Page 1

Instructions

Part No. 77X522

Part No. 77X530 or 77X531

Dyna-Star® HP or HF Pump

Low Level Indicator Kit; Dip

332515E

Stick Kit

Provides a visual reference of remaining fluid level in a tank / reservoir used with the

Dyna-Star HP or HF pump. Low Level Indicators equipped with a user supplied alarm will

also provide an audible and/or visual notification of a low fluid level. For professional use

only.

Low Level Indicator Part No: 77X522

Includes sight glass, electric low level switch and cable. Requires follower plate. Cannot be used with Auto-Fill® Shut Off.

Dip Stick Part No: 77X530 - 90#; 77X531 - 60#

Cannot be used with a follower plate or Auto-Fill Shut Off.

Important Safety Instructions

Read all warnings and instructions in this

manual and in the Dyna-Star HP or HF Pump

instruction manual. Save all instructions.

EN

Page 2

Installation

a

b

Installation

Warnings

See the Dyna-Star HP and HF Pump Instruction manual

for additional warnings.

SKIN INJECTION HAZARD

High-pressure fluid from dispense device, hose leaks,

or ruptured components will pierce skin. This may look

like just a cut, but it is a serious injury that can result in

amputation. Get immediate surgical treatment.

Follow Pressure Relief Procedure in this manual,

when you stop dispensing and before cleaning, checking, or servicing equipment.

Pressure Relief

Follow the Pressure Relief Procedure whenever

you see this symbol.

Installing Low Level Indicator

1. Disconnect Dyna-Star pump from main power

source.

2. If unit has already been in service, relieve pressure

(see Pressure Relief procedure, page 2).

3. Fill reservoir with grease to raise follower plate (if

installed) to an easily accessible level.

NOTE:

• Installing the follower plate and low level will be

easier if the reservoir has been filled with

grease first.

• If a follower plate is not pre-installed, fill tank at

least half full.

