Page 1

Operation

ProMix® PD2K Pr

Automatic Spr

Electronic positive displacement proportioner for fast-setting two-component materials. Automatic

system with Advanced Display Module. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in your

installation, repair, and associated component manuals.

Save these instructions.

See page 3

approvals information.

for model part numbers and

ay Applications

oportioner for

332564B

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Related Manuals ..................................................3

Models................................................................. 4

Warnings ............................................................. 6

Important Isocyanate (ISO) Information.................. 9

General Information ............................................ 10

Advanced Di

ADM Display

USB Downloa

USB Upload P

ADM Keys an

Soft Key Ic

Navigatin

Screen Ico

Pre-Operation Tasks........................................... 17

Pre-operation Checklist ................................ 17

Power On .................................................... 17

Initial System Setup ..................................... 18

Flush Before Using Equipment...................... 18

Valve Settings.............................................. 18

Pressure Relief Procedure .................................. 19

Without Color Change.................................. 19

With Color Change....................................... 19

Operat

Prime a

Sprayi

Purgin

Shutd

Operation Using a Programmable Logic

Network Communications and Discrete

Discrete I/O ................................................. 24

Communication Gateway Module (CGM)

Network Communication I/O Data Map........... 28

Operation Flow Charts ................................. 42

Network Communication - Dynamic

Flow Control System .................................... 57

Run Mode Screens............................................. 58

Opening Screen........................................... 58

splay Module (ADM) ........................ 11

................................................ 11

d Procedure............................ 11

rocedure ................................ 12

d Indicators ............................. 13

ons ............................................. 14

g the Screens ................................ 16

ns ............................................... 16

ion Using Automatic Display Module

(ADM)................................................... 2

nd Fill the System............................. 20

ng...................................................... 21

g ....................................................... 22

own.................................................... 23

Controller (PLC) .................................... 24

I/O................................................. 24

Details ........................................... 27

Command Structure (DCS) ............. 47

Home Screen .............................................. 58

Spray Screen............................................... 62

Fill Screen................................................... 63

Usage Screen.............................................. 64

Jobs Screen ................................................ 65

Errors Screen .............................................. 65

Events Screen ............................................. 65

Setup Mode Screens .......................................... 66

Password Screen......................................... 66

System Screen 1 ......................................... 67

System Screen 2 ......................................... 68

System Screen 3 ......................................... 69

System Screen 4 ......................................... 70

System Screen 5 ......................................... 71

Recipe Screen............................................. 72

Flush Screen ............................................... 73

Pump Screen 1 ............................................ 74

Pump Screen 2 ............................................ 75

Pump Screen 3 ............................................ 76

Pressure Alarm and Deviation Limits............. 76

Calibration Screens...................................... 77

Maintenance Screens................................... 80

Advanced Screen 1...................................... 82

Advanced Screen 2...................................... 83

Advanced Screen 3...................................... 83

0

ation Checks.............................................. 84

Calibr

Pump Pr

Pump Vo

Solven

Color Change.....................................................87

Single Color Systems ................................... 87

Multiple Color Systems................................. 87

System Errors ....................................................88

To Clear Error and Restart............................88

Gun Trigger Input Function ........................... 88

Error Codes................................................. 89

tenance .................................................... 102

Main

Prev

Flu

Cle

Technical Data ................................................. 103

Graco Standard Warranty.................................. 104

essure Check ................................. 84

lume Check.................................... 85

t Meter Calibration ............................. 86

entive Maintenance Schedule .............. 102

shing .................................................... 102

aning the ADM...................................... 102

2

332564B

Page 3

Related Manuals

Related Manuals

Current manua

Manual No. Description

332709

332458

332339 Dosing Pumps, Instructions/Parts

332454

ls are available at www.graco.com.

ProMix PD2K Proportioner for

Automatic Spray Applications,

Repair-Parts

ProMix PD2K Proportioner for

Automatic Spray Applications,

Installation

Color/Catalyst Dispense Valves,

Instructions/Parts

Manual No. Description

332455

333282

332456 Pump Expansion Kits,

Color Change Kits, InstructionsParts

Color Change and Remote Mix

Manifold Kits, Instructions-Parts

Instructions-Parts

332564B 3

Page 4

Models

Models

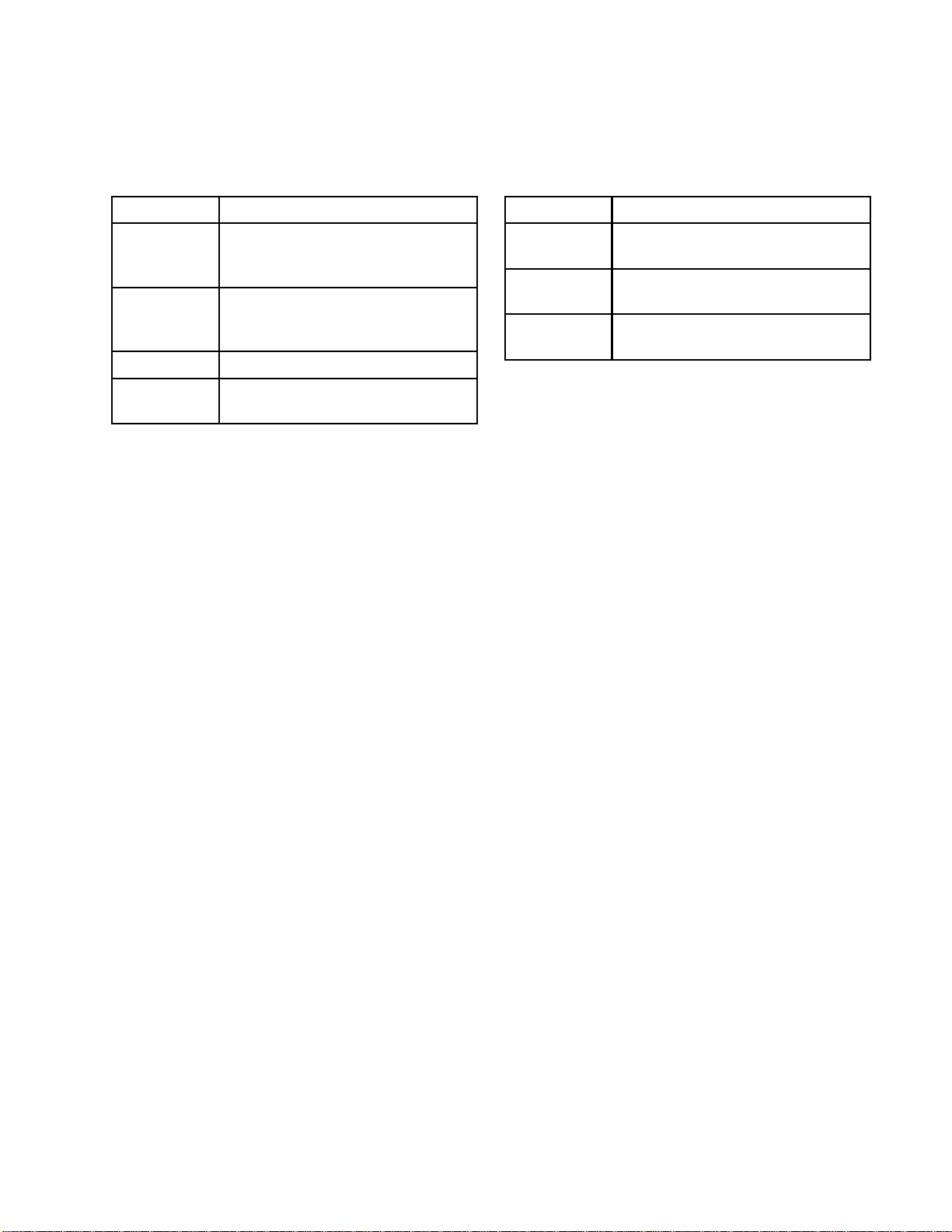

See Figs. 1–6 f

Part No.

AC1000

AC2000

0359

or component identification labels, including approval information and certification.

Series

A

A

Maximum Air Wo

Pressure

100 psi (0.7

7.0 bar)

100 psi (0.7 MPa,

7.0 bar)

MPa,

II 2 G

rking

Maximum Fluid

Pressure

300 psi (2.0

1500 psi (10.34 MPa,

68 MPa, 20.68 bar)

103.4 bar)

Working

Location of PD2K and

Electrical Control Box

(ECB) Labels

Figure 1 Model AC1000 (Low Pressure) Identification

Label

Figure 2 24M672 Control Box Identification Label

4

Continued on the next page.

332564B

Page 5

Figure 3 Model AC2000 (High Pressure)

Identification Label

Models

Figure 4 Non-Intrinsically Safe Color Change Control (Accessory) Identification Label

Figure 5 Intrinsically Safe Color Change Control

(Accessory) Identification Label

Figure 6 Pump Expansion Kit (Accessory) Identification Label

332564B 5

Page 6

Warnings

Warnings

The following

exclamation p

risks. When th

Warnings. Pr

the body of th

warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

oint symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

ese symbols appear in the body of this manual or on warning labels, refer backtothese

oduct-specific hazard symbols and warnings not covered in this section may appear throughout

is manual where applicable.

WARNING

FIRE AND EX

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

•Useonly

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock, Do not use

equipment until you identify and correct the problem.

• Keepaw

PLOSION HAZARD

area free of debris, including solvent, rags and gasoline.

grounded hoses.

orking fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

•Turn

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

6 332564B

off and disconnect power at main switch before disconnecting any cables and before

icing or installing equipment.

serv

and regulations.

Page 7

INTRINSIC SAFETY

Warnings

WARNING

Intrinsical

equipment wi

Follow local

• Be sure your installation complies with national, state, and local codes for the installation of

electrical apparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1

and 2 (Europe) Hazardous Location, including all of the local safety fire codes (for example,

NFPA 33, NEC 500 and 516, OSHA 1910.107, etc.).

• To help prev

•Equipment

Safety. T

unit from

SKIN INJECTION HAZARD

High-pr

skin. Th

immedia

• Do not point dispensing device at anyone or at any part of the body.

•Donotp

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning,

checking, or servicing equipment.

