Page 1

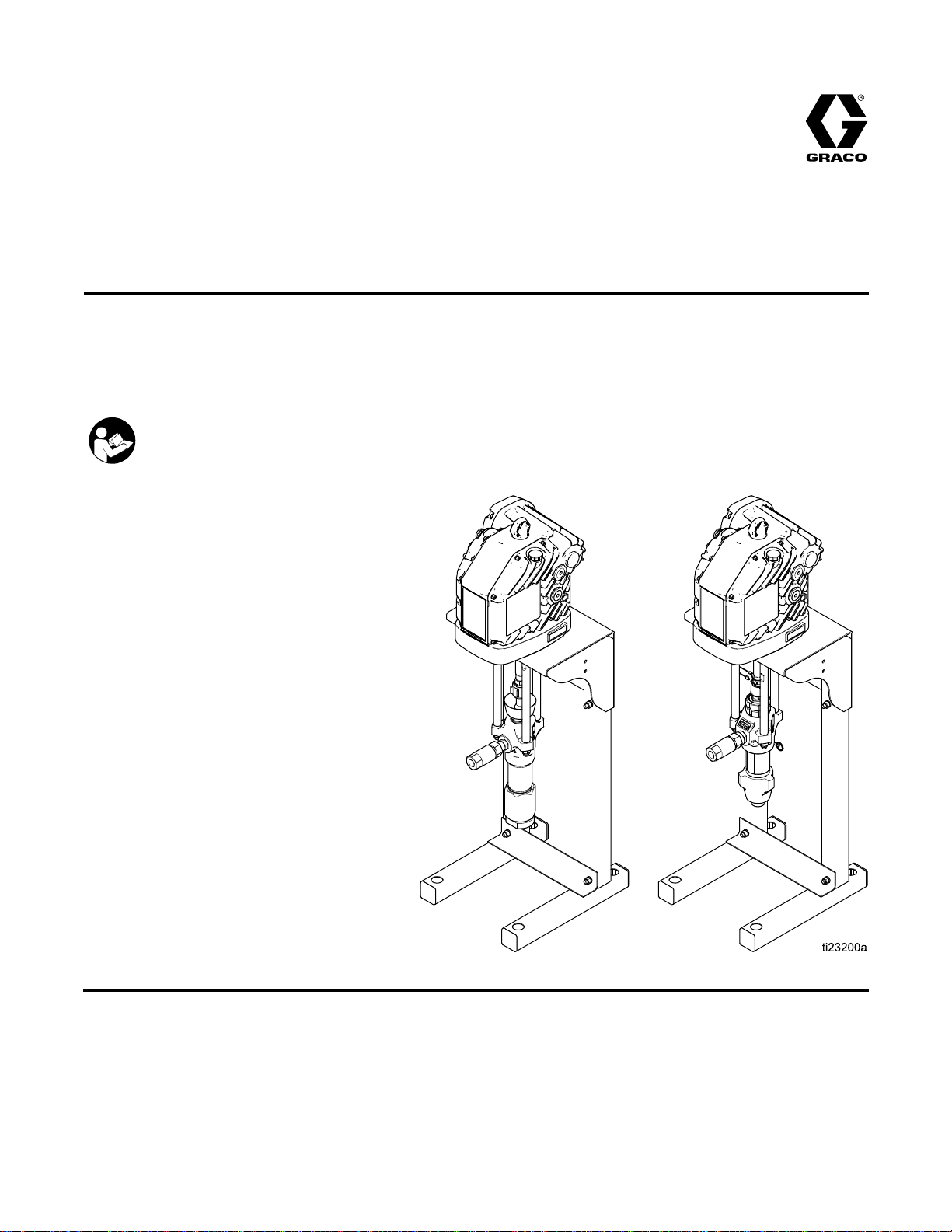

Instructions-Parts

E-Flo®

E-Flo® E-Flo®

Electric

Electric Electric

For

For For

See Technical Data for Maximum

Working Pressure.

See page 3 for model part numbers and

approvals information.

drive

drive drive

professional

professional professional

Important

Important Important

Readallwarningsandinstructionsinthismanual.

Save

Save Save

DC

DC DC

piston

piston piston

use

use use

Safety

Safety Safety

these

instructions.

these these

instructions. instructions.

2–Ball

2–Ball 2–Ball

pumps

pumps pumps

only.

only. only.

for

for for

Instructions

Instructions Instructions

Piston

Piston Piston

low

to

low low

medium

to to

medium medium

volume

volume volume

Pumps

Pumps Pumps

paint

circulation

paint paint

circulation circulation

applications.

applications. applications.

EN

333389A

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

Installation..........................................................7

Location......................................................7

MountthePump..........................................7

PowerSupplyRequirements.........................7

ConnectthePowerSupply...........................10

Grounding...................................................11

FluidLineAccessories.................................12

FillWithOilBeforeUsingEquipment.............12

FlushBeforeUsingEquipment......................12

ControlModuleAccessory............................12

Operation...........................................................13

Startup........................................................13

Shutdown....................................................13

PressureReliefProcedure............................13

Maintenance......................................................14

PreventiveMaintenanceSchedule................14

ChangetheOil.............................................14

CheckOilLevel...........................................14

BearingPre-Load.........................................14

Wet-Cups....................................................14

Flushing......................................................14

Troubleshooting..................................................15

Repair................................................................16

Dura-FloLowers..........................................16

XtremeLowers............................................17

ReassembletheCouplingAdapterandTie

RodstotheMotor...........................19

Parts..................................................................20

XtremePumpAssembly...............................20

Dura-FloPumpAssembly.............................22

PumpMatrix................................................24

Dimensions........................................................26

MountingHolePatterns.......................................27

StandMount................................................27

WallMount..................................................28

PerformanceCharts............................................29

TechnicalData...................................................32

Notes................................................................33

GracoStandardWarranty....................................34

2

333389A

Page 3

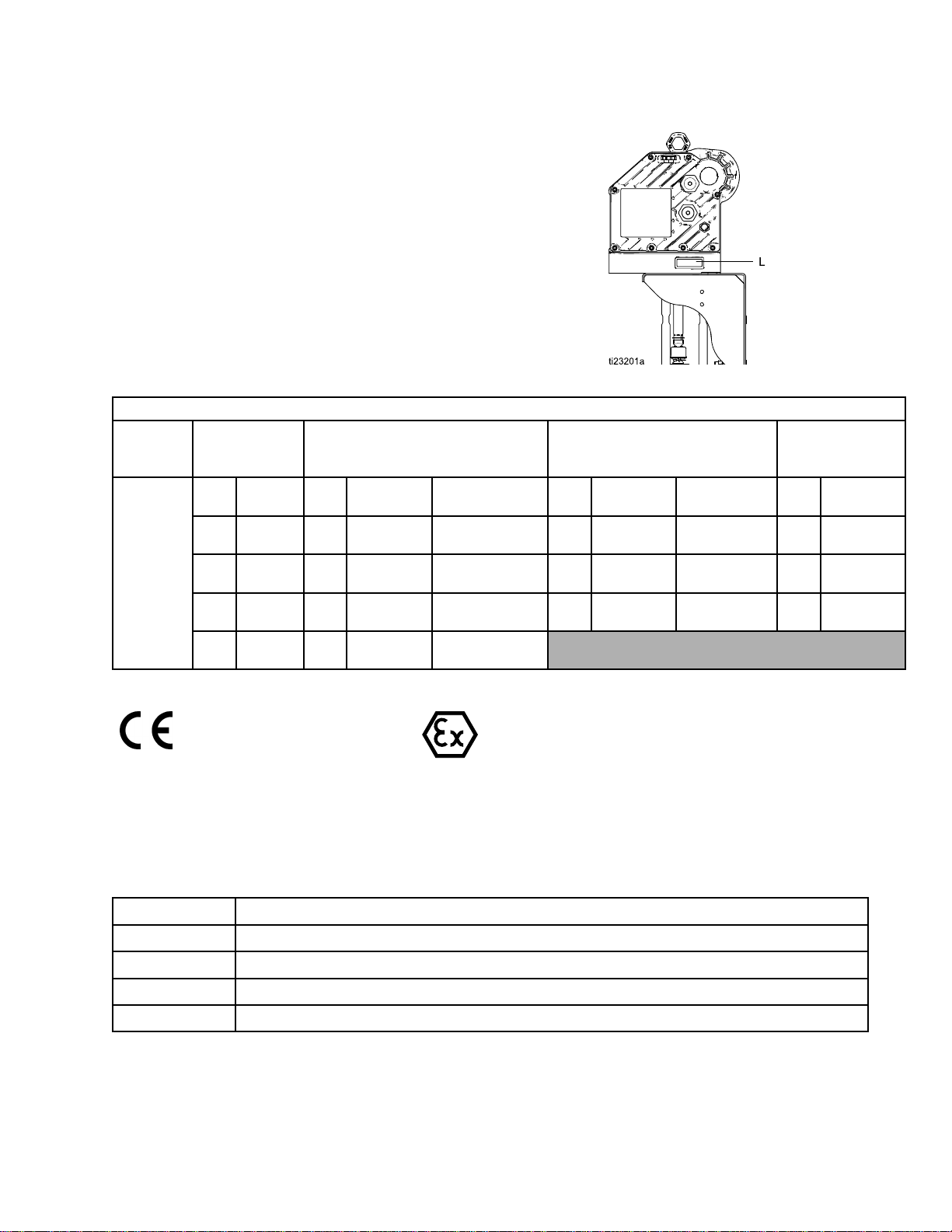

Models

Models Models

Thesixdigitpartnumberforyourequipmentis

printedontheequipmentidenticationlabel(L).

