Page 1

Instructions-Parts

Color Change K

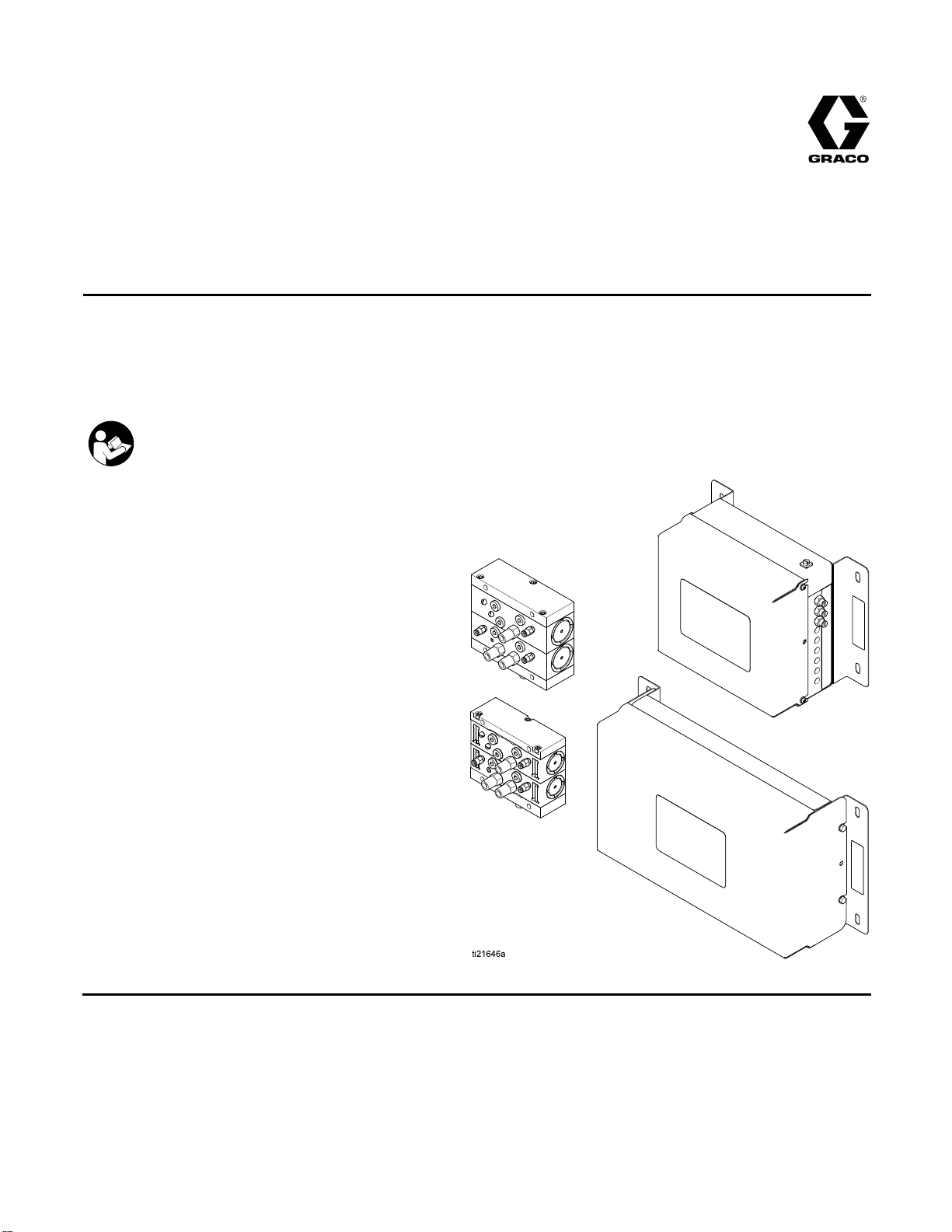

To add optional color change function to ProMix® PD2K Electronic Proportioners. Kits include low or

high pressure color/catalyst change valves and a Non-IS or IS control module.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and in your PD2K

proportioner manual. Save these instructions.

See page 4

numbers a

informat

for model part

nd approvals

ion.

its

332455F

EN

PROVEN QUALITY. LEADING TECHNOLOGY.

