Page 1

Operation

ProMix® PD2K El

ectronic

332562B

Proportioner

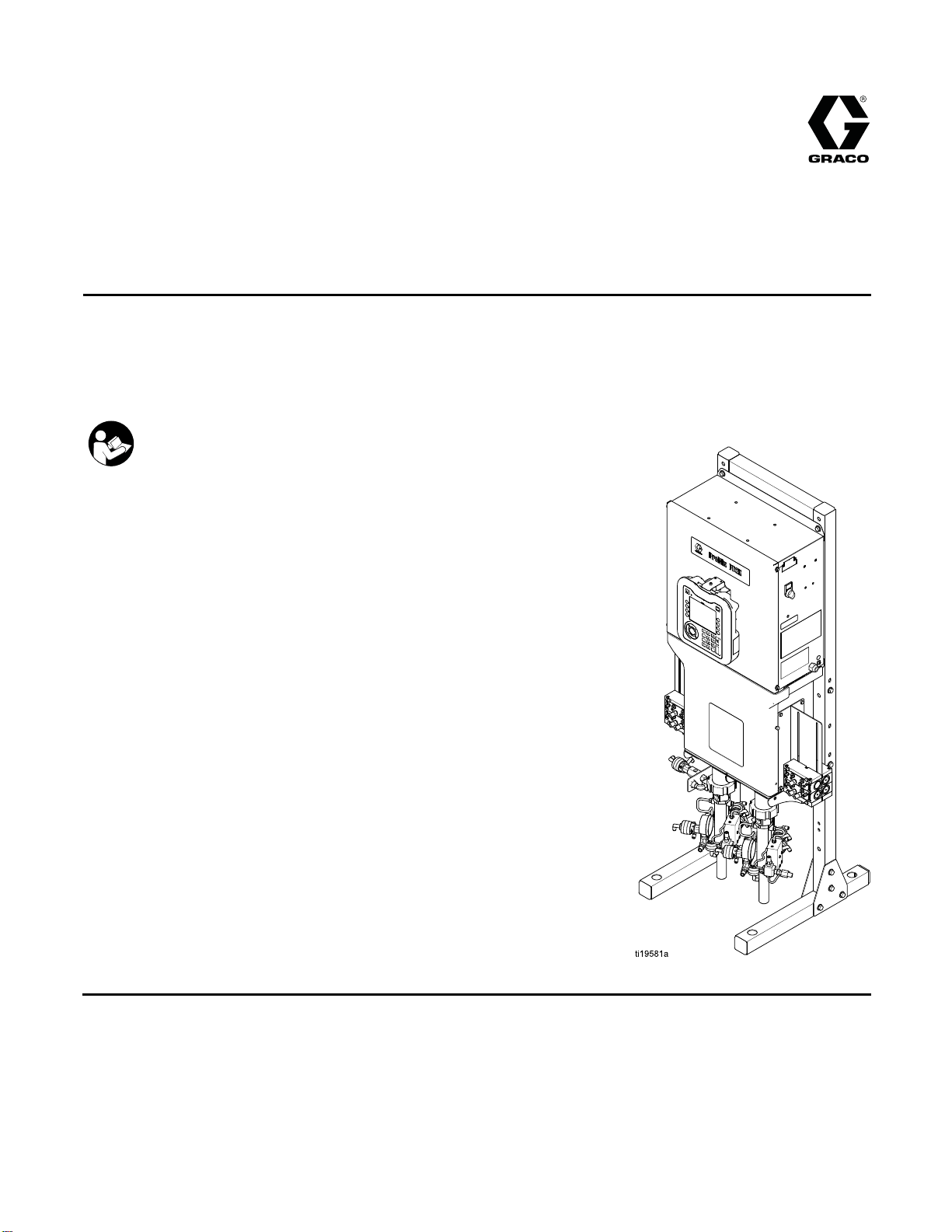

Positive displacement proportioning of 2-component materials helps reduce waste. Manual system with

Advanced Display Module. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in your PD2K

Installation and Repair/Parts manuals.

Save these instructions.

See page 3

approvals information.

for model part numbers and

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Models............................................................... 3

Related Manuals ................................................ 6

Warnings ........................................................... 7

Important Isocyanate (ISO) Information................ 10

Glossary of Terms .............................................. 12

Overview............................................................ 13

Usage ......................................................... 13

Component Identification and

Definition........................................ 13

Advanced Display Module................................... 16

ADM Display................................................ 16

USB Download Procedure............................ 16

USB Upload Procedure ................................ 17

ADM Keys and Indicators ............................. 18

Soft Key Icons ............................................. 19

Navigating the Screens ................................ 21

Screen Icons ............................................... 21

Booth Control ..................................................... 22

Booth Control Display................................... 22

Booth Control Keys and Indicators ................ 23

Operation........................................................... 24

Pre-operation Checklist ................................ 24

Flush Before Using Equipment...................... 24

Power On .................................................... 24

Initial System Setup ..................................... 25

Prime and Fill the System............................. 25

Spraying...................................................... 26

Purging ....................................................... 27

Pressure Relief Procedure............................ 29

Valve Settings..............................................30

Shutdown.................................................... 30

Run Mode Screens............................................. 31

Splash Screen ............................................. 31

Home Screen .............................................. 31

Spray Screen............................................... 34

Fill Screen................................................... 35

Usage Screen.............................................. 36

Jobs Screen ................................................ 37

Errors Screen .............................................. 37

Events Screen ............................................. 37

Setup Mode Screens .......................................... 38

Password Screen......................................... 38

System Screen 1 ......................................... 39

System Screen 2 ......................................... 40

System Screen 3 ......................................... 42

Information for Systems with Multiple

Guns..............................................43

System Screen 4 ......................................... 44

Recipe Screen............................................. 45

Flush Screen ............................................... 47

Pump Screen 1............................................ 48

Pump Screen 2............................................ 49

Pump Screen 3............................................ 50

Calibrate Screen 1 ....................................... 51

Calibrate Screen 2 ....................................... 51

Calibrate Screen 3 ....................................... 52

Maintenance Screen 1 ................................. 53

Maintenance Screen 2 ................................. 53

Maintenance Screen 3 ................................. 53

Maintenance Screen 4 ................................. 54

Advanced Screen 1...................................... 55

Advanced Screen 2...................................... 56

Advanced Screen 3...................................... 56

Advanced Screen 4...................................... 56

ation Checks.............................................. 57

Calibr

Pump Pr

Pump Vo

Solven

Color Change.....................................................60

Single Color Systems................................... 60

Multiple Color Systems................................. 60

System Errors ....................................................61

tenance ...................................................... 74

Main

Prev

Flus

Clea

Technical Data ...................................................75

Graco Standard Warranty.................................... 76

essure Check ................................. 57

lume Check.................................... 58

t Meter Calibration ............................. 59

entive Maintenance Schedule ................ 74

hing ...................................................... 74

ning the ADM........................................ 74

2

332562B

Page 3

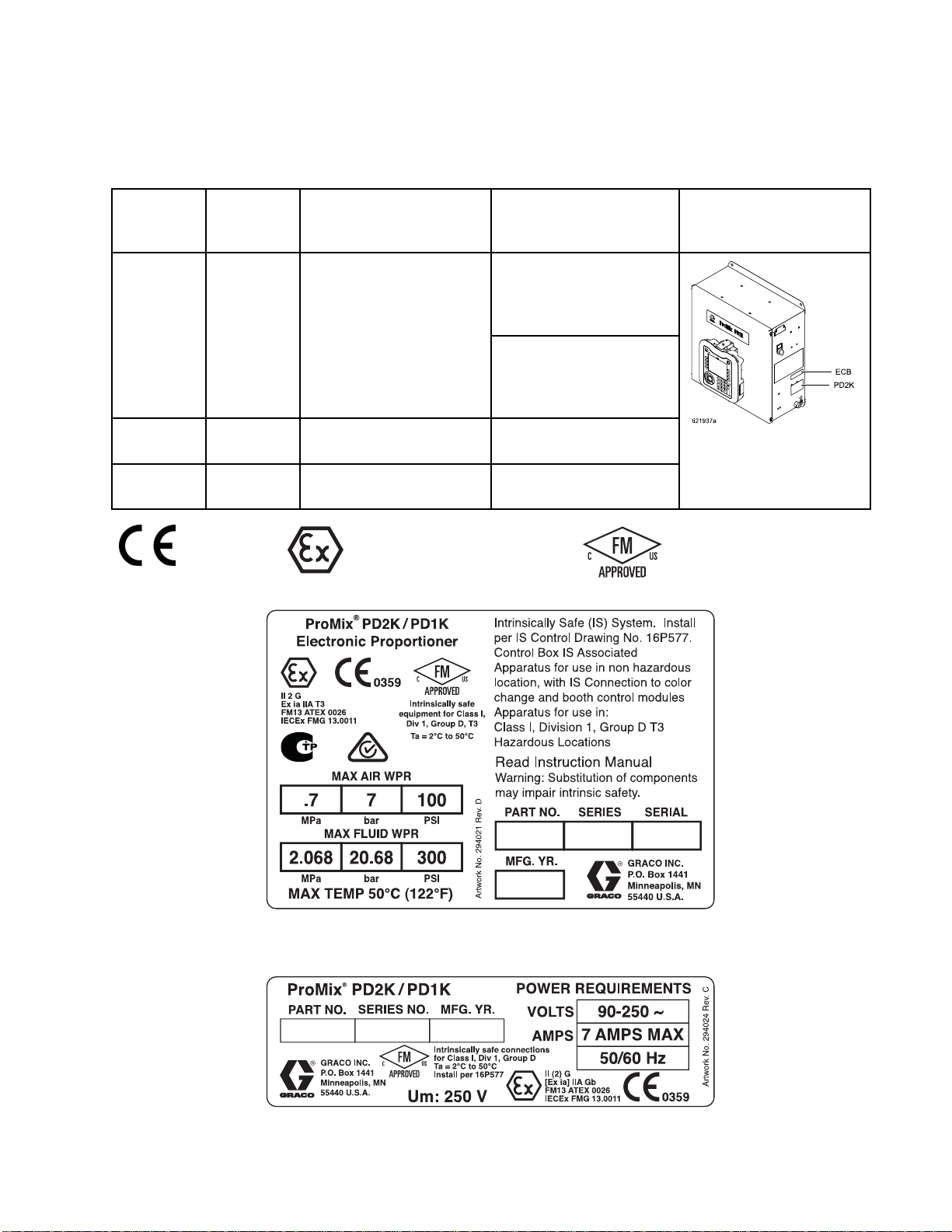

Models

See Figs. 1–7 for component identification labels, including approval information and certification.

Models

Part No.

MC0500

MC1000

MC2000

0359

Series

A

A

A

Maximum Air Working

Pressure

100 psi (0.7 MPa, 7.0 bar)

100 psi (0

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa,

.7 MPa, 7.0 bar)

II 2 G

Maximum Fluid Working

Pressure

With low-

pressure pum

300 psi (2.0

20.68 bar)

With high-

pressure pumps:

1500 psi (10.34 MPa,

103.4 bar)

300 psi (2

20.68 bar

103.4 bar)

ps:

68 MPa,

.068 MPa,

)

Location of PD2K and

Electrical Control Box

(ECB) Labels

Figure 1 Model MC1000 (Low Pressure) Identification

Label

Figure 2 24M672 Control Box Identification Label

Continued on the next page.

332562B 3

Page 4

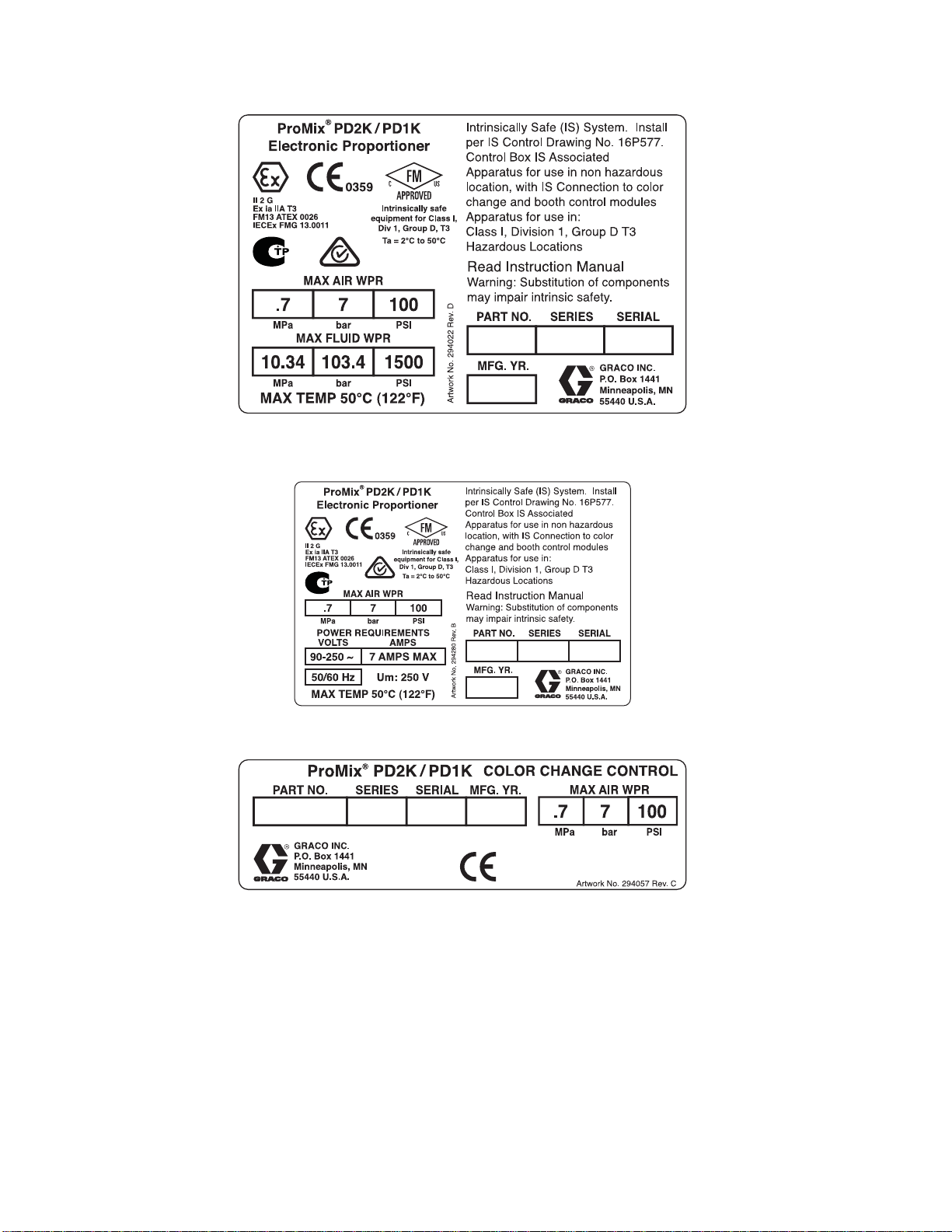

Models

Figure 3 Model MC2000 (High Pressure)

