Page 1

Instructions

Dyna-Star® HP and HF Pump

332518C

Auto-Fill® Shut Off Kit

Used with Dyna-Star HP or HF Pump to fill Graco Tank/Reservoir. For automatic grease

lubrication systems only. Cannot be used with pumps equipped with a dip stick, low level

indicator or follower plate. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and the Dyna-Star HP and HF Pump instruction manual. Save all instructions.

5000 psi (34.47 MPa, 344 bar) Maximum Lubricant Inlet Pressure

3/8 inch npt inlet and outlet

Maximum Flow: 2 gpm (7.57 lpm)

EN

Model: 77X521

Page 2

Warnings

WARNINGWARNINGWARNING

WARNING

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispensing device at anyone or at any part of the body.

+

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturers.

2 332518C

Page 3

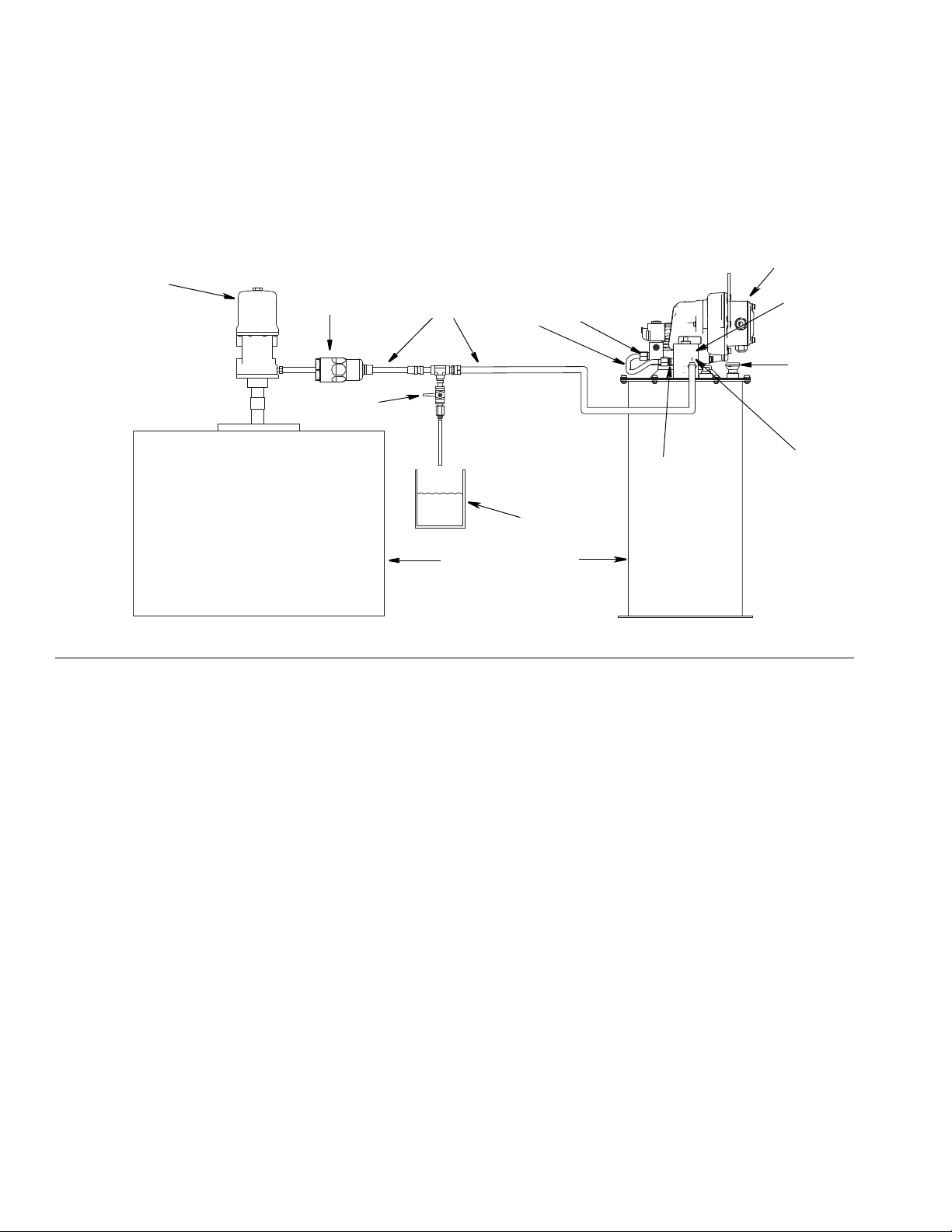

Auto-Fill Shut Off Overview

Auto-Fill Shut Off

Overview

Reference letters used in the following instructions refer

to Parts Table and Drawing shown on the cover of this

manual.

