Page 1

Repair-Parts

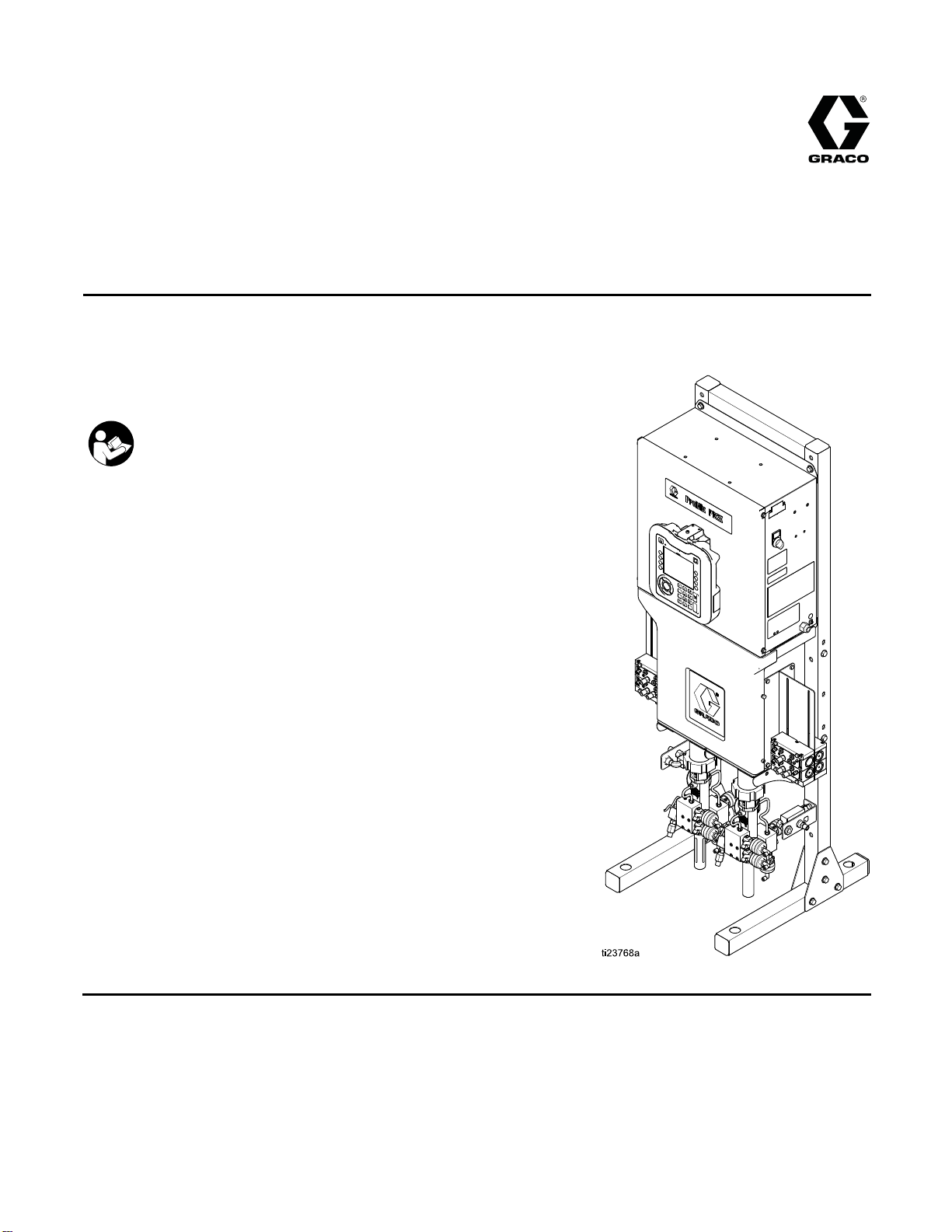

ProMix® PD2K Pr

Automatic Spr

Electronic positive displacement proportioner for fast-setting two-component materials. System for

automatic dispense, with Advanced Display Modules. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in your

installation, operation, and associated component manuals.

Save these instructions.

See page 3

approvals information.

for model part numbers and

ay Applications

oportioner for

332709B

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Models............................................................... 3

Related Manuals ................................................ 5

Warnings ........................................................... 6

Important Isocyanate (ISO) Information................ 9

Troubleshooting.................................................. 10

System Troubleshooting............................... 10

Error Code Troubleshooting.......................... 11

Power Barrier Board Diagnostics .................. 21

Isolation Board Diagnostics .......................... 22

Enhanced Fluid Control Module (EFCM)

Diagnostics .................................... 23

Pump Module Diagnostics ............................ 24

AdvancedDisplay Module Diagnostics........... 25

Notes ................................................................ 26

Electrica

l Schematics.......................................... 27

Optional Cables and Modules....................... 33

Repair................................................................ 34

Before Servicing .......................................... 34

Pressure Relief Procedure............................ 35

Repairing the Advanced Display Module

(ADM)............................................ 36

Servicing the Control Box ............................. 38

Servicing the Fluid Section ........................... 48

Notes ................................................................ 53

Parts.................................................................. 54

Proportioner Parts........................................ 54

Control Box Parts......................................... 57

Solenoid Manifold Parts................................ 60

Technical Data ...................................................61

Graco Sta

ndard Warranty.................................... 62

2

332709B

Page 3

Models

Models

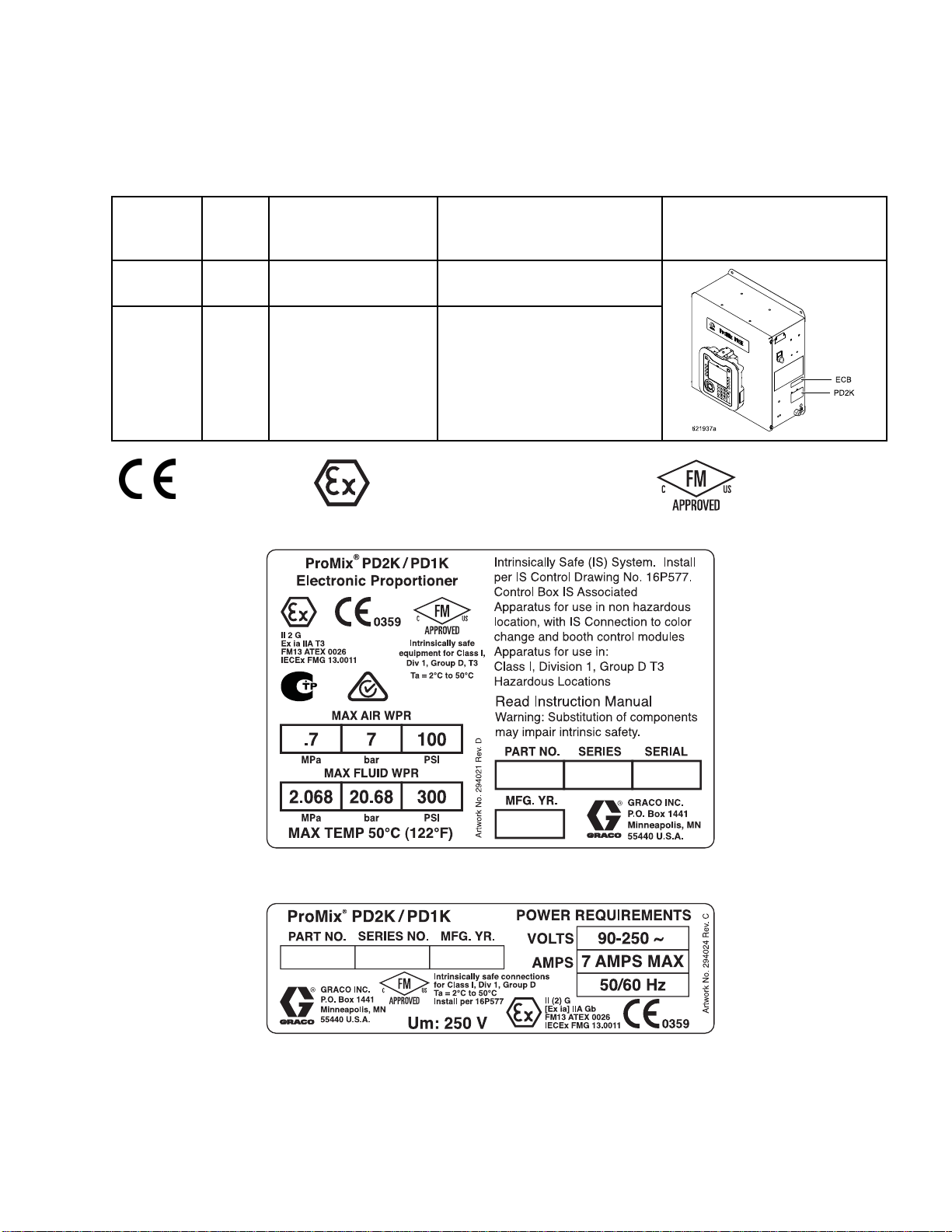

SeeFigs.1–7f

Part No.

AC1000

AC2000

0359

or component identification labels, including approval information and certification.

Series

A

A

Maximum Air Wo

Pressure

100 psi (0.7

7.0 bar)

100 psi (0.7 MPa,

7.0 bar)

MPa,

II 2 G

rking

Maximum Fluid

Pressure

300 psi (2.0

1500 psi (10.34 MPa,

68 MPa, 20.68 bar)

103.4 bar)

Working

Location of PD2K and

Electrical Control Box

(ECB) Labels

Figure 1 Model AC1000 (Low Pressure) Identification

Label

Figure 2 24M672 Control Box Identification Label

Continued on the next page.