Identification Label

Figure 4 Model MC0500 Identification Label

Figure 5 Non-Intrinsically Safe Color Change Control

(Accessory) Identification Label

4

332562B

Page 5

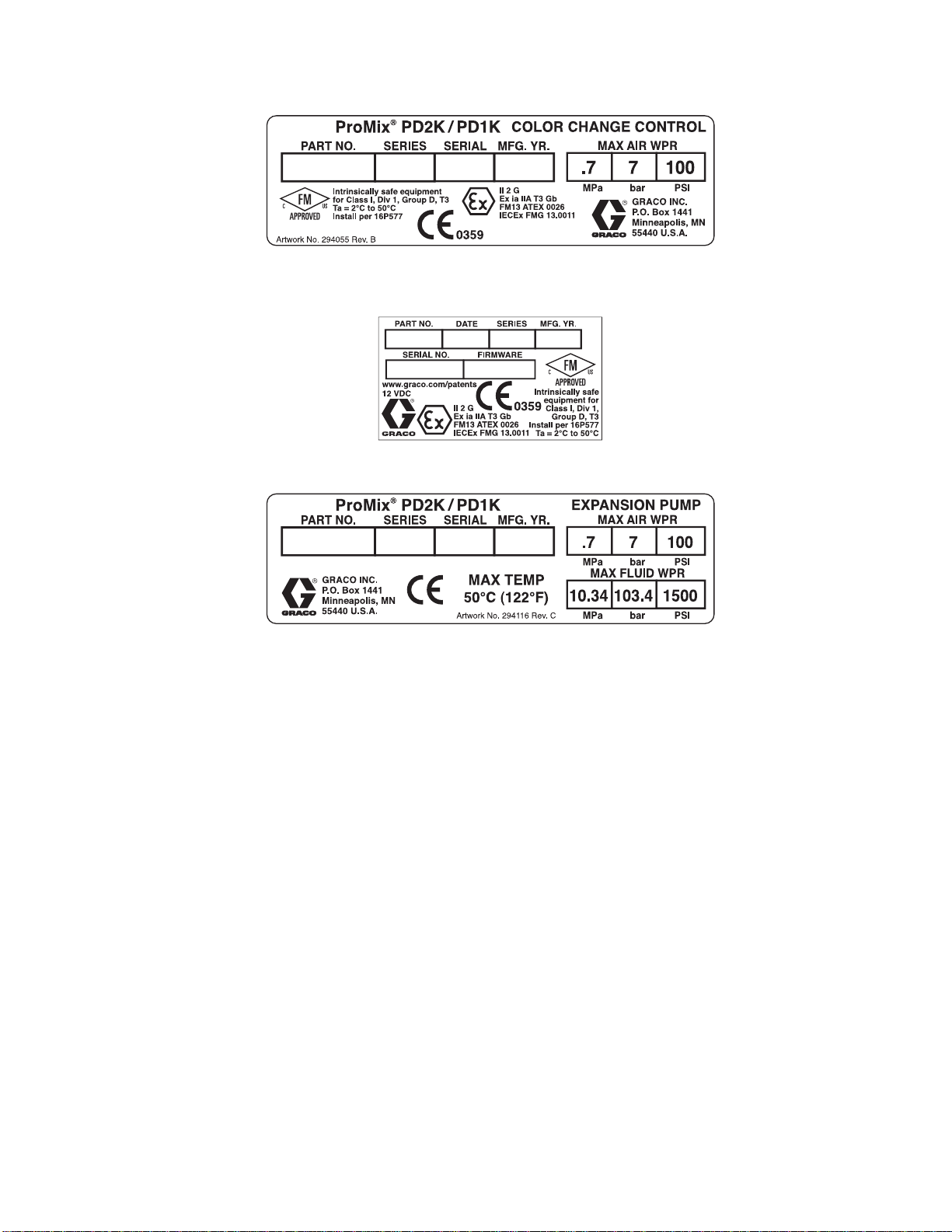

Figure 6 Intrinsically Safe Color Change Control

(Accessory) Identification Label

Figure 7 Booth Control Identification Label

Models

Figure 8 Pump Expansion Kit (Accessory)

Identification Label

332562B 5

Page 6

Related Manuals

Related Manuals

Manual No. Description

3A2800 PD2K Proporti

Manual, Manua

332457 PD2K Proportioner Installation

Manual, Manual Systems

3A2801

332339 Pump Repair-Parts Manual

332454

Mix Manifol

Manual

Color Chan

Manual

oner Repair-Parts

lSystems

d Instructions-Parts

ge Valve Repair-Parts

Manual No. Description

332455

332456 3rd and 4th Pump Kits

334512 PD1K Pump Ex

Color Change Kits InstructionsParts Manual

Instructions-Parts Manual

pansion Kits

Instructio

ns-Parts Manual

6 332562B

Page 7

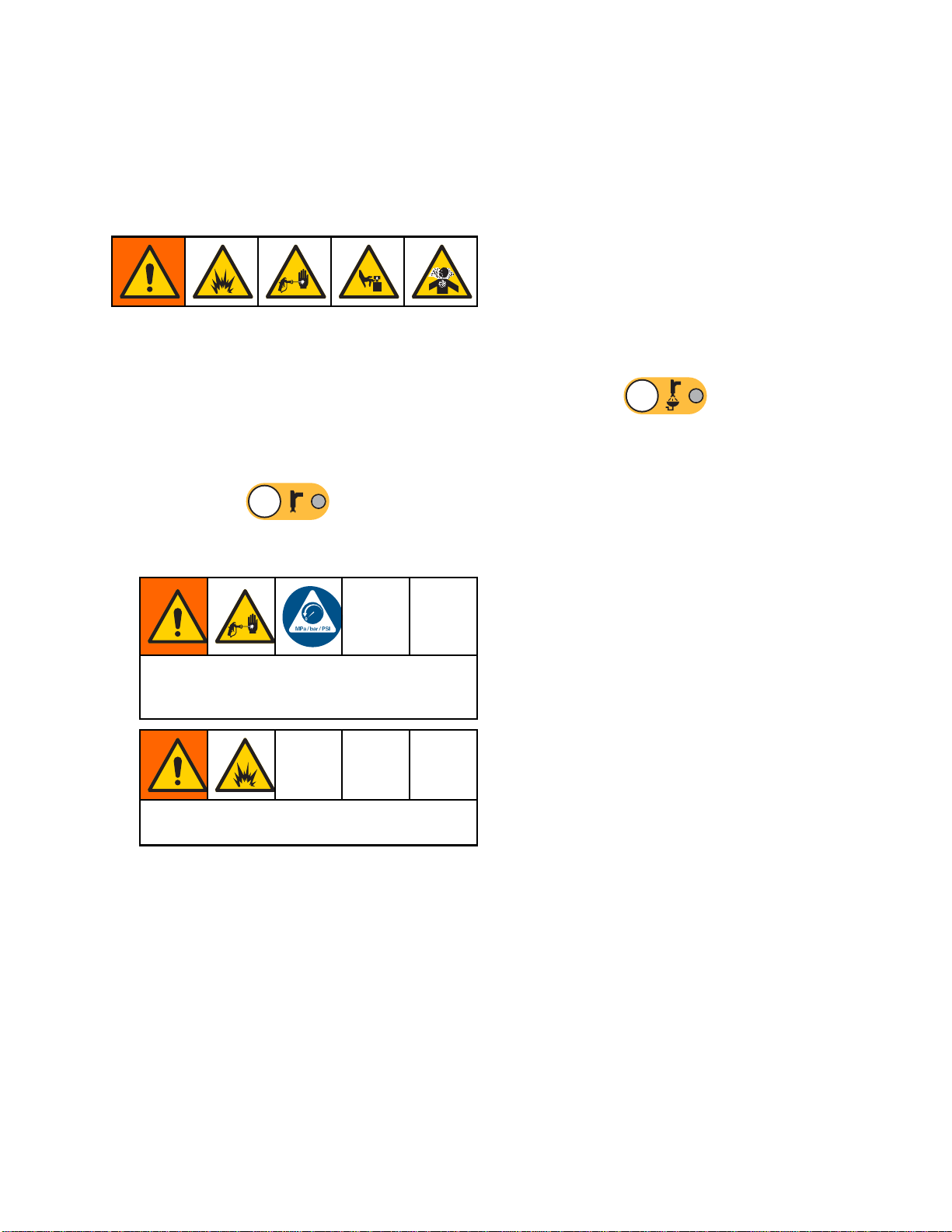

Warnings

Warnings

The following

exclamation p

risks. When th

Warnings. Pr

the body of th

warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

oint symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

ese symbols appear in the body of this manual or on warning labels, refer backtothese

oduct-specific hazard symbols and warnings not covered in this section may appear throughout

is manual where applicable.

WARNING

FIRE AND EX

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

•Keepwork

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

•Useonly

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock, Do not use

equipment until you identify and correct the problem.

• Keepaw

PLOSION HAZARD

area free of debris, including solvent, rags and gasoline.

grounded hoses.

orking fire extinguisher in the work area.

332562B

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

•Turn

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

off and disconnect power at main switch before disconnecting any cables and before

icing or installing equipment.

serv

and regulations.

7

Page 8

Warnings

WARNING

INTRINSIC SAFETY

Intrinsical

equipment wi

Follow local

• Be sure your installation complies with national, state, and local codes for the installation of

electrical apparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1

and 2 (Europe) Hazardous Location, including all of the local safety fire codes (for example,

NFPA 33, NEC 500 and 516, OSHA 1910.107, etc.).

•Tohelpprev

• Equipment

Safety. T

unit from

SKIN INJECTION HAZARD

High-pr

look lik

treatme

• Do not spray without tip guard and trigger guard installed.

• Engage

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not s

• Follow the Pressure Relief Procedure when you stop spraying/dispensing and before

cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

•Check

ly safe equipment that is installed improperly or connected to non-intrinsically safe

ll create a hazardous condition and can cause fire, explosion, or electric shock.

regulations and the following safety requirements.

ent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous

location. See model ID label for the intrinsic safety rating of your model.

• Do not substitute system components as this may impair intrinsic safety.

that comes in contact with the intrinsically safe terminals must be rated for Intrinsic

his includes DC voltage meters, ohmmeters, cables, and connections. Remove the

the hazardous area when troubleshooting.

essure fluid from gun, hose leaks, or ruptured components will pierce skin. This may

e just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

nt.

trigger lock when not spraying.

top or deflect leaks with your hand, body, glove, or rag.

hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

•Keep

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing

clear of moving parts.

equipment, follow the Pressure Relief Procedure and disconnect all power sources.

8 332562B

Page 9

Warnings

WARNING

TOXIC FLUID OR FUMES

Toxic fluids or fumes can cause serious injury or death if splashed in the eyesoronskin,

inhaled, or swallowed.

• Read MSDSs to

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning

equipment.

PERSONAL P

Wear appro

including

equipment

• Protective eyewear, and hearing protection.

• Respirat

manufact

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not op

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not

and c

• Make sure all equipment is rated and approved for the environment in which youareusingit.

• Use equipment only for its intended purpose. Call your distributor for information.

• Rout

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

•Com

priate protective equipment when in the work area to help prevent serious injury,

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

includes but is not limited to:

ors, protective clothing, and gloves as recommended by the fluid and solvent

urer.

erate the unit when fatigued or under the influence of drugs or alcohol.

leave the work area while equipment is energized or under pressure.

alter or modify equipment. Alterations or modifications may void agency approvals

reate safety hazards.

e hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

ply with all applicable safety regulations.

know the specific hazards of the fluids you are using.

ROTECTIVE EQUIPMENT

332562B 9

Page 10

Important Isocy

anate (ISO) Information

Important Iso

Isocyanates (ISO) are catalysts used in two

component materials.

cyanate (ISO) Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read material manufacturer’s warnings and

material MSDS to know specific hazards and

precautions related to isocyanates.

Prevent inhalation of isocyanate mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation

is not available, a supplied-air respirator is required

foreveryoneintheworkarea.

To prevent contact with isocyanates, appropriate

personal protective equipment, including

chemically impermeable gloves, boots, aprons,

and goggles, is also required for everyone in the

work area.

Keep Components A and B Separate

Cross-contamination can result in cured

material in fluid lines which could cause serious

injury or damage equipment. To prevent

cross-contamination:

• Never inte

Bwettedpa

• Never use s

contamina

rchange component A and component

rts.

olvent on one side if it has been

ted from the other side.

Moisture Sensitivity of Isocyanates

Exposure

ISO to pa

crystal

Eventua

will beg

to moisture (such as humidity) will cause

rtially cure; forming small, hard, abrasive

s, which become suspended in the fluid.

lly a film will form on the surface and the ISO

in to gel, increasing in viscosity.

NOTICE

Partially cured ISO will reduce performance and

the life of all wetted parts.

Material Self-ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings

and material MSDS.

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere.

Never store ISO in an open container.

• Keep the ISO pump wet cup or reservoir (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may

contain moisture. Always keep solvent

containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubricant when reassembling.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

10 332562B

Page 11

Important Isocy

anate (ISO) Information

Changing Mate

rials

NOTICE

Changing the material types used in your

equipment requires special attention to avoid

equipment damage and downtime.

