Page 1

Installation

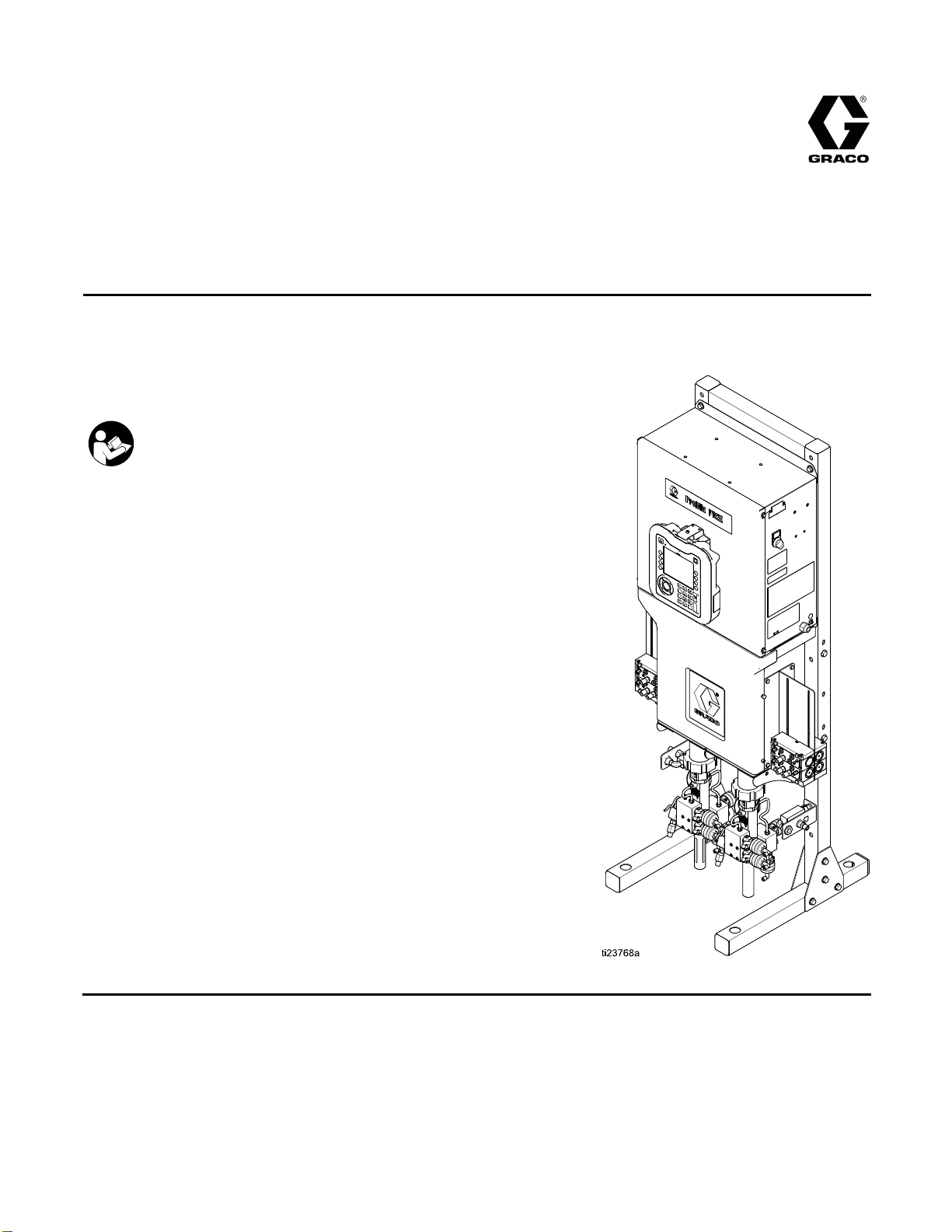

ProMix® PD2K Pr

Automatic Spr

Electronic positive displacement proportioner for fast-setting two-component materials. Automatic

system with Advanced Display Module. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in your

operation, repair, and associated component manuals.

Save these instructions.

See page 3

approvals information.

for model part numbers and

ay Applications

oportioner for

332458B

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Related Manuals ................................................ 2

Models............................................................... 3

Warnings ........................................................... 5

Important Isocyanate (ISO) Information................ 8

System Control Drawing 16P577 ......................... 9

Configure Yo

1. Select a B

2. Select Ho

3. Select a

4. Select N

5. Select I

6. Select P

General Information............................................ 18

Location............................................................. 18

Install t

Air Supply .......................................................... 20

ur System....................................... 11

ase Model ................................ 11

ses ........................................... 13

Spray Gun.................................. 14

on- IS Color and Catalyst

Change Kit

S Remote Color Change

Kits................................................ 16

ump Expansion Kits..................... 17

he Display Module.................................... 19

s ................................... 15

Fluid Supply ....................................................... 21

Fluid Requirements...................................... 21

Single Color Connections ............................. 22

Color Change Connections........................... 22

TSL Cup Kit........................................................ 23

Solvent Mete

Light Tower Accessory........................................ 24

Electrical Supply................................................. 25

Electrical Requirements................................ 25

Electrical Connections.................................. 25

Grounding

Electrical Schematics.......................................... 29

Optional Cables and Modules.............................. 35

Dimensio

Technical Data ...................................................37

Graco Standard Warranty.................................... 38

r Accessory..................................... 24

.......................................................... 26

ns ........................................................ 36

Related Manuals

Current manuals are available at www.graco.com.

Manual No. Description

332709 PD2K Proportioner Repair-Parts

Manual, Automatic Systems

64

3325

332339 Pump Repair-Parts Manual

PD2K Proportioner Operation

Manual, Automatic Systems

Manua

332454

3332

332456 3rd and 4th Pump Kits

lNo.