The Auto-Fill Shut Off is used for refilling the grease

tank/reservoir in an automatic lubrication system. As

grease is added to the reservoir, it pushes the diaphragm up to the top of the reservoir. The diaphragm

then pushes the valve pin and closes the inlet fluid path.

Pressure Relief

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

To relieve pressure in the system, use two wrenches

working in opposite directions on pump outlet fitting to

slowly loosen fitting only until fitting is loose and no

more lubricant or air is leaking from fitting. See F

IG. 1.

FIG. 1

332518C 3

Page 4

Installation

1

C

3 / 4

B

F

G

H

K

J

D

E

L

A

M

Installation

Typical Installation

FIG. 2

A Dyna-Star Pump

B Breather

C Auto-Fill Inlet

D Auto-Fill Outlet

E Pump Manifold / Vent Valve Inlet

F Reservoir

G Pressure Relief Valve (Required, user supplied)

H Fluid Overflow Container

J Remote Filling Station Reservoir

K Remote Filling Station Pump (pneumatic)

L Lubricant Supply Hose (Required, user supplied)

M Filter (recommended if grease/environment is

contaminated)

1 Auto-Fill Shut Off

3 Tube (vent valve)

4 Tube (manifold)

4 332518C

Page 5

Installation

b

a

A

c

d

A

e

g

e

F

j

gg

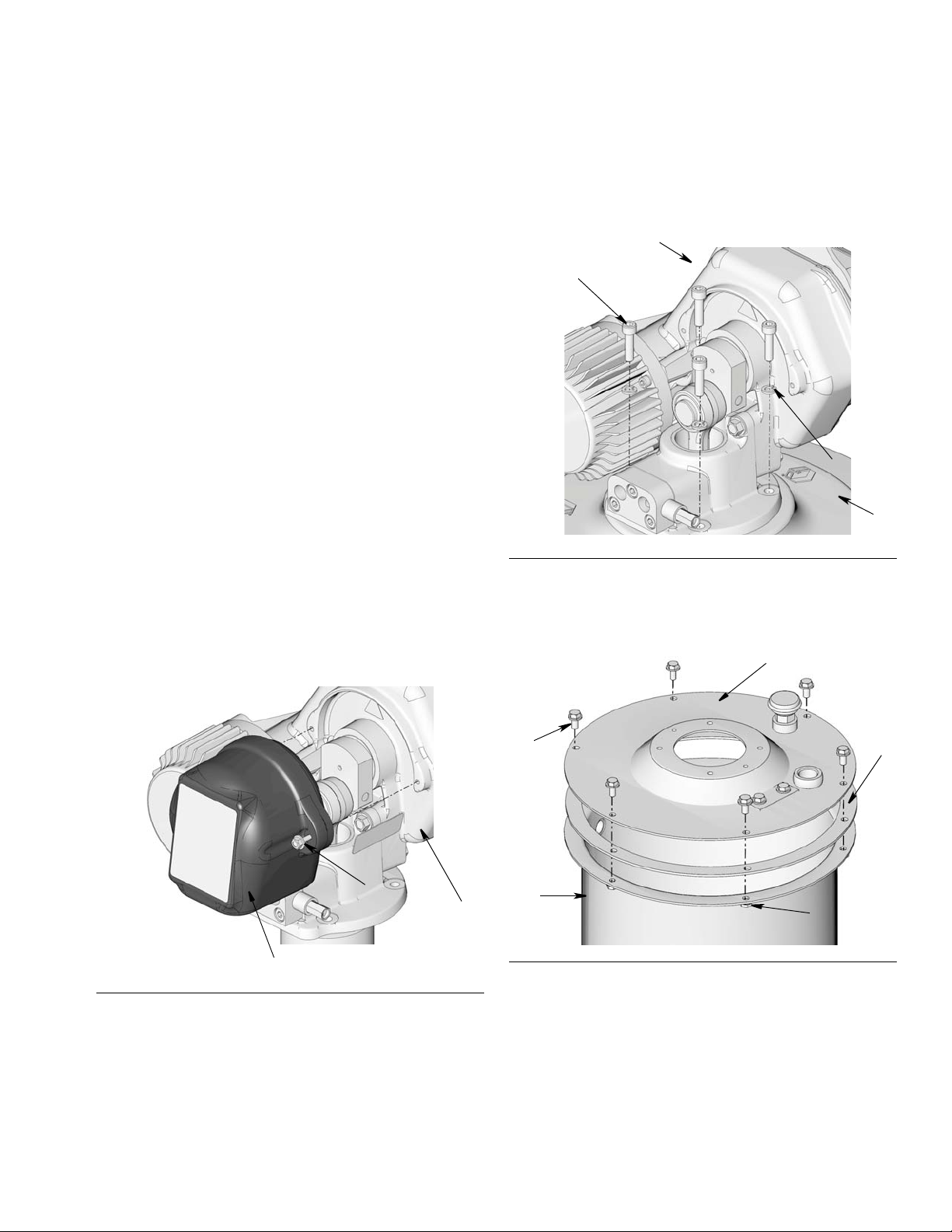

Disassembly

NOTE:

• Reference numbers used in the following instructions refer to Kit Parts provided on the cover of this

manual.

• Upper case letters used in the following instructions

refer to Typical Installation provided on page 4.

• Lower case letters used in the following instructions

refer to component parts or user provided parts not

included in the Kit.

• Steps 1 - 2 only apply to pumps that have already

been in service and are adding an Auto-Fill Shut Off

Valve. For new installations, begin instructions with

Step 3.

1. Disconnect Dyna-Star pump (A) from main power

source.

2. Relieve pressure (see Pressure Relief procedure,

page 3).

3. Loosen bolts (a) and remove cover (b) from

Dyna-Star pump (A) (F

use for installation.

IG. 3). Save these parts to

4. Remove screws (c) and washers (d) holding

Dyna-Star Pump (A) to cover (e) and remove pump

from cover (F

IG. 4). Save these parts to use for

installation.

FIG. 4

5. Remove the bolts (g) and nuts (gg) (holding the

cover (e) to the reservoir (F) (F

IG. 5). Save these

parts to use for installation.

FIG. 3

FIG. 5

6. Remove cover (e) and gasket (j) (F

IG. 5). Save these

parts to use for installation.

7. (If previously installed) remove follower plate

and / or low level indicator or dipstick. Discard these

parts according to applicable guidelines.

