Page 1

Instructions - Parts

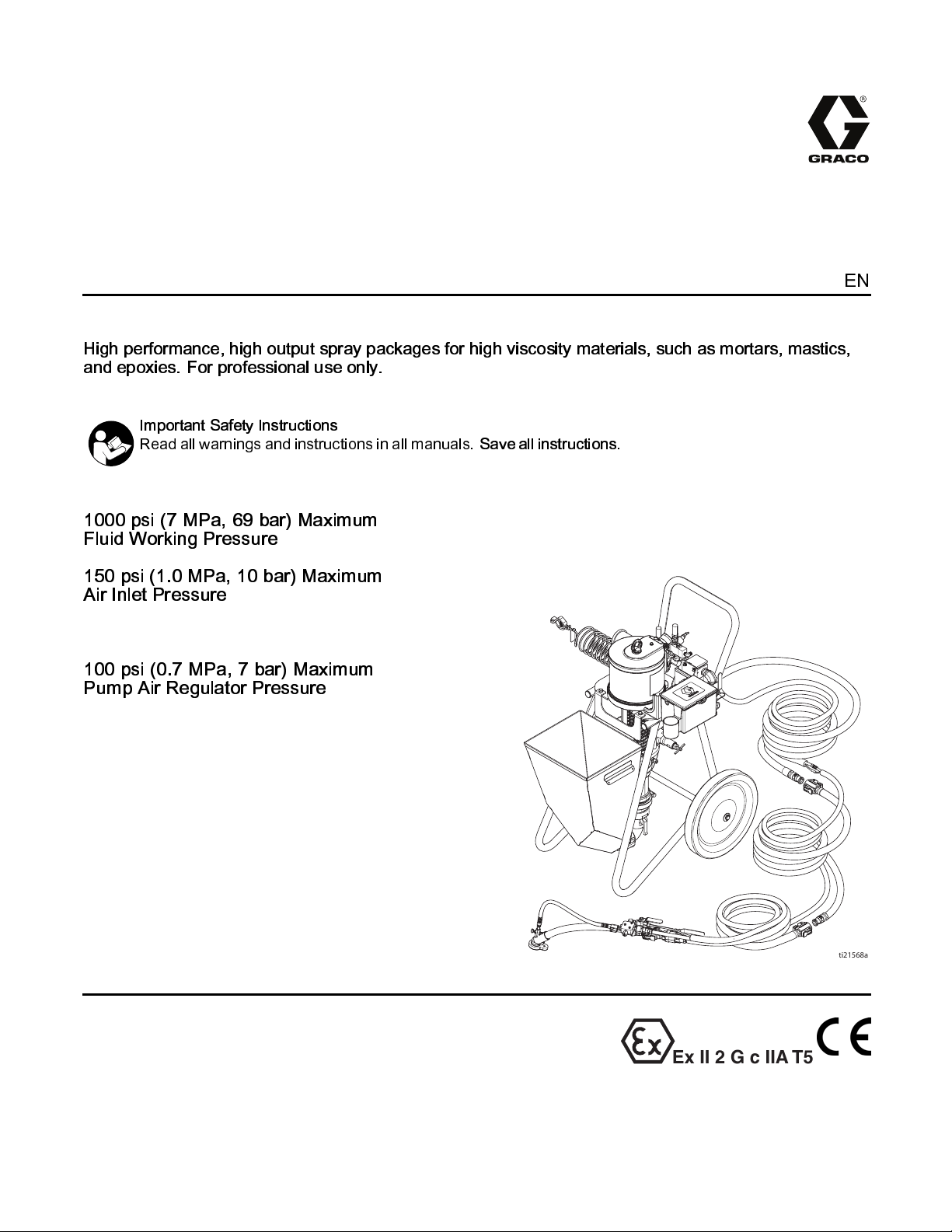

M680 Mortar Sprayer

High performance, high output spray packages for high viscosity materials, such as mortars, mastics,

and epoxies. For professional use only.

Important Safety Instructions

Read all warnings and instructions in all manuals.

1000 psi (7 MPa, 69 bar) Maximum

Fluid Working Pressure

150 psi (1.0 MPa, 10 bar) Maximum

Air Inlet Pressure

100 psi (0.7 MPa, 7 bar) Maximum

Pump Air Regulator Pressure

Save all instructions.

332612A

EN

Ex II 2 G c IIA T5

ti21568a

Page 2

Contents

Related Manuals ................................................ 2

Warnings ........................................................... 3

Models............................................................... 6

Component Identification..................................... 7

Overview ..................................................... 7

Details......................................................... 8

Mortar Spray Applicator................................ 9

HTX 680 (Internal Air) Applicator...................10

System Components.................................... 11

Grounding .......................................................... 12

Setup................................................................. 13

Pressure Relief Procedure .................................. 14

Wet Out the System............................................ 15

Mix the Material.................................................. 18

Prime with Mortar or Epoxy ................................. 19

Spray................................................................. 21

Prevent Packout .......................................... 21

Before S tarti ng or Stopping Material

Flow .............................................. 21

Spraying...................................................... 21

Spray Adjustments (Mortar Spray

Applicator) ............................................ 23

Air Flow Valve Adjustment............................ 23

Material Flow Adjustments............................ 23

Spray Techniques........................................ 24

Installing Nozzle Retaining Cap..................... 24

Material Compatibility................................... 24

Spray Adjustments (HTX 680 Applicator) ............. 25

Flush ................................................................. 26

Notes................................................................. 29

Disassemble and Clean the Pump (Daily).............30

Shutdown...........................................................33

Maintenance ...................................................... 34

Daily Maintenance ....................................... 34

Troubleshooting.................................................. 35

Repair................................................................ 37

Replace Pump Components......................... 37

Replace Air Motor........................................37

Replace Pump Lower ................................... 37

Parts.................................................................. 38

Accessories........................................................44

Technical Specifications...................................... 45

Graco Standard Warranty....................................48

Related Manuals

Manuals are available at www.graco.com.

Component manuals in Engli sh:

Manual Description

332651

332767

332768

312796 NXT Air Motors Instructions - Parts

332649 Pump Lower Instructions - Parts

332650 Pump Instructions - Parts

Mortar Spraying Tips

Mortar Spray Applicators Op erati on -

Parts

HTX 680 Applicator Operation - Parts

2

332612A

Page 3

Warnings

Warnings

The following warnings are f or the setup, use, grounding, maintenance, and repair of this equipment. The

exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific

risks. When these symbols appear in the body of this manual or on warning label s, refer back to these

Warnings. Product-specific hazard symbols and warnings not covered in this section may appear throughout

the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. Se e

• Use only grounded hoses.

• Hold applicator firmly to side of grounded pail when triggering into pail. Do not use pail

liners unless they are antistatic or conductive.

•

Stop operation immediately

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce

skin. This may look like just a cut, but it is a serious injury that can result in amputatio n.

immediate surgical treatment.

• Do not point dispensing device at anyone or at any part of the body.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Followthe

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or d amaged parts immediately.

Pressure Relief Procedure

if static sparking occurs or you feel a shock.Do not u se

Grounding

when you stop dispensing and before cleaning,

work area

instructions.

canigniteorexplode.Tohelp

Get

332612A 3

Page 4

Warnings

WARNING

EQUIPMEN T MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs o r alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For comple te

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

Technical Data

Pressure Relief Procedure

in all equipment manuals.

when equipment is not in use.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing

equipment, follow the

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed i n the eyes or on skin,

inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

Pressure Relief Procedure

and disconnect all power sources.

4

332612A

Page 5

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

SUCTION HAZARD

Powerful suction could cause serious injury.

• Never place hands near the pump fluid inlet when pump is operating or pressurized.

Material Self-ignition

Warnings

WARNING

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings and

material MSDS.

Changing Materials

NOTICE

Changing the material types used in your equipment

requires special attention to avoid equipment damage

and downtime.

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• When changing between epoxies and urethanes

or polyureas, disassemble and clean all fluid

components and change hoses.

332612A 5

Page 6

Models

Models

Includes9:

Model

262927 262909 262926 24T834 24T835 24T836 24T837

Pump installed on Cart

24T837

Basic Spare Parts Kit

1

2

(included in tool box)

Feed Hopper 24T853

3

Standard 35 ft (1.7 m)

Hose Bundle 24T852

Flex Applicator 24T947

4

5

HTX 680 Manifold

Applicator 24U209

Additional Spare Parts

6

7

Additional 25 ft (7.6 m)

Hose Kit 24R254

1

Includes air motor, stainless steel pump lower, zero cavity relief valve, 1 in. male camlock outlet, air controls,

8

✔✔✔✔✔✔✔

✔✔✔✔✔✔✔

✔✔ ✔ ✔

✔✔✔✔✔

✔✔✔

✔✔✔

✔

✔

andthetwowheelcart.

2

Includes gaskets for cam and groove fittings, complete pump repair soft seal kit, and pilot tube repair fittings.

3

Includes 10 gallon (38 liter) stainless steel hopper, hopper mounting, straight and 90 degree 2 inch female

cam lock outlet.

4

Fluid hose portion of kit includes 1 in. x 25 ft fluid hose, 3/4 x 10 ft fluid whip hose, stainless steel shut off ball

valve, and fluid cam lock ends. Air line portion of kit includes 38 ft air line with pump pilot line, air line quick

disconnects, and mesh wrap. Includes 6 mil polyurethane bag tubes for fluid lines and air l ines.

5

Flex applicator includes 23 in. (58 cm) flexible hose with cam lo ck fluid inlet, angled spray head, spray air

volume control, spray air shut off valve, and motor pilot signal control valve, adjustable position center air

injection tube, rubber tip retainer, and include 3 tip sizes. Fl ex applicator is for use in low pressure spraying of

materials that pack out easily and that will be finish-trowe led.