82

iption

Descr

Color Change Valve Repair-Parts

Manual

Color Change Kits InstructionsParts Manual

Instructions-Parts Manual

2

332458B

Page 3

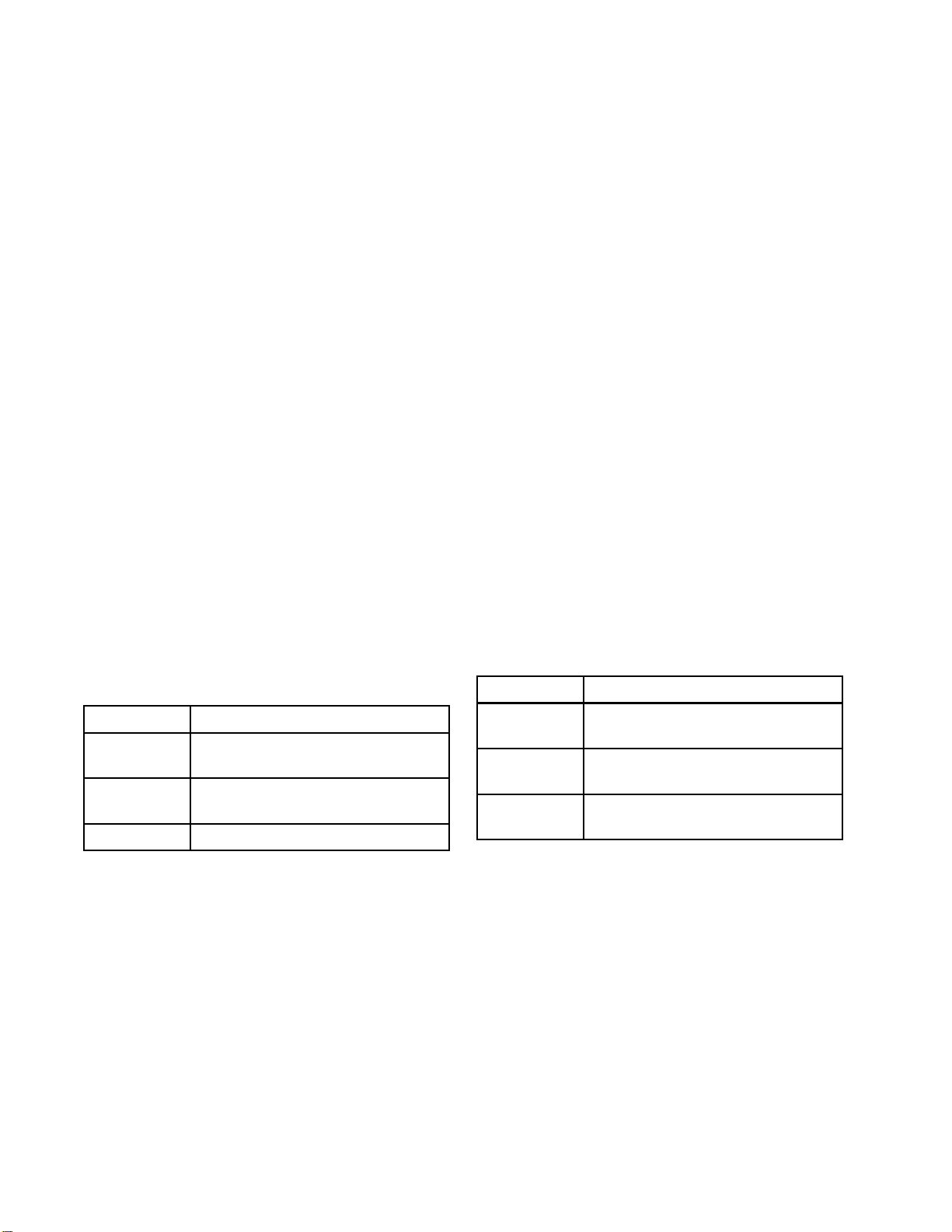

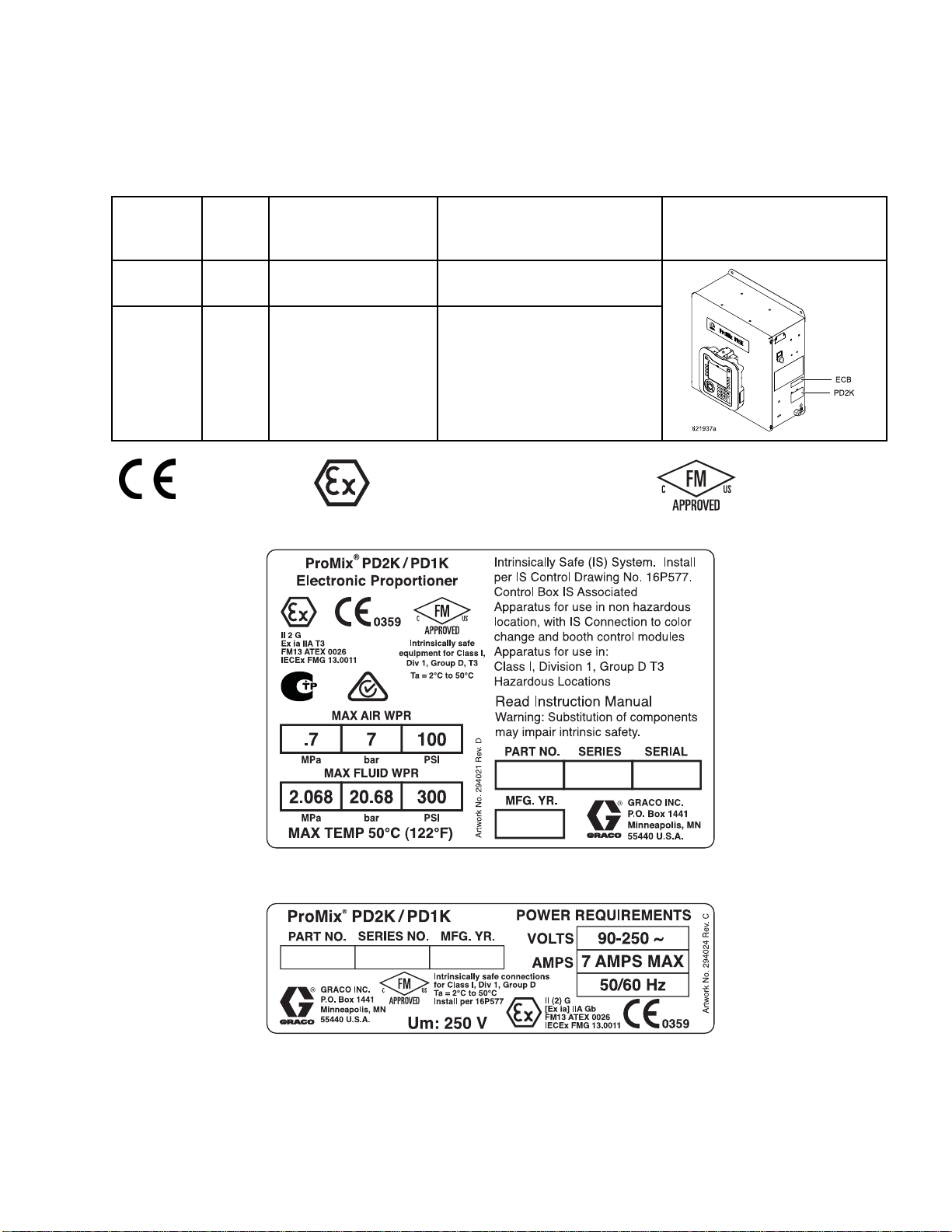

Models

Models

SeeFigs.1–7f

Part No.

AC1000

AC2000

0359

or component identification labels, including approval information and certification.

Series

A

A

Maximum Air Wo

Pressure

100 psi (0.7

7.0 bar)

100 psi (0.7 MPa,

7.0 bar)

MPa,

II 2 G

rking

Maximum Fluid

Pressure

300 psi (2.0

1500 psi (10.34 MPa,

68 MPa, 20.68 bar)

103.4 bar)

Working

Location of PD2K and

Electrical Control Box

(ECB) Labels

Figure 1 Model AC1000 (Low Pressure) Identification

Label

Figure 2 24M672 Control Box Identification Label

Continued on the next page.

332458B 3

Page 4

Models

Figure 3 Model AC2000 (High Pressure)

Identification Label

Figure 4 Non-Intrinsically Safe Color Change Control (Accessory) Identification Label

Figure 5 Intrinsically Safe Color Change Control

(Accessory) Identification Label

Figure 6 Pump Expansion Kit (Accessory) Identification Label

4

332458B

Page 5

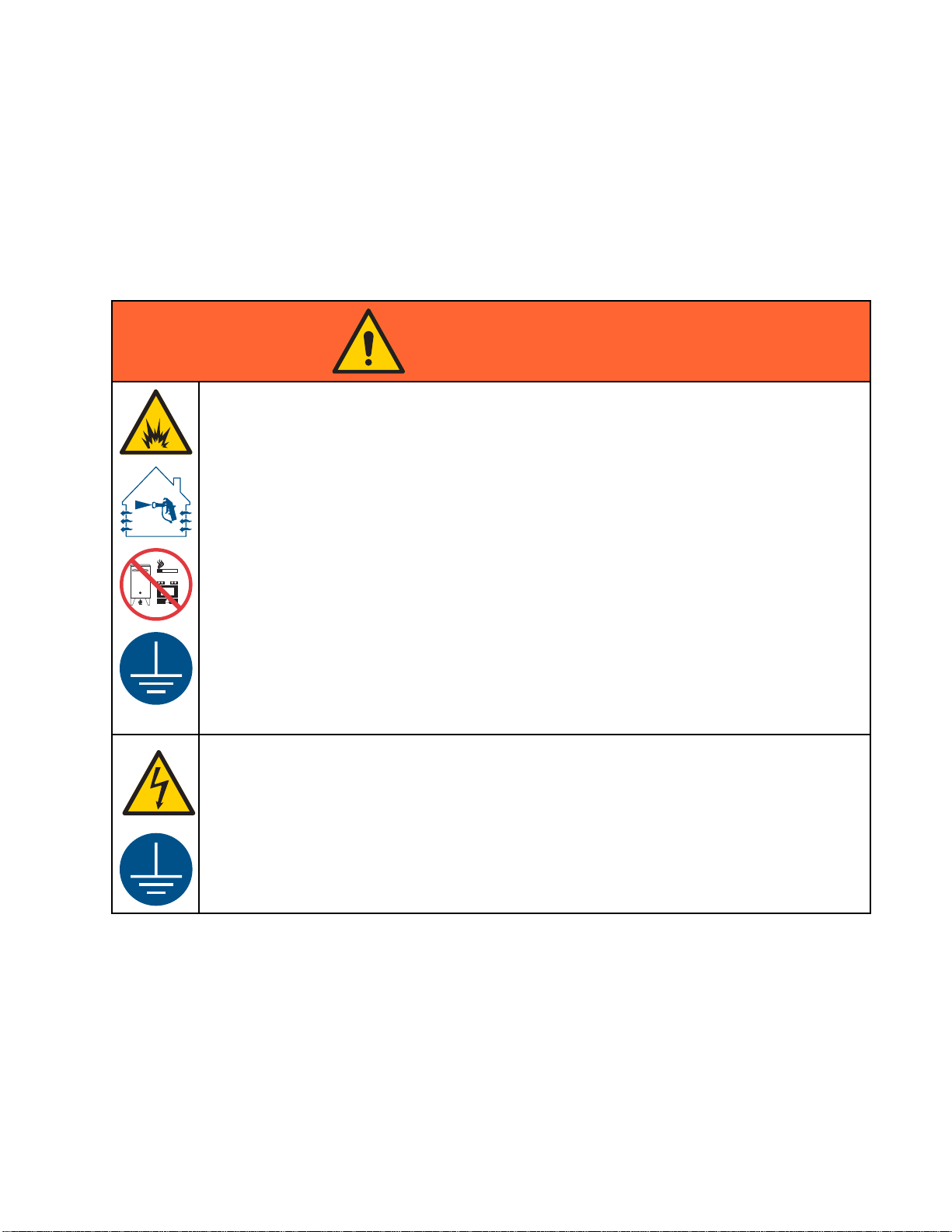

Warnings

Warnings

The following

exclamation p

risks. When th

Warnings. Pr

the body of th

warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

oint symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

ese symbols appear in the body of this manual or on warning labels, refer backtothese

oduct-specific hazard symbols and warnings not covered in this section may appear throughout

is manual where applicable.

WARNING

FIRE AND EX

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

•Keepwork

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

•Useonly

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock, Do not use

equipment until you identify and correct the problem.

• Keepaw

PLOSION HAZARD

area free of debris, including solvent, rags and gasoline.

grounded hoses.

orking fire extinguisher in the work area.

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

•Turn

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes

332458B 5

off and disconnect power at main switch before disconnecting any cables and before

icing or installing equipment.

serv

and regulations.