• When changi

multiple ti

• Always clea

flushing.

• Check with

chemical c

• When chang

or polyur

componen

have amin

often hav

ng materials, flush the equipment

mes to ensure it is thoroughly clean.

n the fluid inlet strainers after

your material manufacturer for

ompatibility.

ing between epoxies and urethanes

eas, disassemble and clean all fluid

ts and change hoses. Epoxies often

es on the B (hardener) side. Polyureas

eaminesontheA(resin)side.

332562B

11

Page 12

Glossary of Term

s

Glossary of Te

Advanced Display Module (ADM) -the

user interface for the system. See

Advanced Display Module, page 16.

Enhanced Flu

controller f

Grand Total - a non-resettable value that shows

the total amount of material dispensed through the

system.

Idle - if the gun is not triggered for a user-settable

value, the system enters Idle mode. Trigger the gun

to resume operation.

Intrinsic

certain co

Job Total - a resettable value that shows the amount

of material dispensed through the system for one job.

A job is complete when the user presses the Job

Complete key on the Booth Control or ADM.

Mix - when cross-linking of the resin (A) and catalyst

(B) occurs.

id Control Module (EFCM) -thefluid

or the system.

ally Safe (IS) - refers to the ability to locate

mponents in a hazardous location.

rms

Potlife Time - the amount of time before a material

becomes unsprayable.

Potlife Volume - the amount of material that is

required to move through the mix manifold, hose, and

applicator before the potlife timer is reset.

Pump Calibration Factor - the amount of material

dispensed per revolution of the motor.

Purge - when all mixed material is flushed from the

mix manifold, hose, and gun.

Purge Time - the amount of time required to flush all

mixed material from the gun.

Run Screens - The Run screens provide a graphical

depiction of system operation and current status.

See RunModeScreens,page31.

Setup Screens - The Setup screens allow the

user to define the system, setup recipes, and

establish system operating parameters. See

Setup Mode Screens, page 38.

Standby - refers to the status of the system.

2

1

332562B

Page 13

Overview

Usage

Overview

This electronic two-component paint proportioner

can blend most two-component paints, including

quick-setting paints (those with a pot life of 5 minutes

and greater).

• The system d

flow, and con

ispenses Material A, monitors fluid

tinually dispenses Material B at ratio.

Component Identification and Definition

Component

Electric

al Control Box

Descripti

• Enhanced

•24VPower

•48VPowe

• Solenoi

•AirFlow

•Relay

•Option

•PumpCo

•CANIso

on

Fluid Control Module (EFCM)

Supply for the barrier board and the EFCM

r Supply for pump motors

d Valves for solvent valve and gun flush box (if present)

Switch

al Pressure Switch for gun flush box (if present)

ntrol Modules (2), one for each pump

lation Board

• Can proportion at ratios from 0.1:1 to 50.0:1

(depending on material, flow rate, pump size

selection, and mix point).

• Will display the last 200 jobs, 200 errors, and 200

events with date, time, and description.

nsically Safe Power Barrier Board

•Intri

Fluid Components • Mix manifold (accessory), which can be attached to the operator’s belt.

• Color/catalyst valve stacks, including pneumatically operated valves for

Material A and B, as well as solvent valves.

• Solvent Flow Switch

• Pumps

• Pressure transducers

anced Display Module

Adv

oth Control

Bo

Use to set up, display, operate, and monitor the system. Use for daily

painting functions including choosing recipes, reading/clearing errors,

and placing the system in Spray, Standby, or Purge mode. Locate in the

non-hazardous area.

e for daily painting functions including choosing recipes,

Us

ading/clearing errors, and placing the system in Spray, Standby, or

re

urge mode. Locate in the hazardous area.

P

332562B 13

Page 14

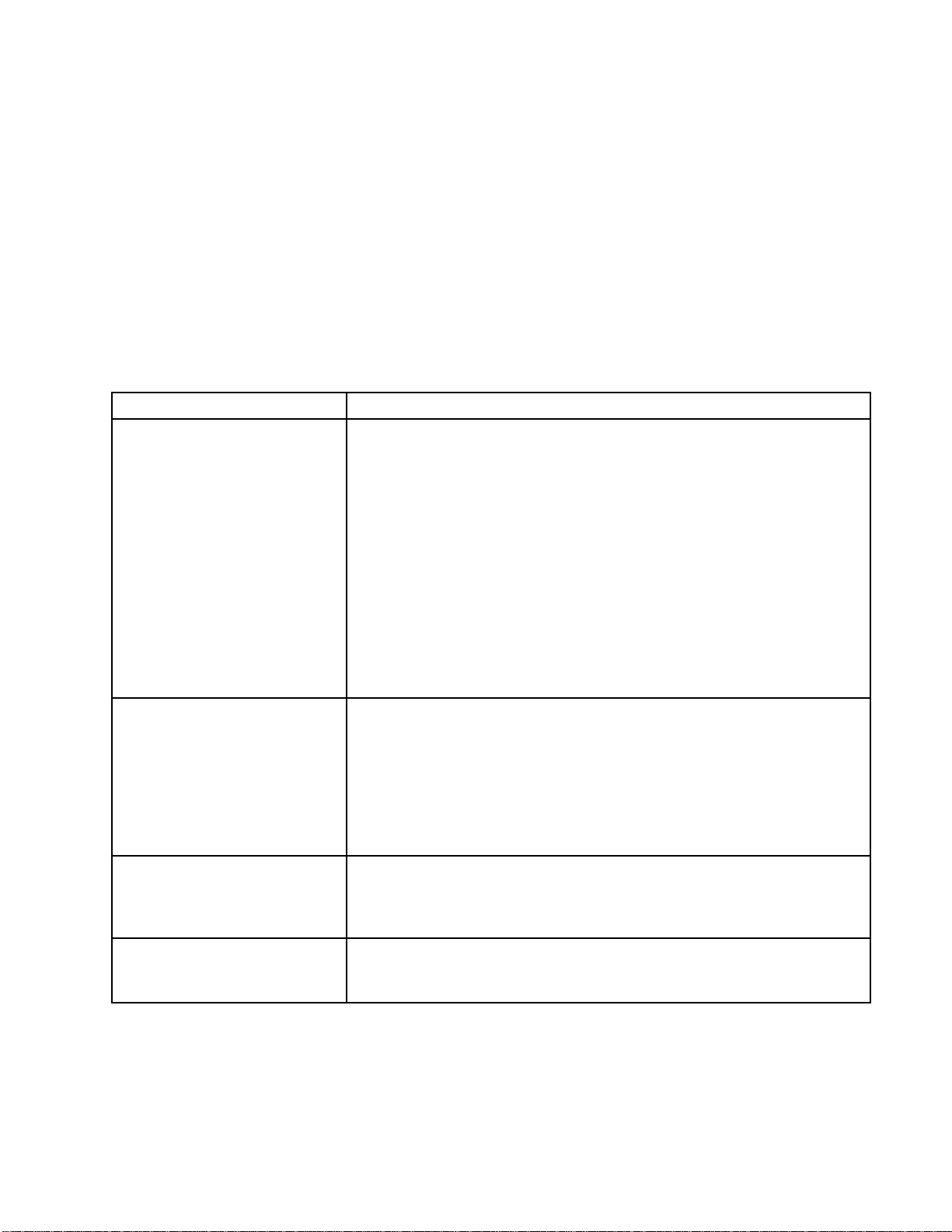

Overview

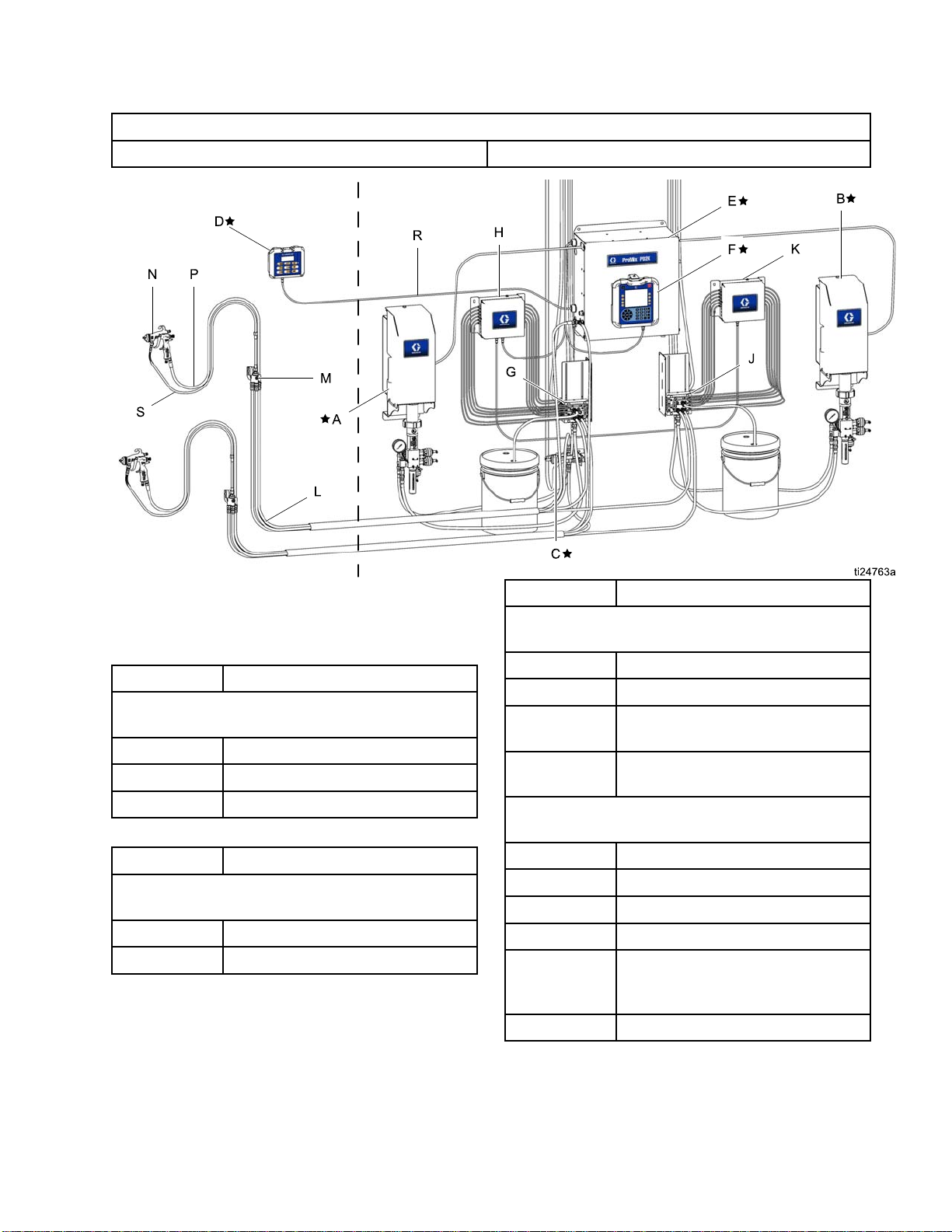

Typical Installation (MC1000, MC2000)

HAZARDOUS (CL

Figure 9

ASSIFIED) LOCATION

NON-HAZARDOU

Component

SLOCATIONONLY

Description

Component

★ Components A through F are included with the

base unit.

A★

B★

C★ Solvent Valve

D★

E★

F★ Advanced Display Module

Description

Material A (Color) Pump

Material B (Catalyst) Pump

Booth Control

Electrical Control Box

Components G through K are included in optional

color change kits.

G Color Change Valves (accessory)

H

J

K

Components L through S are accessories and

must be ordered separately.

L

M

N

P

R

S Gun Fluid Hose (accessory)

Color Change Module (accessory)

Catalyst Change Valves

(accessory)

Catalyst Change Module

(accessory)

Fluid/Air hose Bundle (accessory)

Mix Manifold (accessory)

Air Spray Gun (accessory)

Gun Air Hose (accessory)

Intrinsically Safe CAN Cable (to

connect booth control to electrical

control box)

4

1

332562B

Page 15

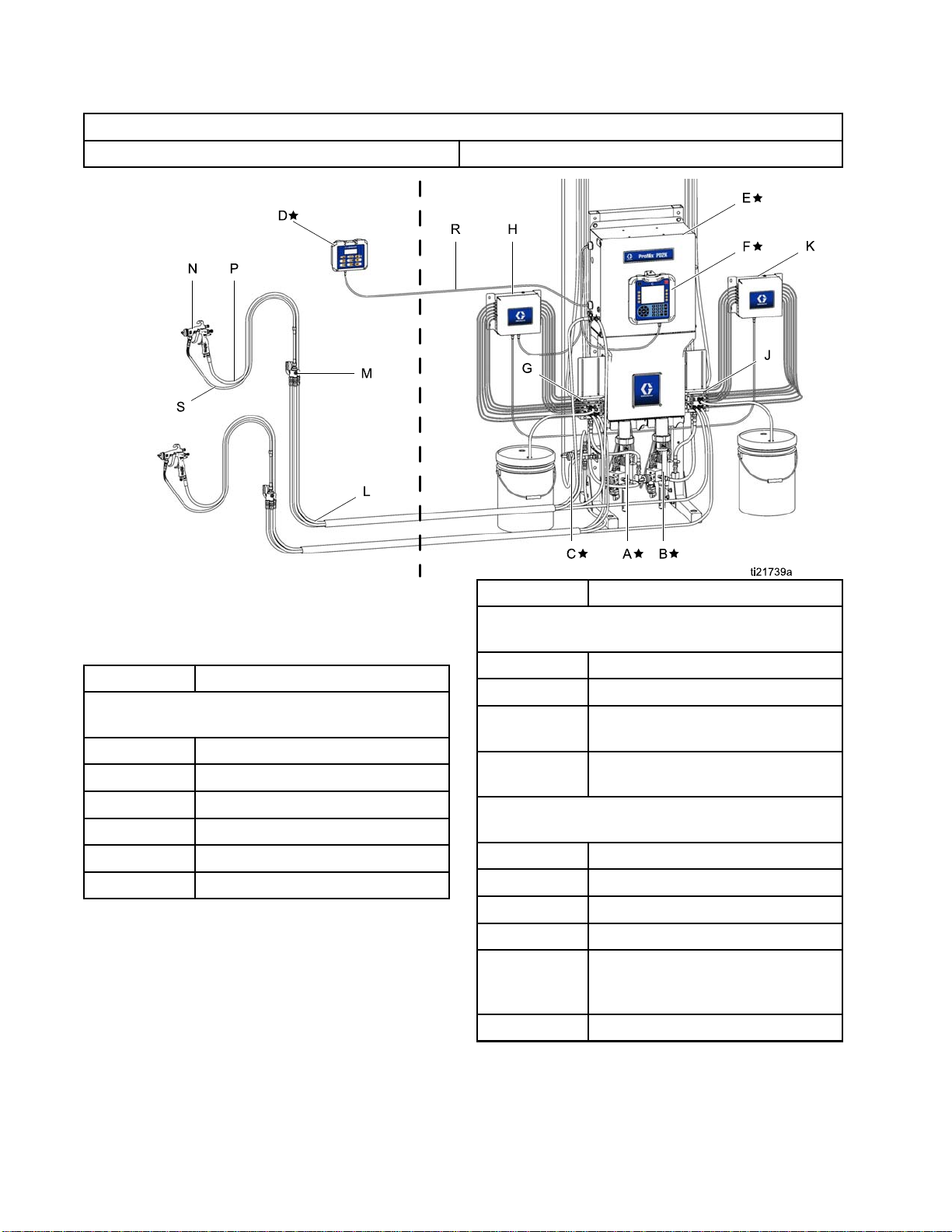

Typical Installation (MC0500)

Overview

HAZARDOUS (CL

Figure 10

ASSIFIED) LOCATION

NON-HAZARDOU

Component

SLOCATIONONLY

Description

Component

★ Components D, E, and F are included with the

base unit.