•Tight

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

ly safe equipment that is installed improperly or connected to non-intrinsically safe

ll create a hazardous condition and can cause fire, explosion, or electric shock.

regulations and the following safety requirements.

ent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous

location. See model ID label for the intrinsic safety rating of your model.

• Do not substitute system components as this may impair intrinsic safety.

that comes in contact with the intrinsically safe terminals must be rated for Intrinsic

his includes DC voltage meters, ohmmeters, cables, and connections. Remove the

the hazardous area when troubleshooting.

essure fluid from dispensing device, hose leaks, or ruptured components will pierce

is may look like just a cut, but it is a serious injury that can result in amputation. Get

te surgical treatment.

ut your hand over the fluid outlet.

en all fluid connections before operating the equipment.

332564B

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

•Pres

TOX

Tox

inh

• Read MSDSs to know the specific hazards of the fluids you are using.

•St

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning

surized equipment can start without warning. Before checking, moving, or servicing

pment, follow the Pressure Relief Procedure and disconnect all power sources.

equi

IC FLUID OR FUMES

ic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

aled, or swallowed.

ore hazardous fluid in approved containers, and dispose of it according to applicable

idelines.

gu

equipment.

7

Page 8

Warnings

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

•Protectivee

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

•Usefluids

in all equ

informat

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

•Checkeq

manufac

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which youareusingit.

•Useequ

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

•Keepc

• Comply with all applicable safety regulations.

yewear, and hearing protection.

and solvents that are compatible with equipment wetted parts. See Technical Data

ipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

ion about your material, request MSDS from distributor or retailer.

uipment daily. Repair or replace worn or damaged parts immediately with genuine

turer’s replacement parts only.

ipment only for its intended purpose. Call your distributor for information.

hildren and animals away from work area.

8 332564B

Page 9

Important Isocy

anate (ISO) Information

Important Iso

Isocyanates (ISO) are catalysts used in two

component materials.

cyanate (ISO) Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read and understand material manufacturer’s

warnings and material MSDS to know specific

hazards and precautions related to isocyanates.

Prevent inhalation of isocyanate mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation

is not available, a supplied-air respirator is required

for everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including

chemically impermeable gloves, boots, aprons,

and goggles, is also required for everyone in the

work area.

Eventually a film will form on the surface and the ISO

will begin to gel, increasing in viscosity.

NOTICE

Partially c

the life of a

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere.

Never store ISO in an open container.

• Keep the ISO pump wet cup or reservoir (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may

contain moisture. Always keep solvent

containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubricant when reassembling.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

ured ISO will reduce performance and

ll wetted parts.

Keep Components A and B Separate

Cross-contamination can result in cured

material in fluid lines which could cause serious

injury or damage equipment. To prevent

cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been

contaminated from the other side.

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will cause

ISO to partially cure; forming small, hard, abrasive

crystals, which become suspended in the fluid.

Chang

Changing the material types used in your

equipment requires special attention to avoid

equipment damage and downtime.

•When

•Alw

•Che

•Wh

ing Materials

NOTIC

changing materials, flush the equipment

tiple times to ensure it is thoroughly clean.

mul

ays clean the fluid inlet strainers after

hing.

flus

ck with your material manufacturer for

mical compatibility.

che

en changing between epoxies and urethanes

polyureas, disassemble and clean all fluid

or

mponents and change hoses. Epoxies often

co

ve amines on the B (hardener) side. Polyureas

ha

tenhaveaminesontheA(resin)side.

of

E

332564B 9

Page 10

General Informa

tion

General Infor

• Reference numbers and letters in parentheses

in the text refer to numbers and letters in the

illustrations.

• Be sure all accessories are adequately sized and

pressure-rated to meet system requirements.

mation

• To protect the screens from paints and solvents,

clear-plastic protective shields (10 per pack) are

available. Order Part No. 197902 for the Advanced

Display Module. Clean the screens with a dry cloth

if necessary.

10 332564B

Page 11

Advanced Displa

yModule(ADM)

Advanced Disp

lay Module (ADM)

ADM Display

The ADM display shows graphical and text

information related to setup and spray operations.

For detail on the display and individual

screens, see Run Mode Screens, page 58,or

Setup Mode Screens, page 66.

Keys are used to input numerical data, enter setup

screens, navigate within a screen, scroll through

screens, and select setup values.

NOTICE

To prevent damage to the softkey buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

1. Enable USB dow

Advanced Scr

2. Remove the co

bottom of the

3. During the d

screen.

4. When the dow

appears on t

be removed

NOTE: If th

than 60 sec

determine

Error Sta

the USB.

5. Insert th

the compu

6. The USB fl

If it doe

within W

een 3, page 83.

ver from the USB port on the

ADM. Insert the USB drive.

ownload, USB BUSY appears on the

nload is complete, USB IDLE

he screen. The USB drive may then

.

e download operation takes longer

onds, the message disappears. To

if the USB is busy or idle, check the

tus bar on the screen. If idle, remove

e USB flash drive into the USB port of

ter.

ash drive window automatically opens.

s not, open the USB flash drive from

indows® Explorer.

nloads. See

1 2 3

4 5 6

7 8 9

0 .

Figure 7 Advanced Display Module

USB Download Procedure

the USB port on the ADM to download or upload

Use

a.

dat

7. Open Gra

8. Open sy

more th

one fol

corres

serial

9. Open D

10. Open L

numbe

recen

11. Open

Exce

They

Micr

NOT

(UT

Mic

12. Alw

the

an one system, there will be more than

der. Each folder is labeled with the

ponding serial number of the ADM. (The

number is on the back of the ADM.)

OWNLOAD folder.

OG FILES folder labeled with the highest

r. The highest number indicates the most

t data download.

logfile. LogfilesopeninMicrosoft®

l® by default if the program is installed.

also can be opened in any text editor of

osoft® Word.

E: All USB logs are saved in Unicode

F-16) format. If opening the log file in

rosoft Word, select Unicode encoding.

ays reinstall the USB cover after removing

USB, to keep the drive free of dirt and dust.

co folder.

stem folder. If downloading data from

332564B

11

Page 12

Advanced Displa

yModule(ADM)

USB Upload Pro

Use this procedure to install a system configuration

file and/or a custom language file.

1. If necessary

Procedure, t

folder struc

2. Insert the US

the compute

3. The USB flash

If it does no

within Win

4. Open the Gr

5. Open the sy

than one sy

folder wi

labeled w

the ADM. (

the modul

, follow the USB Download

o automatically generate the proper

ture on the USB flash drive.

r.

t, open the USB flash drive from

dows Explorer.

aco folder.

stem folder. If working with more

stem, there will be more than one

thin the Graco folder. Each folder is

ith the corresponding serial number of

The serial number is on the back of

e.)

cedure

B flash drive into the USB port of

drive window automatically opens.

6. If installing the system configuration settings file,

place SETTINGS.TXT file into UPLOAD folder.

7. If installing the custom language file, place

DISPTEXT.TXT file into UPLOAD folder.

8. Remove the USB flash drive from the computer.

9. Install the USB flash drive into the USB port of

the ProMix PD2K system USB port.

10. During the upload, USB BUSY displays on the

screen.

11. Remove the USB flash drive from the USB port.

NOTE: If the custom language file was installed,

users can now select the new language from the

Language drop-down menu in the Advanced Setup

Screen 1.

2

1

332564B

Page 13

ADM Keys and Indicators

NOTICE

Advanced Displa

yModule(ADM)

To prevent dam

press the butt

plastic card

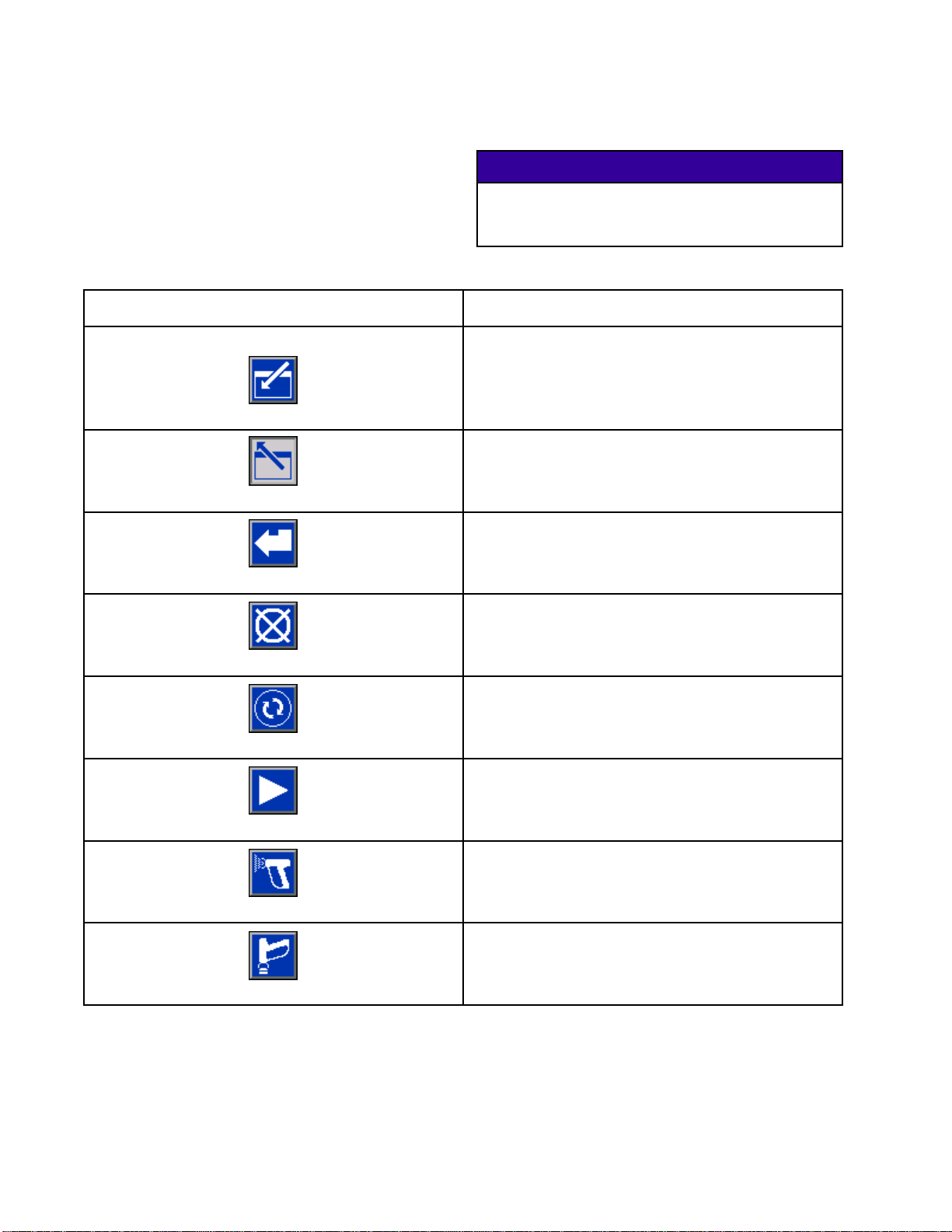

Table 1 : ADM Keys and Indicators

Key Function

Startup/Shutdown

Key and Indicator

Stop

Soft Key

age to the softkey buttons, do not

ons with sharp objects such as pens,

s, or fingernails.