332709B 3

Page 4

Models

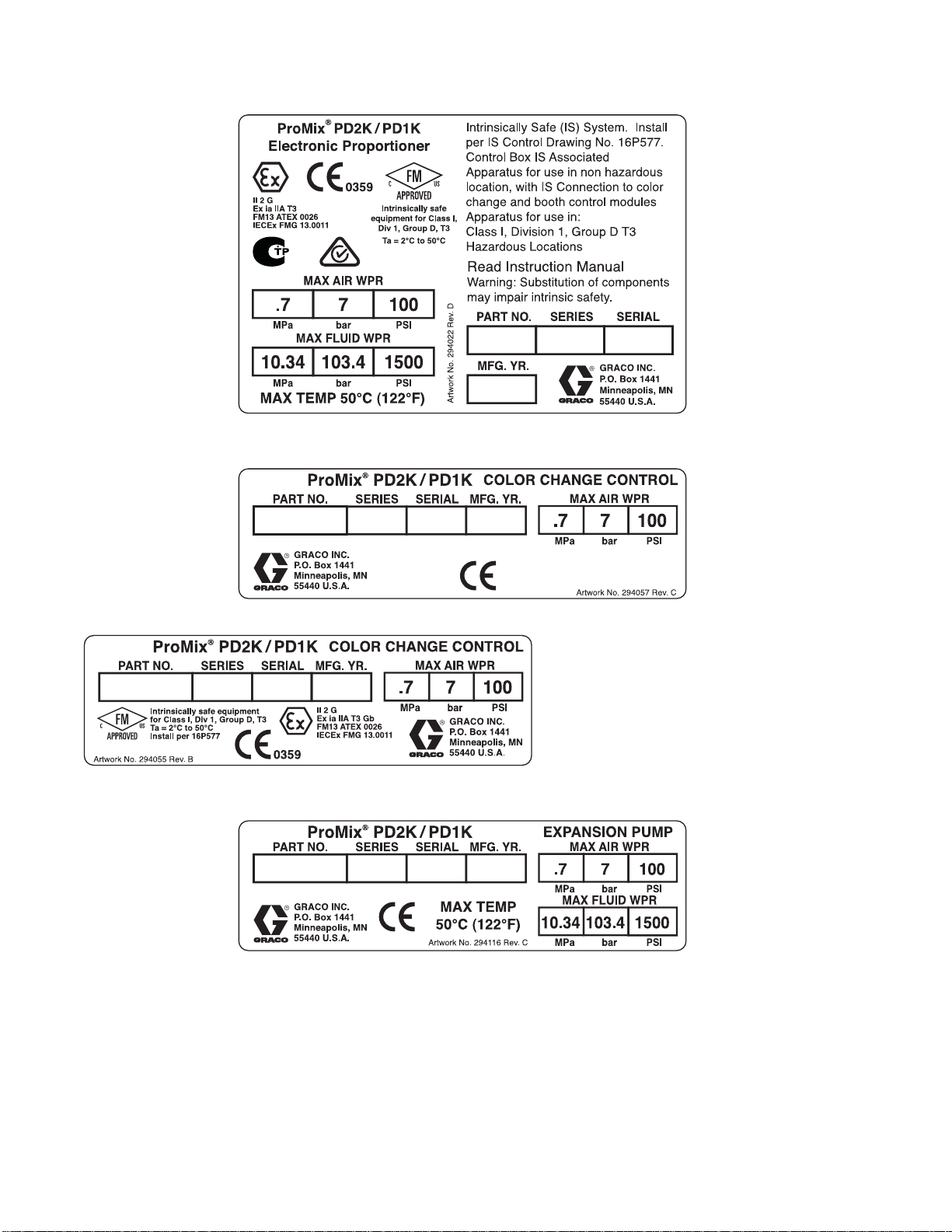

Figure 3 Model AC2000 (High Pressure)

Identification Label

Figure 4 Non-Intrinsically Safe Color Change Control (Accessory) Identification Label

Figure 5 Intrinsically Safe Color Change Control

(Accessory) Identification Label

Figure 6 Pump Expansion Kit (Accessory) Identification Label

4

332709B

Page 5

Related Manuals

Related Manuals

Current manua

Manual No. Description

332458 PD2K Proportioner Installation

332564

332339 Pump Repair-Parts Manual

332454

ls are available at www.graco.com.

Manual, Automatic Systems

PD2K Proport

Manual, Aut

Color Chan

Manual

ioner Operation

omatic Systems

ge Valve Repair-Parts

Manual No. Description

332455

333282

332456 3rd and 4th Pump Kits

Color Change Kits InstructionsParts Manual

Remote Mix Ma

Instructio

Instructions-Parts Manual

ns-Parts Manual

nifold

332709B 5

Page 6

Warnings

Warnings

The following

exclamation p

risks. When th

Warnings. Pr

the body of th

warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

oint symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

ese symbols appear in the body of this manual or on warning labels, refer backtothese

oduct-specific hazard symbols and warnings not covered in this section may appear throughout

is manual where applicable.

WARNING

FIRE AND EX

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

•Useonly

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock, Do not use

equipment until you identify and correct the problem.

• Keepaw

PLOSION HAZARD

area free of debris, including solvent, rags and gasoline.

grounded hoses.

orking fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

•Turn

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

6 332709B

off and disconnect power at main switch before disconnecting any cables and before

icing or installing equipment.

serv

and regulations.

Page 7

INTRINSIC SAFETY

Warnings

WARNING

Intrinsical

equipment wi

Follow local

• Be sure your installation complies with national, state, and local codes for the installation of

electrical apparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1

and 2 (Europe) Hazardous Location, including all of the local safety fire codes (for example,

NFPA 33, NEC 500 and 516, OSHA 1910.107, etc.).

• To help prev

•Equipment

Safety. T

unit from

SKIN INJECTION HAZARD

High-pr

skin. Th

immedia

• Do not point dispensing device at anyone or at any part of the body.

•Donotp

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning,

checking, or servicing equipment.

•Tight

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

ly safe equipment that is installed improperly or connected to non-intrinsically safe

ll create a hazardous condition and can cause fire, explosion, or electric shock.

regulations and the following safety requirements.

ent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous

location. See model ID label for the intrinsic safety rating of your model.

• Do not substitute system components as this may impair intrinsic safety.

that comes in contact with the intrinsically safe terminals must be rated for Intrinsic

his includes DC voltage meters, ohmmeters, cables, and connections. Remove the

the hazardous area when troubleshooting.

essure fluid from dispensing device, hose leaks, or ruptured components will pierce

is may look like just a cut, but it is a serious injury that can result in amputation. Get

te surgical treatment.

ut your hand over the fluid outlet.

en all fluid connections before operating the equipment.

332709B

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

•Pres

TOX

Tox

inh

• Read MSDSs to know the specific hazards of the fluids you are using.

•St

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning

surized equipment can start without warning. Before checking, moving, or servicing

pment, follow the Pressure Relief Procedure and disconnect all power sources.

equi

IC FLUID OR FUMES

ic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

aled, or swallowed.

ore hazardous fluid in approved containers, and dispose of it according to applicable

idelines.

gu

equipment.

7

Page 8

Warnings

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

•Protectivee

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

•Usefluids

in all equ

informat

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

•Checkeq

manufac

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which youareusingit.

•Useequ

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

•Keepc

• Comply with all applicable safety regulations.

yewear, and hearing protection.

and solvents that are compatible with equipment wetted parts. See Technical Data

ipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

ion about your material, request MSDS from distributor or retailer.

uipment daily. Repair or replace worn or damaged parts immediately with genuine

turer’s replacement parts only.

ipment only for its intended purpose. Call your distributor for information.

hildren and animals away from work area.

8 332709B

Page 9

Important Isocy

anate (ISO) Information

Important Iso

Isocyanates (ISO) are catalysts used in two

component materials.

cyanate (ISO) Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read and understand material manufacturer’s

warnings and material MSDS to know specific

hazards and precautions related to isocyanates.

Prevent inhalation of isocyanate mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation

is not available, a supplied-air respirator is required

for everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including

chemically impermeable gloves, boots, aprons,

and goggles, is also required for everyone in the

work area.

Eventually a film will form on the surface and the ISO

will begin to gel, increasing in viscosity.

NOTICE

Partially c

the life of a

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere.

Never store ISO in an open container.

• Keep the ISO pump wet cup or reservoir (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may

contain moisture. Always keep solvent

containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubricant when reassembling.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

ured ISO will reduce performance and

ll wetted parts.

Keep Components A and B Separate

Cross-contamination can result in cured

material in fluid lines which could cause serious

injury or damage equipment. To prevent

cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been

contaminated from the other side.

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will cause

ISO to partially cure; forming small, hard, abrasive

crystals, which become suspended in the fluid.

Chang

Changing the material types used in your

equipment requires special attention to avoid

equipment damage and downtime.

•When

•Alw

•Che

•Wh

ing Materials

NOTIC

changing materials, flush the equipment

tiple times to ensure it is thoroughly clean.

mul

ays clean the fluid inlet strainers after

hing.

flus

ck with your material manufacturer for

mical compatibility.

che

en changing between epoxies and urethanes

polyureas, disassemble and clean all fluid

or

mponents and change hoses. Epoxies often

co

ve amines on the B (hardener) side. Polyureas

ha

tenhaveaminesontheA(resin)side.

of

E

332709B 9

Page 10

Troubleshootin

g

Troubleshooting

NOTE: Check all possible remedies before disassembling the system.