Page 2

Contents

Related Manuals ................................................ 3

Models............................................................... 4

Non-Intrinsically Safe Kits............................. 4

Intrinsically Safe Kits.................................... 6

Warnings ........................................................... 7

Important Isocyanate (ISO) Information................ 10

Isocyanate Conditions.................................. 10

Material Self-ignition..................................... 10

Keep Components A and B Separate............ 10

Moisture Sensitivity of Isocyanates................ 10

Changing Materials ...................................... 11

Setup the Modules.............................................. 12

Setup Non-IS Control Modules...................... 12

Setup IS Control Modules............................. 15

Installa

tion..........................................................17

Mounting

Air Suppl

Groundi

Non-Haz

Hazardo

Install

Install

Connec

the Color Change Control

Module........................................... 17

y.................................................... 17

ng ................................................... 17

ardous Location.............................. 18

us Location ..................................... 20

the Valve Manifolds ............................ 21

the Back Pressure Regulator (High

Pressu

t the Valve Air Lines.......................... 23

re Systems Only)..................23

Connect the Fluid Lines................................ 24

Install an Expansion Kit ................................ 28

Troubleshooting.................................................. 30

Color Change Solenoid Valves ..................... 30

Color Change Board .................................... 32

Electrical S

Repair................................................................ 41

Parts.................................................................. 44

Dimensi

Weights ............................................................. 69

Technical Data ...................................................73

Graco S

chematics.......................................... 34

Optional Ca

Replace a Color Valve.................................. 41

Replace a Solenoid...................................... 42

Replace the ColorChangeBoard Fuse........... 42

Replace the Color Change Board.................. 43

Non-IS Color Change Kits ............................ 45

IS Color Change Kits.................................... 47

Valve Manifolds ........................................... 49

Color Change Control Module Kits ................ 60