332518C 5

Page 6

Installation

2

j

F

e

l

k

m

kk

1

6

n

e

7

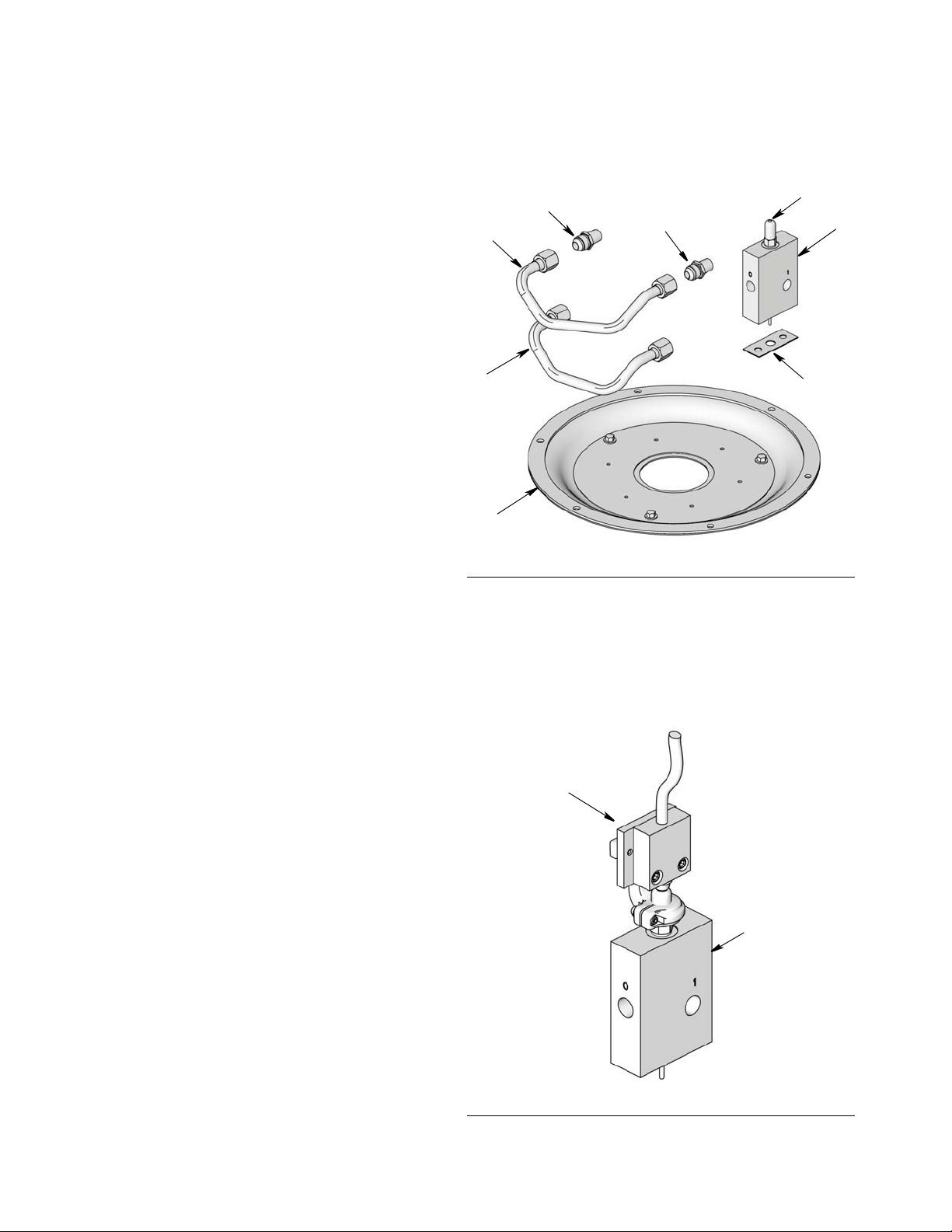

Reassembly

NOTE:

• Reference numbers used in the following instructions refer to Kit Parts provided on the cover of this

manual.

• Upper case letters used in the following instructions

refer to Typical Installation provided on page 4.

• Lower case letters used in the following instructions

refer to component parts or user provided parts not

included in the Kit.

1. Align diaphragm (2) on reservoir (F) (F

ing holes around the rim of diaphragm with the

holes in the top of the reservoir. Refer to F

determine the correct orientation of the diaphragm.

NOTE: The diaphragm (2) has six valves (not pictured). When the diaphragm is correctly installed,

valves will face downward.

IG. 6), match-

IG. 6 to

3. Remove screws (k) and nuts (kk) from accessory

cover plate (l) [installed on the pump reservoir cover

(e)] (F

IG. 7). Remove plate and gasket (m). Discard

screws, nuts, plate and gasket, you will not use

them again.

FIG. 7

4. Align gasket (7) with holes (n) in cover (e) (F

IG. 8).

FIG. 6

2. Install gasket (j) removed in step 6, page 5 over the

diaphragm (2) (F

with the holes in rim of diaphragm.

IG. 6), matching holes in gasket

5. Install Auto-Fill Shut Off Valve (1) over gasket (7).

Install bolts (6) through holes (n). Tighten bolts

securely. See F

IG. 8.

FIG. 8

6 332518C

Page 7

Installation

e

g

j

F

gg

2

1

A

p

Fill

Tu be

Pump

Tu be

B

r

6. Install cover (e) over gasket (j) on reservoir (F) (FIG.

9).

