Page 1

Have a Question?

Call toll-free:

1-888-541-9788

Or visit us at:

www.paintsprayersbygraco.com

Owners Manual

WARNING

Scan QR code or click on link

for operational video.

http://graco.com/tc360op

Project Series Paint Sprayers

Important Safety Instructions

Read all warnings and instructions in this manual and on the

unit, including the power cord. Be familiar with the controls and

the proper usage of the equipment. Save these instructions.

333394H

EN

To avoid fire and explosion, use only

non-flammable or water-based materials, or

non-flammable paint thinners. Do not use

materials which state “FLAMMABLE” on the

packaging. For more information about your

material, request MSDS from distributor or

retailer.

Use oil based materials outdoors or in a

well-ventilated area with a flow of fresh air.

For portable spray applications of water-based and oil-based

non-flammable architectural paints and coatings only.

Not approved for use in explosive atmospheres or hazardous locations.

ti24021a

For Household Use Only.

Page 2

Contents

Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Starting a New Job . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Refilling FlexLiner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

How to Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Dual Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Spray Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Triggering Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Aiming Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Spray Pattern Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cleanup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cleaning VacuValve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Common Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing Spray Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Unclogging Spray Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Flushing a New Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Models 16Y385, 16Y386, 17A466 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parts List- Models 16Y385, 16Y386, 17A466 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Model 17D889 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parts List- Model 17D889 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Graco Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tip

Model Name Voltage

16Y385

17A466

16Y386

17D889

2 333394H

TrueCoat 360

TrueCoat 360 DS

TrueCoat 360 DSP

TrueCoat 360 VSP

120V 0.015 Single Speed 1200 psi (8.3 MPa, 83 bar)

120V 0.015 Dual Speed 900-1300 psi

120V 0.015 Dual Speed

120V 0.015 Variable

Size

Description Maximum Working Pressure

Premium

Speed

Premium

(6.2 MPa, 62 bar - 8.9 MPa,

(6.2 MPa, 62 bar - 8.9 MPa,

(3.5 MPa, 34.5 bar - 8.9 MPa,

Certified to CAN/CSA C22.2 No. 68

Conforms to UL 1450

89 bar)

900-1300 psi

89 bar)

500-1300 psi

89 bar)

110474

Page 3

Important User Information

Important User Information

Thank You for Your Purchase!

Before using your sprayer read this Owners Manual for complete instructions on proper use and

safety warnings.

Congratulations! You have purchased a high-quality paint sprayer made by Graco Inc.

This sprayer is designed to provide superior spray performance with water-based and

oil-based (mineral spirit-type) architectural paints and coatings. This user information is

intended to help you understand the types of materials that can be used with your sprayer.

Please read the information on the material container label to determine if it can be used

with your sprayer. Ask for a Material Safety Data Sheet (MSDS) from your supplier. The

container label and MSDS will explain the contents of the material and the specific

precautions related to it.

Paints, coatings and clean-up materials generally fit

into one of the following 3 basic categories:

WATER-BASED: The container label should indicate that the material can be

cleaned up with soap and water. Your sprayer is compatible with this type of

material. Your sprayer is NOT compatible with harsh cleaners such as

chlorine bleach.

OIL-BASED: The container label should indicate that the material is

COMBUSTIBILE and can be cleaned up with mineral spirits or paint thinner.

The MSDS must indicate that the flash point of the material is above 100° F.

Your sprayer is compatible with this type of material. Use oil-based material

outdoors or in a well-ventilated indoor area with a flow of fresh air. See the

safety warnings in this manual.

FLAMMABLE: This type of material contains flammable solvents such as

xylene, toluene, naphtha, MEK, lacquer thinner, acetone, denatured alcohol,

and turpentine. The container label should indicate that this material is

FLAMMABLE. This type of material is NOT compatible with your sprayer

and CANNOT be used.

333394H 3

Page 4

Important Safety Information

WARNING

ti3509b

WARNING

Important Safety Information

The following warnings are for the setup, use, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to

procedure-specific risks. When these symbols appear in the body of this manual or on warning

labels, refer back to these Warnings. Product-specific hazard symbols and warnings not

covered in this section may appear throughout the body of this manual where applicable.

GROUNDING INSTRUCTIONS

This product must be grounded. In the

event of an electrical short circuit,

grounding reduces the risk of electric

shock by providing an escape wire for

the electric current. This product is

equipped with a cord having a

grounding wire with an appropriate

grounding plug. The plug must be

plugged into an outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

•

Improper installation of the grounding plug

is able to result in a risk of electric shock.

•

When repair or replacement of the cord or

plug is required, do not connect the

grounding wire to either flat blade terminal.

•

The wire with insulation having an outer

surface that is green with or without yellow

stripes is the grounding wire.

•

Check with a qualified electrician or

serviceman when the grounding

instructions are not completely understood,

or when in doubt as to whether the product

is properly grounded.

•

Do not modify the plug provided; if it does

not fit the outlet, have the proper outlet

installed by a qualified electrician.

•

This product is for use on a nominal 120V

circuit and has a grounding plug similar to

the plug illustrated in the figures.

•

Only connect the product to an outlet having

the same configuration as the plug.

•

Do not use an adapter with this product.

Extension Cords:

Use only a 3-wire extension cord

•

that has a grounding plug and a

grounding receptacle that accepts

the plug on the product.

•

An undersized cord results in a

drop in line voltage and loss of

power and overheating.When in

doubt use the next heavier gauge.

The smaller the gauge number the

heavier the cord.

•

When using the sprayer outdoors, use an

extension cord suitable for outdoor use.

•

Make sure your extension cord is not

damaged. When using an extension cord, be

sure to use a cord heavy enough to carry the

current that your sprayer draws. See chart for

appropriate sizes and lengths:

Extension Cord

Conductor Size Length

AWG (American

Wire Gauge)

18

16

14

Metric Maximum

2

2

2

50 ft (15 m)

100 ft (30 m)

200 ft (61 m)

1.0 mm

1.5 mm

2.5 mm

4 333394H

Page 5

Important Safety Information

WARNING

WARNING

FIRE AND EXPLOSION

HAZARD

Flammable fumes, such as solvent

and paint fumes, in work area can

ignite or explode. To help prevent fire

and explosion:

•

Sprayer generates sparks. Do not

spray or flush with flammable

liquids.

•

Use only

water-based materials, or

non-flammable paint thinners.

•

Keep spray area well-ventilated.

Keep a good supply of fresh air

moving through the area.

•

When spraying oil-based material, use

outdoors or in a well-ventilated indoor area

with a flow of fresh air.

•

Do not spray or flush with combustible

materials near an open flame or sources of

ignition.

•

Paint or solvent flowing through the

equipment is able to result in static

electricity. Static electricity creates a risk of

fire or explosion in the presence of paint or

solvent fumes.

•

Keep sprayer at least 10 in. (25 cm) away

from objects while spraying or flushing.

•

Verify all containers and collection systems

are grounded to prevent static discharge.

•

Connect to a grounded outlet and use

grounded extension cords. Do not use a 3 to

2 adapter.

•

Do not use paints or solvents containing

halogenated hydrocarbons.

•

Do not smoke in the spray area.

