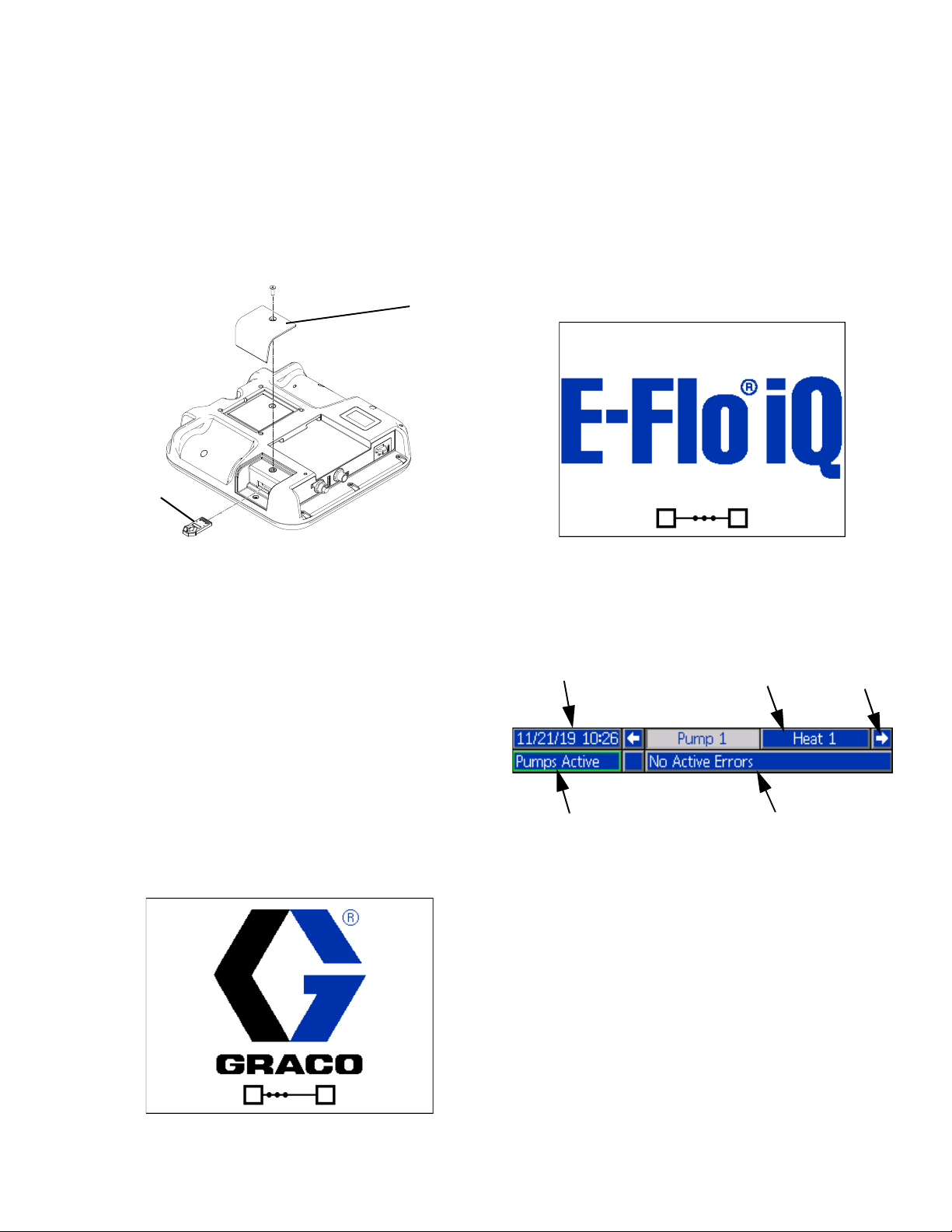

ADM Display Details

CP

Blue Token

Date and Time

Navigation

Arrows

Screen Menu

Status

System Mode

ADM Display Details

Use the Blue Token

The E-Flo iQ system includes a blue token that must be

inserted into the ADM to initiate the E-Flo iQ software.

1. Remove the ADM from the bracket.

2. Use a hex wrench to remove the screws from the

token access cover (CP).

Five seconds after the E-Flo iQ blue token is inserted

into the ADM, the Graco power up screen switches to

the E-Flo iQ power up screen. This screen remains on

while the ADM runs through initialization and

establishes communication with other modules in the

system.

Menu Bar

The Menu Bar appears at the top of each screen (the

following image is only an example).

3. Remove the access cover (CP).

4. Insert and press the blue software token firmly into

the slot.

5. Replace the token access cover (CP) and insert and

tighten the screw that holds it in place.

6. Mount the ADM on the bracket.

Power Up Screen

This screen appears when the ADM is powered up.

Date and Time

The date and time are always displayed in one of the

following formats. The time is always displayed as a

24-hour clock.

•

DD/MM/YY HH:MM

•

YY/MM/DD HH:MM

•

MM/DD/YY HH:MM

Navigation Arrows

The left and right arrows are only visible when screen

navigation is allowed.

333587C 17

Page 18

ADM Display Details

Screen Menu

The screen menu indicates the currently active screen,

which is highlighted. It also indicates the associated

screens that are available by scrolling left and right.

System Mode

The current system mode is displayed in the lower left of

the Menu Bar. System modes include: Pump Active,

Pump Inactive, Job in Cycle, Pre-charge, Heat Inactive,

Heat Off, Heat Soak, Heat at Temp, Heat in Setback.

Status

The current system status is displayed in the lower right

of the Menu Bar.

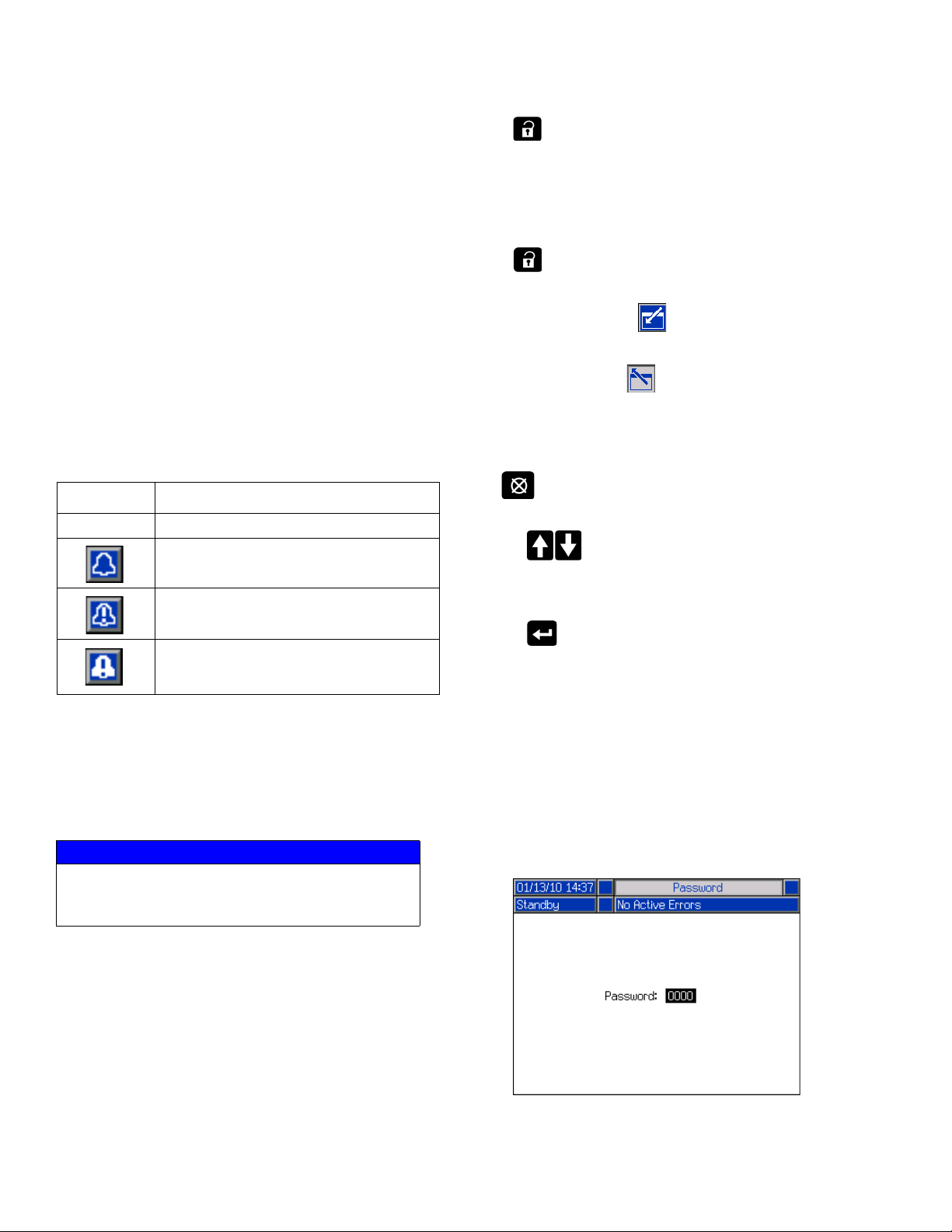

Alarm/Deviation

The current system error is displayed in the middle of

the Menu Bar. There are four possibilities.

Icon Function

No Icon No information or no error has occurred

Advisory

Deviation

Press on any Run screen to switch to the iQ Menu

screens. If the system has a password lock, the

Password screen is displayed. If the system is not

locked (password is set to 0000), iQ Menu Screen 1 is

displayed. Refer to iQ Menu on page 22 for additional

information.

Press on any Setup screen to return to the Run

screen.

Press the Enter soft key to activate the editing

function on any screen.

Press the Exit soft key to exit the editing function

and save any changes.

Use the other soft keys to select the function adjacent to

them.

Use to exit a screen. Using this key while in editing

mode will exit the screen without saving changes.

Use the keys on the ADM to move through the

settings on a screen or drop down menu and to scroll

through multiple screens on the right side of the display.

Alarm

Soft Keys

Icons next to the soft keys indicate which mode or action

is associated with each soft key. Soft keys that do not

have an icon next to them are not active in the current

screen. See Advanced Display Module on page 16

and ADM Soft Keys on page 20.

NOTICE

To prevent damage to the soft key buttons, do not

press buttons with sharp objects such as pens,

plastic cards, or fingernails.

Navigating the Screens

There are two types of screens:

Run screens control operations and display system

status and data.

Setup screens control system parameters and

advanced features. These screens are accessed

through the iQ Menu.

Use the key to choose a field to update, to make a

selection, to save a selection or value, to enter a screen,

or to acknowledge an event.

Set Password

You can set a password to protect access to some

selections on the iQ Menu screens. See iQ Menu on

page 22. It can also be used when changing from

Remote to Local control mode to protect against

inadvertently changing control modes. To set or remove

the password, select Advanced from iQ Menu 2. See

Advanced Setup Screen 1 on page 31.

