Page 1

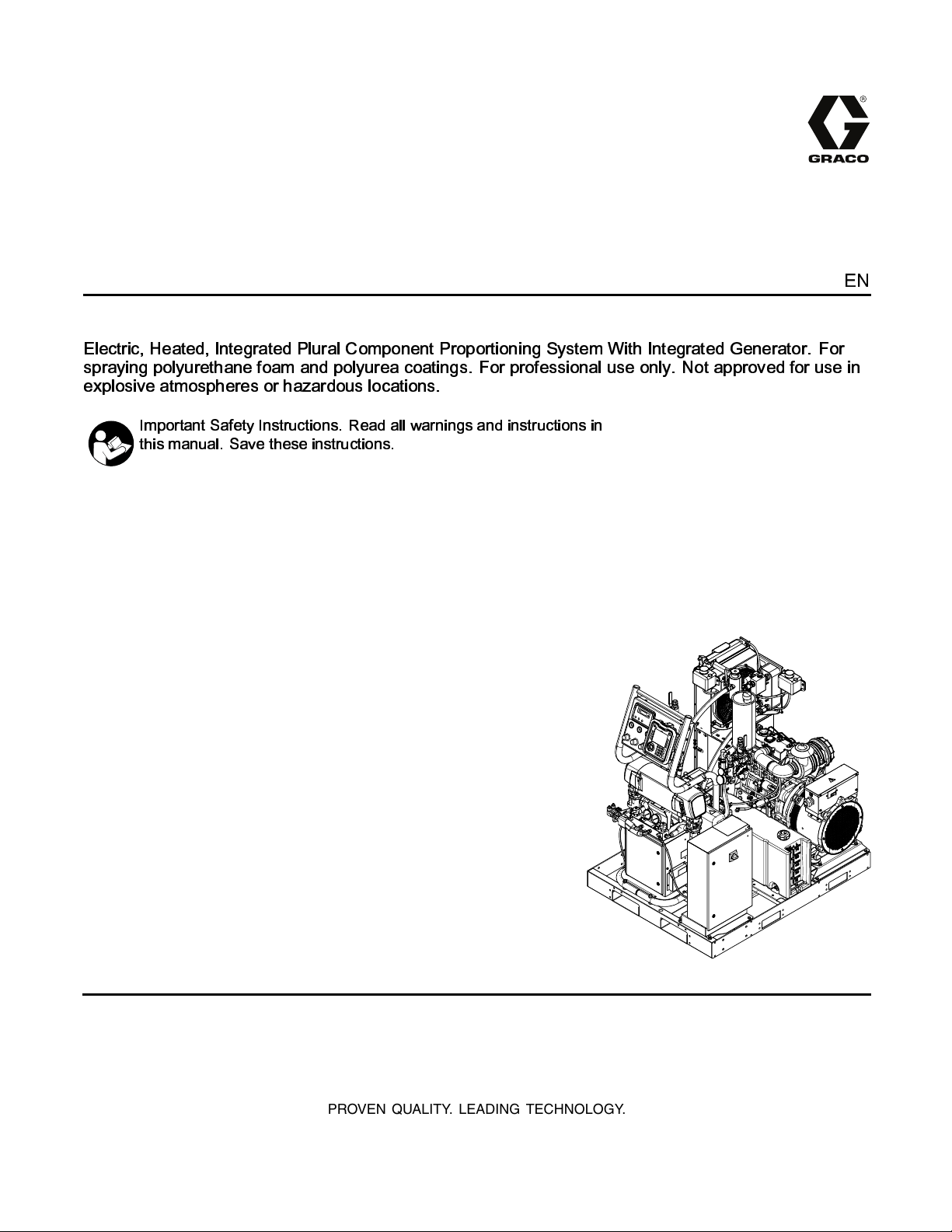

Repair-Parts

Reactor® 2 Elite Integrated

Proportioning System

Electric, Heated, Integrated Plural Component Proportioning System With Integrated Generator. For

spraying polyurethane foam and polyurea coatings. For professional use only. Not approved for use in

explosive atmospheres or hazardous locations.

Important Safety Instructions. Read all warnings and instructions in

this manual. Save these instructions.

332637C

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Warnings .............................................................3