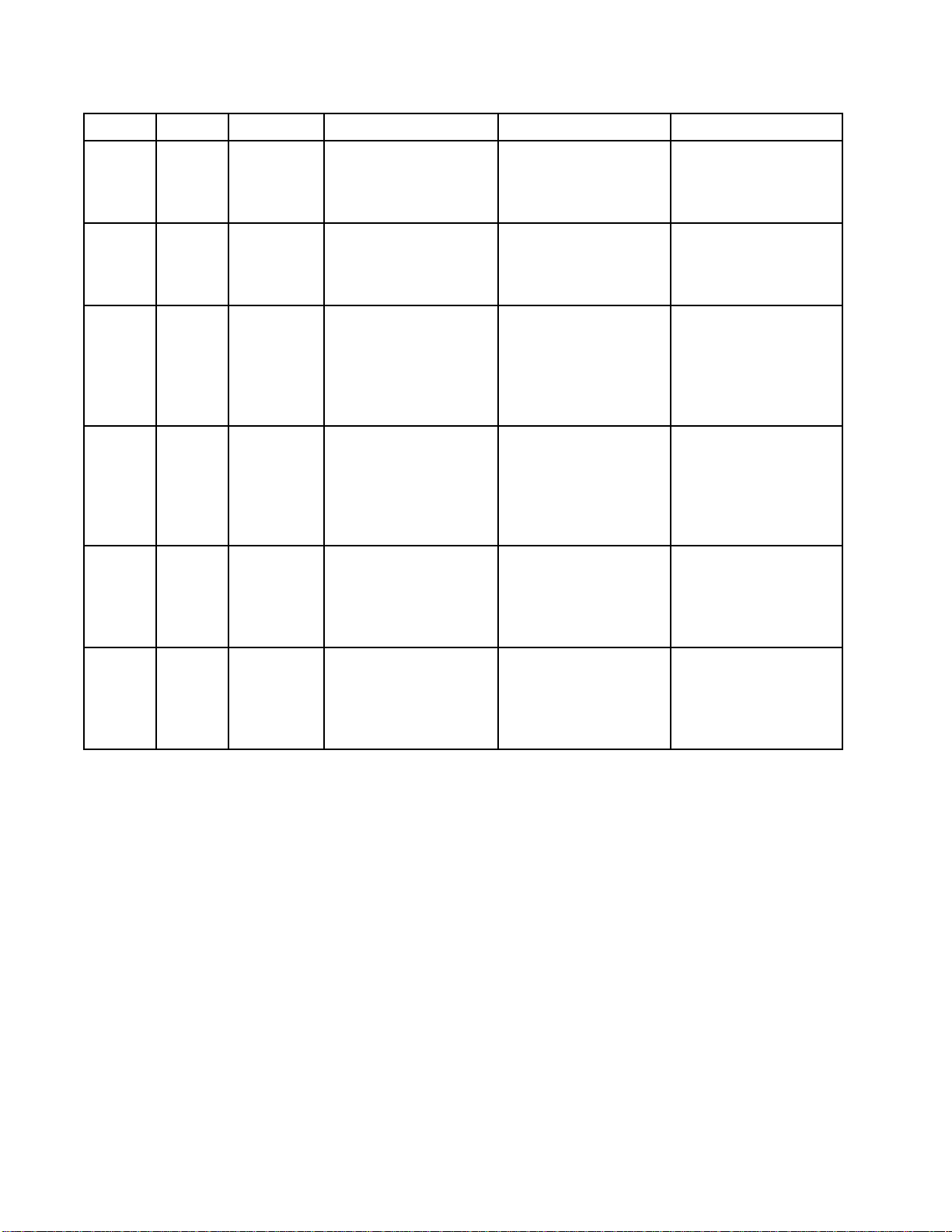

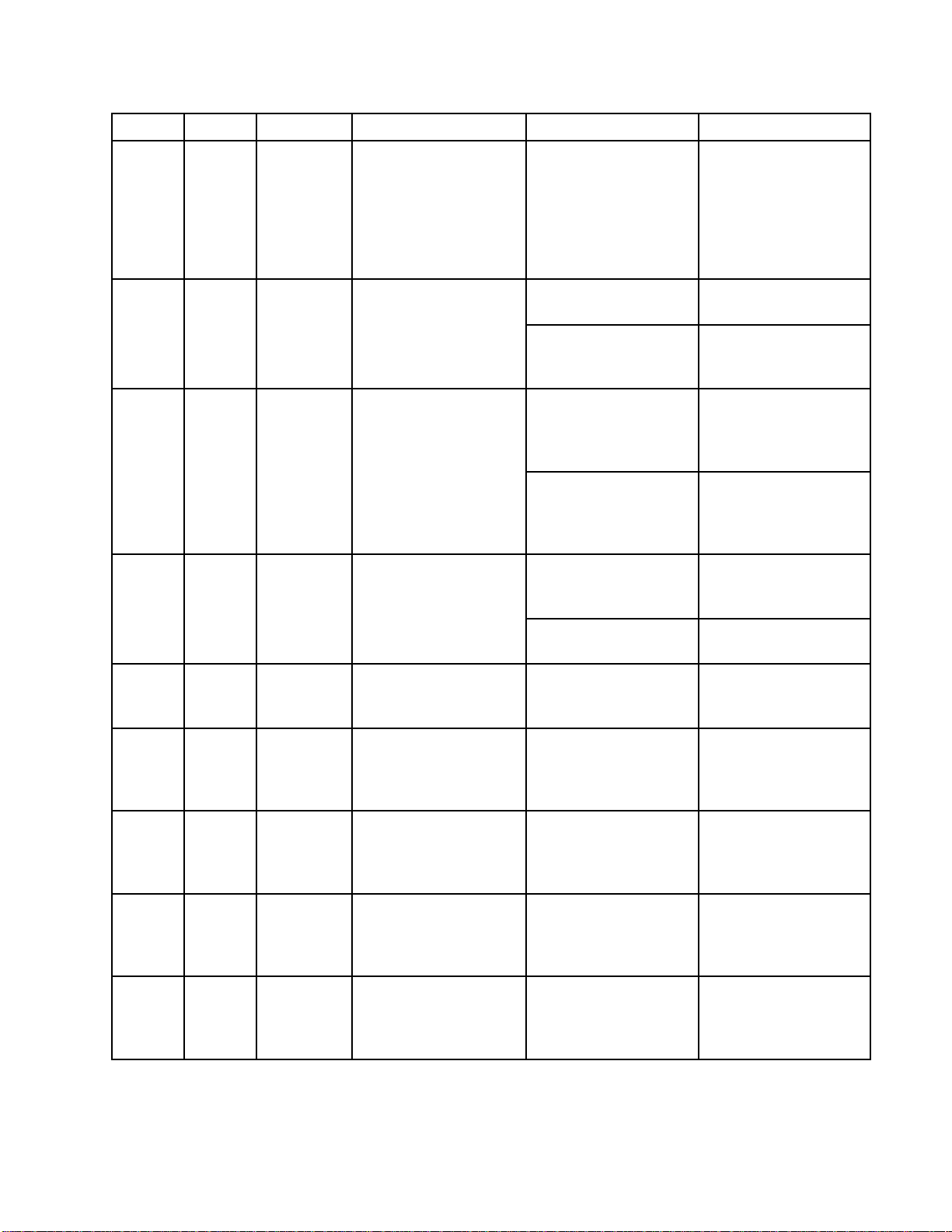

System Troubleshooting

Problem

Unit will not operate.

Pump output low on both strokes.

Pump output low on only one

stroke.

No output. Improperly installed dosing valves.

Cause Solution

Inadequate power supply.

Power switch is off.

Main power is shut off.

Exhausted fluid supply. Refill and reprime pump.

Clogged fluid outlet line, valves,

etc.

Fluid dried on piston rod. Disassemble and clean pump.

Inadequate power supply.

Exhausted fluid supply. Refill and reprime pump.

Clogged fluid outlet line, valves,

etc.

Worn piston packings.

Held open or worn dosing valves.

Worn piston packing.

See Technical Data, page 61.

Turn switch on.

Turn main power switch on.

Clear.

See pump manual. In future, stop

pump at bottom of stroke.

See Technical Data, page 61.

Clear.

Replace. See pump manual.

Check and repair. See pump

manual.

Replace. See pump manual.

Check solenoid connections to

valves. See pump manual.

Pump operates erratically.

Exhausted fluid supply. Refill and reprime pump.

Held open or worn dosing valves.

Worn piston packing.

Check and repair. See pump

manual.

Replace. See pump manual.

10 332709B

Page 11

Troubleshootin

g

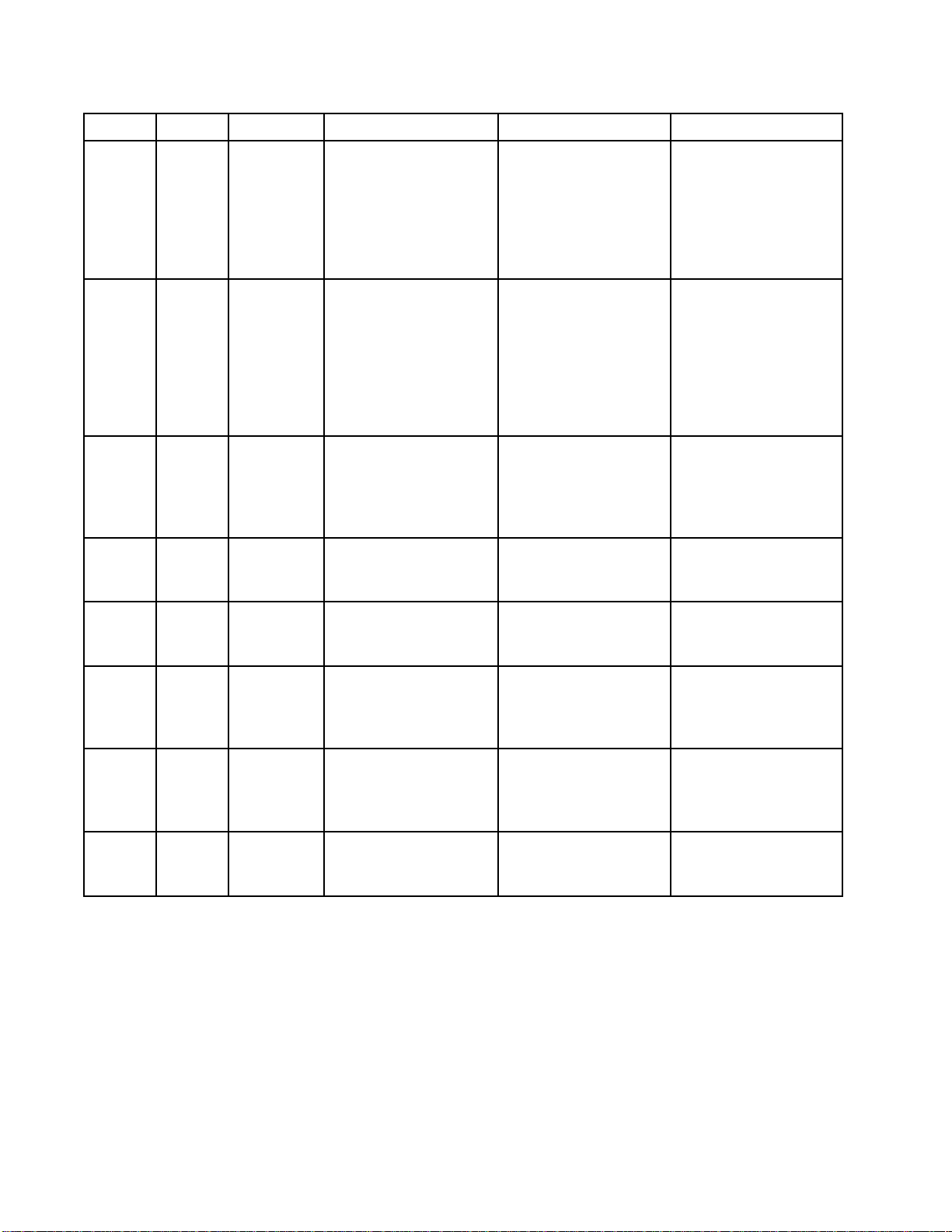

Error Code Tro

System errors alert you of a problem and help

prevent off-ratio spraying. There are three types:

Advisory, Deviation, and Alarm.

An Advisory r

clear itself

A Deviation records an error in the system but does

not shut down the equipment. The deviation must be

acknowledged by the user.

If an Alarm occurs, operation stops.

If any of th

• Alarm buzzer sounds (unless in silent mode).

• Alarm popup screen shows the active alarm code.

• Status bar on the Advanced Display Module shows

the active alarm code.

• Alarm is saved in the date/time stamped log.

Code

B9A0 Advi-

ecords an event in the system, and will

after 60 seconds.

e three types occur:

Type Description Problem

sory

ubleshooting

Volume

Rollove

Current

Batch counter for

rA

material A rolled over.

NOTE: When an error occurs be sure to determine

the code before resetting it. If you forget which code

occurred, the Errors screen displays the 200 most

recent errors, with date, time, and description.

NOTE: In some

is shown as th

applicable

display wil

last digit i

Cause Solution

The tota

reached

capable

starte

error codes listed below, a # symbol

e last digit. This symbol represents the

pump number, which can vary. The unit’s

l show the applicable pump number as the

n the code.

lizer has

maximum

value and

doveratzero.

n/a

B9AX Advi-

sory

B9B0 Advi-

sory

B9BX Advi

sory

B9D#

Advisory

-

Volume

Rollover A

Lifetime

Volume

Rollover B

Current

me

Volu

over B

Roll

time

Life

Volume

Rollover

Pump #

Grand total counter for

material A rolled over.

counter for

Batch

ial B rolled over.

mater

Grand total counter for

material B rolled over.

Grand total counter for

pump # rolled over.

The totalizer has

reached maximum

capable value and

started over at zero.

The totalizer has

reached maximum

capable value and

started over at zero.

otalizer has

The t

hed maximum

reac

ble value and

capa

ted over at zero.

star

The totalizer has

reached maximum

capable value and

started over at zero.

n/a

n/a

n/a

n/a

332709B

11

Page 12

Troubleshootin

g

Code

B9S0

B9SX

CAC#

CA0X

CADX

Type Description Problem

Advisory

Advisory

Alarm

Alarm

Alarm

Volume

Rollover

Solvent

Current

Volume

Rollover

Solvent

Lifetime

Comm.

Error Color

Change #

Comm.

Error ADM

Comm.

Error Fluid

Module

Batch counter

solvent rolle

Grand total counter for

solvent rolled over.

System does not detect

the Color Change

Module #.

System does not detect

the Advanced Display

Module.