Page 6

Warnings

WARNING

INTRINSIC SAFETY

Intrinsical

equipment wi

Follow local

• Be sure your installation complies with national, state, and local codes for the installation of

electrical apparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1

and 2 (Europe) Hazardous Location, including all of the local safety fire codes (for example,

NFPA 33, NEC 500 and 516, OSHA 1910.107, etc.).

•Tohelpprev

• Equipment

Safety. T

unit from

SKIN INJECTION HAZARD

High-pr

skin. Th

immedia

• Do not point dispensing device at anyone or at any part of the body.

•Donotp

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning,

checking, or servicing equipment.

•Tight

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

ly safe equipment that is installed improperly or connected to non-intrinsically safe

ll create a hazardous condition and can cause fire, explosion, or electric shock.

regulations and the following safety requirements.

ent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous

location. See model ID label for the intrinsic safety rating of your model.

• Do not substitute system components as this may impair intrinsic safety.

that comes in contact with the intrinsically safe terminals must be rated for Intrinsic

his includes DC voltage meters, ohmmeters, cables, and connections. Remove the

the hazardous area when troubleshooting.

essure fluid from dispensing device, hose leaks, or ruptured components will pierce

is may look like just a cut, but it is a serious injury that can result in amputation. Get

te surgical treatment.

ut your hand over the fluid outlet.

en all fluid connections before operating the equipment.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

•Pres

TOX

Tox

inh

• Read MSDSs to know the specific hazards of the fluids you are using.

•St

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning

surized equipment can start without warning. Before checking, moving, or servicing

pment, follow the Pressure Relief Procedure and disconnect all power sources.

equi

ICFLUIDORFUMES

ic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

aled, or swallowed.

ore hazardous fluid in approved containers, and dispose of it according to applicable

idelines.

gu

equipment.

6 332458B

Page 7

Warnings

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

•Protectivee

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

•Usefluids

in all equ

informat

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check eq

manufac

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

• Make sure all equipment is rated and approved for the environment in which youareusingit.

•Useequ

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

•Keepc

• Comply with all applicable safety regulations.

yewear, and hearing protection.

and solvents that are compatible with equipment wetted parts. See Technical Data

ipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

ion about your material, request MSDS from distributor or retailer.

uipment daily. Repair or replace worn or damaged parts immediately with genuine

turer’s replacement parts only.

ipment only for its intended purpose. Call your distributor for information.

hildren and animals away from work area.

332458B

7

Page 8

Important Isocy

anate (ISO) Information

Important Iso

Isocyanates (ISO) are catalysts used in two

component materials.

cyanate (ISO) Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read and understand material manufacturer’s

warnings and material MSDS to know specific

hazards and precautions related to isocyanates.

Prevent inhalation of isocyanate mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation

is not available, a supplied-air respirator is required

foreveryoneintheworkarea.

To prevent contact with isocyanates, appropriate

personal protective equipment, including

chemically impermeable gloves, boots, aprons,

and goggles, is also required for everyone in the

work area.

Eventually a film will form on the surface and the ISO

will begin to gel, increasing in viscosity.

NOTICE

Partially c

the life of a

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere.

Never store ISO in an open container.

• Keep the ISO pump wet cup or reservoir (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may

contain moisture. Always keep solvent

containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubricant when reassembling.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

ured ISO will reduce performance and

ll wetted parts.

Keep Components A and B Separate

Cross-contamination can result in cured

material in fluid lines which could cause serious

injury or damage equipment. To prevent

cross-contamination:

• Never interchange component A and component

B wetted parts.

• Never use solvent on one side if it has been

contaminated from the other side.

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will cause

ISO to partially cure; forming small, hard, abrasive

crystals, which become suspended in the fluid.

Chang

Changing the material types used in your

equipment requires special attention to avoid

equipment damage and downtime.

•When

•Alw

•Che

•Wh

ing Materials

NOTIC

changing materials, flush the equipment

tiple times to ensure it is thoroughly clean.

mul

ays clean the fluid inlet strainers after

hing.

flus

ck with your material manufacturer for

mical compatibility.

che

en changing between epoxies and urethanes

polyureas, disassemble and clean all fluid

or

mponents and change hoses. Epoxies often

co

ve amines on the B (hardener) side. Polyureas

ha

ten have amines on the A (resin) side.

of

E

8 332458B

Page 9

System Control D

rawing 16P577

System Contro

Do not substitute or modify system components

as this may impair intrinsic safety. For installation,

maintenance, or operation instructions, read

instruction manuals. Do not install equipment

approved only for non-hazardous location in a

hazardous location. See the identification label for

the intrinsic safety rating for your model.

NOTES FOR SYSTEM CONTROL DRAWING 16P577 (FM13ATEX0026 SYSTEM ASSEMBLY

CERTIFICATE)

l Drawing 16P577

Alternate

Cable Part No. Length ft (m)

16V423

16V424

16V425

M12 CAN Cables, for Hazardous Locations

2.0 (0.6)

3.0 (1.0

6.0 (2.0)

)

16V426

16V427

16V428

29

16V4

16V430

2. The non-intrinsically safe terminals (power rail) must not be connected to any device which uses or

generates more than Um = 250 Vrms or dc unless it has been determined that the voltage has been

adequately isolated.

The electrical enclosure ground screw must be connected to a true earth ground using the supplied

3.

ound strap (223547) or by an equivalent 10 AWG or larger isolated conductor. Resistance from the

gr

lectrical enclosure ground to the true earth ground shall not exceed 1 ohm.

e

4. Multiple earthing of components is allowed. Intrinsically safe apparatus provides isolation from earth to

500 Vrms.

Do not operate system with power barrier cover removed.

6. Installation should be in accordance with ANSI/ISA RP12.06.01 “Installation of Intrinsically Safe Systems

for Hazardous (Classified) Locations” and the National Electrical Code® (ANSI/NFPA 70).

7. Installation in Canada should be in accordance with the Canadian Electrical Code, CAS C22.1, Part I,

Appendix F.

8. For ATEX, install per EN 60079–14 and applicable local and national codes.

10.0 (3.0)

5.0)

15.0 (

25.0 (8.0)

50.0 (16.0)

.0 (32.0)

100

9. For IECEx install per IEC 60079–14 and applicable local and national codes.

332458B 9

Page 10

System Control D

rawing 16P577

NON-HAZARDOUS LOCATION ONLY HAZARDOUS (CLASSIFIED) LOCATION

Class 1, Div 1, Group D, T3 (USA and Canada)

NON-HAZARDOUS LOCATION ONLY

250 VAC MAXIMUM SUPPLY VOLTAGE

POWER IN

PROMIX PD2K

ELECTRICAL ENCLOSURE

(24M672)

POWER

BARRIER

(248192)

COMMUNICATION

BARRIER

(24M485)

FM13ATEX0026

IECEx FMG 13.0011

ASSOCIATED APPARATUS

Class 1, Zone 1

, Group IIA, T3 (ATEX and IECEx)

Ta = 2°C to 50°C

HAZARDOUS (CLASSIFED) LOCATION

CLASS 1, DIV 1, GROUP D, T3 (USA AND CANADA)

CLASS 1, ZONE 1, GROUP IIA, T3 (ATEX AND IECEx)

Ta = 2ºC TO 50ºC

COLOR CHANGE MODULE

(24R219, 24R220, 24R221, 24R222)

J4

OR

J3

CABLE (16V429)

CABLE

CABLE

(24V406, 24V407, 24V408)

(24V409, 24V410, 24V411)

FM13ATEX0026

IECEx FMG 13.0011

INTRINSIC SAFE APPARATUS

COLOR CHANGE MODULE

(16V426)

(24R219, 24R220, 24R221, 24R222)

(24V406, 24V407, 24V408)

(24V409, 24V410, 24V411)

FM13ATEX0026

IECEx FMG 13.0011

INTRINSIC SAFE APPARATUS

(16V426)

BOOTH CONTROL

(24M731)