Important Isocyanate Information........................... 9

Models............................................................... 11

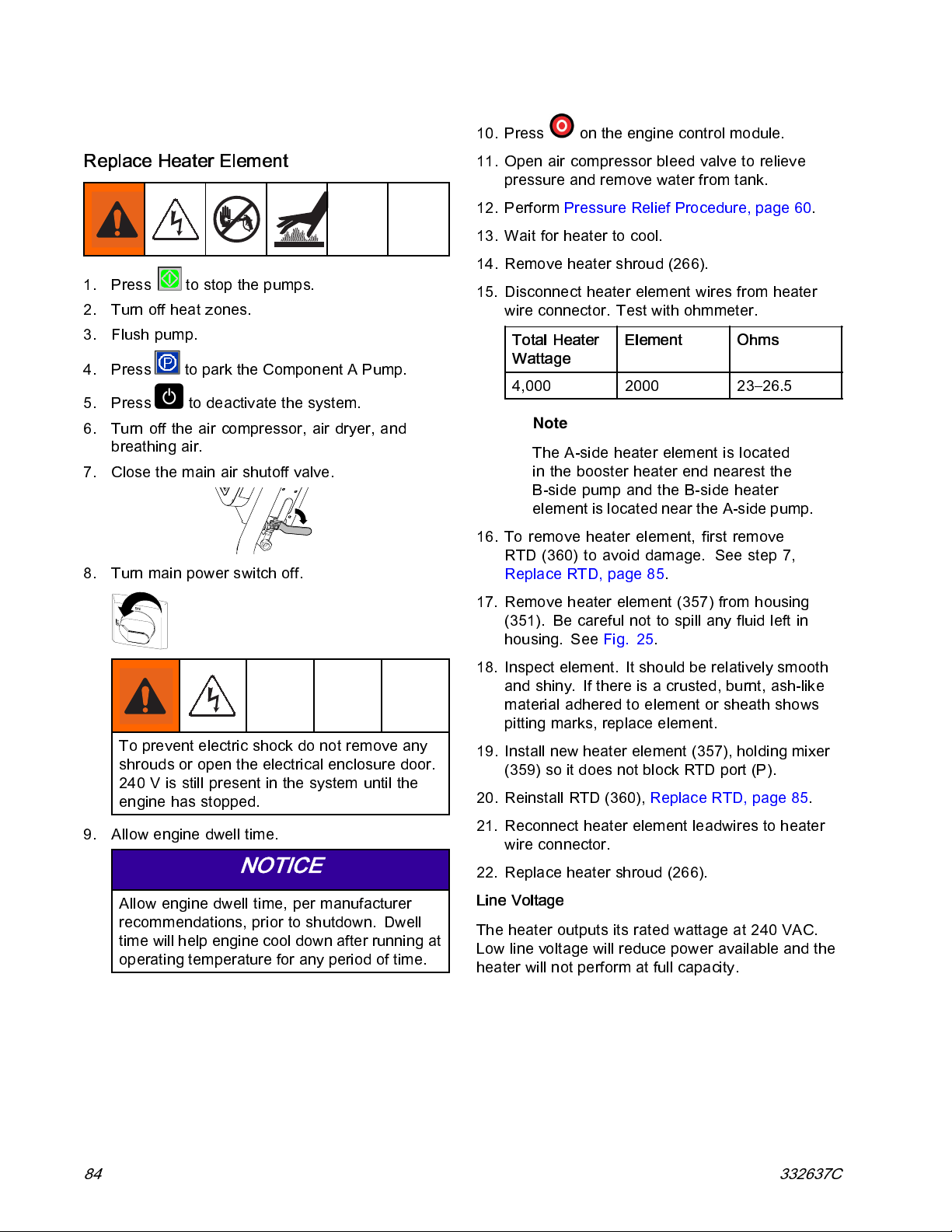

Approvals........................................................... 13

Accessories........................................................13

Supplied Manuals............................................... 14

Related Manuals ................................................ 14

Troubleshooting.................................................. 15

Troubleshoot Errors ..................................... 15

Load Center Diagnostics .............................. 50

Pressure Relief Procedure .................................. 60

Shutdown........................................................... 61

Flushing............................................................. 64

Repair................................................................ 65

Before Beginning Repair...............................65

Flush Inlet Strainer Screen ...........................65

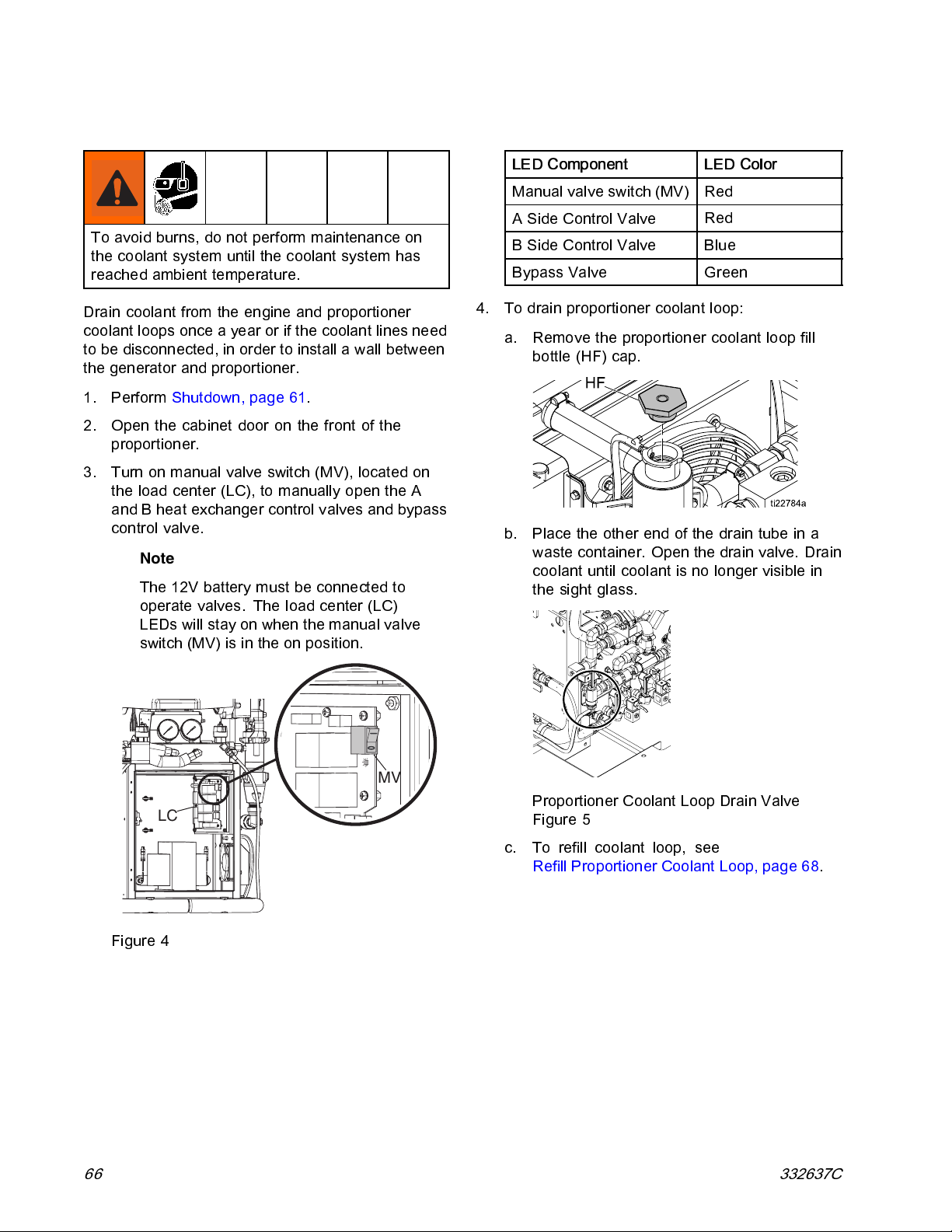

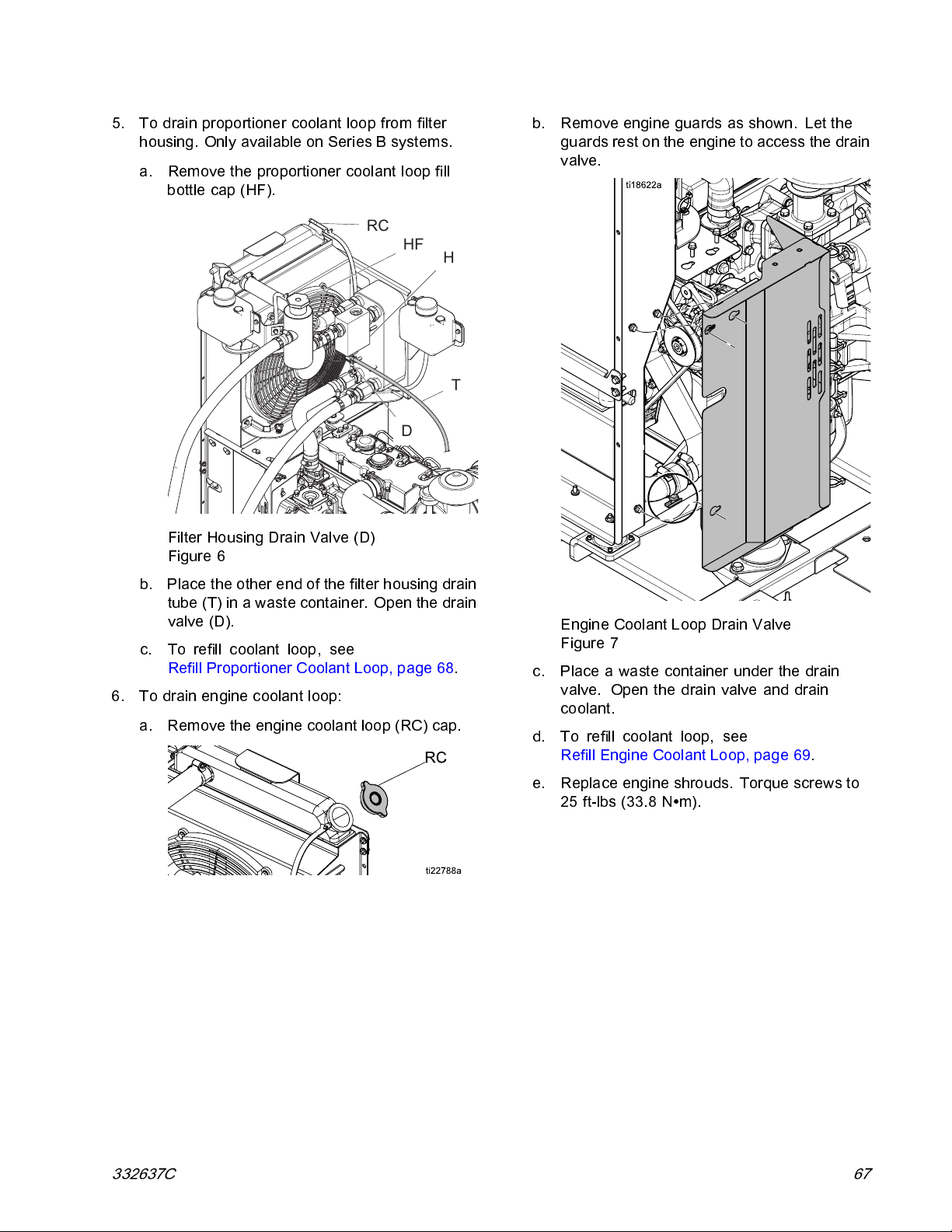

Drain Coolant .............................................. 66

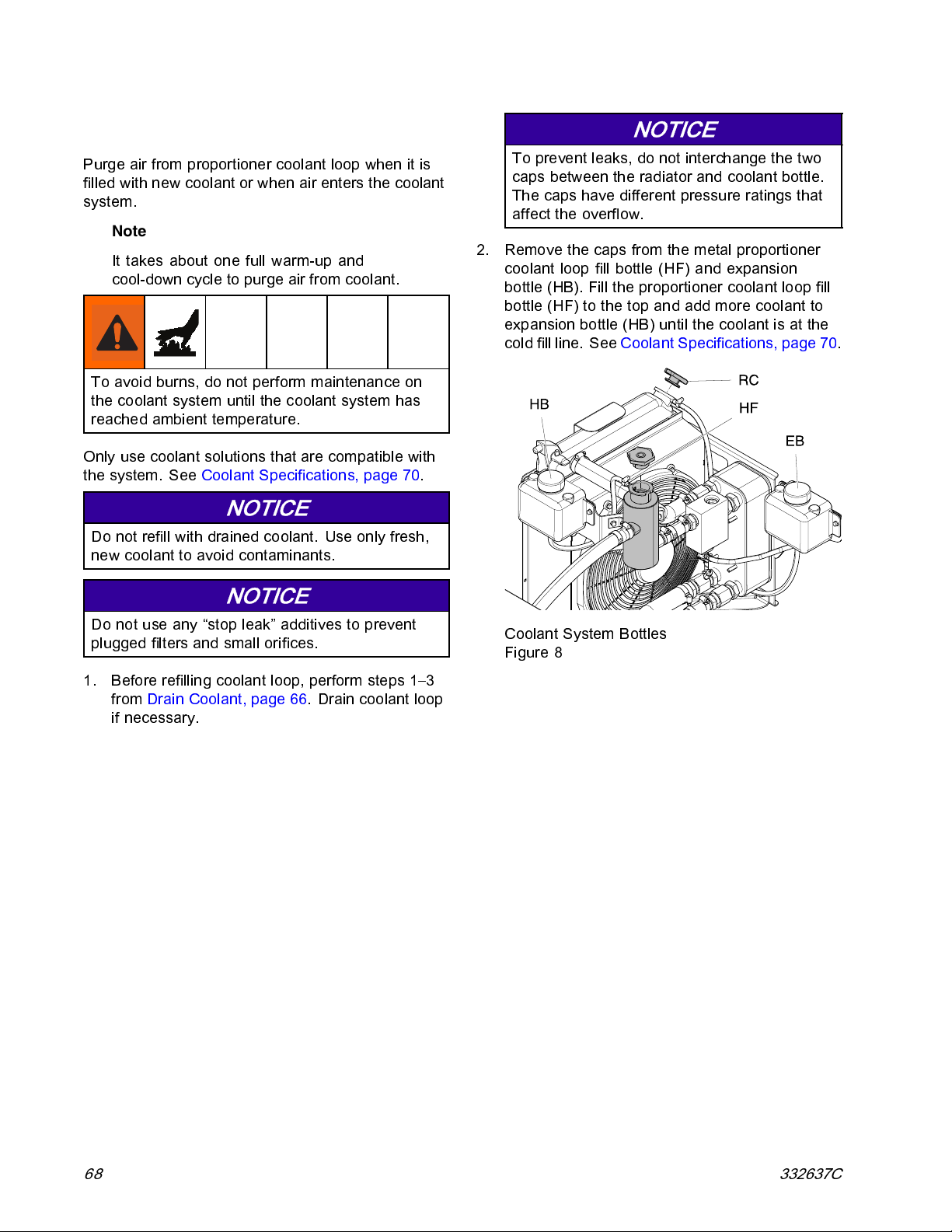

Refill Proportioner Coolant Loop ................... 68

Refill Engine Coolant Loop ........................... 69

Coolant Specifications.................................. 70

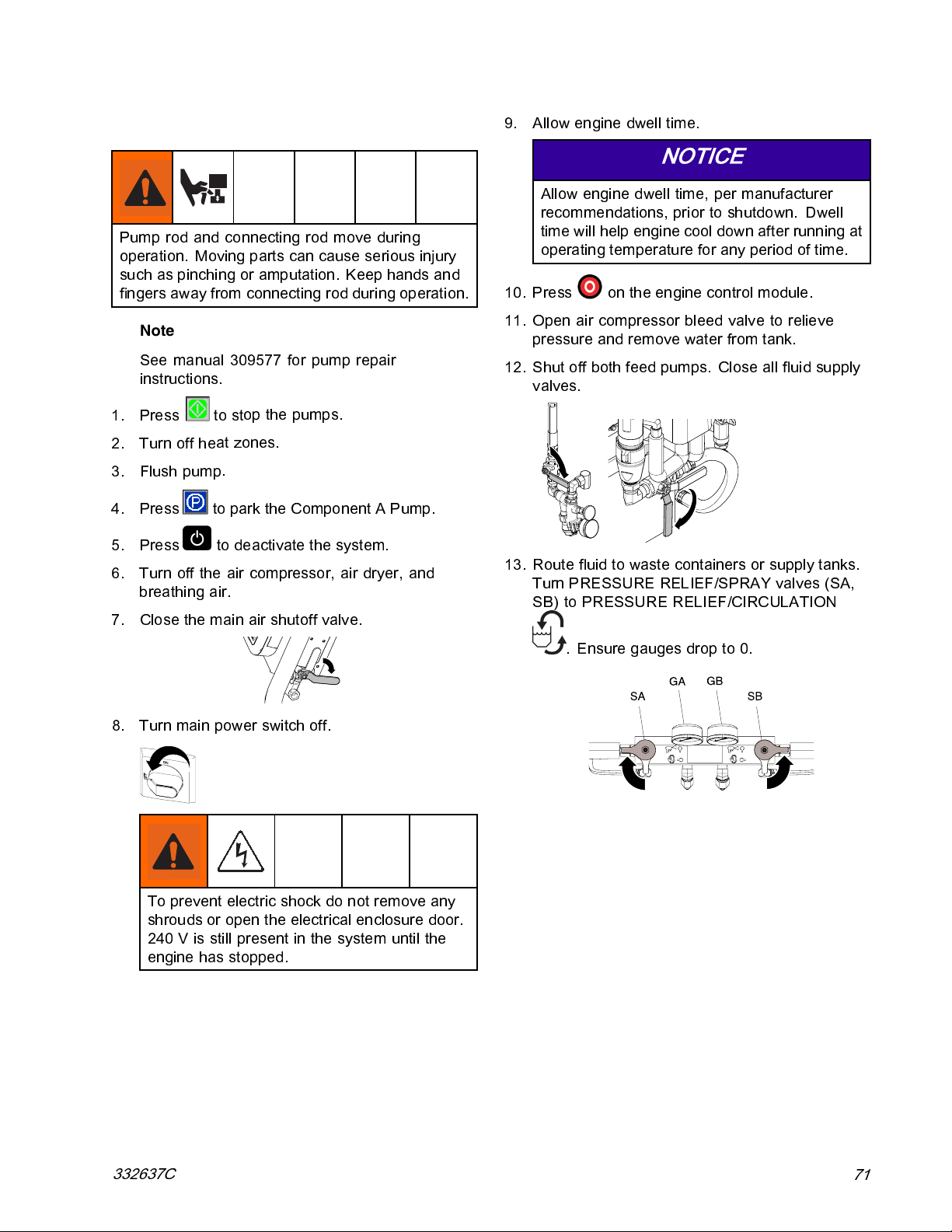

Change Pump Lubricant............................... 70

Remove Pump............................................. 71

Install Pump ................................................ 72

Repair Drive Housing ................................... 73

Repair Electric Motor.................................... 76

Repair Circuit Breaker Module ...................... 77

Replace Load Center Relays and

Fuses ............................................ 79

Replace Load Center ................................... 80

Replace Engine Solenoid Relays ..................80

Replace Fluid Inlet Sensor............................81

Replace Pressure Transducers ..................... 81

Replace Fans .............................................. 82

Repair Booster Heater.................................. 84

Repair Heated Hose.....................................87

Repair Flui d Temperature Sensor

(FTS).............................................88

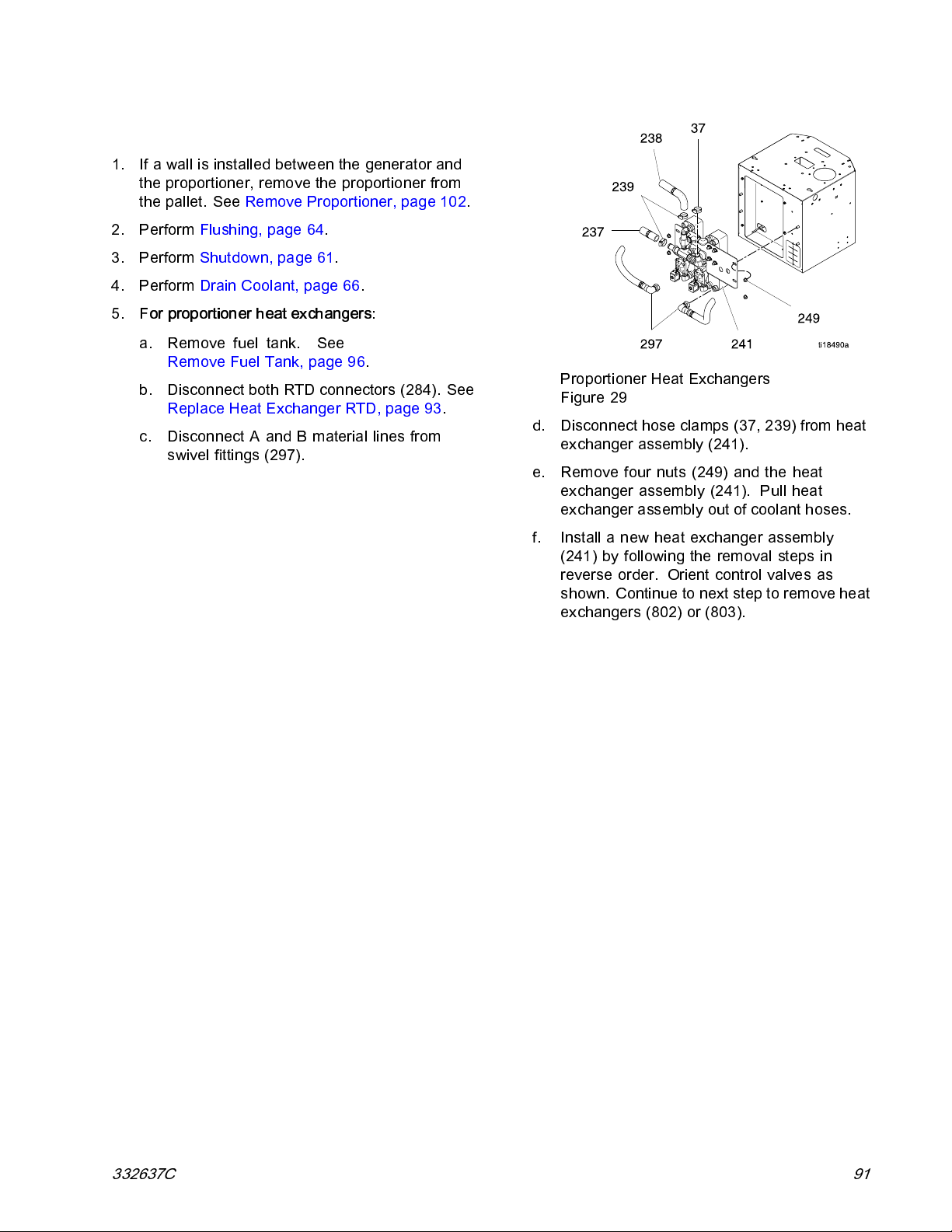

Replace Heat Exchangers............................ 91

Replace Power Supply ................................. 94

Replace Circulation Pump ............................ 95

Repair Filter Housing Filter ........................... 96

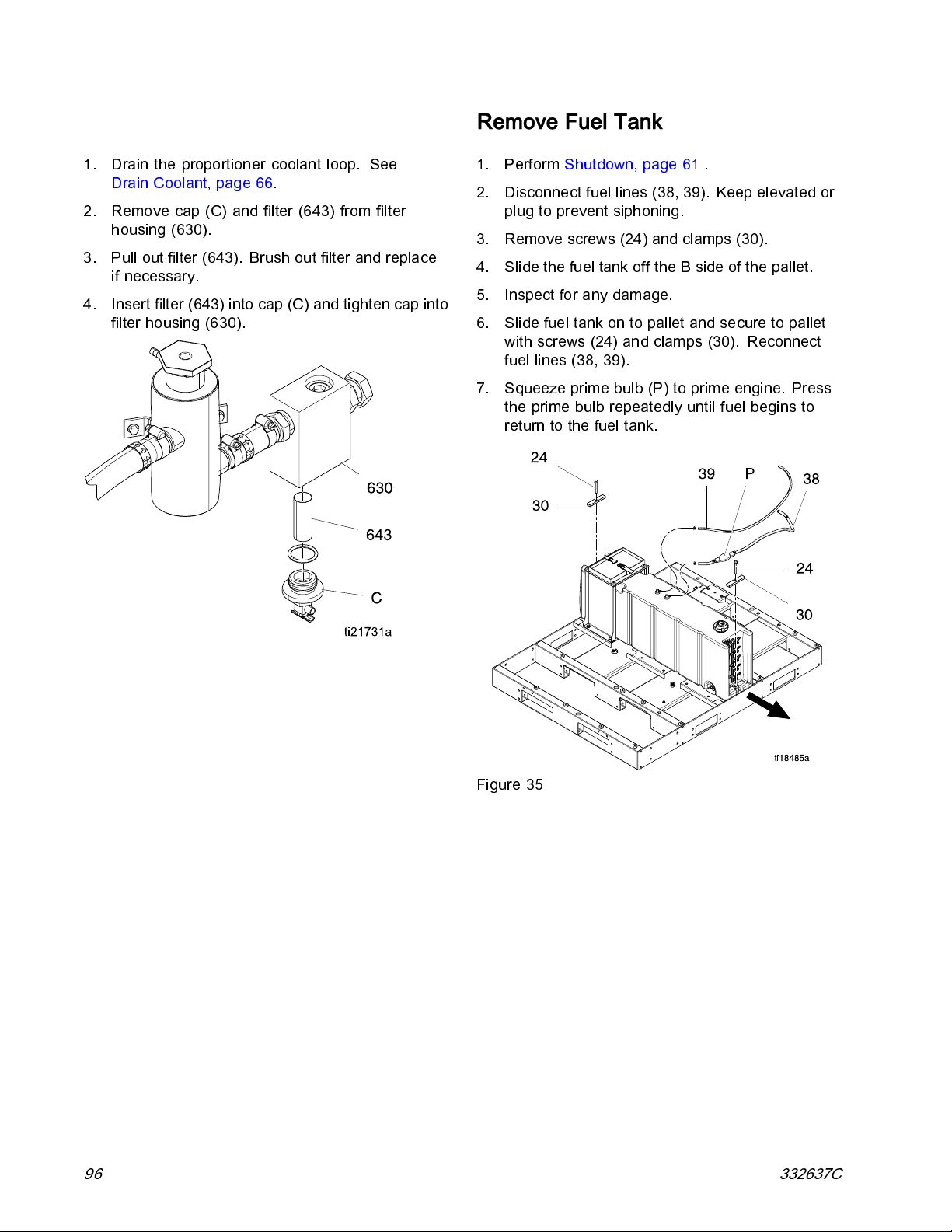

Remove Fuel Tank....................................... 96

Replace Battery ........................................... 97

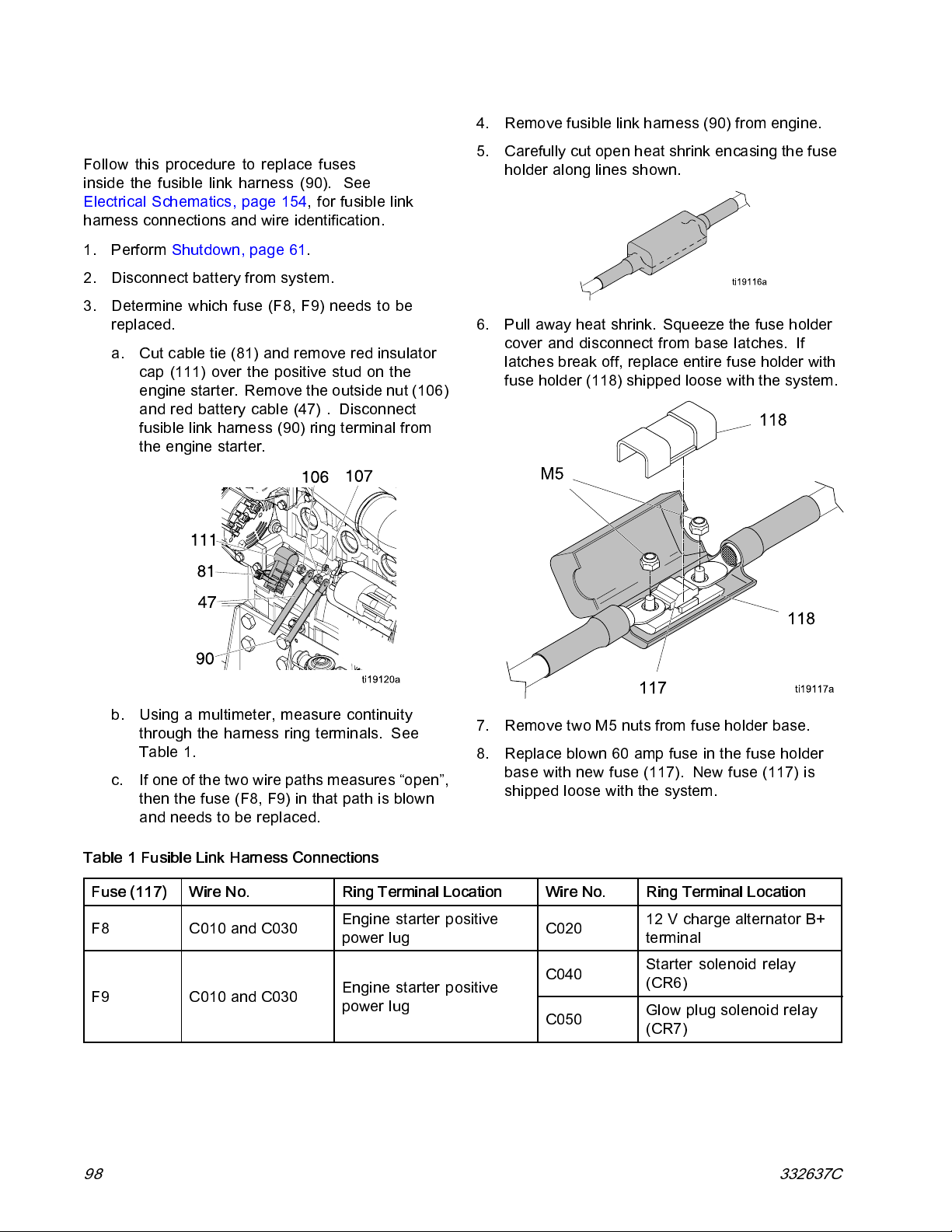

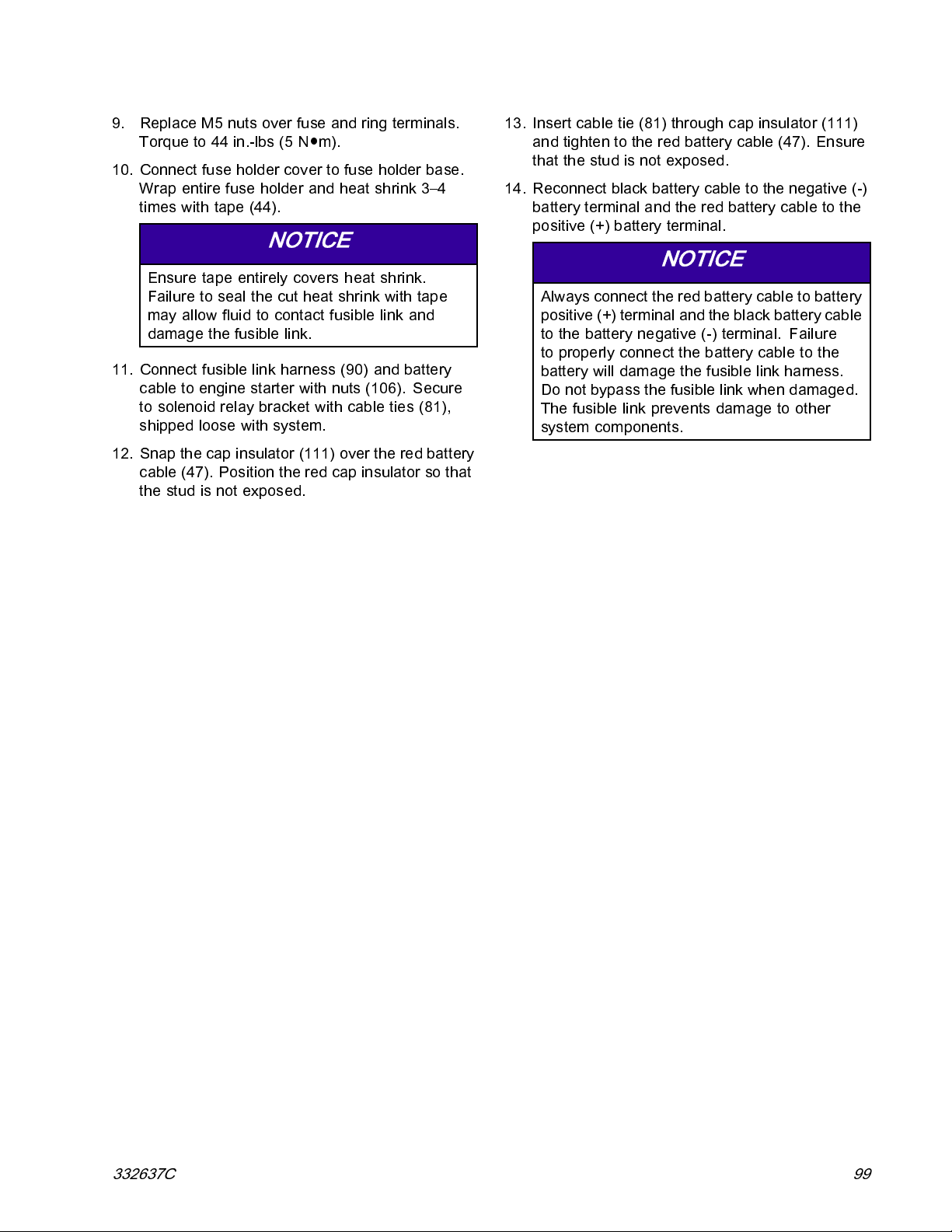

Repair Fusible Link Harness.........................98

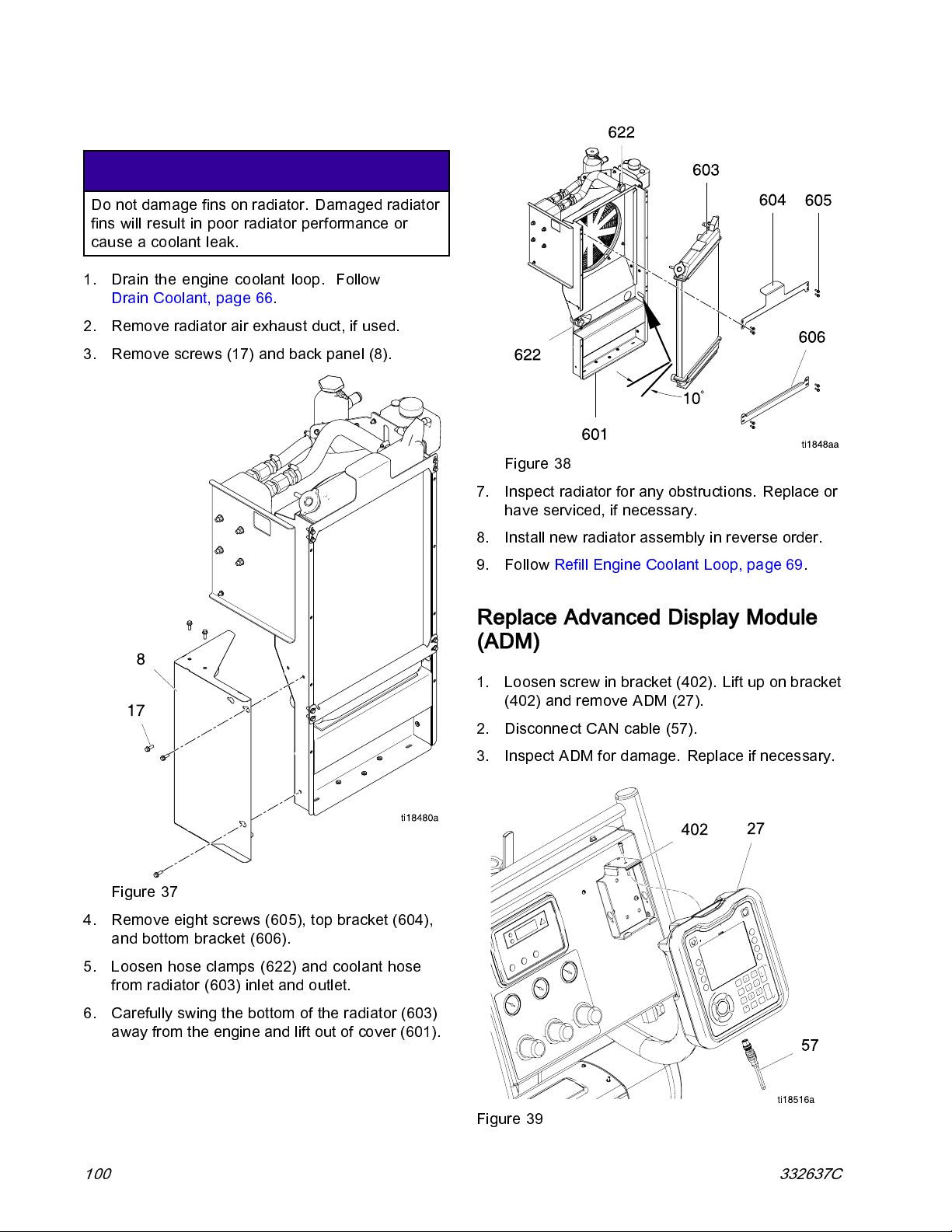

Remove Radiator....................................... 100

Replace Advanced Display Module

(ADM).......................................... 100

Replace Engine Control Module .................. 101

Replace Motor Control Module

(MCM) ......................................... 101

Replace Temperature Control Module

(TCM) .......................................... 101

Remove Proportioner ................................. 102

Repair Engine ............................................ 105

12V Charge Alternator................................ 105

Notes ............................................................. 106

Parts................................................................ 107

Electrical Schematics........................................ 154

Repair and Spare Parts Reference .................... 170

Recommended Rebuild Spare Parts .................. 171

Dimensions...................................................... 172

Technical Specifications.................................... 175

Notes ............................................................. 178

Graco Extended Warranty for Integrated

Reactor® 2 Components ..................... 179

2

332637C

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation p oi nt symbol alerts you t o a general warning and th e hazard symbols refer to procedure-specific

risks. When t hes e symbols appear in th e body of this manual or on w arning labels, refer back t o these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

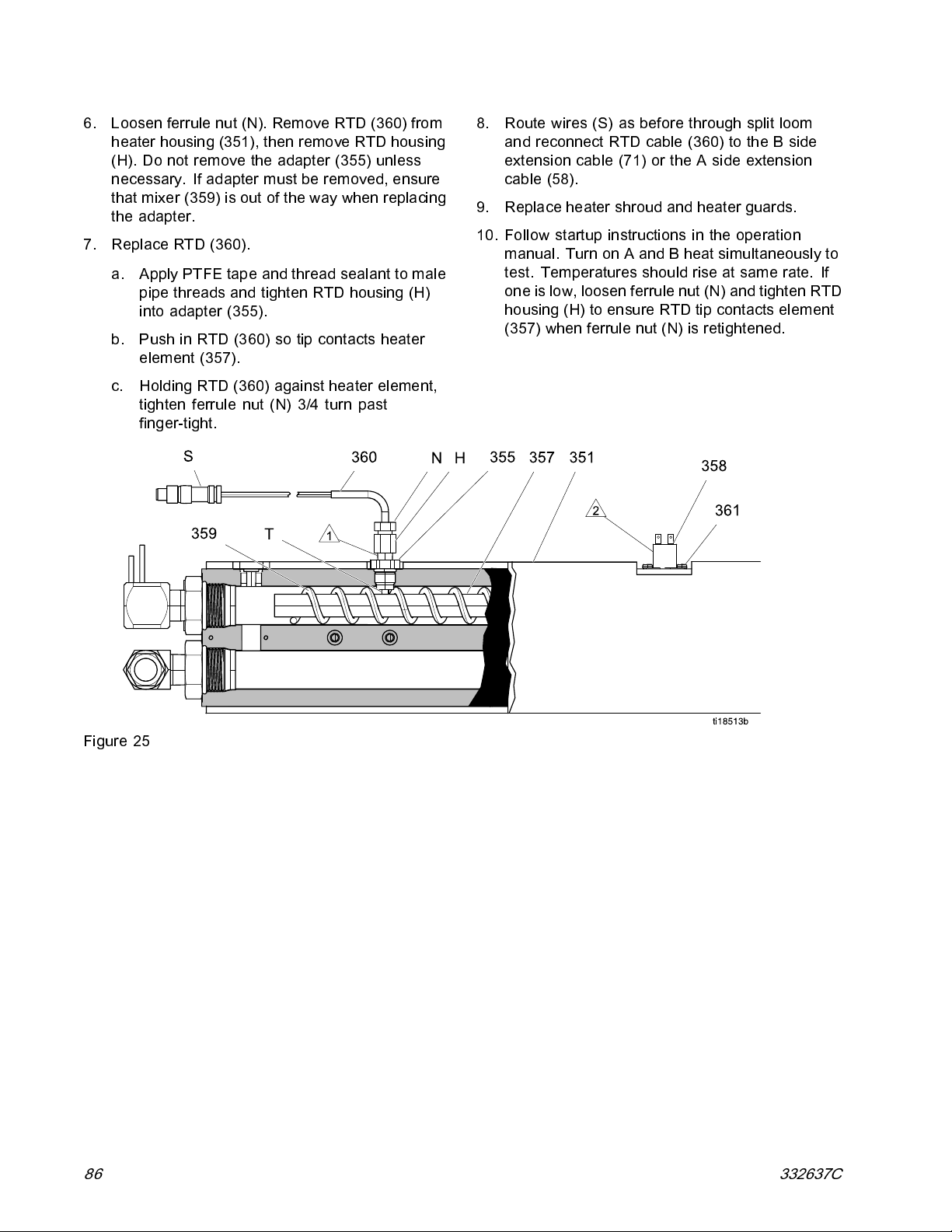

the body of this manual where applicable.

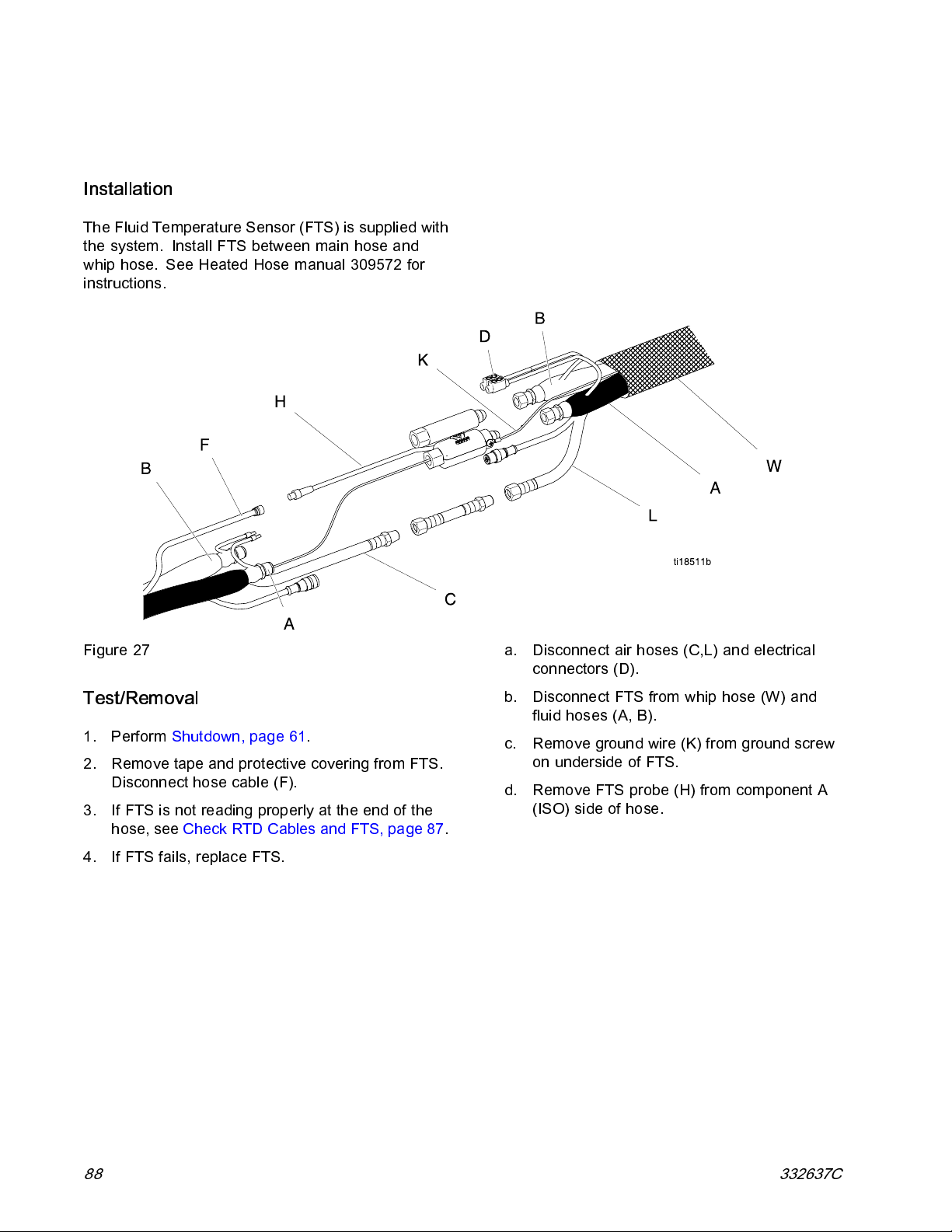

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric sh oc k.

• Turn off and disconnect power at main switch before disconnecting any cables and before

servicing equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

and regulations.

TOXIC FLUID OR FUMES

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallo wed.

• Read MSDSs to know the s pec i fic hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it accordin g to applicable

guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning

equipment.

CARBON MONOXIDE HAZARD

Exhaust contains poisonou s carbon monoxi de , which is colorless and odorless. Breathing

carbon monoxide can cause death.

• Donotoperateinanenclosedarea.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipmen t when in the work area to help prevent serious inj ury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protectio n.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

332637C 3

Page 4

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a s erious injury that can result in amputation.

treatment

• Do not s pra y without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part o f the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

.

Pressure Relief Procedure

when you stop spray i ng an d be fore c l ean ing , ch eck ing ,

Get immediate surgical

Flammable fumes, such as solvent and paint fumes, in

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or u npl ug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unle ss

they are antistatic or conductive.

•

Stop operation immediately

equipment u nti l you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

if static sparking occurs or you feel a shock.Do not use

Grounding

work area

instructions.

canigniteorexplode.Tohelp

4

332637C

Page 5

Warnings

WARNING

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined s paces, includin g hoses, can create a rapid rise in pressure

due to the thermal expansion. Over-pressurization can result in equipment rupture and serious

injury.

• Openavalvetorelievethefluidexpansionduringheating.

• Replace hoses proactively at regular intervals based on your operating conditions.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause serious

chemical reaction and equipment rupture. Failure to follow this warning can result in death,

serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon

solvents or fluids containing such solvents.

• Many other fluids may contain chemicals that can react with aluminum . Contac t y ou r mate rial

supplier for compatibility.

PLASTIC

Many solvents can degrade plastic parts and cause them to fail, which could cause serious

injury or property damage.

• Use only compatible water-based solvents to clean plastic structural or press ure-containing

parts.

•See

solvent manufacturer’s MSDSs and recommendations.

PARTS CLEANING SOLVENT HAZARD

Technical Data

in this and all other equipment instruction ma nua ls . Read fluid and

332637C 5

Page 6

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equip ment and follow the

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and crea te safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cab les away from traffic areas, s ha rp edges, moving parts, and hot su rfac es .

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

Technical Data

Pressure Relief Procedure

in all equipment manuals.

when equipment is not in use.

6 332637C

Page 7

WARNING

BATTERY HAZARD

The battery may leak, explode, cause burns, or cause an explosion if mishandled.

Warnings

• Only use the battery type specified for use with the equipment. See

• Battery maintenance must only be performed or supervised by personnel knowledgeable of

batteries and the required precautions. Keep unauthorized person nel away from battery.

• When replacing the battery, use the same lead-acid automotive battery, with 800 CCA

minimum, specified for use with the equipment. See

• Do not dispose of battery in fire. The battery is capable of exploding.

• Follow local ordinances and/or regulations for disposal.

• Donotopenormutilatethebattery. Releasedelectrolytehasbeenknowntobeharmfulto

theskinandeyesandtobetoxic.

• Remove watches, rings, or other metal objects.