•

Do not operate light switches, engines, or

similar spark producing products in the

spray area.

•

Keep area clean and free of paint or

solvent containers, rags, and other

flammable materials.

•

Know the contents of the paints and

solvents being sprayed. Read all Material

Safety Data Sheets (MSDS) and container

labels provided with the paints and

solvents. Follow the paint and solvents

manufacturer’s safety instructions.

•

Fire extinguisher equipment shall be

present and working.

non-flammable or

SKIN INJECTION HAZARD

High-pressure spray is able to inject

toxins into the body and cause serious

bodily injury. In the event that injection

occurs, get immediate surgical

treatment.

•

Do not aim the sprayer at, or spray any

person or animal.

•

Keep hands and other body parts away

from the discharge. For example, do not

try to stop leaks with any part of the body.

•

Disconnect power when not spraying.

•

Always use the spray tip guard. Do not

spray without spray tip guard in place.

•

Use caution when cleaning and changing

spray tips. In the case where the spray tip

clogs while spraying, follow the

Relief Procedure

the pressure before removing the spray tip

to clean.

•

Do not leave the unit energized or under

pressure while unattended. When the unit is

not in use, unplug the sprayer and follow the

Pressure Relief Procedure

• Check parts for signs of damage.

Replace any damaged parts.

• This system is capable of producing 2000

psi. Use replacement parts or

accessories that are rated a minimum of

2000 psi.

• Do not carry the unit with a finger on the

trigger.

• Verify that all connections are secure

before operating the unit.

• Know how to stop the unit and bleed

pressure quickly. Be thoroughly familiar

with the controls.

, page 14 for relieving

Pressure

, page 14.

ELECTRIC SHOCK HAZARD

This equipment must be grounded.

Improper grounding, setup, or usage

of the system can cause electric

shock.

•

Turn off and disconnect power cord before

servicing equipment.

•

Connect only to grounded electrical outlets.

•

Use only 3-wire extension cords.

•

Ensure ground prongs are intact on power

and extension cords.

•

Do not expose to rain or wet conditions.

Store indoors.

333394H 5

Page 6

Important Safety Information

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious

injury.

•

Always wear appropriate gloves, eye

protection, and a respirator or mask when

painting.

•

Do not operate or spray near children. Keep

children away from equipment at all times.

•

Do not overreach or stand on an unstable

support. Keep effective footing and balance

at all times.

•

Stay alert and watch what you are doing.

•

Do not operate the unit when fatigued or

under the influence of drugs or alcohol.

•

Use only in dry locations. Do not expose to

water or rain.

•

Use in well-lit areas.

•

Do not spray outdoors on windy days.

TOXIC FLUID OR FUMES

HAZARD

Toxic fluids or fumes can cause

serious injury or death if splashed in

the eyes or on skin, inhaled, or

swallowed.

•

Read MSDS’s to know the specific hazards

of the fluids you are using.

•

Store hazardous fluid in approved

containers, and dispose of it according to

applicable guidelines.

PRESSURIZED ALUMINUM

PARTS HAZARD

Use of fluids that are incompatible with

aluminum in pressurized equipment

can cause serious chemical reaction

and equipment rupture. Failure to

follow this warning can result in death,

serious injury, or property damage.

•

Do not use 1,1,1-trichloroethane,

methylene chloride, other halogenated

hydrocarbon solvents or fluids containing

such solvents.

•

Do not use chlorine bleach.

•

Many other fluids may contain chemicals

that can react with aluminum. Contact your

material supplier for compatibility.

PERSONAL PROTECTIVE

EQUIPMENT

Wear appropriate protective equipment when

in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This protective

equipment includes but is not limited to:

•

Protective eye wear, and hearing

protection.

•

Respirators, protective clothing, and gloves

as recommended by the fluid and solvent

manufacturer.

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the

State of California to cause cancer, birth defects

or other reproductive harm. Wash hands after

handling.

6 333394H

Page 7

Component Identification

A

B

C

D

E

F

G

H

N

L

K

S

R

Spray

J

M

ti25736a

P

Prime Pump

Component Identification

A Cup Cover

B FlexLiner

C Cup Support

D VacuValve Cap

E VacuValve Air Hole

F VacuValve Reservoir

GStrainer

H Spray Tip Holder

J Prime Pump/Spray Knob

K Power Cord

L Sprayer Trigger

M Dual Speed Control, HIGH/LOW

Switch (DS and DSP models only)

N Spray Tip, Black (12-inch pattern)

P Spray Tip Guard

R Variable Speed Control (VSP models

S Kickstand

Spray Tip, Gray (4-inch pattern)

only)

333394H 7

Page 8

Start Up

ti23361a

ti24279a

ti23258b

ti23343a

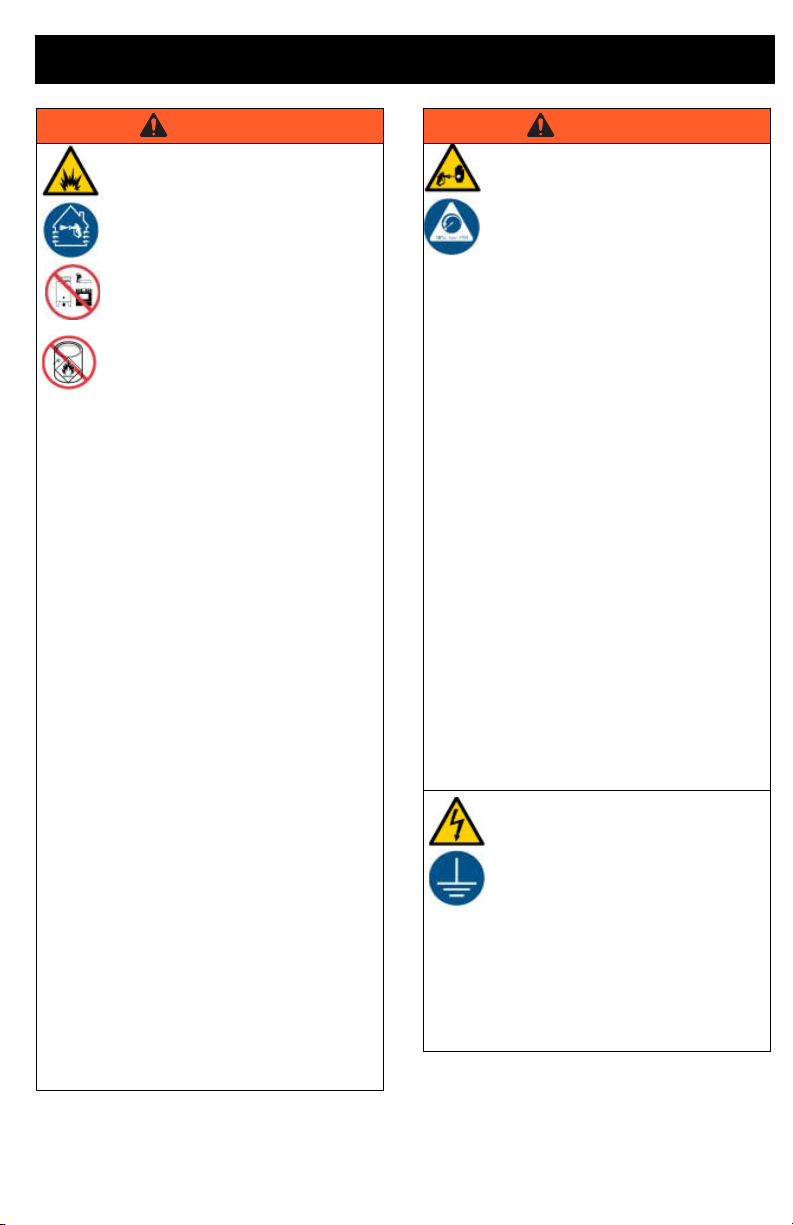

Start Up

Use only water-based or oil-based

(mineral spirit-type) materials with a

flash point greater than 100° F (38° C).