Refertothetablebelowforinformationregardingthe

congurationofyourequipment.

SeePumpMatrix,page24

,foracompletelistof

pumppartnumbers.

Flo

DC

Pump

Part

E EE- --Flo Flo

DC DC

Pump Pump

First

and

First First

and and

Second

Second Second

Digit

Digit Digit

ES

Third

Third Third

Digit

Digit Digit

7145CC3BasicATEX/FM/

8180CC4AdvancedATEX/FM/

9220CC7BasicATEX/IECEx/

0290CC8AdvancedATEX/IECEx/

Number

Part Part

Number Number

Digit

Digit Digit

Lower

Lower Lower

Size

Size Size

Conguration

Conguration Conguration

Fourth

Fourth Fourth

Digit

Digit Digit

Motor

Motor Motor

Control

Control Control

Models

Digit

Digit Digit

Approvals

Approvals Approvals

IECEx

IECEx

TIIS/KCS

TIIS/KCS

Digit

Digit Digit

4Carbon

5Stainless

6Stainless

Fifth

Digit

Fifth Fifth

Digit Digit

Pump

Pump Pump

Material

Material Material

Steel

Steel

Steel

Packings

Packings Packings

3Xtreme

2Leather

4Leather

1PTFE

PTFE

Leather

Digit

Digit Digit

Sixth

Sixth Sixth

0None

1Stand

2Wall

Digit

Digit Digit

Mounting

Mounting Mounting

Type

Type Type

IIA

II IIII2 22G GGc ccIIA IIA

NOTE:

NOTE: NOTE:

Related

Related Related

SeetheE-FloDCMotormanualformotorapprovalsinformation.

Manuals

Manuals Manuals

Manual

Manual Manual

3A2526

3A2527

No.

No. No.

Description

Description Description

Instructions-PartsManual,E-FloDCMotor

Instructions-PartsManual,forE-FloDCControlModuleKit

T3

T3 T3

311762Instructions-PartsManual,XtremeLowers

311827Instructions-PartsManual,Dura-FloLowers

333389A 3

Page 4

Warnings

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanual,referbacktotheseWarnings.Product-specic

hazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughoutthebodyofthismanual

whereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareantistaticorconductive.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

ELECTRIC

ELECTRIC ELECTRIC

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

SHOCK

SHOCK SHOCK

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Tohelp

Grounding

ifstaticsparkingoccursoryoufeelashock,Donotuse

HAZARD

HAZARD HAZARD

instructions.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

BURN

BURN BURN

Equipmentsurfacesanduidthat’sheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

MOVING

MOVING MOVING

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

4

HAZARD

HAZARD HAZARD

PARTS

PARTS PARTS

equipment,followthePressure Pressure

HAZARD

HAZARD HAZARD

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

anddisconnectallpowersources.

333389A

Page 5

WARNING

WARNING WARNING

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

immediate

immediate immediate

•Engagetriggerlockwhennotdispensing.

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

TOXIC

TOXIC TOXIC

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludes

butisnotlimitedto:

surgical

surgical surgical

FLUID

FLUID FLUID

HAZARD

HAZARD HAZARD

treatment.

treatment. treatment.

Pressure

OR

OR OR

PROTECTIVE

PROTECTIVE PROTECTIVE

Relief

Procedure

Relief Relief

Procedure Procedure

FUMES

FUMES FUMES

EQUIPMENT

EQUIPMENT EQUIPMENT

whenyoustopdispensingandbeforecleaning,

Warnings

Get

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

333389A 5

Page 6

Warnings

WARNING

WARNING WARNING

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

MISUSE

MISUSE MISUSE

HAZARD

HAZARD HAZARD

Technical

Data

Data Data

Pressure

inallequipmentmanuals.

Relief

Relief Relief

Technical

Procedure

Procedure Procedure

whenequipmentisnotinuse.

Data

Data Data

6 333389A

Page 7

Installation

Installation

Installation Installation

Wall

Mount

Wall Wall

Mount Mount

SeeWallMountingHolePattern,page28.

Installationofthisequipmentinvolvespotentially

hazardousprocedures.Onlytrainedandqualied

personnelwhohavereadandwhounderstand

theinformationinthismanualshouldinstallthis

equipment.

Location

Location Location

Whenselectingthelocationfortheequipment,keep

thefollowinginmind:

•Theremustbesufcientspaceonallsidesof

theequipmentforinstallation,operatoraccess,

maintenance,andaircirculation.

•Ensurethatthemountingsurfaceandmounting

hardwarearestrongenoughtosupporttheweight

oftheequipment,uid,hoses,andstresscaused

duringoperation.

•Theremustbeastart/stopcontrol(C)

withineasyreachoftheequipment.See

TypicalInstallation,page9

Mount

Mount Mount

Stand

Stand Stand

SeeStandMountingHolePattern,page27

the

Pump

the the

Pump Pump

Mount

Mount Mount

.

1.Selectasolidpositiononawallforthemounting

bracket.Thewallshouldbecapableofsupporting

thepumpandaccessoriesthatwillbeattached

tothebracket,anyadditionalweightoftheuid

usedinthepump,andanystressorstrainthat

maybeappliedduringpumpoperation.

2.Drillfour7/16in.(11mm)diameterholesforthe

mountingbolts,approximately5ft(1.5m)above

theoor,usingthewallbracketasatemplate.

Useanyofthethreemountingholegroupings

3.Boltthebracketsecurelytothewall.Usebolts

designedtoholdinthewall’sconstruction.

4.Placethepumpandaccessoriesoverthe

bracket’smountingholesandsecurewithscrews

(5)andwashers(4)supplied.

Power

Power Power

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,StateandLocalsafetyandrecodes.

Supply

Supply Supply

Requirements

Requirements Requirements

1.Selectalevelsurfaceforthestandtobemounted

to.

2.SecurethestandtotheoorwithM19(5/8in.)

bolts.Useboltsthatengageatleast152mm

(6in.)intotheoortopreventthepumpfrom

tipping.

3.Placethepumpandaccessoriesoverthe

bracket’smountingholesandsecurewithbolts

(5)andwashers(4)supplied.

4.Useshimstolevelthepumpasrequired.

333389A

Thesystemrequiresadedicatedcircuitprotected

withacircuitbreaker.Seetablebelowforpower

supplyrequirements.

Table

Table Table

Model

Model Model

EM0021

EM0022

Power

1 11. ..Power Power

Supply

Supply Supply

Voltage

Voltage Voltage

200–250

Vac

Specications

Specications Specications

Phase

Phase Phase

150/6020A

Hz

Hz Hz

Current

Current Current

7

Page 8

Installation

Hazardous

Hazardous Hazardous

Requirements

Requirements Requirements

Explosion

Explosion Explosion

Allelectricalwiringinthehazardousareamustbe

encasedinClassI,DivisionI,GroupDapproved

explosion-proofconduit.FollowallNational,State,

andLocalelectriccodes.

Aconduitseal(D)isrequiredwithin18in.(457mm)

ofthemotorfortheUSandCanada.SeeFig.3.

Allcablesmustberatedat70°C(158°F).

Area

Cabling

Area Area

Cabling Cabling

Proof

Proof Proof

and

Conduit

and and

Conduit Conduit

Flame

Flame Flame

Useappropriateconduit,connectors,andcable

glandsratedforATEXII2G.FollowallNational,

State,andLocalelectriccodes.

Allcableglandsandcablesmustberatedat70°C

(158°F).