Expansion Kits............................................. 64

ons ........................................................ 66

tandard Warranty.................................... 74

bles and Modules....................... 40

2

332455F

Page 3

Related Manuals

Related Manuals

Manual No. Description

3A2800 PD2K Proporti

Manual, Manua

332457 PD2K Proportioner Installation

Manual, Manual Systems

332562

3A2801

PD2K Propor

Manual, Man

Mix Manifold Instructions-Parts

Manual

oner Repair-Parts

lSystems

tioner Operation

ual Systems

Manual No. Description

332339 Pump Repair-P

332454

332456 3rd and 4th P

Color Change Valve Repair-Parts

Manual

Instructio

ns-Parts Manual

arts Manual

ump Kits

332455F 3

Page 4

Models

Models

Non-Intrinsically Safe Kits

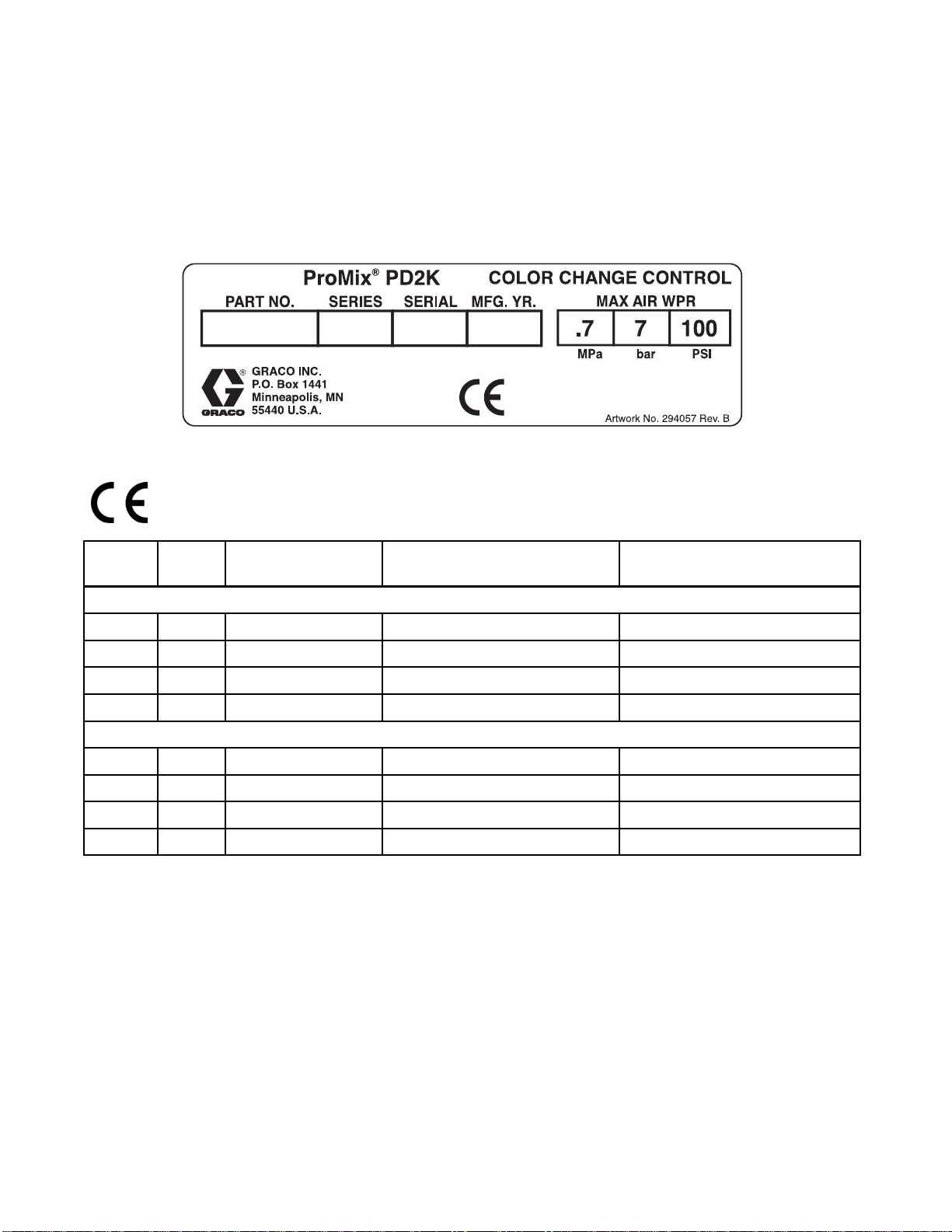

See the modul

information

Figure 1 Non-Intrinsically Safe Color Change Control

Module Label

Kit No.

24R915 A 2 color or 2 catalyst

24R916 A 4 color

e identification label for product part number, maximum air working pressure, and approval

and certification.

Series

Kit Description Maximum Air Working Pressure

(Control Module)

Low Pres

or 4 catalyst

sure Non-Circulating Color Change Kits

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

Maximum Fluid Working

Pressure (Valves)

24R917 A 6 color

24R918 A 8 color

24R919 A 2 color

24R920 A 4 color

921

24R

24R922 A 8 color

A6co

lor

100 psi

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

Low Pressure Circulating Color Change Kits

100 p

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

10

(0.7 MPa, 7.0 bar)

si (0.7 MPa, 7.0 bar)

0psi(0.7MPa,7.0bar)

300 psi

300 p

30

(2.068 MPa, 20.68 bar)

si (2.068 MPa, 20.68 bar)

0 psi (2.068 MPa, 20.68 bar)

4

332455F

Page 5

Models

Kit No.

24R959 A 2 color or 2 cat

24R960 A 4 color or 4 catalyst

24R961 A 6 color

24R962 A 8 color

24T579 A

24T580 A

24R963 A 2 color

24R96

24R965 A 6 color

24R966 A 8 color

Series

4

Kit Descriptio

High Press

2 catalyst (acid

compatible)

4 catalyst (acid

compatible)

A4colo

r

n

High Pressure Non-Circulating Color Change Kits

alyst

ure Acid Compatible Non-Circulating Catalyst Change Kits

High Pr

Maximum Air Wor

(Control Modul

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 M

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

essure Circulating Color Change Kits

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 ps

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

i(0.7MPa,7.0bar)

king Pressure

e)

Pa, 7.0 bar)

Maximum Fluid W

Pressure (Valv

1500 psi (10.

1500 p

si (10.34 MPa, 103.4 bar)

orking

es)