18 333587C

Page 19

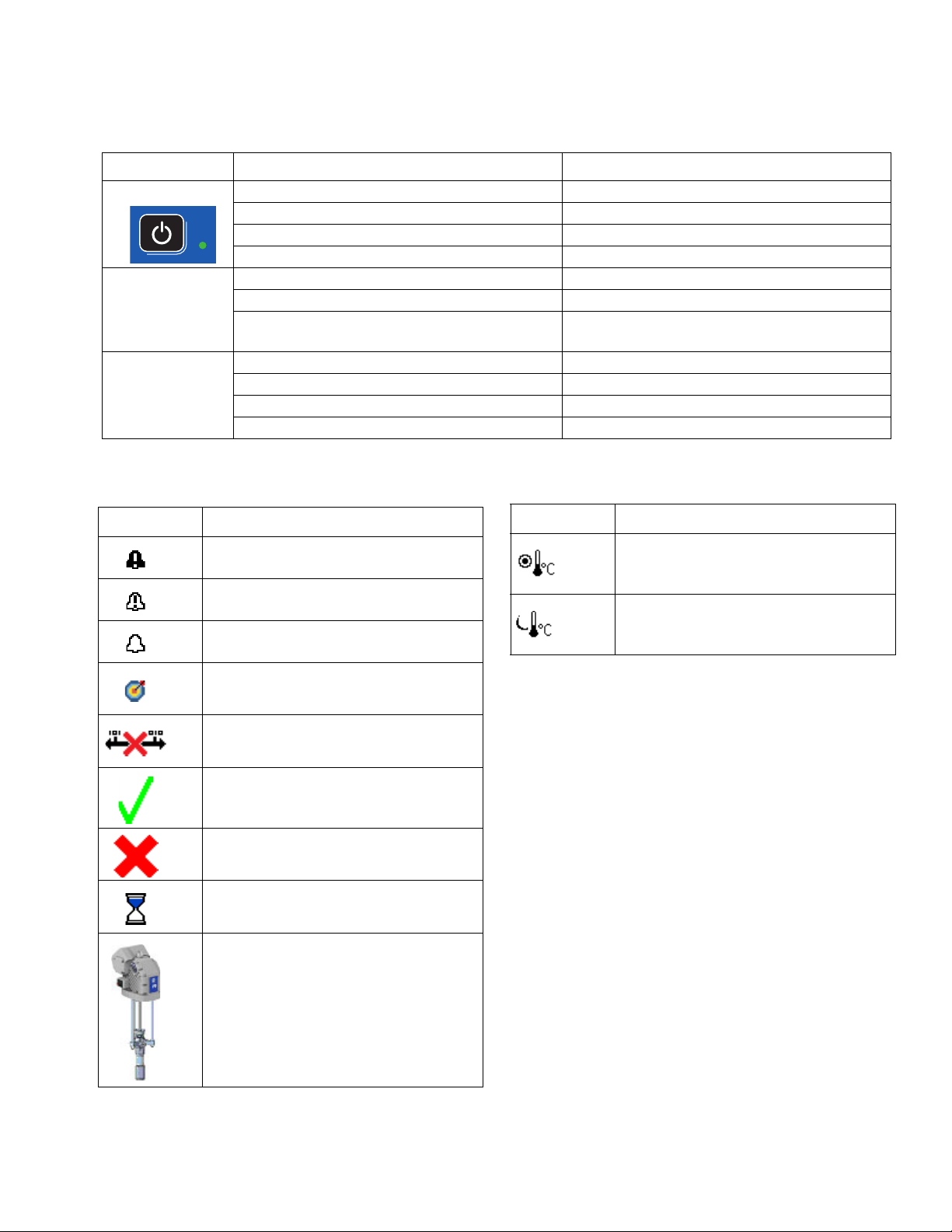

ADM LED Status Descriptions

LED Conditions Description

System Status Green Solid Run Mode, System On

Green Flashing Setup Mode, System On

Yellow Solid Run Mode, System Off

Yellow Flashing Setup Mode, System Off

USB Status (CL) Green Flashing Data recording in progress

Yellow Solid Downloading information to USB

Green and Yellow Flashing ADM is busy, USB cannot transfer information

when in this mode

ADM Status (CN) Green Solid Power applied to module

Yellow Flashing Active Communication

Red Steady Flashing Software upload from token in progress

Red Random Flashing or Solid Module error exists

ADM Icons

ADM Display Details

Icon Function

Alarm - See Troubleshooting, page 53

for more information.

Deviation - See Troubleshooting, page

53 for more information.

Advisory - See Troubleshooting, page

53 for more information.

Target for primary pressure and flow.

Only displayed in priming mode.

Communication Error

No issues found with parameter or

setting value

Missing or unexpected parameter or

setting value

System is processing request

(animated)

Pump position (animated). The pump

coupler will move up and down in real

time and indicate the approximate

position of the pump. The pump will

need to complete one full down stroke

upon each power cycle before the

position is valid.

Icon Function

Zone setpoint temperature showing the

temperature the zone heats too when

the heat is turned on.

Zone setback temperature showing the

setback the zone goes to when the heat

is in setback mode.

333587C 19

Page 20

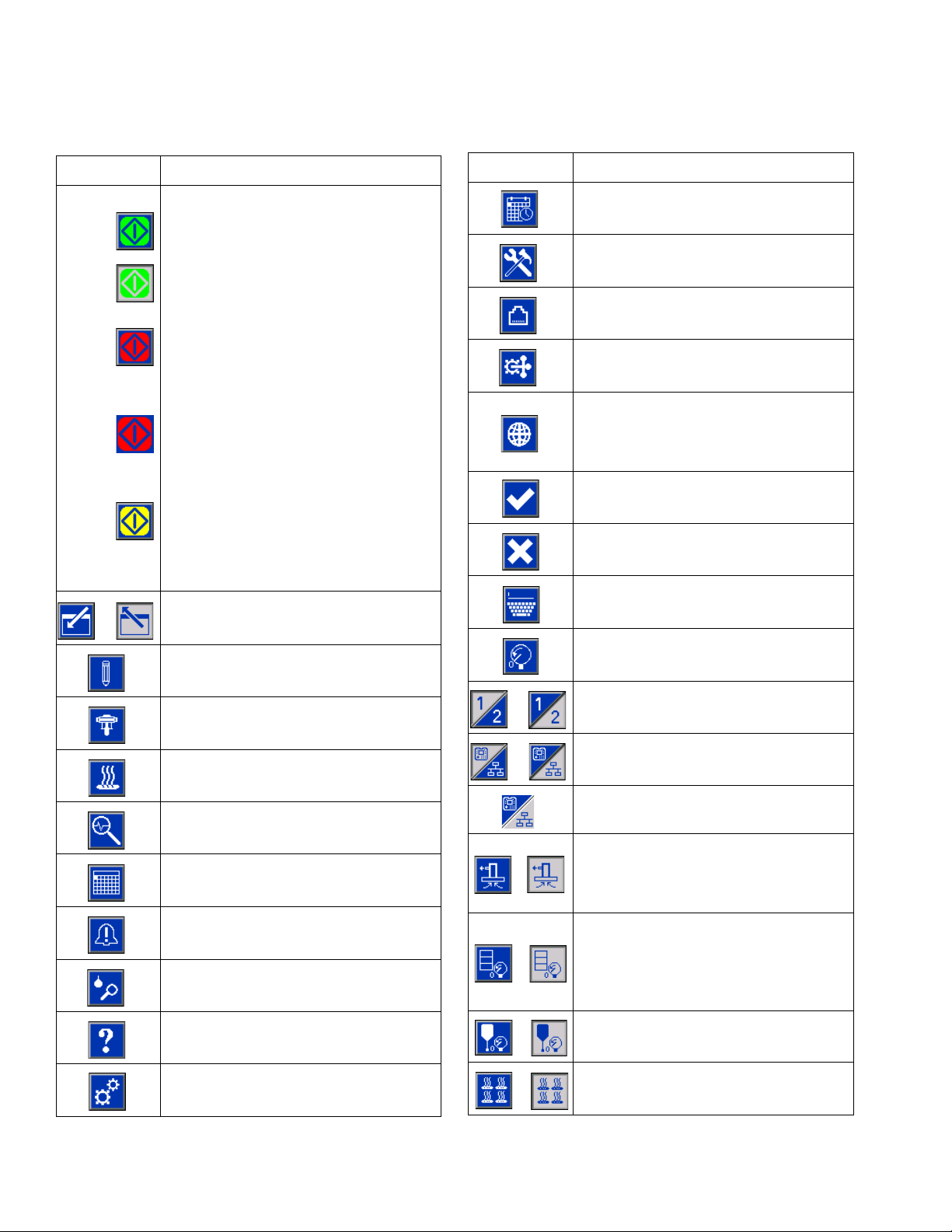

ADM Display Details

ADM Soft Keys

Icon Function

Pump Operation Icon

Green: Start the Pump

Inverted Green: Stop the Pump

Red with Border (enabled): Indicates

that the pump cannot be started due to

an alarm.

Red with No Border (not enabled):

Indicates that the system is not enabled

and the pump cannot be started.

Yellow: Indicates that the pump has an

active alarm but still allows the valve

and platen to be depressurized. The

pump can still be primed only if it is a

“pump not primed” alarm.

Enter or exit editing mode for a

particular screen.

Access the Style Definitions screens.

Icon Function

Access the Advanced System Setup

screens.

Access the Maintenance function.

Access the Fieldbus Gateway Setup

screens.

Access the Integration Feedback

screens.

Globalize selection. Apply a style setting

to all of the styles in Style Definitions or

a heat setting to all of the heat zones in

Heat Settings.

Confirm globalizing a setting.

Cancel globalizing a setting.

Access a keyboard screen to create or

change a style name.

Reset offsets to zero when calibrating

pressure transducers.

Access the Pump Setup screens.

Access the Heat Setup screens.

Access the Diagnostics function.

Access the Events logs.

Access the Errors logs.

Access the Job Log.

Access the Troubleshooting function.

Access the System Setup screen.

Tandem systems only. Toggle between

Pump 1 and Pump 2.

Local / Remote control toggle.

Pump is locked in remote control via

fieldbus interface.

Enter or exit pump priming mode. A “1”

or “2” will show on the icon in Tandem

systems to indicate which pump will be

primed.

Enter or exit drum depressurization

mode. (If equipped with optional fluid

solenoid.) A “1” or “2” will show on the

icon in Tandem systems to indicate

which pump will be depressurized.

Enter or exit valve depressurization

mode.

Turn heat zones on and off.