D★

E★

F★ Advanced Display Module

Component

★ Pumps A and B are required but are sold

separately for system design flexibility.

A★

B★

Description

Booth Control

Electrical Control Box

Description

Material A (Color) Pump

Material B (Catalyst) Pump

Components G through K are included in optional

color change kits.

G Color Change Valves (accessory)

H

J

K

Components L through S are accessories and

must be ordered separately.

L

M

N

P

R

S Gun Fluid Hose (accessory)

Color Change Module (accessory)

Catalyst Change Valves

(accessory)

Catalyst Change Module

(accessory)

Fluid/Air hose Bundle (accessory)

Mix Manifold (accessory)

Air Spray Gun (accessory)

Gun Air Hose (accessory)

Intrinsically Safe CAN Cable (to

connect booth control to electrical

control box)

332562B 15

Page 16

Advanced Displa

yModule

Advanced Display Module

ADM Display

The ADM displ

information

For detail on the display and individual

screens, see Run Mode Screens, page 31,or

Setup Mode Screens, page 38.

Keys are used to input numerical data, enter setup

screens, navigate within a screen, scroll through

screens, and select setup values.

ay shows graphical and text

related to setup and spray operations.

NOTICE

To preven

press the

plastic c

t damage to the softkey buttons, do not

buttons with sharp objects such as pens,

ards, or fingernails.

USB Download Procedure

Use the USB po

data.

1. Enable USB downloads. See

Advanced Screen 3, page 56.

2. Remove the cover from the USB port on the

bottom of the ADM. Insert the USB drive.

3. During the download, USB BUSY appears on the

screen.

4. When the download is complete, USB IDLE

appears on the screen. The USB drive may then

be removed.

NOTE: If the download operation takes longer

than 60 seconds, the message disappears. To

determine if the USB is busy or idle, check the

Error Status bar on the screen. If idle, remove

the USB.

5. Insert the USB flash drive into the USB port of

the computer.

6. The USB flash drive window automatically opens.

If it does not, open the USB flash drive from

within Windows® Explorer.

rt on the ADM to download or upload

1 2 3

4 5 6

7 8 9

ure 11 Advanced Display Module

Fig

0 .

7. Open Graco folder.

8. Open system folder. If downloading data from

more than one system, there will be more than

one folder. Each folder is labeled with the

corresponding serial number of the ADM. (The

serial number is on the back of the ADM.)

9. Open DOWNLOAD folder.

10. Open LOG FILES folder labeled with the highest

number. The highest number indicates the most

recent data download.

11. Open log file. Log files open in Microsoft®

Excel® by default if the program is installed.

They also can be opened in any text editor of

Microsoft® Word.

NOTE: All USB logs are saved in Unicode

(UTF-16) format. If opening the log file in

Microsoft Word, select Unicode encoding.

12. Always reinstall the USB cover after removing

the USB, to keep the drive free of dirt and dust.

16 332562B

Page 17

Advanced Displa

yModule

USB Upload Pro

Use this procedure to install a system configuration

file and/or a custom language file.

1. If necessary

Procedure, t

folder struc

2. Insert the US

the compute

3. The USB flash

If it does no

within Win

4. Open the Gr

5. Open the sy

than one sy

folder wi

labeled w

the ADM. (

the modul

o automatically generate the proper

ture on the USB flash drive.

t, open the USB flash drive from

dows Explorer.

stem folder. If working with more

stem, there will be more than one

thin the Graco folder. Each folder is

ith the corresponding serial number of

The serial number is on the back of

e.)

cedure

, follow the USB Download

B flash drive into the USB port of

r.

drive window automatically opens.

aco folder.

6. If installing the system configuration settings file,

place SETTINGS.TXT file into UPLOAD folder.

7. If installing the custom language file, place

DISPTEXT.TXT file into UPLOAD folder.

8. Remove the USB flash drive from the computer.

9. Install the USB flash drive into the USB port of

the ProMix PD2K system USB port.

10. During the upload, USB BUSY displays on the

screen.

11. Remove the USB flash drive from the USB port.

NOTE: If the custom language file was installed,

users can now select the new language from the

Language drop-down menu in the Advanced Setup

Screen 1.

332562B

17

Page 18

Advanced Displa

yModule

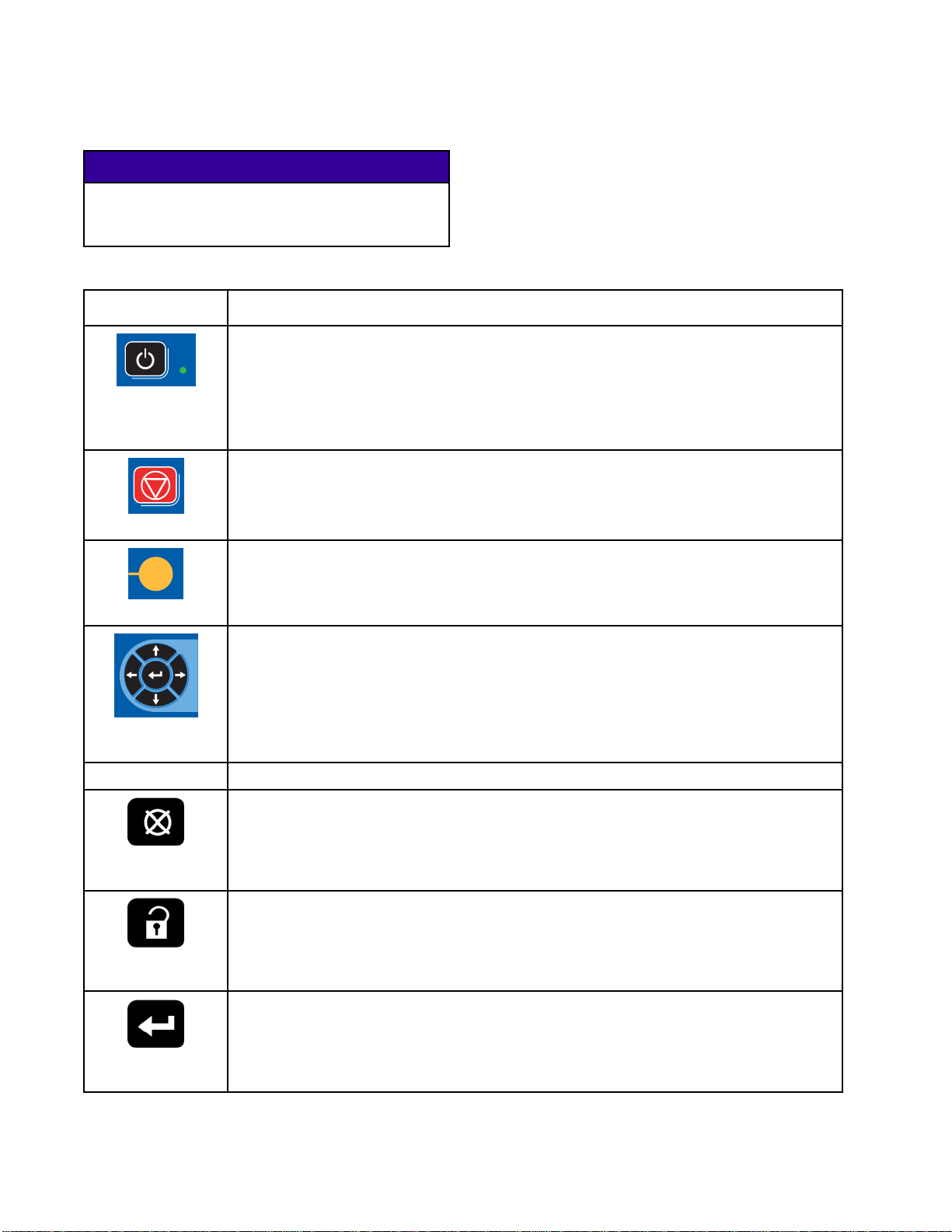

ADM Keys and Indicators

NOTICE

To prevent dam

press the butt

plastic card

Table 1 : ADM Keys and Indicators

Key Function

Startup/Shutdown

Key and Indicator

Stop

Soft Key

age to the softkey buttons, do not

ons with sharp objects such as pens,

s, or fingernails.

Press to startup or shutdown the pump/motor.

• Solid green indicates that power is applied to the motor.

• Solid yellow indicates that power to the motor is off.

• Blinking green or yellow indicates that the system is in Setup mode.

Press to immediately stop the system and remove motor power.

Press to select the specific screen or operation shown on the display directly next to

each key. The top left soft key is the Edit key, which allows access to any settable

fields on a screen.

s

•

Left/Right Arrows:

Use to move from screen to screen.

Navigation Keys

Numeric Keypad

el

Canc

up

Set

ter

En

Up/Down Arrows:

•

menu, or multiple screens within a function.

Use to

Use to cancel a data entry field.

Press to enter or exit Setup mode.

Press to choose a field to update, to make a selection, to save a selection or value, to

enter a screen, or to acknowledge an event.

input values. See ADM Display, page 16.

Use to move among fields on a screen, items on a dropdown

18 332562B

Page 19

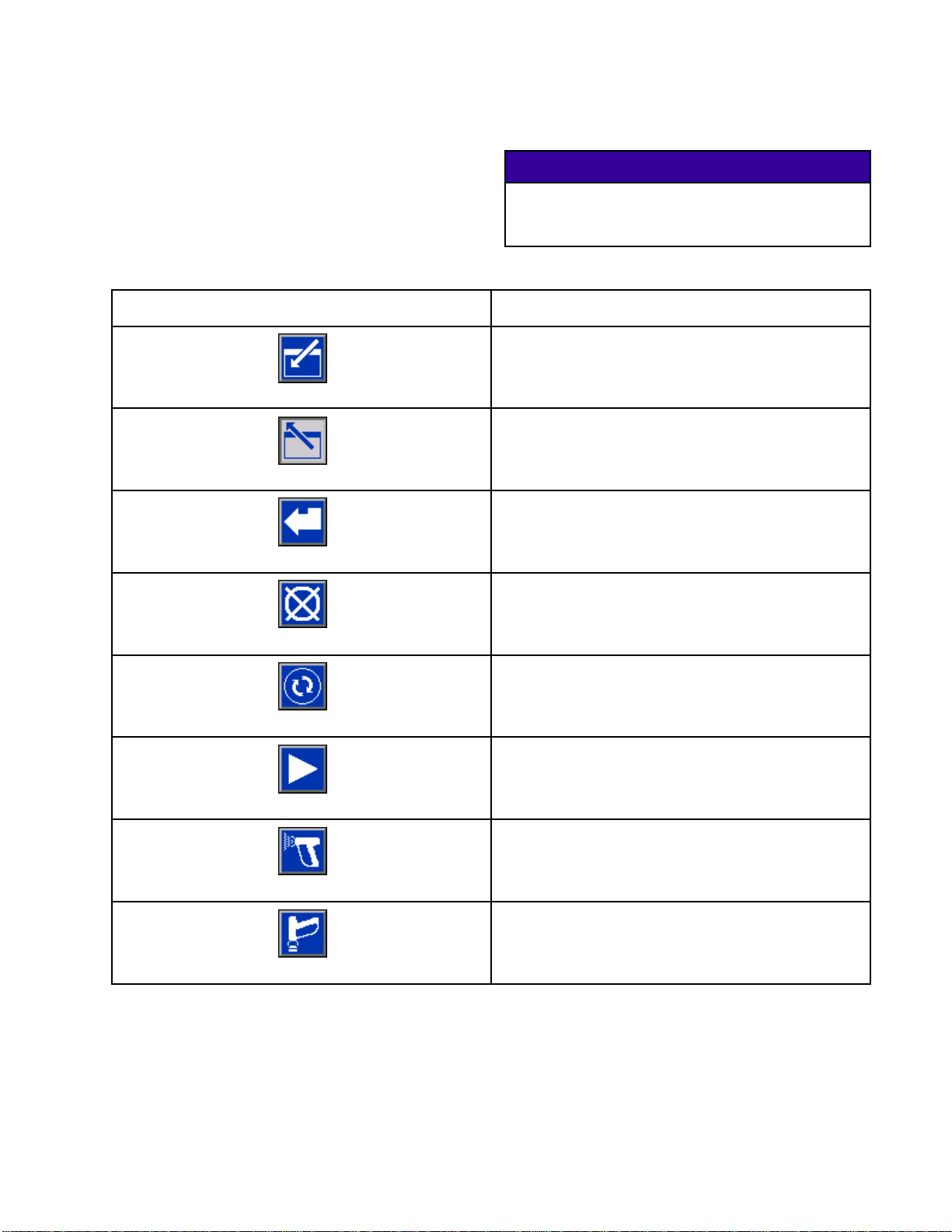

Soft Key Icons

Advanced Displa

yModule

The following icons appear in the ADM display,

directly to the left or right of the soft key which

activates that operation.