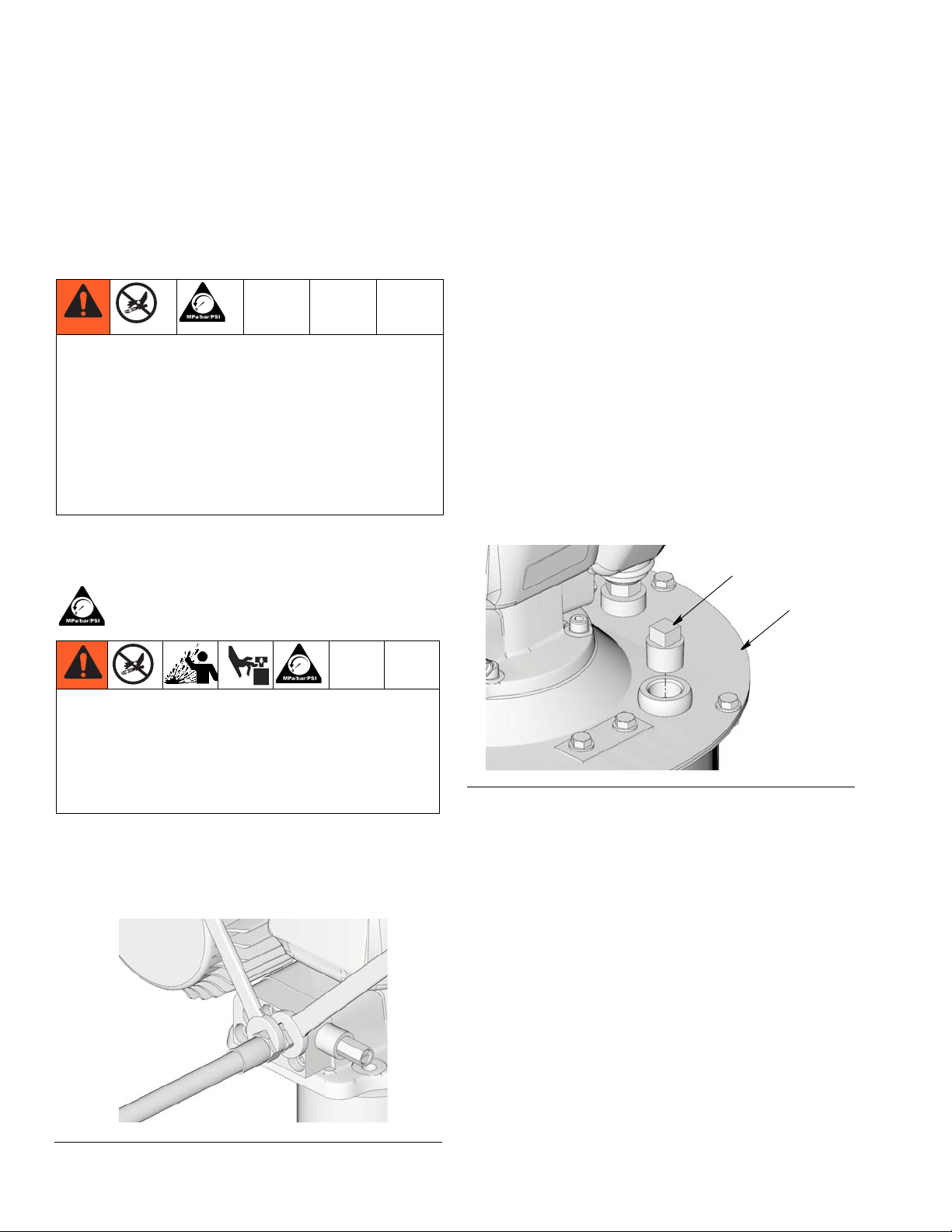

4. Remove plug (a) from cover (b). Discard plug, you

will not reuse it (F

IG. 2).

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection, splashing

fluid and moving parts, follow the Pressure Relief

Procedure when you stop dispensing and before

cleaning, checking, or servicing the equipment.

To relieve pressure in the system, use two wrenches

working in opposite directions on pump outlet fitting to

slowly loosen fitting only until fitting is loose and no

more lubricant or air is leaking from fitting. See F

FIG. 1

IG. 1.