Press to startup or shutdown the pump/motor.

• Solid green indicates that power is applied to the motor.

• Solid yellow indicates that power to the motor is off.

• Blinking green or yellow indicates that the system is in Setup mode.

Press to immediately stop the system and remove motor power.

Press to select the specific screen or operation shown on the display directly next to

each key. The top left soft key is the Edit key, which allows access to any settable

fields on a screen.

s

Left/Right Arrows:

•

Use to move from screen to screen.

Navigation Keys

Numeric Keypad

l

Cance

p

Setu

er

Ent

Up/Down Arrows:

•

menu, or multiple screens within a function.

Use to

Use to cancel a data entry field.

Press to enter or exit Setup mode.

Press to choose a field to update, to make a selection, to save a selection or value, to

enter a screen, or to acknowledge an event.

input values. See ADM Display, page 11.

Use to move among fields on a screen, items on a dropdown

332564B 13

Page 14

Advanced Displa

Soft Key Icons

yModule(ADM)

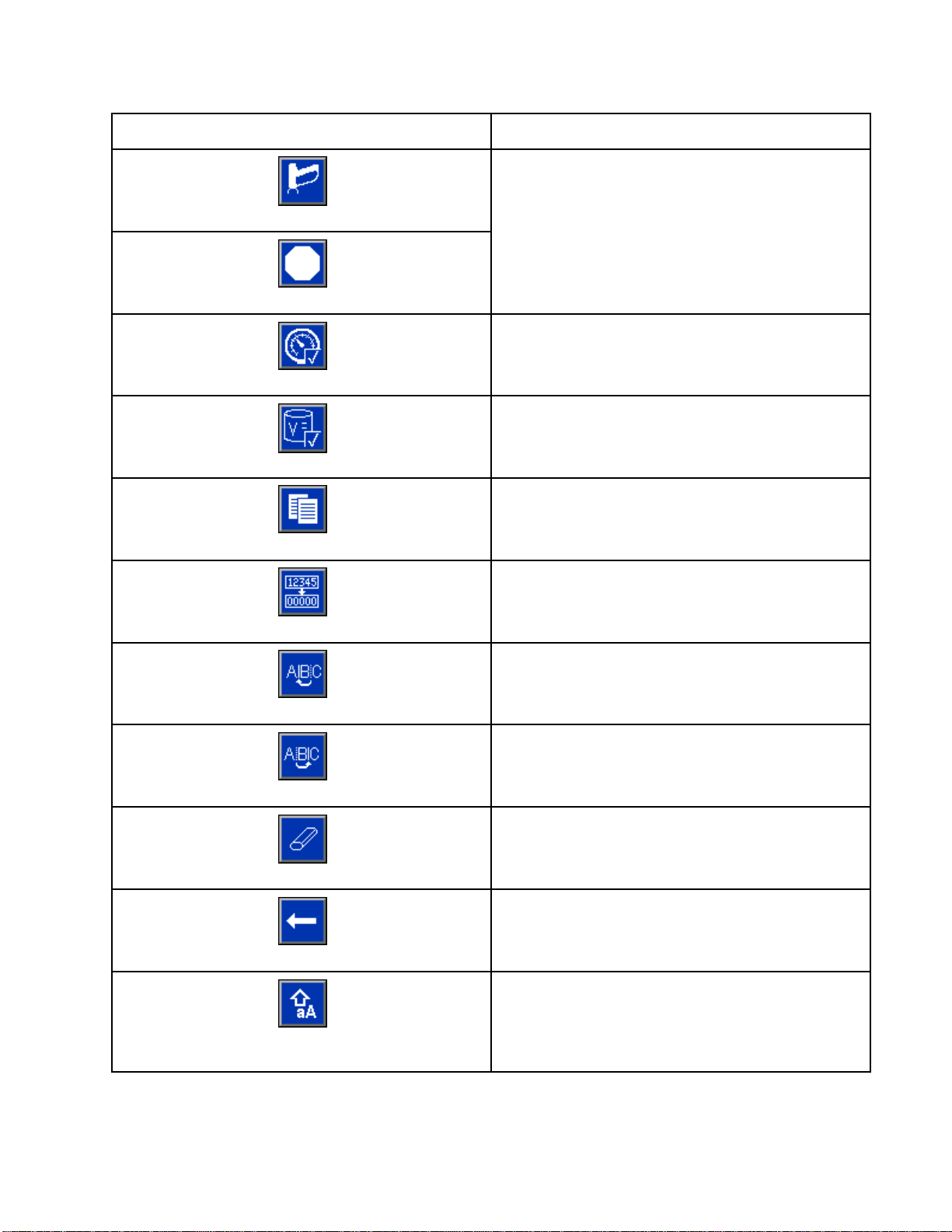

The following icons appear in the ADM display,

directly to the left or right of the soft key which

activates that operation.

Table 2 : Soft Key Functions

Key Function

Enter Screen

Exit Screen

Accept

To prevent damage to the softkey buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Press to enter screen for editing. Highlights editable

data on a screen. Use Up/Down arrows to move

between data fields on the screen.

Press to e

Press to accept calibration value.

Press to cancel or reject calibration value.

NOTICE

xit screen after editing.

Cancel

Prime Pump

Line/Fill/Run

Mix

Purge

Press to start a pump priming procedure.

Press to start a line fill procedure.

Press to start a spray procedure.

Press to start a purge procedure.

4

1

332564B

Page 15

Key Function

Advanced Displa

yModule(ADM)

Standby

Stop

Pressure Check

Volume Check

Job Complete

Counter Reset

Press to stop all pumps and put system in Standby.

Presstostartapumppressurecheck.

Press to st

Press to log the material usage and increment the

job number.

Press to reset the current usage counter.

Appears on the User ID Keyboard screen. Use to

move cursor to the left.

art a pump volume check.

Move Cu

Move Cursor to Right

Upper Case/Lower Case

rsor to Left

Erase All

Backspace

Appears on the User ID Keyboard screen. Use to

move cursor to the right.

Appears on the User ID Keyboard screen. Use to

erase all characters.

ears on the User ID Keyboard screen. Use to

App

se one character at a time.

era

Appears on the User ID Keyboard screen. Use to

change case (upper/lower).

332564B 15

Page 16

Advanced Displa

yModule(ADM)

Navigating th

There are two sets of screens:

• The Run screen

display syst

•TheSetupscr

advanced fea

Press

screens. If the system has a password lock, the

Password screen displays. If the system is not locked

(password is set to 0000), System Screen 1 displays.

Press

Home screen.

Press the Enter soft key

function on any screen.

Press the Exit soft key

Use the other softkeys to select the function adjacent

to them.

e Screens

s control mixing operations and

em status and data.

eens control system parameters and

tures.

on any Run screen to enter the Setup

on any Setup screen to return to the

to activate the editing

to exit any screen.

Screen Icons

As you move through the screens, you will notice

that icons are used frequently to simplify global

communication. The following descriptions explain

what each icon represents.

Screen Icons

User ID

Job Number

Potlife Target Rat

Recipe Number Flow Rate

Pressure Volume

Material B

Material A

Material A+B

Solven

io

t

Calendar Time

Alarm/Advisory

Deviation

16 332564B

Page 17

Pre-Operation T

asks

Pre-Operatio

Pre-operatio

Go through the Pre-Operation Checklist daily, before

each use.

✔

n Checklist

Checklist

System grou

Verify all grounding connections

were made. See Grounding in the

Installation manual.

All connections tight and correct

Verify all

system co

installe

manual.

Fluid supply containers filled

Check co

solvent

nTasks

nded

electrical, fluid, air, and

nnections are tight and

daccordingtotheInstallation

mponent A and B and

supply containers.