Proof

Proof Proof

(ATEX)

(ATEX) (ATEX)

8 333389A

Page 9

Installation

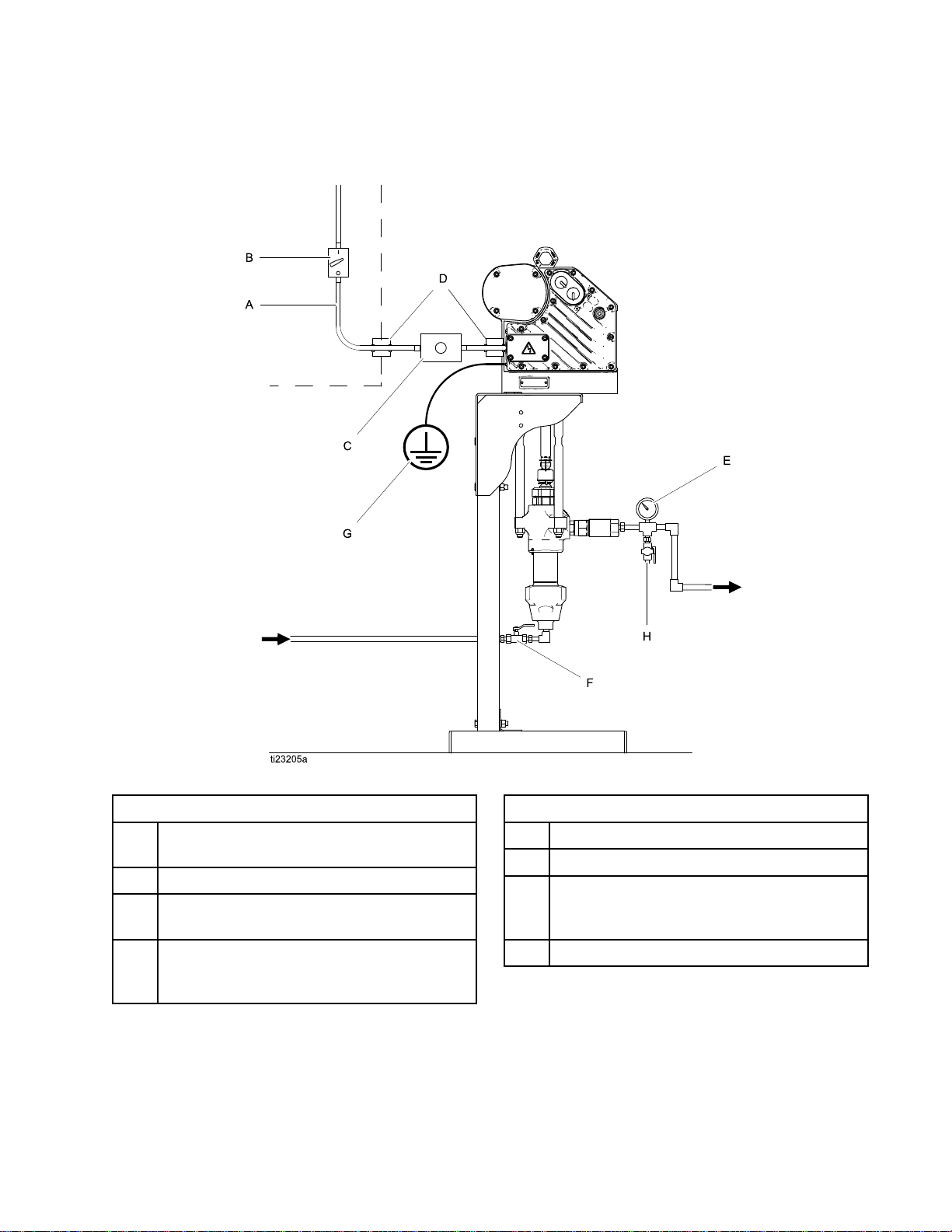

Typical

Typical Typical

Installation

Installation Installation

NON

HAZARDOUS

NON NON

- --HAZARDOUS HAZARDOUS

AREA

AREA AREA

HAZARDOUS

HAZARDOUS HAZARDOUS

AREA

AREA AREA

Figure1TypicalInstallation

Key

for

Fig.

Key Key

for for

A

B

CStart/StopControl(mustbeapprovedfor

D

1

Fig. Fig.

1 1

ElectricalSupply(mustbesealedconduit

approvedforuseinhazardouslocations)

FusedSafetySwitch,withlock

useinhazardouslocations)

ExplosionProofConduitSeal.Required

within18in.(457mm)ofthemotorforthe

USandCanada.

Key

for

Fig.

Key Key

for for

E

F

GPumpGroundWire.Twogroundterminals

HFluidDrainValve

1

Fig. Fig.

1 1

FluidPressureGauge

FluidShutoffValve

areprovidediflocalcoderequiresredundant

groundingconnections.

333389A 9

Page 10

Installation

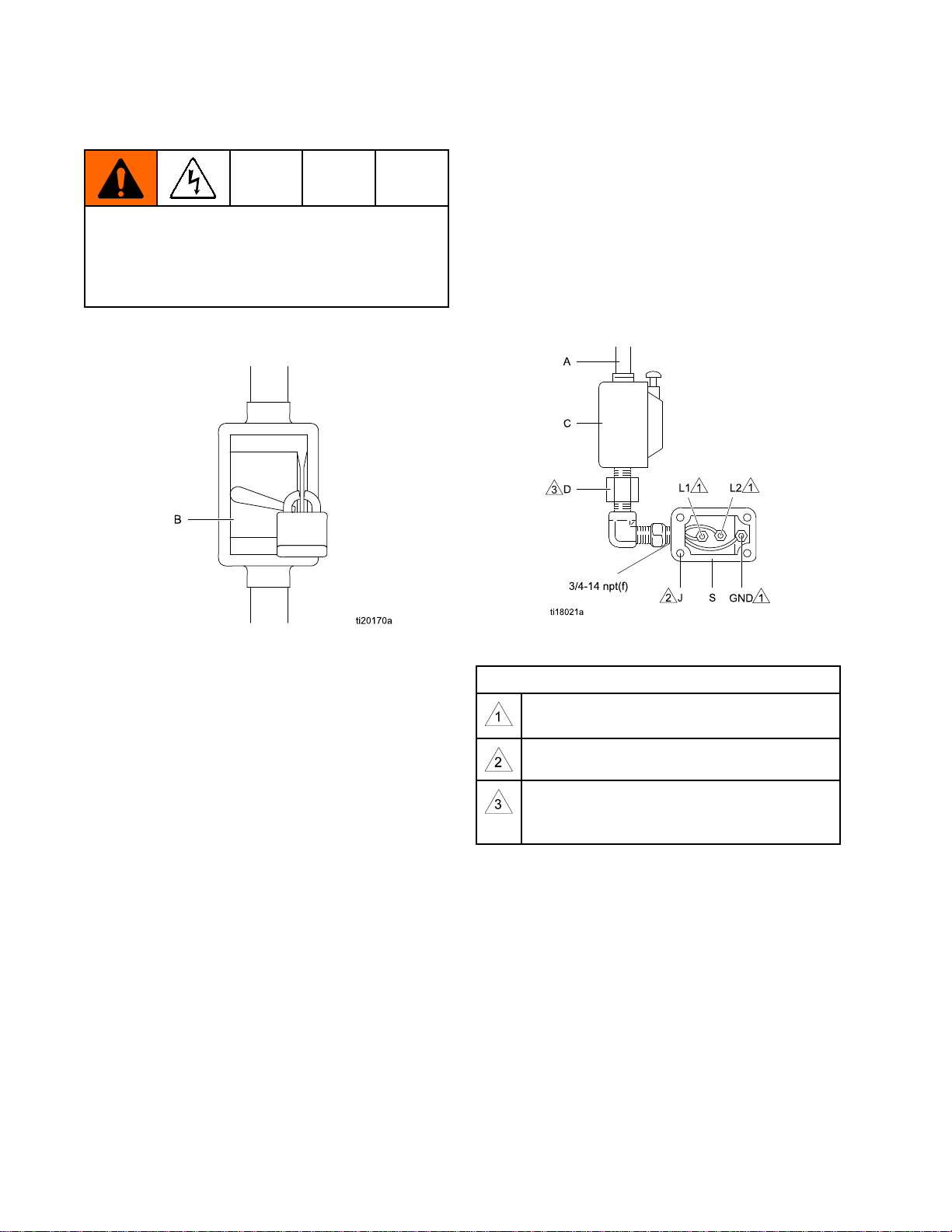

Connect

Connect Connect

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

localcodesandregulations.

1.Ensurethatthefusedsafetyswitch(B,Fig2)is

shutoffandlockedout.

the

Power

the the

Power Power

Supply

Supply Supply

3.Opentheelectricalcompartment(S)onthe

motor.

4.Bringthepowerwiresintotheelectrical

compartmentthroughthe3/4–14npt(f)inletport.

Connectthewirestotheterminals,asshown.

Torquetheterminalnutsto25in-lb(2.8N•m)

Do

not

maximum.Do Do

5.Closetheelectricalcompartment.Torquethe

coverscrewsto15ft-lb(20.3N•m).

over-torque.

not not

over-torque. over-torque.

Figure2LockedOutFusedSafetySwitch

2.SeeFig.3.Installastart/stopcontrol(C)inthe

electricalsupplyline(A),withineasyreachof

theequipment.Thestart/stopcontrolmustbe

approvedforuseinhazardouslocations.

Figure3ConnectthePowerWires

Notes

for

Fig.