6

HTX 680 includes cam lock fluid inlet, angled aluminum spray head, spray air volume control, spray air shut

off valve, and motor pilot signal control valve. HTX 680 uses venturi-type air injection fluid nozzles and

aluminum screw on tip retainer. Includes four nozzle sizes, a Fine Finish adapter, and f our Fine Finish tips.

HTX 680 is for use in medium pressure spray of materials that do not pack out easily.

7

Additional spare parts option includes flex applicator and pole applicator parts (rubber retainer, 3/16, 4/16,

8/16, 9/16 in. tips, and air tube o-ring), HTX applicator parts (nozzle retainer and 4 mm, 6 mm, 8 mm, 10 mm

nozzles and 1/8, 1/4, 3/8, 5/16 in. Fine Finish discs, air check valve, and spool o-rings), and pump rebuild kit.

8

Extends total length to 60 ft (18.3 m). Includes 25 ft x 1 in. fluid hose with cam lock fluid fittings, and 25 ft air

hose assembly with hose quick disconne cts and pilot tube.

9

See Parts, page 38, for details reg arding what is included with each model.

6 332612A

Page 7

Component Identification

Overview

Component Identification

AA

AC

AB

AD

AJ

AF

AK

AE

Figure 1

Key:

AA Material Hopper

AB Air Motor

AC

AD

AE Applicator

AF Material Hose (connects pump to whip

332612A

Lower

Cart

hose)

AK

AGAHAI

AG Material Whip Hose

AH

AI

AJ

AK

Air Supply to Applicator (for Air Assist and

Air Motor ON/OFF Pilot Valve), shown

disconnected

Return Air to Air Motor ON/OFF Pilot Valve

System Air Inlet

Optional hose extension

ti21568a

7

Page 8

Component Identification

Details

D

B

Y

A

F

N

C

J

E

HX

L

K

U

M

P

R

G

W

U

M

G

K

G

W

S

T

S

T

U

T

M

Detailed View

Figure 2

Key:

A

B

Air Inlet, 3/4 npt(f) Claw (Chicago) Fittings

Bleed Type Master Air Valve (required)

C Air Pressure Relief Valve

D

E

FMot

Air Filter (40 micron)

Motor Air Pressure Gauge

or Air Pressure Regulator Adjustment

b

Kno

G Pilot Ball Valve (starts/stops Air Motor)

H Motor Air Pilot Valve

J

KA

L

Zero Cavity Relief Valve

ir Assist Tube

Grounding Wire, required (see

Grounding, page 12)

M

N

V

Needle Valve for Air Assist Flow Control

Air Supply Quick Disconnect to Appl icato r

W

ti21569a

Air Inlet Quick Disconnect (W)

P

R

Fluid Outlet, 1 in. Male Camlock Fitting

Packing Nut/Wet Cup under Spring Guard

S Air Assist Nozzle Position Adjustment

Screw

T Applicator Tip Assembly

U

V

Air Assist Shutoff Ball V al ve

Applicator Material Supply Ball Valve

W Applicator Air Inlet Quick Disconnect

X

Pilot Valve Signal from App li cator Pil ot

Valve (G)

Y

Whip Check Hose Safety Cable

8 332612A

Page 9

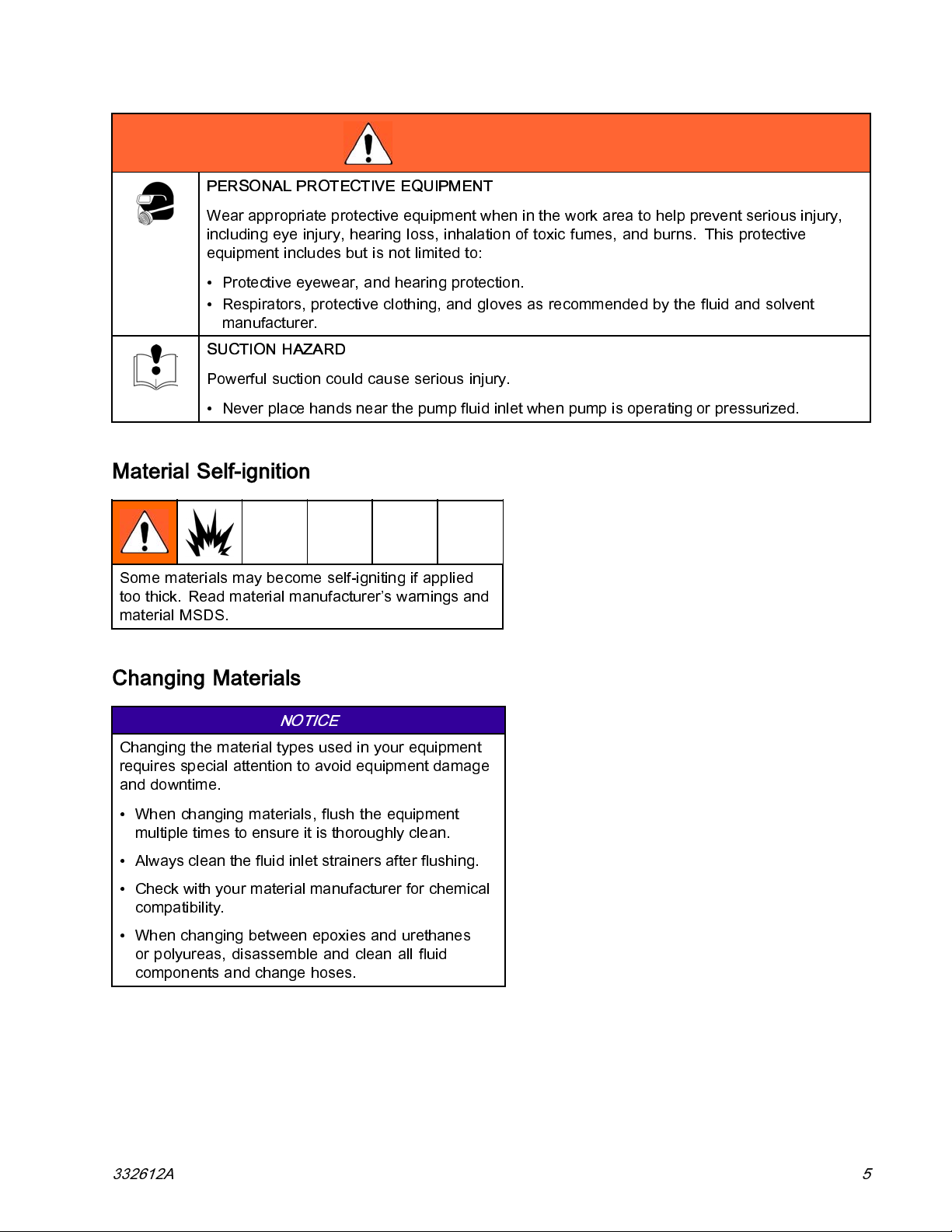

Mortar Spray Applicator

Component Identification

M

Figure 3

Key:

M

U

CA

CB Air Needle (adjustable position)

CC Air Needle Retaining Screw

CD

CE Tip (Nozzle)

CF

Needle Valve for Air Assist Flow Control

Air Assist Shutoff Ball Valve

Air Assist Air Line

Fluid Housing

Rubber Tip Retainer

U

CF

CA

CB

CC

CD

CE

332612A 9

Page 10

Component Identification

HTX 680 (Internal Air) Applicator

DG

Figure 4

Key:

M Needle Valve for Air Assist Flow Control

U Air Assist Shutoff Ball Valve

DA Air Assist Air Line

DB Fluid and Air Manifold

DC Tip (Nozzle)

DD Tip Retainer

DE Air Check Valve

DF Fluid Inlet Swivel

DG Handle

M

DF

DA

DE

U

DB

DD

DC

10 332612A

Page 11

System Components

Component Identification

* Required system components.

To avoid tipping over, ensure cart is on a flat and

level surface. Failure to do so could result in injury

or equipment damage.

* Bleed Type Master Air Valve (B)

• Be sure the valve is easily accessible from the

applicator.

• Required in your system to relieve air trapped

between it and the air motor when the valve is

closed.

– Open to supply air to the motor.

– Close to shut off air to the motor and bleed any

trapped air from the motor.

* Air Pressure Relief Valve (C)

Air Regulator Adjustment (F)

Adjusts air pressure to the motor and fluid outlet

pressure of pump. Read air pressure on gauge (E).

* Zero Cavity Relief Valve (J)

Open valve to relieve pressure if pump or hose

packout occurs. Close valve when spraying.

NOTICE

To prevent material hardening in zero cavity relief

valve, flush the valve after every time it is used.

See Flush, page 26.

To avoid skin injection and splashing, never

open a camlock hose or applicator fitting

whilethereispressureinthefluidline. See

Pressure Relief Procedure, page 14.

Automatically opens to relieve air pressure if set

pressure exceeds preset limit.

Air Filter (D)

Removes harmful dirt and water from compressed

air supply.