• Only use tools with insulated handles. Do not lay tools or metal parts on top of battery.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other bo dy parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Be fore checking, m ov ing, or servicing

equipment, fol low the

Pressure Relief Procedure

Technical Data

and disconnect all power sources.

Technical Data

.

.

332637C

7

Page 8

Warnings

WARNING

ENTAGLEMENT HAZARD

Rotating parts can cause serious injury.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear l oo se clothing, jewelry or long hair while operating equipment.

• Equipment can start without warning. Before checking, moving, or servicing equipment,

follow the

BURN HAZARD

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid

severe burns:

• Do not touch hot fluid or equipment.

CALIFORNIA PROPOSITION 65

The engine exhaust from this product contains a chemical known to the State of California to

cause cancer, birth defects or other reproductive harm.

Pressure Relief Procedure

and disconnect all power sources.

8 332637C

Page 9

Important Isocyanate Information

Isocyanates (ISO) are catalysts used in two component materials.

Important Isocyanate Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mis ts,

vapors, and atomized particulates.

Read material manufacturer’s warnings and

material MSDS to know specific hazards and

precautions related to isocyanates.

Prevent i nh ala tio n of isocy ana te mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If suffic i ent ventilation

is not available, a supplied-air respirator is required

for everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, in cluding

chemically impermeable gloves, boots , aprons,

and goggles, is also required for everyone in the

work area.

Keep Components A and B Separate

Cross-contamination can result in cured

material in fluid lines which could cause serious

injury or damage equipment. To prevent

cross-contamination:

•

Never

interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been

contaminated from the other si de.

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will cause

ISO to partially cure; forming small, hard, abrasiv e

crystals, which become suspended in the fluid.

Eventually a film will form on the surface and the ISO

will begin to gel, increasing in viscosity

Material Self-Ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings

and material MSDS.

NOTICE

Partially cured ISO will reduce performance and

the life of all wetted parts .

• Always use a sealed container with a desiccant

dryer i n the vent, or a nitrogen atmosphere.

Never

store ISO in an open container.

• Keep the ISO pump wet cup or reserv oi r (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may

contain moisture. Always keep solvent

containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubrica nt when reassembling.

332637C 9

Page 10

Important Isocyanate Information

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures

above 90°F (33°C) when not und er pressure,

especially if agitated. To reduce frothing, minimize

preheating in a circulation system.

Changing Materials

NOTICE

Changing the material types used in your

equipment requires special attention to avoid

equipment damage and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after

flushing.

• Check with your materi al manufacturer for

chemical compatibility.

• When changing between epoxies and urethanes

or polyureas, disassemble and clean all fluid

components and change hose s. Epoxies o ften

have amines on the B (hardener) side. Polyureas

often have amines on the B (resin) side.

10 332637C

Page 11

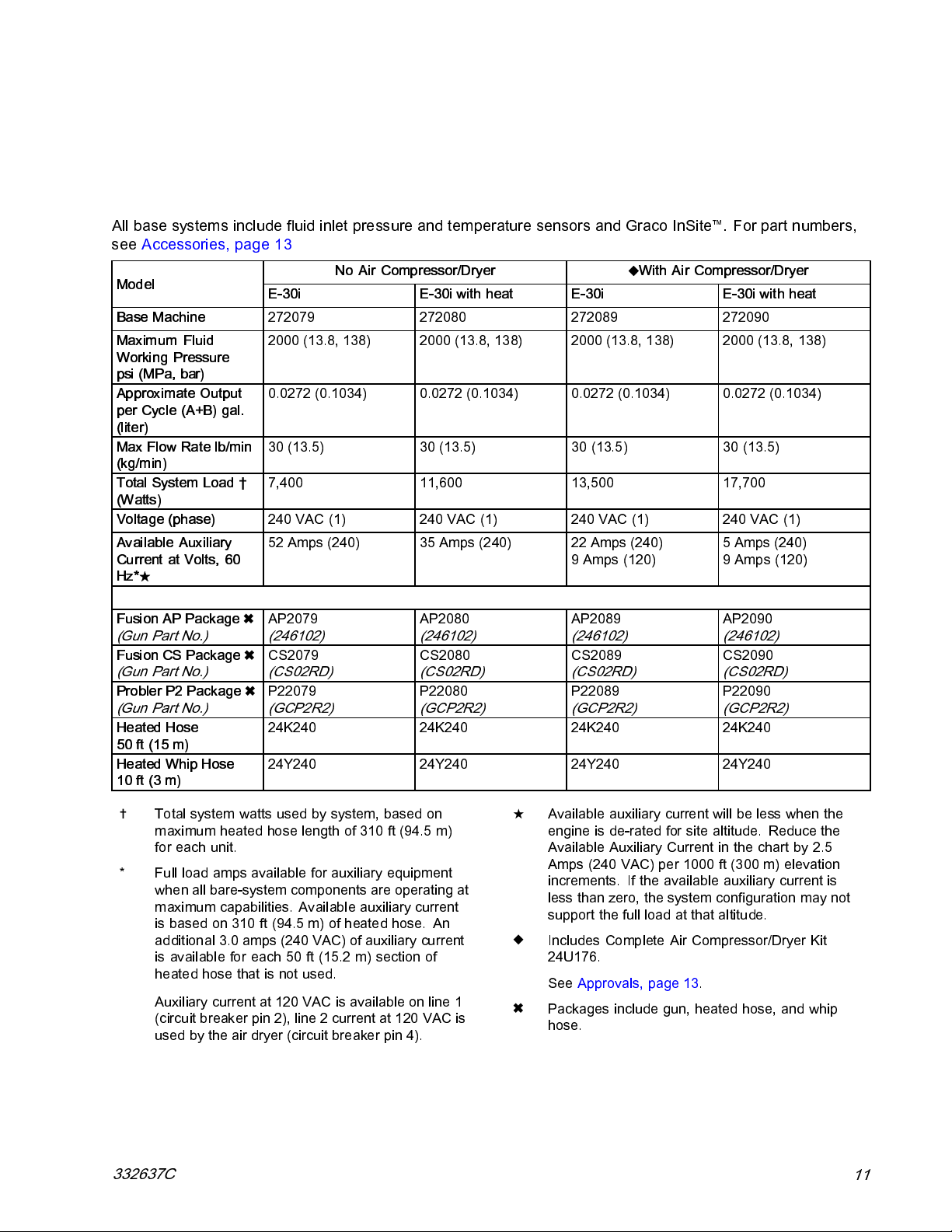

Models

Models

Reactor 2 E-30i Elite

All base systems include fluid inlet pressure and temperature sensors and Graco InSite™. For part numbers,

see Accessories, page 13

Model

Base Machine

Maximum Fluid

Working Pressure

psi (MPa, bar)

Approximate Output

per Cycle (A+B) gal.

(liter)

Max Flow Rate lb/min

(kg/min)

Total System Load †

(Watts)

Voltage (phase)

Available Auxiliary

Current at Volts, 60

Hz*

No Air Compressor/Dryer

E-30i E-30i with heat E-30i E-30i with heat

272079 272080 272089 272090

2000 (13.8, 138) 2000 (13.8, 138) 2000 (13.8, 138) 2000 (13.8, 138)

0.0272 (0.1034) 0.0272 (0.1034) 0.0272 (0.1034) 0.0272 (0.1034)

30 (13.5) 30 (13.5) 30 (13.5) 30 (13.5)

7,400 11,600 13,500 17,700

240 VAC (1) 240 VAC (1) 240 VAC (1) 240 VAC (1)

52 Amps (240) 35 Amps (240) 22 Amps (240)

9 Amps (120)

With Air Compressor/Dryer

5 Amps (240)

9 Amps (120)

Fusion AP Package

(Gun Part No.)

Fusion CS Package

(Gun Part No.)

Probler P2 Package

(Gun Part No.)

Heated Hose

50 ft (15 m)

Heated Whip Hose

10 ft (3 m)

Total system watts used by system, based on

maximum heated hose length of 310 ft (94.5 m)

for each unit.

* Full load amps available for auxiliary equipment

when all bare-system components are operating at

maximum capabilities. Available auxiliary current

is based on 310 ft (94.5 m) of heated hose. An

additional 3.0 amps (240 VAC) of auxiliary current

is available for each 50 ft (15.2 m) section of

heated hose that is not used.

liary current at 120 VAC is available on line 1

Auxi

rcuit breaker pin 2), line 2 current at 120 VAC is

(ci

d by the air dryer (circuit breaker pin 4).

use

AP2079

(246102)

CS2079

(CS02RD)

P22079

(GCP2R2)

24K240 24K240 24K240 24K240

24Y240 24Y240 24Y240 24Y240

AP2080

(246102)

CS2080

(CS02RD)

P22080

(GCP2R2)

AP2089

(246102)

CS2089

(CS02RD)

P22089

(GCP2R2)

Available auxiliary current will be less when the

engine is de-rated for site altitude. Reduce the

Available Auxiliary Current in the chart by 2.5

Amps (240 VAC) per 1000 ft (300 m) elevation

increments. If the available auxiliary current is

less than zero, the system configuration may not

support the full load at that altitude.

Includes Complete Air Compressor/Dryer Kit

24U176.

See Approvals, page 13.

Packages include gun, heated hose, and whip

hose.

AP2090

(246102)

CS2090

(CS02RD)

P22090

(GCP2R2)

332637C

11

Page 12

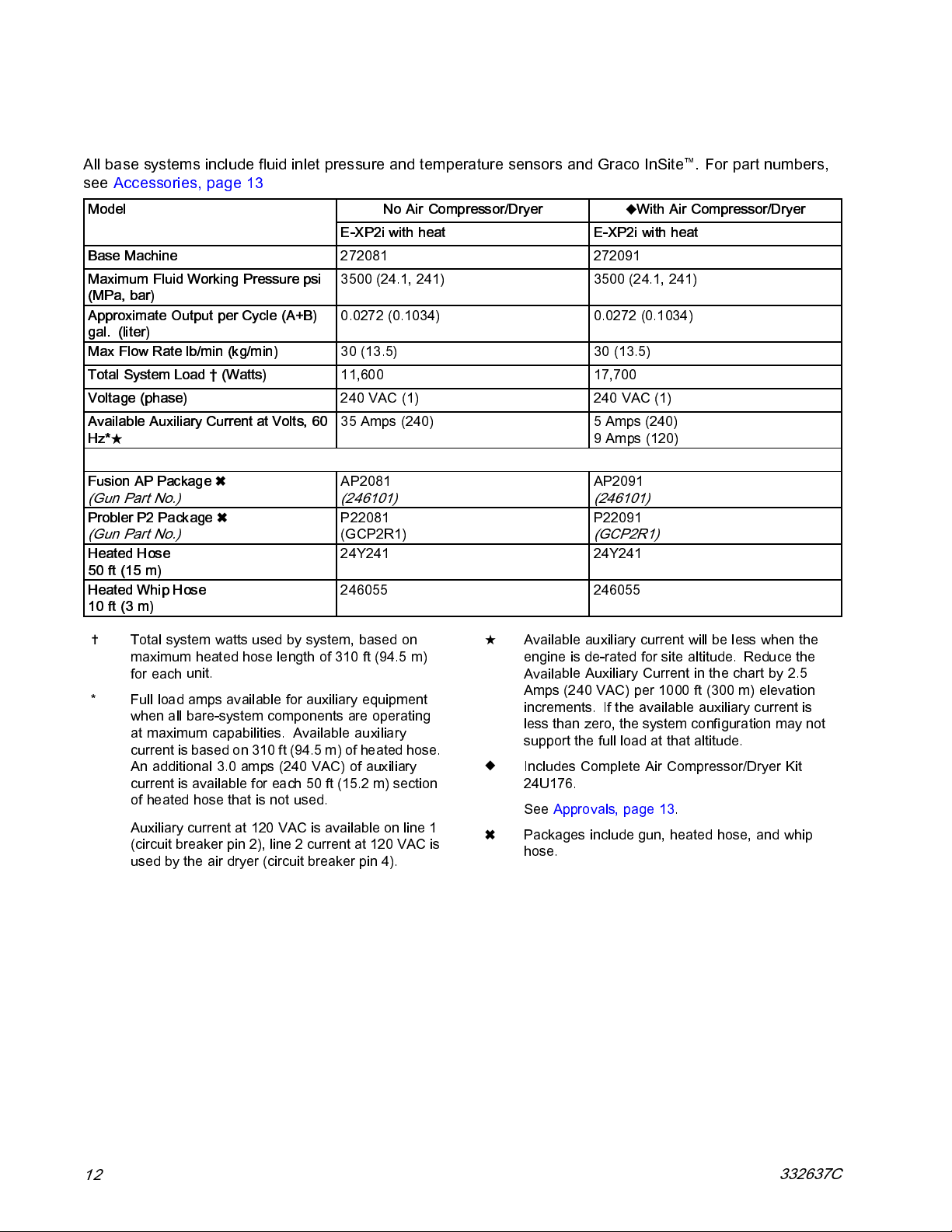

Models

Reactor 2 E-XP2i Elite

All base systems include fluid inlet pressure and temperature sensors and Graco InSite™. For part numbers,

see Accessories, page 13

Model

Base Machine

Maximum Fluid Working Pressure psi

(MPa, bar)

Approximate Output per Cycle (A+B)

gal. (liter)

MaxFlowRatelb/min(kg/min)

Total System Load † (Watts)

Voltage (phase)

Available Auxiliary Current at Volts, 60

Hz*

No Air Compressor/Dryer

E-XP2i with heat E-XP2i with heat

272081 272091

3500 (24.1, 241) 3500 (24.1, 241)

0.0272 (0.1034) 0.0272 (0.1034)

30 (13.5) 30 (13.5)

11,600 17,700

240 VAC (1) 240 VAC (1)

35 Amps (240) 5 Amps (240)

With Air Compressor/Dryer

9 Amps (120)

Fusion AP Package

(Gun Part No.)

Probler

(Gun Par

Heated H

50 ft (15

Heated

10 ft (3

P2 Package

t No.)

ose

m)

Whip Hose

m)

Total sy

maximum

for each

* Full load amps available for auxiliary equipment

when all bare-sys tem components are operating

at maximum capabilities. Available auxiliary

current is based on 310 ft (94.5 m) of heated hose.

An additional 3.0 amps (240 VAC) of auxiliary

current is available for each 50 ft (15.2 m) section

of heated hose that is not used.

Auxiliary current at 120 VAC is available on line 1

(circuit breaker pin 2), line 2 current at 120 VAC is

used by the air dryer (circuit breaker pin 4).

stem watts used by system, based on

heated hose length of 310 ft (94.5 m)

unit.

AP2081

(246101)

P22081

(GCP2R1)

24Y241 24Y241

246055 246055

AP2091

(246101)

P22091

(GCP2R1)

ble auxiliary current will be less when the

Availa

is de-rated for site altitude. Reduce the

engine

ble Auxiliary Current in the chart by 2.5

Availa

Amps (2

increm

less th

suppor

Includes Complete Air Compressor/Dryer Kit

24U176.

See Approvals, page 13.

Packages include gun, heated hose, and whip

hose.

40 VAC) per 1000 ft (300 m) elevation

ents. If the available auxiliary current is

an zero, the system configuration may not

t the full load at that altitude.

12

332637C

Page 13

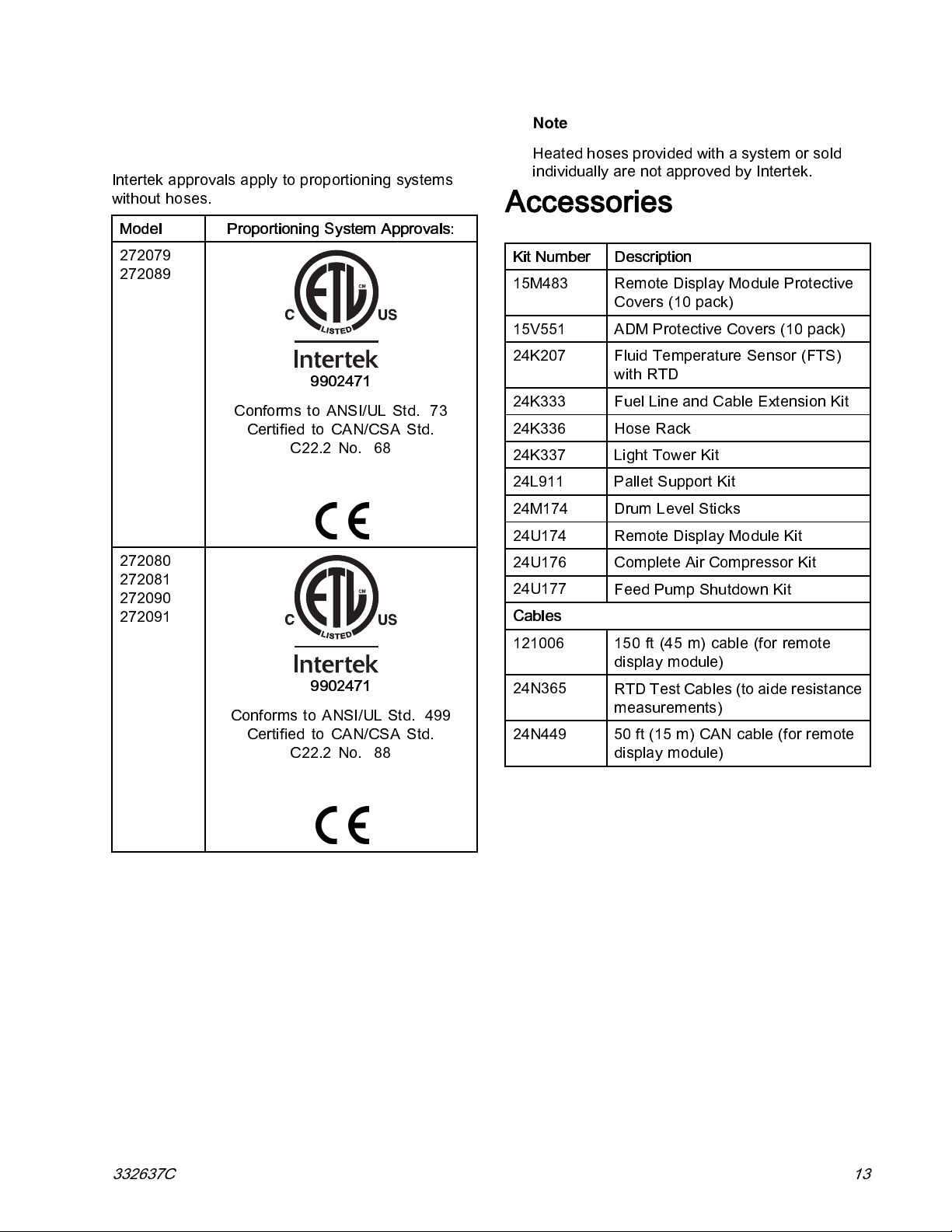

Approvals

Approvals

Intertek approvals apply to proportioning systems

without hoses.

Model

272079

272089

272080

272081

272090

272091

Proportioning System Approvals:

9902471

Conforms to ANSI/UL Std. 73

Certified to CAN/CSA Std.

C22.2 No. 68

Note

Heated hoses provided with a system or sold

individually are not approved by Intertek.

Accessories

Kit Number Description

15M483 Remote Display Module Protective

Covers (10 pack)

15V551

24K207

24K333 Fuel Line and Cable Extension Kit

24K336 Hose Rack

24K337 Light Tower Kit

24L911

24M174 Drum Level Sticks

24U174 Remote Display Module Kit

24U176

24U177

Cables

ADM Protective Covers (10 pack)

Fluid Temperature Sensor (FTS)

with RTD

Pallet Support Kit

Complete Air Compressor Kit

Feed Pump Shutdown Kit

9902471

rms to ANSI/UL Std. 499

Confo

fied to CAN/CSA Std.

Certi

C22.2

No. 88

121006 150 ft (45 m) cable (for remote

display module)

24N365

24N449

RTD Test Cables (to aide resistance

measurements)

50ft(15m)CANcable(forremote

display module)

332637C 13

Page 14

Supplied Manuals

Supplied Manuals

The following m anu al s are shipped with the Reac to r.

Refer to these manuals for detailed equi pm ent

information.

Manuals are also available at www.graco.com.

Manual Description

332636 Reactor 2 Elite Integrated

Proportioning System, Operation

333093 Reactor 2 Elite Integrated

Proportioning System, Startup

Instructions

333094 Reactor 2 Elite Integrated

Proportioning System, Shutdown

Instructions

SEBU8311–02Perkins® Engine, Repair-Parts

Access at www.perkins.com. Go

to Service and Support/manuals.

Select engine family and type code

“GN”.

Contact Perkins for engine warranty

and service.

-

ST

15825–00

33227482

Mecc Alte Self-Regulating Alternator

Series NPE, Repair-Parts

Access at www.meccalte.com.

Select “meccalte” logo / Download

/ Instruction Manuals. Select NPE

instruction manual on page 5. Go to

Support and enter serial number for

Parts List and Help Videos.

Contact Mecc Alte for warranty and

service

Air Compressor, Operation/Mainte-

nance & Parts list.

Access at www.hydrovaneprod-

ucts.com. Go to Warranty & Service

tab and select “contact us” to

request manuals.

Refrigerated Air Dryer, Instruction

manual

Access from S e rvice

Department (724) 746–1100 or

www.spx.com/en/hank i son.

Related Manuals

The following manuals are for accessories used with

the Re ac tor.

Component Manuals in English:

Manuals are available at www.graco.com.

System Manuals

332636

Displacement Pump Manual

309577 Electric Reactor Displacement Pump,

Feed System Manuals

309572 Heated Hose, Instructions-Parts

309852

309815 Feed Pump Kits, Instructions-Parts

309827

Spray Gun Manuals

309550 Fusion ™ AP Gun

312666 Fusion ™ CS Gun

313213 Probler®P2 Gun

Accessory Manuals

332733 Air Compressor and Air Dryer Kit,

332738

332740 Remote Display Module,

3A2574

3A1903 Hose Rack, Instructions-Parts

3A1904

3A1905

3A1906

Reactor 2 E-30i and E-XP2i, Operation

Repair-Parts

Circulation and Return Tube Kit,

Instructions-Parts

Feed Pump Air Supply Kit,

Instructions-Parts

Instructions-Parts

Booster Heat R etrofit Kit,

Instructions-Parts

Instructions-Parts

Pallet Support Kit, Instructions-Parts

Fuel Tank/Battery Move Kit,

Instructions-Parts

Feed Pump Shutdown Kit,

Instructions-Parts

Light Tower Kit, Instructions-Parts

14

332637C

Page 15

Troubleshooting

Troubleshoot Errors

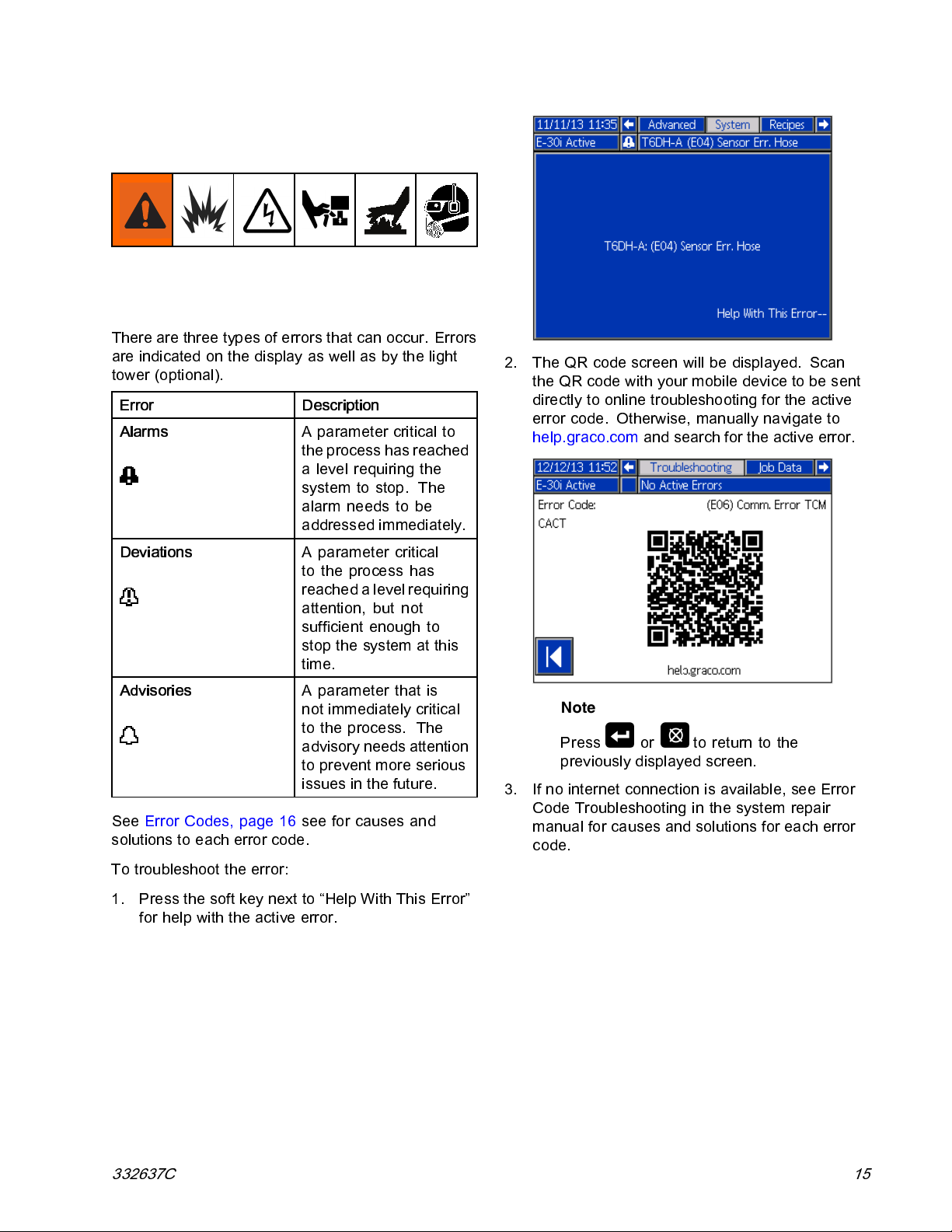

There are three types of errors that can occur. Errors

are indicated on the display as well as by the light

tower (optional).

Error Description

Alarms

A parameter critical to

the process has reached

a level requiring the

system to stop. The

alarm needs to be

addressed immediately.

Troubleshooting

2. TheQRcodescreenwillbedisplayed. Scan

the QR code with your mobile device to be sent

directly to online troubleshooting for the active

error code. Otherwise, manually navigate to

help.graco.com and search for the active error.