Do not use materials which state

“FLAMMABLE” on the packaging. For

more information about your material,

request MSDS from distributor or retailer.

When spraying oil-based material, use

outdoors or in a well-ventilated indoor

area with a flow of fresh air.

Keep spray area well-ventilated. Keep

a good supply of fresh air moving through

the area.

NOTICE

Your sprayer is

cleaners such as chlorine bleach. Using

these cleaners will cause damage to the

sprayer.

NOT

compatible with harsh

2. Fill FlexLiner with material. Securely

tighten cup cover onto cup support.

Tighten so the arrow on the cup cover is

within range of the indicator on the cup

support.

3. Align VacuValve on cup cover with

Prime Pump/Spray knob. Push cup

assembly onto sprayer and twist to lock.

Starting a New Job

If you are using the sprayer for the very first

time, see Flushing a New Sprayer, page 20.

1. Install FlexLiner in the cup support.

4. The VacuValve is an important part of

your new sprayer. It is used to evacuate

the air out of the FlexLiner. Open

VacuValve cap.

8 333394H

Page 9

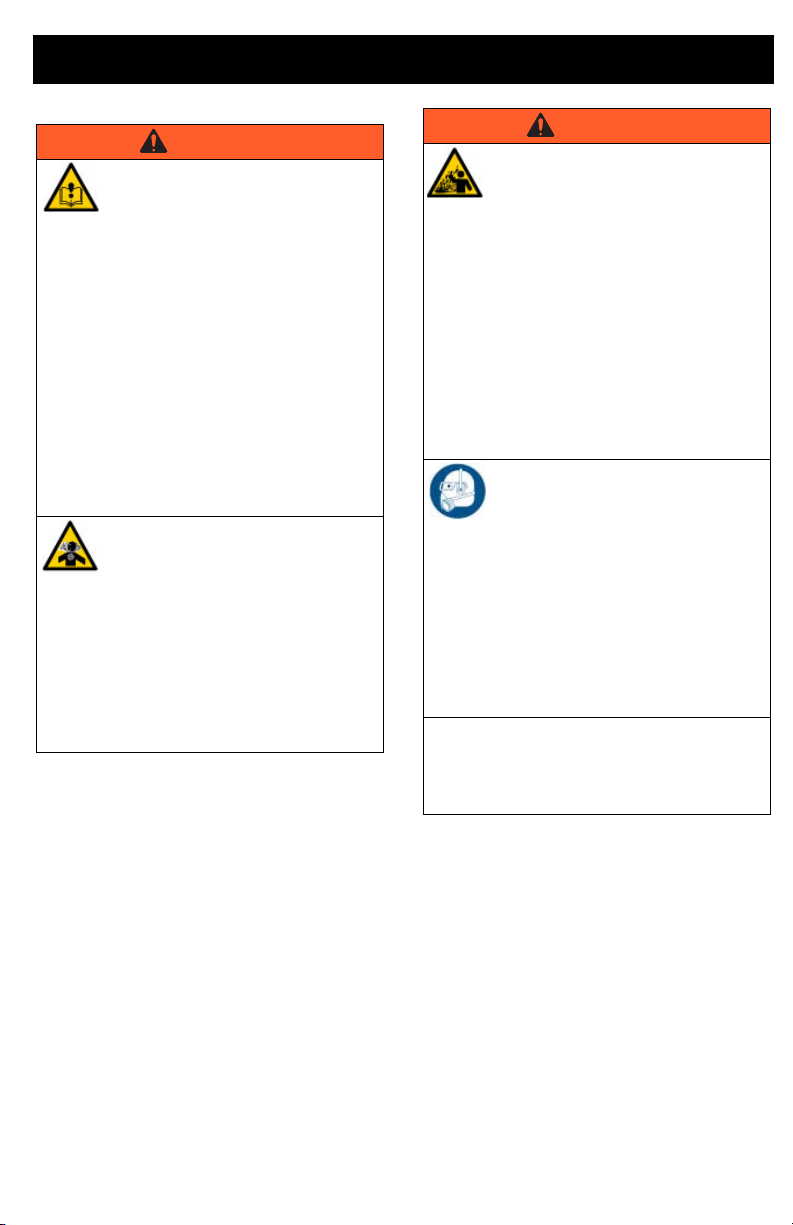

Tilt the sprayer so the VacuValve is the

ti23345a

ti23355a

ti23285a

Prime Pump

ti23354a

ti23288a

Spray

ti23290a

SPRAY UNCLOG

5.

highest point, causing any air in the

FlexLiner to rise to the VacuValve.

Gently squeeze the FlexLiner to

evacuate all air through the VacuValve

air hole. Once you see material enter the

VacuValve reservoir, all air should be

evacuated from the FlexLiner.

6. Stop squeezing the FlexLiner and snap

the VacuValve cap closed. You will hear

the cap click when it is closed properly.

Start Up

9. Turn Prime Pump/Spray knob forward to

spray position.

10. Make certain spray tip is in the spray

position.

7. Plug sprayer into power source.

8. Turn Prime Pump/Spray knob down to

Prime Pump position. To fill sprayer with

fluid, point sprayer into a waste area and

hold the trigger in for

5–10 seconds.

11. You are now ready to spray.

NOTE: For best results; to evacuate all

333394H 9

material from the FlexLiner when the material

is nearly gone, gently squeeze the bottom of

the FlexLiner to push the last of the material

up to the cup lid.

Page 10

Start Up

ti24454a

ti23288a

Spray

ti23369a

If sprayer does not spray, try one of

the steps below:

• Make certain there is only one FlexLiner

in cup support. It is possible for two liners

to nest tightly together and appear as

only one.

• Make certain the cup cover is properly

threaded to the cup support. If threads

are visible below the cup cover when

tight, then the cover is cross-threaded.

Fully remove the cup cover and reinstall

to the cup support so no threads are

visible when tight.

• Repeat steps 2 – 6 on pages 8 – 9 to

ensure all the air is evacuated from the

FlexLiner.

• Make certain the Prime Pump/Spray

knob is in the Spray position.

• If sprayer still does not spray, perform

steps10 and 11 on page 21. If material

sprays while upside down there is air in

the cup. Repeat steps above.