20 333587C

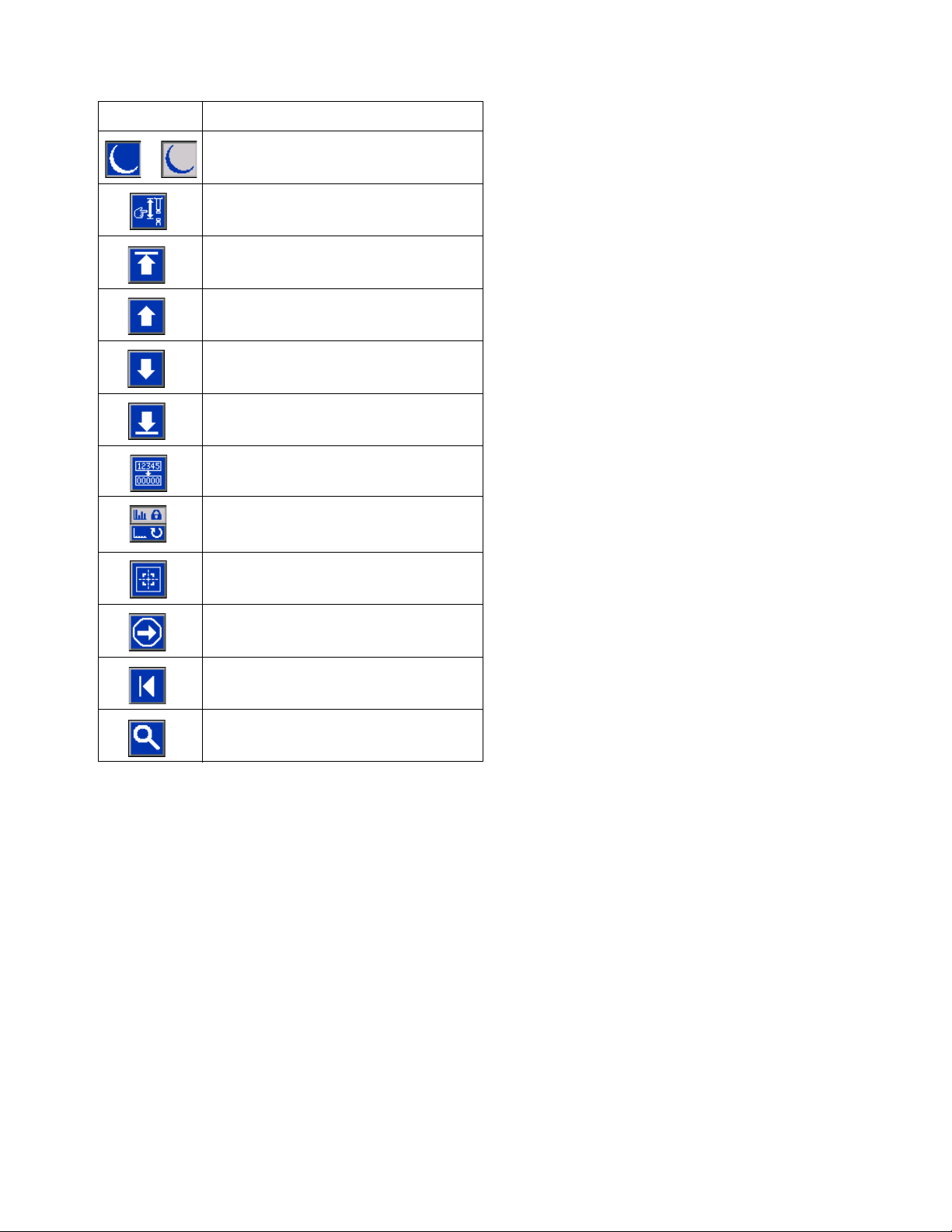

Page 21

Icon Function

Place all heat zones into setback and

out of setback.

Enter or exit manual pump movement

mode.

Move to the top.

Move upward.

Move downward.

Move to the bottom.

Reset Cycle Counter.

Toggle between lifetime and resettable.

ADM Display Details

Calibrate.

Continue.

Previous screen.

Search.

333587C 21

Page 22

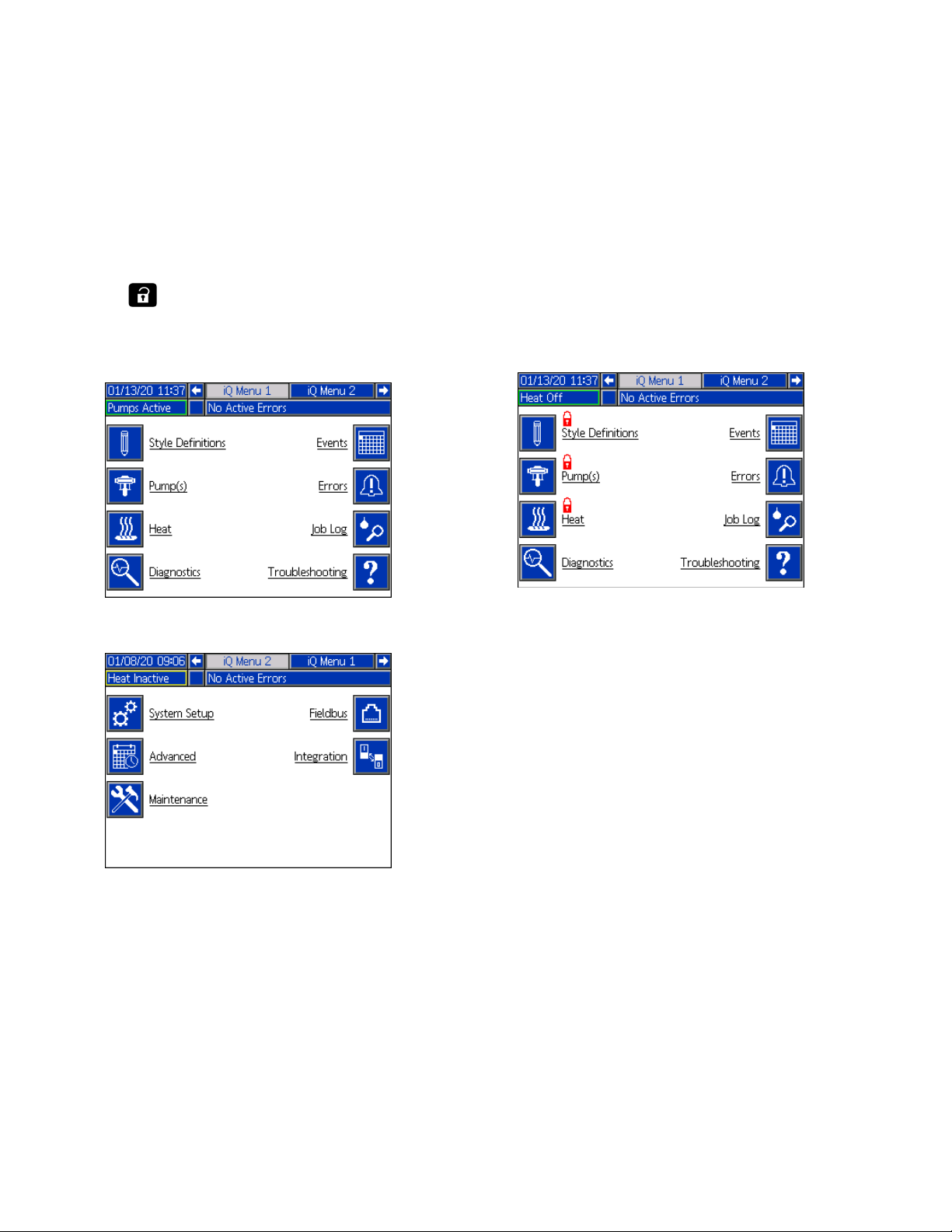

iQ Menu

iQ Menu

The iQ Menu screens provide access to settings that

help to ensure the proper operation and maintenance of

the system. These functions can be performed when the

ADM is either in Active or System OFF Mode.

1. Provide power to the system to turn on the ADM.

2. Press on the ADM from any Run screen to go

to the iQ Menu screens.

iQ Menu Screen 1

If you set a password, the menu will be displayed with

red locks above the menu selections with parameters

that can be changed. Enter your password when

prompted to access these screens.

The selections that do not have a red lock have

information that can be viewed but not changed and

would not require a password. See Advanced Setup

Screen 1 on page 31 for information about setting a

password.

iQ Menu Screen 2

22 333587C

Page 23

Setup

To prevent personal injury from pressurized fluid such

as skin injection or splashing fluid, make sure that all

components in your system are rated to the maximum

pressure the system is capable of attaining. All

components must be rated for maximum pressure

even if the pump is operated below maximum

pressure.

NOTICE

To prevent damage to ADM buttons, do not press the

buttons with sharp objects such as pens, plastic cards,

or fingernails.

NOTICE

To prevent damage to components in the system, all

components must be rated to the maximum pressure

the system is capable of attaining.

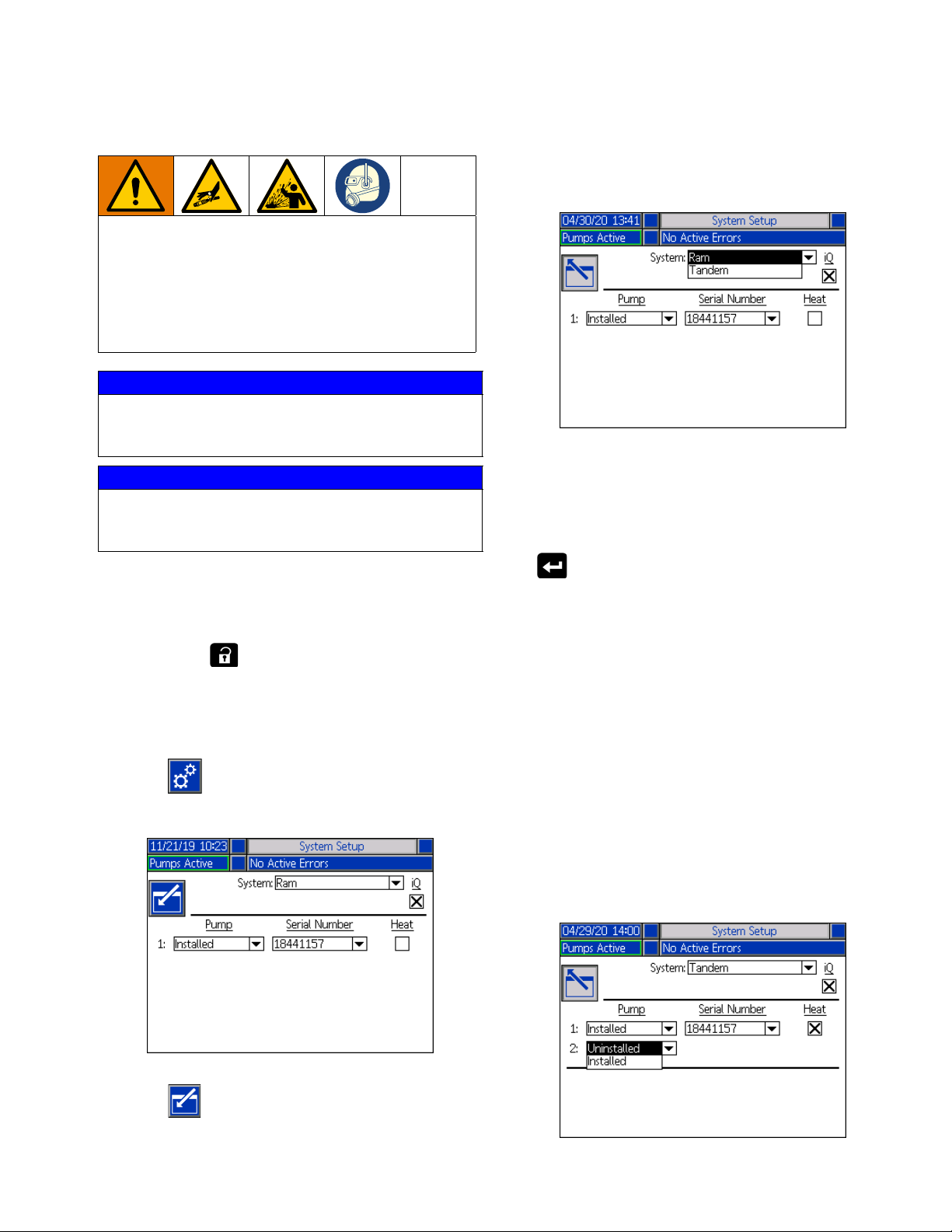

Setup

Use the drop down menu to select the type of system as

either Ram or Tandem.