332612A

11

Page 12

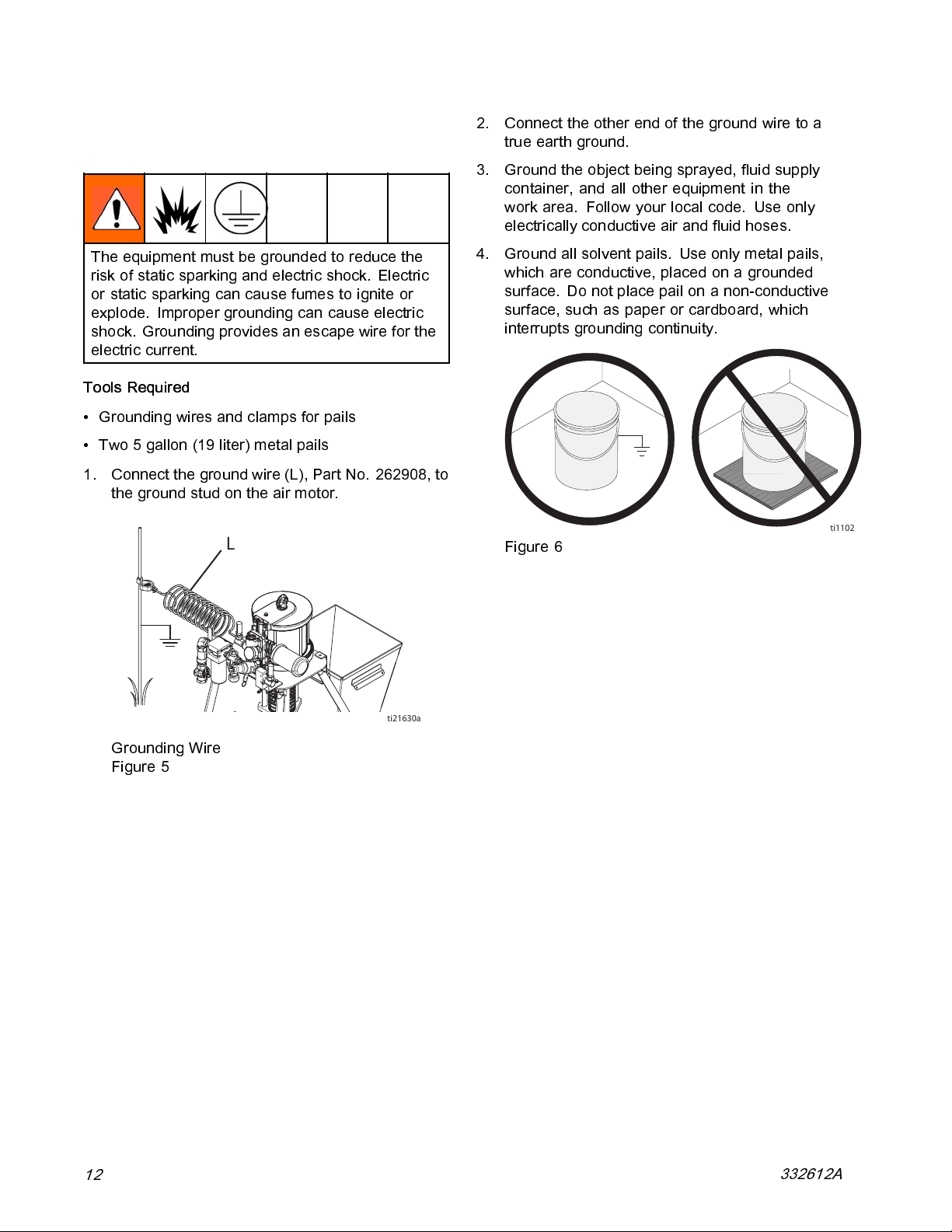

Grounding

Grounding

The equipmen

risk of stati

or static sp

explode. Im

shock. Grou

electric cu

Tools Requ

• Grounding wires and clamps for pails

• Two 5 gallon (19 liter) metal pai ls

1. Connect the ground wire (L), Part No. 262908, to

the ground stud on the air motor.

t must be grounded to reduce the

c sparking and electric shock. Electric

arking can cause fumes to ignite or

proper grounding can cause electric

nding provides an escape wire for the

rrent.

ired

L

2. Connect the other end of the ground wire to a

true earth ground.

3. Ground the object being sprayed, fluid supply

container, and all other equipment in the

work area. Follow your local code. Use only

electrically conductive air and fluid hoses.

4. Ground all solvent pails. Use only metal pails,

which are conductive, placed on a grounded

surface. Do not place pail on a non-conductive

surface, such as paper or cardboard, which

interrupts grounding continuity.

ti1102

Figure 6

Grounding Wire

Figure 5

ti21630a

12

332612A

Page 13

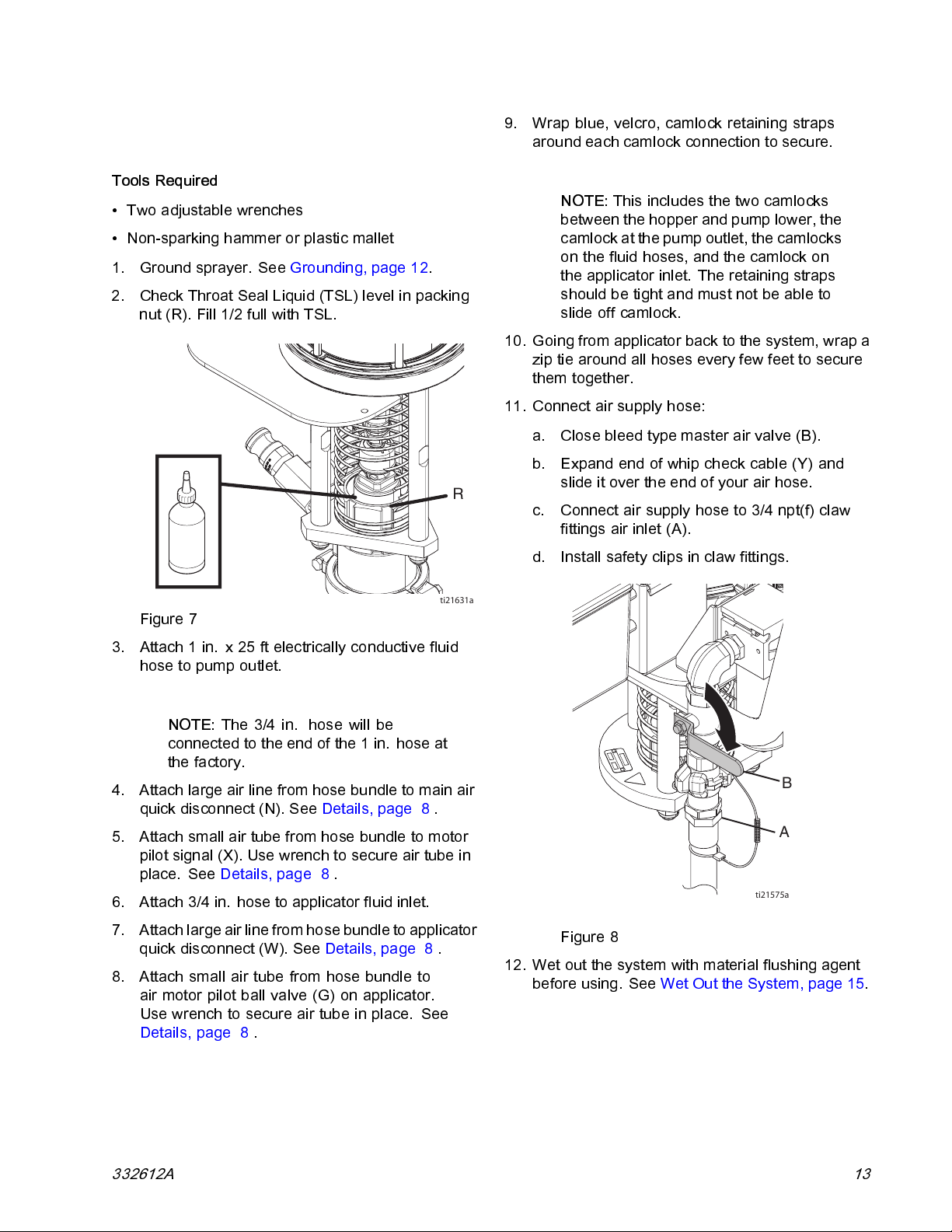

Setup

Setup

Tools Required

• Two adjustable wrenches

• Non-sparking hammer or plastic mallet

1. Ground sprayer. See Grounding, page 12.

2. Check Throat Seal Liquid (TSL) level in packing

nut (R). Fill 1/2 full with TSL.

R

9. Wrap blue, velcro, camlock retaining straps

around each camlock connection to secure.

NOTE:

between the hopper and pump lower, the

camlockat the pump outlet, the camlocks

on the fluid hoses, and the camlock on

the applicator inlet. The retaining straps

should be tight and must not be able to

slide off camlock.

10. Going from applicator back to the system, wrap a

zip tie around all hoses every few feet to secure

them together.

11. Connect air supply hose:

a. Close bleed type master air valve (B).

b. Expand end of whip check cable (Y) and

slide it over the end of your air hose.

c. Connect air supply hose to 3/4 npt(f) claw

fittings air inlet (A).

d. Install safety clips in claw fittings.

This includes the two camlocks

ti21631a

Figure 7

3. Attach1in.x25ftelectricallyconductivefluid

hose to pump outlet.

NOTE:

connected to the end of the 1 in. hose at

the factory.

4. Attach large air line from hose bundle to main air

quick disconnect (N). See Details, page 8 .

5. Attach small air tube from hose bundle to motor

pilot signal (X). Use wrench to secure air tube in

place. See Details, page 8 .

6. Attach 3/4 in. hose to applicator fluid inlet.

7. Attach large air line from hose bundle to applicator

quick disconnect (W ). See Details, page 8 .

8. Attach small air tube from hose bundle to

air motor pilot ball valve (G) on applicator.

Use wrench to secure air tube in place. See

Details, page 8 .

The 3/4 in. hose will be

B

A

ti21575a

Figure 8

12. Wet out the system with material flushing agent

before using. See Wet Out the System, page 15.

332612A 13

Page 14

Pressure Relief Procedure

Pressure Relief Procedure

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipm

is manually

injury from

splashing fl

Pressure R

and before

equipment

1. Flush the

2. Close inc

ent stays pressurized until pressure

relieved. To help prevent serious

pressurized fluid, such as skin injection,

uid and moving parts, fol low the

elief Procedure when you stop spraying

cleaning, checking, or servicing the

.

system. See Flush, page 26.

oming air ball valve (B).