Deviations

Advisories

See Error Codes, page 16 see for causes and

solutions to each error code.

To troublesh oot the error:

1. Press the s oft key next to “Help With This Error”

forhelpwiththeactiveerror.

A parameter critical

to the process has

reacheda level requiring

attention, but not

sufficient enough to

stop the system at this

time.

A parameter that is

not immediately critical

to the process. The

advisory needs attention

to prevent more serious

issues in the future.

3. If no i

Code T

manu

code

Note

Press

previ

nternet connection is available, see Error

roubleshooting in the system repair

al for causes and solutions for each error

.

or to return to the

ously displayed screen.

332637C 15

Page 16

Troubleshooting

Error Codes

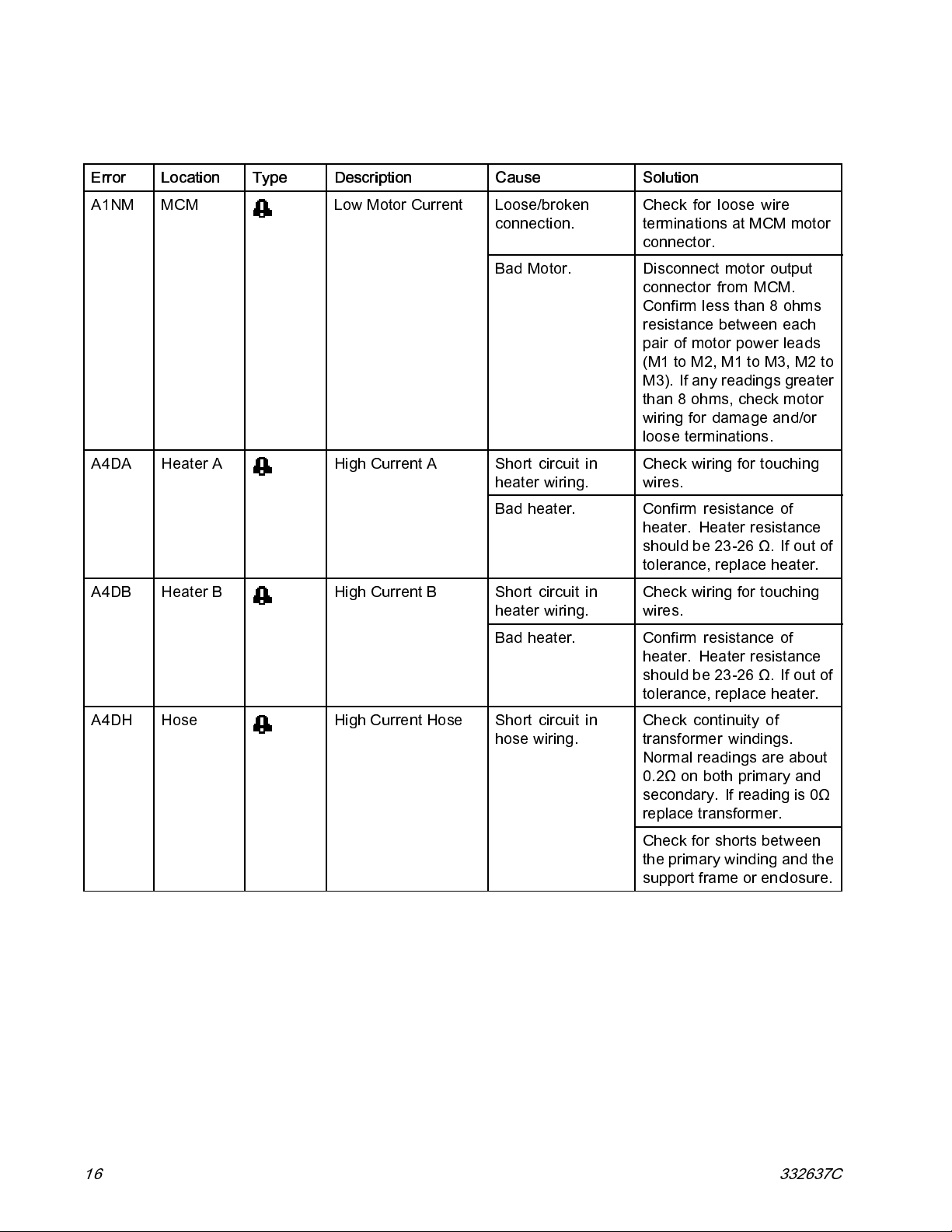

Error Location Type Description Cause Solution

A1NM

A4DA Heater A

A4DB Heater B High Current B

MCM

Low Motor Current

High Current A

Loose/broken

connection.

Bad Motor. Disconnect motor output

Short circuit in

heater wiring.

Bad heater.

Short circuit in

heater wiring.

Bad heater.

Check for loose wire

terminations at MCM motor

connector.

connector from MCM.

Confirm less than 8 ohms

resistance between each

pair of motor power leads

(M1toM2,M1toM3,M2to

M3). If any readings greater

than 8 ohms, check motor

wiring for damage and/or

loose terminations.

Check wiring for touching

wires.

Confirm resistance of

heater. Heater re si stanc e

should be 23-26 Ω. If out of

tolerance, replace heater.

Check wiring for touching

wires.

Confirm resistance of

heater. Heater re si stanc e

should be 23-26 Ω. If out of

tolerance, replace heater.

A4DH Hose

High Current Hose Short circuit in

hose wiring.

Check continuity of

transformer windings.

Normal readings are about

0.2Ω on both primary and

secondary. If reading is 0Ω

replace transformer.

Check for shorts between

the p rimary windin g and the

support frame or enclosure.

16 332637C

Page 17

Troubleshooting

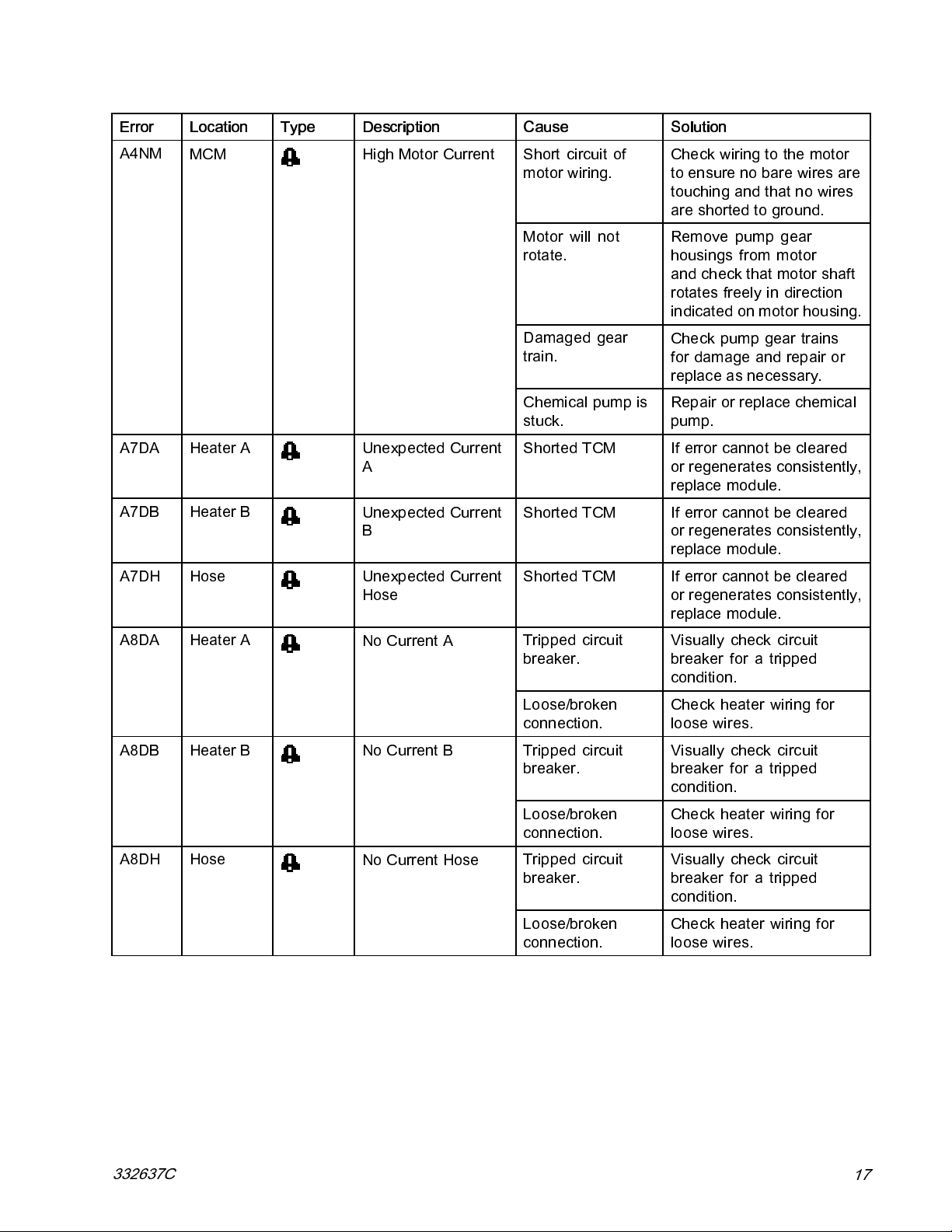

Error Location Type Description

A4NM

A7DA Heater A

A7DB Heater B

A7DH Hose

MCM

High Motor Current

Unexpected CurrentAShorted TCM If error cannot be cleared

Unexpected CurrentBShorted TCM If error cannot be cleared

Unexpected Current

Hose

Cause Solution

Short circuit of

motor wiring.

Motor will not

rotate.

Damaged gear

train.

Chemical pump is

stuck.

Shorted TCM If error cannot be cleared

Check wiring to the motor

to ensure no bare wires are

touching and that no wires

are shorted to ground.

Remove pump gear

housings from motor

and check that motor shaft

rotates freely in direction

indicated on motor housing.

Check pump gear trains

for damage and repair or

replace as necessary.

Repair or replace chemical

pump.

or regenerates consistently,

replace module.

or regenerates consistently,

replace module.

or regenerates consistently,

replace module.

A8DA Heater A

A8DB Heater B

A8DH Hose

No Current A

No Current B

No Current Hose

Tripped circuit

breaker.

Loose/broken

connection.

Tripped circuit

breaker.

Loose/broken

connection.

Tripped circuit

breaker.

Loose/broken

connection.

Visually check circuit

breaker for a tripped

condition.

Check heater wiring for

loose wires.

Visually check circuit

breaker for a tripped

condition.

Check heater wiring for

loose wires.

Visually check circuit

breaker for a tripped

condition.

Check heater wiring for

loose wires.

332637C

17

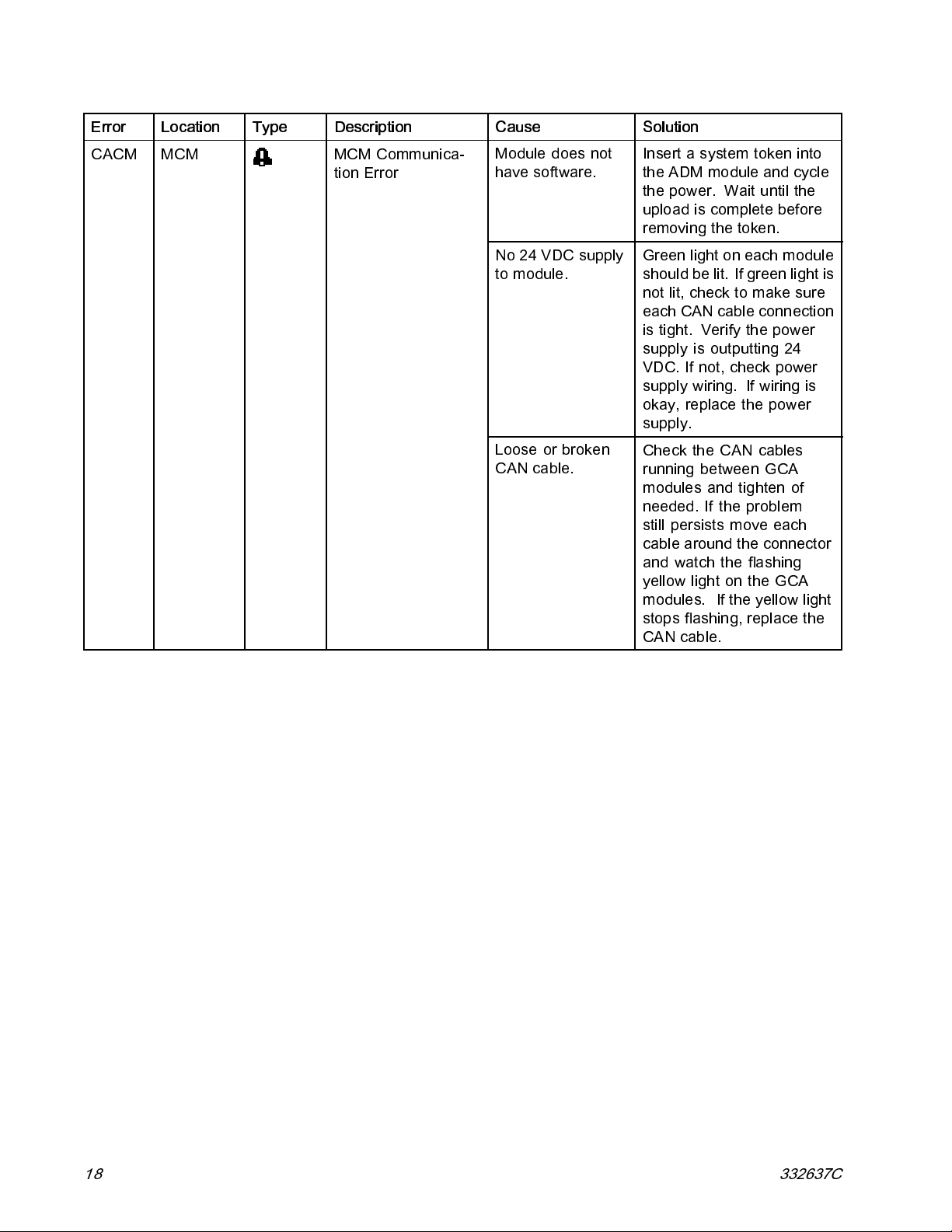

Page 18

Troubleshooting

Error Location Type Description

CACM MCM MCM Communica-

tion Error

Cause Solution

Module does not

have software.

No 24 VDC supply

to module.

Loose or broken

CAN cable.

Insert a system token i n to

the ADM module and cycle

the power. Wait until the

upload is complete before

removing the token.

Greenlightoneachmodule

should be lit. If green light is

notlit,checktomakesure

each CAN cable connection

is tight. Verify the power

supply is outputting 24

VDC. If not, check power

supply wiring. If wiring is

okay, replace the power

supply.

Check the CAN cables

running between GCA

modules and tighten of

needed. If the problem

still persists move each

cablearoundtheconnector

and watch the flashing

yellow light on the GCA

modules. If the yellow light

stops flashing, replace the

CAN cable.

18 332637C

Page 19

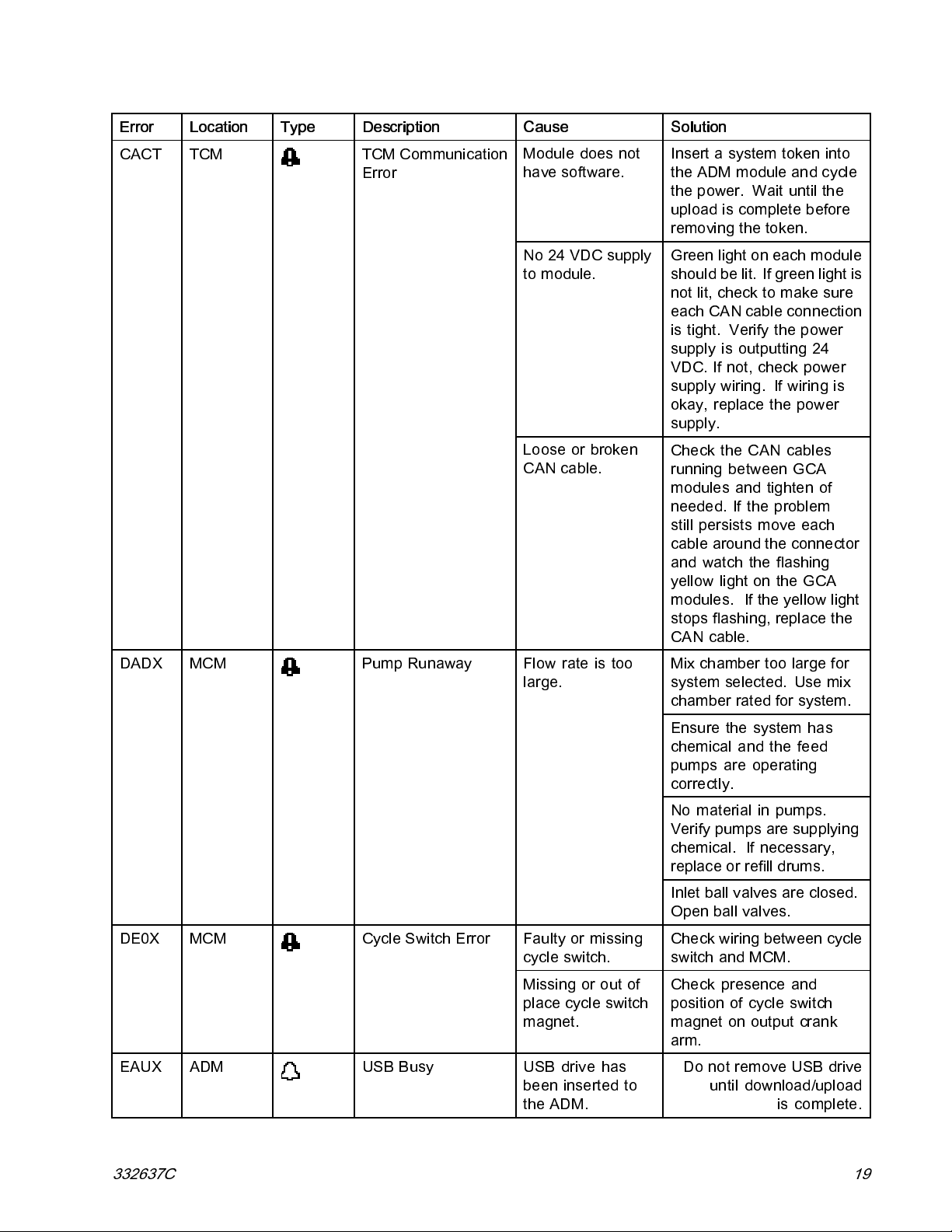

Troubleshooting

Error Location Type Description

CACT TCM TCM Communication

Error

Cause Solution

Module does not

have software.

No 24 VDC supply

to module.

Loose or broken

CAN cable.

Insert a system token into

the ADM module and cycle

the power. Wait until the

upload is complete before

removing the token.

Greenlightoneachmodule

should be lit. If green light is

not lit, check to make sure

each CAN cable connection

is tight. Verify the power

supply is outputting 24

VDC. If not, check powe r

supply wiring. If wiring is

okay, replace the power

supply.

Check the CAN cables

running between GCA

modules and tighten of

needed. If the problem

still persists move each

cablearoundtheconnector

and watch the flashing

yellow light on the GCA

modules. If the yellow light

stops flashing, replace the

CAN cable.

DADX MCM Pump Runaway Flow rate is too

large.

DE0X

EAUX ADM

MCM

Cycle Switch Error

USB Busy USB drive has

Faulty or missing

cycle switch.

Missing or out of

place cycle switch

magnet.

been inserted to

the ADM.

Mix ch am ber too large for

system selected. Use mix

chamber rated for system.

Ensure the system has

chemical and the feed

pumps are operating

correctly.

No material in pumps.

Verify pumps are supplying

chemical. If necessary,

replace or refill drums.

Inlet ball valves are closed.

Open ball valves.

Check wiring between cycle

switch and MCM.

Check presence and

position of cycle switch

magnet on output crank

arm.

Do not remove USB drive

until download/upload

is complete.

332637C 19

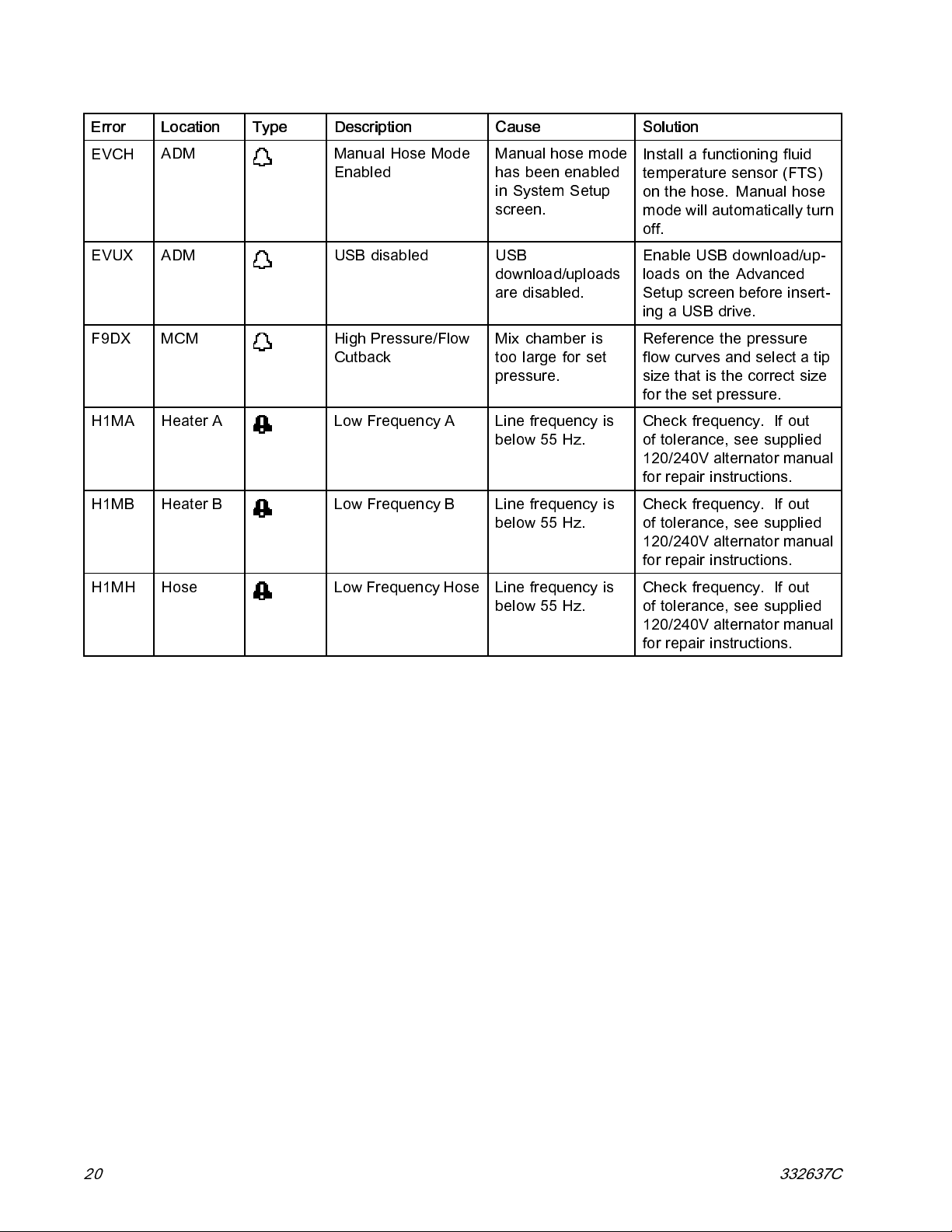

Page 20

Troubleshooting

Error Location Type Description

EVCH

EVUX ADM

F9DX

H1MA Heater A Low Frequency A

H1MB Heater B Low Frequency B Line frequency is

ADM

MCM

Manual Hose Mode

Enabled

USB disabled USB

High Pressure/Flow

Cutback

Cause Solution

Manual hose mode

has been enabled

in System Setup

screen.

download/uploads

are disabled.

Mix chamber is

too large for set

pressure.

Line frequency is

below 55 Hz.

below 55 Hz.

Install a functioning fluid

temperature sensor (FTS)

on the hose. Manu al hose

mode will automatically turn

off.

Enable USB download/up-

loadsontheAdvanced

Setupscreenbeforeinsert-

ing a USB drive.

Reference the pressure

flow curves and select a tip

size that is the correct size

for the set pressure.

Check frequency. If out

of tolerance, see supplied

120/240V alternator manual

for repair instructions.

Check frequency. If out

of tolerance, see supplied

120/240V alternator manual

for repair instructions.

H1MH Hose Low Frequency Hose

Line frequency is

below 55 Hz.

Check frequency. If out

of tolerance, see supplied

120/240V alternator manual

for repair instructions.