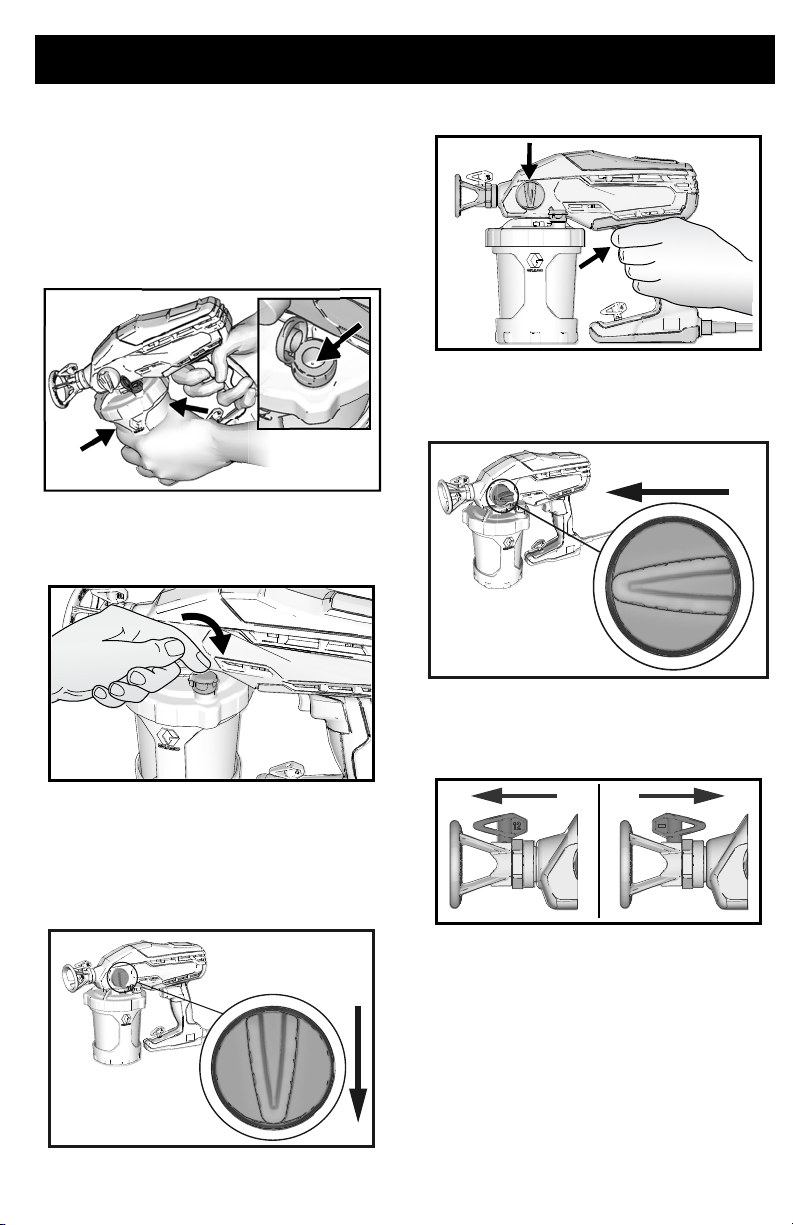

Refilling FlexLiner

If sprayer runs out of paint simply separate

the cup support from the cup cover/sprayer

and refill the FlexLiner.

1. Unplug sprayer from power source.

2. Separate the cup support from the

cover/sprayer.

down on a flat surface. This will keep the

wet paint in the cup cover.

3. Follow steps 2 - 11 in Starting a New

Job, page 8 procedure.

Set the sprayer upside

cup

10 333394H

Page 11

How to Spray

ti23374a

EVEN

FINISH

10 in.

(25 cm)

UNEVEN

FINISH

THICK

THIN

How to Spray

Take a few moments prior to spraying and

review these simple tips to ensure your

spraying project is a success.

Dual Speed Control

(Not available on all units)

The dual speed control feature allows you to

slow down or speed up when spraying.

• Turn the dual speed control to LOW to

slow down the speed of application when

first learning to spray or when spraying

small items that require more control.

• The LOW setting delivers more control

and will reduce overspray when spraying

thinner materials such as stain.

• Turn the dual speed control to HIGH

when you want to get to job done fast and

when spraying large surfaces.

• To reduce overspray, always spray at

lowest speed that results in an

acceptable spray pattern.

Variable Speed Control

(Not available on all units)

The variable speed control feature allows you

infinite speed control to slow down or speed

up to best suit your material and project.

• Turn the variable speed control to lower

speed settings to slow down the speed of

application when first learning to spray or

when spraying small items that require

more control.

• The lower speed settings deliver more

control and will reduce overspray when

spraying thinner materials such as stain.

• Turn the variable speed control to higher

speed settings when you want to get the

job done fast and when spraying large

surfaces.

• To reduce overspray, always start at

lowest speed setting and increase speed

to the minimum setting that results in an

acceptable spray pattern.

Spray Techniques

Use a piece of scrap cardboard to practice

these basic spraying techniques before you

begin spraying the surface.

• Hold sprayer 10 in. (25 cm) from surface

and aim straight at surface. Tilting the

sprayer to direct the spray angle causes

an uneven finish.

• Flex wrist to keep sprayer pointed

straight. Fanning sprayer to direct spray

at angle causes uneven finish.

NOTE: How fast you move the sprayer will

affect spray application. If material is

pulsating, you are moving too fast. If material

drips, you are moving too slow. See

Troubleshooting, page 26.