B

A

ti21632a

Figure 10

To avoid injection and splashing, never open a

camlock hose or applicator fitting whi le there is

pressureinthefluidline.

5. If you suspect the applicator tip or hose is

completely clogged, or that pressure has not

been fully relieved after following the previous

steps, slowly open the zero cavity relief valve (J)

at the pump outlet. See Details, page 8 .

6. If there is still pressure trapped down the line,

very slowly loosen the threaded swivel fitting at

the pump outlet while keeping it covered until the

pressure is relieved.

ti21575a

Figure 9

3. Set air regulator (F) to zero pressure.

4. Hold applicator firmly against a grounded metal

pail. Open the material ball valve (V) on the base

of the applicator.

14

7. Flu s h the zero cavi t y relief va l v e (J). See

Flush, page 26.

NOTICE

To prevent material hardening in zero cavity relief

valve, flush the valve after every use.

332612A

Page 15

Wet Out the System

NOTICE

To prevent

mortar or e

or epoxy in

to stick t

damage an

material curing in system, never load

poxy into a dry system. Loading mortar

to a dry system will cause the material

o internal components and cure causing

d requiring replacement of those parts.

Wet Out the System

3. Partially fill the clean hopper with material

flushing agent, depending on the material you

will be spraying.

4. Turn air regulator adjustment knob (F)

counterclockwise until it stops and gauge (E)

reads zero.

E

Always w

fluid thr

before l

done wit

or comm

fluids a

spraye

et out the system by circulating clean

ough the applicator back into the hopper

oading any mixed mortar. This is normally

h the flushing fluid, but som etimes resin

ercially available concrete pump priming

re used depending on what material is being

d.

• Use the material flushing agent recommended on

the material application data sheet.

• When finished, pump out the excess fluid. Then

drain out remaining fluid by loosening the bottom

cam fitting.

1. Close the bleed type master air valve (B).

F

ti21571a

Figure 12

5. Verify zero cavity relief valve (J) is closed.

6. Place applicator outlet in grounded pail.

7. Open the fluid ball valve (V) on the applicator.

B

A

ti21575a

ti21663a

Figure 11

Figure 13

2. Remove tip from applicator.

332612A 15

Page 16

Wet Out the System

8. Open the motor on/off pil ot ball valve (G) located

on base of applicator.

ti21578a

Figure 14

9. Open bleed type master air valve (B).

10. Rotate the air regulator adjustment knob (F)

clockwise until pump begins to move slowly.

F

ti21570a

Figure 16

NOTICE

To prevent damage to pump seals caused by

cavitation, run the pump slowly until the system

is primed.

B

Figure 15

11. Continue running the pump until all of the flushing

fluid is dispensed into the pail. The system is

now wetted out.

ti21574a

ti21632a

Figure 17

16 332612A

Page 17

Wet Out the System

12. To stop dispensing, close the air motor on/off

pilot ball valve (G) and the main bleed type

master air valve (B).

B

A

ti21575a

Figure 18

13. If needed, drain remaini ng fluid from system.

NOTE:

Materials that separate more easily may

require draining the remaining fluid from the

system. Check material data sheet to determine

whether it is necessary to drain the remaining

fluid from the system.

a. Place grounded metal drain pan beneath

pump lower inlet fittings.

b. Remove hopper and fittings between hopper

and pump lower.

c. Useascrewdrivertoliftthepumplowerinlet

ball. This will drai n the remaining material

from the pump lower. When the pump stops

draining, release the pump lower inlet ball.

d. Install fittings and hopper.

e. Install camlock retaining straps.

f. Startingatthepump,raisethehosebundle

above your head and slowly move towards

the applicator. As you move towards the

applicator, the remaining fluid in the hose will

drain from the applicator into the b ucket.

332612A

17

Page 18

Mix the Material

Mix the Material

Always wet out the pump, hose, and applicator

before loading the mortar o r epoxy material. See

Wet Out the System, page 15.

Always follow the material manufacturer’s instructions

for the material being sprayed. Mortar must be

thoroughly mixed to a smooth consistency before

loading it in the hopper.

• Always add the powder slowly to the fluid while

mixing. Do not add fluid to the powder.

• In non-explosive environments only: Use a

powerful mixer drive such as a minimum 800

watt, 1/2 in. drive, electric drill. Gear reduced

drills work best. Drill should have high torque at

300-1200 rpm.

• A heavy-duty drywall mud “H” blade or large “Jiffy”

blade generally works wel l for mixing.

NOTE:

material to fill the pump and hoses.

It will take most of the first batch of

Managing Mortar After Mixing:

• Paycloseattentiontotheworklifeofthematerial

being used.

• Only mix the mortar kits as needed. Do not let

mixed mortar sit longer than necessary.

• Scrape mortar down the sides of the hopper as

the hopper material level lowers. Do not let older

mortar cure on the walls.

• Occasionally, do not refill the hopper until it is

almost empty. This ensures all material in hopper

is used while fresh.

18 332612A

Page 19

Prime with Mortar or Epoxy

NOTICE

To prevent ma

mortar into a

a dry system w

internal com

and requiri

terial curing in system, never load

dry system. Loading mortar into

ill cause the mortar to stick to

ponents and cure causing damage

ng replacement of those parts.

Prime with Mortar or Epoxy

4. Remove tip from applicator.

5. Fill the clean hopper with at least 4 gallons of the

material to be sprayed. If using 60 ft of material

hose, then fill with 6 gallons.

6. Turn air regulator adjustment knob (F)

counterclockwise until it stops and gauge (E)

reads zero.

E

The applica

priming. Al

fluid into a w

Always cir

for a few mi

1. Wet out the system. See

Wet Out the System, page 15.

2. Mix the Material. See Mix the Material, page 18.

3. Close the bleed type master air valve (B).

tor nozzle or tip must be removed during

ways push out any remaining “wet out”

aste container before circulating mortar.

culate clean mortar back into the hopper

nutes before beginning to spray.

B

F

ti21571a

Figure 20

7. Open the fluid ball valve (V) on the end of the

fluid hose.

8. Place applicator outlet in a grounded metal 5

gallon waste container.

9. Open the motor ON/OFF pilot ball valve (G)

located on base of applicator.

A

ti21575a

Figure 19

332612A 19

Page 20

PrimewithMortarorEpoxy

10. Open bleed type master air valve (B).

B

ti21574a

Figure 21

NOTICE

To prevent damage to pump seals caused by

cavitation, run the pump slowly until the system

is primed.

12. Continue running the pump until a steady stream

of material comes from the applicator.

ti21632a

Figure 23

13. To stop dispensing, close the motor ON/OFF

pilot ball valve (G). Do not close the fluid ball

valve(V)whentheairmotorisrunning.

11. Rotate the air regulator adjustment knob (F)

clockwise until pump begins to move slow ly.

F

ti21570a

Figure 22

ti21579a

Figure 24

14. Place the applicator outlet into the hopper.

15. With the fluid ball valve (V) open, o pen the motor

ON/OFF pilot ball valve (G). Material will begin

dispensing.

16. Recirculate a few gallons of material to be sure

the material is flowing properly.

17. Install a tip onto applicator. The system is now

primed and ready to spray.

20 332612A

Page 21

Spray

Spray

NOTICE

Do not operate the pump motor with the applicator

material ball valve (V) closed. This may cause the

pumporhosetopackout.

Prevent Packout

To avoid “packing out” the pump or hose:

• Use the lowest pressure and largest nozzle size

that provides an acceptable spray pattern. Thi s will

also result in seals and wear parts lasting much

longer.

• Do not use any more fluid hose than is necessary.

• Use an applicator with a rubber tip retainer that will

blow off if it plugs.

Before Starting or Stopping Material

Flow

• Never dead end the pump against the fluid shut-off

ball valve.

• Start and stop the fluid flow with the red-ha ndl ed

brass air motor pilot valve at the applicator.

• Always have the atomizing air turned on before

and after spraying fluid.

Before Starting Material Flow

1. Always open the air assist valve (U) and adjust

air assist needle valve (M) first.

Spraying

NOTICE

Do not allow pump to run without material in the

hopper. It will quickly accelerate to a high speed

causing pump seal damage.

NOTICE

To prevent material curing in system, never load

mortar into a dry system. Loading mortar into

a dry system will cause the mortar to stick to

internal components and cure causing damage

and requiring replacement of those parts.

1. Wet Out the System, page 15.

2. Mix the Material, page 18.

3. Prime with Mortar or Epoxy, page 19.

NOTICE

Failure to flush prior to material curing in the

system will result in damage to system and

may require replacement of all system parts in

contact with the material.

4. Turn air regulator adjustment knob (F)

counterclockwise until it stops and gauge (E)

reads zero.

E

2. Open applicator material ball valve (V) second.

3. Open (turn on) the motor pilot ball valve (G) last.

Before Stopping Material Flow

1. Always close (turn off) the motor pilot ball valve

(G) first.

2. Close applicator material ball valve (V) second.

3. Turn off the air assist valve (U) last.

332612A

F

ti21571a

Figure 25

21

Page 22

Spray

5. Install tip on applicator by stretching rubber

retainer with a screwdriver or screwing on

retainer, depending on your application kit.

Figure 26

6. Open air assist valve (U) and adjust the air assist

needle valve (M). See Details, page 8 .

7. Open the material ball valve (V) on the base of

the applicator.

NOTICE

Do not operate the pump motor with the

applicator material ball valve (V) closed. This

maycausethepumporhosetopackout.

8. Open the pilot ball valve for air motor (G) located

on base of applicator. See Details, page 8 .