20 332637C

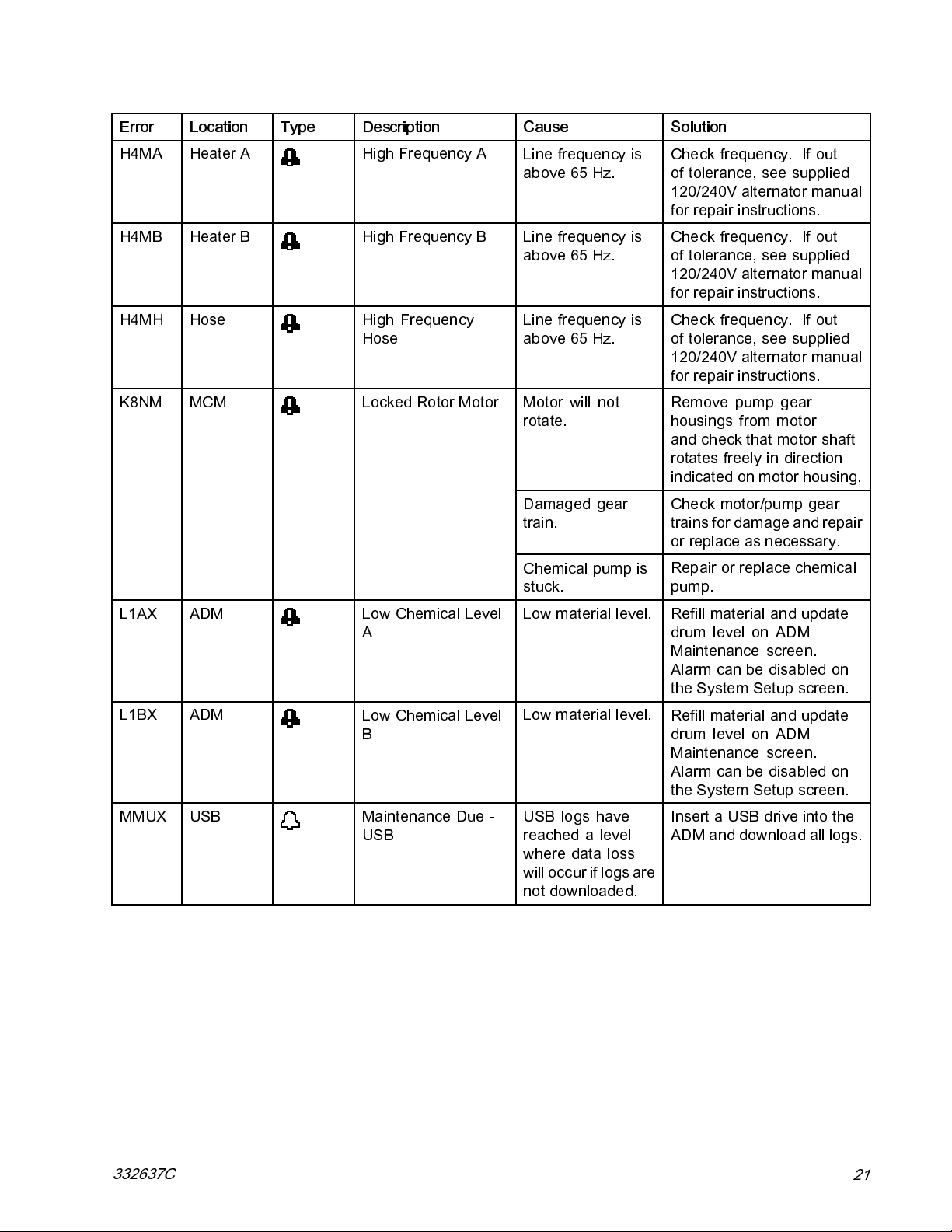

Page 21

Troubleshooting

Error Location Type Description

H4MA Heater A High Frequency A

H4MB Heater B High Frequency B

H4MH Hose High Frequency

Hose

K8NM

MCM

Locked Rotor Motor

Cause Solution

Line frequency is

above65Hz.

Line frequency is

above65Hz.

Line frequency is

above65Hz.

Motor will not

rotate.

Damaged gear

train.

Chemical pump is

stuck.

Check frequency. If out

of tolerance, see supplied

120/240V alternator manual

for repair instructions.

Check frequency. If out

of tolerance, see supplied

120/240V alternator manual

for repair instructions.

Check frequency. If out

of tolerance, see supplied

120/240V alternator manual

for repair instructions.

Remove pump gear

housings from motor

and check that motor shaft

rotates freely in direction

indicated on motor housing.

Check motor/pump gear

trains for damage and repair

or replace as necessary.

Repair or replace chemical

pump.

L1AX ADM

L1BX ADM

MMUX

USB

Low Chemical Level

A

Low Chemical Level

B

Maintenance Due -

USB

Low material level.

Low material level.

USB logs have

reached a level

where data loss

will occur if logs are

not downloaded.

Refill material and update

drum level on ADM

Maintenance screen.

Alarm can be disabled on

the System Setup screen.

Refill material and update

drum level on ADM

Maintenance screen.

Alarm can be disabled on

the System Setup screen.

InsertaUSBdriveintothe

ADM and download all logs.

332637C

21

Page 22

Troubleshooting

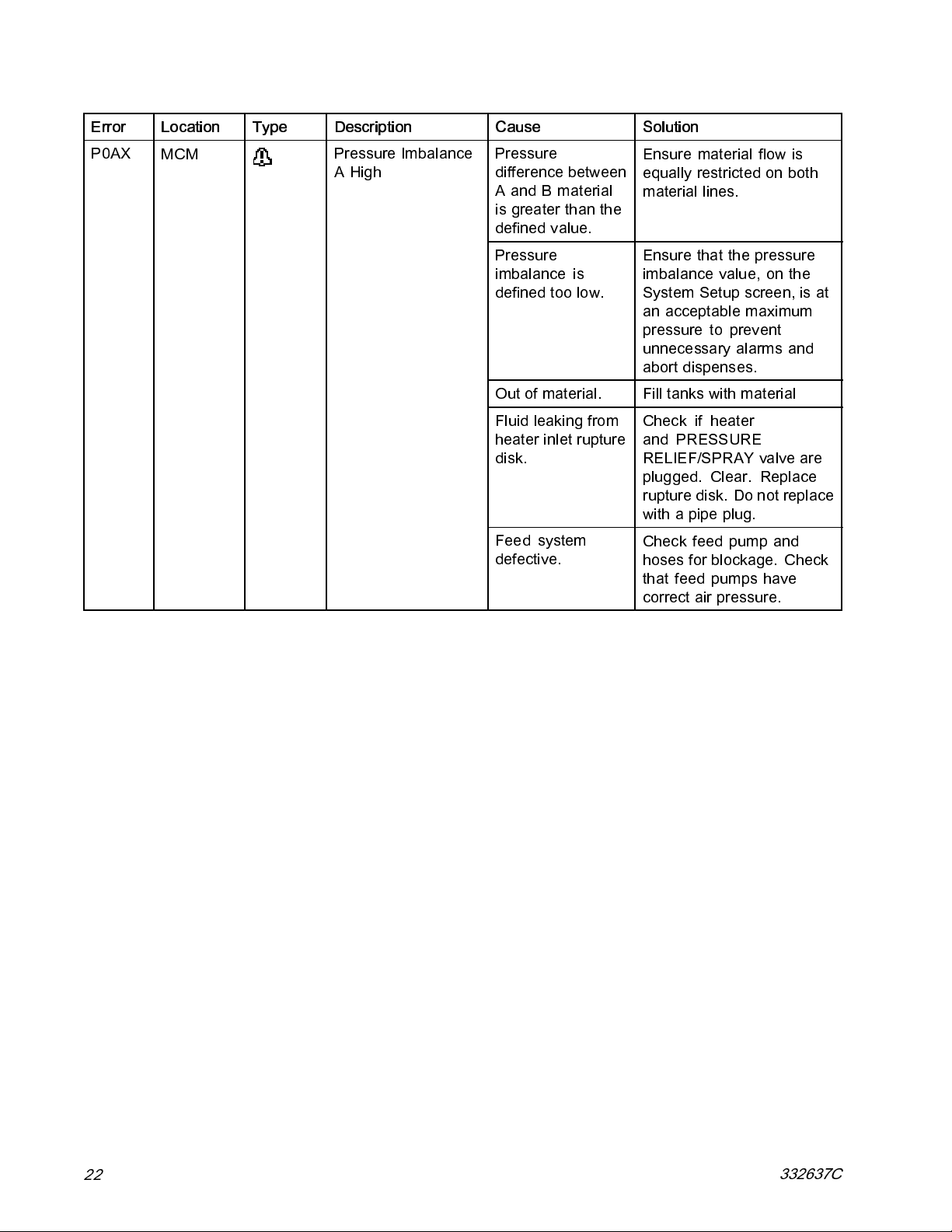

Error Location Type Description

P0AX

MCM

Pressure Imbalance

AHigh

Cause Solution

Pressure

difference between

AandBmaterial

is greater than the

defined value.

Pressure

imbalance is

defined too low.

Out of material. Fill tanks with material

Fluid leaking from

heater inlet ruptu re

disk.

Feed system

defective.

Ensure material flow is

equally restricted on both

material lines.

Ensure that the pressure

imbalance value, on the

System Setup screen, is at

an acceptable maximum

pressure to prevent

unnecessary alarms and

abort dispenses.

Check if he ate r

and PRESSURE

RELIEF/SPRAY valve are

plugged. Clear. Replace

rupture disk. Do not replace

withapipeplug.

Check feed pump and

hoses for blockage. Check

that feed pumps hav e

correct air pressure.

22

332637C

Page 23

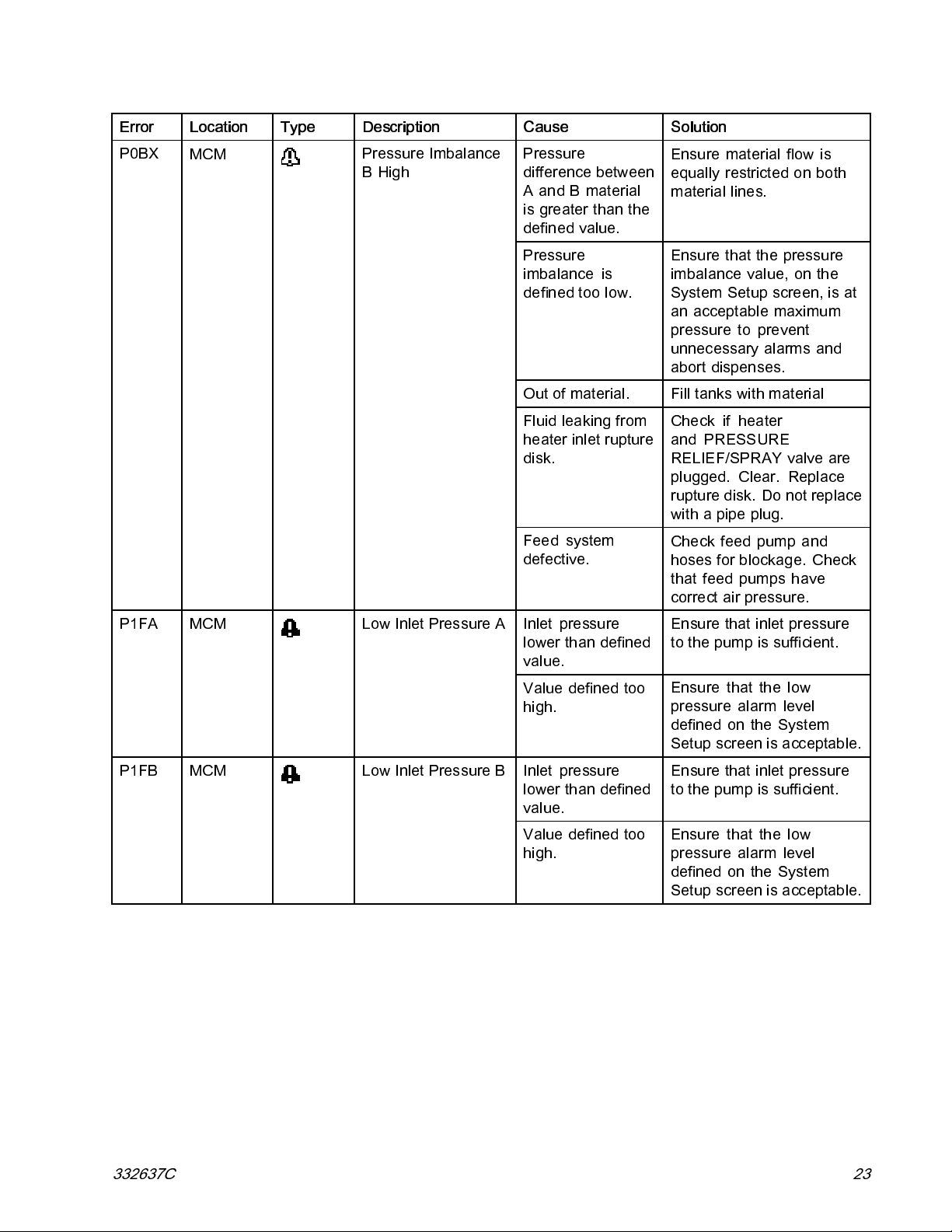

Troubleshooting

Error Location Type Description

P0BX

MCM

Pressure Imbalance

BHigh

Cause Solution

Pressure

difference between

AandBmaterial

is greater than the

defined value.

Pressure

imbalance is

defined too low.

Out of material. Fill tanks with material

Fluid leaking from

heater inlet rupture

disk.

Feed system

defective.

Ensure material flow is

equally restricted on both

material lines.

Ensure that the pressure

imbalance value, on the

System Setup screen, is at

an acceptable maximum

pressure to prevent

unnecessary alarms and

abort dispenses.

Check if heater

and PRESSURE

RELIEF/SPRAY valve are

plugged. Clear. Replace

rupture disk. Do not replace

withapipeplug.

Checkfeedpumpand

hoses for blockage. Check

that feed pumps have

correct air pressure.

P1FA

P1FB

MCM

MCM

Low Inlet Pressure A

Low Inlet Pressure B

Inlet pressure

lower than defined

value.

Value defined too

high.

Inlet pressure

lower than defined

value.

Value defined too

high.

Ensure that inlet pressure

to the pump i s sufficient.

Ensure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

Ensure that inlet pressure

to the pump i s sufficient.

Ensure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

332637C 23

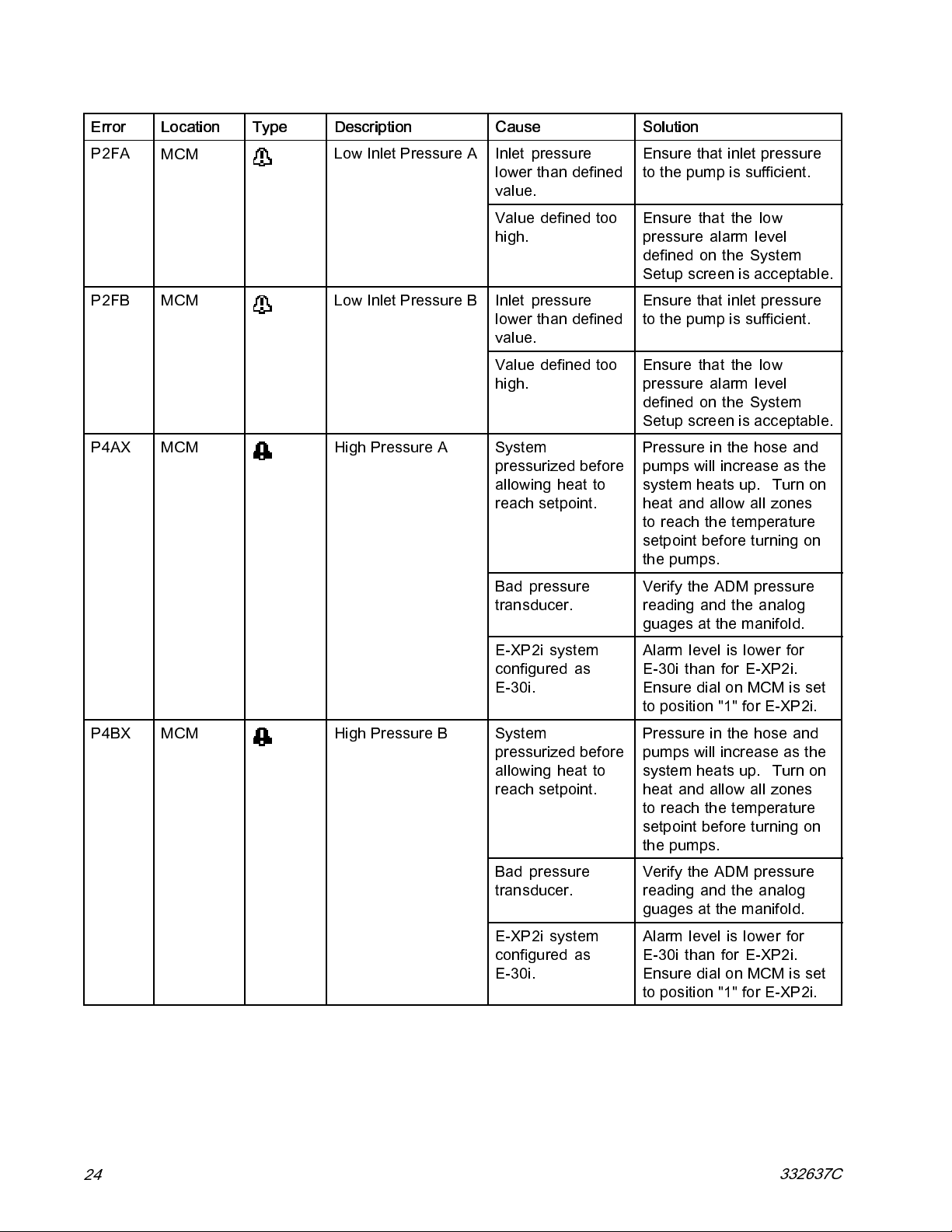

Page 24

Troubleshooting

Error Location Type Description

P2FA

P2FB MCM Low Inlet Pressure B

P4AX

MCM

MCM

Low Inlet Pressure A

High Pressure A

Cause Solution

Inlet pressure

lower than defined

value.

Value defined too

high.

Inlet pressure

lower than defined

value.

Value defined too

high.

System

pressurized before

allowing heat to

reach setpoint.

Ensure that inlet pressure

to the pump is sufficient.

Ensure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

Ensure that inlet pressure

to the pump is sufficient.

Ensure that the low

pressure alarm level

defined on the System

Setup screen is acceptable.

Pressureinthehoseand

pumps wil l increase as the

system h eats up. Turn on

heat and allow all zones

to reach the temperature

setpoint before turning on

the pump s.

P4BX

MCM

High Pressure B

Bad pressure

transducer.

E-XP2i system

configured as

E-30i.

System

pressurized before

allowing heat to

reach setpoint.

Bad pressure

transducer.

E-XP2i system

configured as

E-30i.

Verify the ADM pressure

readingandtheanalog

guages at th e manifold.

Alarm level is lower for

E-30i than for E-XP2i.

Ensure dial on MCM is set

to position "1" for E-XP2i.

Pressureinthehoseand

pumps wil l increase as the

system h eats up. Turn on

heat and allow all zones

to reach the temperature

setpoint before turning on

the pump s.

Verify the ADM pressure

readingandtheanalog

guages at th e manifold.

Alarm level is lower for

E-30i than for E-XP2i.

Ensure dial on MCM is set

to position "1" for E-XP2i.

24

332637C

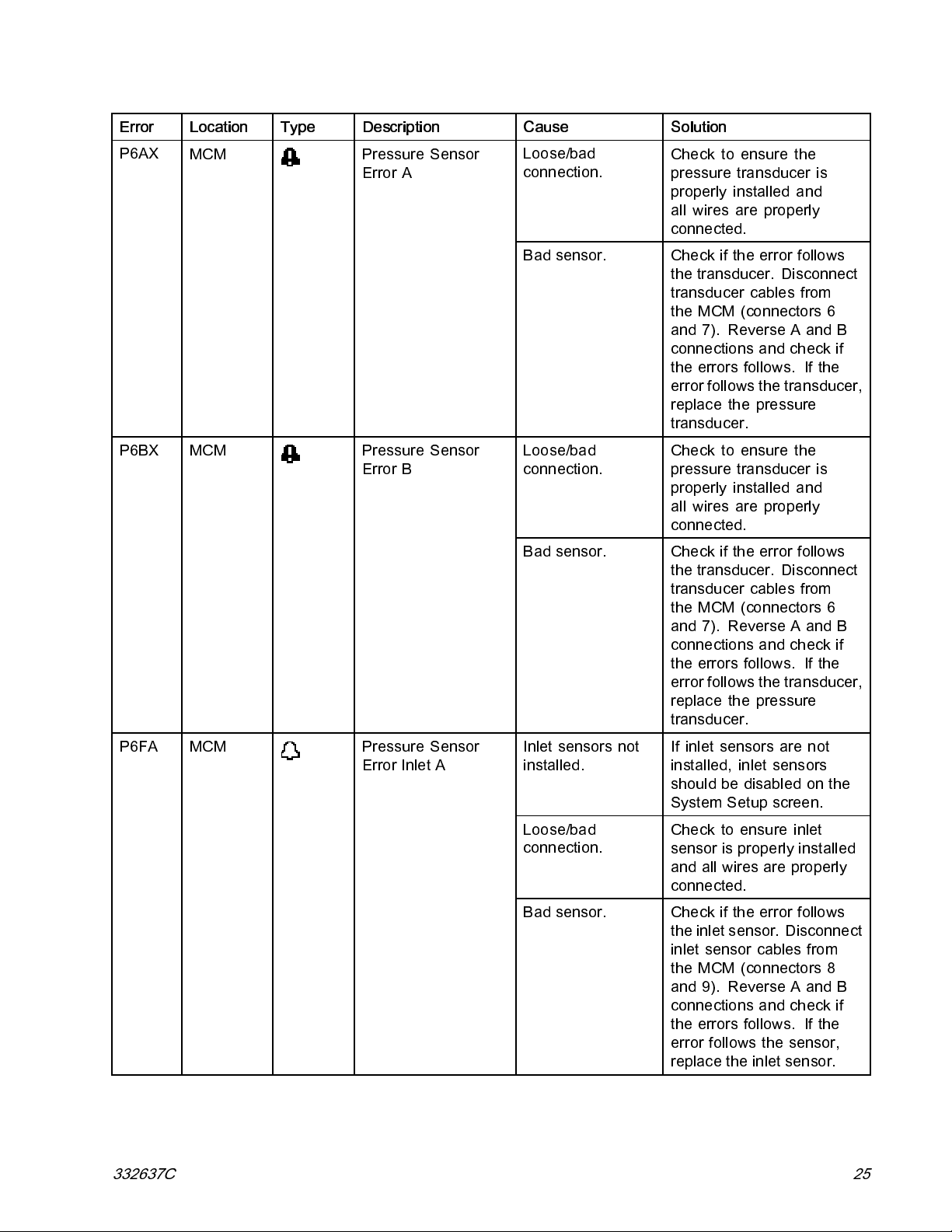

Page 25

Troubleshooting

Error Location Type Description

P6AX

P6BX

MCM

MCM

Pressure Sensor

Error A

Pressure Sensor

Error B

Cause Solution

Loose/bad

connection.

Bad sensor.

Loose/bad

connection.

Bad sensor.

Check to ensure the

pressure transducer is

properly installed and

all wires are properly

connected.

Check if the error follows

the transducer. Disconnect

transducer cables from

the MCM (connectors 6

and7). ReverseAandB

connections and check if

the errors follows. If the

error follows the trans du ce r,

replace the pressure

transducer.

Check to ensure the

pressure transducer is

properly installed and

all wires are properly

connected.

Check if the error follows

the transducer. Disconnect

transducer cables from

the MCM (connectors 6

and7). ReverseAandB

connections and check if

the errors follows. If the

error follows the trans du ce r,

replace the pressure

transducer.

P6FA MCM Pressure Sensor

Error Inlet A

332637C 25

Inlet sensors not

installed.

Loose/bad

connection.

Bad sensor.

If inlet sensors are not

installed, inlet sensors

should be disabled on the

System Setup screen.

Checktoensureinlet

sensor is properly installed

and all wires are properly

connected.

Check if the error follows

the inlet sensor. Disconnect

inlet sensor cables from

the MCM (connectors 8

and9). ReverseAandB

connections and check if

the errors follows. If the

error follows the sensor,

replace the inlet sensor.

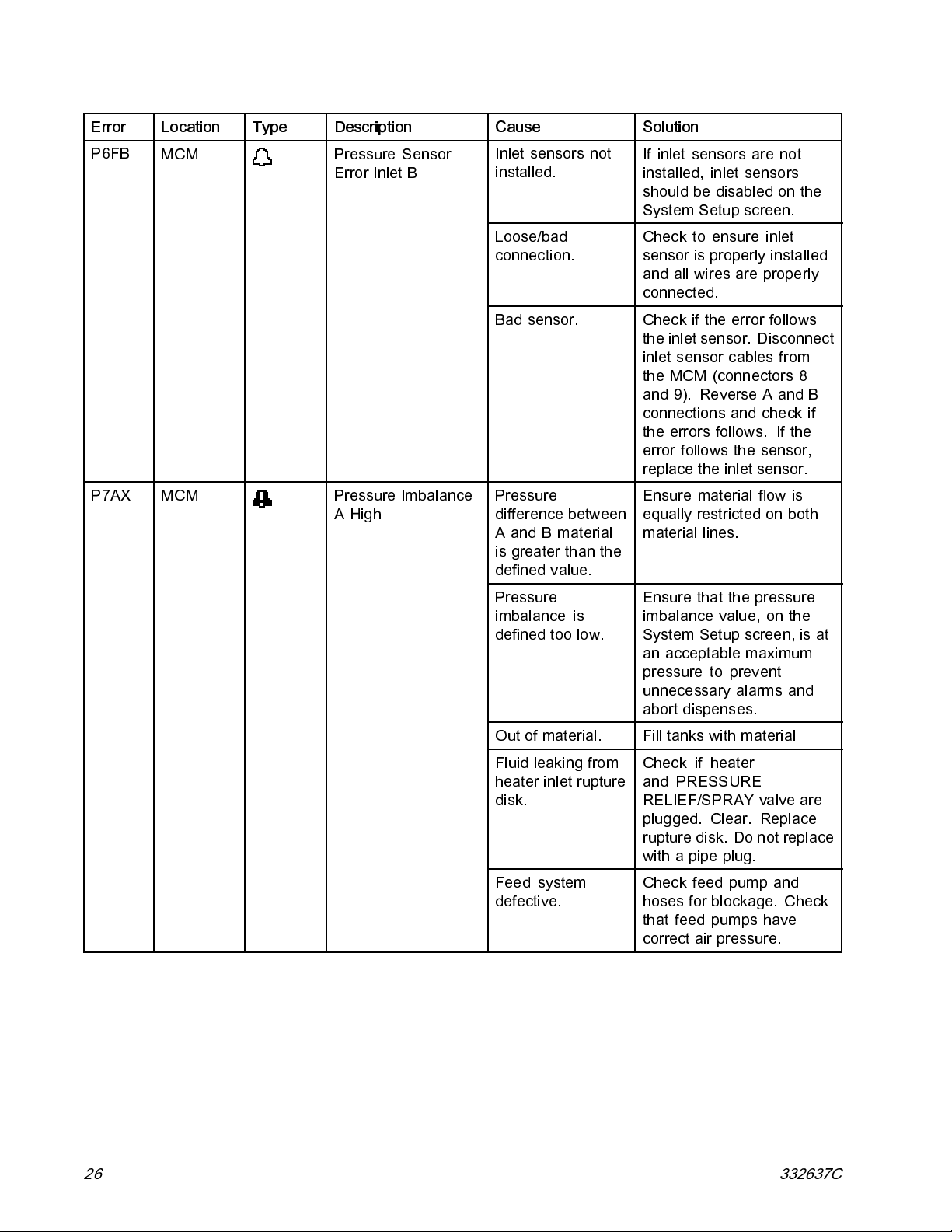

Page 26

Troubleshooting

Error Location Type Description

P6FB

P7AX

MCM

MCM

Pressure Sensor

Error Inlet B

Pressure Imbalance

AHigh

Cause Solution

Inlet sensors not

installed.