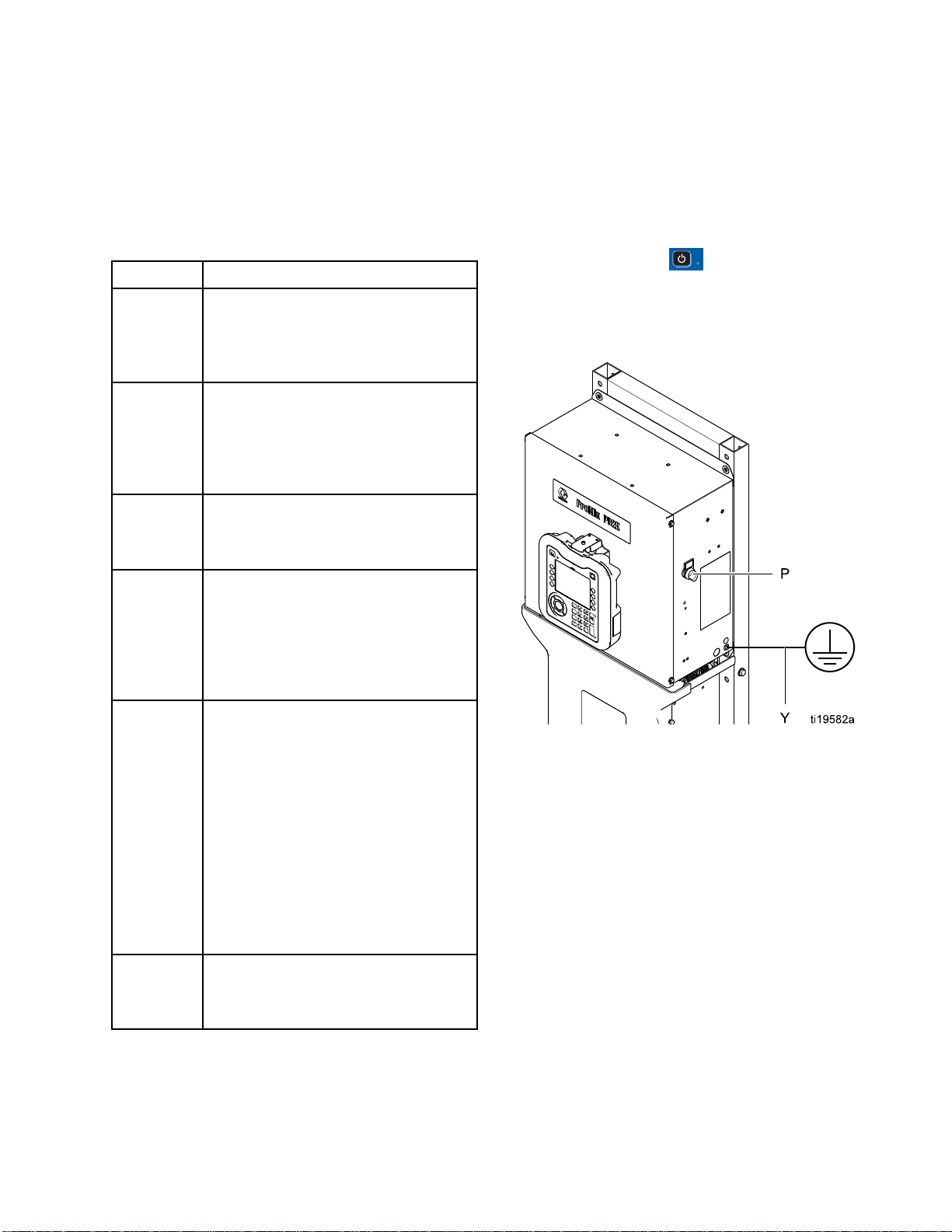

Power On

1. Turn the AC Power Switch (P) ON (I = ON,

0=OFF).

2. The Graco logo will display while the system

initializes, followed by the Home screen.

3. Press the Start key

change from “System Off” to “Startup.” Once

the pumps are powered and are in the Home

position, the system status will change from

“Startup” to “Standby.”

. The system status will

Dose valves set

Check that dose valves are set

1–1/4 turns open. Start with

the settings recommended in

Valve Settings, page 18, then adjust

as needed.

supply valves open and

Fluid

ure set

press

The recommended component A and

B fluid supply pressures are 1/2 to 2/3

of the target spray pressure.

NOTE: Low pressure systems may

be set within a range of ± 100 psi (0.7

MPa, 7 bar); high pressure systems

may be set within a range of ± 300 psi

(2.1 MPa, 21 bar). If the inlet pressure

is higher than the outlet pressure,

ratio accuracy may be affected.

Solenoid pressure set

85-100 psi inlet air supply (0.6-0.7

MPa, 6-7 bar).

Figure 8 Power Switch

332564B

17

Page 18

Pre-Operation T

asks

Initial Syste

1. Change optional setup selections to

desired parameters, as described in

Setup Mode Screens, page 66.

2. Set recipe and flush information as

described in Recipe Screen, page 72 and

Flush Screen, page 73.

m Setup

Flush Before Using Equipment

The pump flui

oil, which

To avoid co

equipment

the equipm

d section was tested with lightweight

is left in the fluid passages to protect parts.

ntaminating your fluid with oil, flush the

with a compatible solvent before using

ent.

Valve Setting

Dose valves and purge valves are factory set with the

hex nut (E) 1-1/4 turns out from fully closed.

Figure 9 Va

s

lve Adjustment

18 332564B

Page 19

Pressure Relief

Procedure

Pressure Reli

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure whenyoustopspraying

and before cleaning, checking, or servicing the

equipment.

ef Procedure

Without Color Change

NOTE: The following procedure relieves all fluid and

air pressure in the system. Use your control interface

to issue the necessary commands to your system.

With Color Change

NOTE: The fol

air pressure

1. Turn off the supply pumps. Open the drain valve

on the supply line fluid filter to relieve pressure in

the supply lines. Do this for each color.

If using an

electrost

2. Trigger the gun to relieve pressure. From

Maintenance Screen 4 on the ADM, check the

box in the field labeled Gun for each color in the

system.

3. Command the system to Purge. Hold the gun

trigger open after the solvent valve shuts off to

relieve all pressure.

lowing procedure relieves all fluid and

in the system.

electrostatic gun, shut off the

atics before flushing the gun.

1. Turn off the supply pumps. Open the drain valve

on the supply line fluid filter to relieve pressure

in the supply line.

2. Command the system to Standby. Trigger the

spray device to relieve pressure.

3. Flush the remote mix manifold and spray device.

See Flush Mixed Material, page 22.

4. Shut off the solvent supply pump. To relieve

pressure, command the system to Purge and

trigger the spray device. When the pressure is

relieved, command the system to Standby to

avoid getting a Purge Incomplete alarm.

5. If pressure remains in the solvent line between

the solvent supply pump and the solvent valve:

• VERY

pres

• Loos

SLOWLY loosen a fitting to relieve

sure gradually.

en the fitting completely.

4. Set the system to Recipe 0 to flush the pumps

and to purge to the spray device. When flushing

is complete the system will go to Standby.

5. Shut off the solvent supply pump. Set the system

to Recipe 0 to flush solvent from the pumps and

to purge to the spray device. Command the

system to Standby after just a couple of seconds,

to avoid getting a Purge Incomplete alarm.

6. If pressure remains in the solvent line between

the solvent supply pump and the solvent valve:

•VERY

pres

• Loos

7. Ver

pum

E: If pressure remains in the solvent line

NOT

ween the solvent supply pump and the solvent

bet

ve,VERYSLOWLYloosenafittingtorelieve

val

essure gradually.

pr

SLOWLY loosen a fitting to relieve

sure gradually.

en the fitting completely.

ify on the ADM Home Screen that neither

p is showing any pressure.

332564B 19

Page 20

Operation Using

Automatic Display Module (ADM)

Operation Usi

Prime and Fill

NOTE: See Run Mode Screens, page 58, for further

screen information, if needed.

NOTE: You mus

or the input

priming the

1. If using an electrostatic gun, shut off the

electrostatics before filling the lines.

2. Adjust the main air pressure. To ensure proper

operation, set the main air pressure as close to

100 psi (0.7 MPa, 7.0 bar) as possible. Do not

uselessthan85psi(0.6MPa,6.0bar).

3. If this is the first time starting up the system, or if

lines may contain air, purge as instructed under

. Flush the System, page 23 The equipment

was tested with lightweight oil, which should be

flushed out to avoid contaminating your material.

s to the color change valves before

pump and filling the entire system.

the System

t prime the input lines to the pumps

ng Automatic Display Module (ADM)

4. If the system is powered down, press

ADM. Make sure that the system is in Standby

mode.

5. Verify that the recipes and the flush sequences

are programmed correctly by checking

the Recipe Screen, page 72 and the

Flush Screen, page 73.

6. Enable the manual override on System Screen 5.

7. Go to the Fill Screen, page 63.

8. Select the desired color to load. Press the Prime

Pump key

through the color stack and out the outlet stack

dump valve.

NOTE: In a single color system, skip step 7 and

prime the pump out to the gun.

9. Press the Fill Line key

the remote mix manifold. The pump will run until

you press the Stop key

. The color will load the pump

to run color out to

to stop the pump.

on the

10. Trigger the gun into a grounded reservoir or

purge receptacle until the line is full, then press

the Stop key

11. Repeat for all material lines.

.

20 332564B

Page 21

Spraying

Operation Using

Automatic Display Module (ADM)

To spray in a multiple color system, also see

Multiple Color Systems, page 87.

NOTE: See Run

screen infor

1. Command the system to Mix. The system will

load the correct mixed material volume.

NOTE: The system will automatically run a Mix

Fill if the recipe is not currently loaded into the

system. The Mix Fill volume calculation includes

the remote mix manifold volume and the mixed

material hose volume. The mixed material hose

volume is determined by the gun hose length and

diameter entered in System Screen 3, page 69,

and the remote to mix hose length and diameter

also entered in System Screen 3, page 69.

Mode Screens, page 58,forfurther

mation, if needed.

2. Adjust the flow rate by changing the target

pressure (in Pressure Mode)orthetargetflow

rate (in Flow Mode) on the Spray Screen or

through the PLC. The fluid flow rate shown on the

Spray screen is the combined total of component

A and B out of the spray device.

NOTE: If spray pressure is adjusted at the ADM

while spraying, it is not saved in the recipe until

the system is put in Standby. This changes the

pressure in the desired recipe.

3. Turn on atomizing air to the gun. Check the spray

pattern as instructed in your spray gun manual.

NOTICE

Do not allow a fluid supply tank to run empty.

This can damage the pumps and lead to the

proportioning of fluid and air that meets the ratio

and tolerance settings of the equipment. This can

further result in spraying uncatalyzed or poorly

catalyzed material.

332564B

21

Page 22

Operation Using

Purging

Automatic Display Module (ADM)

To purge one co

Color Change,

Flush Mixed Ma

There are times when you only want to purge the

remote mix manifold and the spray device, such as:

• end of potlife

• breaks in spraying that exceed the potlife

• overnight shutdown or end of shift

• before servicing the remote mix manifold, hose or

gun.

1. Command the system to Standby.

2. Ifyouareusingahighpressurespraydeviceor

an electrostatic gun, shut off the atomizing air.

lor and fill with a new color, see

page 87.

terial

3. Trigger the spray device to relieve pressure.

4. Set the solvent supply pressure regulator at the

lowest pressure possible. Generally a setting

of 25–50 psi (0.18–0.35 MPa, 1.8–3.5 bar) is

sufficient.