System does not

detect the Enhanced

Fluid Control Module

(EFCM).

for

dover.

Cause Solution

The totalizer has

reached maximum

capable value and

started over at zero.

The totalize

reached maxi

capable valu

started over

This communication

error indicates that

the network has lost

communication with

the Color Change

Module #.

This comm

error ind

the Netwo

communic

the Adva

Module.

This communication

error indicates that

the Network has lost

communication with

the EFCM.

r has

mum

eand

at zero.

unication

icates that

rk has lost

ation with

nced Display

n/a

n/a

Check CAN cable

connections to

the Color Change

Module # and any

interconnected

modules.

Check CAN cable

connecting ADM to the

EFCM.

Check CAN cables

connecting ADM to

the EFCM. Replace

Cable or EFCM as

necessary.

CDC#

Alarm Duplic

Color

Chang

ate

e#

System detects two or

more identical Color

Change Modules.

More than one Color

Change Module with

the same address

is connected in the

system .

Check the system

and remove the extra

color change module.

Re-address one of the

color change boards.

2

1

332709B

Page 13

Troubleshootin

g

Code

CDDX

DA0#

DE0#

Type Description Problem

Alarm Duplicate

Fluid

Module

Alarm Exceeded

Max Flow

Pump #

Alarm Leak

Detecte

Pump #

System sees tw

or more identi

Enhanced Flui

Control Modul

EFCM).

Pump was driven to

its maximum allowed

speed.

This is a

d

test fai

pump can

pressur

Test Pressure.”

“Stall

ult after 30

Will fa

second

o

cal

d

es

manual stall

lure when the

not build

etothetarget

s.

Cause Solution

tating,

thout

FCM

nthe

Check the syst

and remove the

EFCM.

Inspect system for

leaks.

Verify that the pump

is being supplied with

material.

Reduce nozzle size

to create more

restriction. Reduce

paint pressure to lower

the flow rate.

Make sur

and down

line are

al.

materi

Determine if leak is

external or internal

by visually inspecting

the system for fluid

leakage. Fix all loose

or worn hoses, fittings,

and seals. Inspect

all valve seats and

needles for wear, and

replace worn piston or

throat seals.

More than one E

is connected i

system.

System has a leak

or open valve that is

allowing unrestricted

flow.

Pump is cavi

cycling wi

restricti

Viscosit

too thin f

No mater

pump or l

Leak in the system.

on.

y of material is

or nozzle size.

ial in the

ine.

em

extra

e the pump

stream color

loaded with

DF0#

Alar

m

No Stall Up

Pump #

Pump failed the stall

test; did not stall on the

upstroke.

Valve failure, seal

failure, worn rod or

cylinder.

ace inlet and

Repl

let valve and

out

l for up stroke.

sea

lace piston and

Rep

oat seals. Replace

thr

and cylinder as

rod

cessary.

ne

332709B 13

Page 14

Troubleshootin

g

Code

DG0#

DH0#

DK0#

EAUX Advi-

Type Description Problem

Alarm

Alarm

Alarm Position

sory

No Stall

Down

Pump #

No Stall

Pump #

Pump #

USB Busy USB driv

Pump failed th

test;didnots

downstroke.

Pump failed the stall

test; did not stall on

either the upstroke or

the downstroke.

The pump was

detected to be out

of position.

d, download is

inserte

in progr

estall

tall on the

e has been

ess.

Cause Solution

Valve failure

failure, worn

cylinder.

Valve failure, seal

failure, worn rod or

cylinder.

Indicat

is uploa

downloa

,seal

rod or

es USB port

ding or

ding data.

Replace inlet and

outlet valve and seal

for down stroke.

Replace piston and

throat seals. Replace

rod and cylinder as

necessary.

Replace inle

outlet valv

for up and do

strokes. Re

piston and t

seals. Rep

rod and cyl

necessary

Re-enable pump

power to reset pump.

Make sure inlet supply

pressure is not too

high.

Wait for

t and

e and seal

wn

place

hroat

lace

inder as

.

USB Idle.

EB00 Record

EBH#

EBUX Record

EC00

Recor

ord

Rec

d

Stop

Button

Pressed

Home

ete

Compl

Pump #

USB

drive was

removed.

Setup

Value(s)

Changed

Recordofastopbutton

press.

Record of pump

homing is complete.

USB drive was

removed while

downloading or

uploading.

Record of changing

setup variables.

Indicates system stop

key on ADM was

pressed.

ication on the

An ind

ay that the pump

displ

eted the home

compl

ion

funct

Downloading/uploading data on USB was

interrupted by the USB

device being removed.

icates date and time

Ind

n setup values

whe

e changed.

wer

n/a

ion required.

No act

Replace the USB

device and begin

process again.

n/a

4

1

332709B

Page 15

Troubleshootin

g

Code

EF0#

EF1#

Type Description Problem

Alarm Timeout

Startup

Pump #

Alarm Timeout

Shutdown

Pump #

Pump tried but was not

able to move to the

home position within

a specified amount of

time.

Pump tried but was not

able to move to the

park position within a

specified amount of

time.

Cause Solution

Pump dose valves did

not actuate.

Motor could not drive

pumps and linear

actuator.

Pump stroke length

is shortened by

mechanical system

tolerance.

Pump dose valves did

not actuate.

Pump is fi

thick pa

not driv

end of s

or driv

damage

lled with

int and could

epistonto

troke. Motor

eiswornor

d.

Verify air pre

to solenoid va

Verify the val

actuating.

Verify motor is driving

the pump.

Verify corr

assembly of

actuator an

piston rod

manual.

Visually inspect valves

to ensure they are

operating properly;

verify they have air

pressure above 85 psi

(0.6 MPa, 6.0 bar).

Observe

drive as

verify t

genera

ssure

lves.

ves are

ect

linear

d pump

s. See pump

motor and

sembly to

hat the motor is

ting force.

EL00 Record

EM00 Record

EMIX Advi

0

EQU

EQU1

-

sory

Advisory

Record

System

Power On

em

Syst

rOff

Powe

Pump Off

Idle

USB

USB Sys.

Settings

Downloaded

Record of power cycle

(ON).

rd of power cycle

Reco

).

(OFF

umps are not

The p

red and are

powe

le to move.

unab

download

USB

ocess completed,

pr

ive may be removed.

dr

Settings were

downloaded to USB

drive.

Indicates date and

time when system was

started.

Indicates date and

time when system was

turned off.

power was

Pump

ed off or an error

turn

rred.

occu

atransferis

Dat

mpletedtotheUSB

co

vice.

de

User installed USB

device in ADM USB

port.

n/a

n/a

Start pumps by

pressing pump start

key on Advanced

Display module.

ove USB device

Rem

om ADM.

fr

n/a

332709B 15

Page 16

Troubleshootin

g

Code

EQU2

EQU3

EQU4

EQU5

ES00

EVUX Advi-

F1F#

Type Description Problem

Record

Record

Record

Record

Advisory

sory

Alarm Flow Low

USB Sys.

Settings

Uploaded

USB Custom Lang.

Downloaded

USB

Custom

Lang.

Uploaded

USB Logs

Downloaded

Factory

Defaults

USB

Disabled

Fill Pump #

Settings were

uploaded from

drive.

Custom Language was

downloaded to USB

drive.

Custom Language was

uploaded from USB

drive.

Data logs were

downloaded to USB

drive.

Record of defaults

being loaded.

USB drive has been

inserted, downloading

is disabled.

There has been no/low

flow during a fill pump

operation.

USB

Cause Solution

User installe

device in ADM U

port.

User installed USB

device in ADM USB

port.

User installed USB

device in ADM USB

port.

User inst

device in

port.

Configuration of

system is blocking

data transfer.

There is a restriction

on the outlet side of the

pump or color stack.

dUSB

SB

alled USB

ADM USB

n/a

n/a

n/a

n/a

n/a

Change configuration

to enable USB

download function.

Make sure there are

no restrictions in the

color stack and that

thedumpvalveis

actuating.

F1S#

F#

F6

Alarm Flow Low

Purge

Pump #

Alarm Press.

Sens.

Removed

Inlet #

There has been no flow

or low flow during a

pump purge operation.

No inlet pressure

transducer is detected

when the system is

expecting one.

k viscosity

Thic

t requires more

pain

sure to pump.

pres

Restriction in the outlet

side of the pump or

color stack resulting in

the solvent flow being

too low.

Disconnected

transducer.

ease non-mix

Incr

sure if necessary

pres

eate flow during

to cr

ll function.

the fi

Make sure there are

no restrictions in the

system. Increase

non-mix pressure if

necessary to create

flow during the purge

function.

rify transducer

Ve

connected

is

roperly. Replace if

p

econnecting does not

r

liminate the alarm.

e

16 332709B

Page 17

Troubleshootin

g

Code

F7D#

F7S1

F7S2

F8D1 Alarm Flow Not

Type Description Problem

Alarm Flow

Detected

Pump #

Alarm Flow

Detected

Solvent

Gun

Alarm Flow

Detected

Solvent Mix

Detected

Thepumpflow

exceeded 20 cc

flow coming int

mode.

One of the solvent flow

switches is indicating

unexpected solvent

flow.

The system detects

both solvent flow

switches open at the

same time.

No Flow while mixing.

/min

oIdle

Cause Solution

There is a leak in the

system or the gun was

open when the system

went into Idle mode.

Solvent flow switch is

stuck in flow position.

There is a le

the solven

valve.

The EFCM is

damaged.

One or bo

solvent

are stuc

positio

Restriction in the outlet

side of the pump or

color stack.

ak through

t cutoff

th of the

flow switches

kintheflow

n.

Verify there a

leaks in the sy

Make sure the a

switch is actu

properly. Do

trigger the g

atomizing ai

Clean or replace

switch.

Check for leaks and

repair valve.

Unplug both

connectors on the

EFCM.Ifalarmclears,

replace the EFCM.

Clean or

switch.

Make sure there are

no restrictions in the

system.

re no

stem.

ir flow

ating

not

un without

r.

replace

F9D#

MMUX Advi

F#

P1

P2F#

P3D#

Alarm Flow

sory

Alarm Pressure

De

on

ti

Deviation

-

via-

Unstable

Pump #

Maint. USB

Logs Full

Low Inlet

Pump #

essure

Pr

wInlet

Lo

ump #

P

Pressure

High Outlet

Pump #

Thepumpflowrate

did not stabilize while

entering Idle mode.

USBmemoryismore

than 90% full.

The inlet pressure on

pump # is less than

the user-entered alarm

limit.

e inlet pressure on

Th

mp # is less than the

pu

ser-entered deviation

u

imit.

l

The outlet pressure

on pump # is greater

than the user entered

deviation limit.

tflowrateisset

Targe

o.

to zer

Potential leak in the

system.

Configuration

parameter on system

is enabled to generate

this advisory.

arget flow rate.

Set a t

Check the system for

leaks and run manual

stall test.

Complete download to

ensure no data is lost.

Increase inlet

pressure.

crease inlet

In

essure.

pr

Relieve system

pressure.

332709B

17

Page 18

Troubleshootin

g

Code

P3F#

P4D#

P4F#

P6D#

P9D#

Type Description Problem

Deviation

Alarm Pressure

Alarm Pressure

Alarm Press.

Alarm Press.

Pressure

High Inlet

Pump #

High Outlet

Pump #

High Inlet

Pump #

Sens.

