Page 1

Instructions, Repair and Parts

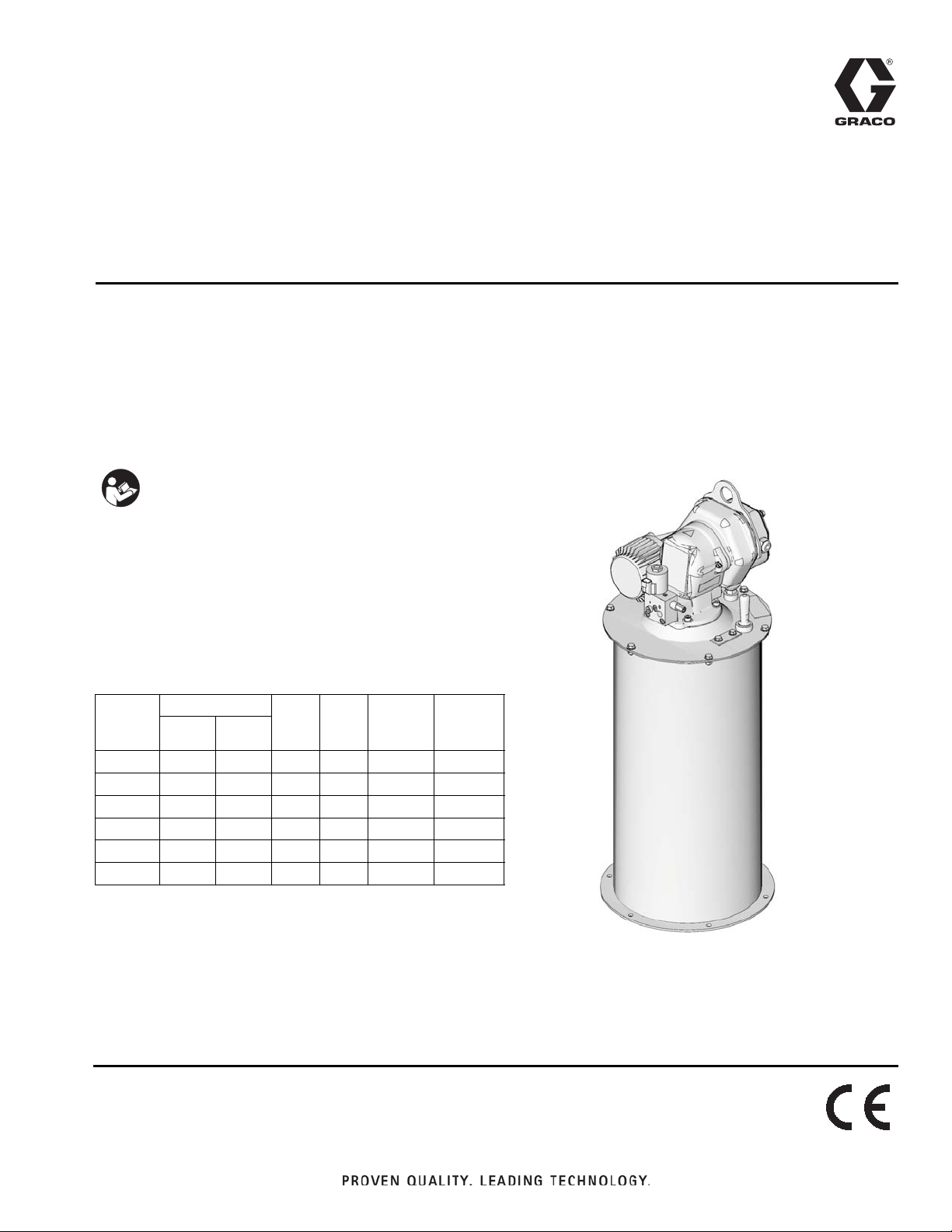

Models 77X100 and 77X101 shown

®

Dyna-Star

Pump System

Provides lubricant flow and pressure to operate a single line parallel automatic lubrication

system. For automatic lubrication systems only.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this man-

ual and the Dyna-Star HP and HF Pump

instruction manual. Save all instructions.