Loose/bad

connection.

Bad sensor.

Pressure

difference between

AandBmaterial

is greater than the

defined value.

If inlet sensors are not

installed, inlet sensors

should be disabled on the

System Setup screen.

Check to ens ure i nl et

sensor is properly installed

and all wires are properly

connected.

Check if the error follows

the inlet sensor. Disconnect

inlet sensor cables from

the MCM (connectors 8

and9). ReverseAandB

connections and check if

the errors follo ws . If the

error follows the sensor,

replace the inlet sensor.

Ensure material flow is

equally restricted on both

material lines.

Pressure

imbalance is

defined too low.

Out of material.

Fluid leaking from

heater inlet ruptu re

disk.

Feed system

defective.

Ensure that the pressure

imbalance value, on the

System Setup screen, is at

an acceptable maximum

pressure to prevent

unnecessary alarms and

abort dispenses.

Fill tanks with material

Check if he ate r

and PRESSURE

RELIEF/SPRAY valve are

plugged. Clear. Replace

rupture disk. Do not replace

withapipeplug.

Check feed pump and

hoses for blockage. Check

that feed pumps hav e

correct air pressure.

26 332637C

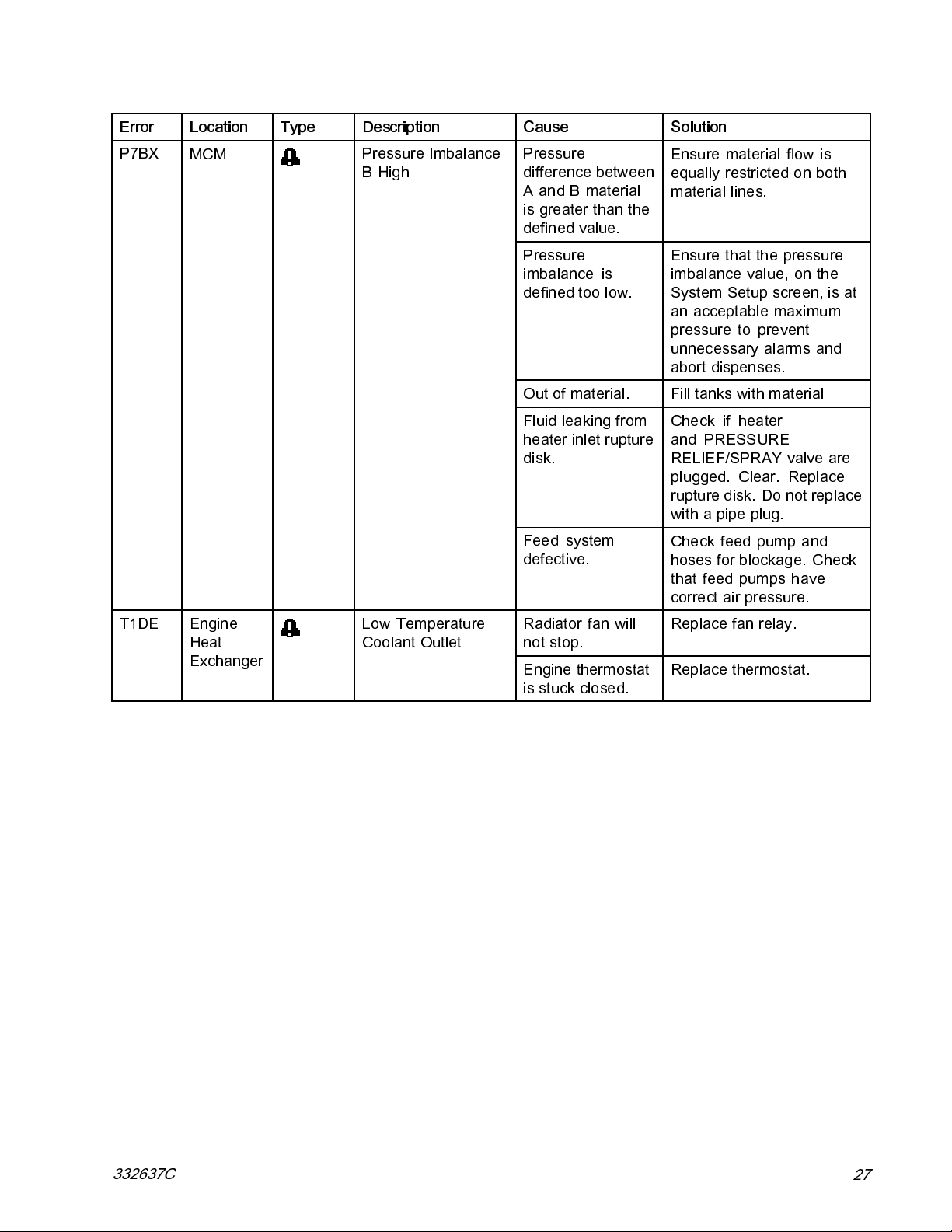

Page 27

Troubleshooting

Error Location Type Description

P7BX

MCM

Pressure Imbalance

BHigh

Cause Solution

Pressure

difference between

AandBmaterial

is greater than the

defined value.

Pressure

imbalance is

defined too low.

Out of material. Fill tanks with material

Fluid leaking from

heater inlet rupture

disk.

Feed system

defective.

Ensure material flow is

equally restricted on both

material lines.

Ensure that the pressure

imbalance value, on the

System Setup screen, is at

an acceptable maximum

pressure to prevent

unnecessary alarms and

abort dispenses.

Check if heater

and PRESSURE

RELIEF/SPRAY valve are

plugged. Clear. Replace

rupture disk. Do not replace

withapipeplug.

Checkfeedpumpand

hoses for blockage. Check

that feed pumps have

correct air pressure.

T1DE Engine

Heat

Exchanger

Low Temperature

Coolant Outlet

Radiator fan will

not stop.

Engine thermostat

is stuck closed.

Replace fan relay.

Replace thermostat.

332637C

27

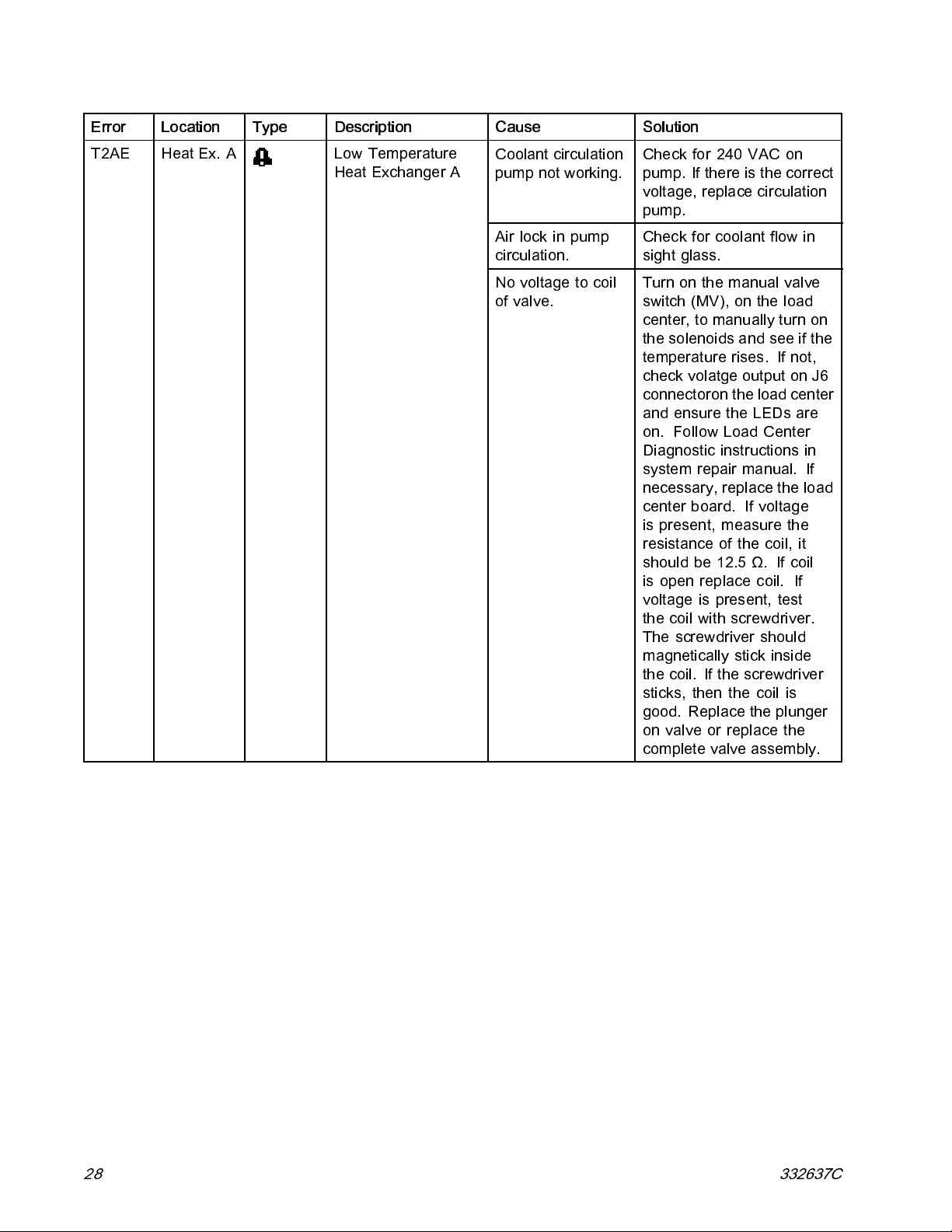

Page 28

Troubleshooting

Error Location Type Description

T2AE Heat Ex. A Low Temperature

Heat Exchanger A

Cause Solution

Coolant circulation

pump not working.

Air lock in pump

circulation.

Novoltagetocoil

of valve.

Check for 240 VAC on

pump. If there is the correct

voltage, replace circulation

pump.

Check for coolan t flow in

sight glass.

Turn on the manual valve

switch(MV),ontheload

center, to manually turn on

the solenoids and see if the

temperature rises. If not,

check volatge output on J6

connectorontheloadcenter

andensuretheLEDs are

on. Follow Load Center

Diagnostic instructions in

system repair manual. If

necessary, replace the load

center board. If voltage

is present, measure the

resistance of the coil, it

should be 12.5 Ω. If coil

is open replace coil. If

voltage is present, test

the coil with screwdriver.

The screwdriver should

magnetically stick inside

the coil . If the screwdriver

sticks, then the coil is

good. Replace the plunger

on valve or replace the

complete valve assembly.

28 332637C

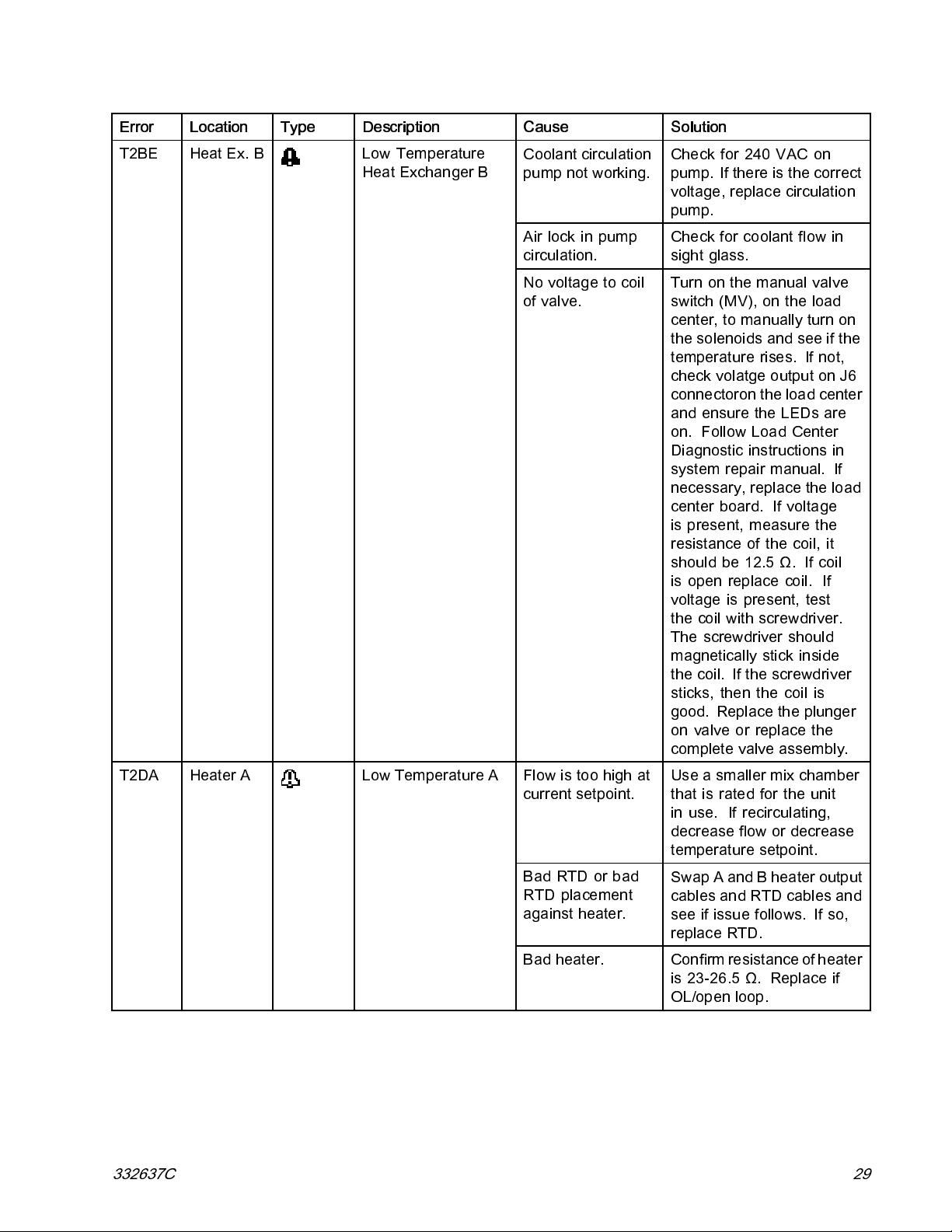

Page 29

Troubleshooting

Error Location Type Description

T2BE Heat Ex. B Low Temperature

Heat Exchanger B

Cause Solution

Coolant circulation

pump not working.

Air lock in pump

circulation.

Novoltagetocoil

of valve.

Check for 240 VAC on

pump. If there is the correct

voltage, replace circulation

pump.

Check for coolant flow in

sight glass.

Turn on the manual valve

switch (MV), on the load

center, to manually turn on

the solenoids and see if the

temperature rises. If not,

check volatge output on J6

connectorontheloadcenter

and ensure the LEDs are

on. Follow Load Center

Diagnostic instructions in

system repair manual. If

necessary, replace the load

center board. If voltage

is present, measure the

resistance of the coil, it

should be 12.5 Ω. If coil

is open replace coil. If

voltage is present, test

the coil with screwdriver.

The screwdriver should

magnetically stick inside

the coil. If the screwdriver

sticks, then the coil is

good. Rep lac e the plunger

on valve or replace the

complete valve assembly.

T2DA Heater A Low Temperature A

332637C 29

Flow is too high at

current setpoint.

Bad RTD or bad

RTD placement

against heater.

Bad heater.

Use a smaller mix chamber

that is rated for the unit

in use. If recirculating,

decrease flow or decrease

temperature setpoint.

Swap A and B heater output

cables and RTD cables and

see if issue follows. If so,

replace RTD.

Confirmresistance of heater

is 23-26.5 Ω. Repl ace if

OL/open loop.

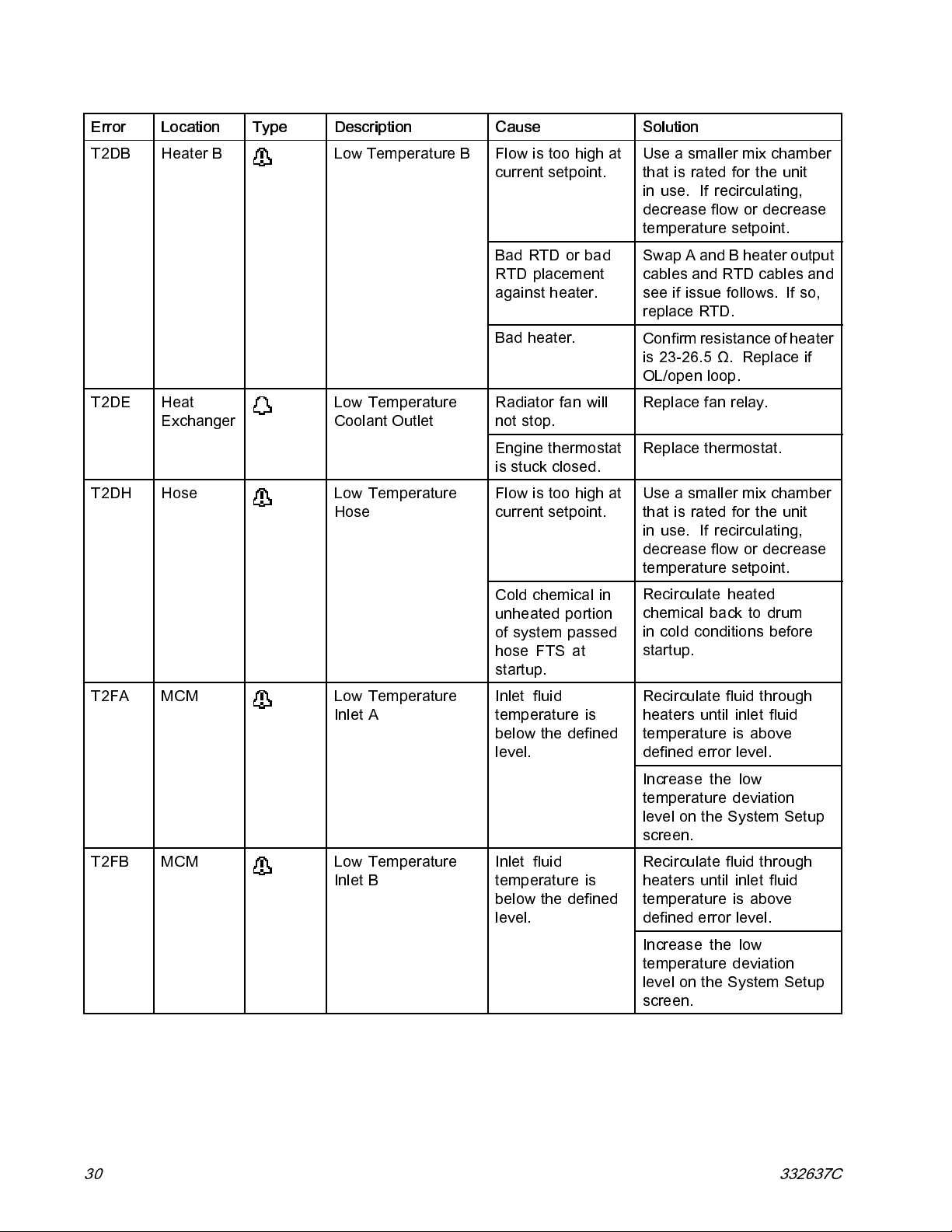

Page 30

Troubleshooting

Error Location Type Description

T2DB Heater B Low Temperature B

Low Temperature

Exchanger

T2DH Hose Low Temperature

Coolant Outlet

Hose

Cause Solution

Flow is too high at

current setpoint.

Bad RTD or bad

RTD placement

against heat er.

Bad heater.

Radiator fan will

not stop.

Engine thermostat

is stuck closed.

Flow is too high at

current setpoint.

Use a smaller mix chamber

that is rated fo r the unit

in use. If recirculating,

decrease flow or decrease

temperature setpoint.

Swap A an d B heater o utpu t

cables and RTD cables and

see if issue follows. If so,

replace RTD.

Confirmresistance of heater

is 23-26.5 Ω. Replace if

OL/open loop.

Replace fan relay.T2DE Heat

Replace thermostat.

Use a smaller mix chamber

that is rated fo r the unit

in use. If recirculating,

decrease flow or decrease

temperature setpoint.

T2FA MCM Low Temperature

Inlet A

T2FB

MCM

Low Temperature

Inlet B

Cold chemical in

unheated portion

of system passed

hose FTS a t

startup.

Inlet fluid

temperature is

below the defined

level.

Inlet fluid

temperature is

below the defined

level.

Recirculate heated

chemical back to drum

in cold conditions before

startup.

Recirculate fluid through

heaters until inlet fluid

temperature is above

defined error level.

Increase the low

temperature deviation

level on the System Setup

screen.

Recirculate fluid through

heaters until inlet fluid

temperature is above

defined error level.

Increase the low

temperature deviation

level on the System Setup

screen.

30 332637C

Page 31

Troubleshooting

Error Location Type Description

T3CH

T3CT TCM TCM Cutback

Hose

Hose Cutback

Cause Solution

Hose current has

been reduced

because hose

has been drawing

current for an

extended period.

High ambient

temperature.

Enclosure fan not

operating.

Module fan not

operating.

Hose setpoint higher than A

and B setpoints. Decrease

hose setpoint.

Hose FTS is in a colder

environment than the rest

of the hose. Expose FTS to

the same environment as

therestofthehose.

Ensure ambient

temperature is below

120°F(48°C) before using

the system.

Ensurefaninelectrical

enclosure is spinning. If it

is not, check fan wiring or

replace fan.

If a TCM fan error (WMI0)

has occurred, fan inside

themoduleisnotworking

properly. Check TCM fan

for debris and clear with

forced air if necessary.

T3NM

T4AE Heat Ex. A High Temperature

MCM

MCM Cutback

Heat Exchanger A

Motor is operating

outside of the

pressure flow

curve.

Manual valve

switch (MV) on

load center is in the

ON position.

A or B side control

valve solenoid is

stuck in the open

position.

Short on load

center board.

The system is running at a

lower setpoint to preserve

motor life. Run the system

at a lower duty cycle or with

a smaller mix chamber.

Open cabinet cover and

turn switch to the OFF

position.

Debris in valve diaphragm

or plunger preventing

spring-loaded closed

function. Disconnect

connector from valve

solenoid cable. If

temperature does not

decrease, rebuild solenoid.

IftheblueandredLEDsare

on while heat is off, the load

center board is bad. See

Load Center Diagnostics in

the system repair manual.

332637C 31

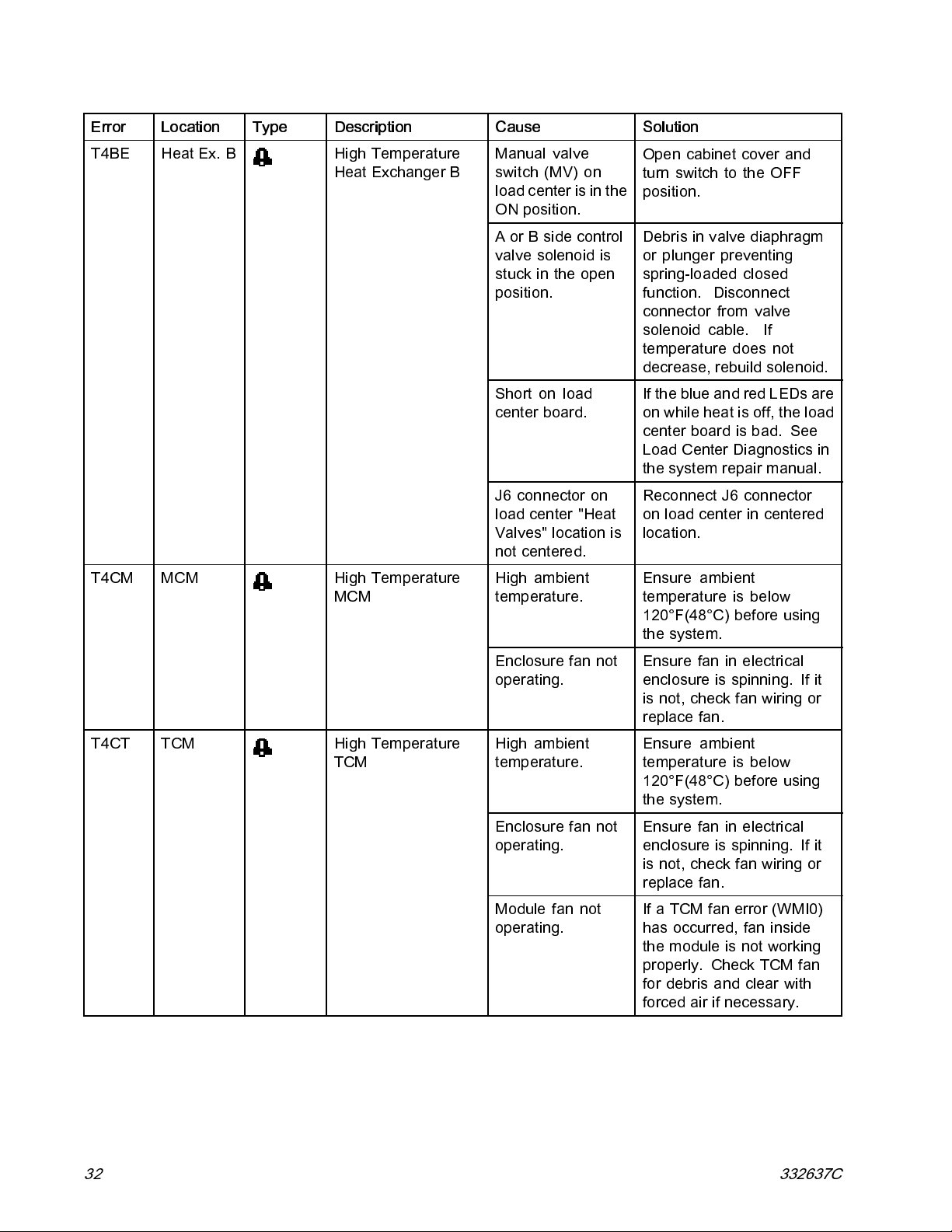

Page 32

Troubleshooting

Error Location Type Description

T4BE Heat Ex. B High Temperature

Heat Exchanger B

Cause Solution

Manual valve

switch (MV) on

load center is in the

ON position.

A or B side control

valvesolenoidis

stuckintheopen

position.

Short on load

center board.

J6 connector on

load center "Heat

Valves" location is

not centered.

Open cabinet cover and

turn switch to the OFF

position.

Debris in valve diaphragm

or plunger preventing

spring-loaded closed

function. Disconnect

connector from valve

solenoid cable. If

temperature does not

decrease, rebuild solenoid.

If the blue and red LEDs are

on while heat is off, the load

center board is bad. See

Load Center Diagnostics in

the system repa ir manual.