Removed

Outlet #

Sens.

Failed

Outlet #

The inlet pressure

on pump # is greater

than the user-entered

deviation limit.

The outlet pr

pump # is grea

the user ente

limit.

The inlet pressure on

pump # is greater than

the user-entered alarm

limit.

No outlet pressure

transducer is detected

when the system is

expecting one

Outlet pressure

transducer has failed.

essure on

ter than

red alarm

Cause Solution

Decrease inlet

pressure.

Relieve syst

pressure.

Decrease inlet

pressure.

Disconnected

transducer.

Outlet pressure

transducer has failed

orthepressureis

above the readable

range.

Verify tra

is connect

properly

reconnec

eliminat

Relieve system

pressure. Verify

connections, or

replace if reconnecting

does not eliminate the

alarm.

em

nsducer

ed

. Replace if

ting does not

e the alarm.

P9F#

QADX

QBDX

Alarm Press.

Sens.

Failed Inlet

#

Alarm

Alarm

Differential

Pressure A

Over B

Differential

Pressure B

Over A

Inlet pressure

transducer has failed.

Low differential

pressure. This alarm is

active only during Mix

mode.

High differential

pressure. This alarm is

active only during Mix

mode.

Inlet pressure

transducer has failed

orthepressureis

above the readable

range.

isaleakonthe

There

.

Bside

The B side pump is

cavitating.

There is a leak on the

Aside.

he A side pump is

T

avitating.

c

Relieve system

pressure. Verify

connections, or

replace if reconnecting

does not eliminate the

alarm.

Check the system

for internal and

external leaks on

all catalyst manifolds

and plumbing.

ck paint supply on

Che

B side, increase

the

nt supply pressure.

pai

Check the system

for internal and

external leaks on

all color manifolds and

plumbing.

Check paint supply on

the A side, increase

paint supply pressure.

18 332709B

Page 19

Troubleshootin

g

Code

QPD1

SND1

SPD1

Type Description Problem

Deviation

Alarm Mix Fill

Alarm

Potlife

Expired

Incomplete

Gun Pur

Incomp

ge

lete

Potlife time h

expired befor

system has mov

the required a

of material (

volume) thro

mixed materi

The system timed out

before the mix fill cycle

loaded the gun with

mixed material.

The system timed out

without reaching the

user-specified volume

of solvent for a purge.

as

ethe

ed

mount

potlife

ugh the

al line.

Cause Solution

Purge process was not

completed.

Solvent supply shut off

or empty.

Mix manifold not set to

spray position.

Spray gun was not

triggered.

Restrictions in mixer,

manifold, or spray gun.

Target flow rate is set

to zero.

Solven

workin

Solvent flow is too low

to actuate the solvent

switch.

t flow switch not

g.

Make sure purge

process is completed.

Verify solvent supply

is available and on,

supply valves are

open.

Set manifold to spray.

Allow flow through gun

during fill process until

the fill complete LED

stops flashing.

Fix restrictions.

Set a target flow rate.

Replace switch.

Increase solvent

pressure to drive a

high purge flow rate

i-

WSUX

WX00 Alarm

XUD

W

WXUU Advi-

Adv

sor

dvi-

A

ory

s

sory

y

USB

Config. Err.

ftware

So

rrors

E

USB

Download

Err.

USB

Upload Err.

USB configuration

file does not match

expected, checked on

startup.

An unexpected

software error has

occurred.

n error occurred

A

hile downloading to

w

he USB drive.

t

An error occurred

while uploading from

the USB drive.

Gun is not triggered. Operator must

continue flushing

for configured time,

until the booth control

indicates purge is

completed.

Valve stuck or broken. Replace valve.

A software update

was not completed

successfully.

ser installed

U

ncompatible USB

i

evice in ADM USB

d

ort.

p

User installed

incompatible USB

device in ADM USB

port.

Reinstall software.

ll Graco Technical

Ca

upport.

S

epeat process with

R

ompatible USB

c

evice.

d

Repeat process with

compatible USB

device.

332709B 19

Page 20

Troubleshootin

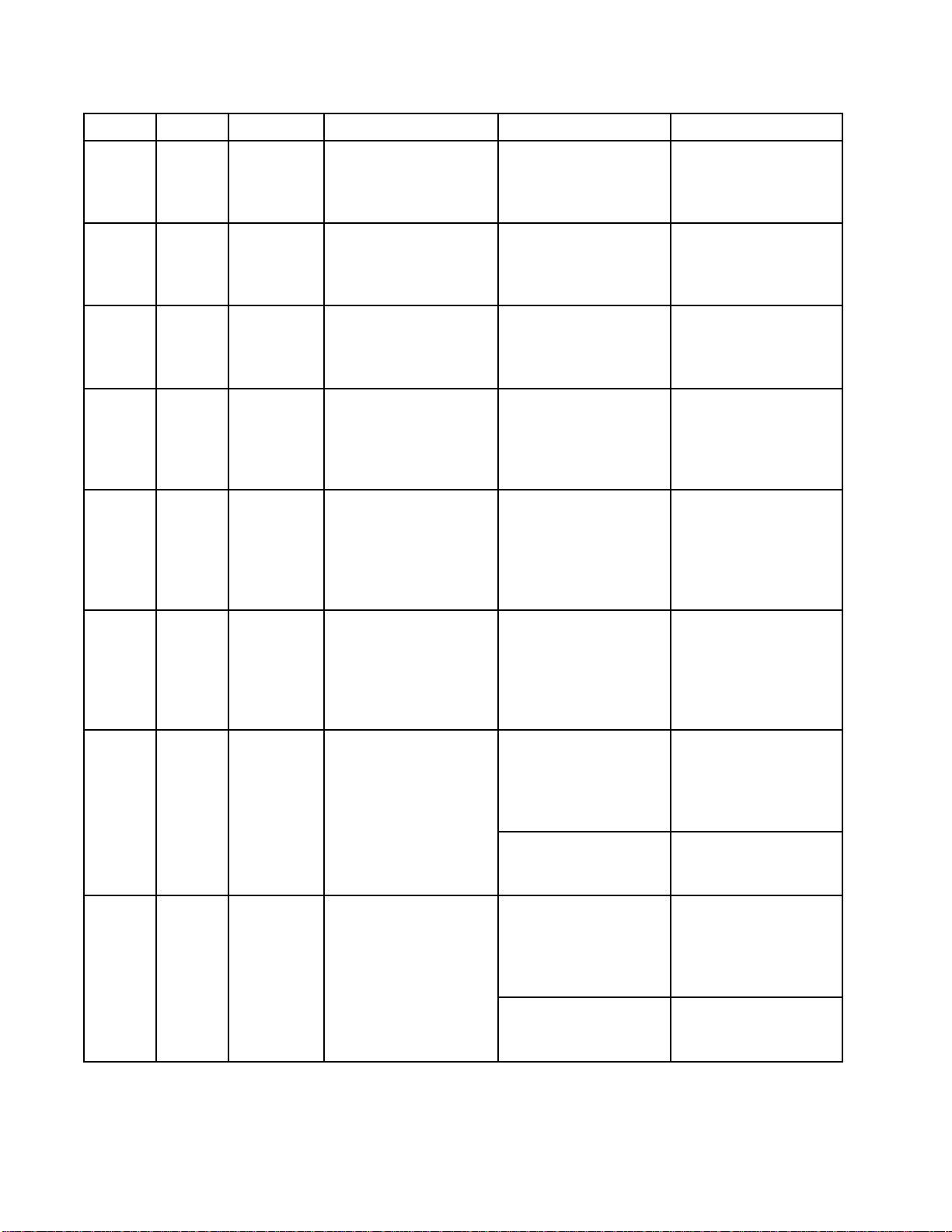

Maintenance Error Codes

g

Perform the re

Code

END#

ENS0

ENT#

MAD#

MAT#

MEB#

MED#

MEF#

MEG#

MES#

MFF#

MFS0

quired maintenance if the following codes occur.

Type Name Description

Record

Record

Record

Advisory

Advisory

Advisory

Advisory

Advisory

ry

Adviso

Advisory

Advisory

sory

Advi

Calibration P

Calibration Solvent

Meter

Calibration Stall Test

Pump #

Maint. Out

Maint. Stall Test

Pump #

Maint. Valve Catalyst

(B) #

Maint. V

Maint. Valve Inlet #

Maint. Valve Gun #

.ValveSolvent

Maint

#

Maint. Meter Flow # Maintenance is due on flow meter.

Maint. Meter Solvent

ump #

let Pump #

alve Outlet #

A calibration test was run on the pump.

A calibration test was run on the solvent meter.

A stall test was completed successfully on pump #.

Maintenance is due on pump.

Maintenance stall test is due on pump.

Maintena

Maintenance is due on outlet valve.

Maintenance is due on inlet valve.

Mainte

Maintenance is due on solvent valve.

tenance stall test is due on solvent meter.

Main

nce is due on catalyst valve.

nance is due on gun valve.

MGH

MGP0

0

Advisory Maint. Filter Fluid

Advisory Maint. Filter Air

ntenance is due on fluid filter.

Mai

Maintenance is due on air filter.