FM13ATEX0026

IECEx FMG 13.0011

INTRINSIC SAFE APPARATUS

Figure 7 System Control Drawing 16P577

10 332458B

Page 11

Configure Your Sy

stem

Configure Your

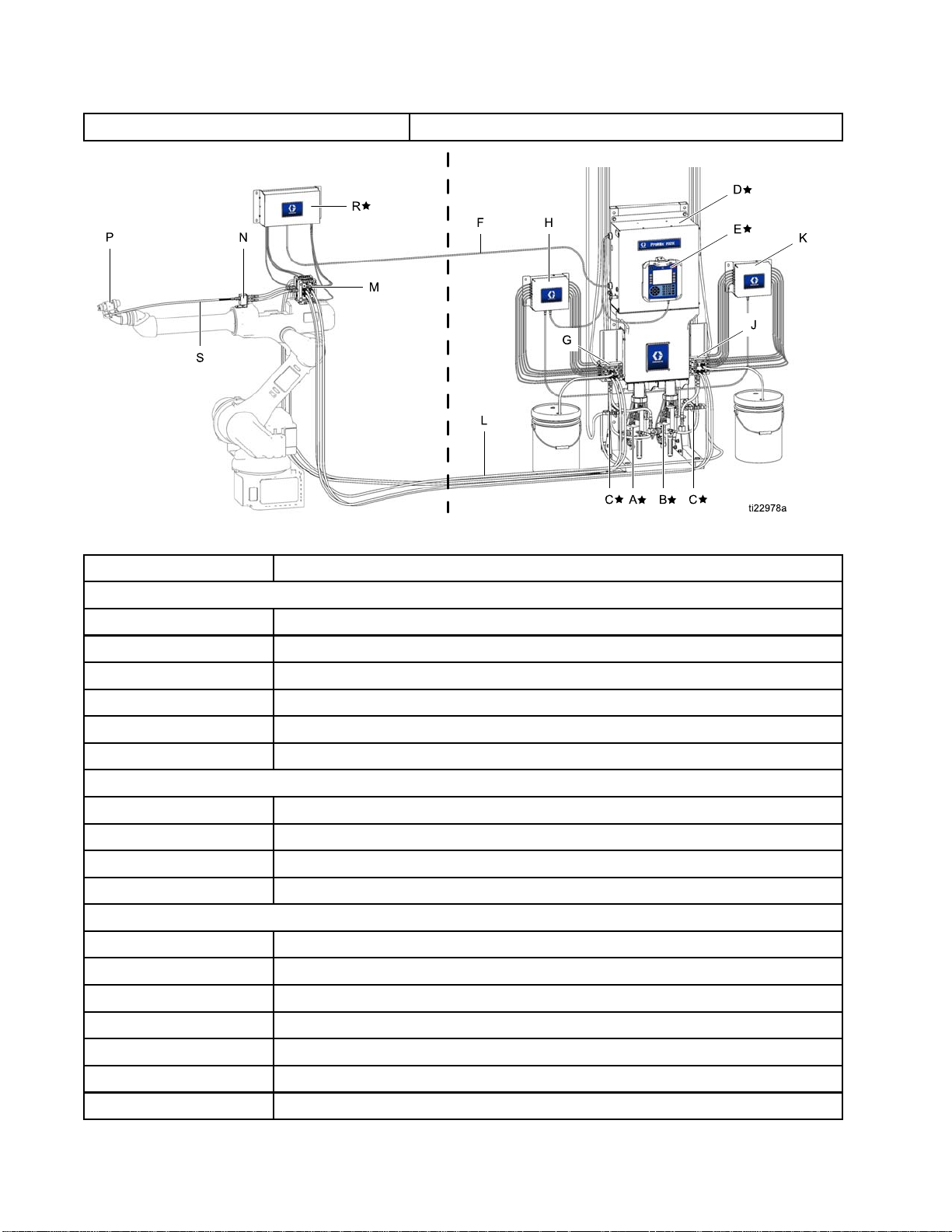

1. Select a Bas

Choose a PD2K base model that meets your

application’s requirements. See Models, page 3 .

Base models i

in the Typic

Component

Fluid Pump

Solvent Flow Switch (C) Confirms solvent flow to gun during purge.

Electrical Control Box (D) The electrical control box includes a barrier board, intrinsically safe

Advanc

nclude components A through F shown

al Installation drawing on the next page.

s (A, B)

ed Display Module (E)

e Model

System

Base unit components are described in the following

table.

Descriptio

Thebasemo

catalyst.

isolation board, 24 Vdc and 48 Vdc power supplies, Enhanced

Fluid Control Module, and Pump Control Modules. The Gateway

communication module, shipped separately, is installed in the electrical

control box. It accepts 90–250 Vac line power and converts that power to

acceptable low voltage signals used by other system components. Install

the electrical control box in the non-hazardous area.

The Adv

and con

n

dels include two fluid pumps, one for resin and one for

Install in the non-hazardous area.

anced Display Module (ADM) enables the user to setup, monitor,

trol the system. Install the ADM in the non-hazardous area.

CAN cable (F) The CAN cable connects the Gateway communication module to theIS

remote mix control module.

332458B

11

Page 12

Configure Your Sy

HAZARDOUS (CLASSIFIED) LOCATION NON-HAZARDOUS LOCATION ONLY

stem

Figure 8 Typical Installation

Component

★ Components A through F are included with the base unit.

A★

B★

C★ Solvent Flow Switch

D★

E★ Advanced Display Module

F★

Components G through K are included in optional color change kits.

G Color Change Valves (accessory, non-hazardous area)

H

J

K

omponents L through S are accessories and must be ordered separately.

C

L

M

Description

Materia

Material B (Catalyst) Pump

Elect

CAN C

Co

Catalyst Change Valves (accessory, non-hazardous area)

Catalyst Change Module (accessory, non-hazardous area)

Fluid/Air Hose Bundle (accessory)

Remote Color Change Manifold (accessory, hazardous area)

l A (Color) Pump

rical Control Box

ommunication Cable

lor Change Module (accessory, non-hazardous area)

N

P

R

S Gun Fluid Hose (accessory)

T

2

1

Remote Mix Manifold (accessory, hazardous area)

Automatic Spray Gun (accessory)

IS Remote Mix Control Module (accessory, hazardous area)

Supply Line Drain Valves (accessory, required, not shown)

332458B

Page 13

Configure Your Sy

stem

2. Select Hose

s

Hose Selection Tool

Use this chart

foryourmixr

foryourappl

to determine the proper size hoses

atio and viscosity., then select hoses

ication.

NOTE: Always use Graco hoses.

Recommended Hose Sizes (internal diameter) for A and B

20 - 50

18

16

14

12

10

Mix

Ratio

8

(X:1)

6

3/8ʺ A

1/8ʺ B

NOTE: Shaded a

of the two adj

acent areas.

3/8ʺ A

1/4ʺ B

reas may use hose sizes from either

1/4ʺ A

1/4ʺ B

4

2

0

10:1 7.5:1 5:1 2.5:1 1:1 1:2.5 1:5 1:7.5 1:10

Thick Resin (A)

Thin Catalyst (B)

Equal

Viscosities

Viscosity Ratio (Resin [A] : Catalyst [B]

1/4ʺ A

3/8ʺ B

Thin Resin (A)

Thick Catalyst (B)

332458B 13

Page 14

Configure Your Sy

1/4 in. (6 mm) ID Hoses

stem

Application Material Pressure Maximum Fluid Working

Pressure

MoistureLok

Catalyst

Nylon

Resin Nylon

Solvent Nylon

Atomizing

Air

Nylon Low

High and

Low

Low

High

Low

High

Low

High

2000 psi (13.

bar)

225 psi (1.6 MPa, 16 bar) 17C967

4100 psi (28.3 MPa, 283

bar)

225 psi (1

4100 psi (28.3 MPa, 283

bar)

225 psi (1.6 MPa, 16 bar) 17C967

4100 ps

bar)

225 psi (1.6 MPa, 16 bar) 17C967

8 MPa, 138

.6 MPa, 16 bar)

i (28.3 MPa, 283

3. Select a Spray Gun

Length

15 ft

(4.6 m)

947078 24T134 24T135

238825 239107 239111

17C967

238825 239107 239111

238825 239107 239111

25 ft

(7.6 m)

24T266 24T267

24T266 24T267

24T266 24T267

24T194 24T195

50 ft

(15.2 m)

Spray Guns

Select an automatic spray gun from the following table.

Application

ventional Air Spray

Con

Electrostatic Air Spray

Conventional

Air-Assisted Spray

Electrostatic Air-Assisted

Spray

Gun Model Gun Manual No.

AirPro 313516

Pro Xs 309297

G40

Pro Xs AA 309298

31

1052

Maximum Fluid Working

Pressure

psi (0.7 MPa, 7 bar)

100

100psi(0.7MPa,7bar)

4000 psi (28 MPa, 280

bar)

000psi(21MPa,210

3

ar)

b

4

1

332458B

Page 15

Configure Your Sy

stem

4. Select Non-

Using the following table, choose the non-IS color/catalyst change kits that meet your application’s

requirements. The kits include a manifold with valves and a control module for installation in the non-hazardous

area. See color change kit manual 333282 for further information.

Table 1 . Low Pressure Color/Catalyst Change Kits (300 psi [2.068 MPa, 20.68 bar])

Kit Part No. Kit Description

Low Pressur

24R915 2 color or 2 catalyst

24R916 4 color or 4 catalyst

24R917 6 color ch

24R918 8 color change valves

Low Pres

24R919 2 color or 2 catalyst

24R920 4 color or 4 catalyst

24R921 6 color

24R922 8 color change valves

IS Color and Catalyst Change Kits

Table 2 . High Pressure Color/Catalyst Change Kits (1500 psi [10.34 MPa, 103.4 bar])

KitPartNo. KitDescription

e Non-Circulating Kits

change valves

change valves

ange valves

sure Circulating Kits

change valves

change valves

change valves

24R959 2 color or 2 catalyst

24R960 4 color or 4 catalyst

24R961 6 color ch

24R962 8 color change valves

24T579 2 catalyst change valves

24T580 4 catalyst change valves

24R963 2 color or 2 catalyst

High Pressu

High Pre

re Non-Circulating Kits

change valves

change valves

ange valves

ssure Acid-Compatible Non-

Circula

High Pressure Circulating Kits

ting Kits

change valves

4

24R96

24R965 6 color change valves

24R966 8 color change valves

r or 4 catalyst

4colo

evalves

chang

332458B 15

Page 16

Configure Your Sy

stem

5. Select IS Re

IS remote color change manifold kits include a

manifold with valves and a control module, which

may be installed in the hazardous area. The remote

color change manifold kit must have the same

number of color valves and catalyst valves as the

color/catalyst change kit you selected in the previous

step. The remote color change manifolds attach to

the robot arm or wall, allowing mixing to occur close

to the point of spray. See color change kit manual

333282 for further information.