333394H 11

Page 12

How to Spray

ti23375a

EVEN FINISH

THICK THINTHIN

ti23376a

ti23378a

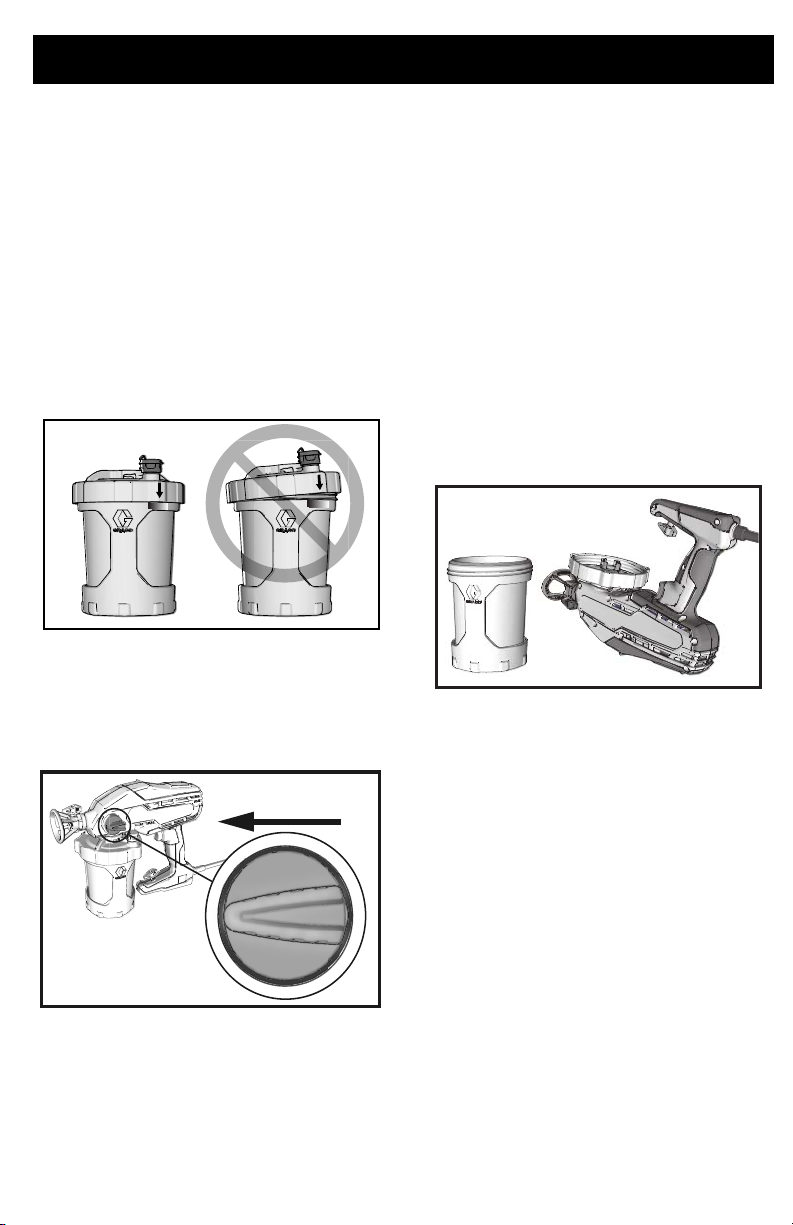

Triggering Sprayer

Aiming Sprayer

Aim sprayer at bottom edge of previous

stroke, overlapping each stroke by half.

Rotating the spray tip guard changes the

pattern to either the vertical or horizontal

orientations.

When spraying vertical corners turn spray tip

guard to the horizontal orientation and move

sprayer up and down.

Pull trigger after starting stroke. Release

trigger before end of stroke. Sprayer must be

moving when trigger is pulled and released.

12 333394H

Page 13

How to Spray

ti23382a

GOOD PATTERN

BAD PATTERN

TAILS

TAILS

Spray Pattern is Pulsating

Spray Pattern Quality

A good spray pattern is evenly distributed as

it hits the surface. If tails persist, material may

need to be thinned.

If material needs to be thinned follow

manufacturers recommendations.

If you see pulsations in the pattern, try the

following:

• On the dual speed models turn the dual

speed control to HIGH

• On the variable speed models turn the

variable speed control to higher setting

• Slow down your speed of movement

• Hold sprayer farther away from surface

• Switch to black (12") spray tip

333394H 13

Page 14

Cleanup

ti23408a

ti23285a

Prime Pump

ti23385a

Cleanup

Use only water-based or oil-based

(mineral spirit-type) materials with

flash point greater than 100° F (38° C).

Do not use materials which state

“FLAMMABLE” on the packaging. For

more information about your material,

request MSDS from distributor or retailer.

Clean in a well-ventilated area. Keep a

good supply of fresh air moving through

the area.

To avoid serious injury or damage to

equipment, do not expose the sprayer

electronics to cleaning fluids. Keep

sprayer at least 10 in. (25 cm) above the

rim of the container when cleaning.

1. Disconnect power (unplug power cord).

2. Turn Prime Pump/Spray Knob down to

PRIME PUMP position to relieve

pressure.

Cleaning Sprayer

Cleaning your sprayer properly and after every

spray job is of the utmost importance! Proper

care and maintenance will make your paint

sprayer last and work for you trouble free.

1. Turn Prime Pump/Spray knob to Prime

Pump to relieve pressure.

2. Separate the cup support with FlexLiner

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

This sprayer builds up an internal

pressure of 2000 psi (14 MPa, 138 bar)

during use. Follow this Pressure Relief

Procedure whenever you stop spraying

and before cleaning, checking, servicing,

or transporting equipment to prevent

serious injury.

14 333394H

from the cup cover/sprayer.

Page 15

Cleanup

ti23387a

ti23383a

ti23384a

ti23388a

3. Set the sprayer upside down on a flat

surface. This will keep the wet paint in

the cup cover. Return excess material to

original container. Hold the FlexLiner in

place when pouring.

4. You can either dispose of the used

FlexLiner and install a new FlexLiner or

clean a used FlexLiner.

5. To clean the sprayer, fill FlexLiner

approximately half-full with appropriate

cleaning fluid (water or mineral spirits).

6. Securely tighten cup cover onto cup

support.

8. Make certain the Prime Pump/Spray

knob is in the Prime Pump position

(pointed down). On models with a dual

speed control switch, set speed control

to HIGH. On variable speed models set

speed control to 10.

9. Turn the sprayer upside down and point

the sprayer into a waste pail. Pull the

trigger for ten seconds.

10. Turn Prime Pump/Spray knob forward to

SPRAY position. Reverse spray tip to

UNCLOG position.

11. While holding the sprayer upside down

point the sprayer into a waste pail. Pull

the trigger for five seconds. Release the

trigger.

12. If second spray tip was used, remove

7. To clean the cup cover and strainer,

secure the cup assembly to the sprayer

and shake the entire sprayer for ten

seconds.

333394H 15

cleaned spray tip from spray tip guard

and install second spray tip. See

Installing Spray Tips, page 18. Repeat

steps 10 and 11 to clean second spray

tip.

Page 16

Cleanup

ti23389a

ti23404a

ti23372a

ti23406a

16. Use a soft cloth to clean the cup support

and cup cover.

13. Remove cup assembly and discard used

fluid. Dispose of used cleaning fluid

properly.

14. Replace cleaning fluid and repeat steps

1- 13 until spray output is clean.

IMPORTANT! For best results, do not spray

more than one cup of water through the tip

while cleaning. If more flushing is needed,

remove the tip from the sprayer to avoid

excessive wear.

15. Remove spray tip and strainer, see

Remove Spray Tip, page 18. Clean with

appropriate cleaning fluid (water or

mineral spirits). A soft brush can be used

to loosen and remove dried material if

needed.

NOTICE

The spray tip guard is permanently

attached to the sprayer. Removal for

cleaning is not necessary and will result in

damage to the sprayer.

Cleaning VacuValve

The VacuValve is an important part of your

sprayer and it should be cleaned after every

use.

1. Remove VacuValve cap from cup cover

and clean it.

2. Clean VacuValve reservoir in lid.

3. Clean VacuValve air hole. If VacuValve

air hole becomes clogged, use a paper

clip to clean the hole.

16 333394H

Page 17

Storage

ti23285a

Prime Pump

ti23707b

ti23388a

NOTICE

Failure to store sprayer with Pump Armor

will result in operational problems the next

time you spray. Always circulate Pump

Armor through the sprayer after cleaning.

Water or solvents other than mineral

spirits left in the sprayer will corrode

and damage the pump.

Pump Armor fluid protects the sprayer while

in storage. It helps protect sprayer against

freezing and corrosion when not in use.

1. Clean the sprayer and cup assembly.

See Cleanup, page 14.

2. Turn Prime Pump/Spray knob down to

the Prime Pump position. Remove cup

support and FlexLiner. Make certain that

VacuValve cap is closed.

Storage

7. With sprayer upside-down attach cup

support with FlexLiner to sprayer.