5. CommandthesystemtoPurgeAorPurgeB.

Trigger the spray device into a grounded metal

pail until the purge sequence is complete. When

done purging, the system automatically switches

to Standby mode, signalling the spray device to

stop spraying.

6. If the system is not completely clean, repeat Step

5.

NOTE: For optimal efficiency, adjust purge

sequence times so only one cycle is required.

7. Trigger spray device to relieve pressure.

8. Adjust the solvent supply regulator back to its

normal operating pressure.

NOTE: The remote mix manifold and gun remain full

of solvent after purging.

To reduce risk of fire and explosion, if using

an electrostatic gun, shut off the electrostatics

before flushing the gun.

2

2

332564B

Page 23

Flush the System

Operation Using

Automatic Display Module (ADM)

To avoid fire and explosion, always ground

equipment and waste container. To avoid injury

from splashing, always flush at lowest possible

pressure.

Follow this procedure before:

• the first time material is loaded into the equipment

•servicing

• shutting down equipment for an extended period

of time

• putting equipment into storage

Single Color System

1. Relieve the pressure. See

Pressure Relief Procedure, page 19.

2. Disconnect the color and catalyst supply lines

from the pump inlet manifolds, and connect

regulated solvent supply lines.

3. Set the solvent supply pressure regulator at the

lowest pressure possible. Generally a setting

of 25–50 psi (0.18–0.35 MPa, 1.8–3.5 bar) is

sufficient.

4. Enable manual override on

System Screen 5, page 71.

5. On the ADM, go to the Fill screen. Set the

Color Change S

1. Relieve the pressure. See

Pressure Relief Procedure, page 19.

2. Attach regulated solvent supply lines as follows:

• Multiple color/single catalyst system: On the

color side, do not disconnect the color supply

line from the inlet manifold of Pump A. Instead,

connect a regulated solvent supply line to the

designated solvent valve on the color valve

manifold. On the catalyst side, disconnect

the catalyst supply line from the inlet manifold

of Pump B, and connect a regulated solvent

supply line.

• Multiple color/multiple catalyst system:

Connect regulated solvent supply lines to

the designated solvent valves on the color

and catalyst valve manifolds. Do not connect

solvent supply lines directly to the inlet

manifolds of the pumps.

3. Set the solvent supply pressure regulator at the

lowest pressure possible. Generally a setting

of 25–50 psi (0.18–0.35 MPa, 1.8–3.5 bar) is

sufficient.

4. On the ADM, go to the Fill screen. Set the

Material to Solvent. Press

will pump solvent from the color valve inlet all the

way to the gun.

5. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun until clean solvent

dispenses.

6. Repeat for each color line.

ystem

. The system

Material to Color (A). Press

will pump solvent through pump A all the way to

the gun.

6. Hold a metal part of the spray device firmly to a

grounded metal pail. Trigger the spray device

until clean solvent dispenses.

7. On the ADM, go to the Fill screen. Set the

Material to Catalyst (B). Press

system will pump solvent through pump B all the

way to the gun.

8. Relieve the pressure. See

Pressure Relief Procedure, page 19

. The system

.The

7. Relieve the pressure. See

Pressure Relief Procedure, page 19

down

Shut

1. Flush out the mixed material to avoid potlife errors

and fluid setup in the lines. See Purging, page 22.

2. Follow the Pressure Relief Procedure, page 19.

3. Close the main air shutoff valve on the air supply

line and on the control box.

4. Press

power to the pumps.

5. Shut off system power (0 position).

on the Display Module to turn off

332564B 23

Page 24

Operation Using

a Programmable Logic Controller (PLC)

Operation Usi

ng a Programmable Logic Controller

(PLC)

Network Communications and Discrete I/O

The ProMix PD2K Automatic system does not use

a Booth Control module. Instead, it uses Network

Communications and has optional Discrete I/O

features to drive the system remotely.

Some automation control elements of the

ProMix PD2K can be driven by a discrete

input

or

network communications. These

options need to be configured at the ADM (see

System Screen 5, page 71). The following features

can be set to ‘Discrete’ or ‘Network’:

• Flow Cont

point (s

• Gun Trig

when the

NOTE: Th

user to

(PLC) i

run all

signal

mode of

Overri

avoid

the au

rol – Means of adjusting the control set

ee Flow Control Set Point below).

ger – Means of signaling the ProMix PD2K

spray device is triggered.

e Manual Override check box enables a

operate the system before the automation

s available. Manual Override can be used to

functions of the system if a proper gun trigger

is provided. It is not intended to be the main

control. Graco recommends that Manual

de be disabled during normal operation to

driving the system in a way that conflicts with

tomation sequence.

Discrete I/O

The ProMix PD

Discrete I/

is necessar

with the PLC

connection

strips on t

inside the

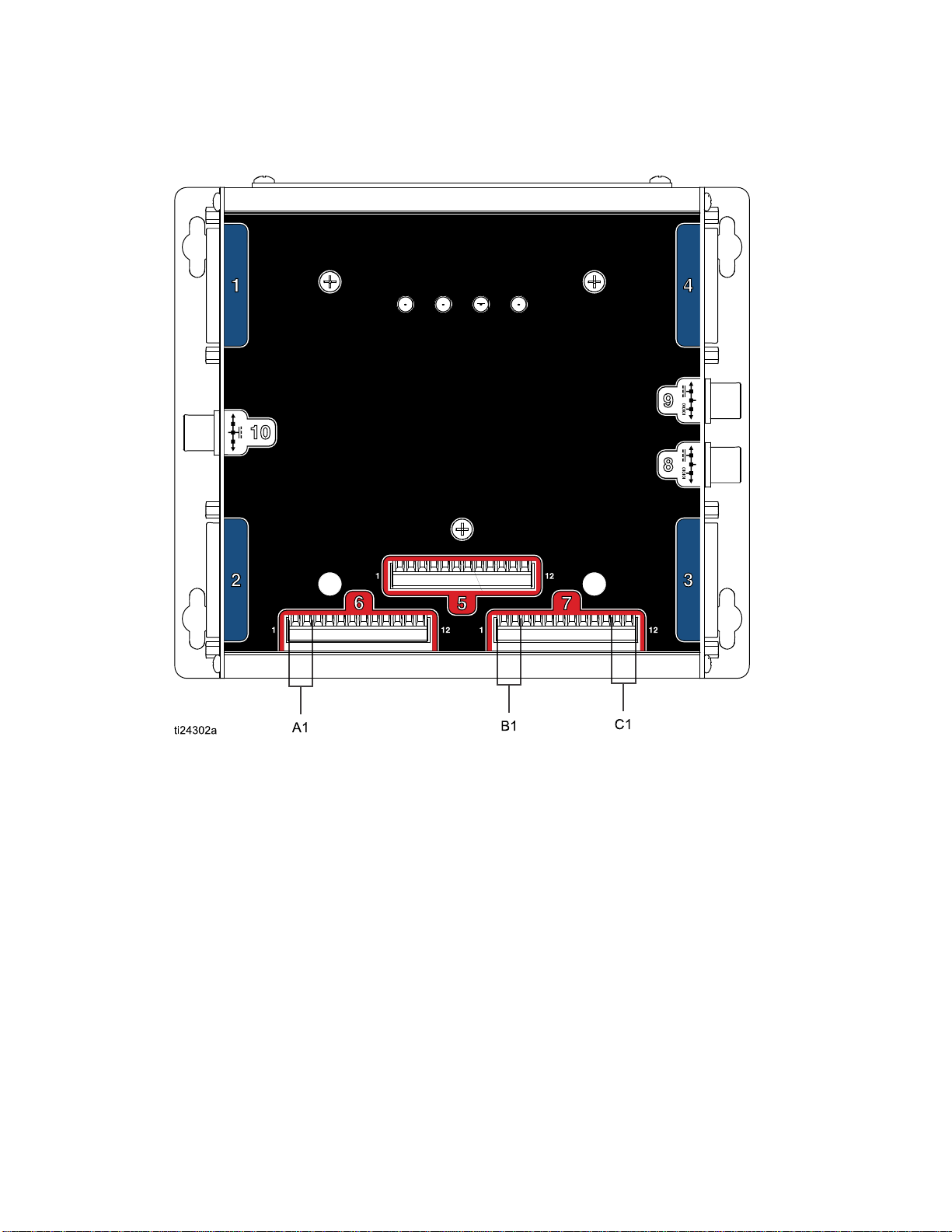

Table 3 and Figure 2 show where discrete I/O

connections are made on the ProMix PD2K.

Table 3 PD2K Discrete I/O Connections

I/O

Description

Gun Trigger

Input

lSet

Contro

Point

Safety

Interlock

Input

2K does not supply power for

O. A clear understanding of these inputs

y to properly integrate the ProMix PD2K

or networking device. Input and output

s are made at the Discrete I/O terminal

he Enhanced Fluid Control Module (EFCM)

control box.

EFCM

Connector

61,2

7

7

Pins Type

Normally Open

Contact

1,2 4-20 mA Input

11,12

Normally Open

Contact

4

2

332564B

Page 25

Operation Using

a Programmable Logic Controller (PLC)

Digital Inputs

• Safety Interlock: This normally open contact works

like a soft emergency stop button. If the ProMix

PD2K reads the input as CLOSED it interrupts

system operation and removes power from the

pumps regardless of the current operating mode.

If the input is read as OPEN, the system operates

normally

NOTE: This digital input is always enabled.

Do not toggle this input to put the system into

Standby mode.

• Gun Trigger: This normally open (maintained)

contact provides a signal to the system to indicate

whether or not a spray device is triggered. This

input provides timing for alarm functions and also

drives the flow control algorithm. If the input is

OPEN the system operates as though the spray

device is off. The input must be maintained

CLOSED to signal that the spray device is

triggered.

NOTE: The Gun Trigger discrete input must be

enabled via Configure Screen 5 on the ADM. If it

is set to ‘Network’ the discrete input is ignored and

the spray device trigger signal is handled via the

network communications.