Table 3 . Low Pressure, Non-Circulating Remote

Color Change Manifold Kits

(300 psi [2

Number

of Color

+ Solvent

Valves

1 24V157

2 24V158 24V331

4 24V159 24V332 24V343

6 24V160 24V333 24V344

8 24V161 24V334 24V345

.068 MPa, 20.68 bar])

mote Color Change Kits

Number of Catalyst + Solvent Valves

12

4

Table 4 . Low Pressure, Circulating Remote Color

Change Manifold Kits

(300 psi [2.06

Number

of Color

+ Solvent

Valves

1 24V166

2 24V167 24V336

4 24V308 24V337 24V347

6 24V309 24V338 24V348

8 24V326 24V339 24V349

12 24V327 24V340 24V350

13–18 24V328

13–24 24V329

13–30 24V330

Table 5 . High-Pressure, Non-Circulating Remote

Color C

(1500 psi [10.34 MPa, 103.4 bar])

8 MPa, 20.68 bar])

Number of Catalyst + Solvent Valves

12

hange Manifold Kits

4

12 24V162 24V335 24V346

13–18 24V163

13–24 24V164

13–30 24V16

5

Number

of Color

+ Solvent

Valves

1 24V35

2 24V360 24V381

4 24V361 24V382 24V396

6 24V3

8 24V363 24V384 24V398

12 24V364 24V385 24V399

18

13–

13–24 24V366

13–30 24V367

Number

24V

of Catalyst + Solvent Valves

12

9

62

365

24V3

83

24V3

4

97

16 332458B

Page 17

Table 6 . High-Pressure, Circulating Remote Color

Change Manifold Kits

(1500 psi [10.

34 MPa, 103.4 bar])

Configure Your Sy

stem

Number

of Color

+ Solvent

Valves

1 24V369

2 24V370 24V389

4 24V371 24V390 24V402

6 24V372 24V391 24V403

8 24V373 24V392 24V404

12 24V374 24V393 24V405

13–18 24V375

13–24 24V376

13–30 24V377

6. Selec

The following table lists available kits to add a third

or fourth pump to your system. Each kit includes

one pump, a pump control module, solenoid, frame,

mounting bracket, and cabling. See pump expansion

kit manual 332456 for further information.

Number of Catalyst + Solvent Valves

12

t Pump Expansion Kits

4

KitPartNo. KitDescription

Low Pre

24R968 Low pressure resin 70cc

ssure Pumps (300 psi [2.068

MPa, 20

.68 bar])

pump

24R970 Low pressure catalyst

35cc pump

High Pressure Pumps (1500 psi [10.34

MPa, 103.4 bar])

24R969 High pressure resin

70cc pump

24R

971

h pressure catalyst

Hig

c pump

35c

332458B

17

Page 18

General Informa

tion

General Infor

• Reference numbers and letters in parentheses

in the text refer to numbers and letters in the

illustrations.

• Be sure all accessories are adequately sized and

pressure-rated to meet system requirements.

• To protect the screens from paints and solvents,

clear-plastic protective shields (10 per pack) are

available. Order Part No. 197902 for the Advanced

Display Module. Clean the screens with a dry cloth

if necessary.

mation

Location

To prevent tipping which can cause serious injury

and equipment damage, the mounting stand

must be securely anchored to the floor or to an

appropriate base. The stand is not intended for

free-standing use or wall mounting.

Mounting the PD2K Base Unit:

• Mount the PD2K in a non-hazardous location.

• Ensure that the mounting surface and mounting

hardware are strong enough to support the weight

of the equipment, fluid, hoses, and stress caused

during operation.

• Do not mount to a wall.

• Secure the stand to the floor with 1/2 in. (13 mm)

bolts which engage at least 6 in. (152 mm) into

the floor to prevent the unit from tipping. See

Dimensions, page 36.

• There must be sufficient space on all sides of

the equipment for installation, operator access,

maintenance, and air circulation. The fans at the

back of the unit require a minimum of 6 in. (152

mm) clearance from the closest surface to ensure

adequate air circulation.

18 332458B

Page 19

Install the Display Module

Install the Disp

lay Module

1. Use the screws

the Advanced D

the Control Bo

2. Snap the Adva

bracket.

Figure

3. Connec

(provi

(M). Th

facto

Modul

9 Install Display Module

t one end of the 5 ft (1.5 m) CAN cable

ded) to the Advanced Display Module

e other end of the cable comes from the

ry connected to the Enhanced Fluid Control

e(EFCM).

(11) to mount the bracket (10) for

isplay Module (12) on the front of

x or on the wall.

nced Display Module into the

Figure 10 A

Ports

Item Descripti

J

K Model Nu

L

M

N

P

R

dvanced Display Module Connection

Battery Cover

USB Drive Interface

CAN Cable Connection

ADM Sta

Accessory Cable

Connection

Token Access Cover

on

mber

tus LEDs

NOTE: For a list of alternate cable lengths, see

Electrical Schematics, page 29. The total length of

all cable used in the system must not exceed 150

ft (45 m).

332458B 19

Page 20

Air Supply

Air Supply

Air Requireme

• Compressed air supply pressure: 85-100 psi

(0.6–0.7 MPa, 6.0-7.0 bar).

• Air hoses: use grounded hoses that are correctly

sized for your system.

• Air regulator and bleed-type shutoff valve: include

in each air line to fluid supply equipment. Install

an additional shutoff valve upstream of all air line

accessories to isolate them for servicing.

Trapped air can cause a pump or dispense

valve to cycle unexpectedly, which could result

in serious injury from splashing or moving parts.

Usebleed-typeshutoffvalves.

nts

This air suppl

switch detec

controller w

NOTE: If ther

example, a se

atomizing a

each gun. Fo

valve at all

ts air flow to the gun and signals the

hen the gun is being triggered.

ir outlet (159c) must be branched to

air line tees.

ies gun atomizing air. The air flow

e is more than one gun (for

parate gun for each color), the

r ease of maintenance, install a ball

To reduce the risk of fire and explosion if using

a Graco electrostatic gun, a shutoff valve must

be installed in the gun air line to shutoff the

atomizing and turbine air to the gun. Contact

your Graco distributor for information on air

shutoff valves for electrostatic applications.

• Air line filter: to filter oil and water out of the air

supply and help avoid paint contamination and

clogged solenoids. See Technical Data, page 37,

for air filtration requirements.

Air Connections

1. Tighten all system air and fluid line connections

as they may have loosened during shipment.

2. Connect the main air supply line to the main air

inlet (136). This air line supplies the solenoids,

valves, and pumps. Do not use this line to supply

the gun’s atomizing air.

3. Connect a separate, dedicated, clean air supply

line to the air inlet (159a) of the air flow switch.

Figure 11 Atomizing Air and Air Manifold Connections

Key

Connection

A Air inlet

C Air cutoff output

M

S Solvent cutoff output

Description

(plugged)

Exhaust muffler

(plugged)

20 332458B

Page 21

Fluid Supply

Fluid Supply

Fluid Require

• Toreduceth

overpressu

cause injur

exceed the

system com

label for t

equipment

• To reduce

injectio

between e

manifold

maintena

Models a

air-ass

to 800 cc

• Fluid supply pressure tanks, feed pumps, or

circulatingsystemscanbeusedtosupplyfluidto

the system.

• Materials can be transferred from their original

containers or from a central paint recirculating line.

n, you must install a shutoff valve

. Use the valves to shut off fluid during

re available to operate air spray (300 psi) or

isted (1500 psi) systems with a capacity of up

/minute (depending on material viscosity).

ments

e risk of equipment

rization and rupture which can

y, including skin injection, do not

pressure rating of the lowest rated

ponent. See the identification

he maximum working pressure of the

.

the risk of injury, including skin

ach fluid supply line and the mix

nce and service.

• Install a 100 m

supply line,

• The supply li

loss of great

circulation

port.

NOTE: The fluid supply must be free of pressure

spikes, which are commonly caused by pump stroke

changeover. Read the supply pressure on the gauge

(P, see figure on next page). Supply capability for

each pump must be at least 2 times the maximum

operating flow rate. Supply pressure must be as

close as possible to the pressure setpoint:

• For low pressure systems, ± 100 psi (0.7 MPa, 7

bar) of setpoint.

NOTE: For low pressure systems, the pressure

should be maintained at 1/2 to 2/3 of the system

operating pressure.

• For high pressure systems, ± 300 psi (2.1 MPa,

21 bar) of setpoint.

ssary, install pressure regulators or a surge

If nece

tank on

Contac

inform

the pump fluid inlet lines to reduce pulsation.

t your Graco distributor for additional

ation.

esh (minimum) fluid filter in the fluid

with a drain valve.

ne should be sized to avoid pressure

er than a few psi between the

header and the proportioner fluid inlet

332458B

21

Page 22

Fluid Supply

Single Color C

NOTE: Check valves (J, L) are provided on the inlet

(K) and outlet (H) manifolds of each pump.

1. Connect the c

inlet fitting

2. Connect the c

outlet fittin

3. Make the sam

NOTE: For isocyanate catalyst materials, moisture

resistant hose is required to supply fluid to the system

andalsoasafluidlinebetweenthepumpandthe

mix manifold.

onnections

olor supply line to the pump fluid

(S).

olor outlet line to the pump fluid

g(R).

e connections on the catalyst side.

Color Change C

If you are installing the color change accessory kit,

make the fluid connections as described in manual

333282.

onnections

Figure 12 Pump Inlet and Outlet Connections

2

2

332458B

Page 23

TSL Cup Kit

TSL Cup Kit

Throat Seal Liquid (TSL) lubricates the pump throat

packings and dosing valves. The PD2K Proportioner

includes two TSL Cup Kits, one for each pump. The

kits supply TSL to the upper throat cartridge of the

color (70 cc) pump, to the upper and lower throat

cartridges of the catalyst (35 cc) pump, and to the

four pump dosing valves.