NOTE: Changing the system type resets the pumps in

the system.

When you select Ram, the only action required at this

screen is if the pump has a heat module installed. Press

It is important to set up the parameters of your system

before operating the E-Flo iQ system. These are

accessed through the iQ Menu. After starting up the

ADM, press the key from the Run screen to go to

the iQ Menu screens. Refer to iQ Menu on page 22.

System Setup Screen

Press the soft key at the iQ Menu screen 2 to

access the System Setup screen.

the key in the Heat box to configure it for heat.

All other fields are automatically set when the blue token

is inserted on an installed system. The System is

displayed as Ram. The box below the iQ icon next to the

System field indicates that it is an E-Flo iQ system.

The Pump shows as Installed. The Serial Number

should match the serial number printed on the driver ID

tag. As a backup to the driver serial number, the serial

number of the current board will be displayed instead.

The serial number for the control board is also displayed

in the detailed software status screens. See Advanced

Setup Screen 4 on page 33.

When you select Tandem, a field for the second pump

is displayed on the screen showing Uninstalled. Select

Installed from the drop down menu.

Press the soft key to enter editing mode.

333587C 23

Page 24

Setup

When you select installed, the Serial Number will be

automatically populated to match the serial number

printed on the driver ID tag on Pump 2.

If Pump 2 has a heat module installed, press the

key in the Heat box to enable it.

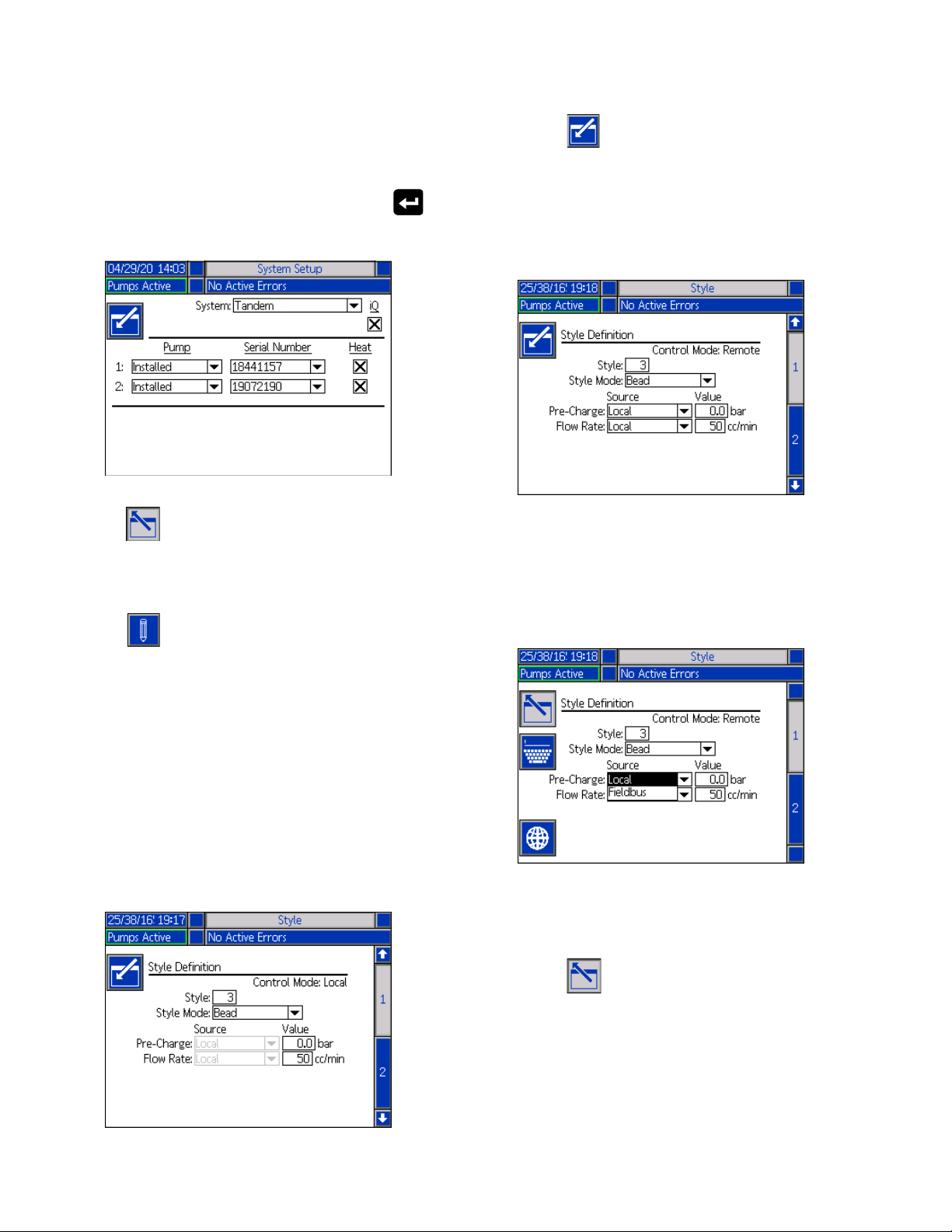

1. Press the soft key to enter editing mode.

2. Enter a Style identifier from 0-16. This is the

designation the system uses for the type of

dispensing based on how you define the style here.

3. Bead is automatically selected as the Style Mode.

Press the soft key to exit editing mode.

Style Definitions

Press the soft key at the iQ Menu screen 1 to

access the Style Definitions setup screens. This function

allows you to identify the style for dispensing material

and configure the settings of the style.

NOTE: Before accessing these settings, you need to

select if your system is running in Local or Remote

control mode. See Control Modes on page 40.

Style Screen 1 - Style Definition

NOTE: When in Local control mode, you cannot select

Source at this screen, but you can still enter Values. The

Source fields can be changed in Remote control mode.

4. From the Source drop-down menus, select the

Pre-Charge and Flow Rate as either Local or

Fieldbus. When you select Local, enter the

appropriate corresponding number in the Value

column. A Fieldbus selection does not require a

value.

NOTE: The optional Communications Gateway Module

(CGM) is required to use fieldbus.

5. Press the soft key to save your changes and

exit editing mode.

24 333587C

Page 25

Setup

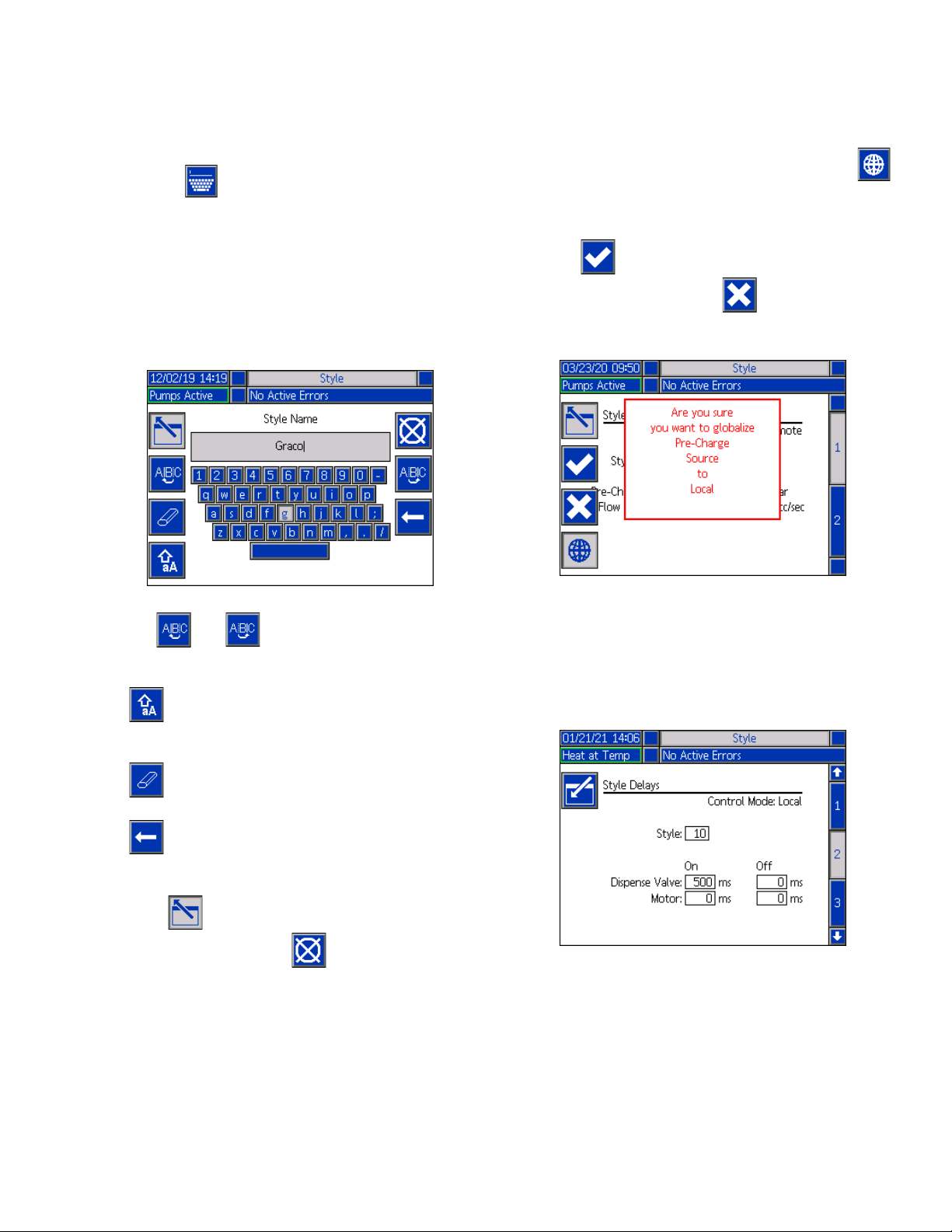

Name the Style

You can also name the Style. While still in Style screen

1, Press the soft key to advance to a keyboard

screen to create or change the name of the style based

on your needs.