34 MPa, 103.4 bar)

332455F 5

Page 6

Models

Intrinsicall

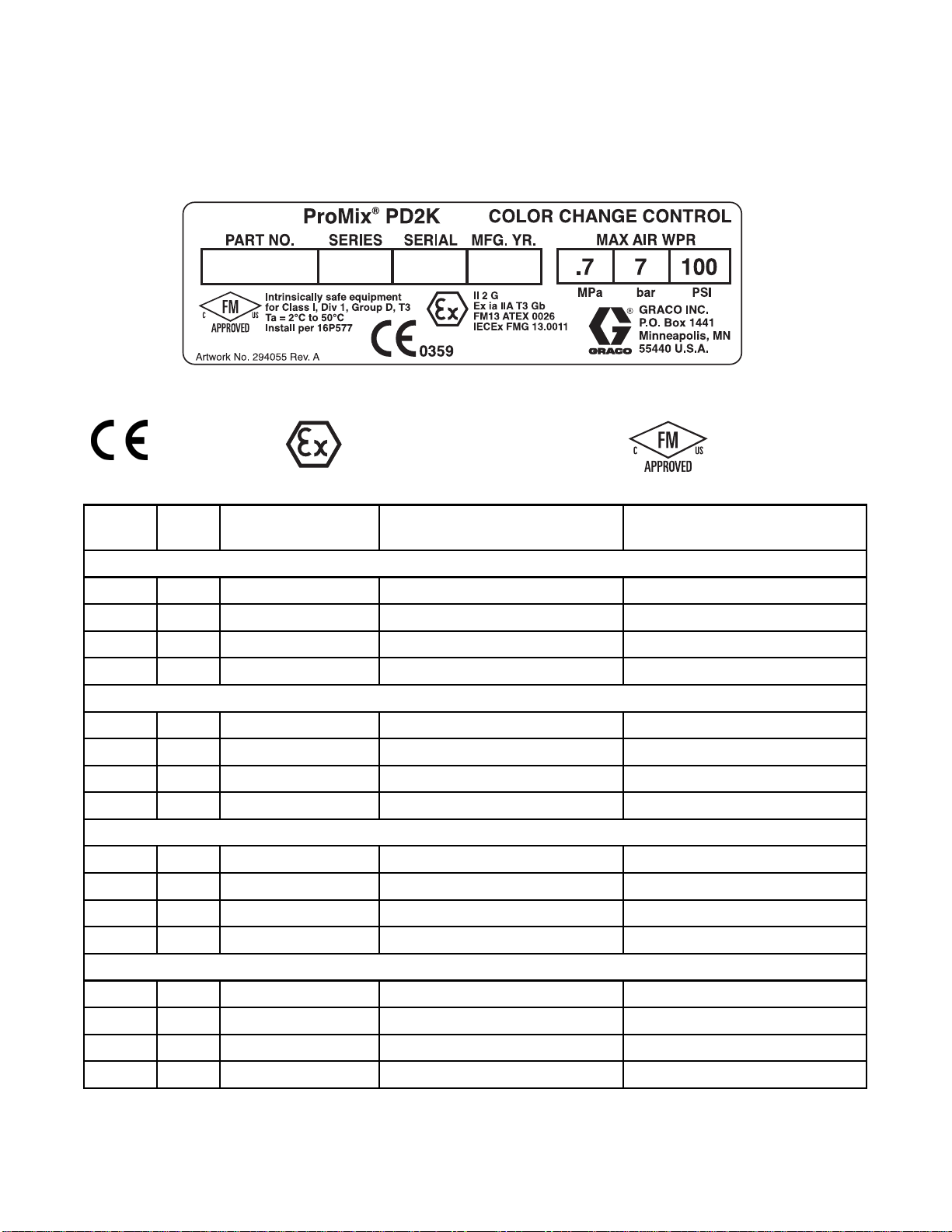

See the module identification label for product part number, maximum air working pressure, and approval

information and certification.

Figure 2 Intrinsically Safe Color Change Control

Module Label

Kit No.

ySafeKits

0359

Series

II 2 G

Kit Description Maximum Air Working Pressure

(Control Module)

Low Pressure Non-Circulating Color Change Kits

Maximum Fluid Working

Pressure (Valves)

24T343 A 2 color or 2 catalyst

24T344 A 4 color or 4 catalyst

24T345 A 6 color

24T346 A 8 color

Low Pressure Circulating Color Change Kits

24T347 A 2 color

24T348 A 4 color

24T349 A 6 color

24T350 A 8 color

High Pressure Non-Circulating Color Change Kits

24T351 A 2 color or 2 catalyst

24T352 A 4 color or 4 catalyst

24T353 A 6 color

24T354 A 8 color

High Pressure Circulating Color Change Kits

24T355 A 2 color

24T356 A 4 color

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 300 psi (2.068 MPa, 20.68 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

24T357 A 6 color

24T358 A 8 color

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

100 psi (0.7 MPa, 7.0 bar) 1500 psi (10.34 MPa, 103.4 bar)