NOTE: TSL mu

No. 206995,

1. Slide the kit mounting bracket (73a) onto any

side of the pump’s hex nut.

2. Place the TSL cup (73) into the bracket (73a).

Routing of the throat seal tubing (73c) should

always slope up to the reservoir.

st be ordered separately. Order Part

1 quart (0.95 liter).

NOTE: The pump’s upper throat cartridge has

three ports (two are plugged). Move a plug (73d)

if necessary so the barbed fitting (73b) can be

put in the port closest to the TSL cup.

3. Check that the o-ring is in place on the barbed

fitting (73b). Apply low strength thread adhesive

and install the fitting in the upper throat cartridge

port. Be sure the other two ports are plugged

(73d).

Figure 13 Install TSL Cup Kit

4. Cataly

throat

st (35 cc) pumps: Repeat for the lower

cartridge.

332458B 23

Page 24

Solvent Meter Ac

cessory

5. If you are lubricating the dosing valves, remove

the plug (73d) and gasket from the valve port (V)

closest to the TSL cup. Check that the o-ring is

in place on the barbed fitting (73b). Apply low

strength thread adhesive and install the fitting in

the valve port (V). NOTE: Do not confuse the

valve port (V) with the air port (W).

Solvent Meter

To install Solvent Meter Kit 280555, see manual

308778.

NOTE: Instal

solvent cuto

l the solvent meter downstream of the

ff switch near the base unit.

Light Tower A

To install Light Tower Kit 24K337, see manual

3A1906.

Accessory

ccessory

NOTE: If you are not lubricating the dosing

valves, remove the unused barbed fittings (73b)

from the bottom of the TSL cup (73). Apply low

strength thread adhesive and install the plugs

and gaskets supplied with the kit.

6. Cut the tubing (73c) to length as required.

Connect the TSL cup fittings to the fittings on the

pump and valves. TSL is gravity-fed from the

cup to the pump and valves; position the fittings

and tubing to prevent kinks and enable the TSL

to flow freely.

7. Fill the cup with TSL.

NOTE: If TSL leaks from the rod guard of the

color (70 cc) pump, be sure the lower u-cup seal

is installed in the lower throat cartridge.

4

2

332458B

Page 25

Electrical Supp

ly

Electrical Su

Improper wiring may cause electric shock or other

serious injury if work is not performed properly. All

electrical wiring must be completed by a qualified

electrician and comply with all local codes and

regulations.

pply

Electrical Requirements

Enclose all cables routed in the spray booth and high

traffic areas in conduit to prevent damage from paint,

solvent, and traffic.

The unit operates with 90-250 VAC, 50/60 Hz input

power, with a maximum of 7 A current draw. The

power supply circuit must be protected with a 15 A

maximum circuit breaker.

• A power supply cord compatible to your local

power configuration is not included. Wire gauge

size must be 8-14 AWG.

Electrical C

See Electrical Schematics, page 29.

1. Verify that

shut off. Op

2. Thread the e

strain reli

3. Connect the

correspon

as shown.

4. Tighten th

5. Close the

6. Follow in

Wire Key

Wire Description

L Line Power

NNeutral

G Ground

onnections

electrical power at the main panel is

en the Control Box cover.

lectrical cord wires through the

ef (S).

wires (L, N, G) securely to the

ding terminals of the terminal block (T),

e strain relief nut securely.

Control Box. Restore power.

structions in Grounding, page 26.

• The input power access port is 22.4 mm (0.88

in.) in diameter. A strain relief is provided which

accepts a cord diameter of 0.157–0.354 in. (4–9

mm). If another cord size is used, a user-supplied,

appropriate size strain relief must be installed.

Figure 14 Control Box Electrical Connection

332458B 25

Page 26

Grounding

Grounding

See illustration on next page.

This equipment must be grounded to reduce the

risk of static sparking and electric shock. Electric

or static sparking can cause fumes to ignite or

explode. Improper grounding can cause electric

shock. Grounding provides an escape wire for the

electric current.

Electrical Control Box

The electrical control box has two ground points.

Both connections must be made.

• Connectthegroundwire(Y)tothegroundscrew

on the electrical control box. Connect the clamp

end to a true earth ground.

• The power supply must be grounded according to

local codes. Connect the power supply ground

wire to the Ground terminal in the electrical control

box. See Electrical Connections, page 25.

Fluid Supply Container

Follow local code.

Color Change

Connect a ground wire from the color change module

to a true earth ground.

Intrinsica

hazardous

ground in t

lly safe color change modules located in the

area must be connected to a true earth

he hazardous area.

Module

Feed Pumps or Pressure Pots

Connect a ground wire and clamp from a true earth

ground to the pumps or pots. See pump or pressure

pot manual.

Air and F

Use grounded hoses only.

luid Hoses

Spray Gun

Follow

the grounding instructions in your gun manual.

Figure 15 Ground Screw and Power Switch

• Non-Electrostatic: Ground the spray gun through

connection to a Graco-approved grounded fluid

supply hose.

• Electrostatic: Ground the spray gun through

connection to a Graco-approved grounded air

supply hose. Connect the air hose ground wire to

a true earth ground.

26 332458B

Page 27

HAZARDOUS LOCATION NON-HAZARDOUS LOCATION

Grounding

Figure 16 System Grounding

Key

1

2

3

4

Electrical Control Box ground screw

Electrical Control Box ground wire

Color Change Module (CC) ground

wires

Intrinsically Safe (IS) cable

332458B

5

6

7

True Earth Ground; check local code

for requirements

Non-Intrinsically Safe cable

Remote Mix Control Module ground

wire

27

Page 28

Grounding

Object Being S

Follow local code.

prayed

Solvent Reservoir or Purge Station

Follow local

reservoir or

surface. Do

stationona

cardboard,

code. Use only a conductive solvent

purge station placed on a grounded

not place the solvent reservoir or purge

nonconductive surface, such as paper or

which interrupts the grounding continuity.

Check Resista

To ensure proper grounding and reduce risk of fire

and explosion, resistance between components

and true earth ground must be less than 1 ohm.

nce

28 332458B

Page 29

Electrical Sche

matics

Electrical Sc

hematics

NOTE: The electrical schematic illustrates all possible

wiring expansions in a ProMix PD2K system. Some

components shown are not included with all systems.

NOTE: See Optional Cables and Modules, page 35 for

a list of cable options.

RELAY

(16U820)

16W159

BREAKOUT MODULE PUMP 2

BREAKOUT MODULE PUMP 4

POWER MODULE

(24R257)

16W159

16W159

(24N527)

(24N527)

SPLITTER

(16P243)

4

CABLE (16T659)

CABLE (16T659)

CABLE (16T659)

CABLE (16T659)

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

OR G3000 METER

(239716, 258718

16M510, 16M519)

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

OR G3000 METER

(239716, 258718

16M510, 16M519)

POWER IN

FAN

UP

(120278)

FAN

UP

(120278)

2 POSITION

SWITCH

(16U725)

CABLE

16T658

LINE FILTER

(16V446)

CABLE

16H078

TERMINAL BLOCK

(114095)

(24N527)

BREAKOUT MODULE PUMP 1

(24N527)

BREAKOUT MODULE PUMP 3

24V

POWER

SUPPLY

(16T660)

48V-10A POWER SUPPLY

TERMINAL BLOCKS WITH FUSES

16W159

FAN

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

FAN

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

Figure 17 Electrical Schematic, Sheet 1

INTEGRATION

GATEWAY

3

GATEWAY

(24R910)

CABLE (15V206)

2

CABLE

3

16T072

CAN

IS BOARD

(24M485)

CABLE

(16T280)

BARRIER

BOARD

(248192)

065161, 065159

5

CABLE

(121227)

AWI

5

(121227)

CABLE

3

(121001)

6

MODULE 1

COLOR CHANGE

CABLE

2

(15V206)

GCA

MODULE

EFCM

(24N913)

FLOW RATE ANALOG IN

1

CABLE (16V429)

(24N935)

COLOR CHANGE

FLOW RATE ANALOG IN

FLOW RATE ANALOG IN

2

CABLE

(15V206)

6

(24N935)

MODULE 2

FLOW RATE ANALOG IN

COLOR CHANGE

2

CABLE

(121003)

2

CABLE

(15V206)

6

6

6

(24N935)

(24N935)

MODULE 3

COLOR CHANGE

CABLE

(15V206)

GUN TRIGGER INPUTS

119159

119159

119159

119159

SOLENOID (121324)

PRESSURE SW (121323)

SOLVENT CUTOFF (121324)

SWITCH (120278)

SWITCH (120278)

SOLVENT METER (258718)

SAFETY INTERLOCK SWITCH

3

ADVANCED

DISPLAY MODULE

CABLE

1

HAZARDOUS LOCATION

NON-HAZARDOUS LOCATION

(24N935)

MODULE 4

MODULE 5

CATALYST CHANGE

CABLE

2

(15V206)

(24E451)

COLOR CHANGE MODULE 7

(24R219)

COLOR CHANGE MODULE 8

(24R219)

(16V426)

BOOTH CONTROL (24M731)

INTERFACES

CATALYST CHANGE

SOLVENT

INPUTS

TOWER

(15X472)

6

MODULE 6

GFB

FLOW

LIGHT

7

7

(24N935)