Notes Notes

for for

Tightenallterminalnutsto25in-lb(2.8N•m)

maximum.Do Do

Tightencoverscrewsto15ft-lb(20.3N•m).

Aconduitseal(D)isrequiredwithin18

in.(457mm)ofthemotorfortheUSand

Canada.

3

Fig. Fig.

3 3

Do

not

over

not not

torque.

over over

- --torque. torque.

10 333389A

Page 11

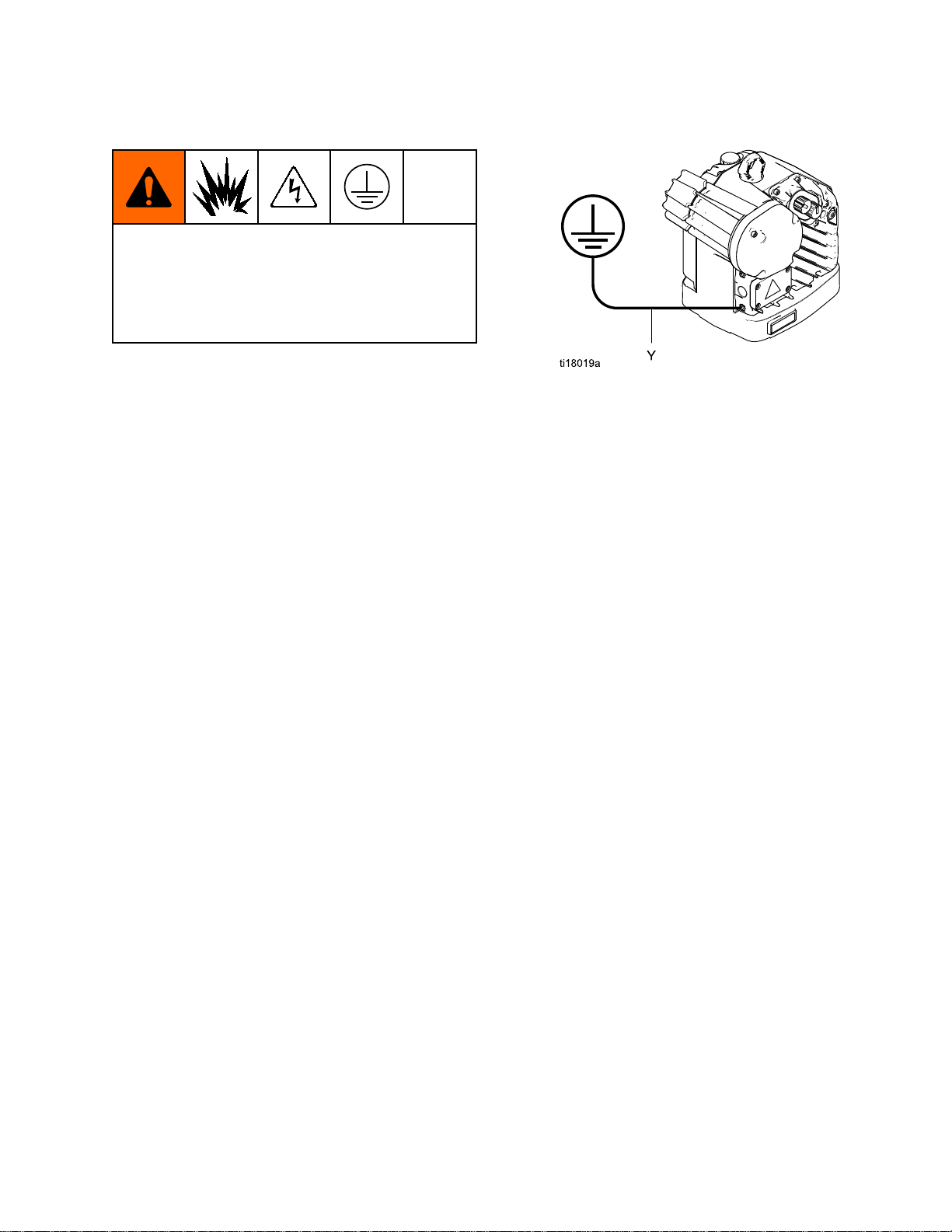

Grounding

Grounding Grounding

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

Pump:

1.Pump: Pump:

attachagroundwire.Tightenthegroundscrew

securely.Connecttheotherendoftheground

wiretoatrueearthground.

NOTE:

NOTE: NOTE:

ofthe24P822ControlModule.Allpumps

connectedtoacommoncontrolmodulemustbe

groundedtothesamegroundpoint.Different

groundpoints(unequalpotential)maycause

currenttoowthroughcomponentcables,

causingincorrectsignals.

SeeFig.4.Loosenthegroundscrewand

Advancedmodelsrequireinstallation

Figure4GroundWire

Fluid

2.Fluid Fluid

3.Fluid Fluid

hoses:

hoses: hoses:

hoseswithamaximumof500ft.(150m)

combinedhoselengthtoensuregrounding

continuity.Checktheelectricalresistanceof

hoses.Iftotalresistancetogroundexceeds25

megohms,replacehoseimmediately

Fluid

supply

supply supply

Useonlyelectricallyconductive

container:

container: container:

Followyourlocalcode.

Installation

333389A

11

Page 12

Installation

Fluid

Fluid Fluid

InstallthefollowingaccessoriesasshowninFig.

1,usingadaptersasnecessary.Alluidlinesand

accessoriesmustberatedtothemaximumworking

pressureof400psi(2.8MPa,28.0bar).

•Fluid Fluid

•Fluid Fluid

•Fluid Fluid

Fill

Fill Fill

SeeFig.5.Beforeusingtheequipment,openthell

cap(P)andaddGracoPartNo.16W645ISO220

silicone-freesyntheticgearoil.Checktheoillevelin

thesightglass(K).Filluntiltheoillevelisnearthe

halfwaypointofthesightglass.Theoilcapacityis

approximately1.5quarts(1.4liters).Do Do

NOTE:

NOTE: NOTE:

suppliedwiththeequipment.

Line

Line Line

Fluid

drain

drain drain

relieveuidpressureinthehoseandcirculation

system.

Fluid

pressure

pressure pressure

adjustmentoftheuidpressure.

Fluid

shutoff

shutoff shutoff

With

With With

Two1quart(0.95liter)bottlesofoilare

Accessories

Accessories Accessories

valve

(H):

valve valve

(H): (H):

requiredinyoursystem,to

gauge

gauge gauge

valve

valve valve

Oil

Before

Oil Oil

Before Before

(F):

(F): (F):

(E):

(E): (E):

shutsoffuidow.

Using

Using Using

formoreprecise

Equipment

Equipment Equipment

Do

not

overll.

not not

overll. overll.

Figure5SightglassandOilFillCap

Flush

Flush Flush

Thepumpuidsectionwastestedwithlightweight

oil,whichisleftintheuidpassagestoprotectparts.

Toavoidcontaminatingyouruidwithoil,ushthe

equipmentwithacompatiblesolventbeforeusing

theequipment.

Before

Before Before

Using

Using Using

Equipment

Equipment Equipment

Control

Control Control

TheControlModuleAccessoryisrequiredwith

AdvancedE-FloDCmotorstoprovidetheinterface

foruserstoenterselectionsandviewinformation

relatedtosetupandoperation.SeetheControl

ModuleAccessoryKitmanualforinstallationand

operationinformation.

Module

Module Module

Accessory

Accessory Accessory

12

333389A

Page 13

Operation

Operation

Operation Operation

Startup

Startup Startup

Tooperatethepump,followtheStartupinstructions

fortheBasicorAdvancedmotorintheMotormanual.

TheAdvancedE-FloDCmotorsrequireinstallationof

the24P822ControlModuleAccessoryKittoprovide

theinterfaceforuserstoenterselectionsandview

informationrelatedtosetupandoperation.Seethe

ControlModuleAccessoryKitmanualforinstallation

andoperationinformation.

Runthepumpataslowspeeduntiltheuidlinesare

primedandallairisforcedoutofthesystem.

NOTE:

NOTE: NOTE:

waterbornepaints.

Shutdown

Shutdown Shutdown

FollowthePressureReliefProcedure,page13.Stop

thepumpatthebottomofitsstroketopreventuid

fromdryingontheexposeddisplacementrodand

damagingthethroatpackings.

Xtremepumpsshouldnotbeusedfor

Pressure

Pressure Pressure

Thisequipmentstayspressurizeduntilpressureis

manuallyrelieved.Tohelppreventseriousinjury

fromsplashinguidandmovingparts,followthe

PressureReliefProcedurewhenyoustopspraying

andbeforecleaning,checking,orservicingthe

equipment.

1.Disengagethestart/stopcontrol(C).SeeFig.1.

2.Shutoffandlockoutthefusedsafetyswitch(B).