HP

332540E

EN

Maximum Working Pressure: 3500 psi (24.1 MPa, 241

bar)

Models:

All models include Tube-in-Tube design, vent valve,

cover and tank.

System

Models

77X100 X X

77X101 X X

77X102 X X

77X103 X X

77X104 X X X

77X105 X X X

*Can only be used with Low Level models.

35/60

Pound

Size

90/120

Pound

Dip

Stick

Low

Level

Follower

Plate*

Auto-Fill

Shut Off

Page 2

Warnings

WARNINGWARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and

gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

+

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

2 332540E

Page 3

Warnings

WARNINGWARNINGWARNING

WARNING

PRESSURIZED EQUIPMENT HAZARD

Over-pressurization can result in equipment rupture and serious injury.

• A pressure relief valve is required at each pump outlet.

• Follow Pressure Relief Procedure in this manual before servicing.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and

create safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

332540E 3

Page 4

Warnings

WARNINGWARNINGWARNING

WARNING

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns:

• Do not touch hot fluid or equipment.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturers.

4 332540E

Page 5

Typical Installation: Injector System

E

D

C

F

B

H

K

G

Front

Back

Low Reservoir

Level Switch

(Level Indicator,

optional)

Pressure Switch

for System Control

Remote Alarm Device

(Light or Horn)

(user provided

Controller

Capabilities

J

K

L

A

M

Motor Control

Board

Pump Power

Pump Signal

Vent Valve

N

P

R

S

Typical Installation: Injector System

The installation shown in below is only a guide for selecting and installing system components. Contact your Graco

distributor for assistance in planning a system to suit your needs.

FIG. 1

Key:

A Lubricant outlet connection

B Pump

C Ignition switch*

D High-pressure lubricant supply lines*

E Injector banks*

M Motor

N Fluid overflow container

P Pump - remote filling station

R Reservoir - remote filling station

S Auto-Fill Shut Off

F Lubrication controller*

G Fill port (not used with Auto-Fill Shut Off)

H Overflow port (not used with Auto-Fill Shut Off)

*User provided

J Breather

K Reservoir

L Vent Valve

332540E 5

Page 6

Typical Installation: Series Progressive System

E

D

C

F

B

H

K

G

FrontBack

Low Reservoir

Level Switch

(Level Indicator,

optional)

Pressure Switch

for System Control

Remote Alarm Device

(Light or Horn)

(user provided

Controller

Capabilities

J

K

A

M

L

N

N

L

N

N

Motor Control

Board

Pump Power

Pump Signal

Typical Installation: Series Progressive System

The installation shown below is only a guide for selecting and installing system components. Contact your Graco distributor for assistance in planning a system to suit your needs.

FIG. 2

Key:

A Lubricant output connection†

B Pump†

C Ignition switch*

D High-pressure lubricant supply lines*

E Primary metering device*

F Lubrication controller*

G Fill port (for reference only; non-tube-in-tube models only)

† The pump outlet requires modification to convert an Injector-based

system to Series Progressive system. Dyna-Star HF and HP Outlet

Adapter Kits 77X543 rated 4000 psi (275.8 bar, 27.58 MPa) and

77X544 rated 5000 psi (344.7 bar, 34.47 MPa) are available from

Graco. Contact Graco Customer Service or your local Graco distributor to identify the correct kit for your installation location.

H Overflow port (for reference only)

J Breather (for reference only)

K Reservoir / Tank (for reference only)

L Secondary metering device

MMotor

N Bearing

*User provided

6 332540E

Page 7

Installation

Installation

Pressure Relief

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop dispensing and

before cleaning, checking, or servicing the

equipment.

To relieve pressure in the system, use two wrenches

working in opposite directions on pump outlet fitting to

slowly loosen fitting only until fitting is loose and no

more lubricant or air is leaking from fitting as shown in

F

IG. 3.

COMPONENT RUPTURE HAZARD

The maximum working pressure of each component

in the system may not be the same. To reduce the

risk of overpressurizing any component in the system, be sure you know the maximum working pressure of each component. Never exceed the

maximum working pressure of the lowest rated component in the system. Overpressurizing any component can result in rupture, fire, explosion, property

damage and serious injury.