6 332455F

Page 7

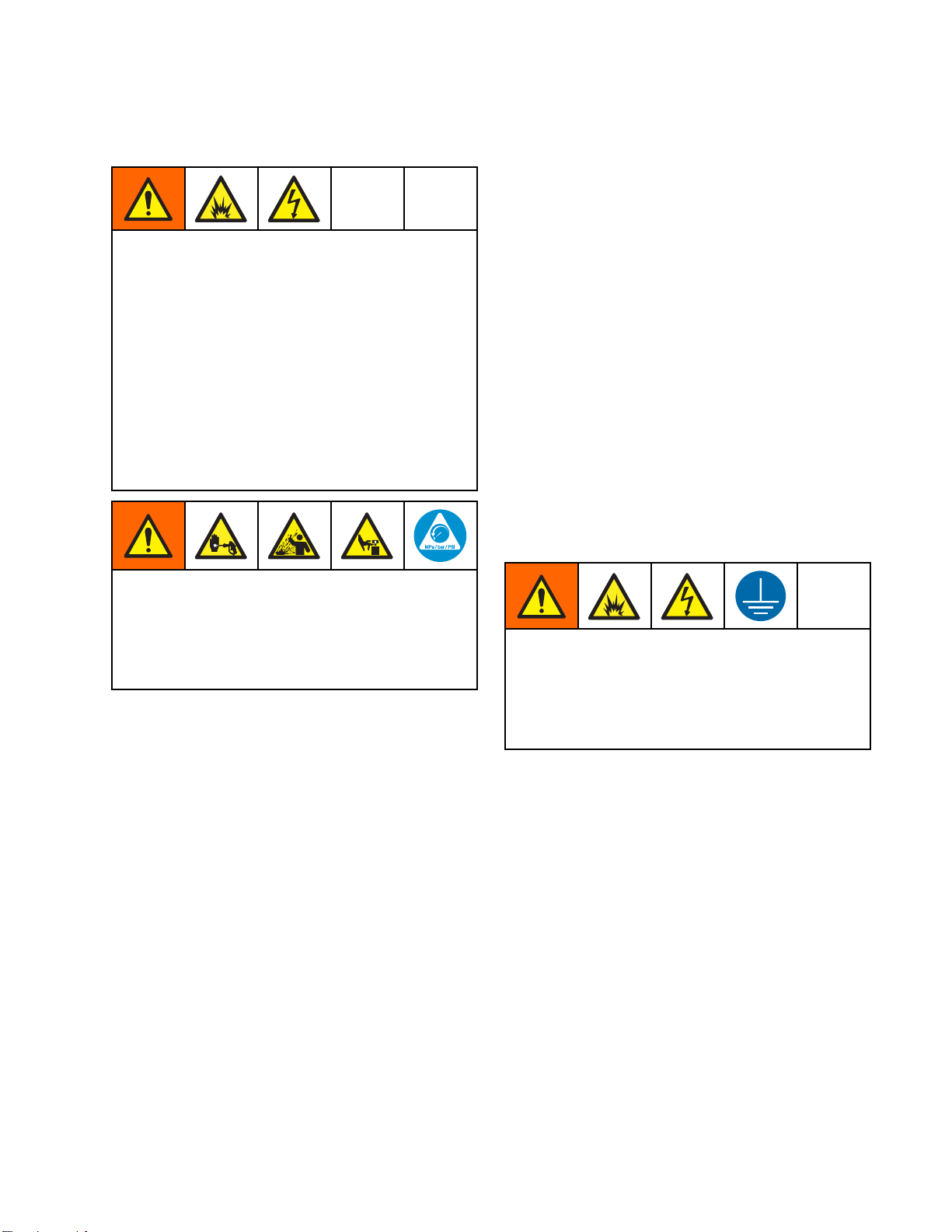

Warnings

Warnings

The following

exclamation p

risks. When th

Warnings. Pr

the body of th

warnings are for the setup, use, grounding, maintenance and repair of this equipment. The

oint symbol alerts you to a general warning and the hazard symbol refers to procedure-specific

ese symbols appear in the body of this manual or on warning labels, refer backtothese

oduct-specific hazard symbols and warnings not covered in this section may appear throughout

is manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable

prevent fir

• Use equipment only in well ventilated area.

• Eliminat

plastic d

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

•Grounda

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless

they are antistatic or conductive.

• Stop op

equipm

• Keep a working fire extinguisher in the work area.

fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

e and explosion:

e all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

rop cloths (potential static arc).

ll equipment in the work area. See Grounding instructions.

eration immediately if static sparking occurs or you feel a shock, Do not use

ent until you identify and correct the problem.

332455F

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can

cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before

servicing or installing equipment.

• Connect only to grounded power source.

lectrical wiring must be done by a qualified electrician and comply with all local codes

•Alle

egulations.

and r

7

Page 8

Warnings

WARNING

INTRINSIC SAFETY

Intrinsically safe equipment that is installed improperly or connected to non-intrinsically safe

equipment will create a hazardous condition and can cause fire, explosion, or electric shock.

Follow local regulations and the following safety requirements.

• Besureyouri

electrical a

and 2 (Europ

NFPA 33, NEC

• To help prevent fire and explosion:

• Do not install equipment approved only for a non-hazardous location in a hazardous

location. See model ID label for the intrinsic safety rating of your model.

• Do not subs

• Equipment that comes in contact with the intrinsically safe terminals must be rated for Intrinsic

Safety. This includes DC voltage meters, ohmmeters, cables, and connections. Remove the

unit from the hazardous area when troubleshooting.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

•Donotsp

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

•Donotp

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying/dispensing and before

cleaning, checking, or servicing equipment.

•Tight

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

en all fluid connections before operating the equipment.

nstallation complies with national, state, and local codes for the installation of

pparatus in a Class I, Group D, Division 1 (North America) or Class I, Zones 1

e) Hazardous Location, including all of the local safety fire codes (for example,

500 and 516, OSHA 1910.107, etc.).

titute system components as this may impair intrinsic safety.

ray without tip guard and trigger guard installed.

ut your hand over the spray tip.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

ssurized equipment can start without warning. Before checking, moving, or servicing

•Pre

ipment, follow the Pressure Relief Procedure and disconnect all power sources.

equ

ICFLUIDORFUMES

TOX

ic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

Tox

aled, or swallowed.

inh

• Read MSDSs to know the specific hazards of the fluids you are using.

ore hazardous fluid in approved containers, and dispose of it according to applicable

•St

idelines.

gu

• Always wear chemically impermeable gloves when spraying, dispensing, or cleaning

equipment.

8 332455F

Page 9

Warnings

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury,

including eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective

equipment includes but is not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent

manufacturer.

EQUIPMENT M

Misuse can

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exce

system com

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data

in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete

information about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

•Turnoffa

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals

and create safety hazards.

•Makesu

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•Donotk

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ISUSE HAZARD

cause death or serious injury.

ed the maximum working pressure or temperature rating of the lowest rated

ponent. See Technical Data in all equipment manuals.

ll equipment and follow the Pressure Relief Procedure when equipment is not in use.

re all equipment is rated and approved for the environment in which you are using it.

ink or over bend hoses or use hoses to pull equipment.