If enabled, it is imperative that this signal be sent

any time the spray device is triggered. Without the

signal, the flow control features will not work.

Analog Inputs

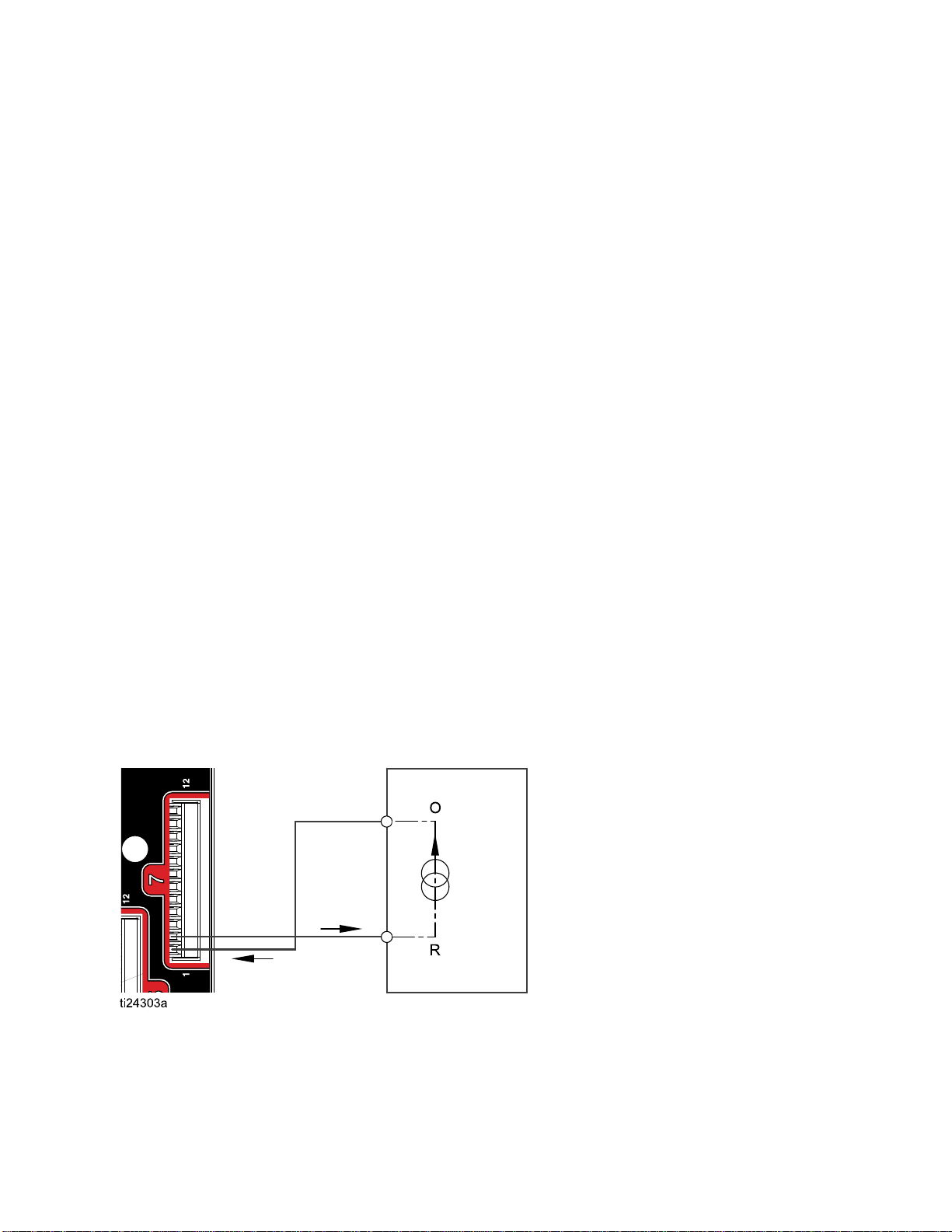

Flow Control Set Point: When enabled, this 4-20mA

signal input is used to set and adjust the operating

flow control set point. The ProMix PD2K scales the

set point linearly from 0 to the Max Set Point setting

(see System Screen 5, page 71).

• In Flow Cont

cc/min, a 4m

is 500 cc/mi

• In Pressur

500 psi, a 4

is 500 psi.

NOTE: The Flow Control discrete input must be

enabled via Configure Screen 5 on the ADM. If

set to ‘Network’ the discrete input is ignored and

set point adjustment is handled via the network

communications.

rol Mode: If the Max Set Point is 500

A signal is 0 cc/min and a 20mA signal

n.

e Control Mode: If the Max Set Point is

mA signal is 0 psi and a 20mA signal

Examples

,

PD2K Discrete Input

e10

Figur

4–20 mA

Flow Control Set Point Input

PLC (4–20 MA Signal)

O = Output

R=Return

332564B 25

Page 26

Operation Using

Figure 11

a Programmable Logic Controller (PLC)

Discrete I/O Connections on EFCM

KEY

A1

B1

C1 Safety Interlock Input

Gun Trigger Input

og Set Point Input

Anal

26 332564B

Page 27

Operation Using

a Programmable Logic Controller (PLC)

Communicatio

n Gateway Module (CGM) Details

CGM Overview

The CGM provides a control link between the PD2K

system and a selected fieldbus. This linkage provides

the means for remote monitoring and control by

external automation systems.

NOTE: The fo

files are ava

• EDS file: DeviceNet or Ethernet/IP fieldbus

networks

• GSD file: PROFIBUS fieldbus networks

• GSDML file: PROFINET fieldbus networks

llowing system network configuration

ilable at www.graco.com.

CGM Kits

The PD2K system comes with a Modbus TCP CGM.

Kits for other communication protocols are available.

Each kit includes all parts needed to install the

CGM, along with Manual 334494, which contains

installation instructions applicable to any kit. See

Manual 312864 or Manual 334183 for information

specific to each protocol, plus repair parts for each

assembly.

CGM Part No.

CGMDNO

CGMEPO

CGMPBO PROFIBUS

CGMPNO PROFINET

24W462

Fieldbus Manual

DeviceNet 312864

EtherNet/

Modbus TCP

IP

312864

312864

312864

334183

332564B

27

Page 28

Operation Using

a Programmable Logic Controller (PLC)

Network Commu

nication I/O Data Map

ProMix PD2K Network Outputs

The ProMix PD2K Network Outputs are Read-Only

and should be treated as inputs to a PLC

or other networking device. These registers

OUTPUT REGIS

The Current System Mode register contains a number that indicates the current operation mode of the PD2K

system.

Number

1

2

3

4

5

TER 00: Current System Mode

Operation Mode

Pump Off

Recipe Change The system is in the process of a color change sequence.

Recipe Change: PurgeAThe system is purging material A as part of a recipe change.

Recipe C

B

Recipe Change: Fill The system is filling the hose from the remote valves to the mix

hange: Purge

Description

The pumps a

operation

The syst

manifold with material as part of a recipe change.

em is purging material B as part of a recipe change.

provide various system and component status,

measurement, and set point values. See

Network Output Data Map (Read Only), page 33.

re currently powered down and the system is not in

.

6MixFil

7

8MixI

9 Purge A

10 Purge B

11

12

3

1

14

l

Mix The system is currently mixing/spraying material.

dle

Standby: Mix Ready

andby: Fill Ready

St

Standby: Mix Not Ready

Standby: Alarm

The system is mixing material at ratio through the mix manifold

and out the gun.

The system has paused mix operation due to the absence of a gun

trigger signal.

system is purging material A while in Standby.

The

The system is purging material B while in Standby.

e system has a valid recipe loaded out to the gun.

Th

The system has a valid recipe loaded in the pumps, but not in the

gun.

he system requires that a recipe change operation be completed.

T

The system has an active alarm.

28 332564B

Page 29

Operation Using

a Programmable Logic Controller (PLC)

OUTPUT REGISTERS 01, 02, 03, and 04: Pump

Status

ThePumpStatu

indicates the

be used for gen

or as an indica

operations.

Pump Command

Table4PumpS

Nu-

Pump

m-

State

ber

0

Off

1

Standby

2 Busy The pump i

3 Flushing

s registers contain a number that

state of Pumps 1 — 4. This status can

eral monitoring of the pump state,

tor for driving independent pump

See INPUT REGISTER 02: Flush/Prime

, page 36.

tates for Output Registers 01–04

Description

The pump is powered down or

not enabled.

The pump is powered but not

currently active.

s currently in

arecipec

operatio

The pump is currently flushing

with solvent

hange or mixing

n.

OUTPUT REGISTER 07: Actual Mix Potlife

Remaining

The Actual Pot

the current am

recipe’s potl

NOTE: If potlife is disabled for the active recipe or at

initial startup this value will be 0xFFFFFFFF.

OUTPUT REGISTER 08: Active Recipe Number

TheActiveR

number of th

• This value is 0 if the system was flushed.

• This value is 61 if the system does not know the

current loaded recipe, if the recipe is invalid, or at

initial startup.

OUTPUT REGISTER 09: Active Recipe Material A

The Activ

number of

the curre

life Remaining register contains

ount of time remaining in the active

ife in seconds.

ecipe Number register contains the

eactiverecipe(1–60).

e Recipe Material A register contains the

the Color (1 – 30) that is associated with

nt recipe.

4 Priming The pump

with mat

OUTPUT REGISTER 05: Actual Mix Flow

The Act

insta

NOTE: This register is valid only during a mix

operation.

OUTPUT REGISTER 06: Actual Mix Ratio

The A

inst

• The value reported is the ratio antecedent

Example

(Material A to Material B)

•Ift

This register is valid only during a mix operation.

ual Mix Flow register reports back the

ntaneous mixing flow rate in cc/min.

ctual Mix Ratio register contains the

antaneous calculated mix ratio.

multiplied by 100. The ratio consequent is always

1.

: Value = 250 >> A mix ratio of 2.5:1

he current recipe ratio is 0:1 (1K recipe) this

lue will be 0.

va

is currently priming

erial.

• This value is 0 if the system was flushed.

• This value is 61 if the current recipe is invalid or at

initial startup.

OUTPUT REGISTER 10: Active Recipe Material B

The Act

the num

with t

• This value is 0 if the system was flushed.