Reconnect J6 connector

on load center in centered

location.

T4CM MCM

T4CT TCM High Temperature

High Temperature

MCM

TCM

High ambient

temperature.

Enclosure fan not

operating.

High ambient

temperature.

Enclosure fan not

operating.

Module fan not

operating.

Ensure ambient

temperature is below

120°F(48°C) before using

the sy ste m.

Ensure fan in electrical

enclosure is spinning. If it

is not, check fan wiring or

replace fan.

Ensure ambient

temperature is below

120°F(48°C) before using

the sy ste m.

Ensure fan in electrical

enclosure is spinning. If it

is not, check fan wiring or

replace fan.

If a TCM fan error (WMI0)

has occurred, fan inside

the mod ule is not working

properly. Check TCM fan

for debris and clear with

forced air if necessary.

32 332637C

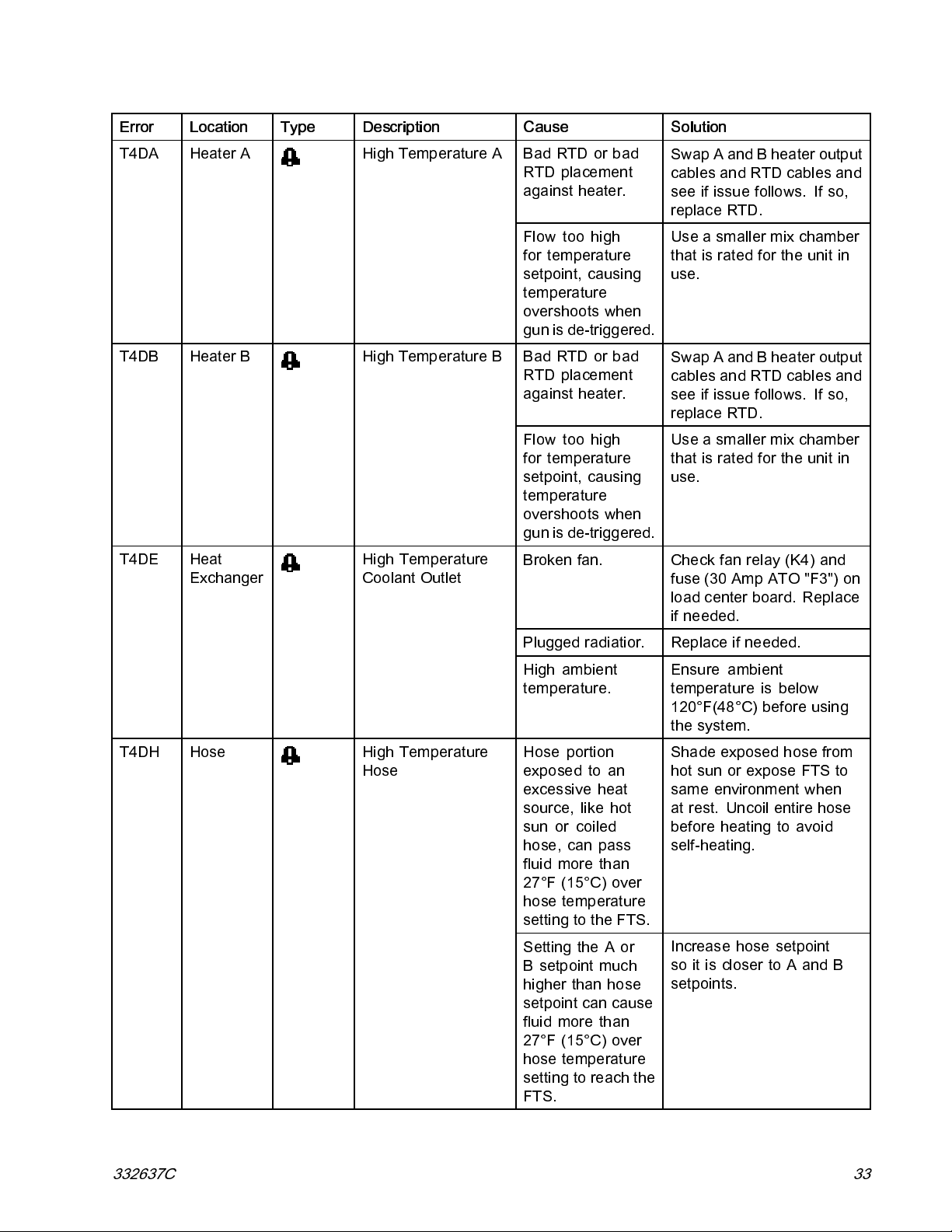

Page 33

Troubleshooting

Error Location Type Description

T4DA Heater A High Temperature A

T4DB Heater B High Temperature B

T4DE Heat

Exchanger

High Temperature

Coolant Outlet

Cause Solution

Bad RTD or bad

RTD placement

against heater.

Flow too high

for temperature

setpoint, causing

temperature

overshoots when

gun is de-triggered.

Bad RTD or bad

RTD placement

against heater.

Flow too high

for temperature

setpoint, causing

temperature

overshoots when

gun is de-triggered.

Broken fan. Check fan relay (K4) and

Swap A and B heater output

cables and RTD cables and

see if issue follows. If so,

replace RTD.

Use a smaller mix chamber

that is rated for the unit in

use.

Swap A and B heater output

cables and RTD cables and

see if issue follows. If so,

replace RTD.

Use a smaller mix chamber

that is rated for the unit in

use.

fuse (30 Amp ATO "F3") on

load center board. Replace

if needed.

T4DH Hose High Temperature

Hose

Plugged radiatior.

High ambient

temperature.

Hose portion

exposed to an

excessive heat

source, like hot

sun or coiled

hose, can pass

fluid more than

27°F (15°C) over

hose temperature

setting to the FTS.

Setting the A or

B setpoint much

higher than hos e

setpoint can cause

fluid more than

27°F (15°C) over

hose temperature

setting to reach the

FTS.

Replace if needed.

Ensure ambient

temperature is below

120°F(48°C) before using

the system.

Shade expo se d hose from

hot sun or expose FTS to

same environment when

at rest. Uncoil entire hose

before heating to avoid

self-heating.

Increase hose setpoint

so it is closer to A and B

setpoints.

332637C 33

Page 34

Troubleshooting

Error Location Type Description

T4EA Heater A High Temperature

Switch A

T4EB Heater B High Temperature

Switch B

Cause Solution

Overtemperature

switch sensed a

fluid temperature

above 230°F

(110°C).

Broken or loose

overtemperature

switch

cable/connection.

Overtemperature

switch failed in the

open position.

Overtemperature

switch sensed a

fluid temperature

above 230°F

(110°C).

Heater was delivered too

much power, causing the

overtemperature switch to

open. RTD is not reading

properly. After the heater

cools down, replace RTD.

Switch closes and the error

canbeclearedwhenthe

heater temperature falls

below 190°F (87°C).

If heater is not actually

over temperature, check

all wiring and connections

between the TCM and the

overtemperature switches.

Replace overtemperature

switch.

Heater was delivered too

much power, causing the

overtemperature switch to

open. RTD is not reading

properly. After the heater

cools down, replace RTD.

Switch closes and the error

canbeclearedwhenthe

heater temperature falls

below 190°F (87°C).

Broken or loose

overtemperature

switch

cable/connection.

Overtemperature

switch failed in the

open position.

If heater is not actually

over temperature, check

all wiring and connections

between the TCM and the

overtemperature switches.

Replace overtemperature

switch.

34 332637C

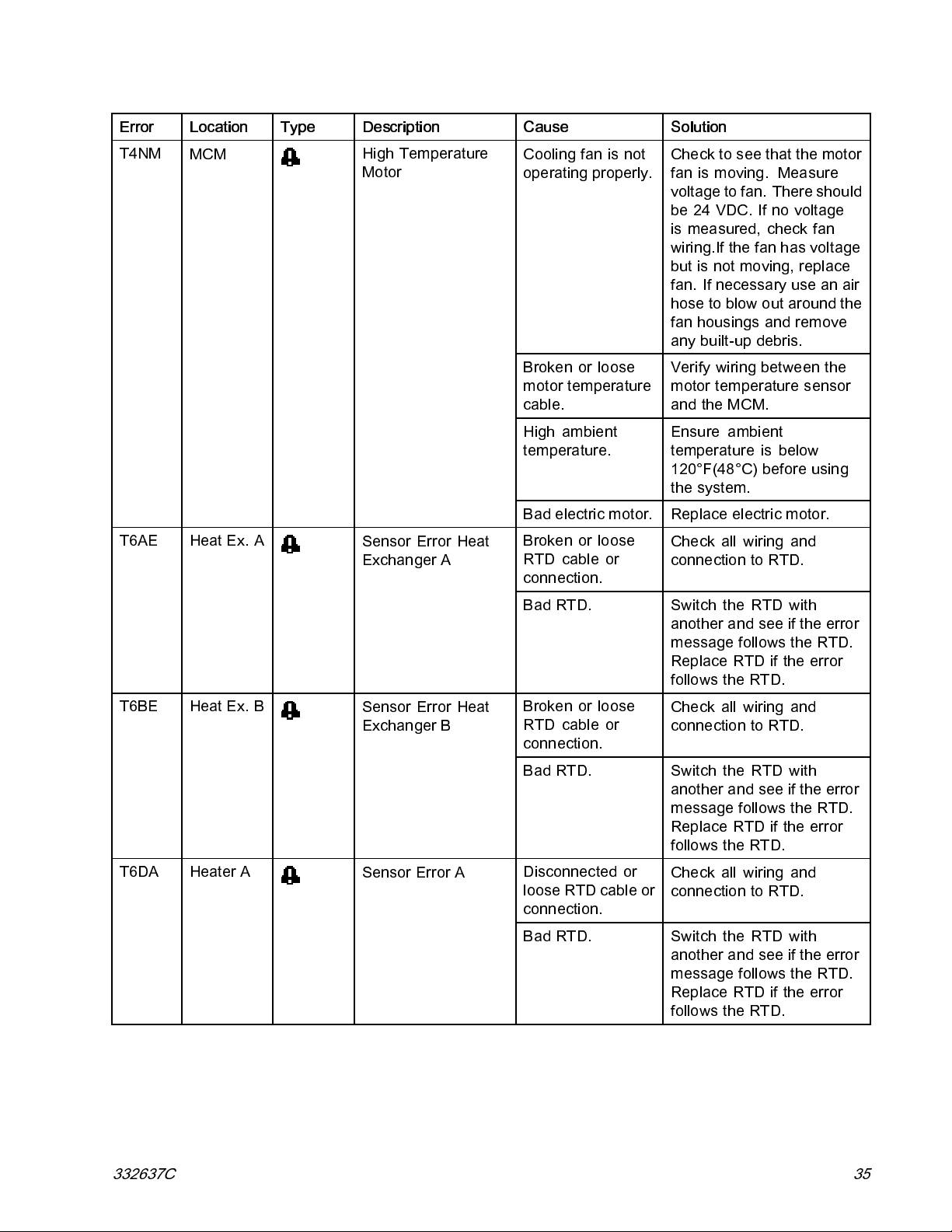

Page 35

Troubleshooting

Error Location Type Description

T4NM

T6AE Heat Ex. A

MCM

High Temperature

Motor

Sensor Error Heat

Exchanger A

Cause Solution

Cooling fan is not

operating properly.

Broken or loose

motor temperature

cable.

High ambient

temperature.

Bad electric motor. Replace electric motor.

Broken or loose

RTD cable or

connection.

Check to see that the motor

fan is moving. Measure

voltagetofan.Thereshould

be 24 VDC. If no voltage

is measured, check fan

wiring.If the fan has voltage

but is not moving, replace

fan. If necessary use an air

hose to blow out around the

fan hous i ngs and re mov e

any built-up debris.

Verify wiring between the

motor temperature sensor

andtheMCM.

Ensure ambient

temperature is below

120°F(48°C) before using

the system.

Check all wiring and

connection to RTD.

T6BE Heat Ex. B

T6DA Heater A

Sensor Error Heat

Exchanger B

Sensor Error A

Bad RTD.

Broken or loose

RTD cable or

connection.

Bad RTD.

Disconnected or

loose RTD cable or

connection.

Bad RTD.

Switch the RTD with

another and see if the error

messagefollowstheRTD.

Replace RTD if the error

follows the RTD.

Check all wiring and

connection to RTD.

Switch the RTD with

another and see if the error

messagefollowstheRTD.

Replace RTD if the error

follows the RTD.

Check all wiring and

connection to RTD.

Switch the RTD with

another and see if the error

messagefollowstheRTD.

Replace RTD if the error

follows the RTD.

332637C 35

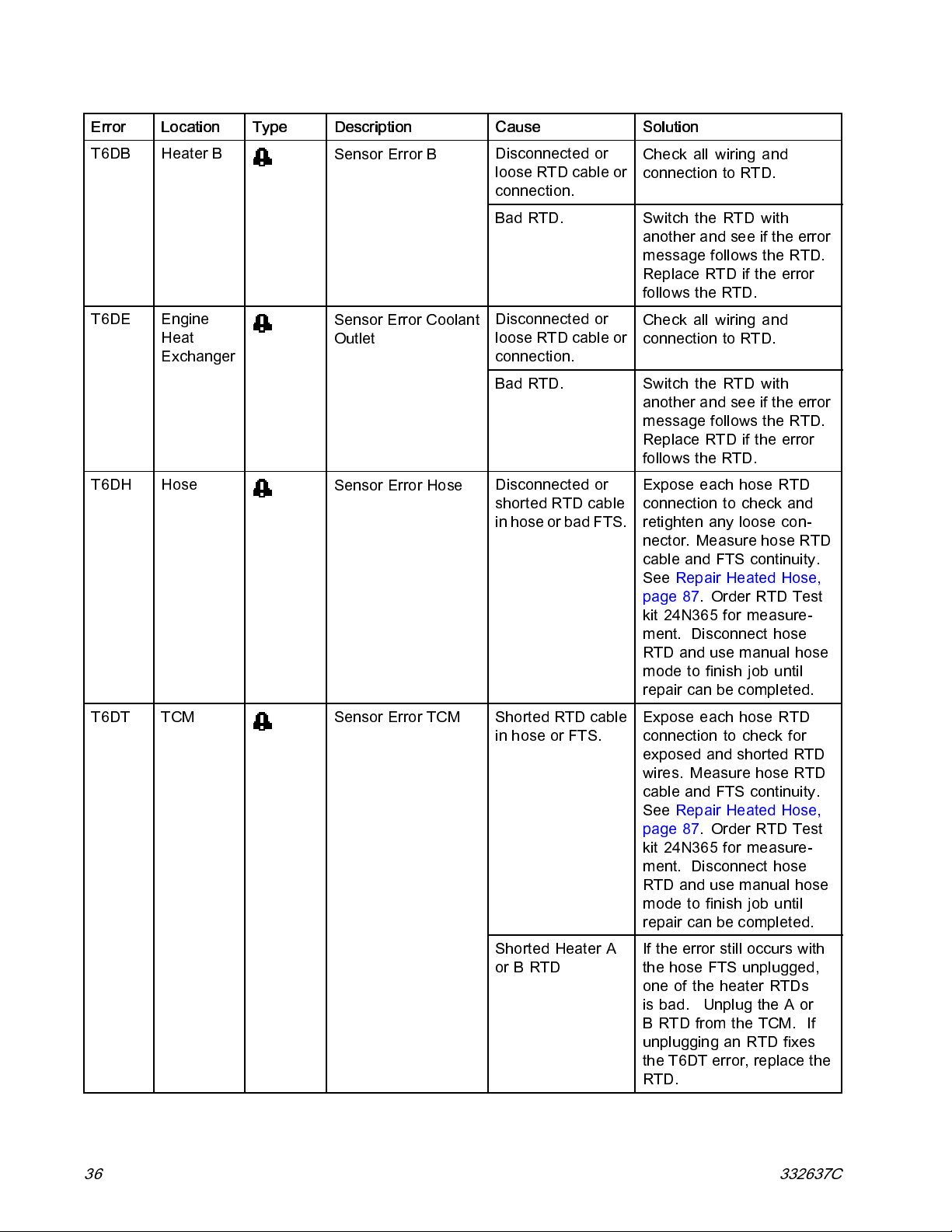

Page 36

Troubleshooting

Error Location Type Description

T6DB Heater B

T6DE Engine

Heat

Exchanger

T6DH Hose

Sensor Error B

Sensor Error Coolant

Outlet

Sensor Error Hose

Cause Solution

Disconnected or

loose RTD cable or

connection.

Bad RTD.

Disconnected or

loose RTD cable or

connection.

Bad RTD.

Disconnected or

shorted RTD cable

in hose or bad FTS .

Check all wiring and

connection to RTD.

Switch the RTD with

another and see if the error

messagefollowstheRTD.

ReplaceRTDiftheerror

follows th e RTD.

Check all wiring and

connection to RTD.

Switch the RTD with

another and see if the error

messagefollowstheRTD.

ReplaceRTDiftheerror

follows th e RTD.

Expose each hose RTD

connection to check and

retighten any loose c on-

nector. Measure hose RTD

cable and FTS continuity.

See Repair Heated Hose,

page 87.OrderRTDTest

kit 24N365 for measure-

ment. Di sconnect hose

RTD and use manual hose

mode to finish job until

repaircanbecompleted.

T6DT

TCM

Sensor Error TCM

Shorted RTD cable

in hose or FTS.

Shorted Heater A

or B RTD

Expose each hose RTD

connection to check for

exposed and shorted RTD

wires. Measure hose RTD

cable and FTS continuity.

See Repair Heated Hose,

page 87.OrderRTDTest

kit 24N365 for measure-

ment. Di sconnect hose

RTD and use manual hose

mode to finish job until

repaircanbecompleted.

If the error still occurs with

the ho se FTS unpl ug ged ,

one of the heater RTDs

is bad. Unplug th e A or

B RTD from the TCM. If

unplugging an RTD fixes

the T6DT error, replace the

RTD.

36 332637C

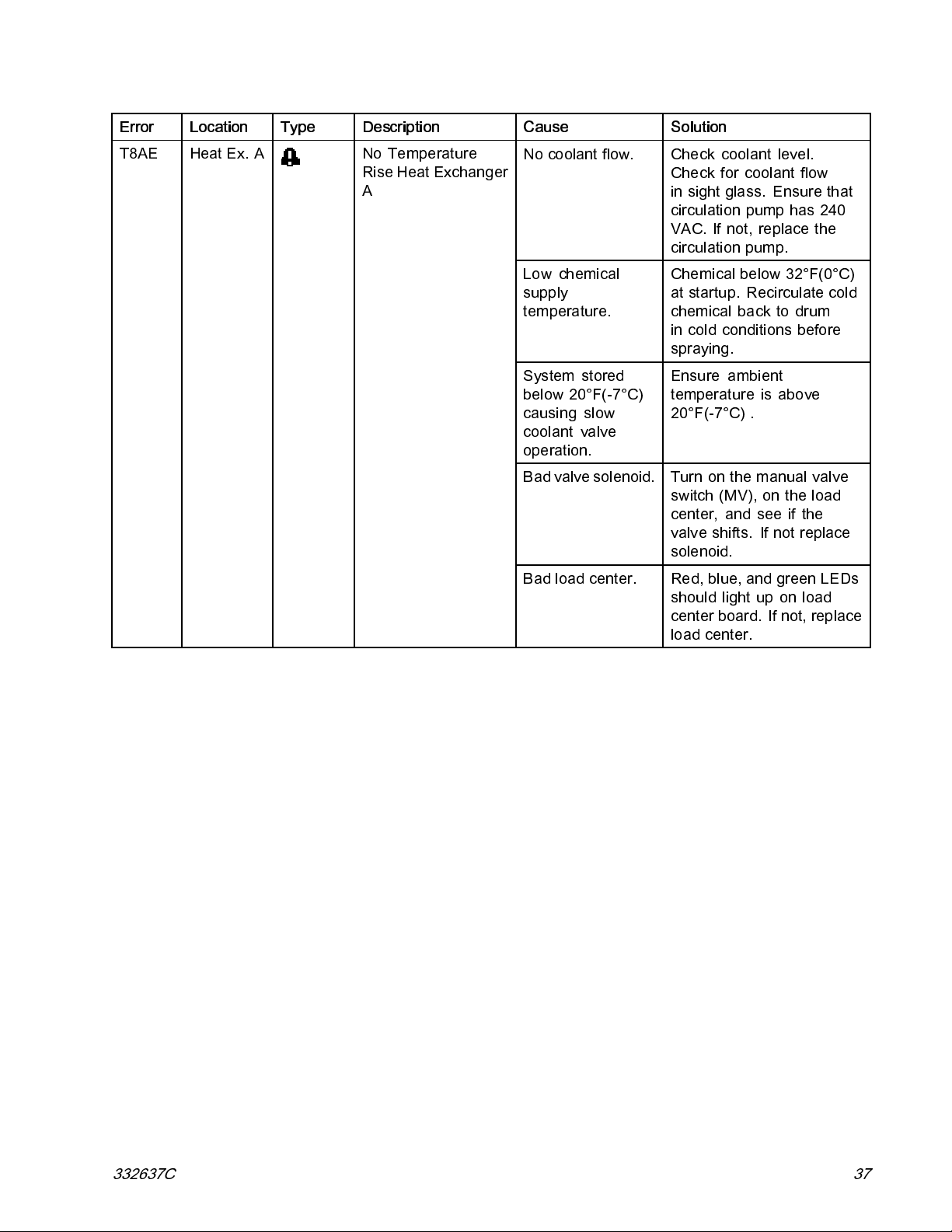

Page 37

Troubleshooting

Error Location Type Description

T8AE Heat Ex. A No Temperature

Rise Heat Ex ch ang er

A

Cause Solution

No coolant flow. Check coolant lev el.

Check for coolant flow

in sight glass. Ensure that

circulation pump has 240

VAC. If not, re pla ce the

circulation pump.

Low ch emi cal

supply

temperature.

System stored

below 20°F(-7°C)

causing slow

coolant valve

operation.

Bad valve solenoid. Turn on the manual valve

Chemical below 32°F(0°C)

at startup. Recirculate cold

chemical back to drum

in cold conditions before

spraying.

Ensure ambient

temperature is above

20°F(-7°C) .

switch (MV), on the load

center, and see if the

valve shifts. If not replace

solenoid.

Bad load center. Red, blue, and green LEDs

should light up on load

center board. If not, replace

load center.

332637C 37

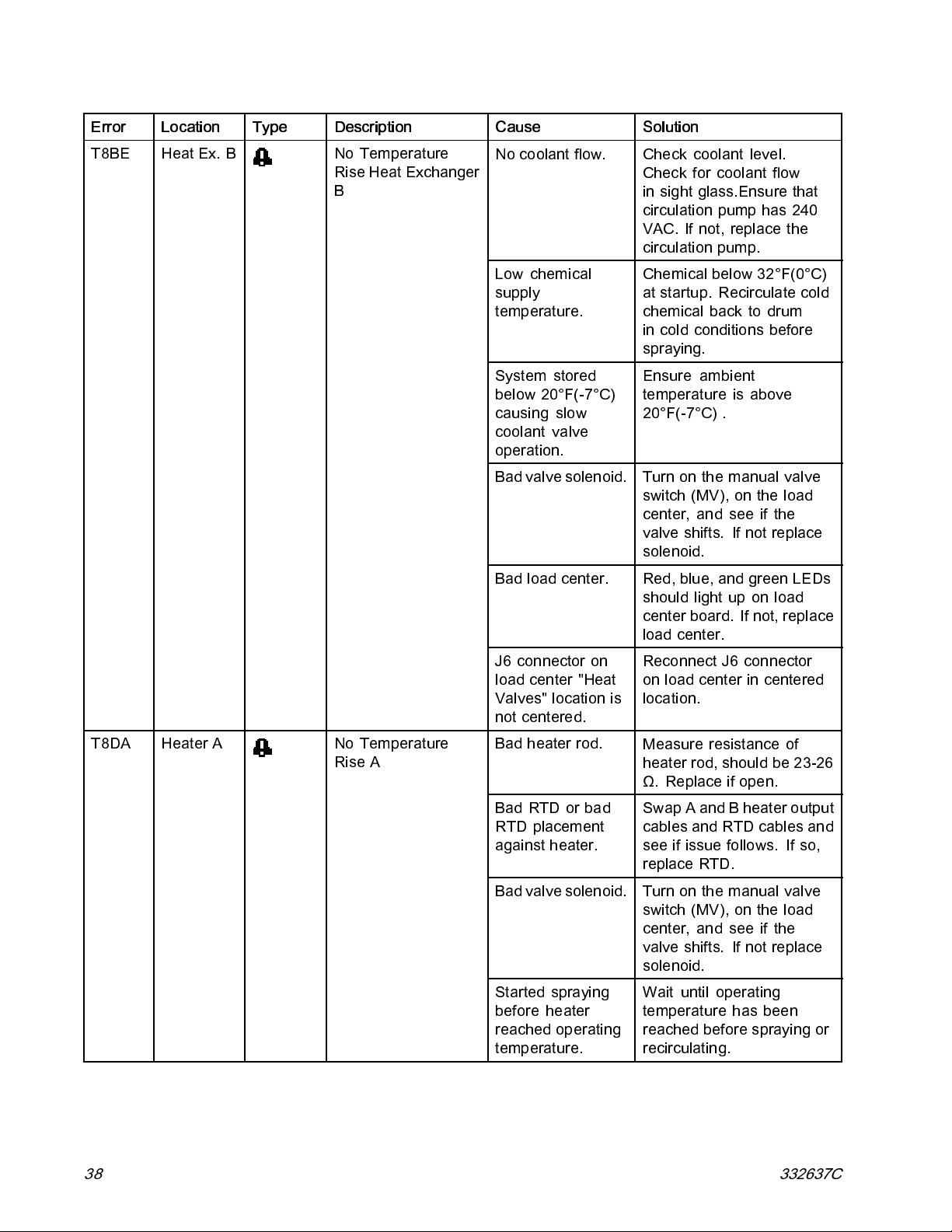

Page 38

Troubleshooting

Error Location Type Description

T8BE Heat Ex. B No Temperature

Rise Heat Exchanger

B

Cause Solution

No coolant flow. Check coolant level.

Check for coolant flow

in sight glass.Ensure that

circulation pump has 240

VAC. If not, replace the

circulation pump.

Low chemical

supply

temperature.

System stored

below 20°F(-7°C)

causing slow

coolant valve

operation.

Bad valvesolenoid. Turn on the manual valve

Chemical below 32°F(0°C)

at startup. Recirculate cold

chemical back to drum

in cold conditions before

spraying.

Ensure ambient

temperature is above

20°F(-7°C) .

switch(MV),ontheload

center, and see if the

valve shifts. If not replace

solenoid.