Material will begin dispensing.

9. Adjust air motor regulator adjustment knob (F)

until desired material flow rate is achieved. Turn

clockwise to increase pressure, counterclockwise

to decrease pressure.

E

F

ti14355a

ti21571a1

Figure 27

NOTE:

See S pray Adjustmen ts (Mortar Spray

Applicator), page 23 or Spray Adjustments (HTX

680 Applicator), page 25for details ab out all of

the adjustments that can be made to the way the

system sprays.

10. If the system is approaching its cure time or the

system will be idle for enough time for material

to begin curing in the system, Flush the system.

See Flush, page 26.

22

NOTICE

Failure to flush prior to material beginning to

cure in the system will result in damage to

system and may require replacement of all

parts in contact with the material.

11. If the flushed system will be idle for more than

90 minutes, Disassemble and Clean the Pump

(Daily). See Disassemble and Clean the Pump

(Daily), page 30.

332612A

Page 23

Spray Adjustments (Mortar Spray Applicator)

Spray Adjustments (Mortar Spray Applicator)

M

Figure 28

Key:

M

U

CA

CB Air Needle (adjustable position)

CC Air Needle Retaining Screw

CD

CE Tip (Nozzle)

CF

Needle Valve for Air Assist Flow Control

Air Assist Shutoff Ball Valve

Air Assist Air Line

Fluid Housing

Rubber Tip Retainer

U

General Adjustments

The spray pattern can be adjusted by changing:

• Tip (CE) size

• Fluid flow, use air motor regulator adjustment knob

(G)

• Air flow, use needle valve (M)

• Air needle (CB) position

Adjust Air Flow:

while adjusting the needle valve (M) for the minimum

air flow necessary for a good pattern. Air bleeds from

the applicator nozzle whenever the applicator air

assist valve (U) is open. Close the val ve to stop the

air flow, if desired. Otherwise, the air valve can stay

open during priming. Ai r must be on prior to fluid flow.

Adjust Air Needle (CB) position:

needle (CB) is slightly behind the tip (CE).

Fully open the air assist valve (U),

Ensure the air

CA

CB

CC

CD

CF

NOTE:

restrict or completely block material flow.

This can result in the retainer (CF) blowing

off. Installing the needle too far back can

raise the pressure behind the fluid enough

to blow the retainer (CF) off and can cause

dripping.

Installing needle too far forward can

CE

Air Flow Valve Adjustment

To decrease air flow, turn valve knob clockwise.

To increase air flow, turn valve knob

counterclockwise.

Check material and thin as needed to maintain the

proper consistency. The material may thicken as it

sits and could slow down application or affect the

spray pattern.

Flush and dry applicator thoroughly at the end of each

use. Tips and retainers must be cleaned by hand.

Material Flow Adjustments

For a lighter spray pattern, adjust the air needle

closer to the fluid nozzle and/or reduce the fluid flow.

For a heavier spray pattern, adjust the air needle

farther back from the fluid tip and/or increase the

fluid flow.

332612A 23

Page 24

Spray Adjustments (Mortar Spray Applicator)

NOTE:

air pressure back into fluid hose, slowing

material flow.

Withdrawing needle too far can force

Spray Techniques

1. Test the spray pattern on cardboard. Hold

the applicator 6-18 in. (150-450 mm) from the

surface. Use this spraying distance for most

applications.

2. Adjust fluid flow until material flow is a dequate.

2. Insert screwdriver through hole in tab of nozzle

retaining cap.

3. Push screwdriver head against notch on

applicator tip and pry nozzle retaining cap over

lip until it snaps into place.

3. Adjust the applicator air assist needle valve to

achieve a uniform round spray pattern.

4. Consider the size of aggregate in the material

and the coarseness of the spray pattern. Larger

nozzles allow heavier patterns.

5. Overlap each stroke 50%. A circular overlapping

pattern may give the best results, and is obtained

by grasping the flex-head and swinging the head

around as the hose flexes.

When spraying small confined areas use the valve

and knob to make fine adjustments without adjusting

the pump.

Typically desired spray pressure is 20-25 psi

(140-170 kPa, 1.4-1.7 bar) on the motor air

regulator (F). Higher pressures may cause excessive

wear on the fluid pump. Select a fluid tip l arge

enough to spray at low pressure. Some materia ls will

packout at higher pressures.

Installing Nozzle Retaining Cap

ti14355a

Figure 29

4. Turn the rubber retainer back and forth to be sure

it is fully seated.

Material Compatibility

NOTICE

To prevent the seals and rubber tip from swelling,

do not leave solvent in the applicato r when not in

use.

The nylon hose in the Flex Applicator is compatible

with solvents. The rubber gasket in the cam and

groove inlet fitting and the rubber nozzle retainer

should be hand cleaned and dried after each use.

1. Place nozzle retaining cap over top lip of

applicator housing.

24

332612A

Page 25

Spray Adjustments (HTX 680 Applicator)

Spray Adjustments (HTX 680 Applicator)

DG

M

Figure 30

Key:

M Needle Valve for Air Assist Flow Control

U Air Assist Shutoff Ball Valve

DA Air Assist Air Line

DB Fluid and Air Manifold

DC Tip (Nozzle)

DD Tip Retainer

DE Air Check Valve

DF Fluid Inlet Swivel

DG Handle

The spray pattern can be adjusted by changing:

• Tip (DC) size

• Fluid flow, use air motor regulator adjustment knob

(G)

• Air flow, use needle valve (M)

The standard applicator adjustment

the air assist valve (U), while adjusting the needle

is to fully open

DA

DE

U

DB

DD

DC

DF

valve (M) for the minimum air flow necessary for a

good pattern.

Air bleeds from the applicator nozzle

the applicator air assist needle valve (M) is open.

Close the valve (U) to stop the majority of air flow, if

desired. Some air will still bleed through valve (U) to

help keep the air passages clean. Otherwise, the air

valve(U)canstayopenduringpriming.Airmustbe

on prior to any fluid flow.

Adjusting the spray pattern

balance the fluid flow and the air to the applicator,

and requires the correct tip size.

Always run full air volume through the applicator

when you are done spraying to remove any fluid

residue. Remove and clean the tip (DC) by hand.

Removeaircheckvalve(DE)tobesurenofluidhas

backed up to the check valve. If it has, remove and

clean air spool valve (U).

Fine Finish pattern discs and adapter kit 287227 is

included and can be added for more pattern control.

See manual 310617.

requires testing to

whenever

332612A 25

Page 26

Flush

Flush

NOTICE

Failure to flush prior to material curing in the

system will result in damage to system and may

require replacement of all system parts in contact

with the material.

NOTICE

If the zero cavity pressure relief valve has been

used to relieve pressure, the valve must be flushed

to prevent material hardening in zero cavity relief

valve. If that is not sufficient, remove, disassemble,

andcleanthevalvethenreinstall.

2. Remove applicator tip and retainer.

ti21643a

Figure 32

• Flush if the materials in the system are about to

reach their cure time.

• Flush any time the flow rate starts to decrease as

this is a sign that material is starting to thicken and

cure.

• Always flush the system at least twice, draining

all material flushing agent between flushes then

replacing with clean material flushing agent.

• For some mortars, it is recommended to flush

every 3 - 5 kits. Others can run continuously

without flushing. See material manufacturer

recommendation.

1. Close the bleed type master air valve (B).

B

3. Place applicator outlet in a waste container. The

wastecontainermustbelargeenoughtohold

all dispensed material.

ti21632a

Figure 33

4. With air assist air flowing, open the material ball

valve (V) on the base of the applicator.

5. Open the pilot ball valve (G) located on base of

applicator.

A

ti21575a

gure 31

Fi

26 332612A

Page 27

Flush

6. Open bleed type master air valve (B) to begin

dispensing.

B

ti21574a

Figure 34

7. When the material level in the hopper is within a

few inches of the material inlet at the bottom:

a. Scrape th e material down the sides of the

hopper.

b. Fill the hopper with water or solvent as the

material runs out and continue dispensing.

8. Keep the hopper filled with material flushing

agent while dispensing.

10. Place applicator in the system hopper with the

outlet pointing down to enable fluid circulation.

NOTE:

If flushing with solvent, do not

submerge the applicator in the solvent.

11. Circulate clean water or solvent:

a. Fill the system hopper with clean water or

solvent.

ti21644a

Figure 36

b. Use a scrub brush to scrub the walls of the

hopper.

ti21657a

re 35

Figu

NOTE:

Be prepared to decrease the air

pressure when the material exiting the

hose changes to water or solvent. Water

and solvent pump more easily so pump

speed will increase.

9. When water or solvent begins to exit the

applicator outlet, close the pilot ball valve (G)

located on base of applicator to stop dispensing.

c. Open the pilot ball valve (G) on applicator to

begin circulating water or solvent.

d. Run the pump at 60-90 cycles per min ute

for 3-5 minutes. Adjust air pressure as

necessary to maintain 60-90 cycles per

minute.

NOTE:

High flushing fluid velocity is

the most important item for effective

cleaning. The fluid hose should

shake while the pump is running.

This is necessary to maximize the

cleaning effects of flushing.

e. While pumping at 60–90 cycles per minute,

close then open the pilot ball valve (G) many

times to clean it. Each time the pilot ball valve

(G) is closed, close then open the fluid ball

valve(V)toflushthefluidballvalve.Ensure

332612A

27

Page 28

Flush

fluid ball valve is open before opening pilot

ball valve (G).

NOTE:

gets hard to operate, it should

be disassembled, cleaned, and

re-packed with grease.

f. Decrease air pressure to air motor back to

operating pressure.

g. Close the air motor pilot ball valve (G).

h. Place applicator outlet in a grounded metal

waste container.

i. Open air motor pilot ball valve (G) to dispense

into grounded metal waste container.

j. Dispense into grounded metal waste

container until hopper is almost empty then

close air motor pilot ball valve (G).

k. Repeat this entire “Circulate clean water

or solvent” step one more time to ensure

system is thoroughly flushed.