332455F 9

Page 10

Important Isocy

anate (ISO) Information

Important Iso

Isocyanates (ISO) are catalysts used in two

component materials.

cyanate (ISO) Information

Isocyanate Conditions

Spraying or dispensing materials containing

isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read material manufacturer’s warnings and

material MSDS to know specific hazards and

precautions related to isocyanates.

Prevent inhalation of isocyanate mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation

is not available, a supplied-air respirator is required

foreveryoneintheworkarea.

To prevent contact with isocyanates, appropriate

personal protective equipment, including

chemically impermeable gloves, boots, aprons,

and goggles, is also required for everyone in the

work area.

Keep Components A and B Separate

Cross-contamination can result in cured

material in fluid lines which could cause serious

injury or damage equipment. To prevent

cross-contamination:

• Never interchange component A and component

Bwettedparts.

• Never use solvent on one side if it has been

contaminated from the other side.

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will cause

ISO to partially cure; forming small, hard, abrasive

crystals, which become suspended in the fluid.

Eventually a film will form on the surface and the ISO

will begin to gel, increasing in viscosity.

NOTICE

Partially cured ISO will reduce performance and

the life of all wetted parts.

• Always use a sealed container with a desiccant

Material Self-ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings

and material MSDS.

10 332455F

dryer in the vent, or a nitrogen atmosphere.

Never store ISO in an open container.

• Keep the ISO pump wet cup or reservoir (if

installed) filled with appropriate lubricant. The

lubricant creates a barrier between the ISO and

the atmosphere.

• Use only moisture-proof hoses compatible with

ISO.

• Never use reclaimed solvents, which may

contain moisture. Always keep solvent

containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubricant when reassembling.

NOTE: The amount of film formation and rate of

crystallization varies depending on the blend of ISO,

the humidity, and the temperature.

Page 11

Important Isocy

anate (ISO) Information

Changing Mate

rials

NOTICE

Changing the material types used in your

equipment requires special attention to avoid

equipment damage and downtime.

• When changi

multiple ti

• Always clea

flushing.

• Check with

chemical c

• When chang

or polyur

componen

have amin

often hav

ng materials, flush the equipment

mes to ensure it is thoroughly clean.

n the fluid inlet strainers after

your material manufacturer for

ompatibility.

ing between epoxies and urethanes

eas, disassemble and clean all fluid

ts and change hoses. Epoxies often

es on the B (hardener) side. Polyureas

eaminesontheA(resin)side.

332455F

11

Page 12

Setup the Module

s

Setup the Modu

Setup Non-IS C

NOTE: The PD2K System can use up to four pumps

and six color change modules in the non-hazardous

area. Use the following table to understand how

many color change modules are needed for the

number of pumps in your system, and which module

should be associated to which pump.