Table 2 : Soft Key Functions

Key Function

Enter Screen

Exit Screen

Accept

To prevent damage to the softkey buttons, do not

press the buttons with sharp objects such as pens,

plastic cards, or fingernails.

Press to enter screen for editing. Highlights editable

data on a screen. Use Up/Down arrows to move

between data fields on the screen.

Press to ex

Press to accept calibration value.

Press to cancel or reject calibration value.

NOTICE

it screen after editing.

Cancel

Prime Pump

Line/Fill/Run

Mix

Purge

Press to start a pump priming procedure.

Press to start a line fill procedure.

Press to start a spray procedure.

Press to start a gun purge procedure.

332562B 19

Page 20

Advanced Displa

Key Function

yModule

Standby

Stop

Pressure Check

Volume Check

Job Complete

Counter Reset

Press to stop all pumps and put system in Standby.

Presstostartapumppressurecheck.

Press to st

Press to log the material usage and increment the

job number.

Press to reset the current usage counter.

Appears on the User ID Keyboard screen. Use to

move cursor to the left.

art a pump volume check.

Move Cu

Move Cursor to Right

Upper Case/Lower Case

rsor to Left

Erase All

Backspace

Appears on the User ID Keyboard screen. Use to

move cursor to the right.

Appears on the User ID Keyboard screen. Use to

erase all characters.

ears on the User ID Keyboard screen. Use to

App

se one character at a time.

era

Appears on the User ID Keyboard screen. Use to

change case (upper/lower).

20 332562B

Page 21

Advanced Displa

yModule

Navigating th

There are two sets of screens:

• The Run screen

display syst

• The Setup scr

advanced fea

Press

screens. If the system has a password lock, the

Password screen displays. If the system is not locked

(password is set to 0000), System Screen 1 displays.

Press

Home screen.

Press the Enter soft key

function on any screen.

Press the Exit soft key

e Screens

s control mixing operations and

em status and data.

eens control system parameters and

tures.

on any Run screen to enter the Setup

on any Setup screen to return to the

to activate the editing

to exit any screen.

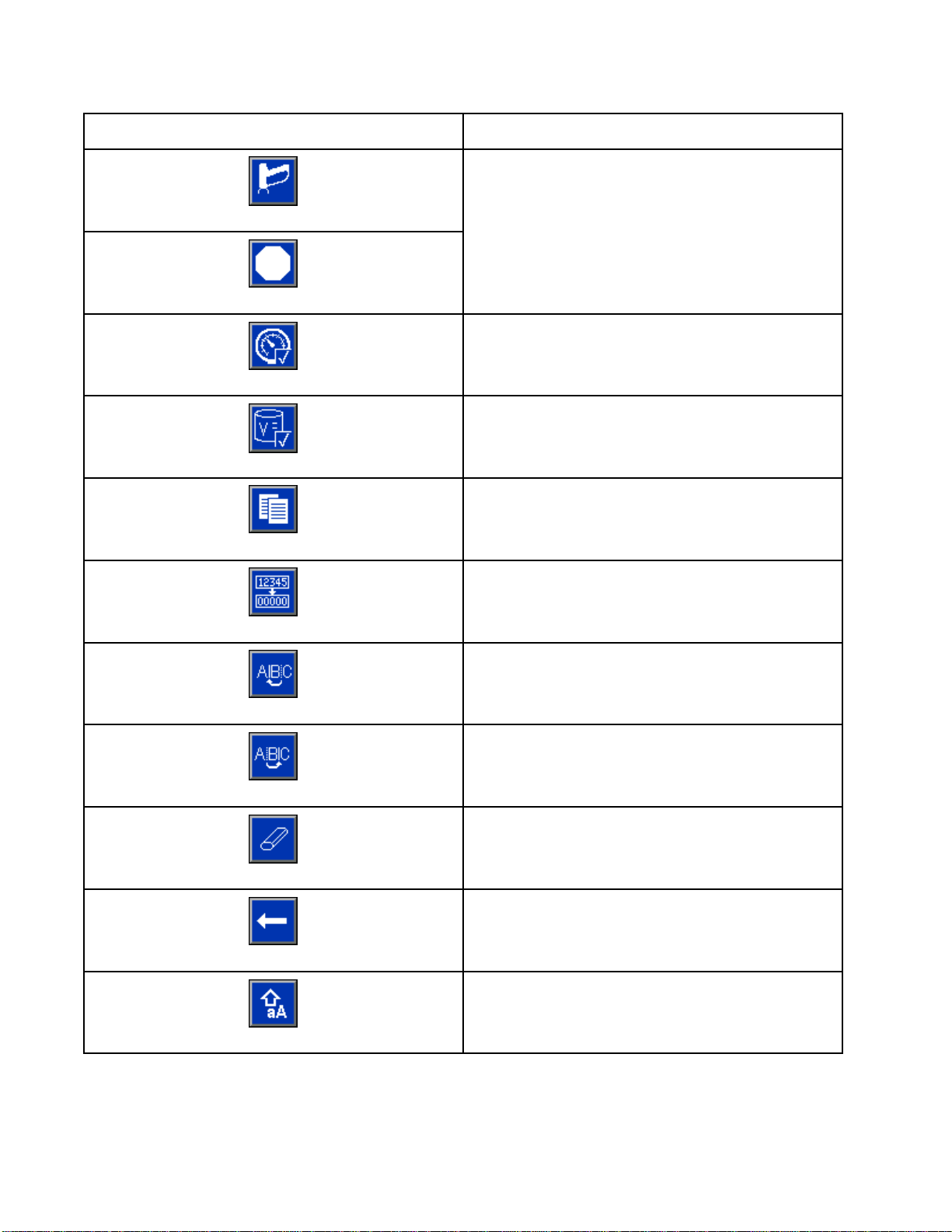

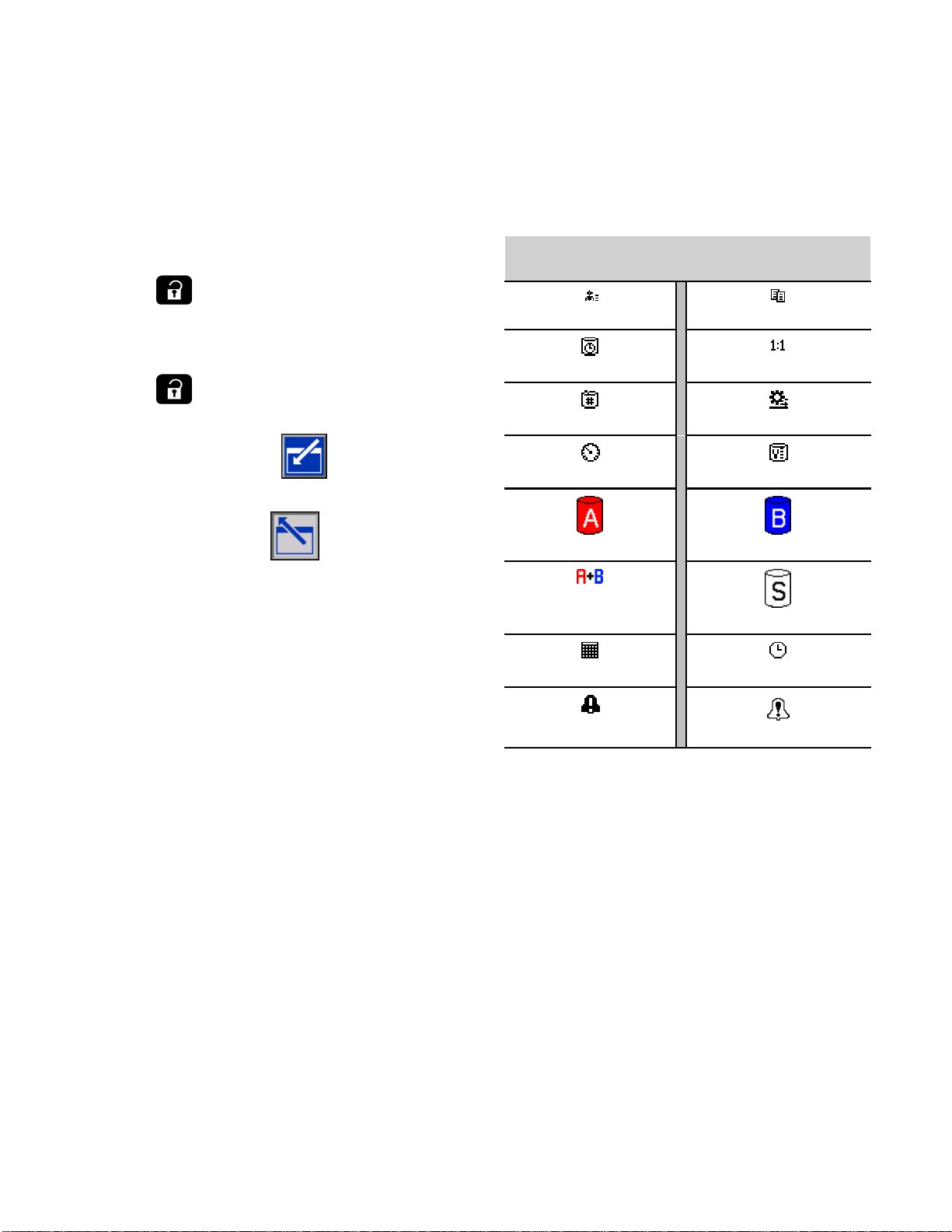

Screen Icons

As you move through the screens, you will notice

that icons are used frequently to simplify global

communication. The following descriptions explain

what each icon represents.

Screen Icons

User ID Job Number

Potlife Target Rati

Recipe Number Flow Rate

Pressure Volume

Material A Material B

o

Use the other softkeys to select the function adjacent

to them.

Material A+B

Calendar Time

Alarm/Advisory

Solven

Deviation

t

332562B

21

Page 22

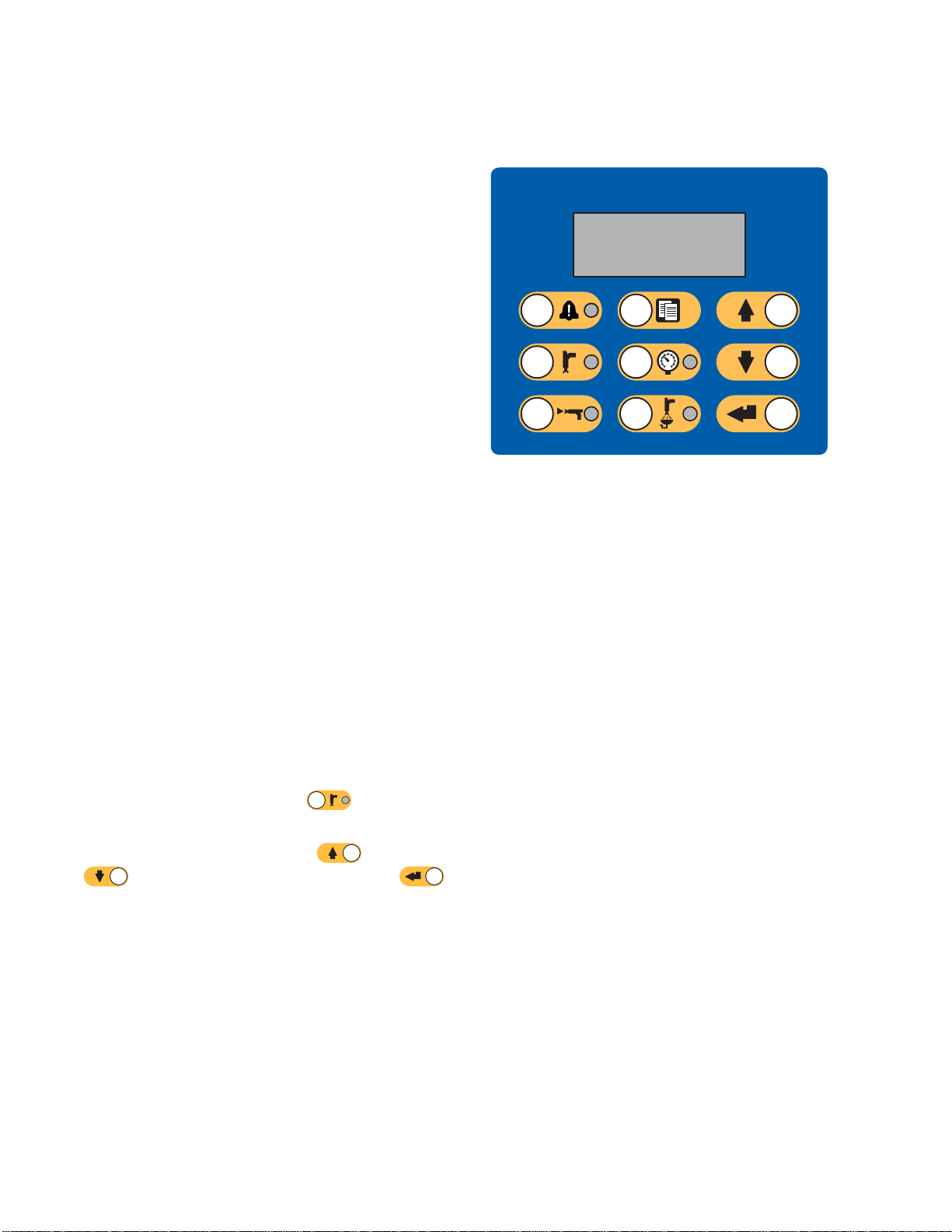

Booth Control

Booth Control

Booth Control

The booth control is the main control device

used by the operator for daily painting functions

including: changing recipes, signaling job complete,

reading/clearing alarms, and placing the system in

Standby, Mix, or Purge mode. It is typically mounted

inside the booth or near the painter.