NOTE: The Style identifier is a system requirement. The

Style Name option is not required. It is intended as a

user-defined description for the application of each

dispensing style. An example might be: Trunk Hem. The

maximum length is 11 characters.

Apply a Style Setting Globally

While still in Style screen 1, pressing the globalize

soft key applies a style setting across all of the styles. A

message will appear prior to completing the change.

Press the soft key to complete applying the

selected parameter. Press the soft key to cancel

the globalization.

Use the and soft keys to scroll the keyboard

to select letters.

The soft key changes back and forth from lower

and upper case.

The soft key erases everything you have typed.

The soft key is the backspace to delete one letter

at a time.

Press the soft key to save the name and exit the

keyboard screen. Press the soft key to exit the

screen without saving. Both actions return you to Style

screen 1.

Style Screen 2 - Delays

Use the ADM Directional Keypad (CH) to navigate to

Style screen 2.

Set the valve and motor On and Off delays.

333587C 25

Page 26

Setup

Style Screen 3 - Integration

Use the ADM Directional Keypad (CH) to navigate to

Style screen 3.

NOTE: You can only make changes to this screen in

Remote mode. In Local mode, the screen appears as

shown below.

1. In Remote mode, press the soft key to enter

editing mode.

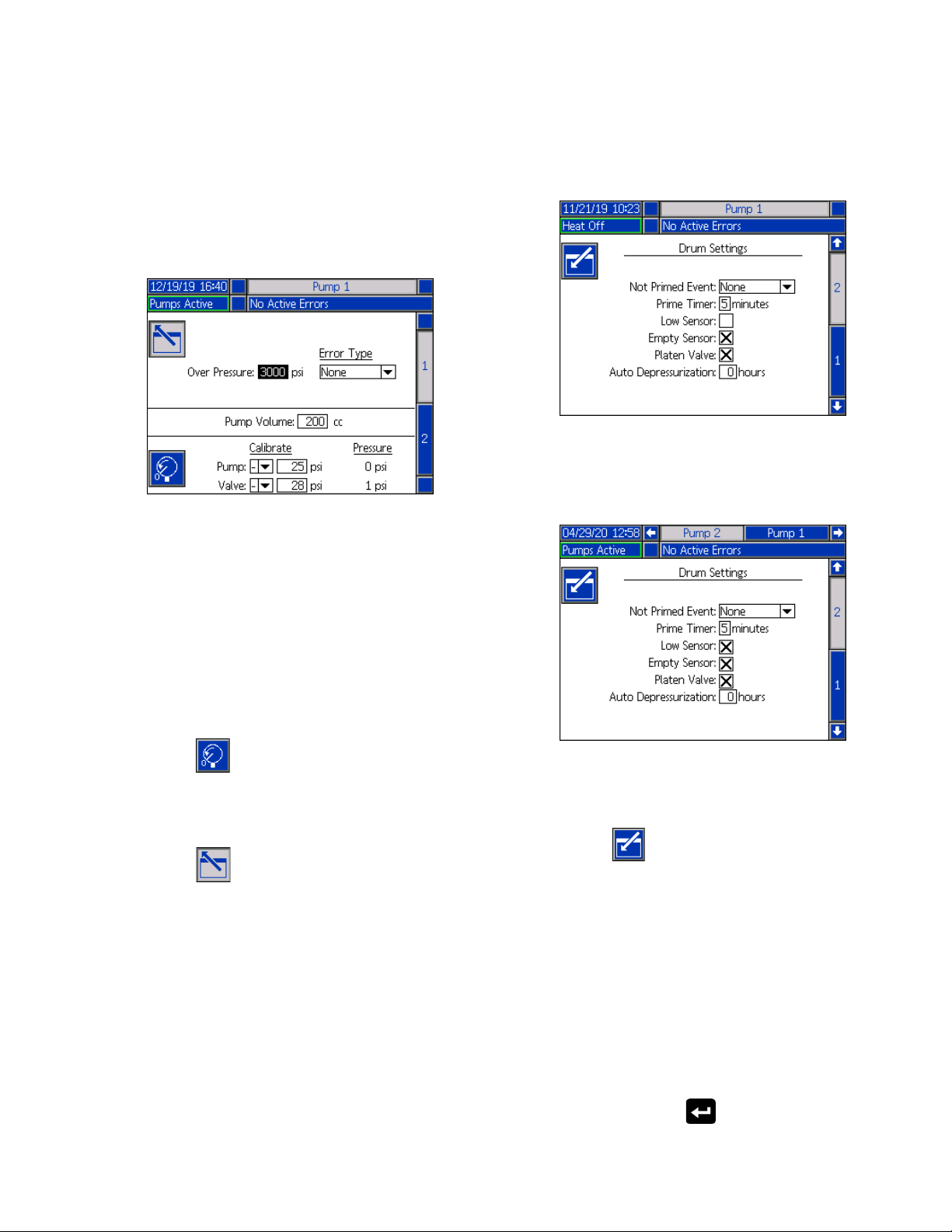

Pump Settings

Press the soft key at iQ Menu screen 1 to access

the Pump setup screens. This function allows you to

configure the operating settings for the pump and drum

depending on the mode of operation.

Pump Screen 1 - Pump Settings

The following description is the same for both Ram and

Tandem selections. For Tandem, Pump 1 and Pump 2

are shown in the Menu Bar. Use the ADM Directional

Keypad to select each pump for configuration. The

Tandem screen is shown below.

2. Set Style Enable and Go Signal fields to either

Discrete or Fieldbus depending on your

requirements. It is recommended that you select

Discrete for the Go Signal to avoid start and stop

delays.

3. Set Dispense Complete to Discrete, Fieldbus, or

Timer. If you select Timer, enter the number of

seconds for the timer from 0-999.

4. Press the soft key to save your changes and

exit editing mode.

26 333587C

NOTE: in Tandem systems, it is recommended that both

pumps should be configured with identical pimp

settings.

Follow these steps to configure the operating settings for

each pump in a Tandem system or a single pump in a

Ram system.

1. Press the soft key to enter editing mode.

2. Configure the Over Pressure setting by entering a

pressure limit.

Page 27

Setup

3. Select Alarm, Deviation, or None from the drop

down menu for the Error Type.

NOTE: The Over Pressure error will be triggered if the

limit is exceeded for 1 second. An Alarm sends an error

message and deactivates the system. A Deviation

sends an error message but the system continues to

operate.

4. The Pump Volume shows the pump size in cc and

can be changed in editing mode if needed.

Pump Screen 2 - Drum Settings

Use the ADM Directional Keypad (CH) to navigate to

Pump screen 2.

As with the first pump screen, Pump Screen 2 shows

both pumps in the Menu Bar in a Tandem system as

shown below.

NOTE: Pressure transducers are calibrated at the

factory, but calibration may be necessary after extended

use. The pump transducer offset and the valve

transducer offset are shown in the Calibrate section.

5. Relieve pressure in the system using Valve

depressurization. See Depressurization Mode on

page 40.

6. Press the soft key to automatically reset the

offsets to zero. You can also manually change the

values and select minus or plus from the drop down

menus as appropriate for the calibration.

7. Press the soft key to save your changes and

exit editing mode.

The steps for configuring the settings are the same for

both Ram and Tandem.

1. Select the soft key to enter editing mode.

2. Select the error type from Alarm, Deviation, and

None for the Not Primed Event. This is triggered

when a drum is replaced and the pump has not yet

been primed. If Alarm is selected, the pump must be

primed after replacing a drum and before returning

to normal operation.

3. Enter the length of the pump Prime Timer between

1 and 9 minutes. Five minutes is the default value.

See Priming Mode on page 41.

4. By default, the Low Sensor box is unchecked

(disabled). Press the key to enable the drum

low deviation.

333587C 27

Page 28

Setup

5. By default, the Empty Sensor box is checked

(enabled). Press the key to disable the drum

empty alarm if needed.

NOTE: The Low Sensor and Empty Sensor errors are

triggered 3 seconds after reaching a critical level.

6. Press the key to enable the Platen Valve

setting. This must be enabled to be able to change

flow rates between dispenses and to allow platen

depressurization. This setting only applies to an

E-Flo iQ system that has a Platen Valve installed.

7. Auto Depressurization allows the platen valve to

open and depressurize the system back to the

platen based on this setting. Enter a value between

1 and 24 hours.

NOTE: The Platen Valve must be enabled on the screen

to trigger Auto Depressurization. If heat is installed, it

places the system into setback. A zero value in the field

disables this feature.

8. Press the soft key to save your changes and

exit editing mode.