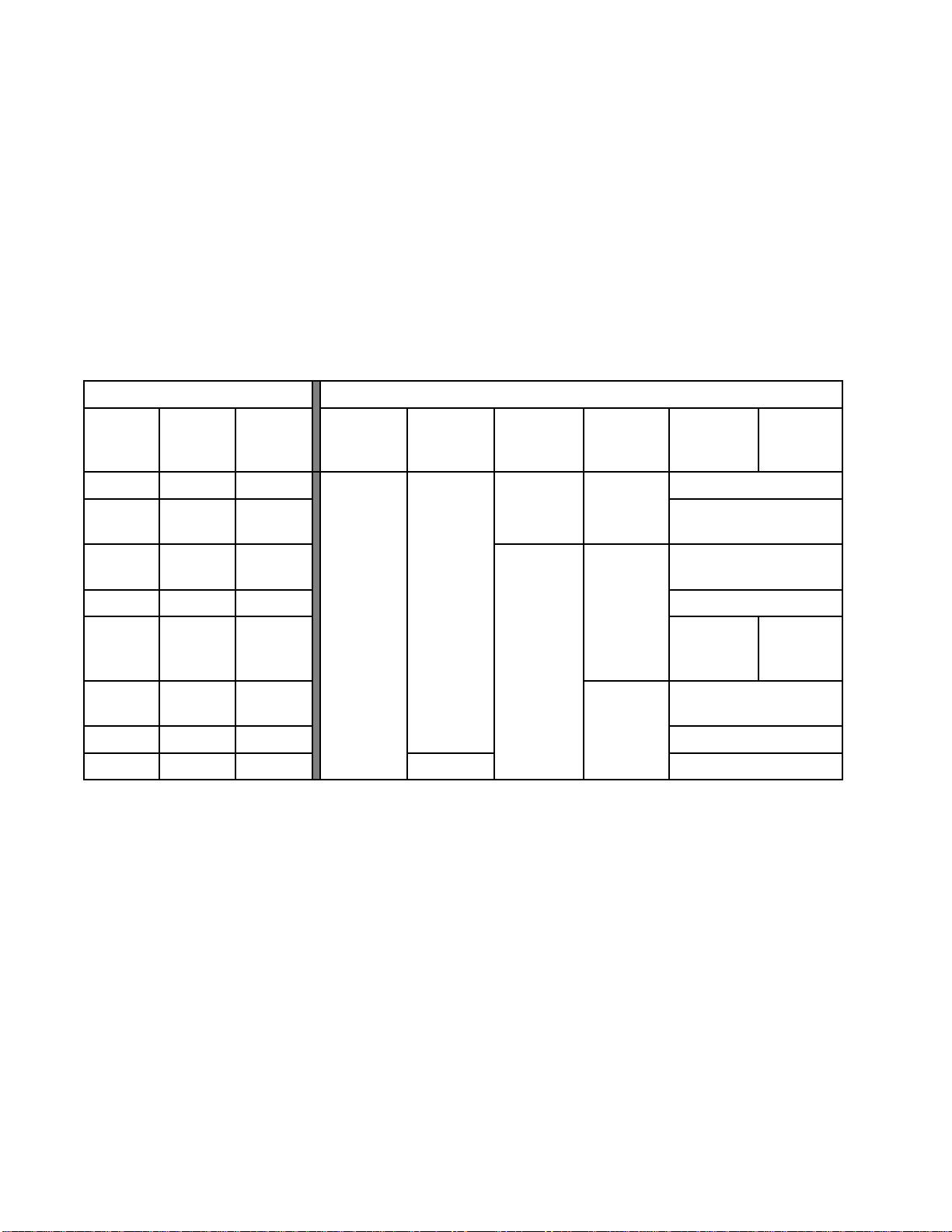

Table 1 . Relationship of Non-IS Color Change Control Modules to Pumps

System Pump Configuration Color Change Control Modules, Colors, and Catalysts

Color

Pump(s)

1 0 1 Not Applicable

112

213

Catalyst

Pump(s)

ontrol Modules

Total

Pumps

les

Module 1

(Colors

1–8)

Module 2

(Colors

9–16)

All Non-IS modules ship from the factory as Module

1 (Colors 1–8). Labels for Modules 2 through 6

areprovidedwiththemodulekit. Affixthelabels

according to your system configuration.

Module

3(Colors

17–24)

Pump # 1 Pump # 1

Module 4

(Colors

25–30)