The booth co

formats:

• R-xx (active recipe)

• P-xx (recipe loaded in the pumps)

• G-xx (recipe loaded in the gun)

The booth control display circulates through the

recipe and error status:

•Display

spray (t

same rec

not show

spray. (

•Iftheg

the pum

altern

ntrol displays the recipe in the following

s the recipe number (R-xx) when ready to

he pumps and gun are loaded with the

ipe). If the display is on steady and does

recipe 0 or 61, the system is ready to

Recipe 61 indicates an unknown material.)

un is loaded with one recipe (G-xx) and

ps with another (P-xx), the display will

ate between the two recipes.

Display

Figure 12 Booth Control

•Ifanal

and th

ackno

the LE

will a

Press and hold the Standby key

to turn the pumps on or off.

To select a new recipe, scroll Up

If Enter is not pressed within 5 seconds, the system

will revert to the existing recipe.

arm occurs, the alarm code is displayed

e red Alarm indicator will flash until

wledged. After the alarm is acknowledged,

D will be on steady and the recipe number

lternate with the code.

for 2 seconds

or Down

to the desired recipe, then press Enter .

2

2

332562B

Page 23

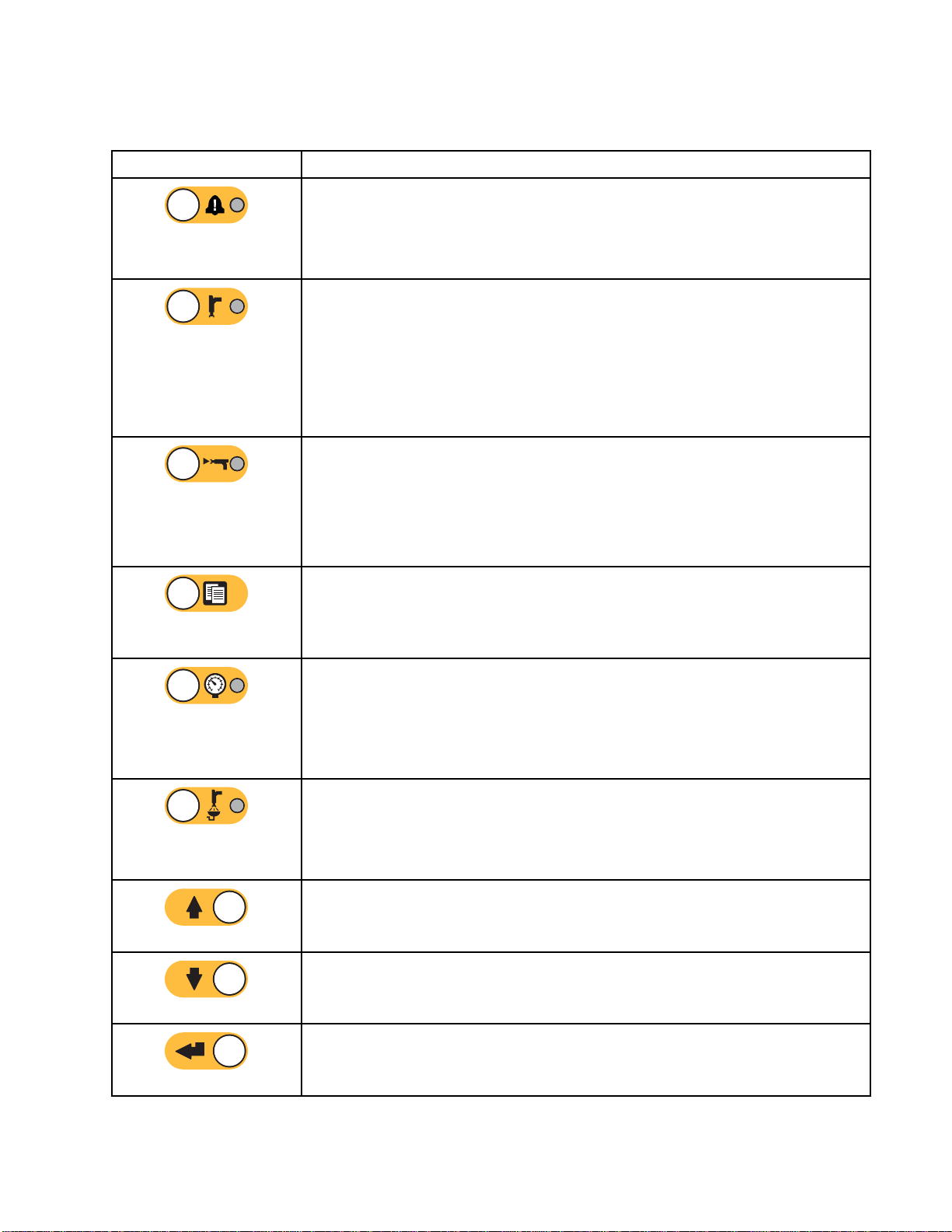

Booth Control

Booth Control

Key/Indicator

Alarm Reset K

Indicator

Standby Mode Key

and Indicator

Mix Mode K

Indicat

ey and

or

Keys and Indicators

Definition and Function

• Red LED is soli

• Red LED blink

ey and

any level.

• Press key to a

• Starts Standby mode.

• Green LED remains lit while in Standby mode.

• Green LED blinks when the system is on and is not mixing or purging. In Idle

mode, the Standby LED and the Mix LED both blink.

• Green LED blinks during pump maintenance checks.

• Press and hold the key to startup or shutdown the pumps.

• Starts Mix mode.

• Green LED remains lit while in Mix mode.

• Green LED blinks during a mix fill. If there is no fluid flow for 30 sec after

starting mix fill, the process must be restarted.

• In Idle mode, the Mix LED and the Standby LED both blink.

d when an alarm condition is present.

s when an event requiring user acknowledgement occurs at

cknowledge. LED shuts off after alarm is cleared.

Job Complete Key

Pressure Control Key

and Indicator

ge Mode Key and

Pur

icator

Ind

Up Key

own Key

D

• Signal

•Presst

• Starts Pressure Change mode.

• Green LED blinks while in Pressure Change mode.

• To change the pressure, press the Pressure Control key and use the Up/Down

• Starts Purge mode.

• Green LED remains lit while in Purge mode.

• Green LED blinks when gun needs to be purged and is waiting for purge to

•Sc

•Sc

• Scrolls recipe numbers down.

• Scrolls pressure value down in Pressure Change mode.

s that job is complete, and resets A, B, and solvent totalizers.

o display the current job number on the booth control. Press a second

o log the current job and increment to the next job number. Times out

time t

5 seconds of inactivity.

after

keys to select the desired pressure. Pressure Change mode times out after 5

seconds of inactivity. Stored recipe is only updated at the end of a spray mode.

begin.

rolls recipe numbers up.

rolls pressure value up in Pressure Change mode.

• Enters selected recipe and starts color change sequence.

• Accepts pressure value change.

Enter Key

332562B 23

Page 24

Operation

Operation

Pre-operatio

Go through the Pre-Operation Checklist daily, before

each use.

✔

n Checklist

Checklist

System grou

Verify all grounding connections

were made. See Grounding in the

Installation manual.

All connections tight and correct

Verify all

system co

installe

manual.

Fluid supply containers filled

Check co

solvent

Dose valves set

Check that dose valves are set

1–1/4 turns open. Start with

the settings recommended in

Valve Settings, page 30, then adjust

as needed.

nded

electrical, fluid, air, and

nnections are tight and

d according to the Installation

mponent A and B and

supply containers.

Flush Before U

The pump fluid section was tested with lightweight

oil, which is left in the fluid passages to protect parts.

To avoid contaminating your fluid with oil, flush the

equipment with a compatible solvent before using

the equipment.

sing Equipment

Power On

1. Turn the AC

2. The Graco l

initializ

3. Press the Start key

change from “System Off” to “Startup.” Once

the pumps are powered and are in the Home

position, the system status will change from

“Startup” to “Standby.”

Power Switch ON (I = ON, 0 = OFF).

ogo will display while the system

es, followed by the Home screen.

. The system status will

supply valves open and

Fluid

ure set

press

The recommended component A and

B fluid supply pressures are 1/2 to 2/3

of the target spray pressure.

NOTE: Low pressure systems may

be set within a range of ± 100 psi (0.7

MPa, 7 bar); high pressure systems

may be set within a range of ± 300 psi

(2.1 MPa, 21 bar). If the inlet pressure

is higher than the outlet pressure,

ratio accuracy may be affected.

Solenoid pressure set

85-100 psi inlet air supply (0.6-0.7

MPa, 6-7 bar).

Figure 13 Power Switch

4

2

332562B

Page 25

Operation

Initial Syste

1. Change optional setup selections to

desired parameters, as described in

Setup Mode Screens, page 38.

2. Set recipe and flush information as

described in Recipe Screen, page 45 and

Flush Screen, page 47.

m Setup

Prime and Fill the System

NOTE: See Ru

screen inf

NOTE: Be sure the mix manifold is set to the SPRAY

position.

NOTE: You must prime the input lines to the pumps

or the inputs to the color change valves before

priming the pump and filling the entire system.

n Mode Screens, page 31,forfurther

ormation, if needed.

4. If the system is powered down, press

ADM. Make sure that the system is in Standby

mode.

5. Verify that the recipes and the flush sequences

are programmed correctly by checking

the Recipe Screen, page 45 and the

Flush Screen, page 47.

6. Go to the Fill Screen, page 35.

7. Select the desired color to load. Press the Prime

Pump key

through the color stack and out the outlet stack

dump valve.

NOTE: Inasinglecolorsystem,skipstep7and

prime the pump out to the gun.

8. Press the Fill Line key

the mix manifold. The pump will run until you

press the Stop key

9. Trigger the gun into a grounded metal pail until

. The color will load the pump

to run color out to

to stop the pump.

on the

1. If using an electrostatic gun, shut off the

electrostatics before filling the lines.

2. Adjust the main air pressure. To ensure proper

operation, set the main air pressure as close to

100 psi (0.7 MPa, 7.0 bar) as possible. Do not

use less than 85 psi (0.6 MPa, 6.0 bar).

3. If this is the first time starting up the system, or if

lines may contain air, purge as instructed under

Purging, page 27. The equipment was tested

with lightweight oil, which should be flushed out

to avoid contaminating your material.

the line is full, then press the Stop key

10. Repeat for all material lines.

.

332562B 25

Page 26

Operation

Spraying

To spray in a multiple color system, also see

Multiple Color Systems, page 60.

NOTE: See Run

screen infor

Mode Screens, page 31, for further

mation, if needed.

3. Press Mix

LED will turn on solid to indicate the system is

mixing. Adjust the flow rate by changing the

target pressure. The fluid flow rate shown on the

Spray screen is the combined total of component

A and B out of the gun.

again. The Mix Mode

1. Set the desi

position.

2. Press Mix

correct mixed material volume. The Mix Mode

LED and the recipe display on the booth control

will blink during the mix fill. If the gun is loaded

with one recipe (G-xx) and the pumps with

another (P-xx), the display will alternate between

the two recipes. When the mix fill is completed,

the display will show R-xx, and the system will

go into Standby Mode.

NOTE: The system will automatically run a Mix

Fill if the recipe is not currently loaded into the

system. The Mix Fill volume calculation includes

the mix manifold volume and the mixed material

hose volume. The mixed material hose volume is

determined by the gun hose length and diameter

entered in System Screen 2, page 40.

red mix manifold to the SPRAY

. The system will load the

• If the fluid fl

spray press

booth contr

• If the fluid

spray pres

booth cont

NOTE: If sp

or booth co

the recip

changes t

4. Turn on at

pattern a

NOTE: Do not use the first 4-5 oz. (120-150 cc)

of material as it may not be thoroughly mixed due

to errors while priming the system. The Spray LED

must be on.

ow rate is too low: increase the

ure setting on the Spray screen or

ol.

flow rate is too high: decrease the

sure setting on the Spray screen or

rol.

ray pressure is adjusted at the ADM

ntrol while spraying, it is not saved in

e until the system is put in Standby. This

he pressure in the desired recipe.

omizing air to the gun. Check the spray

s instructed in your spray gun manual.

NOTICE

Do not allow a fluid supply tank to run empty.

This can damage the pumps and lead to the

proportioning of fluid and air that meets the ratio

and tolerance settings of the equipment. This can

further result in spraying uncatalyzed or poorly

catalyzed material.

26 332562B

Page 27

Purging

Operation

To purge one co

Color Change,

Flush Mixed Ma

There are times when you only want to purge the mix

manifold and gun, such as:

• end of potli

•breaksinsp

• overnight

• before ser

1. Press Standby

2. If you are using a high pressure gun or an

electrostatic gun, shut off the atomizing air.

lor and fill with a new color, see

page 60.

terial

fe

raying that exceed the potlife

shutdown or end of shift

vicing the mix manifold, hose or gun.

.

3. Trigger the gun to relieve pressure.

4. Set the solvent supply pressure regulator at the

lowest pressure possible, to avoid splashing or

an injection injury. Generally a setting of 25–50

psi (0.18–0.35 MPa, 1.8–3.5 bar) is sufficient.

5. Set the mix manifold to the FLUSH position.

6. Press Purg

a grounded

is complet

automati

signalli

7. If the sys

NOTE: Fo

sequenc

8. Trigger

trigger

cally switches to Standby mode,

ng the user to release the trigger.

tem is not completely clean, repeat.

e times so only one cycle is required.

the gun to relieve pressure. Engage the

lock.

e

metal pail until the purge sequence

e. When done purging, the system

r optimal efficiency, adjust purge

. Trigger the gun into

If you ar

the tri

clean i

If using an electrostatic gun, shut off the

electrostatics before flushing the gun.

e using a high pressure gun, engage

gger lock. Remove the spray tip and

t separately.

9. If the s

10. Adjust

normal

NOTE: T

solve

he mix manifold and gun remain full of

nt after purging.

pray tip was removed, reinstall it.

the solvent supply regulator back to its

operating pressure.