8. Holding sprayer upside-down over a

waste container, pull sprayer trigger for

three seconds.

3. Separate the cup support with FlexLiner

from the cup cover/sprayer. Set the

sprayer upside down on a flat surface.

4. Remove strainer from pump opening.

5. With the sprayer upside-down pour

approximately 2 oz. (60 ml) Pump Armor

into pump opening.

6. Install strainer into pump opening.

333394H 17

9. Turn Prime Pump/Spray knob forward to

spray position. Remove cup assembly

and pour any remaining Pump Armour

back into Pump Armor bottle. Replace

child-resistant cap and tighten securely

for storage.

10. Store sprayer indoors in a cool, dry

place. Store in an upright position

only. Never store sprayer with material

in the cup.

Page 18

Common Procedures

ti23563a

LOCKING TAB SLOT

LOCKING

REMOVE

SPRAY TIP

TAB

ROTATE

SPRAY TIP 90

o

Common Procedures

Installing Spray Tips

Do not put your hand in front of the spray tip.

Two spray tips are available for use with this

sprayer. The black tip produces a 12-inch

wide spray pattern. The gray tip produces a

4-inch wide spray pattern.

Either spray tip may be used to spray materials that are recommended to be sprayed

with a 0.015 tip size. See material container

for spray tip size recommendations.

Install Spray Tip

1. While holding the spray tip 90 degrees

from either the SPRAY or UNCLOG

position, align spray tip locking tab with

the locking tab slot in the spray tip guard.

2. Push the spray tip all the way into the

spray tip guard.

3. Rotate the spray tip to the SPRAY

position.

NOTE: Make certain spray tip locking tab is

pushed all the way into the slot in the spray tip

guard. You should not be able to remove the

spray tip from the spray tip guard when it is in

the Spray or Unclog positions.

NOTE: If the locking tab slot in the spray tip

guard is blocked, preventing installation of

the spray tip, rotate the spray tip guard until it

is visually aligned with the internal hole, then

install the spray tip.

NOTICE

The spray tip guard is permanently

attached to the sprayer. Removal for

cleaning is not necessary and will result in

damage to the sprayer.

•

Spray tips wear with use and abrasive

paint and need periodic replacement.

• If the spray pattern is poor, yo u may have

a worn spray tip. Replace spray tip. See

Spray Pattern Diagnostics, page 28.

NOTICE

Spray tips must be cleaned or stored in

Remove Spray Tip

1. Perform Pressure Relief Procedure,

2. Rotate the spray tip 90 degrees from

3. Pull the spray tip straight out of the spray

18 333394H

page 14.

either the SPRAY or UNCLOG position.

tip guard.

appropriate cleaning fluid (water or mineral

spirits) immediately after use to ensure

material is not allowed to dry in spray tip.

Failure to do so will result in damage to the

spray tip. See Cleanup, page 14.

Page 19

Unclogging Spray Tip

ti23285a

Prime Pump

ti23290a

SPRAY UNCLOG

ti23359a

10

ti25737a

ti23288a

Spray

In the event that particles or debris clog the

spray tip, this sprayer is designed with a

reversible spray tip that quickly and easily

clears the particles without disassembling the

sprayer.

1. Perform Pressure Relief Procedure,

page 14.

2. To unclog spray tip, turn Prime

Pump/Spray knob down to Prime Pump

position.

Common Procedures

5. Variable speed models:

Set speed control to 10.

6. Aim sprayer at waste area, turn Prime

Pump/Spray knob forward to spray

position. Pull trigger to clear clog.

3. Reverse spray tip to UNCLOG position.

7.

Turn Prime Pump/Spray knob down to

Prime position.

Rotate spray tip back to

SPRAY position. Turn Prime

Pump/Spray knob forward to SPRAY

4. Dual speed models:

Move speed control switch to HIGH

setting.

position, and resume spraying.

8. If spray tip is still clogged, you may have

to repeat steps 2 - 7, or replace with new

spray tip assembly. See Installing

Spray Tips, page 18.

333394H 19

Page 20

Common Procedures

ti23249b

ti23676a

ti23361a

ti23383a

ti24279a

Flushing a New Sprayer

This sprayer arrives from the factory with a

small amount of test material in the system.

It is important that you flush this material

from the sprayer before using it for the

first time.

1. Remove cup assembly from the sprayer

by turning and pulling down.

2. Unscrew cup cover from the cup support.

4. Fill FlexLiner with water.

5. Securely tighten cup cover onto cup

support.

Tighten so the arrow on the cup

cover is within range of the indicator on

the cup support.

3. Make certain FlexLiner is in the cup

support.

20 333394H

Page 21

6. Align VacuValve on cup cover with

ti23258b

ti23388a

ti23389a

Prime Pump/Spray knob. Push cup

assembly onto sprayer and twist to lock.

Common Procedures

7. Plug sprayer into power source.

8. Make certain the Prime Pump/Spray

knob is in the Prime Pump position

(pointed down). On models with a dual

speed control switch, set speed control

to HIGH. On variable speed models set

speed control to 10.

9. Turn the sprayer upside down and point

the sprayer into a waste pail. Pull the

trigger for three seconds.

10. Turn Prime Pump/Spray knob forward to

SPRAY position. Rotate spray tip 180

degrees to UNCLOG position.

11. While holding the sprayer upside down

point the sprayer into a waste pail. Pull

the trigger for three seconds.

IMPORTANT! For best results, do not spray

more than one cup of water through the tip

while cleaning. If more flushing is needed,

remove the tip from the sprayer to avoid

excessive wear.

12.

Sprayer is now flushed and ready for

use. See Start Up, page 8.

IMPORTANT! The motor has a built-in

feature to protect itself from overuse. If the

motor stops, the thermal switch has tripped.

Do not return sprayer to store. The motor

will operate normally after cooling for 20-30

minutes.

333394H 21

Page 22

Replacement Parts

8

19

19

20

24

13a

13b

12

7

8

5

1

10

2

6

3

4

9

18

17

16

14

15

22

ti23460a

ti23568a

26

Replacement Parts

Models 16Y385, 16Y386, 17A466

22 333394H

Page 23

Replacement Parts

Parts List- Models 16Y385, 16Y386, 17A466

Ref.

1 Kit, pump

2 All models 16Y425 O-ring

3 All models 16W849 Strainer

4 All models 17A219 Kit, needle assembly includes 5 and spray tip 17A222

5 All models 17A220 Kit, pump outlet

6 All models 17A402 Prime Pump/Spray valve

7 All models 17A221 Kit, Prime Pump/Spray knob includes qty. 1 of ref. 8

8 All models 119236 Screw, T-15 (torque 8-10 in-lb / 0.9-1.1 N

9 All models 17A223 Spray tips, (black/12-inch pattern, gray/4-inch pattern)

10 All models 16X880 Reciprocator assembly

12 Control, electronic includes motor, power cord and switch

13a 16Y386, 17A466 16X868 Switch, dual speed control

13b 16Y385 16X869 Plug

14 All models 16W846 Support, 32 oz. cup

15 All models 17A226 Kit, 32oz., FlexLiner (3-pack)

16 All models 17B636 Cover, cup

17 All models 115719 O-ring

18 All models 16X806 VacuValve cap

19 16Y385, 17A466 17A227 Kit, enclosure blue includes qty. 13 of ref. 8,

20 All models 16Y680 Label, USA

22 All models 16Y678 Label, control

23 All models 16Y636 Label, warning and model number, side (not shown)

24 Label, brand

25 All models 17A198 Label, warning, cord (not shown)

26 16Y386 17C468 Case, storage

Replacement Danger and Warning labels, tags, and cards are available at no cost.