• Read and follow instructions supplied with each sys-

tem component.

• Reference letters used in the following Installation

instructions, refer to Typical Installation Key, page

5.

Wiring

Grounding

FIG. 3

The equipment must be bonded (grounded) directly

to the truck. Grounding reduces the risk of static

shock due to static build up on the equipment.

System Configuration and Wiring

NOTE: Cable wiring harness kits are available from

Graco. See Parts page 11 for a complete list of available

kits.

Fuses

NOTICE

Fuses (user supplied) are required on all models. To

avoid equipment damage:

• Never operate the Dyna-Star Pump models without a fuse installed.

• A fuse of the correct voltage and amperage must

be installed in line with the power entry to the

system. Graco recommends using 35A fuses.

332540E 7

Page 8

Operation

Reservoir Installation

HEAVY EQUIPMENT HAZARD

Equipment is heavy. To avoid injury:

• Be sure unit is securely mounted before operation.

• Do not lift pressurized equipment.

• Lifting or moving heavy equipment incorrectly can

cause serious injury. To avoid serious injuries,

such as muscle strain or back injuries, when

moving pump always use a lifting aid secured to

the pump lift ring. See Technical Data, in the pump

instruction manual for pump weight.

1. Mount Reservoir on sturdy, flat surface. Note location of Fill Port (G) and Lubricant Outlet Connection

(A) for easy access once installed.

2. Connect High Pressure Lubricant Supply Line (D) to

the Lubricant Outlet Connection (A).

3. Ground system (see Grounding). Mount reservoir

to grounded chassis member.

Operation

• Read and follow instructions supplied with each sys-

tem component.

• Reference letters used in the following Installation

instructions, refer to Typical Installation Key, page

5.

Start-up

Do not insert finger into the overflow port while filling

a reservoir equipped with a follow plate. Injury or

amputation could result.

Priming

1. After reservoir/tank is completely filled, remove high

pressure lubricant supply line (D) from the outlet.

2. Connect power to pump.

Pump Installation

Pump installation instructions are provided in the

Dyna-Star HP or HF Pump instruction manual 332514

provided with your system.

Vent Valve Kit

The vent valve is used to reduce system pressure and

allow the injector to reset. When energized, grease is

pumped out through the outlet port (marked 0) on the

vent valve. When de-energized, it vents pressure internally to tank.

Refer to the Dyna-Star HP or HF Vent Valve Kit manual

332515 for installation and operation instructions.

Auto-Fill Shut Off

The Auto-Fill Shut Off is used refilling the grease

tank/reservoir instead of the fill port (G). When the

grease level in the tank is full, the Auto-Fill Shut Off

automatically ends the filling operation. Refer to the

Auto-Fill Shut Off Kit instruction manual 332518 for

complete instructions and additional information.

3. Start pump and run pump until all air has been

expelled and fluid flow is continuous.

4. Reconnect the high pressure lubricant supply line

(D) to outlet.

8 332540E

Page 9

Operation

Filling Reservoir

There are two reservoir filling options; Fill Port (G) or

Auto-Fill Shut Off (S). Only one method of filling can be

used.

Filling Reservoir With Fill Port (G)

NOTICE

To prevent damage to the unit:

• Check Breather vent (J) for proper operation

before filling reservoir.

• Open Overflow Port (H) before filling for visual

inspection of lubricant level.

• Do not fill beyond Overflow Port (H).

• Do not use Overflow Port (H) to fill reservoir.

1. Connect lubricant supply hose from remote filling

station pump to Fill Port (G).

2. Remove plug from Overflow Port (H).

Filling Reservoir With Auto-Fill Shut Off (S)

Refer to Auto-Fill Shut Off Kit instruction manual

332518.

Shutdown

For normal system shut down, disconnect power by

turning off the ignition switch (C).

3. Slowly turn on supply lubricant until level of lubricant

reaches Overflow Port (H).

NOTE: For systems with a follower plate, fill unit until

the follower plate reaches the Overflow Port (H).