332562B

27

Page 28

Operation

Flush the System

Follow this procedure before:

• the first time m

• servicing

• shutting dow

of time

• putting equi

Single Colo

1. Relieve th

Pressure R

2. Disconnec

from the pu

regulate

3. Set the so

lowest pr

an inject

psi (0.1

4. Set the m

5. On the AD

aterial is loaded into the equipment

n equipment for an extended period

pment into storage

rSystem

epressure. See

elief Procedure, page 29.

t the color and catalyst supply lines

mp inlet manifolds, and connect

d solvent supply lines.

lvent supply pressure regulator at the

essure possible, to avoid splashing or

ion injury. Generally a setting of 25–50

8–0.35 MPa, 1.8–3.5 bar) is sufficient.

ix manifold to the SPRAY position.

M, go to the Fill screen. Set the

Color Change System

1. Relieve the pressure. See

Pressure Relief Procedure, page 29.

2. Attach regulated solvent supply lines as follows:

• Multiple col

color side, d

line from the

connect a re

designated

manifold. O

the catalys

of Pump B, a

supply lin

• Multiple c

Connect re

the desig

and catal

solvent s

manifold

3. Set the s

lowest p

an injec

psi (0.1

or/single catalyst system: On the

o not disconnect the color supply

inlet manifold of Pump A. Instead,

gulated solvent supply line to the

solvent valve on the color valve

n the catalyst side, disconnect

t supply line from the inlet manifold

nd connect a regulated solvent

e.

olor/multiple catalyst system:

gulated solvent supply lines to

nated solvent valves on the color

yst valve manifolds. Do not connect

upply lines directly to the inlet

s of the pumps.

olvent supply pressure regulator at the

ressure possible, to avoid splashing or

tion injury. Generally a setting of 25–50

8–0.35 MPa, 1.8–3.5 bar) is sufficient.

Material to Color (A). Press

will pump solvent through pump A all the way to

the gun.

6. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun until clean solvent

dispenses.

7. On the ADM, go to the Fill screen. Set the

Material to Catalyst (B). Press

system will pump solvent through pump B all the

way to the gun.

8. Relieve the pressure. See

Pressure Relief Procedure, page 29

. The system

.The

4. Set the m

5. On the A

(A). En

6. Select

7. If the

Prime softkey

solvent into the selected pump and out the outlet

dump valve.

8. Press the Fill softkey

the selected Color (A) line with solvent until the

user presses Stop

9. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger the gun until clean solvent

dispenses.

10. Repeat for each color line.

11. Relieve the pressure. See

Pressure Relief Procedure, page 29.

ix manifold to the SPRAY position.

DM, go to the Fill screen. Select Color

ter the color number in the box to the right.

the Flush Line box.

solvent is not already loaded, press the

. The system will prime

. The system will flush

.

28 332562B

Page 29

Operation

Pressure Reli

Follow the Pressure Relief Procedure

whenever you see this symbol.

This equipment stays pressurized until pressure

is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure whenyoustopspraying

and before cleaning, checking, or servicing the

equipment.

ef Procedure

Without Color Change

NOTE: The following procedure relieves all fluid and

air pressure in the system.

1. Turn off the supply pumps. Open the drain valve

on the supply line fluid filter to relieve pressure

in the supply line.

NOTE: If your system does not include a drain

valve on the supply line, set the mix manifold

With Color Change

NOTE: The following procedure relieves all fluid and

air pressure in the system.

1. Turn off the su

on the supply l

the supply li

NOTE: If your

valveonthes

SPRAY and pr

B dosing pum

pumps. Repe

If you are using a high pressure gun, engage

the trigger lock. Remove the spray tip and

clean it separately.

If using

statics before flushing the gun.

electro

pply pumps. Open the drain valve

ine fluid filter to relieve pressure in

nes. Do this for each color.

system does not include a drain

upply line, set the mix manifold to

ess

ps a couple of times to drain the

at for each color.

an electrostatic gun, shut off the

.CycletheAand

to SPRAY and press

and B dosing pumps a couple of times to drain

the pumps.

2. Press Standby

relieve pressure.

3. Set the mix manifold to FLUSH.

Flush the mix manifold and gun. See

Flush Mixed Material, page 27.

4. Shut off the solvent supply pump. To relieve

pressure, press Purge

the gun. Press Standby

pressure is relieved, to avoid getting a Purge

Incomplete alarm.

NOTE: If pressure remains in the solvent line

between the solvent supply pump and the solvent

valve,VERYSLOWLYloosenafittingtorelieve

pressure gradually.

.CycletheA

. Trigger the gun to

and trigger

when

2. Set the mix manifold to SPRAY. Trigger the gun

to relieve pressure. Repeat for each color.

3. Press Purge

Hold the gun trigger open after the solvent valve

shuts off to relieve all pressure.

4. Set the system to Recipe 0 to flush the system

from the pumps to the gun. When flushing is

complete the system will go to Standby.

5. Shut off the solvent supply pump. To relieve

pressure, press Purge

the gun. Press Standby

pressure is relieved, to avoid getting a Purge

Incomplete alarm.

NOTE: If pressure remains in the solvent line

between the solvent supply pump and the solvent

valve, VERY SLOWLY loosen a fitting to relieve

pressure gradually.

. Repeat for each color.

and trigger

when

332562B 29

Page 30

Operation

Valve Setting

Dose valves and purge valves are factory set with the

hex nut (E) 1-1/4 turns out from fully closed.

Figure 14 Valve Adjustment

s

Shutdown

1. Flush out the mixed material to avoid potlife errors

and fluid setup in the lines. See Purging, page 27.

2. Follow the Pressure Relief Procedure, page 29.

3. Close the main air shutoff valve on the air supply

line and on the control box.

4. Press

power to the pumps.

5. Shut off system power (0 position).

on the Display Module to turn off

30 332562B

Page 31

Run Mode Screens

Run Mode Scree

NOTE: Selection fields and buttons that are

grayed-out on the screens are not currently active.

ns

Splash Screen

At power up,

approximat

screen.

the Graco logo will display for

ely 5 seconds, followed by the Home

Home Screen

The Home screen displays the current status of the

system. The following table details the information

shown.

Figure 15 Splash Screen

To view pump flow rates and pressures

(as shown), select “Diagnostic Mode” on

System Screen 1, page 39.

Figure 16 Home Screen, in Mix Mode with

Diagnostics On

332562B 31

Page 32

Run Mode Screens

Home Screen Key

Key Description Details

ADateandTime

BMenuBar

C Status B

ar

See Advanced Screen 1, page 55,toset.

Run Screens. U

different Ru

• Home (shown in Diagnostic Mode)

• Spray (see Spray Screen, page 34)

• Fill (see Fill Screen, page 35)

• Potlife (present only when “Multiple Guns is selected on System Screen 3, page 42.Seealso

Information for Systems with Multiple Guns, page 43.

• Usage (see Usage Screen, page 36)

•Jobs(seeJobs Screen, page 37)

•Errors(seeErrors Screen, page 37)

•Events(seeEvents Screen, page 37)

System S

•PumpOff

• Standby

•Startup

•Mix

se left and right arrow keys to scroll through the

n screens:

tatus: Displays the current mode of operation:

• Change Recipe

•Idle

•PrimePump

• Calibrate

• Fill

•Purge

• Shutdown

D

Error Status

ays any active error code.

Displ

•StallTest

• Maintenance Test

32 332562B

Page 33

Key Description Details

E Pump Animation and

Diagnostic Information

Run Mode Screens

F

G Material (A or B)

H

J

K Pump Inlet Pressure

L Pump Flow Rate

M

N

P Pump Indicator Light

S Solvent Flow Rate Shows solvent flow rate, if a solvent meter is attached.

T

Pump Number (1

Available Colors

Pump Inlet C

Pump Outlet Color

Pump Outl

• Clear = power off

• Yellow = standby

• Green = active

Gun An

imation

–4)

olor

et Pressure

Shows

Gun an

•

mixed material in gun and displays active recipe at gun.

imation changes to show:

(Mix

Fill)

•

PurgeinGFB)

(Gun

U

V

W

X

Y

Z

Active Recipe (

Current Ratio (

Potlife Time Remaining (

Total Volume for the Current

Job (

Current Flow Rate (

Current Pressure (

)

)

)

)

)

•

•

•

)

(Mix With Air Flow)

(Recipe Standby)

urge)

(P

•

Standby, in GFB)

•

•

(Purged Gun in

(Solvent Standby)

MixWithNoAirFlow)

(

332562B 33

Page 34

Run Mode Screens

Spray Screen

The Spray screen displays the following information:

• Active Recipe

• Target Ratio

• Actual Ratio

• Target Press

• Actual Pres

• Actual Flow

• Potlife Re

•GunAnimat

sure

maining

(can be changed on this screen)

ure (can be changed on this screen)

ion

Figure 18 Spray Screen, in Mix Mode

Figure 17 Spray Screen, in Standby Mode

e 19 Spray Screen, in Idle Mode

Figur

34 332562B

Page 35

Fill Screen

The Fill screen displays the following information for

the pump assigned to the current color:

Run Mode Screens

• Material. Se

The pump anim

show the sele

enter the pum

• Flush Line (

Select this

material li

sequence 1.

To prime the pumps and fill the lines,firstread

Prime and Fill the System, page 25.

1. Press the Edit softkey

for editing.

2. Select Color (A).

3. Enter the color number in the box to the right.

4. If the selected material is not already loaded,

press the Prime softkey

prime Color (A) into the selected pump through

the selected color valve and out the outlet dump

valve.

lect Color (A), Catalyst (B), or Solvent.

ation at the top of the screen will

cted material. If solvent is selected,

pnumberintheboxtotheright.

only for systems with color change).

box if you want to flush the specified

ne with solvent. The system uses flush

to open the screen

. The system will

Figure 20 Fill Screen, Color (A) Selected

5. Press the Fill softkey

attempt to fill the Color (A) lines until the user

presses Stop

container.

6. Repeat for Catalyst (B).

ush the system (pump and fluid lines), see

To fl

sh the System, page 28.

Flu

To flush only the pump:

1. Press the Edit softkey

for editing.

2. Select Solvent.

3. Enter the pump number in the box to the right.

4. Press the Prime softkey

flush solvent through the selected pump and out

thedumpvalve.

. Trigger the gun into a waste

. The system will

to open the screen

. The system will

e 21 Fill Screen, Solvent Selected

Figur

332562B 35

Page 36

Run Mode Screens

Usage Screen

The first Usage screen displays the current job usage

and grand total usage of component A, B, A+B, and

solvent (S). The second Usage screen displays the

total volume pumped for all available materials.

1. Press the Edit softkey

for editing.

2. To enter or change the User ID (

field to open the User ID Keyboard screen,

and enter the desired name (10 characters

maximum).

3. To log the current job, press the Job Complete

softkey

fields and increment to the next job number.

The Grand Totals cannot be cleared. See the

Jobs Screen, page 37, to review past jobs.

4. Press the Edit softkey

. This will clear the current usage

to open the screen

), select the

to close the screen.

Figure 23 User ID Keyboard Screen

e 24 Usage Log

Figur

Figure 22 Usage Screen

36 332562B

Page 37

Run Mode Screens

Jobs Screen

The Jobs screen displays the 200 most recent job

numbers, recipes, and A+B volumes in a log, with

date, time, and User ID.

Figure 25 Jobs Screen

Errors Screen

The Errors screen displays the 200 most recent Error

Codes in a log, with date, time, and description.

Figure 26 Errors Screen

Events Screen

The Events screen displays the 200 most recent

Event Codes in a log, with date, time, and description.

Figure 27 Events Screen

332562B 37

Page 38

Setup Mode Scree

ns

SetupModeScr

Press on any Run screen to enter the Setup

screens.

NOTE: Selection fields and buttons that are

grayed-out on the screens are not currently active.

If the system

screen disp

has a password lock, the Password

lays. See Password Screen, page 38.

eens

Password Screen

Figure 28 Password Screen

Enter the 4 digit password, then press

screen 1 will open, allowing access to the other

Setup screens.

.System

Entering an incorrect password clears the field.

Reenter the correct password.

To assign a password, see

Advanced Screen 1, page 55.

38 332562B

Page 39

Setup Mode Scree

ns

System Screen

System screen 1 includes the following fields which

define your system.

Figure 29 System Screen 1, During Standby

1

Diagnostic Mode

Select this box to display flow rate and pressure for

eachpumpontheHome Screen, page 31.

Color Pumps

Enter the number of color pumps in your system.

Catalyst Pumps

Enter the number of catalyst pumps in your system.

Non-Mix Pressure

Enter a lower pressure for use when not mixing and

spraying (for example during fill or flushing).

NOTE: Low

(0.7 MPa,

pressur

bar) low

Solvent

pressure systems may be set 100 psi

7 bar) lower than target pressure; high

e systems may be set 300 psi (2.1 MPa, 21

er than target pressure.

Meter

Figure 30 System Screen 1, During Idle

Select t

The Sol

Solven

Enter

Selec

Selec

The A

Auto

Sele

his box if your system uses a solvent meter.

vent K-Factor field will then become active.

tK-Factor

the solvent meter K-Factor.

t Gun Flush Box

t this box if your system uses a gun flush box.

utodump function will then become selectable.

dump

ct this box to activate the Autodump function.

332562B 39

Page 40

Setup Mode Scree

ns

System Screen

System screen 2 sets the following system operating

parameters.

Figure 31 System Screen 2, in Standby Mode

2

Mix Pressure Tolerance

The pressure of one component must be within

a percentage (±) of the pressure of the other

component during spray or mix. Set the desired Mix

Pressure Tolerance in this field. The default is 75%.

Mix Idle Timeout

The air flow switch (AFS) detects air flow to the gun

and signals that the gun is triggered. If you are not

using an air flow switch, the system does not know if

the gun is spraying. If a pump failed you could spray

pure resin or catalyst without knowing. This should

be caught by the Mix No Flow Timeout; the default

is 5 seconds. The Mix Idle Timeout will trigger Idle

mode, which will run a pump stall test to check for

leaks, then put the pumps in Standby (holding their

current position) after the designated period of time.

Enter the desired Mix Idle Timeout in this field.