FIG. 9

7. Securely fasten cover (e) in place on top of reservoir

(F) using bolts (g) and nuts (gg) removed in Step 5,

page 5.

• Fill tube (outer): directs grease to the bottom of

the pump during the fill operation. As grease is

filled into the reservoir, the diaphragm moves

up. When the grease level in the reservoir has

reached full, the diaphragm pushes the valve

pin up, closing off fluid path, ending the fill operation.

• Pump tube (inside): when pump is operating,

grease is drawn out of the bottom of the pump

reservoir, through the pump tube and dispensed

to the lubrication points.

HINT: To ensure the cover is tightened correctly,

turn nuts (gg) until it is snug to reservoir. Then turn it

one more half turn.

NOTE: Do not over tighten cover (e) to reservoir (F).

Over tightening could crush the gasket (j) between the

cover and reservoir; pushing the gasket out of place and

breaking the seal.

8. Install pump down-tube (p) through opening in the

center of the cover (e) and hole in the center of the

diaphragm (2) as shown in F

IG. 10.

FIG. 11

NOTE: When the pump (A) is correctly installed, the

breather (B) will be below the control box (r) as shown in

F

IG. 12.

FIG. 12

FIG. 10

NOTE: The pump down tube has two parts (F

IG. 11):

332518C 7

Page 8

Installation

c

d

A

e

b

a

5

4

C

E

5

D

F

G

9. Securely fasten pump (A) to cover (e) using screws

(c) and washers (d). Use a wrench to tightened

securely.

FIG. 13

10. Reinstall cover (b) using bolts (a). Use a wrench to

tighten bolts securely.

11. The Auto-Fill Shutoff Kit includes two supply

hoses/tubes (3 or 4 as shown on the cover.) Only

one hose/tube is used. Discard the hose/tube you

do not use.

• Supply tube (4) (marked with the 16V750 alumi-

num tag) and two connector fittings (5) are used

for manifold assemblies. Supply tube (3) can be

discarded. It is not used for a manifold installation.

a. Install connector fittings (5) to manifold inlet

(E) and Auto-Fill Shut Off outlet (D). Wrench

tighten each fitting (5) securely.

b. Install end of supply tube (4) to manifold inlet

(E) first and then install the other end of the

supply tube to the Auto-Fill Shut Off outlet (D)

and as shown in F

IG. 15.

HINT: For easier installation, loosen (but do not entirely

remove) screws (G) securing manifold (F) to pump. This

will allow the manifold to remain in a loosely mounted

state while installing the supply tube (4). After tube has

been installed securely, re-tighten manifold screws (G)

to secure manifold (F) to pump.

FIG. 14

FIG. 15

8 332518C

Page 9

Installation

3

C

E

5

D

5

F

G

G

1

• Supply tube (3) (marked with the 16X381 aluminum tag) and two connector fittings (5), are

used for vent valve assemblies. Supply tube (4)

can be discarded. It is not used for a vent valve

installation.

a. Install connector fitting (5) to Auto-Fill Shut

Off outlet (D) and Vent Valve inlet (E).

b. Install end of supply tube (3) to Vent Valve

inlet (E) first. Then install the other end of the

supply tube to the Auto-Fill Shut Off outlet (D)

as shown in F

IG. 16.

HINT: For easier installation, loosen (but do not entirely

remove) screws (G) securing vent valve (F) to pump.

This will allow the vent valve to remain in a loosely

mounted state while installing the supply tube (3). After

tube has been installed securely, re-tighten vent valve

screws (G) to secure vent valve (F) to pump.

sible location between the remote filling station

pump (K) and the Auto-Fill Shut Off (1). This pressure relief valve is used to relieve pressure in the

refill line and to reset the Auto-Fill Shut Off. See Typical Installation, page 4.

NOTE:

• Operator must monitor system while filling tank

to prevent accidental fluid overflow.

• A Pressure Relief Kit: 247902 is available from

Graco. Contact your distributor or Graco Customer Service for additional information about

this kit.

• In some setups the pressure relief valve (G) can

be installed directly to the Auto-Fill Shut Off (1)

as shown in F

IG. 17.