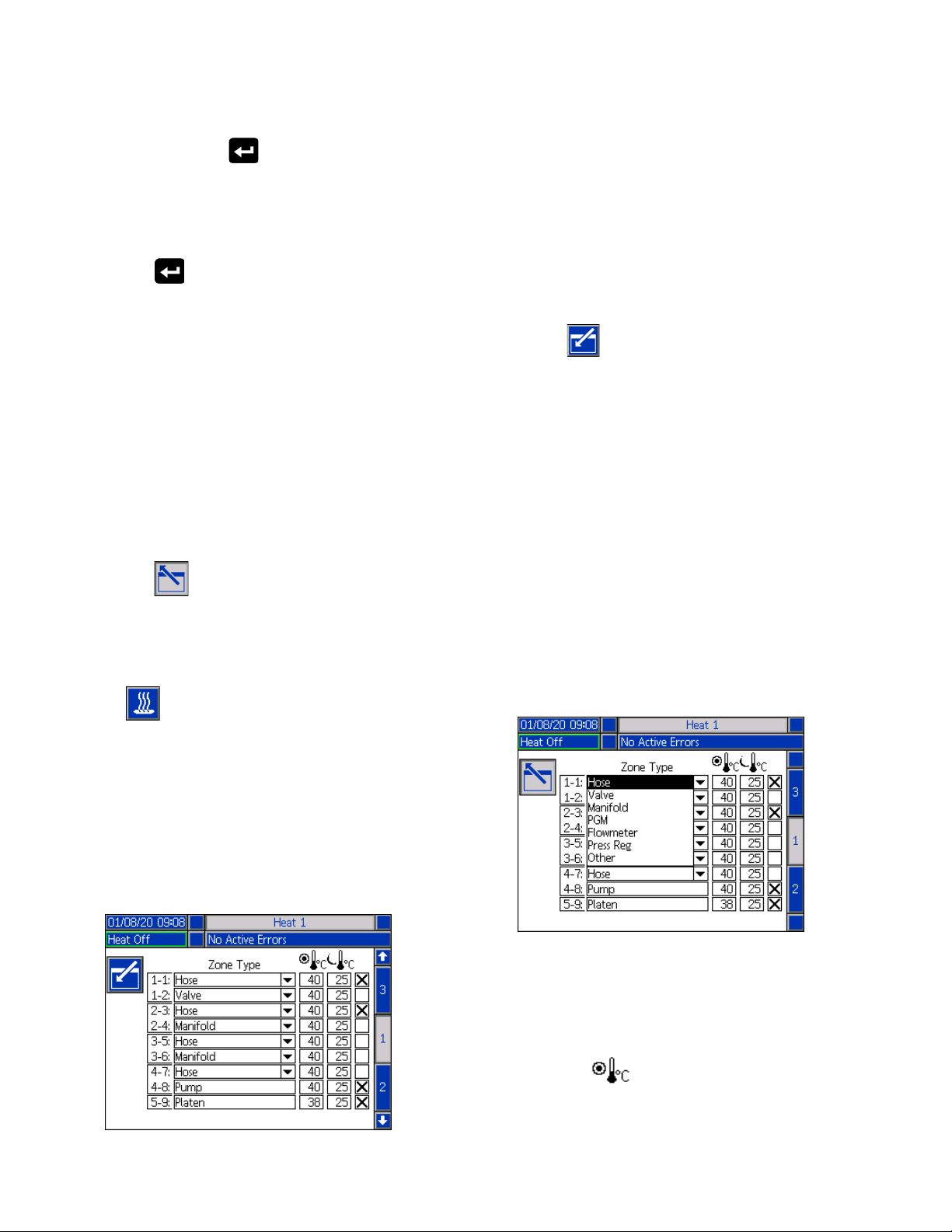

Heat Settings

NOTE: For Tandem systems, read this section first, then

refer to Tandem Heat Setup Screen 1 on page 29.

The heat zone number in the first column corresponds

to the connector and heat zone on the Automatic

Multi-Zone (AMZ) heat control. For example, heat zone

number 4-7 corresponds to connector 4 and heat zone

7. For information about the AMZ, refer to the E-Flo iQ

Supply Systems, Installation-Parts manual. See

Related Manuals on page 3.

1. Press the soft key to enter editing mode.

2. The Zone Type column refers to the system

component that the zone is heating. Select a zone

type from the drop down menu for each zone. The

options available in the drop down menu are:

•Hose

•Valve

• Manifold

• PGM (Precision Gear Motor)

• Flowmeter

• Press Reg (Pressure Regulator)

•Other

NOTE: The correct zone type has to be selected for the

zone to properly heat. If an incorrect zone type is

selected, errors, overshoots, and long heat up times can

occur.

Press the soft key at the iQ Menu screen 1 to

access the Heat setup screens. These screens allow

you to configure the operating settings for the Heat

function.

NOTE: Heat must be selected at the System Setup

screen for these selections to be available. See the

System Setup Screen on page 23.

Heat Setup Screen 1

NOTE: There are two other zone types: platen and

pump. The zones for these are always 4-8 and 5-9,

respectively, as shown above.

3. Enter a temperature for the zone setpoint

temperature ( ) column. This is the setpoint

that the zone heats to when the heat is turned on.

The temperature units can be changed from °C to

°F in the Advanced settings screens. See

Advanced Setup Screen 2 on page 32.

28 333587C

Page 29

Setup

4. Enter a temperature for the zone setback

temperature ( ) column. This is the setback that

the zone goes to when the heat is in setback. The

temperature units can be changed from °C to °F in

the Advanced settings screens. See Advanced

Setup Screen 2 on page 32.

NOTE: If you change a setpoint temperature to a value

below the current setback temperature, that value

becomes the new setback temperature. If you increase

a setback temperature to a value above the current

setpoint temperature, that value becomes the new

setpoint temperature.

5. The column on the right side of the zone setback

temperature column is for enabling the zone. Use

the key to enable zones.

NOTE: When enabled, the zone will be displayed on the

Heat Run screen. When the box is disabled, the zone

will not be displayed on the Heat Run screen and the

errors for that zone will be ignored. See Heat Run

Screen on page 42.

Tandem Heat Setup Screen 1

Read all of Heat Setup Screen 1 starting on page 28

before reading this section.

The Heat Setup screens for Ram and Tandem are the

same in appearance except Tandem has an additional

column to the right for the second pump.

One of the advantages of a Tandem system is

continuous operation if a pump needs to be shut down

for any reason, such as changing a drum of material. In

a heated system, it is equally important to maintain heat

for the entire system when one of the pumps is shut

down.

NOTE: Heated systems have a red and black Power

Junction Box Switch (AK) that removes power to

everything EXCEPT heat on the ram supply unit. This

allows a ram supply unit to continue to heat the system

with the power to the ram turned off. See Power

Disconnect on page 14 for more information.

The Tandem Heat setup screen 1 allows you configure

how you want heat to be controlled for the entire system.

6. Press the soft key to save your changes and

exit editing mode.

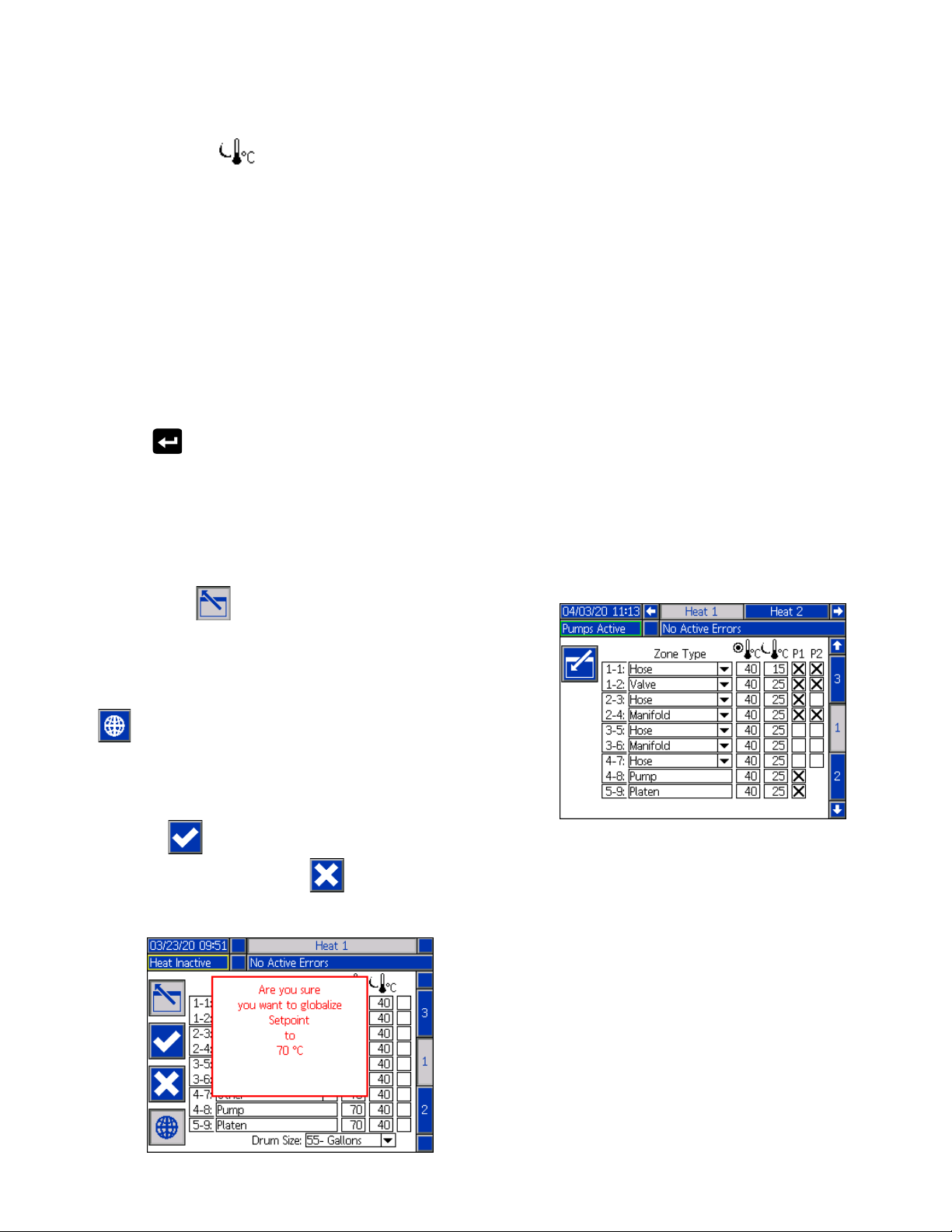

Apply a Heat Setting Globally

While still in Heat Setup screen 1, press the globalize

soft key to apply a setpoint or setback heat setting

across all of the heat zones.

A message will appear prior to completing the change.

Press the soft key to complete applying the

selected parameter. Press the soft key to cancel

the globalization.

Heat 1 in the Menu Bar is for the Heat Control Box (AX)

on the Pump 1 ram and Heat 2 is for the Heat Control

Box (AX) on the Pump 2 ram. The heat control box on

each ram controls heat to its pump, platen, and the hose

that runs from the pump to the Ball Valve (S) on the

Tandem Block (R).

Since all components from the Tandem Block R) to the

Dispense Valve (B) are shared by both pumps and need

to be heated continuously while the system is in

operation, you can designate one pump to control the

shared components at this screen.

NOTE: The cables for heat from the shared components

must be connected to the Heat Control Box (AX) on the

designated pump.

333587C 29

Page 30

Setup

In this example, the heat control box on Pump 1 (P1) is

the one selected to heat the shared components

running from the Tandem Block (R) to the Dispense

Valve (B).

1. Press the soft key to enter editing mode.

2. Configure your Zone Type and setpoint and setback

temperatures as described in Heat Setup Screen 1

on page 28.

3. Use the key to enable the zones under P1 that

will control the heat for the entire system.

NOTE: Since P1 will be the heat control for the shared

components, you need to enable the same zones for P2

while at the Heat 1 screen. This sets P1 to control the

heat for its pump, platen, and hose while also controlling

the heat for the components that P1 and P2 share.

4. Use the key to enable the zones under P2 that

are enabled under P1.

5. Use the ADM Directional Keypad (CH) to move to

Heat 2 in the Menu Bar.

6. Use the key to enable only the pump and

platen zones and the zone for the hose that runs

from the ram supply unit for P2 to the Ball Valve (S)

on the Tandem Block (R) since all others are

controlled by P1.