CABLE

1

(16V426)

332458B 29

Page 30

Electrical Sche

matics

SPLITTER

(16P243)

UNUSED

UNUSED

POWER

SUPPLY

(16T660)

L (BROWN)

N03 N03

2 POSITION

SWITCH

(16U725)

N04 N04

CABLE

(16T658)

L N

LINE

FILTER

(16V446)

L GRND N

CABLE

(16H078)

L N GRND

TERMINAL

BLOCK

(114095)

L N GRND

345

24V

2

1

UNUSED

GRND (GRN/YEL)

N (BLUE)

CABLE (16V429)

1

CONTINUED ON PAGE 3

2

3

CABLE

(15V206)

1 2 3 4 5

CAN IS BOARD

2

(NON IS)

(IS)

4

(24M485)

1 2 3 4 5

UNUSED

1 2 3 4 5

CABLE

(16T280)

1 2 3

1

2

3

BARRIER

BOARD

(248192)

13 A1(+) A2(-)

RELAY

14

N L GRND

48V-10A

POWER SUPPLY

(16U820)

+ -

+ - + - + - + -

F4

F3

F2

F1

+ - + - + - + -

DETAIL A, LOW PRESSURE

PUMPS (24M706, 24M714)

BREAKOUT MODULE

(24N527)

2

1 2 3 4 5 1 2 3 4

WIRE HARNESS

(24P684)

CABLE (121227)

16T072

1 2 3 4 5

1

3

UNUSED

UNUSED

RED WIRE (065161)

BLACK WIRE (065159)

1 2 3 4 5 1 2 3 4

(24R257)

POWER MODULE

3

DRAIN/FOIL

CABLE

1

2

3

4

5

P3

GATEWAY

(24R910)

1

2

3

P4

4

5

AWI

(121227)

3

1

2

3

P3

4

5

INTEGRATION

5

GFB INTERFACE

(121324)

SOLVENT CUTOFF (121324)

SOLVENT

METER

(258718)

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GROUND BAR

BREAKOUT MODULE PUMP 1 (24N527)

2

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 1

SEE DETAIL A OR B

3

1 2 3 4 5 1 2 3 4 5 1 2

TWISTED PAIR CABLE (16W159)

5

4

PUMP 1

PUMP 1

(16P289 OR 16P290)

INLET TRANSDUCER

(16P289 OR 16P290)

OUTLET TRANSDUCER

DETAIL B, HIGH PRESSURE

PUMPS (24M707, 24M715)

BREAKOUT MODULE

2

1 2 3 4 5 1 2 3 4

GATEWAY

5

6

1 2 3 4

(24N527)

WIRE HARNESS

(24P685)

1

2

3

P4

4

5

+12VDC

COM

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

UNUSED

PUMP 1

+24VDC

V/P FOR FLUID REG.

PUMP 1

MANIFOLD

UNUSED

UNUSED

UNUSED

CABLE

(121001)

3

1

7

3 4

5 6 7 8

COM

COM

+24VDC

UP

DOWN

PUMP 1

G3000

METER

PUMP 1

(EITHER, 239716,

258718,16M510,

OR 16M519)

(16P812 QTY 2)

MAC SERIES 46

3

5

4

3

10

2

1

1

2

3

8

4

5

1

2

3

4

5

6

5

7

8

9

10

11

12

25 PIN D-SUB CABLE

(16T659)

1 2 3 4

+48V

COM

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GRND

SCREW

DRAIN/FOIL

CONTINUED ON PAGE 3

GCA MODULE

EFCM

(24N913)

12

4

252423222120191817161413121110 15987654321

BREAKOUT MODULE PUMP 2 (24N527)

2

1 2 3 4 5 1 2 3 4

+48V

COM

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 2

SEE DETAIL A OR B

(24P658)

FAN PUMP 1

252423222120191817161413121110 15987654321 252423222120191817161413121110 15987654321

3

1 2 3 4 5 1 2 3 4 5 1 2

4

PUMP 2

(16P289 OR 16P290)

INLET TRANSDUCER

5

PUMP 2

OUTLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

6

1 2 3 4

PUMP 2

(16P289 OR 16P290)

V/P FOR FLUID REG.

25 PIN

(16T659)

D-SUB CABLE

4

1

7

3 4

COM

COM

+24VDC

+24VDC

UP

DOWN

PUMP 2

PUMP 2

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

5 6 7 8

PWR (RED)

SIG (WHITE)

G3000

METER

PUMP 2

(EITHER, 239716,

258718,16M510,

OR 16M519)

COM (BLACK)

SHIELD/GRN

GRND

SCREW

1 2 3 4

+48V

88

COM

+48V

FAN PUMP 2

252423222120191817161413121110 15987654321

COM

(24P658)

DRAIN/FOIL

UNUSED UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED UNUSED

UNUSED

UNUSED UNUSED

POWER IN

UNUSED

UNUSED

DRAIN/FOIL

1 2 3 4 5 6 7 8 9

PUMP ENCODER AND MOTOR

MOTOR

MOUNTING

SCREW

UNUSED

UNUSED UNUSED

(16P037)

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED UNUSED UNUSED

UNUSED

12

11

12

11

10

1 2 3 4 5 6 7 8 9

10

1 2

1 2 3 4 5 6 7 8 9

PUMP ENCODER AND MOTOR

MOTOR

MOUNTING

SCREW

10

(16P036)

1 2 3 4 5 6 7 8 9

UNUSED

10

Figure 18 Electrical Schematic, Sheet 2, Part 1

CONTINUED ON THE NEXT PAGE

30 332458B

Page 31

GUN TRIGGER INPUTS

SIG

1

COM

2

SIG

3

COM

4

SIG

5

COM

6

6

7

SIG

8

COM

9

SIG

10

COM

11

SIG

12

1

2

3

4

5

6

7

7

8

9

10

11

12

1

2

3

9

4

5

COM

FLOW RATE ANALOG IN 1

FLOW RATE ANALOG COMMON 1

FLOW RATE ANALOG IN 2

FLOW RATE ANALOG COMMON 2

FLOW RATE ANALOG IN 3

FLOW RATE ANALOG COMMON 3

FLOW RATE ANALOG IN 4

FLOW RATE ANALOG COMMON 4

SIG

COM

SIG

COM

CABLE

(121003)

3

GCA MODULE

EFCM

(24N913)

34

252423222120191817161413121110 15987654321 252423222120191817161413121110 15987654321

119159

GFB PRESSURE SWITCH (121323)

SOLVENT FLOW SWITCH 1 (120278)

SOLVENT FLOW SWITCH 2 (120278)

SAFETY INTERLOCK SWITCH

1

ADVANCED

2

DISPLAY MODULE

3

4

(24E451)

5

Electrical Sche

1

2

LIGHT

3

TOWER

4

(15X472)

5

matics

25 PIN

(16T659)

D-SUB CABLE

4

5

PUMP 3

(16P289 OR 16P290)

OUTLET TRANSDUCER

252423222120191817161413121110 15987654321

6

1 2 3 4

PUMP 3

V/P FOR FLUID REG.

3 4

COM

+24VDC

+24VDC

UP

PUMP 3

PUMP 3

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

COM

DOWN

7

5 6 7 8

G3000

METER

PUMP 3

(EITHER, 239716,

258718,16M510,

PWR (RED)

OR 16M519)

1

BREAKOUT MODULE PUMP 3 (24N527)

3

2

1 2 3 4 5 1 2 3 4 1 2 3 4 5 1 2 3 4

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 3

SEE DETAIL A OR B

4

1 2 3 4 5 1 2 3 4 5 1 2

PUMP 3

(16P289 OR 16P290)

INLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

Figure 19 Electrical Schematic, Sheet 2, Part 2

CONTI

NUED ON THE NEXT PAGE

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GRND

SCREW

25 PIN D-SUB CABLE

(16T659)

8

1 2 3 4

+48V

+48V

COM

COM

(24P658)

FAN PUMP 3

4

2

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 4

SEE DETAIL A OR B

5

PUMP 4

(16P289 OR 16P290)

OUTLET TRANSDUCER

252423222120191817161413121110 15987654321

6

1 2 3 4

V/P FOR FLUID REG.