FIG. 17

FIG. 16

12. Install a (user supplied) lubricant supply hose (L)

between Auto-Fill Shut Off inlet (C) (F

IG. 15 or FIG.

16) and the remote filling station pump (K).

COMPONENT RUPTURE HAZARD

The maximum working pressure of each component

in the system may not be the same. To reduce the

risk of overpressurizing any component in the

system, be sure you know the maximum working

pressure of each component. Never exceed the

maximum working pressure of the lowest rated

component in the system. Overpressurizing any

component can result in rupture and/or property

damage and serious injury.

13. A pressure relief valve (G) and overflow container

(H) (for collecting excess fluid that drains during

pressure relief) must be installed in an easily acces-

332518C 9

Regulate pressure to the pump so that no fluid line,

component or accessory is over pressurized.

Page 10

Installation

pin

up

1

bv

G

dt

H

pin

drops

14. Turn on remote filling station pump (K) and fill reservoir (F) until the indicator pin on the Auto-Fill Valve

(1) pushes up as shown in F

IG. 18; pressure in the

refill pump (K) builds and the pump stalls.

FIG. 18

15. Turn off air supply to refill pump (K).

16. Relieve remote filling station pump pressure using

the following Remote Filling Station Pressure Relief

procedure:

Remote Filling Station Pressure Relief

The following Pressure Relief Procedure is only

used with the Auto-Fill Shut Off Valve to relieve

remote filling station and lubricant supply line

pressure.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

a. To relieve pressure between the refill pump and

Auto-Fill Shut Off, open ball valve (bv) (F

IG. 19).

Pressure will be released and excess fluid will

drain out of the drain tube (dt) and into the lubrication collection container (H).

FIG. 19: In line installation shown

b. Close ball valve (bv) when all pressure has

been relieved.

NOTE: The pin may not drop and the Auto-Fill

may not reset because the tank is full. However,

when the pump begins using the grease, the pin

resets. The pin must reset before the next cycle

of refilling.

FIG. 20

17. Disconnect lubrication supply hose (L) from Auto-Fill

(1).

18. Install plug in Auto-Fill inlet or supply hose (L) inlet

to prevent contaminants from entering the pump.

10 332518C

Page 11

Troubleshooting

Problem Cause Solution

Refilling pump, stalls. Pressurized

tank is not refilling.

Auto-Fill Shut Off Valve is in closed

condition and has not reset

Installation

1. Disconnect refilling line.

2. Relieve all line pressure using

the Remote Filling Station Pressure Relief procedure provided

on page 10.

Make sure valve pin is down. See

Remote Filling Station Pressure

Relief procedure, Step b, page 10.