If you have this

model sprayer

16Y385, 17A466 17A217 Complete pump assembly includes 2, 3, 4, 5, 6, 7, 8

16Y385, 17A466 17A218 Pump housing includes 2, 3, 5

16Y386 17B415 Complete pump assembly includes 2, 3, 4, 5, 6, 7, 8

16Y386 17B416 Pump housing includes 2, 3, 5

16Y385 17A224 Single speed, 120 V (not shown)

16Y386, 17A466 17B653 Dual speed, 120 V

16Y386 17A649 Kit, enclosure gray includes qty. 13 of ref. 8,

16Y385 16Y677 TrueCoat 360

16Y386 17A473 TrueCoat 360 DSP

17A466 16Y679 TrueCoat 360 DS

All models 17F518 Kit, 42 oz. cup (not shown)

- - - 243104 Pump Armor, not shipped with sprayer 32 oz (not shown)

Order

Part

Number

Description

•m)

333394H 23

Page 24

Replacement Parts

8

19

29

19

20

24

12

13

7

8

5

1

10

2

6

3

4

9

18

17

16

14

15

22

28

26

27

ti25730a

Replacement Parts

Model 17D889

24 333394H

Page 25

Parts List- Model 17D889

Replacement Parts

Ref.

1 Kit, pump

2 All models 16Y425 O-ring

3 All models 16W849 Strainer

4 All models 17A219 Kit, needle assembly includes 5 and spray tip 17A222

5 All models 17A220 Kit, pump outlet

6 All models 17A402 Prime Pump/Spray valve

7 All models 17A221 Kit, Prime Pump/Spray knob includes qty. 1 of ref. 8

8 All models 119236 Screw, T-15 (torque 8-10 in-lb / 0.9-1.1 N

9 All models 17A223 Spray tips, (black/12-inch pattern, gray/4-inch pattern)

10 All models 16X880 Reciprocator assembly

12 17D889 17F068 Control, electronic includes motor, power cord and switch

13 17D889 17D844 Adapter, variable speed control

14 17D889 17D850 Support, cup, 42 oz.

15 17D889 17F005 Kit, 42 oz., FlexLiner (3-pack)

16 All models 17B636 Cover, cup

17 All models 115719 O-ring

18 All models 16X806 VacuValve cap

19 17D889 17A649 Kit, enclosure gray includes qty. 13 of ref. 8

20 All models 16Y680 Label, USA

22 All models 16Y678 Label, control

23 All models 16Y636 Label, warning and model number, side (not shown)

24 17D889 17F154 Label, brand, TrueCoat 360 VSP

25 All models 17A198 Label, warning, cord (not shown)

26 17D889 17C468 Case, storage

27 17D889 17F069 Kit, enclosure, variable speed includes sight glass,

28 17D889 17F364 Kickstand

29 17D889 17D843 Sight glass

Replacement Danger and Warning labels, tags, and cards are available at no cost.

If you have this

model sprayer

17D889 17B415 Complete pump assembly includes 2, 3, 4, 5, 6, 7, 8

17D889 17B416 Pump housing includes 2, 3, 5

All models 17F518 Kit, 42 oz. cup includes 14, 15, 28

- - - 243104 Pump Armor, not shipped with sprayer 32 oz (not shown)

Order

Part

Number

Description

•m)

Variable speed, 120 V

includes 13, 29, qty. 2 of ref 8

333394H 25

Page 26

Troubleshooting

Have a Question?

Call toll-free:

1-888-541-9788

Or visit us at:

www.paintsprayersbygraco.com

Troubleshooting

Check everything in this Troubleshooting

Table before you bring the sprayer to an

authorized service center.

Sprayer Diagnostics

Problem Cause Solution

Sprayer makes no sound

when trigger is pulled

Sprayer makes sound but

no material is sprayed

when trigger is pulled

Power supply. Verify power to sprayer.

Motor has overheated. Wait 20-30 minutes for motor to

Electronic control failure. Replace electronic control.

Sprayer is not primed. Prime the pump. See Starting a

Prime Pump/Spray knob is in PRIME

PUMP position.

Spray tip is not in SPRAY position. Turn spray tip to SPRAY

Spray tip is clogged. See Unclogging Spray Tip,

cool.

New Job, page 8.

Make certain there is only one

FlexLiner in the cup support.

Make certain the cup cover is

properly threaded to the cup

support. If threads are visible

below the cup cover when tight,

fully remove and reinstall to the

cup support so no threads are

visible when tight.

Make certain the cup cover is

tightened to cup support so the

arrow on cup cover is within

range of indicator on cup

support.

Make certain the cup assembly is

properly locked on the sprayer.

Make certain all the air is out of

the FlexLiner and the VacuValve

is properly closed.

Clean VacuValve reservoir and

air hole. See , page 16.

Clean Sprayer. See Cleanup,

page 14.

Turn Prime Pump/Spray knob

forward to SPRAY position.

position.

page 19.

26 333394H

ti24021a

Page 27

Troubleshooting

Problem Cause Solution

Sprayer makes sound

but no material is

sprayed when trigger is

pulled (cont’d)

Sprayer sprays with poor

results

Paint leaks from sprayer

trigger area.

Paint leaks out of the cup

threads.

Speed control is set too low. On models with a dual speed

No or low material in material cup. Refill FlexLiner with material and

Spray tip is partially clogged. See Unclogging Spray Tip,

Spray tip is not in correct position Rotate spray tip to SPRAY

Incorrect spray tip for application of

material.

Spray tip is worn or damaged Replace spray tip. See

Material being sprayed is aerated

because it was shaken.

Material being sprayed is too cold to

spray.

Pump has reached its maximum life. Replace pump.

Cup not properly seated.

control switch, set speed control

switch to HIGH. On variable

speed models, increase speed

until unit sprays.

prime the pump. See Refilling

FlexLiner, page 10.

page 19

position.

Install different size spray tip.

See Installing Spray Tips, page

18.

Installing Spray Tips, page 18.

Do NOT shake material. Stir the

material or check the

manufacturer’s recommendation

for the material being sprayed.

Warm material.

Make certain that there is only

one FlexLiner in cup support.

Make certain the cup cover is

properly threaded to the cup

support. If threads are visible

below the cup support when

tight, fully remove the cup cover

and reinstall to the cup support

so no threads are visible when

tight.

Make certain the cup cover is

tightened to the cup support so

the arrow on the cup cover is

within range of the indicator on

the cup support.

Avoid flexing or pushing on the

cup support when you evacuate

the air out of the FlexLiner.

Avoid pulling down on the

FlexLiner when you evacuate the

air out of the FlexLiner.

Make certain there is no damage

to the FlexLiner lip or the cup

cover gasket.