See Air F

Mix No Fl

low Switch (AFS) Function, page 61.

ow Timeout

re 32 System Screen 2, in Mix Mode

Figu

The air

and sig

switch

no fluid

resin o

Timeou

desig

Enter

See Air Flow Switch (AFS) Function, page 61.

flow switch (AFS) detects air flow to the gun

nals that the gun is triggered. If the air flow

indicates that the gun is triggered, but there is

flow through a pump, you could spray pure

r catalyst without knowing. The Mix No Flow

t will cause the system to shutdown after the

nated period of time. The default is 5 seconds.

the desired shutdown time in this field.

40 332562B

Page 41

Setup Mode Scree

ns

Stall Test Pressure

Set the minimum stall test pressure. The setting

should be approximately 50 psi (0.35 MPa, 3.5 bar)

higher than the highest inlet pressure.

Pump Stall Test

Set the duration for the pump stall test. See

Calibrate Screen 1, page 51.

Maximum Leak Rate

Enter the maximum allowable leak rate for a pump

stall test.

Mix Fill Set Point

Set a higher pressure for use while mix filling.

This higher pressure decreases the time needed

to fill the gun. Once the gun is filled, the system

uses the recipe’s target pressure setpoint (set on

Recipe Screen, page 45)formixing.

The default v

ignores the M

Non-Mix Pres

while mix fil

alue is 0. When set to 0, the system

ix Fill Set Point and instead uses the

sure (set on System Screen 1, page 39)

ling.

332562B

41

Page 42

Setup Mode Scree

ns

System Screen

System screen 3 sets the following system operating

parameters.

Figure 33 System Screen 3

3

Multiple Guns

Enable this option if multiple guns will be loaded

with mixed material at the same time. This feature

will track the pot life of up to 60 different guns. See

Information for Systems with Multiple Guns, page 43.

Gun Hose Length

Enter the length of the hose from the mix manifold

to the gun.

Gun Hose Diameter

Enter the diameter of the hose from the mix manifold

to the gun. The minimum diameter is 1/8 in. (3 mm).

Mix At Wall

Select this box if a remote mix manifold is used in

your system.

NOTE: If Multiple Guns is enabled, the Gun Hose

Length, Gun Hose Diameter, and Mix at Wall fields

are disabled.

gure 34

Fi

Figure 35

Hose Length and Diameter

Enter the length and diameter of the hose from the

remote color stack to the remote mix manifold, for

both A and B hoses.

NOTE: These fields are enabled only if Mix at Wall

is enabled.

2

4

332562B

Page 43

Setup Mode Scree

ns

Information f

The Multiple guns feature enables the ability to

simultaneously track up to 60 different mixed material

recipes, each loaded into a dedicated gun. This

feature is enabled on System Screen 3, page 42.

Recipe Scree

Because the s

recipe, the

could be uni

disabled on

appear on th

hose lengt

aparticul

h and diameter for a gun that will spray

ar recipe.

or Systems with Multiple Guns

n

ystem has a dedicated gun for each

associated hose length and diameters

que. Therefore, these parameters are

System Screen 3, page 42, and now

e Recipe Screen, page 45. Enter the

Changing Recipes or Purging

When Multiple Guns is enabled, the Spray Screen

allows the user either to change the active recipe

(the recipe that is loaded in the pumps) or to purge

a particular gun (recipe). Select either Recipe or

Purge from the dropdown menu and enter the recipe

number. Use the Purge soft key to purge the active

recipe.

These actio

Control. Us

the active

Booth Cont

active cur

the desir

Purge is n

will reve

nsalsocanbedoneusingtheBooth

e the normal procedure to change

recipe or to purge the active gun. See

rol, page 22. To purge a gun that is not

rently, scroll Up

ed recipe. Then press Purge

ot pressed within 5 seconds, the system

rt to the active recipe number.

or Down to

.If

Figure 36

Potlife Screen

In Run mode, the Potlife Screen appears in the menu

bar between Fill and Usage. This screen displays

how much time remains in the potlife of any given

recipe (gun). Recipes are highlighted and show

remaining potlife time only if that gun is filled with

mixed material and has a non-zero potlife.

igure 37

F

Figure 38

332562B 43

Page 44

Setup Mode Scree

ns

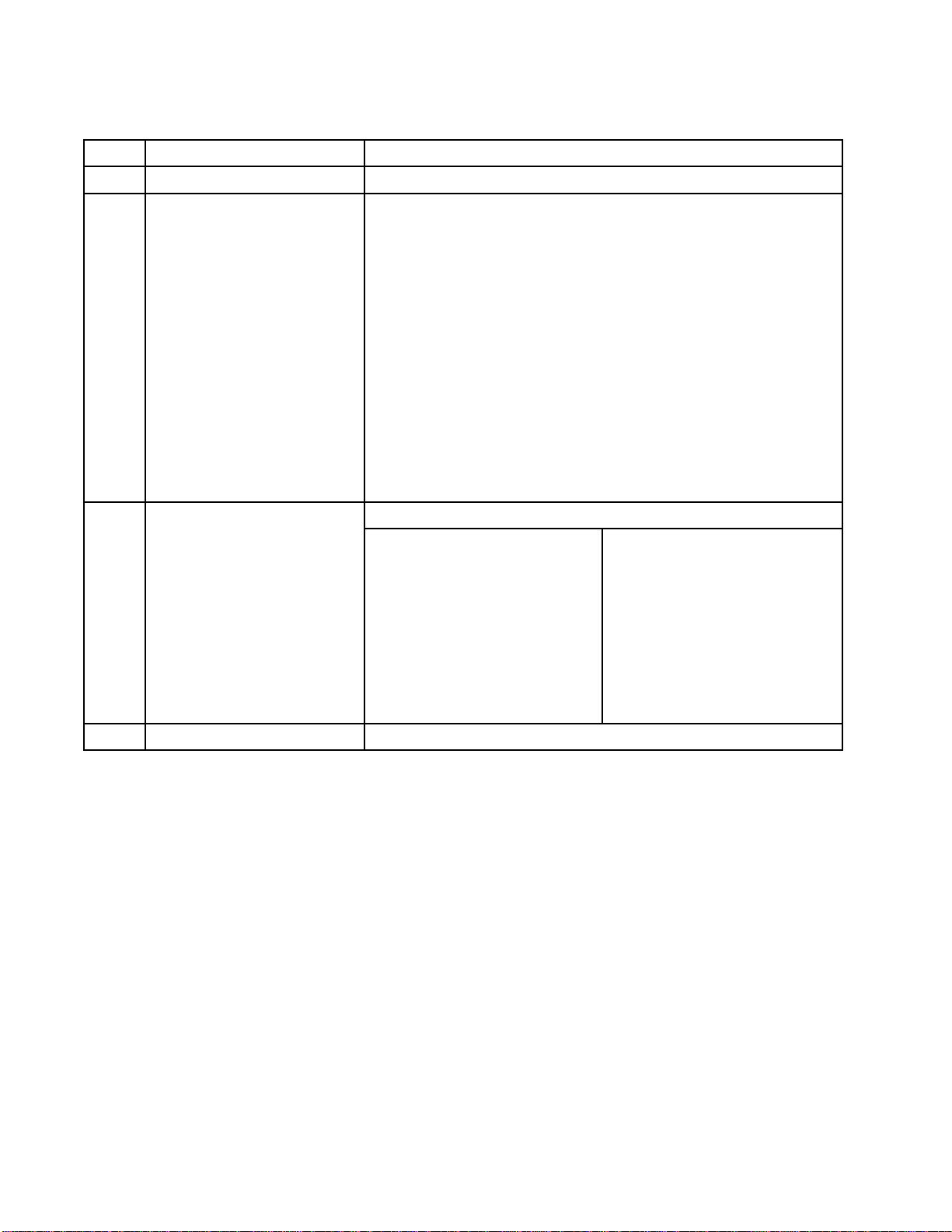

System Screen

System screen 4 sets the following system operating

parameters. This screen is needed only for systems

that use AWI.

Figure 39 System Screen 4

4

Gateway ID

Select the desired Gateway ID from the dropdown

menu.

Enable

Uncheck Enable while setting the IP Address, Subnet

mask, Gateway, DNS1 or DNS2. When the settings

are loaded, check the Enable box to write the new

settings to the selected Gateway.

Checkthisb

that the PLC

ox to enable the selected Gateway so

can communicate with it.

DHCP

Select thi

Configurat

unique IP a

renews the

the netwo

Gateway fi

the addre

s box if your system has a Dynamic Host

ionProtocol(DHCP).Thisprotocolassigns

ddresses to devices, then releases and

se addresses as devices leave and rejoin

rk. If selected, the IP Address, Subnet, and

elds will not be editable and will display

sses supplied by the DHCP.

TCP/IP

Use the r

mask, Ga

emaining fields to set the IP address, subnet

teway, DNS1, and DNS2.

4

4

332562B

Page 45

Recipe Screen

Setup Mode Scree

ns

Figure 40 Valid Recipe Screen

Recipe

Enter the desired recipe number (1-60).

Recipe 0

UseRecipe0toflushthesystem.

• If a recipe (1–60) is loaded: Select Recipe 0 to flush

the previously active pumps and purge the gun.

• If Recipe 0 or 61 is loaded: SelectRecipe0to

flush all pumps and purge the gun.

Enabled

Selecting “Enabled” makes the selected recipe

accessible from the booth control, in addition to the

ADM. The booth operator can then quickly select a

desired recipe, without scrolling through all 60.

Color (A) Valve

Enter the desired color valve number (1-30).

NOTE: If you enter a number which is not valid in

your system configuration, the field will be highlighted

and the recipe becomes invalid. For example, if your

configuration has 8 color valves and you enter 30,

the field will appear as shown below.

Figure 41 Invalid Recipe Screen

Catalyst (B) Valve

Enter the desired catalyst valve number (1-4).

NOTE: If you enter a number which is not valid in

your system configuration, the field will be highlighted

and the recipe is invalid. For example, if your

configuration has 1 catalyst valve and you enter 4,

the field will be highlighted and the recipe is invalid.

Flush Sequence

Enter the desired flush sequence (1-5). For hard

to flush colors, select a longer sequence. 1 is the

default, and should be designated for the longest,

most thorough flush duration.

If Mix at Wall is enabled on System Screen 3, enter

the desired flush sequence (105) for the color (A)

valve and the catalyst (B) valve. The gun purge time

for each material depends on the flush sequence

assigned to each. See Flush Screen, page 47.If

materials A and B require different purge times,

assign separate flush sequences. Set the necessary

gun purge time for each. For hard to flush colors,

select a longer sequence. Flush sequence 1 is the

default, and should be designated for the longest,

most thorough flush duration.

Mix Ratio

Enterthedesiredmixratio(0to50.0):1.

Potlife Time

Enter the potlife time (0 to 999 minutes). Entering

0 disables this function.

332562B 45

Page 46

Setup Mode Scree

ns

Pressure Low Limit

Enter the lowest target pressure which the operator

is allowed to enter from the Spray screen or booth

control. The default is 5 psi (.035 MPa, 0.35 bar).

Target Pressure

Enter the desired target spray pressure. This is the

pressure the pumps will maintain at the outlet. The

default is 20 psi (0.14 MPa, 1.4 bar).

Pressure High Limit

Enter the highest target pressure which the operator

is allowed to enter from the Spray screen or booth

control. The default is 300 psi (2.1 MPa, 21.0 bar).

NOTE: If you en

system’s par

the recipe is

psi (10.5 MPa

the field will

invalid.

ter an invalid pressure for your

ameters, the field will be highlighted and

invalid. For example, if you enter 1500

, 105 bar) in a low pressure system,

be highlighted and the recipe becomes

46 332562B

Page 47

Flush Screen

Figure 42 Flush Screen

Flush Number

Setup Mode Scree

ns

Gun Purge Time

Enter the gun purge time (0 to 999 seconds).

Initial Flush

Entertheinitialflushvolume(0to9999cc).

Final Flush

Enter the final flush volume (0 to 9999 cc).

Wash Cycles

A Wash Cycle activates the pump with the valves

closed, to use pumping motion to thoroughly clean

the pump. Enter the desired number of wash cycles

(0 to 99). Entering a number will make the Strokes

per Cycle field active.

Enter the desired flush sequence (1-5). For hard

to flush colors, select a longer sequence. 1 is the

default, and should be designated for the longest,

most thorough flush duration.

Strokes per Wash Cycle

Enter the desired pump strokes per wash cycle (0

to 99). Default is 1.

332562B

47

Page 48

Setup Mode Scree

Pump Screen 1

ns

NOTE: Your system may include 2, 3, or 4 pumps.

Information for each pump is accessible under a

separate tab in the menu bar at the top of the screen.

Select the tab for the desired pump. Each pump has

three screens. Only the screens for Pump 1 are

shown here, but the same fields appear on all.

Pump screen

define the pu

Figure 43 Pump Screen 1 — Resin Pump

1 includes the following fields which

mp.

Select Color Change

Select this box if your system uses color change.

Materials

Enter the number of materials used in your system.

Each color change module controls 8 colors.

Total Hose Length

Compute the length of the hoses from the supply

stack to the pump and from the pump to the outlet

stack. Enter the total length.

Pump Hose Diameter

Enter the diameter of the supply and output hoses.

Valve Mapping

Remote Valve Map

NOTE: Th

if the pu

selecte

System

is valve mapping dropdown menu displays

mp is a resin pump with Color Change

d on this screen and Mix at Wall enabled on

Screen 3, page 42.

Figure 44 Pump Screen 1 — Catalyst Pump

Pump Size

Select 35cc or 70cc, as appropriate.

Inlet Pressure

Select one of the following:

• Disabled

Select whether to use the standard color change

valve mapping or one of two alternate color change

valve mappings for the remote valve stack. See the

Color Change and Remote Mix Manifold manual

333282 for more information.

Valve Map

NOTE:

if th

sele

Select whether to use the standard color change

valve mapping or the alternate color change valve

mapping for the catalyst pump(s). See the Color

Change and Remote Mix Manifold manual 333282

for more information.

This valve mapping dropdown menu displays

e pump is a catalyst pump with Color Change

cted on this screen.

Available Colors

The module displays the number of colors available

in your system. This field is not editable.

• Monitor, to track inlet pressure

48 332562B

Page 49

Pump Screen 2

Setup Mode Scree

ns

Pump screen 2 sets the pressure transducer settings

for the pump.