4. Disconnect lubricants supply hose from Fill Port (G).

5. Plug Fill Port (G) and Overflow Port (H).

NOTICE

Never allow pump to run dry of the fluid being pumped.

Running a pump dry can damage the pump.

332540E 9

Page 10

Parts List

1a

1b

4

3e

3d

3h

3f

3k

3c

3a

3g

3j

3a

3d

3l

3m

3n

3c

8

9

10

Parts List

Model 77X100: Dyna-Star Pump, 60#, Dip Stick, Reservoir, Cover, Vent Valve

Model 77X101: Dyna-Star Pump, 90#, Dip Stick, Reservoir, Cover, Vent Valve

Ref.

No. Part No. Description Qty

1

1

1

1

1

1

2

8

8

1

1

1

1

4

1

4

1

1

1

1

1

1

1

1 77X011 KIT, pump and vent valve,

includes 1a and 1b, Dyna-Star

60#, models 77X100, see instruction manual 332514

77X012 KIT, pump and vent valve,

includes 1a and 1b, Dyna-Star

90#, models 77X101, see instruc-

1a PUMP

1b VENT VALVE, see instruction

tion manual 332514

manual 332519

3 77X535 KIT, reservoir, 60# grease,

includes 3a-3n,

models 77X100

77X536 KIT, reservoir, 90# grease,

includes 3a-3n

models 77X101

3a . PLUG, pipe

3c . NUT, flanged, hex

3d . SCREW, cap, flange head

3e . BREATHER

3f 194868 . GASKET, cover

3g . PAIL, reservoir, 60#, included in

kit 77X535

. PAIL, reservoir, 90#, included in

kit 77X536

3h 16V394 . COVER, reservoir

3j 109114 . SCREW, cap

3k 15M442 . GASKET, pump

3l 104572 . WASHER, lock, spring

3m 16V396 . SEAL

3n 16V395 . COVER

4 77X531 KIT, dip stick, 60#, grease, see

instruction manual 332515

77X530 KIT, dip stick, 90#, grease, see

instruction manual 332515

8

9

10

195341 LABEL, notice, breather

16U728 LABEL, over pressurize warning

15H108 LABEL, pinch warning

Replacement Danger and Warning labels, tags and

cards are available at no cost.

10 332540E

Page 11

1a

1b

5a

3e

3h

5b

5e

3a

3g

3j

3a

3d

5f

3l

5c

5d

3f

3i

3c

3k

8

9

10

9

Parts List

Model 77X102: Dyna-Star Pump, 60#, Auto-Fill Shut Off, Reservoir, Cover, Vent Valve

Model 77X103: Dyna-Star Pump, 90#, Auto-Fill Shut Off, Reservoir, Cover, Vent Valve

Ref.

No. Part No. Description Qty

1 77X011 KIT, pump and vent valve, includes 1a

and 1b, Dyna-Star 60#, models

77X100, see instruction manual

77X012 KIT, pump and vent valve, includes 1a

1a PUMP

1b VENT VALVE, see instruction manual

3 77X535 KIT, reservoir, 60# grease, includes

77X536 KIT, reservoir, 90# grease, includes

3a . PLUG, pipe

3c . NUT, flanged, hex

3d . SCREW, cap, flange head

3e . BREATHER

3f 194868 . GASKET, cover

3g . PAIL, reservoir, 60#, included in kit

3h 16V394 . COVER, reservoir

3i 104663 . PLUG, pipe

3j 109114 . SCREW, cap

3k 15M442 . GASKET, pump

3l 104572 . WASHER, lock, spring

5 77X521 VALVE, auto-fill shut off, see instruc-

5a VALVE, auto shut off 1

5b DIAPHRAGM, assembly 1

5c TUBE, vent valve 1

5d FITTING, connector, 3/8 in. npt* x JIC 2

5e BOLT, M8 x 1.25 x 2 mm 2

5f SEAL, auto shutoff valve 1

8 195341 LABEL, notice, breather

9 16U728 LABEL, over pressurize warning

10 16U727 LABEL, pinch warning

332514

and 1b, Dyna-Star 90#, models

77X101, see instruction manual

332514

332519

3a-3l,

models 77X100

3a-3l,

models 77X101

77X535

. PAIL, reservoir, 90#, included in kit

77X536

tion manual 332518

Replacement Danger and Warning labels, tags and

cards are available at no cost.