20 332709B

Page 21

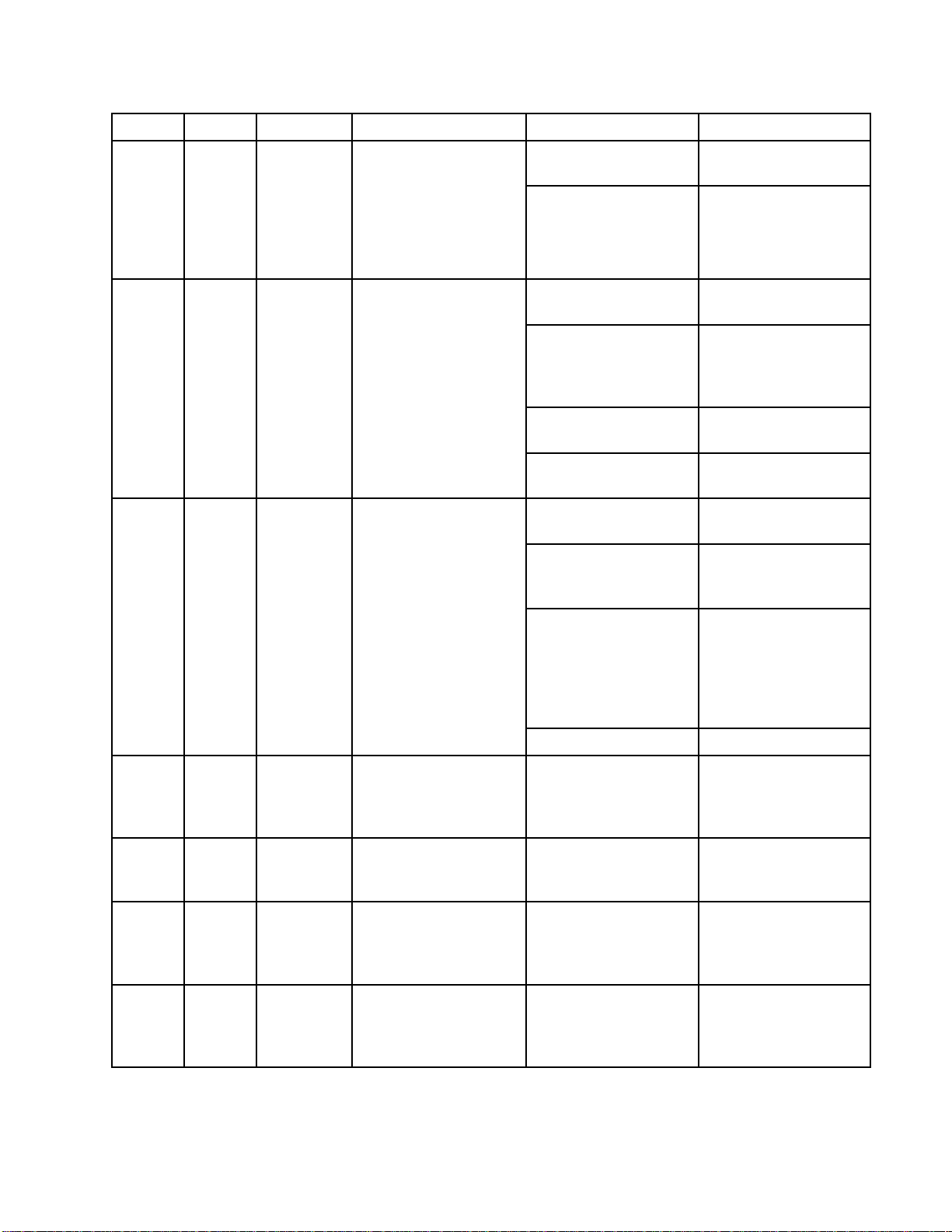

Power Barrier Board Diagnostics

Troubleshootin

g

Figure 7 Power Barrier Board

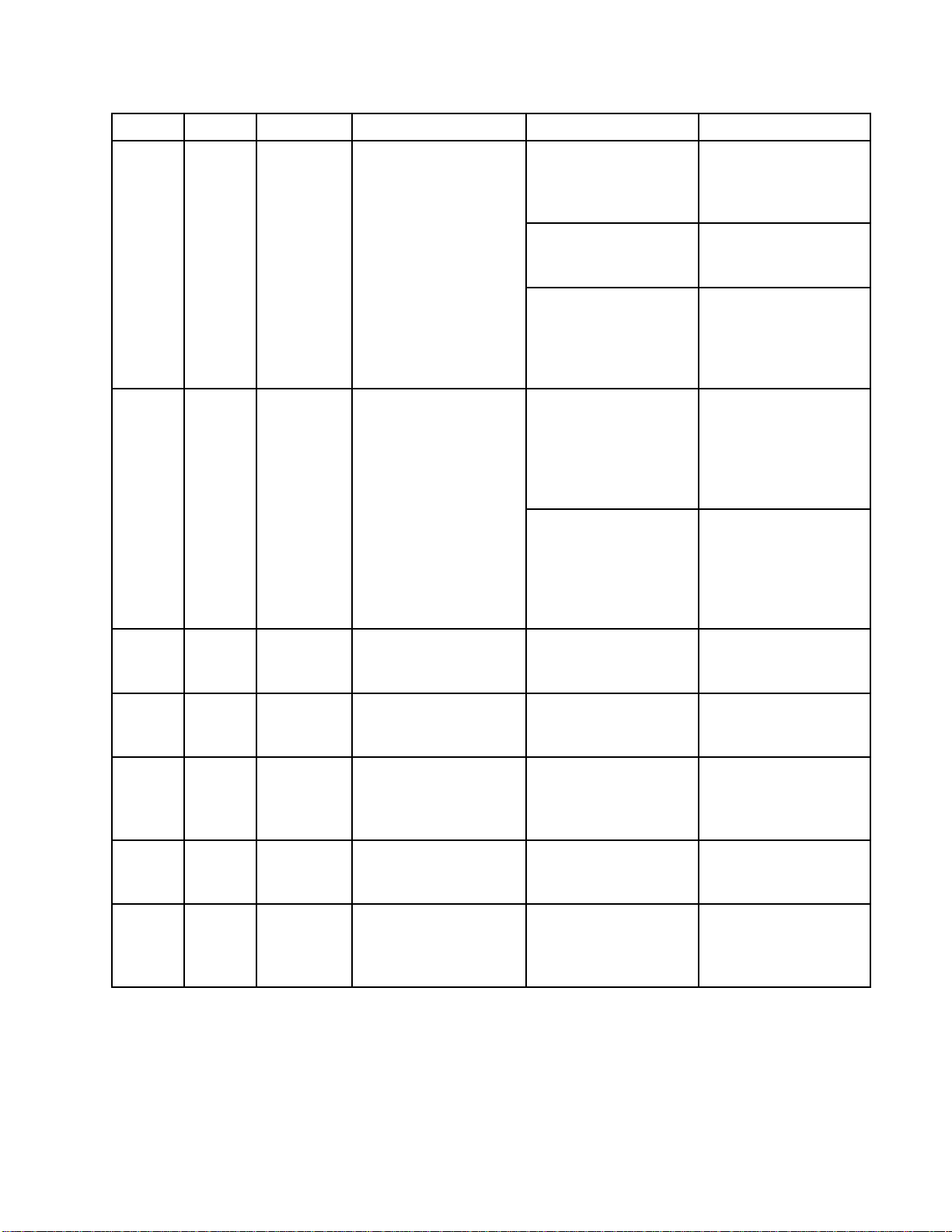

Table 1 . Power Barrier Board Diagnostics

ID

D4

D5

F3 Fuse, 400 mA, 250 V

F4 Fuse, 400 mA, 250 V

J4

J5

Component or Indicator

LED (green) IS Power

LED (green)

Connector

Connector +12 Vdc intrinsically safe power output

332709B

Function

Power

If either F3 or F4 is blown, there is no power

to the IS location. D4 is out.

24 Vdc power input

21

Page 22

Troubleshootin

g

Isolation Board Diagnostics

Figure 8 Isolation Board

Table 2 . Isolation Board Diagnostics

ID

D6

D7

D8

D14

J1

J2

J3

4

J

S1 Pushbutton Switch For Non IS connectors. If switch S1 is off, yellow LED (D14) is

S2 Pushbutton Switch For Intrinsically Safe connectors. If switch S2 is off, yellow LED

Compo

LED (yellow) IS Communication

LED (green) IS Power

LED

LED (yellow) Non-IS Communication

Connector Non-IS, Gateway

Co

Connector Intrinsically Safe, Barrier Board

Connector Intrinsically Safe, Optional Color Change Module

nent or Indicator

(green)

nnector

Function

-IS Power

Non

n-IS, Optional Color Change Module

No

steady on. Push switch to turn switch on.

(D6) is steady on. Push switch to turn switch on.

2

2

332709B

Page 23

Troubleshootin

g

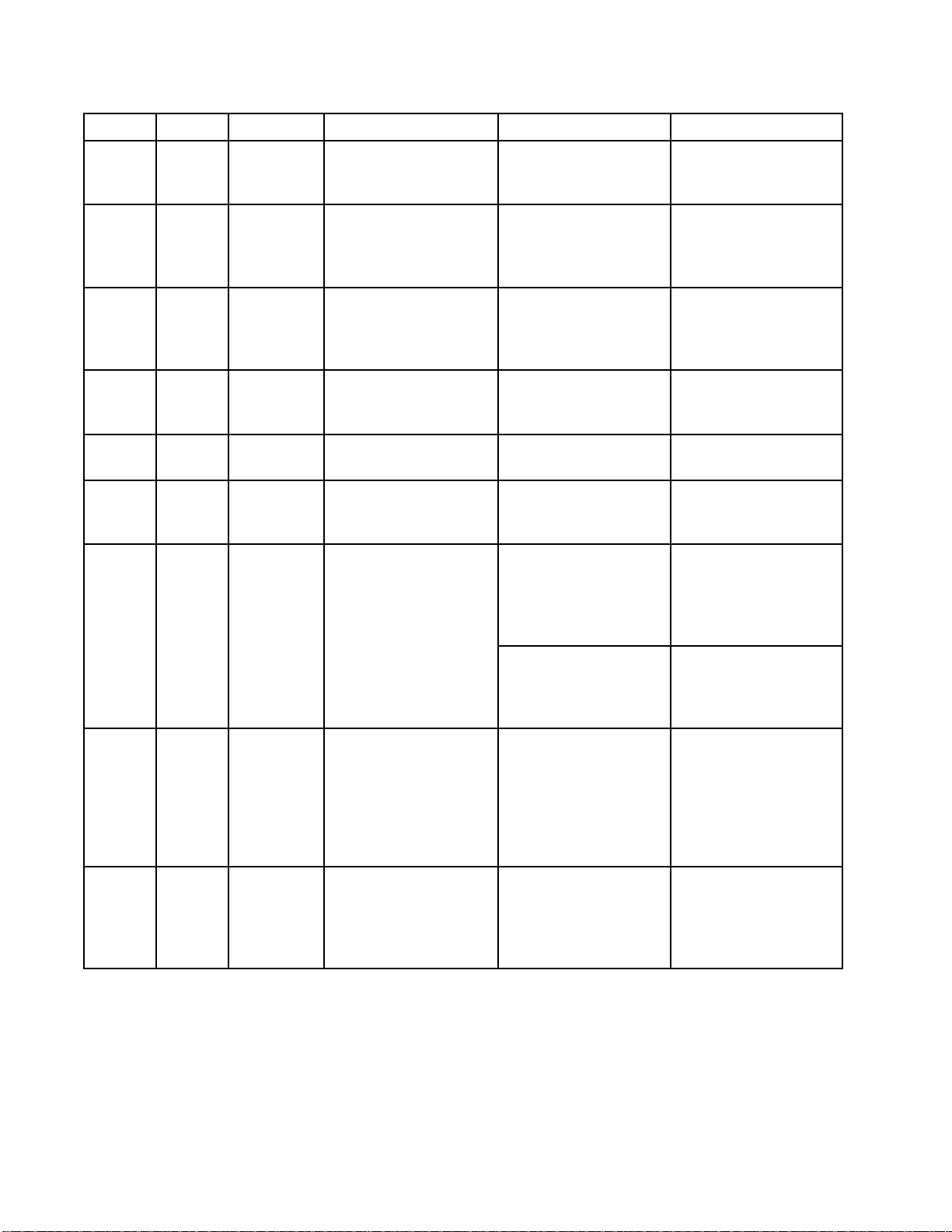

Enhanced Flui

Figure 9 Enhanced Fluid Control Module

Table 3 . Enhanced Fluid Control Module Diagnostics

d Control Module (EFCM) Diagnostics

ID

1 25 pin connector Pump 1 Module

2 25 pin connector Pump 2 Module

3 25 pin connector

4 25 pin connector

5

6 12 pin connector

7

8 5 pin connector

9 5 pin connector Advanced Display Module

10 5 pin connector 24 Vdc Input

CPLD (D37) LED (orange)

POW (D19) LED (green)

CAN (D69) LED (yellow) Communication.

ERR (D38) LED (red) Blinks an error code. If the LED is on steady,

Component or Indicator

12 pin connector

12 pin connector

Function

Pump 3 Module (accessory)

Pump 4 Module (accessory)

Multiple purpose I/O

Multiple purpose I/O

Multiple purpose I/O

24 Vdc Power/CAN (Communication Barrier)

Heartbeat

Power

the system is down. Cycle power.