T8DA Heater A No Temperature

Rise A

Bad load center. Red, blue, and green LEDs

should light up on load

center board. If not, replace

load center.

J6 connector on

load center "Heat

Valves" location is

not centered.

Bad heater rod.

Bad RTD or bad

RTD placement

against heat er.

Bad valvesolenoid. Turn on the manual valve

Started spraying

before heater

reached operating

temperature.

Reconnect J6 connector

on load center in centered

location.

Measure resistance of

heater rod, should b e 2 3-26

Ω. Replace if open.

Swap A an d B heater o utpu t

cables and RTD cables and

see if issue follows. If so,

replace RTD.

switch(MV),ontheload

center, and see if the

valve shifts. If not replace

solenoid.

Wait until operating

temperature has been

reached before spraying or

recirculating.

38 332637C

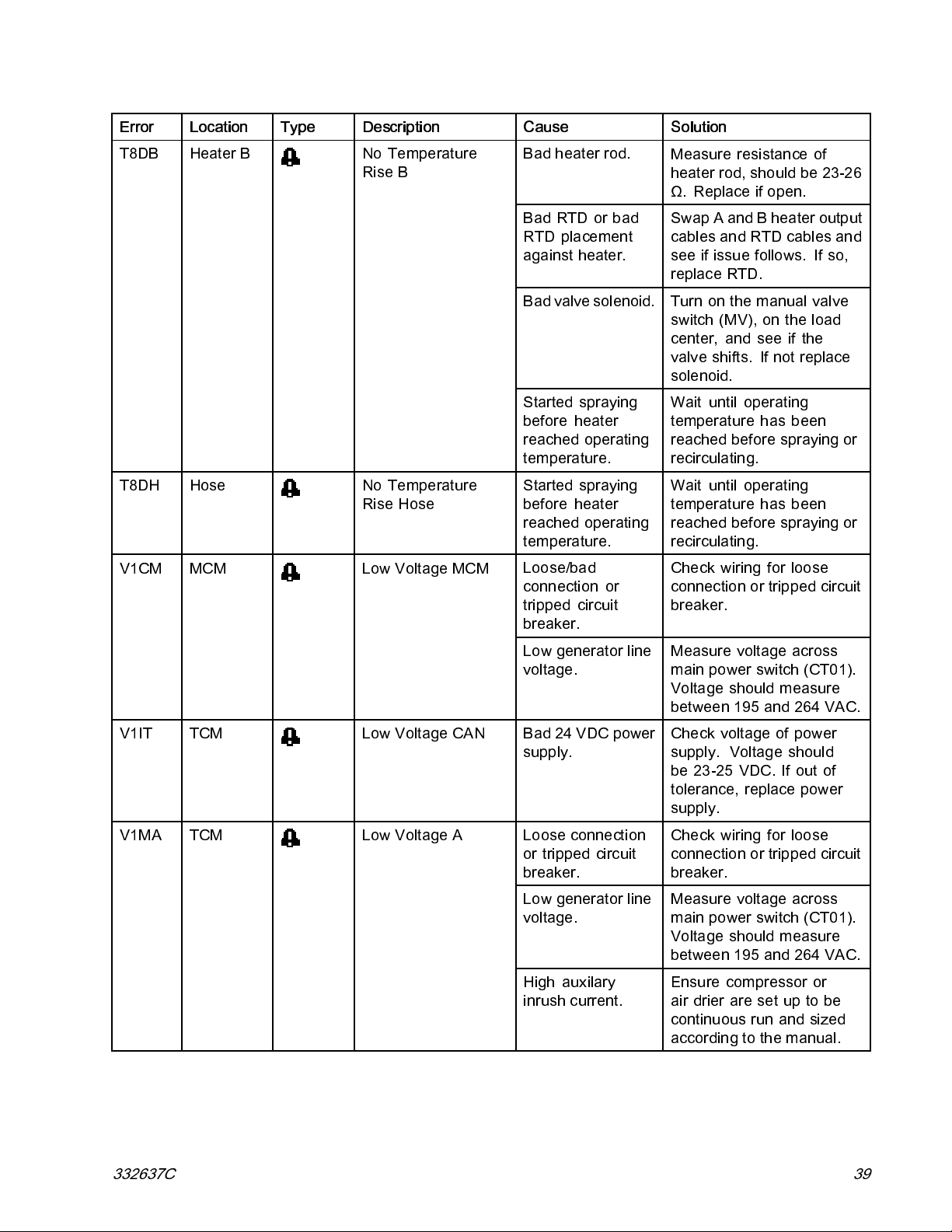

Page 39

Troubleshooting

Error Location Type Description

T8DB Heater B No Temperature

Rise B

T8DH Hose No Temperature

Rise Hose

V1CM MCM Low Voltage MCM

Cause Solution

Bad heater rod.

Bad RTD or bad

RTD placement

against heater.

Bad valve solenoid. Turn on the manual valve

Started spraying

before heater

reached operating

temperature.

Started spraying

before heater

reached operating

temperature.

Loose/bad

connection or

tripped circuit

breaker.

Measure resistance of

heater rod, should be 23-26

Ω. Replace if open.

Swap A and B heater output

cables and RTD cables and

see if issue follows. If so,

replace RTD.

switch (MV), on the load

center, and see if the

valve shifts. If not replace

solenoid.

Wait until operating

temperature has been

reached before spraying or

recirculating.

Wait until operating

temperature has been

reached before spraying or

recirculating.

Check wiring for loose

connection or tripped circuit

breaker.

Low generator line

voltage.

V1IT TCM Low Voltage CAN Bad 24 VDC power

supply.

V1MA

TCM

Low Voltage A

Loose connection

or tripped circuit

breaker.

Low generator line

voltage.

High auxilary

inrush current.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

Check voltage of power

supply. Voltage should

be 23-25 VDC. If out of

tolerance, replace power

supply.

Check wiring for loose

connection or tripped circuit

breaker.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

Ensure compressor or

air drier are set up to be

continuous run and sized

accordingtothemanual.

332637C 39

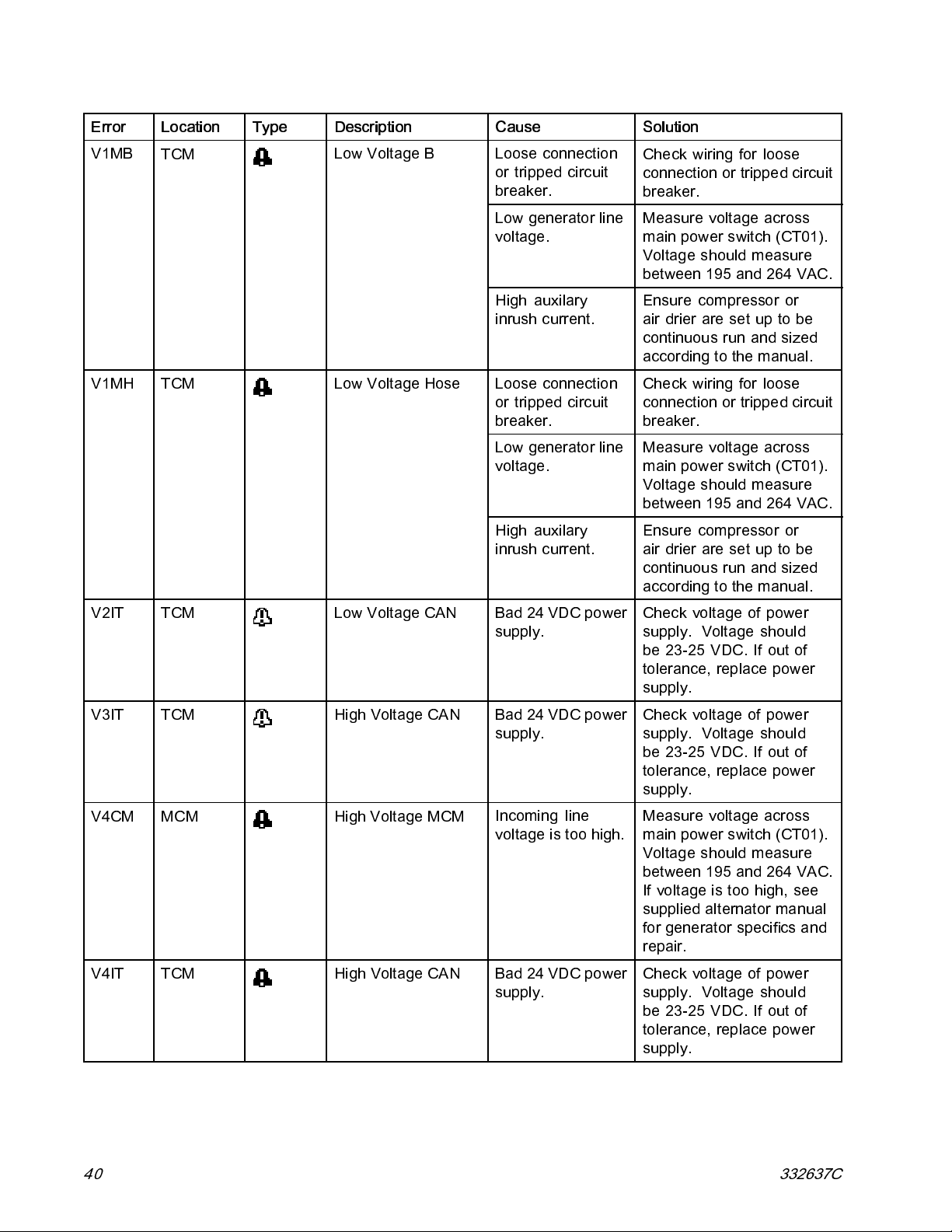

Page 40

Troubleshooting

Error Location Type Description

V1MB

V1MH

TCM

TCM

Low Voltage B

Low Voltage Hose

Cause Solution

Loose connection

or tripped circuit

breaker.

Low generator line

voltage.

High auxilary

inrush current.

Loose connection

or tripped circuit

breaker.

Low generator line

voltage.

High auxilary

inrush current.

Check wiring for loose

connection or tripped circuit

breaker.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

Ensure compressor or

air drier are set up to be

continuous run and sized

accordingtothemanual.

Check wiring for loose

connection or tripped circuit

breaker.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

Ensure compressor or

air drier are set up to be

continuous run and sized

accordingtothemanual.

V2IT TCM Low Voltage CAN Bad 24 VDC power

supply.

V3IT

V4CM MCM High Voltage MCM

V4IT

TCM

TCM

High Voltage CAN Bad 24 VDC power

supply.

Incoming line

voltage is too high.

High Voltage CAN Bad 24 VDC power

supply.

Check voltage of power

supply. Voltage should

be 23-25 VDC. If out of

tolerance, replace power

supply.

Check voltage of power

supply. Voltage should

be 23-25 VDC. If out of

tolerance, replace power

supply.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

If voltage is too high, see

supplied alternator manual

for generator specifics and

repair.

Check voltage of power

supply. Voltage should

be 23-25 VDC. If out of

tolerance, replace power

supply.

40 332637C

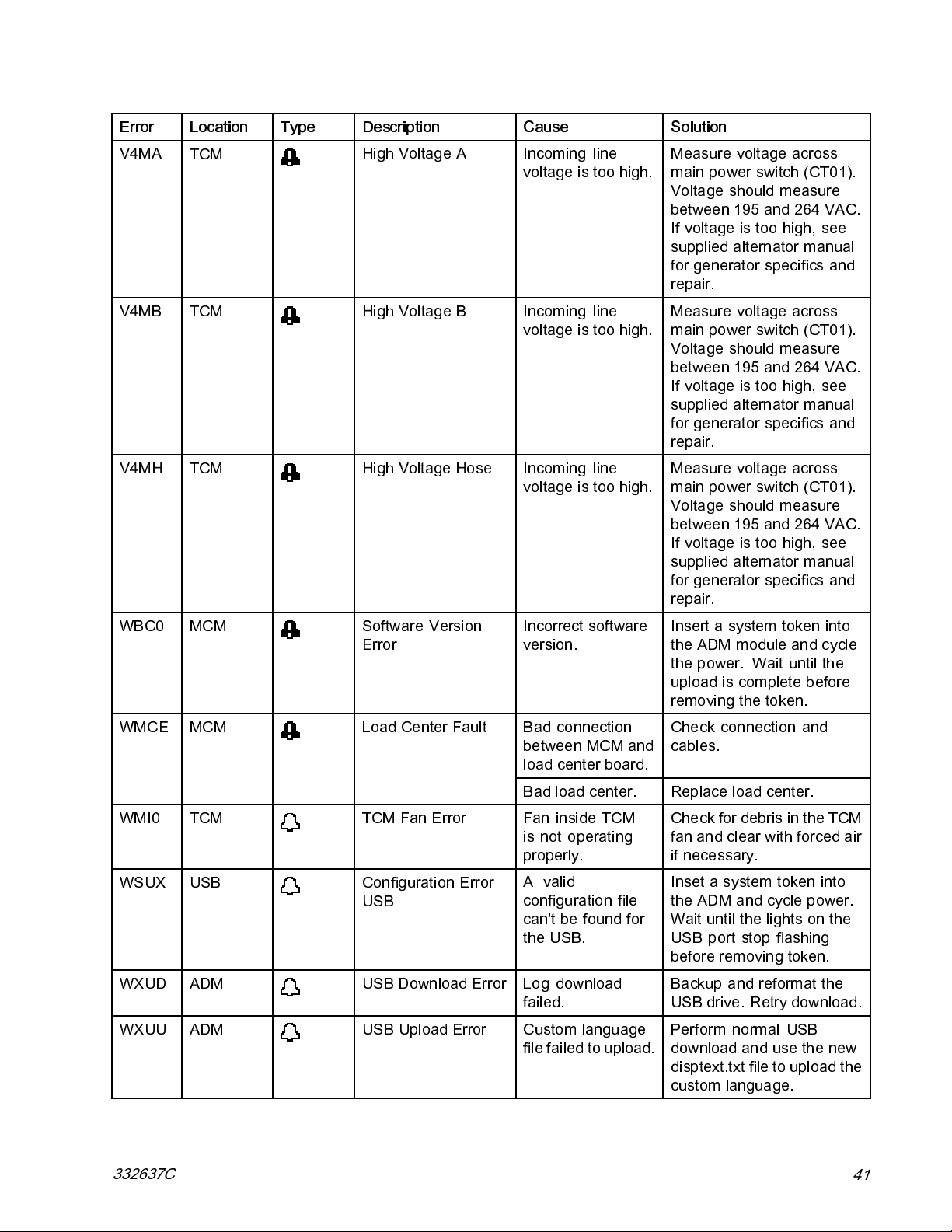

Page 41

Troubleshooting

Error Location Type Description

V4MA

V4MB

V4MH TCM High Voltage Hose Incoming line

TCM

TCM

High Voltage A Incoming line

High Voltage B Incoming line

Cause Solution

voltage is too high.

voltage is too high.

voltage is too high.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

If voltage is too high, see

supplied alternator manual

for generator specifics and

repair.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

If voltage is too high, see

supplied alternator manual

for generator specifics and

repair.

Measure voltage across

main power switch (CT01).

Voltage should measure

between 195 and 264 VAC.

If voltage is too high, see

supplied alternator manual

for generator specifics and

repair.

WBC0 MCM Software Version

Error

WMCE MCM Load Center Fault

WMI0

WSUX USB Configuration Error

WXUD ADM

WXUU ADM USB Upload Error Custom language

TCM

TCM Fan Error Fan inside TCM

USB

USB Download Error

Incorrect software

version.

Bad connection

between MCM and

load center board.

Bad load center. Replace load center.

is not operating

properly.

Avalid

configuration file

can't be found for

the USB.

Log download

failed.

filefailedtoupload.

Insert a system token into

the ADM module and cycle

the power. Wait until the

upload is complete before

removing the token.

Check connection and

cables.

Check for debris in the TCM

fan and clear with forced air

if necessary.

Inset a system token into

the ADM and cycle power.

Wait unti l the lights on the

USB port stop flashing

before removing token.

Backup and reformat the

USB drive. Retry download.

Perform normal USB

download and use the new

disptext.txt file to upload the

custom language.

332637C

41

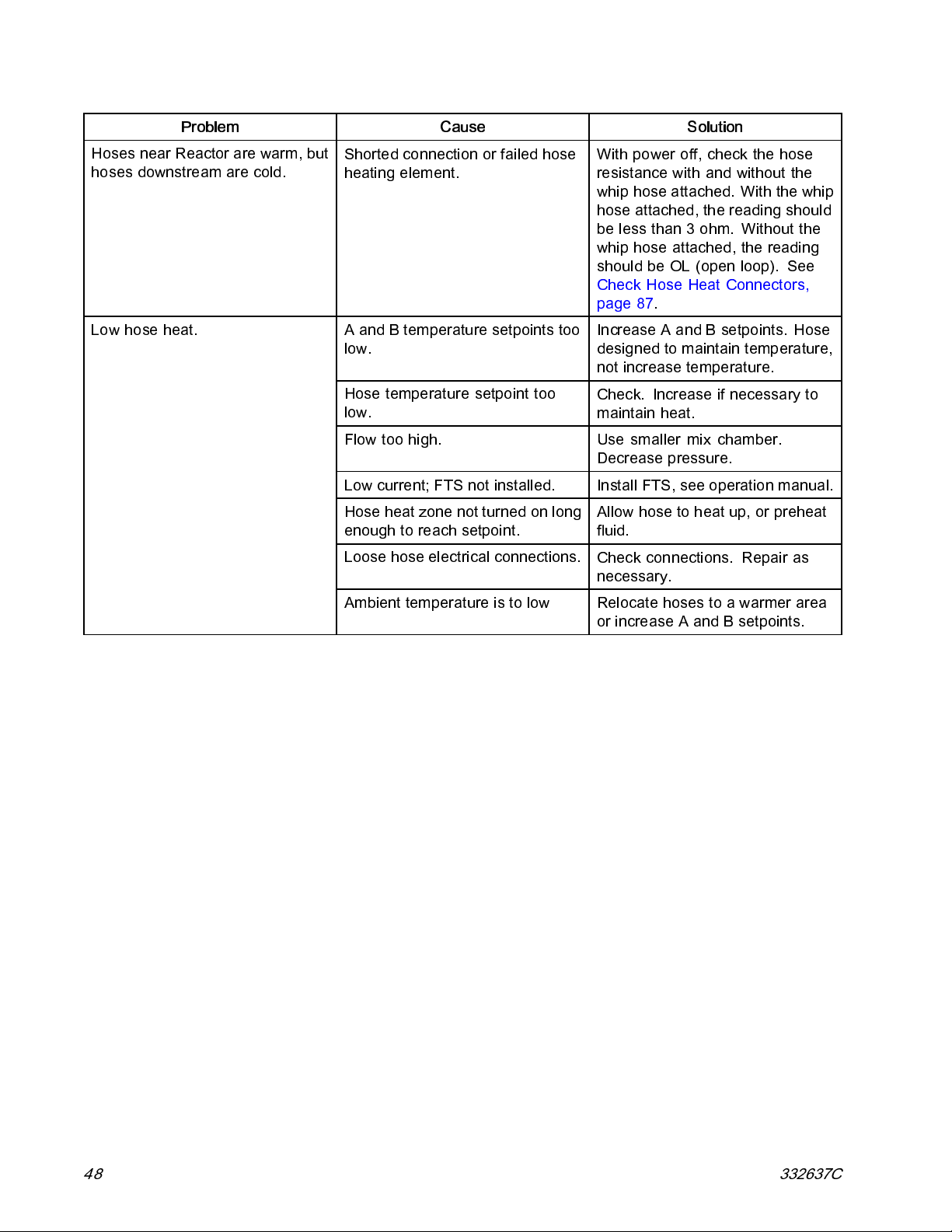

Page 42

Troubleshooting

System

See Supplied Manuals, page 14, for air compressor service or warranty contact information.

Before performing any troubleshooting procedures:

1. Relieve Pressure. See Pressure Relief Procedure, page 60.

2. Turn main power switch OFF.

3. Allow equipment to cool.

Problem Cause Solution

Reactor ADM does not turn on. No power.

Turn main power switch ON.

Turn circuit breakers ON, see

Repair Circuit Breaker Module,

page 77.

Check circuit breaker (CB10). See

Repair Circuit Breaker Module,

page 77.

Electric motor does not operate.

Electric motor runs erratically. Failed motor bearings. Replace motor, see

Loose co nne cti on s. Check MCM connections. See

Electrical Schematics, page 154.

Tripped circuit breaker (CB02). Reset breaker, see Repair Circuit

Breaker Module, page 77.Check

240VAC at output of breaker.

Shorted windings. Replace motor, see

Repair Electric Motor, page 76.

Repair Electric Motor, page 76.

42

332637C

Page 43

Problem Cause Solution

Electric motor cooling fan not

working.

Pump output low.

Fluidleakinpumppackingnut

area.

No pressure on one side. Fluid leaking from heater inlet

Air compressor does not start.

Air dryer cooling fan not running. Only runs after hot air flow. Normal operation.

Air dryer not draining water.

Tripped circuit breaker (CB03). Reset circuit breaker (CB03).

Check 240VAC at output of

breaker.

Loose wire.

Fan blade obstructed. Remove obstruction.

Defective fan. Replace. See

Obstructed fluid hose or gun; fluid

hose ID too small.

Worn piston valve or intake valve

in displacement pump.

Pressure setpoint too high. Reduce setpoint and output will

Worn throat seals.

rupture disk (372).

Tripped circuit breaker (CB04). Reset circuit breaker (CB04).

Not wired correctly. See

Compressor starter overheated

from rapid multiple start and stop

procedures.

Power not turned on at dryer.

No air usage. Check after air flowing.

Check. See

Electrical Sch em ati cs , page 154.

Replace Motor Fan, page 82.

Open, clear; use hose with larger

ID.

See pump manual.

increase.

Replace. See pump manual.

Check if heater and PRESSURE

RELIEF/SPRAY valve (SA or SB)

are plugged. Clear. Replace

rupture disk (372) with a new one;

do not replace with a pipe plug.

Electrical Sch em ati cs , page 154.

Let starter cool down for 2 minutes

then press reset on the air

compressor electrical enclosure

and start.

TurndryerswitchON(|).

Troubleshooting

332637C 43

Page 44

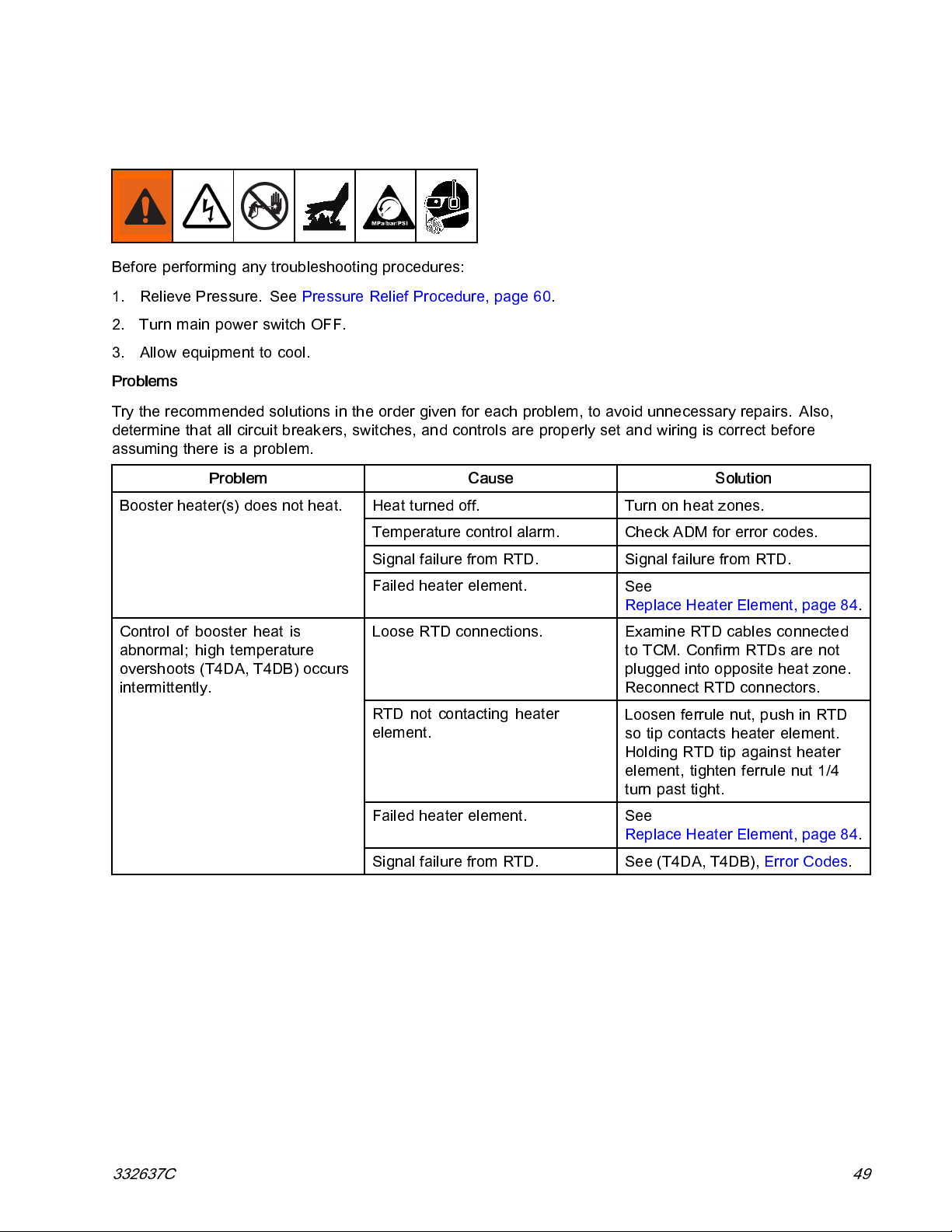

Troubleshooting

Coolant System

Problem Cause Solution

Proportioner Coolant Loop

Air bubbles in sight glass .

Heat exchanger coolant flow

stopped. No flow in sight glass.

Material slo wly heats up.

Heat ex ch ang er coolant in sight

glass is a milky color.

A or B material heats up slower

than the other.

A or B material cooling down

slower than the other.

Air trapped in heat exchanger

coolant.

Coolant hoses between the

proportioner coolant loop and

engine coolant loop were modified

and created a high point air pocket.

Proportioner coolant loop

expansion bottle is empty.

Circulation pump stopped running. Check circuit breaker. Check

Bypass control valve does not

open.

Coolant filter plugged. Clean or repla ce filter in filter

A and B control valves are not

opening fully.

System stored below 20°F(-7°C).