• This value is 61 if the current recipe is invalid or at

• This value is 0 if the current recipe ratio is 0:1 (1K

OUTPUT REGISTER 11: Active Recipe Material A

Flush Sequence

The

reg

(1 –

cur

If the current recipe is invalid this value reflects the

Flush Sequence associated with Material A pump

of recipe 0.

ive Recipe Material B data register contains

ber of the Catalyst (31 – 34) that is associated

he current recipe.

initial startup.

recipe).

Active Recipe Material A Flush Sequence

ister contains the number of the Flush Sequence

5) that is associated with the Color pump of the

rent recipe.

332564B 29

Page 30

Operation Using

a Programmable Logic Controller (PLC)

OUTPUT REGISTER 12: Active Recipe Material B

Flush Sequence

The Active Recipe Material B Flush Sequence

register contains the number of the Flush Sequence

(1 – 5) that is associated with the Catalyst pump of

the current recipe.

• If the current recipe is invalid this value reflects the

Flush Sequence associated with Material B pump

of recipe 0.

• This value is 0 if the current recipe ratio is 0:1 (1K

recipe)

OUTPUT REGISTER 13: Active Recipe Ratio Set

Point

The Active Recipe Ratio Set Point data register

contains the ratio set point associated with the

current recipe.

• The value reported is the ratio antecedent

multiplied by 100. The ratio consequent is always

1.

Example

(Material A to Material B)

• This value is 0 if the current recipe ratio is 0:1 (1K

: Value = 250 >> A mix ratio of 2.5:1

recipe)

OUTPUT REGISTER 19: Actual Pump 1 Fluid

Pressure

OUTPUT REGIST

Pressure

OUTPUT REGISTER 21: Actual Pump 3 Fluid

Pressure

OUTPUT REGISTER 22: Actual Pump 4 Fluid

Pressure

These regis

pressure on

OUTPUT REGISTER 23: Gun 1 Trigger Input Status

The Gun 1 Trigger Input Status register contains the

status of the Gun Trigger Discrete Input.

•Thevaluei

triggere

•Thevalue

triggere

This data register is valid only for systems configured

to use the discrete input for the Gun Trigger.

d).

d).

Gun Trigger Signal, page 71

OUTPUT REGISTER 24: Gun 2 Trigger Input Status

ER 20: Actual Pump 2 Fluid

ters contain the instantaneous fluid

the outlet of pumps 1–4 in PSI.

s0iftheinputisOPEN(gunnot

is 1 if the input is CLOSED (gun

See

.

OUTPUT REGISTER 14: Active Recipe Potlife

Timeout Set Point

The Active Recipe Potlife Timeout Set Point register

contains the set point for the potlife time associated

with the current recipe in minutes.

• This value is 0 if the potlife time is disabled for the

current recipe.

OUTPUT REGISTER 15: Actual Pump 1 Flow Rate

OUTPUT REGISTER 16: Actual Pump 2 Flow Rate

OUTPUT REGISTER 17: Actual Pump 3 Flow Rate

OUTPUT REGISTER 18: Actual Pump 4 Flow Rate

These registers contain the instantaneous flow rate

of Pumps 1–4 in cc/min.

This is NOT the mix flow rate. For mix flow rate see

Actual Mix Flow

.

OUTPUT

OUTPUT REGISTER 26: Gun 4 Trigger Input Status

REGISTER 25: Gun 3 Trigger Input Status

These registers are not used.

OUTPU

Statu

The Safety Interlock Input Status register contains

the status of the Safety Interlock Discrete Input.

• The value will be 0 if the input is OPEN (Normal).

• The value will be 1 if the input is CLOSED (Safety

See

OUTPUT REGISTERS 28 – 36: DCS Command

Structure

See Dynamic Command Description, page 47.

T REGISTER 27: Safety Interlock Input

s

Stop).

Safety Interlock in Digital Inputs, page 25

.

30 332564B

Page 31

Operation Using

a Programmable Logic Controller (PLC)

OUTPUT REGISTER 37: Time

TheTimeregis

since the Unix

• The actual value reported is not important. This

register should be used for diagnosing status of

communication between the ProMix PD2K and the

networking device.

This register is NOT currently available with the

Modbus Communications Gateway Module.

ter contains a count of total seconds

Epoch (January 1, 1970).

OUTPUT REGISTER 38 – 40: Software Version

The Software V

“minor,” and “

These registers are NOT currently available with the

Modbus Communications Gateway Module.

ersion registers contain the “major,”

build” revisions of the ADM software.

332564B 31

Page 32

Operation Using

Notes

a Programmable Logic Controller (PLC)

32 332564B

Page 33

Operation Using

Network Output Data Map (Read Only)

a Programmable Logic Controller (PLC)

Network

Output ID

00 40100

Modbus

Register

Parameter Name Data Type Units Range

uint32

Current Syste

Mode

m

NONE

1=PumpOff

2 = Recipe Change

3 = Recipe Change:

Purge A

4=RecipeCh

Purge B

5 = Recipe Change: Fill

6=MixFil

7=Mix

8=MixIdle

9=Purge

10 = Purge B

11 = Sta

12 = Standby: Fill Ready

13 = Standby: Mix Not

Ready

14 = S

ange:

l

A

ndby: Mix Ready

tandby: Alarm

01 40102

02 40104

03 40106

Pump 1 Status

ump 2 Status

P

Pump 3 Status

uint32

uint32

uint32

NONE

ONE

N

NONE

0=Off

1 = Standby

2=Busy

Flushing

3=

4 = Priming

=Off

0

1 = Standby

2=Busy

3 = Flushing

4 = Priming

0=Off

1 = Standby

2=Busy

3 = Flushing

4 = Priming

332564B 33

Page 34

Operation Using

a Programmable Logic Controller (PLC)

04 40108

05 40110 Actual Mix Flow uint32 cc/min 1 - 1600

06 40112 Actual Mix Ratio uint32

07 40114

08 40116 Active Re

09 40118 Active Recipe

10 40120 Active Recipe

11 40122 Active

12 40124 Active Recipe

Pump 4 Status

Actual Mix Potlife

Remaining

cipe

Number

Material A

Material B

Recipe

al A Flush

Materi

Sequen

Material B Flush

Sequence

ce

uint32

uint32

uint32

uint32

uint32

uint32

uint32

NONE

NONE

sec

NONE

NONE

NONE

NONE

NONE

0=Off

1 = Standby

2=Busy

3 = Flushing

4 = Priming

0 - 5000

0 – 59940

0-61

1-30,61

31 - 34, 61

1-5

1-5

13 40126 Active Recipe

Ratio Set Point

0140

4

8

134

14 4012

15 40130 Actual Pump 1

16 40132 Actual Pump 2

17 40

18 40136 Actual Pump 4

19 40138 Actual Pump 1

0

2

21 40142 Actual Pump 3

22 40144 Actual Pump 4

ve Recipe

Acti

ife Time Set

Potl

t

Poin

Flow Rate

Flow Rate

tual Pump 3

Ac

ow Rate

Fl

Flow Rate

Fluid Pressure

ctual Pump 2

A

Fluid Pressure

Fluid Pressure

Fluid Pressure

uint32

32

uint

uint32 cc/min 0 - 800

uint32 cc/min 0 - 800

nt32

ui

uint32 cc/min 0 - 800

uint32

int32

u

uint32

uint32

NONE

min 0 - 99

/min

cc

SI

P

PSI

PSI

PSI

0 - 5000

800

0-

0 - 1500

-1500

0

0 - 1500

0 - 1500

9

34 332564B

Page 35

Operation Using

a Programmable Logic Controller (PLC)

23 40146

24 40148

25 40150

26 40152

27 40154

28 40200

29 40202

30 402

04

Gun 1 Trigger

Input Status

Gun 2 Trigger

Input Status

Gun 3 Trigge

Input Stat

Gun 4 Trigger

Input Status

Safety Interlock

Input Status

Comman

Acknow

Command Return

0

Command Return

1

r

us

d

ledge

uint32

uint32

uint32

uint32

uint32

uint32

uint32 N/A N/A

t32

uin

NONE

NONE

NONE

NONE

NONE

NONE

N/A N/A

0 = Gun not triggered

1 = Gun trigger

0 = Gun not triggered

1 = Gun triggered

0=Gunnottr

1 = Gun triggered

0 = Gun not triggered

1=Guntri

0=Open

1 = Closed

0:=NOP

1=BUSY

2=ACK

3=NAK

4=ER

ed

iggered

ggered

R

31 40206

32 40208

33 40210

34 40212

35 40214

36 40216

37 N/A Time uin32

38 N/A

39 N/A

40 N/A

mmand Return

Co

2

Command Return

3

Command Return

4

Command Return

5

Command Return

6

Command Return

7

Software Version

–Major

Software Version

–Minor

Software Version

– Build

uint32 N/A N/A

uint32 N/A N/A

uint32 N/A N/A

uint32 N/A N/A

uint32 N/A N/A

uint32 N/A N/A

uint32

uint32

uint32

sec

NONE

NONE

NONE

0 – 4,294,967,295

0–99

0–99

0–999

These registers are not used.

DCS Register

332564B 35

Page 36

Operation Using

a Programmable Logic Controller (PLC)

ProMix PD2K Network Inputs

The ProMix PD2K Network Inputs are Write-Read capable, but should be treated as outputs from a PLC or

other networking device. These registers allow the user to control system operation and configure system

settings remotely. Invalid values (i.e. out of bounds or not consistent with system configuration) will be ignored

by the ProMix PD2K. All values must be written as integers. Floating point numbers are not supported.

Do not rely on

NOTE: The PD2K system does not refresh the values for these registers. At power up all input registers

initialize to invalid values.

INPUT REGISTER 00: System Mode Command

The System M

to initiate

Figures 5 –

Number

1

2 Power Pumps

3

4

5

6Mix Thesy

7

8 Purge B The system purges only Material B out through the gun.

these registers for Read status, other than to confirm data that has been written and accepted.

ode Command register accepts a number that represents a command to the PD2K system

a particular operation. Some operation modes may be initiated only under certain conditions (see

9 for details).