332709B 23

Page 24

Troubleshootin

g

Pump Module Diagnostics

Figure 10 Pump Module

Table 4 . Pump Module Diagnostics

ID

1 25 pin connector

2 5 pin connector Pump connection

3 5 pin connector Motor encoder connection

4 5 pin connector Pump Inlet Transducer

5

6 4 pin connector Not used

7 8 pin connector

8 4 pin connector

9

10

11

24V

48V

Component or Indicator

5 pin connector

LED (red) Pump Up Valve Output

LED (red) Pump Down Valve Output

LED (red)

LED (green)

LED (green)

Function

Input from EFCM

Pump Outlet Transducer

Dose Valve Solenoids

48 Vdc Input Power and fan connection

Not used

24 Vdc power supplied

48 Vdc power supplied

4

2

332709B

Page 25

Advanced Display Module Diagnostics

Troubleshootin

g

Figure 11 Advanced Display Module

Table 5 . Advanced Display Module Diagnostics

ID

D1

D6

J1 8 pin connector Token port

J2 8 pin

J3 5 pin connector

J7 5 pin connector

Compone

LED (yellow/green) Green: USB inserted

LED (red/yellow/green) Green: Power

nt or Indicator

connector

Function

Yellow

Yello

Red: Error

USB port

Lig

CAN power/communication port

: USB communication

w: Communication

ht tower (accessory)

332709B 25

Page 26

Notes

Notes

26 332709B

Page 27

Electrical Sche

matics

Electrical Sc

hematics

NOTE: The electrical schematic illustrates all possible

wiring expansions in a ProMix PD2K system. Some

components shown are not included with all systems.

NOTE: See Optional Cables and Modules, page 33 for

a list of cable options.

RELAY

(16U820)

16W159

BREAKOUT MODULE PUMP 2

BREAKOUT MODULE PUMP 4

POWER MODULE

(24R257)

16W159

16W159

(24N527)

(24N527)

SPLITTER

(16P243)

4

CABLE (16T659)

CABLE (16T659)

CABLE (16T659)

CABLE (16T659)

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

POWER IN

FAN

FAN

2 POSITION

SWITCH

(16U725)

CABLE

16T658

LINE FILTER

(16V446)

CABLE

16H078

TERMINAL BLOCK

(114095)

(24N527)

BREAKOUT MODULE PUMP 1

(24N527)

BREAKOUT MODULE PUMP 3

24V

POWER

SUPPLY

(16T660)

48V-10A POWER SUPPLY

TERMINAL BLOCKS WITH FUSES

16W159

FAN

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

FAN

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

Figure 12 Electrical Schematic, Sheet 1

INTEGRATION

GATEWAY

3

AWI

GATEWAY

(24R910)

CABLE (15V206)

2

CABLE

3

16T072

CAN

IS BOARD

(24M485)

CABLE

(16T280)

BARRIER

BOARD

(248192)

065161, 065159

5

CABLE

(121227)

5

(121227)

CABLE

3

(121001)

6

(24N935)

MODULE 1

COLOR CHANGE

CABLE

2

(15V206)

GCA

MODULE

EFCM

(24N913)

FLOW RATE ANALOG IN

FLOW RATE ANALOG IN

1

CABLE (16V429)

2

CABLE

(15V206)

6

(24N935)

MODULE 2

COLOR CHANGE

FLOW RATE ANALOG IN

FLOW RATE ANALOG IN

2

CABLE

(15V206)

6

6

6

(24N935)

(24N935)

MODULE 3

COLOR CHANGE

COLOR CHANGE

CABLE

2

(15V206)

GUN TRIGGER INPUTS

119159

119159

119159

119159

SOLENOID (121324)

PRESSURE SW (121323)

SOLVENT CUTOFF (121324)

SWITCH (120278)

SWITCH (120278)

SOLVENT METER (258718)

SAFETY INTERLOCK SWITCH

3

ADVANCED

CABLE

DISPLAY MODULE

(121003)

CABLE

1

(24N935)

MODULE 4

MODULE 5

CATALYST CHANGE

CABLE

2

(15V206)

(24E451)

COLOR CHANGE MODULE 7

(24R219)

COLOR CHANGE MODULE 8

(24R219)

(16V426)

BOOTH CONTROL (24M731)

HAZARDOUS LOCATION

NON-HAZARDOUS LOCATION

INTERFACES

SOLVENT

6

MODULE 6

CATALYST CHANGE

GFB

FLOW

INPUTS

LIGHT

TOWER

(15X472)

7

7

(24N935)

CABLE

1

(16V426)

332709B

27

Page 28

Electrical Sche

matics

SPLITTER

(16P243)

UNUSED

UNUSED

POWER

SUPPLY

(16T660)

L (BROWN)

N03 N03

2 POSITION

SWITCH

(16U725)

N04 N04

CABLE

(16T658)

L N

LINE

FILTER

(16V446)

L GRND N

CABLE

(16H078)

L N GRND

TERMINAL

BLOCK

(114095)

L N GRND

345

24V

2

1

UNUSED

GRND (GRN/YEL)

N (BLUE)

CABLE (16V429)

1

CONTINUED ON PAGE 3

2

3

CABLE

(15V206)

1 2 3 4 5

CAN IS BOARD

2

(NON IS)

(IS)

4

(24M485)

1 2 3 4 5

UNUSED

1 2 3 4 5

CABLE

(16T280)

1 2 3

1

2

3

BARRIER

BOARD

(248192)

13 A1(+) A2(-)

RELAY

14

N L GRND

48V-10A

POWER SUPPLY

(16U820)

+ -

+ - + - + - + -

F4

F3

F2

F1

+ - + - + - + -

DETAIL A, LOW PRESSURE

PUMPS (24M706, 24M714)

BREAKOUT MODULE

(24N527)

2

1 2 3 4 5 1 2 3 4

WIRE HARNESS

(24P684)

CABLE (121227)

16T072

1 2 3 4 5

1

3

UNUSED

UNUSED

RED WIRE (065161)

BLACK WIRE (065159)

1 2 3 4 5 1 2 3 4

(24R257)

POWER MODULE

3

DRAIN/FOIL

CABLE

1

2

3

4

5

P3

GATEWAY

(24R910)

1

2

3

P4

4

5

AWI

(121227)

3

1

2

3

P3

4

5

INTEGRATION

5

GFB INTERFACE

(121324)

SOLVENT CUTOFF (121324)

SOLVENT

METER

(258718)

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GROUND BAR

BREAKOUT MODULE PUMP 1 (24N527)

2

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 1

SEE DETAIL A OR B

3

1 2 3 4 5 1 2 3 4 5 1 2

TWISTED PAIR CABLE (16W159)

5

4

PUMP 1

PUMP 1

(16P289 OR 16P290)

INLET TRANSDUCER

(16P289 OR 16P290)

OUTLET TRANSDUCER

DETAIL B, HIGH PRESSURE

PUMPS (24M707, 24M715)

BREAKOUT MODULE

2

1 2 3 4 5 1 2 3 4

GATEWAY

5

6

1 2 3 4

(24N527)

WIRE HARNESS

(24P685)

1

2

3

P4

4

5

+12VDC

COM

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

UNUSED

PUMP 1

+24VDC

V/P FOR FLUID REG.

PUMP 1

MANIFOLD

UNUSED

UNUSED

UNUSED

CABLE

(121001)

3

1

7

3 4

5 6 7 8

COM

COM

+24VDC

UP

DOWN

PUMP 1

G3000

METER

PUMP 1

(EITHER, 239716,

258718,16M510,

OR 16M519)

(16P812 QTY 2)

MAC SERIES 46

3

5

4

3

10

2

1

1

2

3

8

4

5

1

2

3

4

5

6

5

7

8

9

10

11

12

25 PIN D-SUB CABLE

(16T659)

1 2 3 4

+48V

COM

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GRND

SCREW

DRAIN/FOIL

CONTINUED ON PAGE 3

GCA MODULE

EFCM

(24N913)

12

4

252423222120191817161413121110 15987654321

BREAKOUT MODULE PUMP 2 (24N527)

2

1 2 3 4 5 1 2 3 4

+48V

COM

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 2

SEE DETAIL A OR B

(24P658)

FAN PUMP 1

252423222120191817161413121110 15987654321 252423222120191817161413121110 15987654321

3

1 2 3 4 5 1 2 3 4 5 1 2

4

PUMP 2

(16P289 OR 16P290)

INLET TRANSDUCER

5

PUMP 2

OUTLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

6

1 2 3 4

PUMP 2

(16P289 OR 16P290)

V/P FOR FLUID REG.

25 PIN

(16T659)

D-SUB CABLE

4

1

3 4

COM

COM

+24VDC

+24VDC

UP

DOWN

PUMP 2

PUMP 2

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

7

5 6 7 8

METER

PUMP 2

(EITHER, 239716,

258718,16M510,

PWR (RED)

SIG (WHITE)

COM (BLACK)

G3000

OR 16M519)

SHIELD/GRN

GRND

SCREW

1 2 3 4

+48V

88

COM

+48V

FAN PUMP 2

252423222120191817161413121110 15987654321

COM

(24P658)

DRAIN/FOIL

UNUSED UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED UNUSED

UNUSED

UNUSED UNUSED

POWER IN

UNUSED

UNUSED

DRAIN/FOIL

1 2 3 4 5 6 7 8 9

PUMP ENCODER AND MOTOR

MOTOR

MOUNTING

SCREW

UNUSED

UNUSED UNUSED

UNUSED

12

11

10

(16P037)

UNUSED

UNUSED

1 2 3 4 5 6 7 8 9

UNUSED

UNUSED UNUSED UNUSED

UNUSED

12

11

1 2

MOTOR

MOUNTING

SCREW

1 2 3 4 5 6 7 8 9

PUMP ENCODER AND MOTOR

10

10

(16P036)

1 2 3 4 5 6 7 8 9

UNUSED

10

Figure 13 Electrical Schematic, Sheet 2, Part 1

CONTINUED ON THE NEXT PAGE

28 332709B

Page 29

GUN TRIGGER INPUTS

SIG

1

COM

2

SIG

3

COM

4

SIG

5

COM

6

6

7

SIG

8

COM

9

SIG

10

COM

11

SIG

12

1

2

3

4

5

6

7

7

8

9

10

11

12

1

2

3

9

4

5

COM

FLOW RATE ANALOG IN 1

FLOW RATE ANALOG COMMON 1

FLOW RATE ANALOG IN 2

FLOW RATE ANALOG COMMON 2

FLOW RATE ANALOG IN 3

FLOW RATE ANALOG COMMON 3

FLOW RATE ANALOG IN 4

FLOW RATE ANALOG COMMON 4

SIG

COM

SIG

COM

CABLE

(121003)

3

GCA MODULE

EFCM

(24N913)

34

252423222120191817161413121110 15987654321 252423222120191817161413121110 15987654321

119159

GFB PRESSURE SWITCH (121323)

SOLVENT FLOW SWITCH 1 (120278)

SOLVENT FLOW SWITCH 2 (120278)

SAFETY INTERLOCK SWITCH

1

ADVANCED

2

DISPLAY MODULE

3

4

(24E451)

5

Electrical Sche

1

2

3

4

5

LIGHT

TOWER

(15X472)

matics

25 PIN

(16T659)

D-SUB CABLE

4

5

PUMP 3

(16P289 OR 16P290)

OUTLET TRANSDUCER

252423222120191817161413121110 15987654321

6

1 2 3 4

PUMP 3

V/P FOR FLUID REG.