Make certain that the FlexLiner

lip and cup cover gasket is free of

debris and dried paint.

Replace FlexLiner.

.

333394H 27

Page 28

Troubleshooting

ti15526a

Spray Pattern Diagnostics

Problem Cause Solution

Spray pattern is pulsating: Operator is moving too

fast while spraying.

Slow speed of movement.

Spray tip is clogged. Unclog spray tip or clean spray

Material difficult to

atomize.

Spray pattern has tails: Speed control is set too

Spray pattern has

dripping/sagging:

low.

Material may need to be

thinned.

Incorrect spray tip for

application of material.

Material not compatible

with sprayer.

Spray tip is worn or

damaged.

Operator is moving too

slowly while spraying.

Sprayer is too close to

target surface.

Holding trigger while

changing spray direction.

Speed control switch is set

too high.

Spray tip is worn or

damaged.

tip see Unclogging Spray Tip,

page 19.

On models with a dual speed

control switch, set speed control

to HIGH. On variable speed

models, increase speed until

desired pattern is achieved.

Hold sprayer farther away from

surface.

Switch to black (12”) spray tip.

See Installing Spray Tips,

page 18.

On models with a dual speed

control switch, set speed control

to HIGH. On variable speed

models, increase speed until

desired pattern is achieved.

Thin material follow paint

manufacturer’s

recommendations.

Install different size spray tip.

See Installing Spray Tips,

page 18.

Switch material.

Replace spray tip. See

Installing Spray Tips, page 18.

Move sprayer faster while

spraying.

Move sprayer away from

surface 10 in. (25 cm)

Release trigger when changing

directions.

On models with a dual speed

control switch, set speed control

to LOW. On variable speed

models, decrease speed until

desired pattern is achieved.

Replace spray tip. See

Installing Spray Tips, page 18.

28 333394H

Page 29

Problem Cause Solution

ti15523a

ti15523a

ti15527a

ti15527a

ti15525a

ti15525a

ti15552a

Spray pattern is too narrow: Sprayer is too close to

target surface.

Incorrect spray tip for

application of material.

Spray tip is worn or

damaged.

Spray pattern is too wide: Sprayer is too far away

from target surface.

Incorrect spray tip for

application of material.

Troubleshooting

Move sprayer away from

surface 10 in. (25 cm)

Install different size spray tip.

See Installing Spray Tips,

page 18.

Replace spray tip. See

Installing Spray Tips, page 18.

Move sprayer closer to surface.

Install different size spray tip.

See Installing Spray Tips,

page 18.

Spray pattern “spits” at the end or

beginning:

Spray tip continues to drip or ooze

material after trigger is released:

Excess material has

accumulated on spray tip

guard assembly or spray

Clean spray tip guard. See

Unclogging Spray Tip, page

19.

tip is partially clogged.

Spray tip not inserted

completely into spray tip

See Installing Spray Tips,

page 18.

guard.

Spray tip is worn. Replace spray tip. See

Installing Spray Tips, page 18.

Spray tip is worn. Replace spray tip. See

Installing Spray Tips, page 18.

Spray tip not inserted

completely into spray tip

See Installing Spray Tips,

page 18.

guard.

If above solutions do not solve the problem, replace the

needle assembly.

333394H 29

Page 30

Technical Data

Technical Data

Hand-Held Sprayer

U.S. Metric

Max Working Pressure

TrueCoat 360 1200 psi 8.3 MPa, 83 bar

TrueCoat 360 DS/DSP/VSP 1300 psi 9 MPa, 90 bar

Maximum Amperage 2.5 Amps 2.5 Amps

Weight

TrueCoat 360, 360 DS/DSP 3.5 lb (18 in.cord) 1.6 kg (45 cm cord)

TrueCoat 360 VSP 3.75 lb (18 in.cord) 1.7 kg (45 cm cord)

Dimensions:

Length (All models) 12.50 in. 31.75 cm

Width (All models) 5.25 in. 13.34 cm

Height 360, 360 DS/DSP 9.75 in. 24.77 cm

Height 360 VSP 11.8 in. 29.97 cm

Storage Temperature Range 32° to 113° F 0° to 45° C

Operating Temperature Range 40° to 90° F 4° to 32° C

Storage Humidity Range

Power Cord 18 AWG, 3-wire, 18 in.

Electrical Power Requirement 120 Vac, 60 Hz, 15A, 1 phase

Duty Cycle 50% 50%

Maximum tip orifice 0.015 in. 0.38mm

0% to 95% relative

humidity,

non-condensing

Pump damage will occur if fluid freezes in pump.

Damage to plastic parts may result if impact occurs in low temperature conditions.

Changes in paint viscosity at very low or very high temperatures can affect sprayer

performance.

0% to 95% relative humidity,

non-condensing

2

1.0 mm

, 3-wire, 45 cm

30 333394H

Page 31

Graco Limited Warranty

Graco Limited Warranty

Graco warrants to the original purchaser that this product will be free from defects in material and

workmanship for one (1) year from the date of purchase when operated and maintained in accordance

with Graco's written recommendations and instructions. This product is designed and intended for

personal, non-income producing, household purposes only. This warranty is void if the product is used

for any other purposes, including but not limited to commercial, institutional, industrial, agricultural, rental

or income producing purposes. This warranty does not cover general wear and tear or any malfunction,

damage or wear caused by misapplication, abrasion, corrosion, inadequate or improper maintenance,

abuse, negligence, misuse, accident, tampering, substitution of non-Graco component parts, or

alterations, service or repairs by anyone other than a Graco authorized service center, or any use,

maintenance or repairs not specifically described in Graco's written recommendations and instructions.

In addition, this warranty specifically excludes general wear and tear of the pump, valves, needle

assembly and spray tips.

This warranty is conditioned upon the prepaid return of the product claimed to be defective and proof of

purchase to a Graco authorized service center for verification of the claimed defect. To find a Graco

authorized service center, please call 1-888-541-9788 or visit us online at www.graco.com. If the claimed

defect is verified, Graco will repair or replace the product free of charge. The product will be returned to

the original purchaser transportation prepaid. If inspection of the product does not disclose any defect in

material or workmanship, repairs will be made at a reasonable charge to you, which charges may include

the costs of parts, labor and transportation. Repair or replacement of the product under this warranty will

not interrupt or extend the warranty period or create a new warranty period.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSES

IS LIMITED TO ONE (1) YEAR FROM THE DATE OF PURCHASE. SOME STATES AND PROVINCES

DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE

LIMITATION MAY NOT APPLY TO YOU.

To the extent permitted by law, Graco's sole obligation and buyer's sole remedy for any breach of

warranty shall be as set forth above. IN NO EVENT WILL GRACO BE LIABLE FOR ANY INDIRECT,

INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE SALE OR USE

OF THIS PRODUCT. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR

LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER

RIGHTS WHICH VARY FROM STATE TO STATE OR PROVINCE TO PROVINCE.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés,

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-888-541-9788 to identify the nearest

distributor.

333394H 31

Page 32

All written and visual data contained in this document reflects the latest product information available at

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 333394

the time of publication.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2014, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revision H, February 2015

Loading...

Loading...