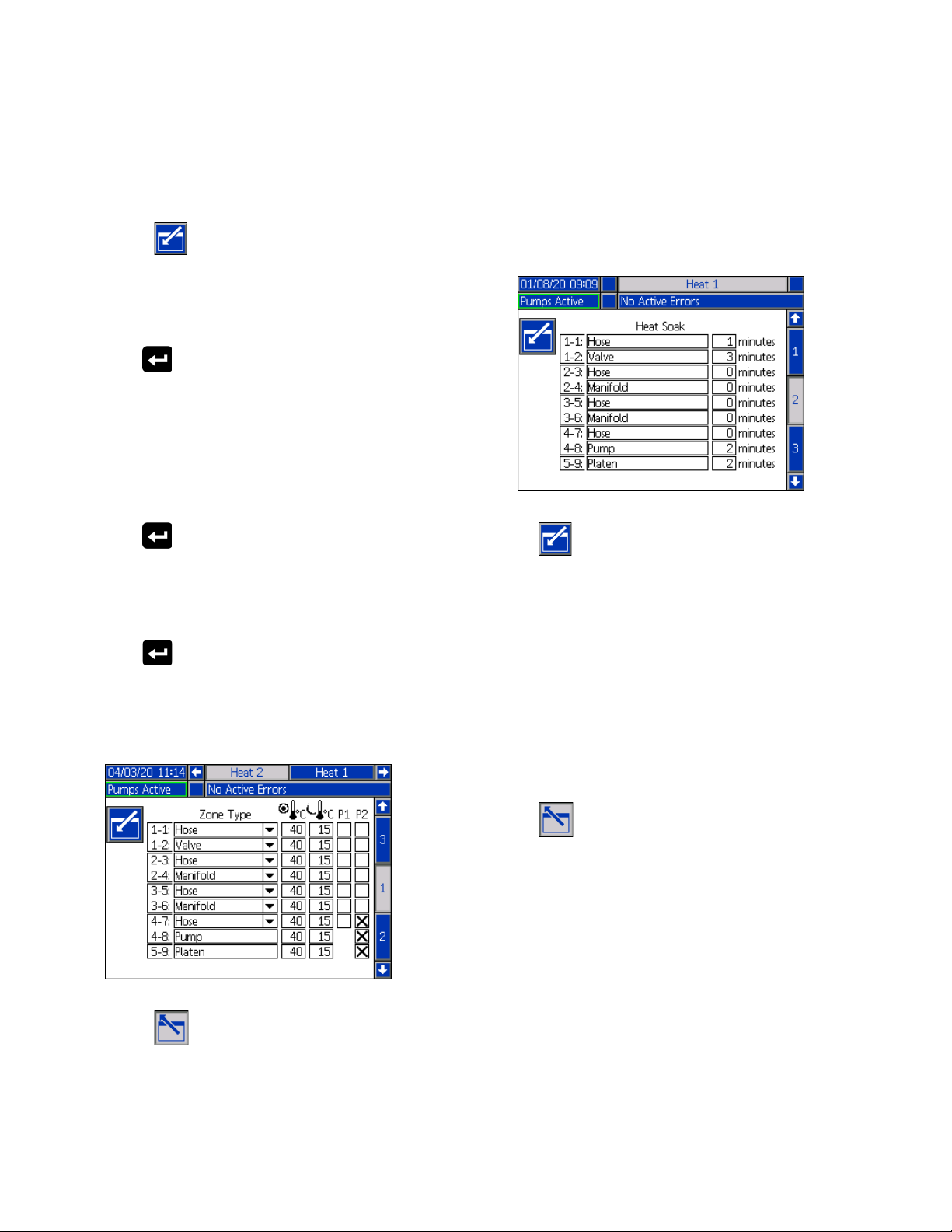

Heat Setup Screen 2 - Heat Soak

Use the ADM Directional Keypad (CH) to navigate to

Heat screen 2. This screen is the same for Ram and

Tandem except for the additional Heat 2 selection in the

Menu Bar. Make sure you configure heat soak time for

both Heat 1 and Heat 2 in a Tandem system.

Press the soft key to enter editing mode.

The heat soak time in the far right column is the amount

of additional time that the heat zone needs to ensure

that the material is heated evenly throughout after the

zone is up to temperature. Enter a time in minutes.

NOTE: Three minutes is the minimum amount of heat

soak time needed to make sure that the dispense valve

is completely up to temperature.

The Zone Types can only be changed at the Heat Setup

screen 1. See Heat Setup Screen 1 on page 28.

Press the soft key to save your changes and exit

this screen.

7. Press the soft key to save your changes and

exit editing mode.

30 333587C

Page 31

Setup

Heat Setup Screen 3

Use the ADM Directional Keypad (CH) to navigate to

Heat screen 3. The Tandem screen is shown below. The

Ram screen is identical except for only having Heat 1 in

the Menu Bar. Make sure you configure these settings

for both Heat 1 and Heat 2 in a Tandem system.

1. Press the soft key to enter editing mode.

2. In the Temp Offset Errors section, set the variance

in degrees allowed from a zone temperature setting

before a deviation and alarm is triggered. The

default values are 15 for deviations and 25 for

alarms. You can enter other temperature values.

For example, if the zone temperature is set at 50

degrees and you set +15 degrees for a High

Deviation and +25 degrees for a High Alarm, the

deviation will occur when the temperature reaches

65 (50 +15) and the alarm will occur when it reaches

75 (50 + 25).

heated. To avoid overshooting material heat, select

the appropriate option based on the running

temperature.

NOTE: If material heat overshoots on a particular heat

rate setting, select a slower heat rate.

Running Temperature Heat Rate Option

26° C - 40° C Slow

41° C - 55° C Normal

56° C - 70° C Fast

5. The Drum Size at the bottom of the screen shows

the size of the drum for that ram supply unit. Select

the correct drum size from the two options: 5 Gallon

Drum and 55 Gallon Drum. The correct drum size

must be selected to properly heat the platen.

6. Press the soft key to save your changes and

exit this screen.

Advanced Setup

Use the ADM directional keypad (BH) to change to iQ

Menu screen 2. Press the soft key to access the

Advanced Setup screens. This function allows you to

configure the operating settings for E-Flo iQ system.

Advanced Setup Screen 1

1. Press the soft key to enter editing mode.

The same applies to the Low Alarm and Low

Deviation settings. In the same example at 50

degrees with a Low Deviation of -15 and a Low

Alarm of -25, the deviation will occur when the

temperature reaches 35 (50-15) and the alarm will

occur when it reaches 25 (50-25).

NOTE: These offsets apply to all of the heat zones in

the Ram or Tandem system.

3. The Heat Idle Timeout feature provides the

capability to deactivate heat after the pump has not

moved for a selected number of hours. Enter the

number of hours in the box provided.

4. Select a Heat Rate Option from the drop down

menu. The available options are slow, normal, and

fast. The heat rate controls how fast the material is

333587C 31

2. Select the Language from the drop down menu.

Available languages are English, Spanish, French,

German, traditional Chinese, Japanese, Korean,

Portuguese, Italian, and Russian.

Page 32

Setup

3. Select a Date Format from the drop down menu.

The available formats are mm/dd/yy, dd/mm/yy,

yy/mm/dd.

4. Enter numeric values for the month, day, and

two-digit year in the Date field.

5. Enter numeric values in the Time field for the

24-hour clock in hours and minutes.

6. Enter the number of minutes of inactivity before the

Screen Saver turns off the screen back-lighting.

Enter a 0 to leave it on constantly. Press any key to

disable the screen saver.

7. For the Password, enter any numbers from 0001 to

9999. To remove the password, change the

password to 0000. This disables the password

function.

NOTE: When you use a password, some iQ Menu

selections will require the password for access. See iQ

Menu on page 22 for additional information.

8. For the Password Timeout, enter a time in minutes

that allows you to temporarily move throughout the

screens without having to enter a password. The

timeout starts after returning to the Run screen.

Once the time has expired, you must enter the

password again.

9. Enabling the Display Control Password feature

requires you to enter the password before switching

from Remote to Local control mode. See Control

Modes on page 40. This protects against

inadvertently changing out of Remote control mode.

If the password is disabled by being set to 0000, this

feature will not function even if it is set to Enable.

Press the soft key to save your changes and exit

editing mode.

1. Press the soft key to enter editing mode.

2. Select between psi, bar, and MPa for the Pressure

Units.

3. Select the Rate between x/min and x/sec.

4. Select the Flow Rate from cc, gal(US), gal(UK),

oz(US), oz(UK), liters, or cycles.

5. Select the Drum Volume from cc, gal(US), gal(UK),

oz(US), oz(UK), liters, or cycles.

6. Select the Temperature between °C and °F.

7. For Enabled Temp Adjustments, use the key to

select to Enable or Disable temperature

adjustments. Enabling this feature allows you to

change temperature setpoints and setbacks through

the Heat Run screen. See Heat Run Screen on

page 42.

8. Press the soft key to save your changes and

exit editing mode.

Advanced Setup Screen 3

Advanced Setup Screen 2

Use the ADM directional keypad (BH) to navigate to

Advanced Screen 2. This screen allows you to select

units of measurement, rates, and the type of

temperature scale to use for the operation of your

system.

32 333587C

Use the ADM Directional Keypad (CH) to navigate to

Advanced Screen 3. The parameters on this screen

pertain to USB downloads.

Page 33

Setup

1. Press the soft key to enter editing mode.

2. USB downloads automatically begin when a USB

drive is inserted. Use the key to disable this

feature in the Disable USB Downloads/Uploads box.

3. If you do not want USB log errors to be generated

on the ADM, use the key to disable this feature

in the Disable USB Log Errors box.

4. For the Download Depth: Last feature, set the

desired download depth using the keypad and

key to enter the desired number of days. This

specifies how many days worth of pump data will be

kept in the USB logs. Once the logs fill up, the

oldest recording will be overwritten.

5. To enable a time frame range of data to download

upon insertion of a USB drive, use the key in

the Data Range Prompt Enable box.

6. Press the soft key to save your changes and

exit editing mode.

Advanced Setup Screen 4

Use the ADM Directional Keypad (CH) to navigate to

Advanced Screen 3.

This screen can be used to view the version of software

used in the system. Additionally, this screen is used to

update the system software using a USB drive with the

latest software and a Graco black token. The latest

software is provided on Help.graco.com.

Refer to the ADM Token In-System Programming

manual for a detailed description of this screen. See

Related Manuals on page 3.

Connect Light Tower Assembly

1. Order the 255468 Light Tower Accessory as a

diagnostic indicator for the E-Flo iQ System.

2. Connect the cable from the light tower to the digital

I/O port (CS) on the ADM (AF).

Signal Description

Off System is not active

Green Only On System is active and no errors are

present

Blinking Green Heat is warming up

Yellow On An advisory exists

Blinking Yellow A deviation exists

Red solid The system is shut down due to

an alarm occuring

NOTE: See Troubleshooting on page 53 for error

definitions.