FIG. 2

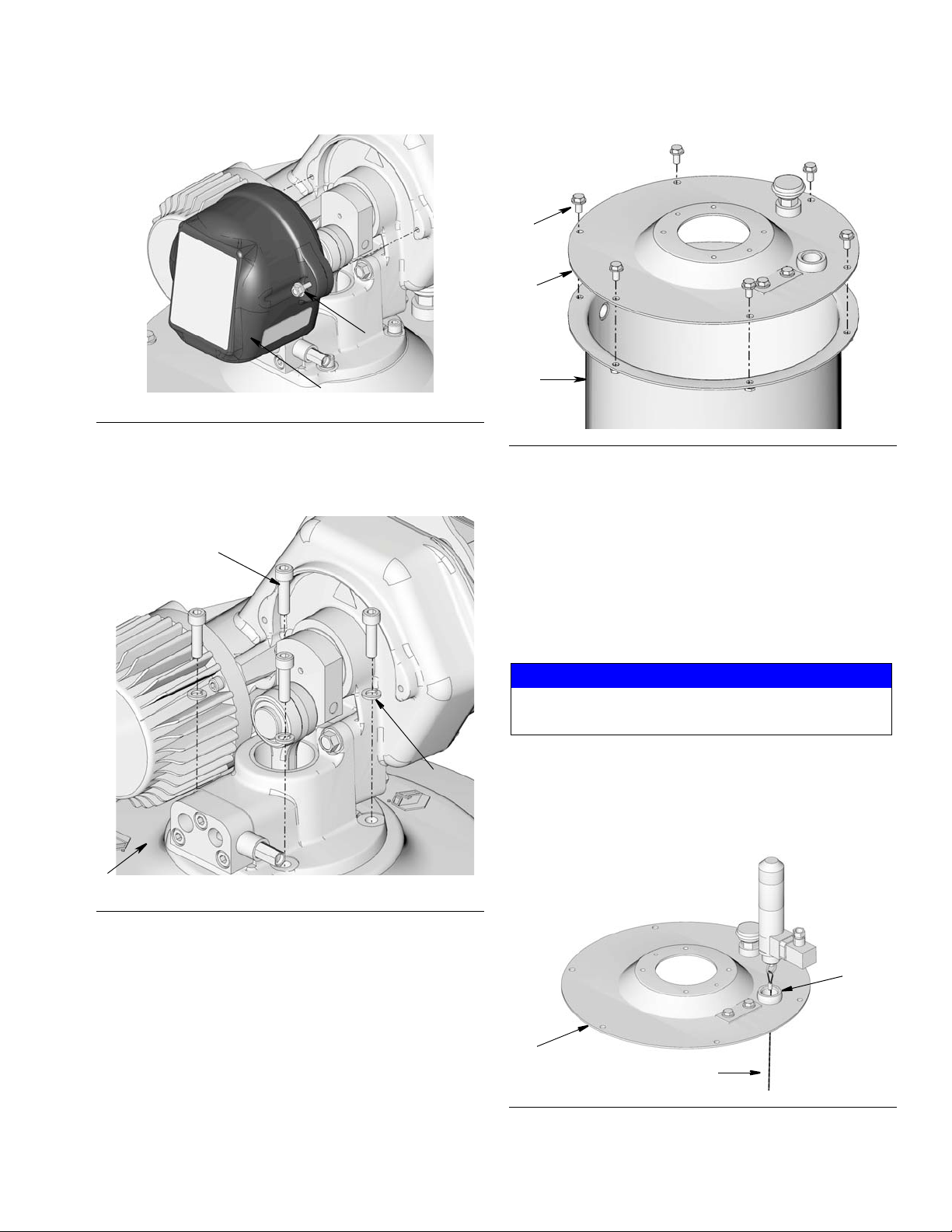

5. Loosen bolts (c) and remove cover (d) from

Dyna-Star pump (F

IG. 3).

2 332515E

Page 3

FIG. 3

d

c

e

f

b

g

b

h

j

aa

b

6. Remove screws (e) and washers (f) holding

Dyna-Star Pump to reservoir cover (b) and remove

pump from cover (F

IG. 4).

Installation

FIG. 5

8. (If previously installed) remove follower plate from

inside reservoir.

FIG. 4

7. Remove the screws (g) (holding the reservoir cover

(b) to the reservoir (h) (F

IG. 5).

9. Determine the correct cable length to use for your

pump reservoir.

• Short cable is used with 60# reservoirs.

• Long cable is used with 90# reservoirs.

Remove and discard the cable you are not using and the

Notice label attached to the cables.

NOTICE

Failure to use the correct cable length could result in

inaccurate level indication and low level shutdown.

10. For easy wiring, make sure the DIN connector is

facing out (F

IG. 6). Feed the low level cable (j)

through accessory hole (aa) in the reservoir cover

(b). Wrench tighten low level in place.

FIG. 6

332515E 3

Page 4

Installation

k

j

p

n

r

m

m

h

b

j

g

11. Remove one of the screws (k) from the follower

plate (m) (F

IG. 7).

12. Install screw (k) through the hole (n) in the cable

bracket (p) located at the end of the low level cable

(j) and then through the screw hole (r) in the follower

plate (m) (F

IG. 7). Tighten screw securely.

NOTE: Cable bracket (p) is slightly bent. Be sure to

install so the bracket will sit flat against the surface

of the follower plate.

FIG. 8

F

IG. 7

13. Install follower plate (m) on top of grease inside reservoir (h) with the cone side facing up. Press follower plate firmly into grease to remove all air

pockets.

14. Place reservoir cover (b) on top of reservoir (h).

NOTE: When reservoir cover (b) is correctly

installed on reservoir (h), the low level cable (j)

(installed between the low level indicator and follower plate (m) will be aligned in a straight and vertical line as shown in F

IG. 8.

15. Replace and tighten screws (g) securely (F

FIG. 9

IG. 9).