When the fluid ball valve

12. After performing the previous step at least twice,

drain remaining flushing fluid from system:

a. Place grounded metal drain pan beneath

pump lower inlet fittings.

b. Remove hopper and fittings between hopper

and pump lower.

c. Use a screwdriver to lift the pump lower inlet

ball. This will drain the remaining material

from the pump lower. When the pump stops

draining, release the pump lower inlet ball.

d. Install fittings and hopper.

e. Install camlock retaining straps.

f. Starting at the pump, raise the ho se bundle

above your head and slowly move towards

the applicator. As you move towards the

applicator, the remaining fluid in the hose will

drain from the applicator into the bucket.

13. Disassemble and clean the pump at the end

of every day. The procedure takes about 10

minutes. See Disassemble and Clean the Pump

(Daily), page 30.

28 332612A

Page 29

Notes

Notes

332612A 29

Page 30

Disassemble and Clean the Pump (Daily)

Disassemble and Clean the Pump (Daily)

Suggested Tools

• 5/8 in. box end wrench or 5/8 in. socket and ratchet

• Rubber mallet (to break items loose, if necessary)

BM

BL

BU

BJ

BP

BK

BE

BH

BD

BT

BT

BI

BF

BG

BS

BV

BB

BC

BN

BA

BR

Figure 37

30 332612A

ti21645a

Page 31

Key

BA Inlet Elbow with Camlock

BB Inlet Housing Clamp

BC Inlet Housing Assembly

BD Inlet Ball

BE Inlet Ball Stop

BF Pump Rod Assembly

BG Outlet Ball Stop

BH Piston Seal

BI Cylinder

BJ Cylinder Clamp

BK Outlet Housing

BL Throat Packing

BM Packing Nut (non-adjustable)

BN Hopper

BP Pump Outlet

BR Hopper Release Camlock

BS Outlet Ball

BT Cylinder O-rings

BU Outlet Housing Lock Nut

BV Ball Cage Spring

Disassemble and Clean the Pump (Daily)

NOTE:

As items are disassembled, use a

soft brush and water or a compatible solvent

to clean components.

1. Flush the system. See Flush, pag e 26.Stop

pump near bottom of its stroke.

2. Perform Pressure Relief Procedure. See

Pressure Relief Procedure, page 14.

3. With fluid pressure relieved, remove material

hose from pump outlet (BP).

4. Disconnect hopper at outlet camlock (BR) then

remove hopper (BN).

5. Remove inlet elbow (BA).

6. Tip cart back so it rests on the back of the cart.

Always Keep Spare Parts Stocked

Always keep spare parts stocked to ensure getting

back up and running as quickly as possible. Parts

to keep stocked include:

• Cam and groove fitting gaskets

• Spray tips

•Tipretainer

• Rod and cylinder seals

• Cylinder o-rings

• Other parts as needed

To prevent skin inj ection and splashing, never

open a camlock hose or applicator fitting

while there is pressure in the fluid li ne. See

Pressure Relief Procedure, page 14.

See the figure at the begin ni ng of this section for part

references.

ti21655a

Figure 38

7. While holding onto the inlet housing (BC), use

a5/8in. wrenchtoloosenthetwonutson

the inlet housing clamp (BB) then remove inlet

housing (BC).

8. Remove inlet ball stop (BE) and ball cage spring

(BV).

9. Use 5/8 in. wrench (64) to loosen the two nuts on

the cylinder clamp (BJ) then remove cylinder (BI).

10. Disconnect pump rod (see the following figure):

a. Pushpistonrodprotectivespringupand

away from coupling assembly (BF1-BF3).

Disassemble and clean the pump at the end of every

day. The procedure takes about 10 minutes.

b. Remove clip (BF1), and slide coupling cover

(BF2)uptoremovecoupling(BF3).

332612A 31

Page 32

Disassemble and Clean the Pump (Daily)

9. Slide cylinder (BI) over rod (BF) with o-ring (BT)

installed between outlet housing (BK) and

cylinder (BI).

BF1

BF2

Figure 39

11. Pull rod (BF) down and out of outlet housing (BK).

12. Remove outlet ball stop (BG) from rod (BF) by

pushing o-rings off of ball stop (BG).

13. Loosen and remove packing nut (BM) then

remove throat packing (BL).

14. Useabrushandsolventtocleanallloosepieces.

NOTE:

The pump rod (BF) is not disassembled

unless the piston packing or seat needs to be

replaced.

NOTE:

The inlet housing (BC) is not

disassembled unless the inlet seat needs to be

replaced.

Assemble the Pump

1. Loosely install throat packing (BL) with the open

end facing into the pump.

BF3

NOTE:

If the o-ring (BT) does not stay in

place while assembling the cylinder (BI)

to the housing (BK), the cart may need

to be tipped upright to install properly.

ti21656a

After clamp is installed, tip cart back to

horizontal position to finish assembly.

10. Use cylinder clamp (BJ) to secure cylinder (BI)

to outlet housing (BK).

NOTE:

Each clamp has one flat so that

only one wrench is required to tighten

clamp. Align bolt head with flat then

useawrenchonthenuttotighten.

Tighten both sides of the clamp evenly to

approximately 10 ft-lb (14 N•m).

11. Install inlet ball (BD), ball cage spring (BV), and

inlet ball stop (BE) in inlet housing (BC).

12. With inlet ball (BD), ball cage spring (BV), and

inlet ball stop (BE) in place, place o-ring (BT)

between cylinder (BI) and inlet housing (BC)

then use inlet housing clamp (BB) to install inlet

housing (BC) onto cylinder (BI).

2. Install packing nut (BM) hand-tight.

3. Lubricate the ball s (BS, BD) to ensure they do

not stick.

4. Install outlet ball (BS), out let ball stop (BG) with

o-rings into rod (BF). Ensure outlet ball stop

o-rings are in the grooves on the outlet ball stop

rod.

5. Grease the packing on the rod (BF).

6. Gently slide rod (BF) through throat packing (BL).

7. Install coupling (BF3), slide coupling cover (BF2)

over coupling, then install clip (BF1) to secure

pump rod (BF) to air motor.

8. Use a flat-tip screwdriver and a plastic mallet to

tighten packing nut (BM) until it stops.

NOTE:

This is not an adjustable packing

but the packing nut (BM) does need to

be tight against the throat packing (BL).

NOTE:

Each clamp has one flat so that

only one wrench is required to tighten

clamp. Align bolt head with flat then

useawrenchonthenuttotighten.

Tighten both sides of the clamp evenly to

approximately 10 ft-lb (14 N•m).

13. Install inlet elbow (BA) onto inlet housing (BC).

14. Tip cart up.

15. Install hopper (BN) onto the hopper bracket and

connect to inlet elbow (BA).

16. Install material hose onto pump outlet (BP).

32 332612A

Page 33

17. Wrap blue, velcro, camlock retaining straps

around each camlock connection to secure.

Shutdown

NOTE:

between the hopper and pump lower, the

camlock at the pump outlet, the camlocks

on the fluid hoses, and the camlock on

the applicator inlet. The retaining straps

should be tight and must not be able to

slide off camlock.

18. Add TSL to the packing nut (BM) until 1/2 full.

This includes the two camlocks

Shutdown

NOTICE

To prevent rust, never leave water or water-based

fluid in pump overnight.

1. Flush the system. See Flush, page 26.

NOTE:

flush with water first, then with a rust inhibitor,

such as mineral spirits solvent (also called white

spirit), to prevent rust.

If you are pumping water-based fluid,

2. Perform Disassemble and Clean the Pump

(Daily) procedure. See Disassemble and Clean

the Pump (Daily), page 30.

332612A 33

Page 34

Maintenance

Maintenance

Preventative Maintenance

The operating conditions of your particular system determine how often maintenance is required. Establish

a preventive maintenance schedule by recording when and what kind of maintenance is needed, and then

determine a regular schedule for checking your system.

Daily Maintenance

1. Flush the system. See Flush, page 26.

2. Relieve pressure. See

Pressure Relief Procedure, page 14.

3. Perform the Disassemble and Clean the Pump

(Daily) procedure at the end of every day. See

Disassemble and Clean the Pump (Daily), page

30.

4. Drain water from air filter.

5. Clean hopper with a scrub pad. It is

recommended that you clean the outside of the

sprayer using a cloth and compatible solvent.

6. Check hoses, tubes, and couplings. Tighten all

fluid connections before each use.

7. Check and replace camlock gaskets as needed.

Corrosion Protection

NOTICE

To prevent rust, never leave water or water-based fluid

in pump overnight.

Always flush the pump before the fluid dries on the displacement rod. First, flush with water or a compatible

solvent, then with oil. Relieve the pressure, but leave the oil in the pump to protect the parts from corrosion.

Cart Maintenance

Periodically lubricate the axle between points A and

B with lightweight o il. See the following figure.

Keep the cart clean by wiping up spills dai ly, using a

compatible solvent.

A

B

ti21634a

Cart Assembly

Figure 40

34 332612A

Page 35

Troubleshooting

To prevent sk

open a camloc

while there

Pressure Re

1. Perform Pre

Pressure Re

2. Check all p

solutions

pump.

PROBLEM — CAUSE — SOLUTION

Example:

•

Problem.

–

Cause.

♦ S olu tio n.

in injection and splashing, never

k hose or applicator fitting

is pressure in the fluid line. See

lief Procedure, page 14.

ssure Relief Procedure. See

lief Procedure, page 14.

ossible problems, causes, and

listed below before disassembling

Troubleshooting

•

Output low on both strokes.