333587C 33

Page 34

Startup

AE

Connect

Hose

Startup

Letters in parenthesis are used in this section for reference to callouts in the Component Identification sec-

tion starting on page 11.

Flush the Pump

To avoid fire and explosion, always ground the equipment and the waste container. To avoid static spark-

ing and injury from splashing, always flush at the

lowest possible pressure.

NOTE: Pumps (AC) are tested with lightweight oil,

which is left in to protect the Pump parts. If the material

you are using may be contaminated by the oil, flush it

out with a compatible solvent before using the Pump

(AC).

3. Connect a hose to the 1 in. npt fitting on the top of

the Check Valve Block (AE). Place the other end of

the hose into a grounded waste container.

4. Turn on the Disconnect Switch (AZ). If using a

heated system, also turn on the Power Junction Box

switch (AK).

5. Press the Startup button (CA) on the ADM (AF) to

enable the system.

6. At the ADM (AF) Run screen, press the soft key

next to the icon to enter editing mode.

Always flush at the lowest pressure possible. Check

connectors for leaks and tighten as necessary. Flush

with a fluid that is compatible with the material being dis-

pensed and the equipment wetted parts.

NOTE: Check with your material manufacturer or supplier for recommended flushing fluids and flushing fre-

quency.

NOTICE

To prevent damage to the pump from rust, never

leave water or water-based fluid in a carbon steel

pump overnight. If you are pumping a water-based

fluid, flush with water first. Then flush with a rust

inhibitor, such as mineral spirits. Relieve pressure,

but leave the rust inhibitor in the pump to protect

parts from corrosion.

For information about Priming the system, refer to

Priming Mode on page 41.

1. Follow the Pressure Relief Procedure on page 46.

2. Place a pail of compatible solvent in the Ram (AA).

7. Press the soft key to enter the pump priming

mode. Two fields appear on the screen next to the

pump: target pressure (top) and target flow (bot-

tom).

8. Enter 100 psi (0.7 MPa, 7 bar) as the target pres-

sure and enter 25 cc/min as the target flow.

9. Press the soft key to initiate the Pump (AC)

and start flushing the system. This loads the solvent

into the Pump (AC).

10. Adjust pressure as necessary and flush the system

until clear solvent flows from the hose.

11. Press the soft key to stop the Pump (AC).

12. Press the soft key to exit editing mode.

13. Follow the Pressure Relief Procedure on page 46.

14. Remove the solvent pail from the Ram (AA).

15. Repeat steps 1 through 14 for the second pump in a

Tandem system.

34 333587C

Page 35

Load Material

Platen Valve

Port with Cap

Recirculation

Hose (ZB)

Platen Wiper

Platen Bleed

Stick

The following steps are required when you are loading

material in the system for the first time. This procedure

should be performed after the E-Flo iQ system is

installed, flushed, and ready for operation. Refer to the

E-Flo iQ Supply System Installation-Parts manual for

installation. See Related Manuals on page 3.

Startup

7. Place a full pail or drum of material on the Ram (AA)

base and center it under the Platen (AD). Then

remove the drum cover and smooth the surface of

the material with a straightedge.

8. To prevent air from being trapped under the Platen

(AD), scoop fluid from the center of the pail/drum to

the sides to make the surface concave.

9. Adjust the pail/drum to make sure it is aligned with

the Platen (AD).

10. Remove the Platen Bleed Stick to open the Platen

Bleed Port (AH).

For additional information about the E-Flo iQ Run

screens, including priming and depressurization, see

Operation on page 38.

NOTE: For an E-Flo iQ system with a Platen Valve (AY)

installed, you need to ensure that the Platen Valve

setting is enabled in the Pump Settings on the ADM

before starting this procedure. See Pump Screen 2 -

Drum Settings on page 27.

NOTE: For Tandem systems, complete all steps in the

following sections on both ram supply units before

performing the steps in Load the Hose and Dispense

Valve:

• Prepare the Pump

• Load the Platen and Platen Valve

• Load the Pump

• Load the Platen Valve and Recirculation Hose

Prepare the Pump

1. For Tandem Systems, ensure the Ball Valves (S) on

the Tandem Block (R) are closed.

2. Turn on the Disconnect Switch (AZ). If using a

heated system, also turn on the Power Junction Box

switch (AK).

NOTE: If a Platen Valve (AY) is installed on the system,

do not connect the Recirculation Hose (ZB) to the Platen

Valve Port until you have completed loading material

through the system.

11. With your hands away from the pail/drum and the

Platen (AD), move the Ram Director Valve (BC)

down to lower the Ram (AA) until the Platen (AD)

rests on the lip of the pail/drum.

12. Return the Ram Director Valve (BC) to the neutral

position.

Load the Platen and Platen Valve

3. Open the Main Air Slider Valve (BA) on the

Integrated Air Control and set the Ram Air

Regulator (BB) to 40 psi (.20 MPa, 2.0 bar).

4. Move the Ram Director Valve (BC) up to raise the

Ram (AA) to its full height.

5. Set the Ram Director Valve (BC) to neutral

(horizontal position).

6. Lubricate the Platen Wiper with grease or another

lubricant compatible with the material being loaded.

333587C 35

1. For Tandem systems, ensure the Ball Valves (S) on

the Tandem Block (R) are closed.

2. Move the Ram Director Valve (BC) down to lower

the ram until material appears at the Platen Bleed

Port (AH).

3. Return the Ram Director Valve (BC) to the neutral

position.

4. Replace the Platen Bleed Stick that was removed in

step 8 in Prepare the Pump.

Page 36

Startup

5. If a Platen Valve (AY) is installed on the system,

remove the cap from the Platen Valve Port located

on the platen.

6. Move the Ram Director Valve (BC) down to lower

the ram again until material appears the Platen

Valve Port.

7. Return the Ram Director Valve (BC) to the neutral

position.

8. Replace the Platen Valve Port cap.

Load the Pump

1. For Tandem systems, ensure the Ball Valves (S) on

the Tandem Block (R) are closed.

2. Move the Ram Director Valve (BC) down to lower

the Ram (AA).

3. At the ADM (AF), press the soft key to enter

the pump priming mode. Two fields appear on the

screen next to the pump: target pressure (top) and

target flow (bottom).

4. Enter 100 psi (0.7 MPa, 7 bar) as the target

pressure and enter 25 cc/min as the target flow.

NOTE: Loading the material at the low pressure and

flow rate in step 3 keeps the Pump (AC) from cavitating,

since there is no material loaded in the Pump (AC).

NOTE: Priming mode has a timer that is shown to the

left of the priming mode icon and counts down when the

priming starts. The default is 5 minutes. If time expires

before you are done loading material to the system,

press the soft key to restart priming mode. Your

target pressure and flow settings remain the same.

Load the Platen Valve and Recirculation

Hose

NOTE: The following steps only apply to systems that

include the Platen Valve (AY). For systems without a

Platen Valve, go to step 1 in Load the Hose and Valve.

1. For Tandem systems, ensure the Ball Valves (S) on

the Tandem Block (R) are closed.

2. Place the Recirculation Hose (ZB) into a waste

container.

3. While still in pump priming mode and with the target

pressure still set at 100 psi (0.7 MPa, 7 bar) and the

target flow at 25 cc/min, press the soft key to

enter the platen depressurization mode.

4. Press the soft key to start the Pump (AC).

5. Increase pressure and flow rates on the screen as

necessary.

6. Run the Pump (AC) until a steady stream with no air

flows out of the Recirculation Hose.

7. Press the soft key to stop the Pump (AC).

8. Press the soft key to exit the platen

depressurization mode.

9. Move the Ram Director Valve (BC) to the neutral

position.

10. Remove the cap from the Platen Valve Port.

11. Install the Recirculation Hose (ZB) to the Platen

Valve Port and tighten until secure.

5. Open the Pump Bleed Valve (AM) and place a

waste container below it to catch material.

6. Press the soft key to start the Pump (AC).

7. Increase pressure and flow rates on the screen as

necessary to fill the Pump (AC) with material.

8. When a steady stream of material with no air comes

out of the Pump Bleed Valve (AM), close the valve.

9. Press the soft key to stop the Pump (AC).

36 333587C

NOTE: It is important to load the Platen Valve (AY) and

Recirculation Hose (ZB) with material before connecting

it to the Platen Valve Port to ensure no air is introduced

into the material. Failure to follow these steps could

cause air pockets in the material.

Load the Hose and Dispense Valve

NOTE: For Tandem systems, ensure that the previous

four sections are completed for both ram supply units

before performing these steps.

1. On a Tandem system, open the Ball Valves (S) on

the Tandem Block (R).

Page 37

2. Place a waste container below the Dispense Valve

(A).

3. Ensure all fittings are secure from the Pump (AC)

out to the Dispense Valve (A).

4. While still in pump priming mode and with the target

pressure still set at 100 psi (0.7 MPa, 7 bar) and the

target flow at 25 cc/min, press, the soft key to

enter the valve depressurization mode on Pump 1.

5. Press the soft key to start the Pump (AC). This

will open the Dispense Valve (A) and allow the

pump to run at the set pressure and flow rate.

6. Increase pressure and flow targets as necessary

until a steady stream with no air flows out of the

Dispense Valve (A).

7. Press the soft key to stop the Pump (AC).

Startup

5. Press the soft key to enter the pump priming

mode.

6. To control the flow of material, set your target

pressure and target flow in the fields that are

displayed above the line and style number. Ensure

that the target prime pressure is at least 100 psi

below current system operating pressure, but not

less than 400 psi below current operating pressure.

8. Press the soft key to exit the valve

depressurization mode.

9. Press the soft key to exit priming mode

Tandem Priming when Changing Drums

When priming one ram supply unit of a Tandem system,

the other ram does not need to be stopped when you

want to change material drums. The other pump can

continue running and dispensing material.

NOTE: This can only be performed when the system is

in Remote control mode. For priming pumps in Local

mode during operation, see Priming Mode on page 41.

1. Press the soft key to change to Remote

control mode. If PLC lockout is active, the inactive

pump must be primed through the CGM.

2. Adjust the drum to make sure it is aligned with the

Platen (AD). See Prepare the Pump on page 35.

3. Open both Ball Valves (S) on the Tandem Block (R).

7. Open the Pump Relief Valve (ZC) on the ram and

place a waste container below it to catch material.

8. Press the soft key to start the priming process.

9. Allow adequate amount of time for air to escape the

system through the Pump Relief Valve (ZC) while

priming. At least 30 seconds with no air pockets is

recommended.

NOTE: A timer shows to the left of the priming mode

icon and counts down during priming. The default is 5

minutes but can be adjusted between 1 and 9 minutes.

See Pump Screen 2 - Pump Settings on page 27.

10. When a steady stream of material with no air comes

out of the Pump Relief Valve (ZC), close the Pump

Relief Valve.

11. To manually stop the priming process at any time,

press the soft key. If you do not manually stop

the process, it will automatically stop when the timer