4 332515E

Page 5

Installation

b

m

t

s

e

f

d

c

16. Slide pump down-tube through hole in the center of

the reservoir cover (b) and hole in the center of the

follower plate (m) as shown in F

IG. 10.

FIG. 10

NOTE: When pump is correctly installed, the breather (t)

will be below the control box (s) as shown in F

IG. 11.

17. Replace screws (e) and washers (f) and wrench

tighten securely (F

IG. 12).

FIG. 12

18. Reinstall cover (d) using bolts (c) (F

IG. 13). Use a

wrench to tighten bolts securely.

FIG. 11

FIG. 13

332515E 5

Page 6

Installation

External Alarm or Warning Light (Optional)

An external (user supplied) alarm or warning light can

be added to the Low Level Indicator to provide an audible or visual signal in a low level situation.

NOTICE

To avoid premature failure and the loss of fluid/low

level indication:

• Do not exceed the rating of the Low Level Sensor Switch by connecting excessive lights or

audible signals.

• Level Sensor Switch is rated for a maximum of

32 VDC and 10 Watts. Maximum switch current

is 0.4 AMPS.

1. Connect the DIN connector on the Low Level Indicator to the (user supplied) alarm device. Connection

is made to PINS 1 and 3 of the DIN, Form “A” Field

Wireable Adapter. See F

IG. 14.

FIG. 14

2. Connect Dyna-Star pump to main power source.

3. Start system following pump start up procedure

included in the Dyna-Star HP or HF Pump Manual

provided with your system.

6 332515E

Page 7

Low Level Visual Indication Sight Glass

sight

glass

Green (G)

sight

glass

Red (R)

Green (G)

sight

glass

Green (G)

Red (R)

Low Level Visual Indication Sight Glass

FIG. 15

Normal Level Mark (FIG. 15) - Red rod is completely

covered by the green tube (G) and no red is visible in

sight glass. This appearance indicates that the lubrication supply container has sufficient material. No additional lubricant needs to be added.

FIG. 17

Low Level Mark (F

visible with green tube (G) at lowest level. This appearance indicates that the main lubrication supply container

is low and needs to be refilled.

IG. 17) - Red rod (R) is completely

FIG. 16

Low Level Range (F

covered by the green tube (G). Some red is partially visible at the top of the sight glass. This appearance indicates that the lubrication supply container is

approaching the low level mark and needs to be refilled.

IG. 16) - Red rod (R) is partially

For models equipped with a (user provided) external

alarm, when the fluid has reached this low level mark,

the sensor switch closes, activating the alarm.

332515E 7

Page 8

Dip Stick Installation

a

aa

b

c

b

aa

1. Remove plug (a) from cover (b). Discard plug, you will not reuse it (FIG. 18).

FIG. 18

2. Slide dipstick through hole (aa) in cover (b) and into reservoir (F

IG. 18 and FIG. 19). Wrench tighten it in place.

FIG. 19

3. To determine the level of the fluid remaining in the reservoir, loosen and remove dip stick (c) from reservoir cover

(b).

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2013, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 332515

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised February 2014

Page 9

Dip Stick Installation

4. Use a clean rag to wipe oil/grease from end of dip

stick (c).

5. Insert dipstick (c) through hole (aa) in cover (b) as

far down as it will go and then remove it again. Visually inspect level of oil/grease remaining on dip stick.

332515E 9

Page 10

Low Level Indicator Technical Data

Low Level Indicator Technical Data

Low level sensor switch Normally open sensor switch, closes upon low level

Operating temperature range -50°F to 150°F (-45°C - 65°C)

Electrical Ratings

Switching Power 10 Watt Max.

Switching Current 0.4A-Max.

Switching Voltage 5 - 32 VDC

Contact Resistance 0.150 Initial Ohms - Max.

Body Thread 3/4 inch npt(m)

Wetted Parts

Cable Nylon coated stainless steel

Crimp Tab Stainless steel

Dip Stick Technical Data

Body Thread 3/4 inch npt(m)

Wetted Parts Zinc plated steel

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

10 332515E

Loading...

Loading...