Operation Mode

No OP

Remote Stop The system stops all current operations and turns off power to the

Recipe

Mix Fill

Purge A The system purges only Material A out through the gun.

Change

Descripti

The system takes no action.

The system powers on or powers off the pumps.

pumps.

The sys

The system fills the mix manifold and gun with material at ratio for

a valid recipe.

on

tem initiates a recipe change. (See also Register 7.)

stem initiates a mix/spray cycle.

9

Standby The system puts all active pumps into Standby mode.

36 332564B

Page 37

Operation Using

a Programmable Logic Controller (PLC)

INPUT REGISTER 01: Pump Flush Sequence/Prime

Material Selection

ThePumpFlush

register is us

Pump Command r

below) to inde

pump.

• Write a value between 1 and 5 if flushing a pump.

• Write a value between 1 and 30 if priming a Color

pump.

• Writeavaluebetween31and34ifpriminga

Catalyst pump.

NOTE: It is important that the user know which

material is assigned to each pump. An invalid

selection will be ignored by the ProMix PD2K.

INPUT REG

The Flush/Prime Pump Command register is used in

conjunction with the Pump Flush Sequence/Prime

Material Selection register (see INPUT REGISTER

01) to independently prime or flush an inactive pump.

The desired pump MUST be in Standby mode.

Confirm by reading the corresponding Pump Status

output register (see OUTPUT REGISTERS 01 – 04).

Sequence/Prime Material Selection

ed in conjunction with the Flush/Prime

egister (see INPUT REGISTER 02

pendently prime or flush an inactive

ISTER 02: Flush/Prime Pump Command

INPUT REGISTER 03: Mix (Pump 1) Control Set

Point

The Mix Contro

adjust the mix

as the fluid con

a1Krecipe. It

system will i

• If the system is configured for Flow Control this

value can be set between 5 and 1600 cc/min for a

2K recipe, and between 5 and 800 for a 1K recipe.

See Fluid Control on System Screen 5, page 71.

• If the system is configure for Pressure Control this

value can be set between 0 and the maximum

pump pressure in PSI. See Fluid Control on

System Screen 5, page 71.

NOTE: The Flow Control must be configured to

‘Network’ via System Screen 5 on the ADM. If set

to ‘Discrete’ this register is ignored and set point

adjustment is handled via the discrete input. See

Analog Inputs, page 25.

INPUT REG

INPUT REGISTER 05: Pump 3 Control Set Point

INPUT REGISTER 06: Pump 4 Control Set Point

l Set Point register is used to set and

ing fluid control set point. It also is used

trol set point for pump 1 when running

can be changed at any time, and the

mmediately adjust to the new set point.

ISTER 04: Pump 2 Control Set Point

If an invalid Flush Sequence or invalid material

number is written to the Pump Flush Sequence/Prime

Material Selection register then the Flush/Prime

command will be ignored. The user must know

what material is assigned to each pump. (See

Color Change Kits Instruction Manual 332455 for

color/catalyst pump mapping.)

NOTE:

inact

conti

the s

is co

mode

oper

If two pumps are currently mixing and an

ive pump is commanded to flush or prime it will

nue its operation to completion without affecting

ystem mode status. When the mixing operation

mplete, the system status will reflect Standby

while the flushing/priming pump completes its

ation.

These r

INPUT REGISTER 07: Go to Recipe Number

The Go to Recipe Number register is used as a

queue for the next recipe to be loaded when a recipe

change is initiated. A number between 0 and 60 can

be written to this register. However, a recipe must be

enabled via the ADM before it can be loaded. See

Recipe Screen, page 72.

NOTE

chan

egisters are not used.

: Writing to this register does not trigger a recipe

ge.

See Color Change Sequence, page 44.

332564B 37

Page 38

Operation Using

a Programmable Logic Controller (PLC)

INPUT REGISTER 08: Clear Active Alarm

The Clear Acti

acknowledge a

may resume ope

condition has

register to ac

more than one

recent alarm

should be per

alarms. See fi

ve Alarm register is used to

n alarm remotely so that the system

ration. Be sure that the alarm

been alleviated. Write a 1 to this

knowledge the latest active alarm. If

alarm is currently active only the most

will be acknowledged. A repeated write

formed to clear any remaining active

gure 9.

(See System Errors, page 88 for more information

on clearing alarms.)

NOTE: This register is not polled by the ProMix

PD2K. An alarm is cleared only when a value of ‘1’

is written to this register. It is recommended that the

automation reset this register by writing a 0 to it at all

other times to avoid inadvertently clearing an alarm.

INPUT REG

ISTER 09: Job Complete

The Job Complete register is used to log the current

job remotely. Write a ‘1’ to the register to command

theProMixPD2Ktoflagajobcomplete.

INPUT REGISTER 10: Gun 1 Trigger

TheGun1Trigg

ProMix PD2K wh

triggered. Th

spray device i

provides timi

the flow contr

er register is used to signal the

en the automatic spray device is

is signal should be sent any time the

s triggered. The state of this register

ng for alarm functions and also drives

ol algorithm.

NOTE: If enabled, it is imperative that this signal be

sent any time the spray device is triggered. Without it

the flow control features will not work.

• Write a value of ‘1’ to signal that the gun is

triggered.

• Write a value of ‘0’ to signal that the gun is NOT

triggered.

NOTE: This

is set to ‘N

If it is se

gun trigg

Digital I

critical

provide a

register is used only if the Gun Trigger

etwork’ via System Screen 5 on the ADM.

t to ‘Discrete’ this register is ignored and

er is handled via the discrete input. See

nputs, page 25.

NOTE: Because timing is so

for flow control Graco recommends that users

discrete input to minimize latency effects.

(See Usage Screen, page 64 for more information on

Job Logs and Job Complete.)

NOTE: Th

PD2K. A

is writ

automa

other t

is register is not polled by the ProMix

job is logged only when a value of ‘1’

ten to this register. It is recommended the

tion reset this register by writing a 0 to it at all

imes to avoid inadvertently logging a job.

Input Register 10

Gun Trigger

Discrete Signal

ProMix PD2K

Gun Trigger State

e 12 Gun Trigger Timing (Network and Discrete

Figur

ls Shown

Signa

10 1 0

INPUT REGISTER 11: Gun 2 Trigger

INPUT REGISTER 12: Gun 3 Trigger

T REGISTER 13: Gun 4 Trigger

INPU

These registers are not used.

INPUT REGISTERS 14 – 21: DCS Command

Structure

e Dynamic Command Description, page 47.

Se

38 332564B

Page 39

Notes

Operation Using

a Programmable Logic Controller (PLC)

332564B 39

Page 40

Operation Using

a Programmable Logic Controller (PLC)

Network Input Data Map (Write/Read)

Network

Input ID

00 40156

01 40158

02 40160

Modbus

Register

Parameter Name Data

Type

System Mode Co

Pump Flu

Materia

Flush/Prime Pump Command

sh Sequence #/Prime

l#

mmand

uint32

uint32

uint32

Units Range

NONE

NONE

NONE

0=No

1=PowerPump

2=RemoteStop

3 = Recipe Change

4 = Mix Fill

5=Mix

6=PurgeA

7=PurgeB

8 = Standby

1 - 5, 1 - 34

0=NoOP

1=Flus

2=PrimePump1

3=FlushPump2

4=Pri

s

hPump1

me Pump 2

03 40162

0170

4

164

04 40

05 40166

06 40168

7

0

08 40172

09 40174

10 40176

11 40178

(Pump 1) Control Set Point

Mix

Pump 2 Control Set Point

Pump 3 Control Set Point

ump 4 Control Set Point

P

Go to Recipe Number

Clear Active Alarm

Job Complete

Gun 1 Trigger

Gun 2 Trigger

uint32 cc/min or

PSI

nt32

ui

uint32 cc/min or

uint32 cc/min or

int32

u

uint32

uint32

uint32

uint32

/min or

cc

I

PS

PSI

PSI

NONE

NONE 1 = Clear Active Alarm

NONE

NONE

NONE

5=FlushPump3

6=PrimePump3

ush Pump 4

7=Fl

8=PrimePump4

1 - 1600

1600

1-

1 - 1600

1 - 1600

,1-60

0

1 = Trigger job complete

0 = Gun not triggered

1 = Gun triggered

0 = Gun not triggered

1 = Gun triggered

40 332564B

Page 41

Operation Using

a Programmable Logic Controller (PLC)

12 40180

13 40182

14 40184

15 40186

16 40188

17 40190

18 40192

19 40194

20 40196

21 40198

These

Gun3Trigger

Gun4Trigger

Command Arg

Command Argument 1

Command Argument 2

Command A

Command Argument 4

Command Argument 5

Comman

DCS Command

registers are not used.

rgument 3

dArgument6

ument 0

uint32

uint32

uint32

uint32

uint32

uint32

uint32

uint32

uint32

uint32

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE

NONE See Command Table

DCS Register

0 = Gun not triggered

1 = Gun trigger

0 = Gun not triggered

1 = Gun triggered

N/A

N/A

N/A

N/A

N/A

N/A

N/A

ed

332564B

41

Page 42

Operation Using

a Programmable Logic Controller (PLC)

Operation Flo

w Charts

Purge Mode Sequence

Purge A System Command

Write ‘6’ to Input Register 00

Is system in Standby or

System Mode = Purge A

(Output Register 00 = ‘9’)

System opens color solvent valve at remote stack to allow

solvent flow through mix manifold and out gun.

Pumps Off?

YES

NOTE: Purge B command works

similarly with the catalyst lines and

solvent flow switch 2.

NO

No action taken.

Either pumps are currently

running or an alarm condition

exists.

Purge time set according to the flush sequence assigned to

NO

System Mode = Standby: Mix Not Ready

System closes color solvent valve at remote stack.

material A in recipe.

Is solvent flow switch 1 ON?

YES YES

Purge time expired?

YES

(Output Register 00 = ‘13’)

NO

NO

Purge no flow timeout expired?

No solvent flow detected.

Generate alarm.

2

4

332564B

Page 43

Operation Using

Inactive Pump Flush and Prime Sequences

a Programmable Logic Controller (PLC)

Write Flush Sequence #

(1-5) to Output Register 01

Write

Flush Pump Command