3.Opentheuiddrainvalve(H),havingawaste

containerreadytocatchdrainage.Leaveopen

untilyouarereadytopressurizesystemagain.

Relief

Relief Relief

Procedure

Procedure Procedure

333389A 13

Page 14

Maintenance

Maintenance

Maintenance Maintenance

Preventive

Preventive Preventive

Theoperatingconditionsofyourparticularsystem

determinehowoftenmaintenanceisrequired.

Establishapreventivemaintenancescheduleby

recordingwhenandwhatkindofmaintenanceis

needed,andthendeterminearegularschedulefor

checkingyoursystem.

Change

Change Change

NOTE:

NOTE: NOTE:

200,000–300,000cycles.Afterthebreak-inperiod,

changetheoilonceayear.

1.SeeFig.6.Placeaminimum2quart(1.9liter)

2.Reinstalltheoildrainplug(25).Torqueto25–30

3.SeeFig.7.Openthellcap(P)andaddGraco

4.Reinstallthellcap.

Changetheoilafterabreak-inperiodof

containerundertheoildrainport.Removethe

oildrainplug(25).Allowalloiltodrainfromthe

motor.

ft-lb(34–40N•m).

PartNo.16W645ISO220silicone-freesynthetic

gearoil.Checktheoillevelinthesightglass(K).

Filluntiltheoillevelisnearthehalfwaypointof

thesightglass.Theoilcapacityisapproximately

1.5quarts(1.4liters).Do Do

Maintenance

Maintenance Maintenance

the

Oil

the the

Oil Oil

Do

Schedule

Schedule Schedule

not

overll.

not not

overll. overll.

Check

Check Check

SeeFig.7.Checktheoillevelinthesightglass(K).

Theoillevelshouldbenearthehalfwaypointofthe

sightglasswhentheunitisnotrunning.Iflow,open

thellcap(P)andaddGracoPartNo.16W645ISO

220silicone-freesyntheticgearoilasrequired.The

oilcapacityisapproximately1.5quarts(1.4liters).

Do

Do Do

Figure7SightglassandOilFillCap

Bearing

Bearing Bearing

SeeFig.7.Thebearingpre-loads(R)arefactory

setandarenotuseradjustable.Donotadjustthe

bearingpre-loads.

Oil

Level

Oil Oil

Level Level

not

overll.

not not

overll. overll.

Pre

Load

Pre Pre

- --Load Load

Figure6OilDrainPlug

14

Wet

Cups

Wet Wet

- --Cups Cups

Checkthewet-cupdaily.Keepthewet-cup1/3lled

withGracoThroatSealLiquid(TSL™)orcompatible

solvent.

Flushing

Flushing Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithauidthatiscompatiblewiththeuid

beingdispensedandtheequipmentwettedparts.

333389A

Page 15

Troubleshooting

Troubleshooting

Troubleshooting Troubleshooting

NOTE:

NOTE: NOTE:

Checkallpossibleremediesbeforedisassemblingthepump.

NOTE:

NOTE: NOTE:

manualforfurtherinformation.

TheLEDonthemotorwillblinkifanerrorisdetected.SeeError Error

Problem

Problem Problem

Pumpoutputlowonbothstrokes.

Pumpoutputlowononlyone

stroke.

Nooutput.Improperlyinstalledballcheck

Pumpoperateserratically.

Pumpwillnotoperate.

Cause

Cause Cause

Inadequatepowersupply.

Exhausteduidsupply.Rellandreprimepump.

Cloggeduidoutletline,valves,

etc.

Wornpistonpacking.

Heldopenorwornballcheck

valves.

Wornpistonpacking.

valves.

Exhausteduidsupply.Rellandreprimepump.

Heldopenorwornballcheck

valves.

Wornpistonpacking.

Inadequatepowersupply.

Error

Code

Troubleshooting

Code Code

Troubleshooting Troubleshooting

Solution

Solution Solution

SeePowerSupplyRequirements,

page7

Clear.

Replace.Seelowermanual.

Checkandrepair.Seelower

manual.

Replace.Seelowermanual.

Checkandrepair.Seelower

manual.

Checkandrepair.Seelower

manual.

Replace.Seelowermanual.

SeePowerSupplyRequirements,

page7.

.

inthemotor

Exhausteduidsupply.Rellandreprimepump.

Cloggeduidoutletline,valves,

etc.

Fluiddriedonpistonrod.Disassembleandcleanpump.

Clear.

Seelowermanual.Infuture,stop

pumpatbottomofstroke.

333389A 15

Page 16

Repair

Repair

Repair Repair

Dura

Dura Dura

Disassembly

Disassembly Disassembly

1.Stopthepumpatthebottomofitsstroke.

2.Relievethepressure.See

3.Disconnectthehosesfromthelowerandplug

4.Loosenthecouplingnut(11)andremovethe

5.Removethecouplingnutfromthepistonrod(R).

6.Unscrewthelocknuts(8)fromthetierods(6).

7.Separatethemotor(3)andlower(7).

Flo

Lowers

- --Flo Flo

Lowers Lowers

Toavoidcrushinginjuriesormusclestrains,use

cautionwhendisconnectingthelower,itcanweigh

upto25kg(55lbs).

thePressureReliefProcedure,page13

theendstopreventuidcontamination.

collars(10).SeeFig.8.

4.Insertthecollars(10)intothecouplingnut(11).

Tightenthecouplingnut(11)ontothecoupling

adapter(9)andtorqueto90–100ft-lb(122–135

N•m).

5.Flushandtestthepumpbeforereinstalling

itinthesystem.Connecthosesandush

thepump.Whileitispressurized,checkfor

smoothoperationandleaks.Adjustorrepair

asnecessarybeforereinstallinginthesystem.

Reconnectthepumpgroundwirebefore

.

operating.

NOTE:

NOTE: NOTE:

lowersrequirecheckvalve(35)tobeinstalled.

WhenusedwithE-FloDCmotors,Dura-Flo

Torepairthelower,seetheDura-FloLower

instructionmanual311827.Thereareno

user-serviceablepartsinthemotor.Contactyour

Gracorepresentativeforassistance.

Reassembly

Reassembly Reassembly

NOTE:

NOTE: NOTE:

havebeendisassembledfromthemotor(3),see

ReassembletheCouplingAdapterandTieRodsto

theMotor,page19

1.Assemblethecouplingnut(11)tothepistonrod

2.Orientthelower(7)tothemotor(3).Position

3.Screwthetierodlocknuts(8)ontothetierods

Ifthecouplingadapter(9)andtierods(6)

(R).SeeFig.8.

thelower(7)onthetierods(6).Lubricatethe

threadsofthetierods(6).

(6).Tightenthelocknuts(8)andtorqueto50-60

ft-lb(68-81N•m).

Figure8Dura-FloPumpAssembly

16 333389A

Page 17

Repair

Xtreme

Xtreme Xtreme

Disassembly

Disassembly Disassembly

Toavoidcrushinginjuriesormusclestrains,use

cautionwhendisconnectingthelower,itcanweigh

upto25kg(55lbs).

1.Stopthepumpatthebottomofitsstroke.

2.Relievethepressure.See

thePressureReliefProcedure,page13.

3.Disconnectthehosesfromthelowerandplug

theendstopreventuidcontamination.

4.Removeclip(2)andslidecouplingcover(10)up

toremovethecoupling(11).

Lowers

Lowers Lowers

5.Unscrewthenuts(8)andremovethelower(7).

Useawrenchtoholdthetierodatstokeepthe

rodsfromturning.

Torepairthelower,seetheXtremeLowerinstruction

manual311762.Therearenouser-serviceableparts

inthemotor.ContactyourGracorepresentativefor

assistance.

333389A

17

Page 18

Repair

Reassembly

Reassembly Reassembly

NOTE:

NOTE: NOTE:

havebeendisassembledfromthemotor(3),see

ReassembletheCouplingAdapterandTieRodsto

theMotor,page19

1.Orientthelower(7)tothemotor(3).Position

2.Screwthetierodlocknuts(8)ontothetierods

3.Raisethemotorshaft.Placethecouplingcover

4.Flushandtestthepumpbeforereinstalling

Ifthecouplingadapter(9)andtierods(6)

thelower(7)onthetierods(6).Lubricatethe

threadsofthetierods(6).

(6).Tightenthelocknuts(8)andtorqueto50-60

ft-lb(68-81N•m).

(10)ontothecouplingadapter(9)andlowerthe

motorshaft.Placethecoupling(11)ontothe

lower(7)andslidethecouplingcover(10)over

thecoupling(11).Insertclip(2).

itinthesystem.Connecthosesandush

thepump.Whileitispressurized,checkfor

smoothoperationandleaks.Adjustorrepair

asnecessarybeforereinstallinginthesystem.

Reconnectthepumpgroundwirebefore

operating.