1

1

1

1

1

1

2

6

6

1

1

1

1

1

1

4

1

4

1

1

1

1

Parts List

332540E 11

Page 12

Parts List

1a

1b

3e

3d

3h

3f

3k

3c

3a

3g

3j

3a

3d

3n

3l

3m

3c

6

7

10

9

8

Parts List

Ref.

No. Part No. Description Qty

1 77X011 KIT, pump and vent valve, includes 1a

and 1b, Dyna-Star 60#, models

77X100, see instruction manual

332514

77X012 KIT, pump and vent valve, includes 1a

and 1b, Dyna-Star 90#, models

77X101, see instruction manual

332514

1a PUMP

1b VENT VALVE, see instruction manual

332519

3 77X535 KIT, reservoir, 60# grease, includes

77X536 KIT, reservoir, 90# grease, includes

3a 100737 . PLUG, pipe

3c . NUT, flanged, hex

3d . SCREW, cap, flange head

3e . BREATHER

3f 194868 . GASKET, cover

3g . PAIL, reservoir, 60#, included in kit

3h 16V394 . COVER, reservoir

3j 109114 . SCREW, cap

3k 15M442 . GASKET, pump

3l 104572 . WASHER, lock, spring

3m 16V396 . SEAL

3n 16V395 . COVER

6 77X522 KIT, low level, see instruction manual

7 77X500 KIT, plate, follower 60# / 90#

8

9

10

195341 LABEL, notice, breather

16U728 LABEL, over pressurize warning

15H108 LABEL, pinch warning

3a-3n, models 77X100

3a-3n, models 77X101

77X535

. PAIL, reservoir, 90#, included in kit

77X536

332515

Replacement Danger and Warning labels, tags and

cards are available at no cost.

Cable Harness Kits (all models)

1

1

1

1

1

1

2

8

8

1

1

1

1

1

4

1

4

1

1

1

1

1

1

1

Part No. Description

77X527 KIT, cable, power series progressive system only.

77X528 KIT, cable, power extension, 15 ft (4.6 m). Used with

77X529 KIT, cable, power injector system only. For use with

24N402 KIT, cable, 6 ft (1.8 m), vent valve, 2 pin. For use

12 332540E

Used with 77X528

77X527 and 77X529

77X528

with vent valve control.

Page 13

Technical Data

Technical Data

Maximum working pressure 3500 psi (24.1 MPa, 241 bar

Pump wetted parts See Dyna-Star HP and HF Pump manual: 332514

Vent valve wetted parts See Dyna-Star HP and HF Vent Valve Kit manual: 332519

Reservoir wetted parts steel, buna-n rubber

Reservoir overflow port size 1/2 inch npt

Reservoir fill port size 1/2 inch npt

Lubricant outlet port size 3/8 npt (f)

Grease capacity

Model 77X101, 77X103, 77X105 90 lb. (41 kg)

Model 77X100, 77X102, 77X104 60 lb. (27 kg)

Sound Data: All pumps See Dyna-Star HP and HF Pump manual: 332514

332540E 13

Page 14

Dimensions

A

B

C

D

E

F

G

Dimensions

60 lb Models 90 lb Models

Ref

A 30.5 77.47 38.0 96.52

B 14.5 36.83 14.5 36.83

C 1/2 inch npt 1/2 inch npt

D 1/2 inch-14 npt 1/2 inch-14 npt

E 14.5 36.83 14.5 36.83

F 19.4 49.28 27.0 36.83

G

14 332540E

US (inch) Metric (cm) US (inch) Metric (cm)

7/16 inch

Ø hole - 6; 13-7/8 inch bolt circle

Page 15

Notes

Notes

332540E 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

To place an order, contact your Graco distributor or to identify the nearest distributor call,

Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 332540

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

June 2014

Loading...

Loading...