–

Air line restricted or air supply inadequate.

Valves closed or clogged.

♦ Clear air li n e; increase air supply. Check that

valves are open.

–

Fluid hose/applicator obstructed; hose ID too

small.

♦ Clear hose or applicator*; use hose with larger

ID.

•

Output low on down-stroke.

–

Open or worn intake valve.

♦ Clear or service intake valve.

•

Output low on up-stroke.

–

Open or worn piston valve or packings.

♦ Clear piston valve; replace packings.

•

Does not operate.

–

Air mot

♦ Remove valve by disconnecting swivel unions.

–

Valve closed or clogged.

♦ Clear air line; increase air supply. Check that

–

Fluid hose or applicator obstructed.

♦Clea

–

Drie

♦ Clean rod; always stop pump at bottom of

–

Air motor parts dirty, wo rn or damaged.

♦ Cl ean or repair air motor. S ee motor manual.

or pilot valve (211) is faul ty.

Connect hose directly to air motor. Operate

motor directly with air regulator (210).

valves are open.

nhoseorapplicator.*

d fluid on displacement rod or inlet ball.

stroke; keep wet-cup filled with compatible

solvent. Be sure inlet ball moves freely.

•

Erratic accelerated speed.

–

Fluid supply exhausted, clogged suction.

♦ Refill hopper and prime pump.

–

Open or worn piston valve or packings.

♦ Clear piston valve; replace packings.

–

Open or worn intake valve.

♦ Clear or service intake valve.

•

Cycles or fails to hold pressure at stall.

–

Worn check balls, seats, or piston packing.

♦ Service lower. See Disassemble and Clean

thePump(Daily),page30.

332612A 35

Page 36

Troubleshooting

•

Poor finish or irregular spray pattern.

–

Incorrect fluid pressure at applicator.

•

Motor powered but nothing comes out of hose.

–

Pump is packed out with dry or cured material.

♦ S ee applicator manua l; read fluid

manufacturer’s recommendations.

–

Inadequate air assist air pressure.

♦ Adjust air assist needle valve.

–

Dirty, worn, or damaged spray applicator.

♦ Servi c e spra y appl i cator. See spra y appl icator

manual.

•

Cannot open or close air motor pilot ball valve on

applicator.

–

Dirty air clogged the air motor pilot valve.

♦ If no ball valve is immediately available:

Bypass the air motor pilot valve so air is

always supplied to air motor, regardless of

applicator pilot valve position. Then control

fluid flow by adjusting air regulator pressure

up and down as needed. Install new pilot ball

valve when one becomes available.

•

Cannot open or close fluid ball valve on hose at

applicator.

–

Mortar cured in valve due to insufficient flushing.

♦ If no ball valve is immediately available:

Relieve pressure in system, remove ball valve,

then control fluid flow by adjusting air regulator

up and down as needed.

♦ Disassembly, clean, and repack ball valve with

lithium grease.

♦ Disassemble and Clean the Pump (Daily),

page 30

–

Hose is packed out with dry or cured material.

♦ Reverse hose and try to push out bad material.

♦ S om e materia ls may need only 1 in. inn er

diameter fluid line all the way to the applicator.

•

Material is too thick to push through hose without

packing out.

–

3/4in.x10ftwhiphoseistoorestrictive.

♦ Remove 3/4 in. x 10 ft whip hose from bundle

at applicator end. Move fluid ball valve to end

of 1 in. x 25 ft hose. Coil up extra air hose at

machine end.

♦ Thin and mix material thoroughly to a lower

viscosity.

♦ Use a pump system priming fluid (slime). See

Wet Out the System, page 15.

* To determine if fluid hose or applicator is obstructed,

follow Pressure Relief Procedure, page 14.

Disconnect fluid hose and place a container at pump

fluid outlet to catch any fluid. Turn on air power just

enough to start pump. If pump starts, the obstruction

is in fluid hose or applicator.

♦ Replace ball val ve.

36 332612A

Page 37

Repair

Repair

7. Tighten tie rod nuts (44).

8. Connect pump rod. S ee figure shown previously

in this section.

To prevent skin inj ection and splashing, never

open a camlock hose or applicator fitting while

there is pressure in the fluid line. Perform

Pressure Relief Procedure, page 14, before

performing any repair procedure.

Replace Pump Components

To replace any pump components

(excluding the air motor), perform the

Disassemble and Clean the Pump (Daily), page 30,

procedure.

Replace Air Motor

1. Perform Pressure Relief Procedure, page 14.

2. Note location of small air tube connections on air

motor then remove air tubes.

3. Disconnec

a. Push piston rod protective spring up and

t pump rod (see the following figure):

away from coupling assembly (BF1-BF3).

9. Connect small air tubes to ai r motor.

Replace Pump Lower

Perform this procedure to replace the entire

pump lower with a new or different pump lower.

To repair or replace any internal components

in the pump (excluding the air motor), perform

Disassemble and Clean the Pu mp (Daily), page 30.

1. Perform Pressure Relief Procedure, page 14.

2. Disconnect pump lower from hopper.

3. Disconnect material hose from pump lower outlet.

4. Disconnect pump rod (see the following figure):

a. Pushpistonrodprotectivespringupand

away from coupling assembly (BF1-BF3).

b. Remove clip (BF1), and slide coupling cover

(BF2)uptoremovecoupling(BF3).

b. Remove clip (BF1), and slide coupling cover

(BF2) up to remove coupling (BF3).

BF1

Figure 41

4. Loosen three tie rod nuts (44), then loosen

and rem ove tie rods (42) from ai r motor. See

Parts, page 38.

5. Remove air motor.

6. Align air motor with tie rods (42) then tighten tie

rods to air motor.

BF2

BF1

BF3

5. Loosen three tie rod nuts (44), then loosen

ti21656a

6. Remove pump lower.

7. Align new pump lower with tie rods (42) then

8. Tighten tie rod nuts (44).

9. Connect pump rod. S ee figure shown previously

10. Connect pump lower to hopper.

Figure 42

and rem ove tie rods (42) from ai r motor. See

Parts, page 38.

tighten tie rods to air motor.

in this section.

BF2

BF3

ti21656a

332612A 37

Page 38

Parts

Parts

M680 Systems

4

3

1

65

7

67

68

66

49

4

8

47

41

48

45

6

7

50

7

18

53

4

51

42

5

46

20

6

3

2

7

26

15

1

14

1

17

1

44

5

7

20

10

13

43

3

11,55,58

Assemble fitting (15) and zero cavity relief

valve (17) then assemble to swivel (14)

1

with relief hole pointing downward or at the

pump.

Apply pipe sealant to all non-swiveling pipe

2

threads.

Apply clear, liquid petrolatum to axles (1)

3

before assembling wheels (2).

12,55,58

Pack grease around the end of the

zero-cavity relief valve in front of the

4

threads.

Torque to 50–60 ft-lb (68–81 N∙m).

5

Torque to 145–155 ft-lb (197–210 N∙m).

6

Apply medium strength thread-locking fluid

7

to threads.

ti22048a

Quantity

f

Re

1262914CART 1111111

2 116406

3113436RING,retaining 2222222

4

38 332612A

Pa

---

rt

Description

WHEEL

MODULE, air controls; see

Air Controls

T83424T83524T83624T837

24

2222222

1111111

2909262926262927

26

Page 39

Parts

Quantity

Ref Part

6 104572 WASHER, lock spring

7■

8 155470 SWIVEL, union, 90 degree 1 1 1 1 1 1 1

10■

11■ 16V510 CAM AND GROOVE, elbow,

12■ 16V509 CAM AND GROOVE, 2 inch x

13■ 16U536 HOPPER 1 1 1 1

14 160022 UNION, adapter 1 1 1 1 1 1 1

15 127082 TEE, branch, female 1 1 1 1 1 1 1

17 16W513 VALVE, relief, zero cavity 1 1 1 1 1 1 1

18

20■

29 114958 STRAP, tie 10 10 10 10 10

30 110198 COUPLER, line, air 1 1 1 1 2

31 159841 BUSHING, 3/8 x 1/4 in. 1 1 1 1 2

32 169970 FITTING, line air 1 1 1 1 2

33 24U209 APPLICATOR, texture, pole 1 1 2

34 24T947 APPLICATOR, texture, flexible 1 1 1

41◆ M34LN0 MOTOR, air 1 1 1 1 1 1 1

42◆ 16U817 ROD, tie, 10-5/8 3 3 3 3 3 3 3

43◆ 24R253 LOWER, pump (see manual

44◆

45◆

46◆ 244819 COUPLING, assembly 1 1 1 1 1 1 1

47◆

48◆ 244820 CLIP, hairpin with lanyard 1 1 1 1 1 1 1

49◆ 262908

50◆ 111799 SCREW, cap, hex head 1 1 1 1 1 1 1

51◆ 16V671 GUARD, spring 1 1 1 1 1 1 1

53

55** 16W506 GASKET, 2 in, coupler, cam

57** 16W490 O-RING, pump cylinder

59** 16A443 NOZZLE, 3/16 inch 1

60** 16A444 NOZZLE, 1/4 inch 1

61** 16A448 NOZZLE, 1/2 inch 1

62** 16A449 NOZZLE, 9/16 inch 1

63** 16W508

64** 127265 TOOL, wrench, ratchet 1 1 1 1 1 1 1

114193 SCREW, machine, hex washer

---

---

---

101712

15H392 ROD, adapter 1 1 1 1 1 1 1

197340 COVER, coupler 1 1 1 1 1 1 1

186620

▲

Description

head

BRACKET, hopper 1 1 1 1

2inch

1-1/2 npt

PLUG, tubing, cart 2 2 2 2 2 2 2

NUT, hex, flange, serrated 8 6 8 6 8 6 8

332649)

NUT, lock

WIRE, ground, with clamp

LABEL, symbol, ground

and groove (6–pack)

(10–pack)

KIT, seals, pump

24T834 24T835 24T836 24T837 262909 262926 262927

4444444

12 10 12 10 12 10 12

1111

1111

1111111

3333333

1111111

1111111

2222

2222222

1

332612A 39

Page 40

Parts

Quantity

Ref Part

65

66

67 113505

68 107251 SCREW, machine, panhead

98 24T854 BUNDLE, hose, 35 ft 1 1 1 1 1

99 24R254 BUNDLE, hose, extension, 25

▲

*

Parts included in Pack Out Hose Clean Kit 16W601 (purchase separately).