NOTE:

NOTE: NOTE:

lowersrequirecheckvalve(33)tobeinstalled.Figure9XtremePumpAssembly

WhenusedwithE-FloDCmotors,Xtreme

18 333389A

Page 19

Repair

Reassemble

Reassemble Reassemble

NOTE:

NOTE: NOTE:

adapter(9)andtierods(6)havebeendisassembled

fromthemotor(3),toensureproperalignmentofthe

motorshafttothepistonrod(R).

1.SeeFig.10.Screwthetierods(6)intothemotor

Usethisprocedureonlyifthecoupling

(3)andtorqueto50-60ft-lb(68-81N•m).

the

Coupling

the the

Coupling Coupling

Adapter

Adapter Adapter

and

Tie

and and

Rods

Tie Tie

Rods Rods

2.Screwthecouplingadapter(9)intothemotor

shaftandtorqueto90–100ft-lb(122–135N•m).

3.Reassemblethepumptothemotor.Use

theapplicableinstructionsforyourpump;

Dura-Flo,page16orXtreme,page18.

to

the

to to

Motor

the the

Motor Motor

Figure10PumpAssembly

333389A 19

Page 20

Parts

Parts

Parts Parts

Xtreme

Xtreme Xtreme

SeeModels,page3foranexplanationofthepumppartnumber.

Pump

Pump Pump

Assembly

Assembly Assembly

20 333389A

Page 21

Parts

Ref

Ref Ref

1

2244820

3

3a▲16M130LABEL,warning1

3b16W645

4

5

615F837

7

8107112NUT,lock,hex3

915H392ADAPTER1

10197340

11244819NUT,coupling1

12

Part

Part Part

SeePumpMatrix,page24

SeePumpMatrix,page24MOTOR,Basic;seemotormanual;includes

SeePumpMatrix,page24

SeePumpMatrix,page24BOLT

SeePumpMatrix,page24

SeePumpMatrix,page24STAND,oor

Description

Description Description

KIT,mountingbracket,pump;includesitems

4and5;seemanual311619

CLIP,hairpin

items3aand3b

OIL,gear,synthetic;ISO220silicone-free;

1quart(0.95liter);notshown

WASHER

ROD,tie

PUMP,displacement;seelowermanual1

COLLAR,coupling

Qty

Qty Qty

1

1

1

2

4

4

3

2

1

3316T480VALVE,check1

34

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

SeePumpMatrix,page24FITTING

1

333389A

21

Page 22

Parts

Dura

Dura Dura

SeeModels,page3foranexplanationofthepumppartnumber.

Flo

Pump

- --Flo Flo

Pump Pump

Assembly

Assembly Assembly

22

333389A

Page 23

Parts

Ref

Ref Ref

1

3

3a▲16M130LABEL,warning1

3b16W645

4

5

615H562

7

8101712NUT,lock3

915H370ADAPTER1

10184129

11186925NUT,coupling1

12

34

Part

Part Part

SeePumpMatrix,page24

SeePumpMatrix,page24MOTOR;BasicorAdvanced;seemotor

SeePumpMatrix,page24

SeePumpMatrix,page24

SeePumpMatrix,page24

SeePumpMatrix,page24STAND,oor

SeePumpMatrix,page24

Description

Description Description

KIT,mountingbracket,pump;includesitems

4and5;seemanual311619

manual;includesitems3aand3b

OIL,gear,synthetic;ISO220silicone-free;

1quart(0.95liter);notshown

WASHER

BOLT

ROD,tie

PUMP,displacement;seelowermanual1

COLLAR,coupling

FITTING

Qty

Qty Qty

1

1

2

4

4

3

2

1

1

35

▲ReplacementDangerandWarninglabels,tags,

andcardsareavailableatnocost.

24S039

VALVE,check1

333389A 23

Page 24

Parts

Pump

Pump Pump

Pump

Pump Pump

Part

Part Part

ES0340

ES0341

ES0342

ES9340

ES9341

ES9342

ES8340

ES8341

ES8342

ES0350

ES0351

ES0352

ES0450

Matrix

Matrix Matrix

Pump

Pump Pump

Series

No.

Series Series

No. No.

AEM0021

A255143256193EM0021100133100101

A255143EM0021100133100101

AEM0021

A255143256193EM0021100133100101

A255143EM0021100133100101

AEM0021

A255143256193EM0021100133100101

A255143EM0021100133100101

AEM0021247192

A255143256193EM0021100133100101247192

A255143EM0021100133100101247192

AEM0022247192

Mounting

Mounting Mounting

Bracket

Bracket Bracket

(Ref

1)

(Ref (Ref

1) 1)

Floor

Floor Floor

Stand

Stand Stand

(Ref

12)

(Ref (Ref

12) 12)

Motor

Motor Motor

(Ref

3)

(Ref (Ref

3) 3)

Washer

Washer Washer

(Ref

4)

(Ref (Ref

4) 4)

Bolt

Bolt Bolt

(Ref

5)

(Ref (Ref

5) 5)

Lower

Lower Lower

Pump

Pump Pump

(Ref

(Ref (Ref

L29AC115C257

L29AC115C257

L29AC115C257

L22AC115C257

L22AC115C257

L22AC115C257

L18AC1

L18AC1

L18AC1

7)

7) 7)

Fitting

Fitting Fitting

(Ref

34)

(Ref (Ref

34) 34)

175013

175013

175013

16C946

16C946

16C946

16C946

ES0451

ES0452

ES9350

ES9351

ES9352

ES9450

ES9451

ES9452

ES8350

ES8351

ES8352

ES8450

ES8451

ES8452

ES7360

ES7361

ES7362

A255143256193EM0022100133100101247192

A255143EM0022100133100101247192

AEM0021247190

A255143256193EM0021100133100101247190

A255143EM0021100133100101247190

AEM0022247190

A255143256193EM0022100133100101247190

A255143EM0022100133100101247190

AEM0021261657190724

A255143256193EM0021100133100101261657190724

A255143EM0021100133100101261657190724

AEM0022261657190724

A255143256193EM0022100133100101261657190724

A255143EM0022100133100101261657190724

AEM0021247168190724

A255143256193EM0021100133100101247168190724

A255143EM0021100133100101247168190724

16C946

16C946

16C946

16C946

16C946

16C946

16C946

16C946

ES7460

ES7461

ES7462

24

AEM0022247168190724

A255143256193EM0022100133100101247168190724

A255143EM0022100133100101247168190724

333389A

Page 25

Parts

Pump

Pump Pump

Part

Part Part

ES0740

ES0741

ES0742

ES9740

ES9741

ES9742

ES8740

ES8741

ES8742

ES0750

ES0751

ES0752

ES0850

ES0851

ES0852

Pump

Pump Pump

Series

No.

Series Series

No. No.

AEM0023

A255143256193EM0023100133100101

A255143EM0023100133100101

AEM0023

A255143256193EM0023100133100101

A255143EM0023100133100101

AEM0023

A255143256193EM0023100133100101

A255143EM0023100133100101

AEM0023247192

A255143256193EM0023100133100101247192

A255143EM0023100133100101247192

AEM0024247192

A255143256193EM0024100133100101247192

A255143EM0024100133100101247192

Mounting

Mounting Mounting

Bracket

Bracket Bracket

(Ref

1)

(Ref (Ref

1) 1)

Floor

Floor Floor

Stand

Stand Stand

(Ref

12)

(Ref (Ref

12) 12)

Motor

Motor Motor

(Ref

3)

(Ref (Ref

3) 3)

Washer

Washer Washer

(Ref

4)

(Ref (Ref

4) 4)

Bolt

Bolt Bolt

(Ref

5)

(Ref (Ref

5) 5)

Lower

Lower Lower

Pump

Pump Pump

(Ref

(Ref (Ref

L29AC115C257

L29AC115C257

L29AC115C257

L22AC115C257

L22AC115C257

L22AC115C257

L18AC1

L18AC1

L18AC1

7)

7) 7)

Fitting

Fitting Fitting

(Ref

34)

(Ref (Ref

34) 34)

175013

175013

175013

16C946

16C946

16C946

16C946

16C946

16C946

ES9750

ES9751

ES9752

ES9850

ES9851

ES9852

ES8750

ES8751

ES8752

ES8850

ES8851

ES8852

ES7760

ES7761

ES7762

ES7860

ES7861

AEM0023247190

A255143256193EM0023100133100101247190

A255143EM0023100133100101247190

AEM0024247190

A255143256193EM0024100133100101247190

A255143EM0024100133100101247190

AEM0023261657190724

A255143256193EM0023100133100101261657190724

A255143EM0023100133100101261657190724

AEM0024261657190724

A255143256193EM0024100133100101261657190724

A255143EM0024100133100101261657190724

AEM0023247168190724

A255143256193EM0023100133100101247168190724

A255143EM0023100133100101247168190724

AEM0024247168190724

A255143256193EM0024100133100101247168190724

16C946

16C946

16C946

16C946

16C946

16C946

ES7862

A255143EM0024100133100101247168190724

333389A 25

Page 26

Dimensions

Dimensions

Dimensions Dimensions

A

A A

58.00in.(1473mm)17.00in.(432mm)19.88in.(505mm)