332518C 11

Page 12

Parts

4

3

2

5

5

1

8

7

9

1

Parts

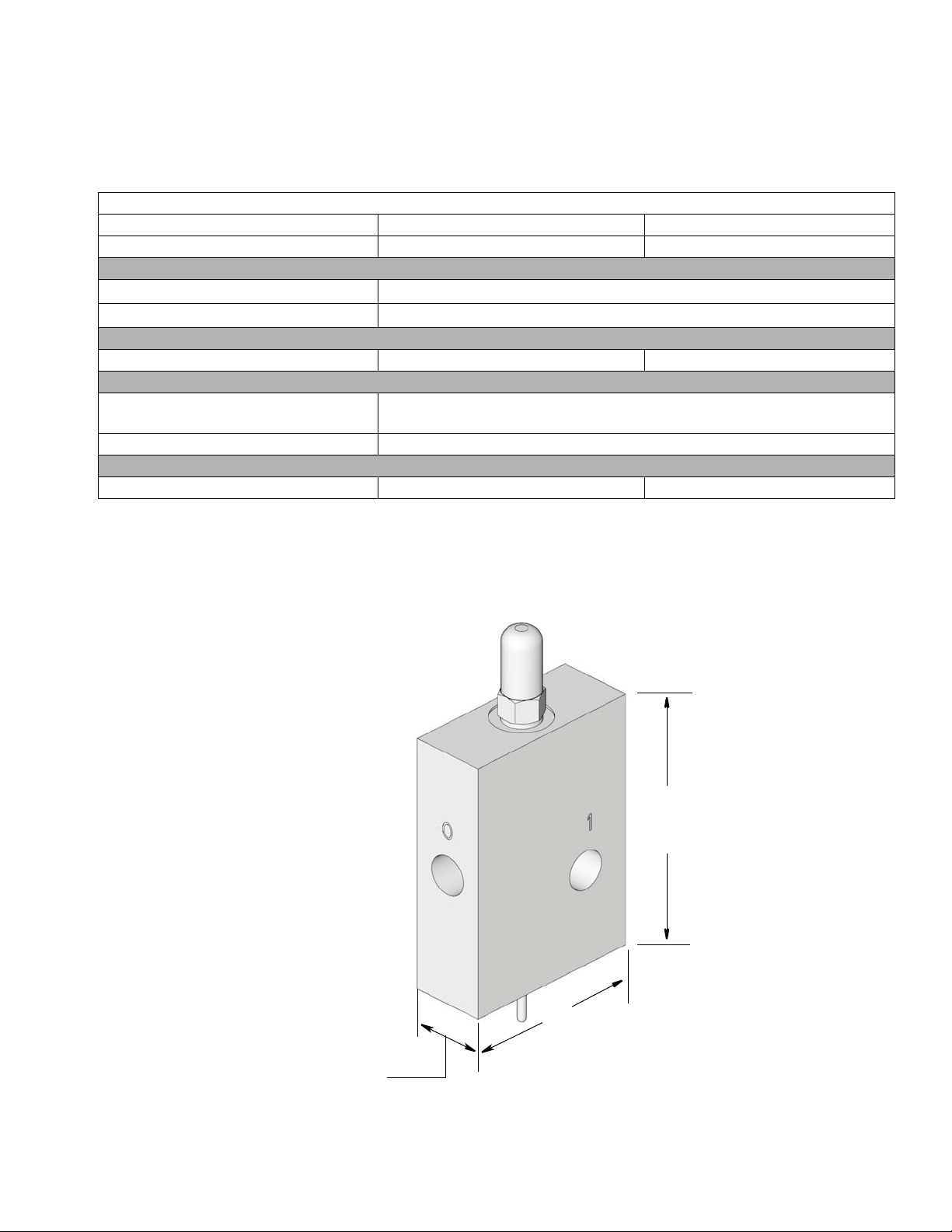

Model 77X521 (FIG. 21)

Ref Part No. Description Qty

1 16V582 VALVE, auto shut off 1

2 16V748 DIAPHRAGM, assembly 1

3 16X381 TUBE, vent valve 1

4 16V750 TUBE, manifold 1

5 121311 FITTING, connector, 3/8 in. npt*

x JIC

6 16X389 BOLT, M8 x 1.25 x 2 mm (not

shown)

7 16V396 SEAL, auto shutoff valve 1

8 404157 CAP 1

*Prior to installation, apply thread sealant or PTFE Tape

to all npt tapered pipe threads.

2

2

Accessories

Remote Electric Signaling (FIG. 22)

Remote electric signaling can be added to the Auto-Fill

Shut Off. Contact your Graco distributor or Graco Customer service for assistance when ordering these parts.

Ref Part No. Description

563272 SWITCH, cycle

9

563273 SWITCH, submersible

Filter Assembly (see M, page 4)

Part No. Description

77X523 FILTER

Pressure Relief Assembly (see G, page 4)