3 4

COM

+24VDC

+24VDC

UP

PUMP 3

PUMP 3

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

7

COM

DOWN

5 6 7 8

PWR (RED)

G3000

METER

PUMP 3

(EITHER, 239716,

258718,16M510,

OR 16M519)

1

BREAKOUT MODULE PUMP 3 (24N527)

3

2

1 2 3 4 5 1 2 3 4 1 2 3 4 5 1 2 3 4

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 3

SEE DETAIL A OR B

4

1 2 3 4 5 1 2 3 4 5 1 2

PUMP 3

(16P289 OR 16P290)

INLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

Figure 14 Electrical Schematic, Sheet 2, Part 2

CONTI

NUED ON THE NEXT PAGE

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GRND

SCREW

25 PIN D-SUB CABLE

(16T659)

8

1 2 3 4

+48V

+48V

COM

COM

(24P658)

FAN PUMP 3

4

2

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 4

SEE DETAIL A OR B

5

PUMP 4

(16P289 OR 16P290)

OUTLET TRANSDUCER

252423222120191817161413121110 15987654321

6

1 2 3 4

V/P FOR FLUID REG.

PUMP 4

3 4

COM

+24VDC

+24VDC

UP

PUMP 4

PUMP 4

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

7

COM

DOWN

1

BREAKOUT MODULE PUMP 4 (24N527)

3

4

1 2 3 4 5 1 2 3 4 5 1 2 1 2 3 4

PUMP 4

(16P289 OR 16P290)

INLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

5 6 7 8

PWR (RED)

SIG (WHITE)

G3000

METER

PUMP 4

(EITHER, 239716,

258718,16M510,

OR 16M519)

+48V

COM (BLACK)

SHIELD/GRN

GRND

SCREW

8

COM

FAN PUMP 4

+48V

COM

(24P658)

332709B 29

Page 30

Electrical Sche

matics

FLUSH

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

*FLUSH

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 13

COLOR 14

COLOR 15

COLOR 16

CABLE (15V206)

2

MANIFOLD

MANIFOLD

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

2

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

FROM CAN IS BOARD (24M485) ON PAGE 2

2

345

1

COLOR

CHANGE

MODULE 1

(COLORS

6

1 THRU 8)

J8

J15

J14

1

2

6

J16

J10

345

COM

5

+12VDC

4

COM

J9

3

+12VDC

2

COM

1

+12VDC

6

COM

5

+12VDC

4

COM

3

+12VDC

2

COM

1

+12VDC

6

COM

5

+12VDC

4

COM

3

+12VDC

2

COM

1

+12VDC

CABLE

J8

J15

J14

2

345

1

COLOR

CHANGE

MODULE 2

(COLORS

9 THRU 16)

6

2

345

1

J16

J10

J9

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

MANIFOLD

MANIFOLD

DUMP

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

DUMP*

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 13

COLOR 14

COLOR 15

COLOR 16

FLUSH

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

FROM CAN IS BOARD (24M485) ON PAGE 2

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

1

2

3

4

5

6

1

2

3

J15

4

5

6

1

2

3

J14

4

5

6

CATALYST

CHANGE

MODULE 5

(CATALYST

1 THRU 4)

J8

2

1

6

345

J16

J10

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

6

5

4

J9

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

2

*FLUSH

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

+12VDC

+12VDC

+12VDC

COM

+12VDC

COM

+12VDC

COM

COM

COM

COM

CABLE

1

17 THRU 24)

2

3

J8

4

5

6

1

2

3

J15

4

5

6

1

2

3

J14

4

5

6

2

345

1

COLOR

CHANGE

MODULE 3

(COLORS

6

4

5

3

2

J9

J16

J10

1

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

Figure 15 Electrical Schematic, Sheet 3

* May be unused in some configurations.

CONTINUED ON THE NEXT PAGE

MANIFOLD

DUMP*

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

2

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

CABLE (15V206)

*FLUSH

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

22

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CABLE

2

1

COLOR

CHANGE

MODULE 4

(COLORS

25 THRU 32)

J8

J15

J14

2

1

345

6

345

J16

J10

J9

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP*

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

30 332709B

Page 31

FLUSH

CATALYST 3

CATALYST 4

FLUSH

CATALYST 1

CATALYST 2

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

22

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CATALYST

CHANGE

MODULE 6

(CATALYST

3 THRU 4)

J8

J15

J14

2

1

CABLE

5

4

CATALYST

CHANGE

MODULE 5

(CATALYST

1 THRU 2)

J8

J15

J14

2

1

6

345

2

3

6

345

J9

J16

J10

1

J9

J16

J10

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

MANIFOLD

Electrical Sche

DUMP

CATALYST 3

CATALYST 4

DUMP

CATALYST 1

CATALYST 2

matics

Figure 16 Electrical Schematic, Sheet 3, Alternate

Configuration for Catalyst Change Control

INUED ON THE NEXT PAGE

CONT

2

CABLE

2

345

1

COLOR

CHANGE

MODULE 4

(COLORS

25 THRU 32)

(15V206)

332709B 31

Page 32

Electrical Sche

matics

FROM CAN IS BOARD (24M485) ON PAGE 2

COLOR FLUSH

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

COLOR 13

COLOR 14

COLOR 15

COLOR 16

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

+12VDC

+12VDC

+12VDC

COM

+12VDC

COM

+12VDC

COM

COM

COM

COM

1

2

3

4

5

6

1

2

3

J15

4

5

6

1

2

3

4

J14

5

6

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

2

345

1

COLOR

CHANGE

MODULE 7

(COLORS

33 THRU 40)

J8

7

2

345

1

CABLE

2

345

1

COLOR

CHANGE

MODULE 8

(COLORS

41 THRU 48)

J8

7

J15

J14

5

3

4

J16

J10

J16

J10

2

J9

J9

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

(16V426)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

NON-HAZARDOUS LOCATION

HAZARDOUS LOCATION

MANIFOLD

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

MANIFOLD

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

CATALYST FLUSH

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 22

COLOR 23

COLOR 24

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

1

CABLE

5

BOOTH CONTROL

3

4

(24M731)

2

(16V426)

1

Figure 17 Electrical Schematic, Sheet 3, Hazardous

Location

32 332709B

Page 33

Electrical Sche

matics

Optional Cabl

NOTE: The total length of all cable used in the system must not exceed 150 ft (45 m). See the

Electrical Schematics, page 27.

M12 CAN Cables, for Hazardous Locations

NOTE: The total length of cable used in the

hazardous location must not exceed 120 ft (36 m).

Cable Part N

16V423

16V424

16V425

16V426

16V427

16V428

16V429

16V430

M12 CAN Ca

15U531

15U532

15V205

15V206

15V207

15V208

15U533

15V213

CAN Cables, for Non-Hazardous

Part No.

Cable

125306

123422

121000

121227

121001

121002

121003

120952

121201

121004

121228

es and Modules

o.

Location

Locations Only

Length ft (m

2.0 (0.6)

3.0 (1.0)

6.0 (2.0)

10.0 (3.0)

15.0 (5.0)

25.0 (8.0)

50.0 (16.

100.0 (32

bles, for Non-Hazardous

sOnly

2.0 (0.6)

3.0 (1.0)

6.0 (2.0)

10.0 (3.0)

15.0 (5.0)

25.0 (8.0)

50.0 (16.0)

100.0 (32.0)

Lengt

1.0 (0

1.3 (0

1.6 (

2.0 (

3.0 (

5.0 (

10.0

13.

20.

25.

50.

0)

hft(m)

.3)

.4)

0.5)

0.6)

1.0)

1.5)

(3.0)

0 (4.0)

0 (6.0)

0 (8.0)

0 (15.0)

.0)

25 Pin D-SUB Cables, for Non-Hazardous

Locations Only

16T659

)

16V659

Alternates f

for Non-Haza

Module Part

CGMDN0*, DeviceNet CGMPB0*, Profibus

CGMEP0*, Ethernet IP CGMPN0*, Profinet

* You must purchase Map Token Kit 17C087 for

usewiththesekits.

by Part Num

Module Par

24T557 2 color/2

24T558 4 color/4

24T559 6 color/6

24T560 8 color/

by Part Number (Factory Configuration), for

24T571 2 color/2 catalyst

24T572 4 color/2 catalyst

24T573 6 color/2 catalyst

24T574 8 color/2 catalyst, 13–24

24T774 12 color/2 catalyst

24T775 4 color/4 catalyst

24T776 6 color/4 catalyst

24T777 8 color/4 catalyst

24T778 12 color/4 catalyst, 13–30

24T779 13–18 color

or Communication Module 24R910,

No.

Alternate

Non-Hazar

Alternates for Color Change Modules

s for Color Change Modules

ber (Factory Configuration), for

tNo.

Hazardous Locations Only

2.5 (0.8)

6.0 (1.8)

rdous Locations Only

Module Part

dous Locations Only

Descripti

color

color

on

catalyst

catalyst

catalyst

8 catalyst

No.

332709B 33

Page 34

Repair

Repair

Before Servi

• Servicing the electrical control box exposes you

to high voltage. To avoid electric shock, turn off

power at the main circuit breaker before opening

the enclosure.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

cing

1. Flush the system as explained in your

PD2K Operation Manual if service time

may exceed pot life time. Follow the

Pressure Relief Procedure, page 35 before

servicing fluid components.

2. Close the main air shutoff valve on the air supply

line.

3. Shut off the power switch (P) at the electrical

control box.

4. If servicing the electrical control box, shut off

power at the main circuit breaker before opening

the enclosure.

• Do not substitute or modify system components

as this may impair intrinsic safety.

NOTICE

To avoid damaging the circuit boards when

servicing the control box, wear Part No. 112190

grounding strap on your wrist and ground

appropriately.

To avoid electrical component damage, remove all

system power before plugging any connectors.

Figure 18 Control Box Power Switch

34 332709B

Page 35

Repair

Pressure Reli

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure whenyoustopspraying

and before cleaning, checking, or servicing the

equipment.

ef Procedure

Without Color Change

NOTE: The following procedure relieves all fluid and

air pressure in the system. Use your control interface

to issue the necessary commands to your system.

1. Turn off the supply pumps. Open the drain valve

on the supply line fluid filter to relieve pressure

in the supply line.

NOTE: If your system does not include a drain

valve on the supply line, command the system to

Mix. Cycle the A and B dosing pumps a couple

of times to drain the pumps through the spray

device.

2. Command the system to Standby. Trigger the

spray device to relieve pressure.

3. Flush the remote mix manifold and spray device.

4. Shut off the solvent supply pump. To relieve

pressure, command the system to Purge and

trigger the spray device. When the pressure is

relieved, command the system to Standby to

avoid getting a Purge Incomplete alarm.

5. If pressure remains in the solvent line between

the solvent supply pump and the solvent valve:

• VERY SLOWLY loosen a fitting to relieve

pressure gradually.

• Loosen the fitting completely.

With Color Change

NOTE: The following procedure relieves all fluid and

air pressure in the system.

1. Turn off the s