26 333389A

B

B B

C

C C

Page 27

MountingHolePatterns

Mounting

Mounting Mounting

Stand

Stand Stand

Mount

Mount Mount

Hole

Hole Hole

Patterns

Patterns Patterns

Dimension

Dimension Dimension

A

B

C16.88in.(429mm)

D

333389A

Measurement

Measurement Measurement

19.88in.(505mm)

14.50in.(368mm)

17.00in.(432mm)

27

Page 28

MountingHolePatterns

Wall

Wall Wall

Mount

Mount Mount

Dimension

Dimension Dimension

A

B

C12.4in.(314mm)

D

E

F

G5.3in.(133mm)

H

J

K

L

M

N

P

Measurement

Measurement Measurement

17.8in.(451mm)

14.5in.(368mm)

9.0in.(229mm)

5.4in.(137mm)

7.4in.(187mm)

2.0in.(51mm)

1.0in.(25mm)

1.6in.(41mm)

2.7in.(69mm)

4.4in.(112mm)

Four0.562in.(14mm)diameterholesformountingtostand

Four0.438in.(11mm)diameterholesformountingtowall

28 333389A

Page 29

PerformanceCharts

A

B

C

A

B

C

0

400

(2.8, 28)

800

(5.5, 55)

1200

(8.3, 83)

1600

(10.0, 1 10)

2000

(13.8, 138)

2400

(16.6, 166)

2800

(19.3, 193)

3200

(22.1, 221)

3600

(24.8, 248)

0.0

1.0

2.0

3.0

4.0

5.0

(0)

(200)

(400)

(600)

(800)

(1000)

6.0

(1200)

7.0

(1400)

8.0

9.0

0.0 0.1

(0.38)

0.2

(0.76)

0.3

(1.14)

0.4

(1.52)

0.5

(1.90)

0.6

(2.28)

0.7

(2.66)

0.8

(3.04)

3 8 14 21

0.9

(3.42)

1.0

(3.80)

A

B

C

A

B

C

Performance

Performance Performance

Charts

Charts Charts

Tondtheuidpressure(psi/bar/MPa)ataspecic

uidow(gpm/lpm)andpercentageofmaximum

force:

1.Locatethedesireduidowinthescaleatthe

bottomofthechart.

2.Followtheverticallineuptotheintersectionwith

theselectedpercentageofmaximumforce(see

Key

theKey Key

below).

3.Followlefttotheverticalscaletoreadtheuid

outletpressure.

Table

Table Table

2 22. ..E EE- --Flo Flo

Flo

DC

with

Dura

Flo

145

DC DC

with with

Dura Dura

- --Flo Flo

Lower

145 145

Lower Lower

CYCLES

CYCLES CYCLES

Key

Key Key

NOTE:

NOTE: NOTE:

Performance

to totoPerformance Performance

Charts

Charts Charts

Thechartsshowthemotoroperatingat

100%,70%,and40%ofmaximumforce.These

valuesareapproximatelyequivalenttoanairmotor

operatingat100,70,and40psi.

Pressure

Pressure Pressure

MaxPressure

70%Pressure

40%Pressure

Motor

Amps/Watts

Motor Motor

Amps/Watts Amps/Watts

MaxPressure

70%Pressure

40%Pressure

PER

MINUTE

PER PER

MINUTE MINUTE

FLUID

FLUID FLUID

PRESSURE:

PRESSURE: PRESSURE:

psi(bar,MPa)

333389A 29

MOTOR

MOTOR MOTOR

(WATTS)

(WATTS) (WATTS)

FLUID

FLOW:

FLUID FLUID

FLOW: FLOW:

gpm(lpm)

AMPS

AMPS AMPS

Page 30

PerformanceCharts

0

400

(2.8, 28)

800

(5.5, 55)

1200

(8.3, 83)

1600

(10.0, 1 10)

2400

(16.6, 166)

2800

(19.3, 193)

0.0 (0)

(200)

(400)

(600)

(800)

(1000)

(1200)

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

2 8 15 21

0.0 0.1

(0.38)

0.2

(0.76)

0.3

(1.14)

0.4

(1.52)

0.5

(1.90)

0.6

(2.28)

0.7

(2.66)

0.8

(3.04)

0.9

(3.42)

1.0

(3.80)

2000

(13.8, 138)

B

C

A

B

C

A

0

400

(2.8, 28)

600

(4.1, 41)

200

(1.4, 14)

800

(5.5, 55)

1000

(6.9, 69)

1200

(8.3, 83)

1400

(9.7, 97)

1600

(10.0, 1 10)

1800

(12.4, 124)

0.0 (0)

(200)

(400)

(600)

(800)

(1000)

(1200)

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

2 8 15 21

0.0 0.2

(0.76)

0.4

(1.52)

0.6

(2.28)

0.8

(3.04)

1.0

(3.80)

1.2

(4.56)

2000

(13.8, 138)

B

C

A

B

C

A

Table

Table Table

FLUID

FLUID FLUID

PRESSURE:

PRESSURE: PRESSURE:

psi(bar,MPa)

3 33. ..E EE- --Flo Flo

Flo

DC

with

Dura

DC DC

with with

Flo/Xtreme

Dura Dura

- --Flo/Xtreme Flo/Xtreme

180

Lower

180 180

Lower Lower

CYCLES

CYCLES CYCLES

FLUID

FLUID FLUID

PER

MINUTE

PER PER

MINUTE MINUTE

MOTOR

MOTOR MOTOR

(WATTS)

(WATTS) (WATTS)

FLOW:

FLOW: FLOW:

gpm(lpm)

AMPS

AMPS AMPS

Table

Table Table

FLUID

FLUID FLUID

PRESSURE:

PRESSURE: PRESSURE:

psi(bar,MPa)

4 44. ..E EE- --Flo Flo

Flo

DC

with

Dura

DC DC

with with

Flo/Xtreme

Dura Dura

- --Flo/Xtreme Flo/Xtreme

220

Lower

220 220

Lower Lower

CYCLES

CYCLES CYCLES

FLUID

FLUID FLUID

PER

MINUTE

PER PER

MINUTE MINUTE

FLOW:

FLOW: FLOW:

gpm(lpm)

30 333389A

MOTOR

MOTOR MOTOR

(WATTS)

(WATTS) (WATTS)

AMPS

AMPS AMPS

Page 31

PerformanceCharts

0

200

(1.4, 14)

400

(2.8, 28)

600

(4.1, 41)

800

(5.5, 55)

1000

(6.9, 69)

1200

(8.3, 83)

1400

(9.7, 97)

1600

(10.0, 1 10)

0.0 (0)

(200)

(400)

(600)

(800)

(1000)

(1200)

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

0.0 1.2

(4.56)

1.4

(5.32)

2 8 15 2 1

0.2

(0.76)

0.4

(1.52)

0.6

(2.28)

0.8

(3.04)

1.0

(3.80)

B

C

A

B

C

A

Table

Table Table

FLUID

FLUID FLUID

PRESSURE:

PRESSURE: PRESSURE:

psi(bar,MPa)

5 55. ..E EE- --Flo Flo

Flo

DC

with

Dura

DC DC

with with

Flo/Xtreme

Dura Dura

- --Flo/Xtreme Flo/Xtreme

290

Lower

290 290

Lower Lower

CYCLES

CYCLES CYCLES

FLUID

FLUID FLUID

PER

MINUTE

PER PER

MINUTE MINUTE

MOTOR

MOTOR MOTOR

(WATTS)

(WATTS) (WATTS)

FLOW:

FLOW: FLOW:

gpm(lpm)

AMPS

AMPS AMPS

333389A 31

Page 32

TechnicalData

Technical

Technical Technical

Flo

DC

E EE- --Flo Flo

Maximum

Maximum Maximum

Maximum

Maximum Maximum

Maximum

Maximum Maximum

Maximum

Maximum Maximum

Input

Input Input

Input

Input Input

Power

Power Power

Ambient

Ambient Ambient

Sound

Sound Sound

Oil

Oil Oil

Oil

Oil Oil

Weight

Weight Weight

Fluid

Fluid Fluid

Fluid

Fluid Fluid

Wetted

Wetted Wetted

Pumps

DC DC

Pumps Pumps

uid

uid uid

potential

potential potential

continuous

continuous continuous

Flow

Flow Flow

voltage

voltage voltage

current

current current

inlet

port

inlet inlet

port port

temperature

temperature temperature

data

data data

capacity

capacity capacity

specication

specication specication

inlet

size

inlet inlet

size size

outlet

size

outlet outlet

size size

parts

parts parts

Data

Data Data

U.S.