FIG. 21

Part No. Description

247902 PRESSURE RELIEF

12 332518C

FIG. 22

Page 13

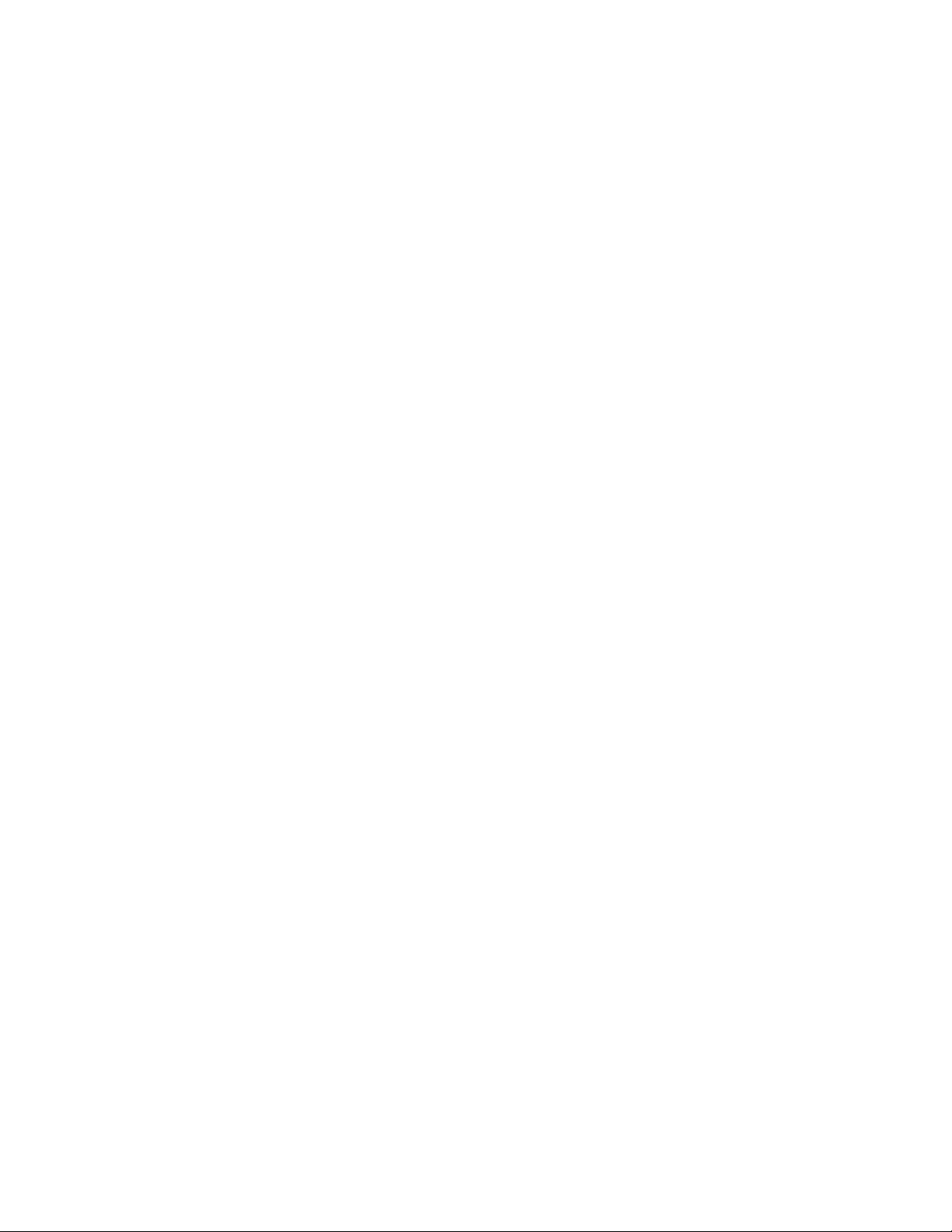

Technical Data

1.13 in.

2.75 in.

5.0 in.

12.7 cm

6.9 cm

2.8 cm

Technical Data

.

Auto-Fill Shutoff Valve for Dyna-Star HP or HF Pump

US Metric

Maximum working pressure 5000 psi 34.4 MPa, 344 bar

Inlet/Outlet Sizes

Outlet (marked “0”)

Inlet (refill - marked “1”)

Maximum flow 2 gpm 7.6 lpm

Wetted Parts

Valve neoprene rubber, zinc plated parts, stainless steel, chrome plated parts,

plastic acetal

Seal fluorocarbon

Temperature

Working temperature -13° F to +122°F -25°C to +50°C

3/8 in. npt(f)

3/8 in. npt(f)

Dimensions

332518C 13

Page 14

Graco Information

To place an order, contact your Graco distributor or to identify the nearest distributor call,

Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 332518

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

February 2014

Loading...

Loading...