■

◆

**

---

---

---

Replacement Danger and Warning labels, tags, and cards are available at no cost.

Parts included in Hopper Replacement Kit 24T853 (purchase separately).

Parts included in Pump 16W514 (purchase separately). See manual 332650.

Spare parts shipped with machine.

Not for sale.

Description

BRACKET,toolbox 1111111

KIT, tool box

NUT,keps,hexhead 4444444

ft

24T834 24T835 24T836 24T837 262909 262926 262927

1111111

4444444

1

40 332612A

Page 41

Air Controls

213

Parts

222

219

2

220

211

206

207

225

209

222

223

208

205

204

216

212

201

202

221

215

202

203

206

218

214

210

224

ti22050a

Apply pipe sealant to all non-swiveling pipe threads.

1

Assemble one end of lanyard between ball valve (207) and fitting (208). One end hangs loose.

2

Ref Part Description Qty

201 262658 FILTER, air, 40 micron 1

202 158491 FITTING, nipple 2

203 C20432 FITTING, cross, pipe 1

204 C20461 FITTING, nipple, reducing,

---

205

206 159239 FITTING, nipple, pipe,

207 113332 VALVE, ball, vented, 0.750 1

208 113429 COUPLING, universal,

209 113430 COUPLING, universal,

210 104267 REGULATOR, air 1

211 16W146 VALVE, 3-way, pilot

---

212

hex

FITTING, elbow, street 1

reducing

3/4–14 npt male

3/4–14 npt female

operated

BRACKET, air controls 1

Ref Part Description Qty

213 160430 GAUGE, pressure, air 1

214 155470 FITTING, swivel, union, 90

degree

215 101950 SCREW, socket head cap,

1

216 115942 NUT, hex, flange head 2

218 110198 COUPLER, line, air 1

2

219 127313 FITTING, elbow 1

220 111881

221 100737 PLUG, pipe 1

1

222 218093 HOSE, coupled 1

1

223 162505 FITTING, union, swivel 1

224 113498 VALVE, safety, 110 psi 1

225 16W586 CABLE, lanyard, whip

1

1/4x2.5inch

MUFFLER

check

1

2

1

1

---

Not for sale.

332612A

41

Page 42

Parts

Zero Cavity Relief Valve, 16W513

3

2 4

305

307

Useassemblytool15T630toinstallseal

1

(304).

Apply medium strength thread-locking fluid

2

to threads prior to installing seat (305).

Ref Part Description Qty

301 - - - HOUSING, end 1

302 16U807 STEM 1

303 15M189 SPACER, backup, seal 1

304 15M529 SEAL, check valve 1

---

Not for sale.

308

301

306

3

302

303

304

1 3

4

ti22051a

Apply lithium grease to seal, thread, and

3

o-ring.

Torque to 95–105 in-lb (10.7–11.9 N∙m).

4

Ref Part Description Qty

305 16V956 SEAT 1

306 15Y627 O-RING, PTFE 1

307 16V957 HOUSING 1

308 102915 PIN, drive 1

42

332612A

Page 43

Hose Bundles

416,456,458

432

431

432

431

452

416

424

425

416,456,458

423

428

Parts

454

430

424

430

454

425

ti22047a

427

425

Quantity

24T852 (25

ft air hose

bundle)

Ref Part

Description

24T854 (35

ft bundle)

24R254 (25

ft bundle)

24U331 (38

ft air hose

bundle)

416 289874 COUPLER KIT, 1 in. female cam/groove 2 1

421 24U184 COVER, hose, plastic, 2 in. x 50 ft 1 1

422 24U185 COVER, hose, plastic, 3 in. x 50 ft 1 1 1 1

423 16W512 HOSE, fluid, 3/4 in., coupled, 10 ft 1

424 16W511 HOSE, fluid, 1 in., coupled, 25 ft 1 1

425* 15T116 COUPLER, male, cam and groove, 1 in. 2 1

426* 158585 FITTING, nipple 1 1

427 127232 VALVE, ball, 1 inch, stainless steel,

11

1000 psi

428 24T762 HOSE, air and pilot in scuff jacket, 38 ft 1

429 114958 STRAP, tie 10 10

430 110198 COUPLER, line, air 1 1 1 1

431 159841 BUSHING, 3/8 x 1/4 in. 1 1 1 1

432 169970 FITTING, line air 1 1 1 1

452 24T829 HOSE, bundle, air, 26 ft 1 1

454

127312 FITTING, 1/4 to 1/4 tube 1 1 1 1

456 16W507 GASKET, coupler, 1 in. (6–pack) 2 2

458 240296 STRAP (4–pack) 2 2

426

*

Parts included in Pack Out Hose Clean Kit 16W601 (purchase separately).

---

Not for sale.

332612A 43

Page 44

Accessories

Accessories

Pole Applicator, 24T946

Ideal for spraying in long-reach, open areas and

low-pressure spraying of materials that packout

easily and that will be finish-troweled. The pol e

applicator is similar to the Flexible Applicator, but

with a pipe in place of the hose. See manual 332767.

Includes:

• 30 in. (76 cm) aluminum pipe with cam lock fluid

inlet

• Angled spray head

• Spray air volume control

• Spray shut-off valve

• Motor pilot signal control valve

• Adjustable position center air injection tube

• Rubber tip retaine r

• 4 different-sized tips

44

332612A

Page 45

Technical Specifications

Technical Specifications

Mortar and Epoxy Sprayer Package

U.S.

Maximum Working Pressure 1000 psi 7 MPa, 70 bar

Maximum Air Inlet Pressure 100 psi 0.7 MPa, 7 bar

Minimum Inlet Air Flow (Typical) 30 standard cubic feet per minute

Minimum Inlet Air Flow (Pump

Only)

PressureRatio(FluidtoAir)

Air Motor Piston Diameter 7.5 in. 191 mm

Stroke Length

Lower Output

Flow Rate at 30 cycles per minute 5.44 gpm 20.6 lpm

Flow Rate at 60 cycles per minute 10.88 gpm 41.2 lpm

Air In le t Size 3/4 npt(f) (Chicago Fitti ng )

Fluid Inlet Size 2 in. Cam Groove (Male)

Fluid Outlet Size 1 npt(f) with a 1 in. Cam and Groove Fitting

Weight (without fluid)

Sound Pressure 118 d B(A )*

Sound Power 118 d B(A )*

Dimensions

Height 44.5 in. 113 cm

Width 27.5 in. 70 cm

Depth (pump on cart only)

Deep (pump on cart with hopper)

Maximum Pump Speed

(Do not exceed maximum recommended pump speed of fluid pump to prevent premature pump wear)

Spraying 40 cycles per minute (typi call y less tha n 10 cycles per minute)

Flushing

Wetted Parts

Entire System Stainless steel, UHMWPE, nylon, plated steel, anodized

Pump

Hose Kits

Notes

*

Spraying simulated acoustical texture under typical conditions as specified by the material maufacturer.

8 scfm per gallon at 100 psi

4.75 in. 120 mm

41.9 cu. in. per cycle 686 cc per cycle

250 lb

(with 25 ft of 1 in. hose and

10 ft of 3/4 in. hose)

32 in. 81 cm

37 in. 94 cm

60–90 cycles per minute (only when pumping flushing fluid)

aluminum, FX-75

Stainless steel, carbide, PTFE, UHMWPE, solvent-resistant o-rings

Nylon core, plated carbon steel fittings, anodized alu-

minum, nitrile gaskets

0.85 cubic meters per minute

0.06 cubic meters per minute

10:1

(with7.6mof25mmhoseand

3.0 m of 19 mm hose)

Metric

per liter at 7 bar

113 kg

332612A 45

Page 46

Technical Specifications

M680 Performance Chart

(with 30–weight oil)

Pump Cycles Per Minute

10020 504030

1000

D

800

Pump

Outlet Flui d

Pressure in

psi

600

C

B

400

A

200

0

012345678910

Ref

A Fluid Pressu re at 20 psi Air

B Fluid Pressu re at 40 psi Air

C Fluid P

Description

ressureat70psiAir

E

Flow Rate in Gallons Per Minute

H

60

50

G

Air Flow in

40

Standard

Cubic Feet

30

F

Per Minute

20

10

0

D Fluid Pressure at 100 psi Air

E

F

G Air Consumption at 70 psi Air

H Air Consumption at 100 psi Air

Air Consumption at 20 psi Air

Air Consumption at 40 psi Air

46 332612A

Page 47

Standard

Cubic Feet

Per Minute

of Air (Cubic

Meters Per

Hour)

Technical Specifications

M680 Applicator Air Consumption

(100 psi feed to the machine)

30

20

10

0

1.0 2.0 3.0 4.0 5.0

Needle Valve Turns Open from Closed

332612A

47

Page 48

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for use.

With the exc

twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance

with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco

be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation,

operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized

Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace

free of charge any defective parts. The equipment will be returned to the original purchaser transportation

prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be

made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The

buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages for lost

profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall be available.

Any action for breach of warranty must be brought within two (2) years of the date of sale.