U.S. U.S.

working

working working

size

size size

pressure

pressure pressure

ModelsES0xxx

ModelsES9xxx

ModelsES8xxx

ModelsES7xxx

uid

pressure

uid uid

pressure pressure

cycle

rate

cycle cycle

rate rate

range

range range

436000/v(volumeoflower

Maximumowisdeterminedbythesizeofthepumplower.

GracoPartNo.16W645ISO220silicone-freesyntheticgearoil

Pumppackage(motor,1000cc

lower,stand,andtierods):220lb

1520psi10.48MPa,104.8bar

2030psi14MPa,140bar

2430psi16.75MPa,167.5bar

3040psi20.96MPa,209.6bar

3000/v(volumeoflowerincc)=bar

incc)=psi

20cpm

SeePerformanceCharts,page29.

200–250Vac,singlephase,50/60Hz

20Amaximum

3/4–14npt(f)

32–104°F0–40°C

Lessthan70dB(A)

1.5quarts1.4liters

Pumppackage(motor,1000cc

lower,stand,andtierods):99.8kg

1–1/2npt(f)

3/4npt(f)[145cc-180cc]

1npt(f)[220cc-290cc]

SeeLowerPumpmanual.

Metric

Metric Metric

32 333389A

Page 33

Notes

Notes

Notes Notes

333389A 33

Page 34

Graco

Graco Graco

GracowarrantsallequipmentreferencedinthisdocumentwhichismanufacturedbyGracoandbearingits

nametobefreefromdefectsinmaterialandworkmanshiponthedateofsaletotheoriginalpurchaserfor

use.Withtheexceptionofanyspecial,extended,orlimitedwarrantypublishedbyGraco,Gracowill,fora

periodoftwelvemonthsfromthedateofsale,repairorreplaceanypartoftheequipmentdetermined

byGracotobedefective.Thiswarrantyappliesonlywhentheequipmentisinstalled,operatedand

maintainedinaccordancewithGraco’swrittenrecommendations.

Thiswarrantydoesnotcover,andGracoshallnotbeliableforgeneralwearandtear,oranymalfunction,

damageorwearcausedbyfaultyinstallation,misapplication,abrasion,corrosion,inadequateorimproper

maintenance,negligence,accident,tampering,orsubstitutionofnon-Gracocomponentparts.Norshall

Gracobeliableformalfunction,damageorwearcausedbytheincompatibilityofGracoequipment

withstructures,accessories,equipmentormaterialsnotsuppliedbyGraco,ortheimproperdesign,

manufacture,installation,operationormaintenanceofstructures,accessories,equipmentormaterials

notsuppliedbyGraco.

Thiswarrantyisconditionedupontheprepaidreturnoftheequipmentclaimedtobedefectivetoan

authorizedGracodistributorforvericationoftheclaimeddefect.Iftheclaimeddefectisveried,Graco

willrepairorreplacefreeofchargeanydefectiveparts.Theequipmentwillbereturnedtotheoriginal

purchasertransportationprepaid.Ifinspectionoftheequipmentdoesnotdiscloseanydefectinmaterial

orworkmanship,repairswillbemadeatareasonablecharge,whichchargesmayincludethecostsof

parts,labor,andtransportation.

THIS

WARRANTY

THIS THIS

WARRANTY WARRANTY

IMPLIED,

IMPLIED, IMPLIED,

OF

FITNESS

OF OF

FITNESS FITNESS

Graco’ssoleobligationandbuyer’ssoleremedyforanybreachofwarrantyshallbeassetforthabove.

Thebuyeragreesthatnootherremedy(including,butnotlimitedto,incidentalorconsequentialdamages

forlostprots,lostsales,injurytopersonorproperty,oranyotherincidentalorconsequentialloss)shall

beavailable.Anyactionforbreachofwarrantymustbebroughtwithintwo(2)yearsofthedateofsale.

GRACO

GRACO GRACO

MERCHANTABILITY

MERCHANTABILITY MERCHANTABILITY

ACCESSORIES,

ACCESSORIES, ACCESSORIES,

GRACO.

GRACO. GRACO.

aresubjecttothewarranty,ifany,oftheirmanufacturer.Gracowillprovidepurchaserwithreasonable

assistanceinmakinganyclaimforbreachofthesewarranties.

InnoeventwillGracobeliableforindirect,incidental,specialorconsequentialdamagesresultingfrom

Gracosupplyingequipmenthereunder,orthefurnishing,performance,oruseofanyproductsorother

goodssoldhereto,whetherduetoabreachofcontract,breachofwarranty,thenegligenceofGraco,or

otherwise.

FORGRACOCANADACUSTOMERS

ThePartiesacknowledgethattheyhaverequiredthatthepresentdocument,aswellasalldocuments,

noticesandlegalproceedingsenteredinto,givenorinstitutedpursuantheretoorrelatingdirectlyor

indirectlyhereto,bedrawnupinEnglish.Lespartiesreconnaissentavoirconvenuquelarédactiondu

présentedocumentseraenAnglais,ainsiquetousdocuments,avisetprocéduresjudiciairesexécutés,

donnésouintentés,àlasuitedeouenrapport,directementouindirectement,aveclesprocédures

concernées.

MAKES

MAKES MAKES

Theseitemssold,butnotmanufacturedbyGraco(suchaselectricmotors,switches,hose,etc.),

Standard

Standard Standard

IS

EXCLUSIVE,

IS IS

INCLUDING

INCLUDING INCLUDING

FOR

FOR FOR

EXCLUSIVE, EXCLUSIVE,

BUT

NOT

BUT BUT

NOT NOT

PARTICULAR

A AAPARTICULAR PARTICULAR

NO

WARRANTY,

NO NO

WARRANTY, WARRANTY,

AND

FITNESS

AND AND

EQUIPMENT,

EQUIPMENT, EQUIPMENT,

FITNESS FITNESS

MATERIALS

MATERIALS MATERIALS

Warranty

Warranty Warranty

AND

IS

IN

LIEU

OF

ANY

AND AND

IS IS

IN IN

LIEU LIEU

LIMITED

LIMITED LIMITED

AND

AND AND

TO

TO TO

PURPOSE.

PURPOSE. PURPOSE.

DISCLAIMS

DISCLAIMS DISCLAIMS

FOR

FOR FOR

PARTICULAR

A AAPARTICULAR PARTICULAR

OR

OR OR

OF OF

WARRANTY

WARRANTY WARRANTY

ALL

ALL ALL

COMPONENTS

COMPONENTS COMPONENTS

OTHER

ANY ANY

OTHER OTHER

OF

OF OF

IMPLIED

IMPLIED IMPLIED

PURPOSE,

PURPOSE, PURPOSE,

WARRANTIES,

WARRANTIES, WARRANTIES,

MERCHANTABILITY

MERCHANTABILITY MERCHANTABILITY

WARRANTIES

WARRANTIES WARRANTIES

IN

CONNECTION

IN IN

SOLD

SOLD SOLD

CONNECTION CONNECTION

BUT

NOT

BUT BUT

NOT NOT

EXPRESS

EXPRESS EXPRESS

OR

WARRANTY

OR OR

WARRANTY WARRANTY

OF

OF OF

WITH

MANUFACTURED

MANUFACTURED MANUFACTURED

WITH WITH

OR

OR OR

BY

BY BY

Graco

Graco Graco

ForthelatestinformationaboutGracoproducts,visitwww.graco.com.Forpatentinformation,see

www.graco.com/patents.

To

To To

Phone:

Phone: Phone:

Allwrittenandvisualdatacontainedinthisdocumentreectsthelatestproductinformationavailableatthetimeofpublication.Graco

place

an

place place

an an

612-623-6921or or

Information

Information Information

order,

order, order,

contactyourGracoDistributororcalltoidentifythenearestdistributor.

or

Toll

Free:

Toll Toll

Free: Free:

1-800-328-0211Fax: Fax:

reservestherighttomakechangesatanytimewithoutnotice.

OriginalInstructions.ThismanualcontainsEnglish,MM333389

Graco

Graco Graco

International

International International

GRACO

GRACO GRACO

INC.

AND

INC. INC.

Copyright

Copyright Copyright

SUBSIDIARIES

AND AND

SUBSIDIARIES SUBSIDIARIES

2014,

Graco

2014, 2014,

Inc.

Graco Graco

Inc. Inc.

Headquarters:

Headquarters: Headquarters:

Ofces:

Ofces: Ofces:

P.O.

• ••P.O. P.O.

All

Graco

All All

Graco Graco

www.graco.com

Fax:

612-378-3505

Belgium,China,Japan,Korea

BOX

1441

BOX BOX

1441 1441

manufacturing

manufacturing manufacturing

Minneapolis

MINNEAPOLIS,

• ••MINNEAPOLIS, MINNEAPOLIS,

locations

locations locations

MN

55440-1441

MN MN

55440-1441 55440-1441

are

registered

are are

registered registered

ISO

to totoISO ISO

USA

• ••USA USA

9001.

9001. 9001.

Loading...

Loading...