PUMP 4

3 4

COM

+24VDC

+24VDC

UP

PUMP 4

PUMP 4

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

7

COM

DOWN

1

BREAKOUT MODULE PUMP 4 (24N527)

3

4

1 2 3 4 5 1 2 3 4 5 1 2 1 2 3 4

PUMP 4

(16P289 OR 16P290)

INLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

5 6 7 8

PWR (RED)

SIG (WHITE)

G3000

METER

PUMP 4

(EITHER, 239716,

258718,16M510,

OR 16M519)

+48V

COM (BLACK)

SHIELD/GRN

GRND

SCREW

8

COM

+48V

FAN PUMP 4

COM

(24P658)

332458B 31

Page 32

Electrical Sche

matics

FLUSH

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

*FLUSH

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 13

COLOR 14

COLOR 15

COLOR 16

CABLE (15V206)

2

MANIFOLD

MANIFOLD

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

COM

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

2

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

FROM CAN IS BOARD (24M485) ON PAGE 2

2

345

1

COLOR

CHANGE

MODULE 1

(COLORS

6

COM

5

+12VDC

4

COM

J9

3

+12VDC

2

COM

1

+12VDC

6

COM

5

+12VDC

4

COM

3

+12VDC

2

COM

1

+12VDC

6

COM

5

+12VDC

4

COM

3

+12VDC

2

COM

1

+12VDC

J8

J15

J14

1

1 THRU 8)

6

2

345

J16

J10

CABLE

(15V206)

2

345

1

COLOR

CHANGE

MODULE 2

(COLORS

6

9 THRU 16)

J8

J15

J14

1

2

6

J16

J10

345

COM

5

+12VDC

4

COM

J9

3

+12VDC

2

COM

1

+12VDC

6

COM

5

+12VDC

4

COM

3

+12VDC

2

COM

1

+12VDC

6

COM

5

+12VDC

4

COM

3

+12VDC

2

COM

1

+12VDC

MANIFOLD

MANIFOLD

DUMP

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

DUMP*

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 13

COLOR 14

COLOR 15

COLOR 16

FLUSH

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

FROM CAN IS BOARD (24M485) ON PAGE 2

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CATALYST

CHANGE

MODULE 5

(CATALYST

1 THRU 4)

J8

J15

J14

2

1

6

345

J16

J10

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

6

5

4

J9

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

2

*FLUSH

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

MANIFOLD

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

+12VDC

COM

+12VDC

COM

+12VDC

COM

COM

COM

COM

COM

COM

COM

CABLE

1

17 THRU 24)

2

3

J8

4

5

6

1

2

3

J15

4

5

6

1

2

3

J14

4

5

6

2

345

1

COLOR

CHANGE

MODULE 3

(COLORS

6

4

5

3

2

J9

J16

J10

1

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

Figure 20 Electrical Schematic, Sheet 3

* May be unused in some configurations.

CONTINUED ON THE NEXT PAGE

MANIFOLD

DUMP*

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

2

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

CABLE (15V206)

*FLUSH

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

22

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CABLE

2

1

COLOR

CHANGE

MODULE 4

(COLORS

25 THRU 32)

J8

6

J15

J14

2

1

345

345

J16

J10

J9

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP*

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

32 332458B

Page 33

FLUSH

CATALYST 3

CATALYST 4

FLUSH

CATALYST 1

CATALYST 2

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

22

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CATALYST

CHANGE

MODULE 6

(CATALYST

3 THRU 4)

J8

J15

J14

2

1

CABLE

5

4

CATALYST

CHANGE

MODULE 5

(CATALYST

1 THRU 2)

J8

J15

J14

2

1

6

345

2

3

6

345

J9

J16

J10

1

J9

J16

J10

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

(15V206)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

COM

+12VDC

COM

+12VDC

COM

+12VDC

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

MANIFOLD

Electrical Sche

DUMP

CATALYST 3

CATALYST 4

DUMP

CATALYST 1

CATALYST 2

matics

Figure 21 Electrical Schematic, Sheet 3, Alternate

Configuration for Catalyst Change Control

INUED ON THE NEXT PAGE

CONT

2

CABLE

25 THRU 32)

2

345

1

COLOR

CHANGE

MODULE 4

(COLORS

(15V206)

332458B 33

Page 34

Electrical Sche

matics

FROM CAN IS BOARD (24M485) ON PAGE 2

COLOR FLUSH

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

COLOR 13

COLOR 14

COLOR 15

COLOR 16

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

1

2

3

4

J8

5

6

1

2

3

J15

4

5

6

1

2

3

4

J14

5

6

1

1

2

3

J8

4

5

6

1

2

3

J15

4

5

6

1

2

3

J14

4

5

6

2

345

1

COLOR

CHANGE

MODULE 7

(COLORS

33 THRU 40)

7

2

345

1

CABLE

2

345

1

COLOR

CHANGE

MODULE 8

(COLORS

41 THRU 48)

7

5

2

3

4

J9

J16

J10

J9

J16

J10

1

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

(16V426)

6

5

4

3

2

1

6

5

4

3

2

1

6

5

4

3

2

1

NON-HAZARDOUS LOCATION

HAZARDOUS LOCATION

MANIFOLD

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

MANIFOLD

CATALYST FLUSH

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 22

COLOR 23

COLOR 24

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

1

CABLE

5

BOOTH CONTROL

(24M731)

(16V426)

2

3

1

4

Figure 22 Electrical Schematic, Sheet 3, Hazardous

Location

34 332458B

Page 35

Optional Cables

and Modules

Optional Cabl

es and

Modules

NOTE: The total length of all cable used in the system must not exceed 150 ft (45 m). See the

Electrical Schematics, page 29.

M12 CAN Cables, for Hazardous Locations

NOTE: The total length of cable used in the

hazardous location must not exceed 120 ft (36 m).

Cable Part No. Length ft (m)

16V423

16V424

16V425

16V426

16V427

16V428

16V429

16V430

M12 CAN Cables, for Non-Hazardous

Locations Only

15U531

15U532

15V205

15V206

15V207

15V208

15U533

15V213

CAN Cables, for Non-Hazardous

Locations Only

Cable Part No. Length ft (m)

125306

123422

121000

121227

121001

121002

121003

120952

121201

121004

121228

2.0 (0.6)

3.0 (1.0)

6.0 (2.0)

10.0 (3.0)

15.0 (5.0)

25.0 (8.0)

50.0 (16.0)

100.0 (32.0)

2.0 (0.6)

3.0 (1.0)

6.0 (2.0)

10.0 (3.0)

15.0 (5.0)

25.0 (8.0)

50.0 (16.0)

100.0 (32.0)

1.0 (0.3)

1.3 (0.4)

1.6 (0.5)

2.0 (0.6)

3.0 (1.0)

5.0 (1.5)

10.0 (3.0)

13.0 (4.0)

20.0 (6.0)

25.0 (8.0)

50.0 (15.0)

16T659

16V659

Module Part No. Module Part No.

CGMDN0*, DeviceNet CGMPB0*, Profibus

CGMEP0*, Ethernet IP CGMPN0*, Profinet

* You must purchase Map Token Kit 17C087 for

usewiththesekits.

Module Part No. Description

24T557 2 color/2 catalyst

24T558 4 color/4 catalyst

24T559 6 color/6 catalyst

24T560 8 color/8 catalyst

24T571 2 color/2 catalyst

24T572 4 color/2 catalyst

24T573 6 color/2 catalyst

24T574 8 color/2 catalyst, 13–24

24T774 12 color/2 catalyst

24T775 4 color/4 catalyst

24T776 6 color/4 catalyst

24T777 8 color/4 catalyst

24T778 12 color/4 catalyst, 13–30

24T779 13–18 color

25 Pin D-SUB Cables, for Non-Hazardous

Locations Only

2.5 (0.8)

6.0 (1.8)

Alternates for Communication Module 24R910,

for Non-Hazardous Locations Only

Alternates for Color Change Modules

by Part Number (Factory Configuration), for

Non-Hazardous Locations Only

Alternates for Color Change Modules

by Part Number (Factory Configuration), for

Hazardous Locations Only

color

color

332458B 35

Page 36

Dimensions

Dimensions

Figure 23

Figure 25

A

58.20

in.

(1478

mm)

wit

ADM

14.5

in.

(368

mm)

Figure 24

B

h

hout

wit

ADM

11.12

in.

(282

mm)

C

22.0 in.

(559

mm)

DE F

19.26

in.

(489

mm)

2.0 in.

(51 mm)

18.0 in.

(457

mm)

G

17.26

in.

(438

mm)

HJ

0.52 in.

(13

mm)

Minimum

6in (152 mm)

from mounting

surface

36 332458B

Page 37

Technical Data

Technical Data

Positive Displacement

Proportioner

Maximum fluid working

pressure:

AC1000 Air Spray

Systems

AC2000 Air-Assisted

Spray Systems

Maximum wo

pressure:

Air supply: 85–100 psi

Air filter

ation for air logic

Air filtr

(user-s

ration for atomizing

Air filt

er-supplied):

air (us

Mixing ratio range:

Fluids handled:

rking air

inlet size:

upplied):

one or

• solvent and waterborne paints

• polyurethanes

two component:

U.S.

300 psi 2.1 MPa, 21 ba

1500 psi 10.5 MPa, 10

100 psi 0.7 MPa, 7.

5micron

30 micr

(minimum) filtration required; clean and dry air

on (minimum) filtration required; clean and dry air

3/8 npt(f

0.1:1

0.6–0.7 M

)

to 50:1, ±1%

Metric

r

5bar

0bar

Pa, 6.0–7.0 bar)

• epoxies

• acid catalyzed varnishes

• moisture sensitive isocyanates

5000 centipoise

Viscosity range of fluid:

Fluid filtration

(user-supplied):

Maximum fluid flow: 800 cc/minute (depending on material viscosity)

luid outlet size:

F

xternal power supply

E

requirements:

Operating temperature

range:

Storage temperature

range:

Weight of base model

(approximate):

Sound data: Less than 75 dB(A)

Wetted parts:

17–4PH SST, 303 SST, 304 SST, Tungsten carbide (with nickel binder),

0 - 250 Vac, 50/60 Hz, 7 amps maximum draw

9

15 amp maximum circuit breaker required

8 to 14 AWG power supply wire gauge

36 to 122°F 2 to 50°C

–4 to 158°F –20 to 70°C

195 lb 88 kg

20–

0meshminimum

10

1/4 npt(m)

perfluoroelastomer; PTFE, PPS, UHMWPE

332458B 37

Page 38

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for use.

With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period of

twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance

with Grac

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage o

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco

be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation,

operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized

Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace

free of charge any defective parts. The equipment will be returned to the original purchaser transportation