Catalyst

1–2

Module # 5

Pump # 2

Module

Pump # 2

Catalyst

3–4

#5

2 0 2 Not Applicable

Pump # 1

224

314

303

404

Pump # 1

Pump#3

Pump # 2

Pump # 3

Pump # 4

Module

#5

Pump # 2

Module # 5

Pump # 2

Not Applicable

Not Applicable

Module

#6

Pump # 4

2

1

332455F

Page 13

Setup the Module

s

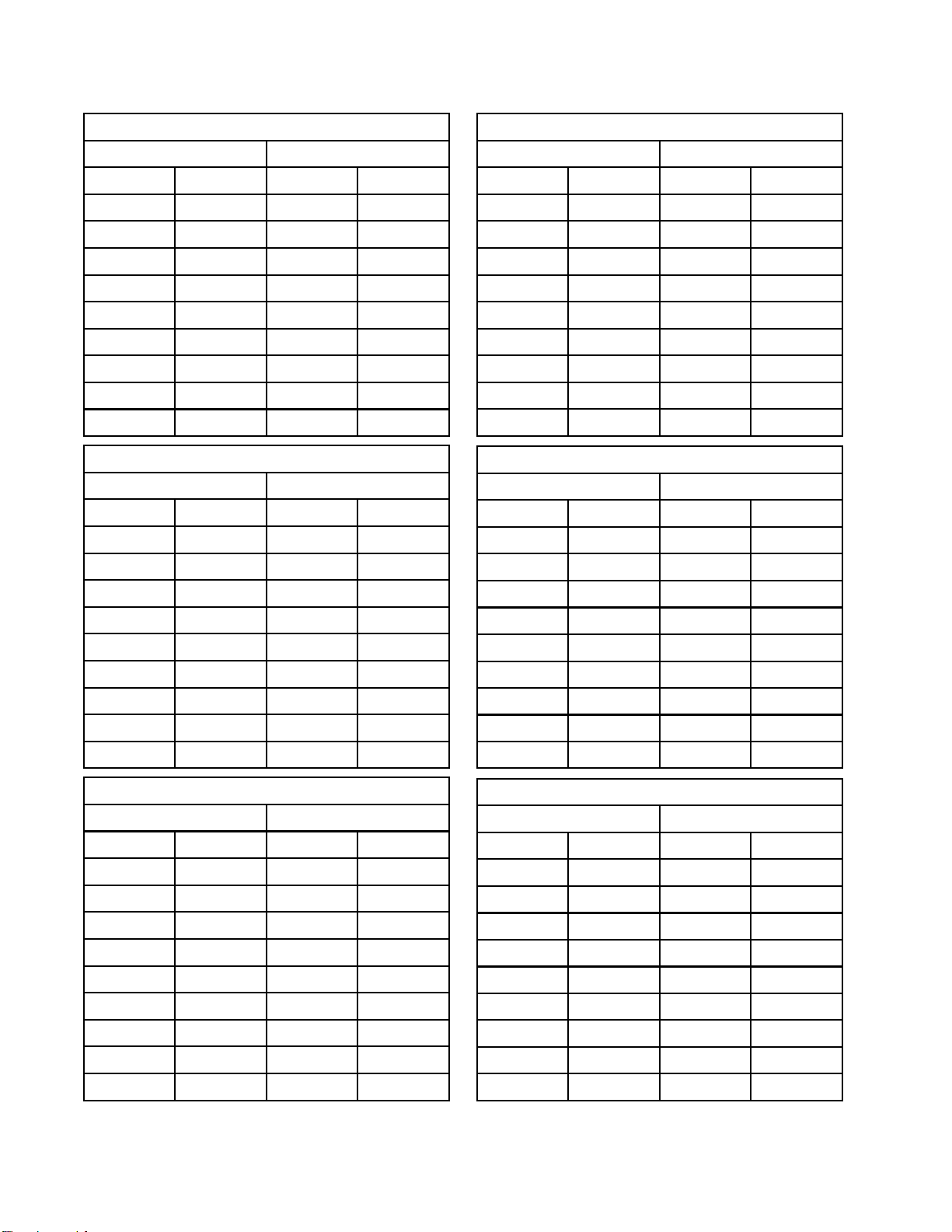

Configure each module according to its designated

number, as follows:

NOTICE

To avoid damaging the circuit boards, wear Part

No. 112190 grounding strap on your wrist and

ground appropriately.

To avoid elec

system power

1. Remove elec

2. Open the col

S4, S5, and S

switches a

3. For each module, set the switches to ON or OFF,

as shown in the following table.

trical component damage, remove all

before plugging any connectors.

trical power from the system.

or change module. Locate switches

6 on the control module board. The

re shipped in the OFF position.

Non-IS Control Module Switch Settings

Control

S6 S5 S4

Module

Module 1

Module 2

Module 3

Module 4

Module 5

Module 6

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

4. Use the following figure and tables to determine

the solenoid valve assigned to each valve in the

valve manifold.

NOTE: There can be only one solvent valve and one

dump valve per pump.

Inlet Manifold Outlet Manifold

Figure 3 Non-IS Control Module

332455F 13

Page 14

Setup the Module

s

Non-IS Control Module 1

Inlet Manifol

Solenoid

1

2

3

4

5

6

7

8

9

Inlet Manifold Outlet Manifold

Solenoid

1

2

3

4

5

6

7

8

d

Valve

Solvent

Color 1

Color 2

Color 3

Color 4

Color 5

Color 6

Color 7

Color 8

Non-IS Control Module 2

Valve

(Solvent)*

Color 9

Color 10

Color 11

Color 12

Color 13

Color 14

Color 15

Outlet Manifo

Solenoid

1Dump

2

3

4

5

6

7

8

9

Solenoid

1

2

3

4

5

6

7

8

ld

Valve

Color 1

Color 2

Color 3

Color 4

Color 5

Color 6

Color 7

Color 8

Valve

(Dump)*

Color 9

Color 10

Color 11

Color 12

Color 13

Color 14

Color 15

Non-IS Control Module 4

Inlet Manifol

Solenoid

1

2

3

4

5

6

7

8 Not Used 8 Not Used

9NotUse

Inlet Manifold Outlet Manifold

Solenoid

1

2

3

4

5

6 Not Used 6 Not Used

7

8 Not Used 8 Not Used

d

Valve

(Solvent)*

Color 25

Color 26

Color 27

Color 28

Color 29

Color 30

d

Non-IS Control Module 5

Valve

(Solvent)*

Catalyst 1

Catalyst 2

Catalyst 3

Catalyst 4

Not Used

Outlet Manifo

Solenoid

1

2

3

4

5

6

7

9NotUse

Solenoid

1

2

3

4

5

7

ld

Valve

(Dump)*

Color 25

Color 26

Color 27

Color 28

Color 29

Color 30

Valve

(Dump)*

Catalyst 1

Catalyst 2

Catalyst 3

Catalyst 4

Not Used

d

9

Inlet Manifold Outlet Manifold

Solenoid

1

2

3

4

5

6

7

8

9

* There should be only one solvent valve and one dump valve per pump.

4

1

Color 16

Non-IS Control Module 3

Valve

(Solvent)*

Color 17

Color 18

Color 19

Color 20

Color 21

Color 22

Color 23

Color 24

9

Solenoid

1

2

3

4

5

6

7

8

9

Color 16

Valve

(Dump)*

Color 17

Color 18

Color 19

Color 20

Color 21

Color 22

Color 23

Color 24

9 Not Used 9 Not Used

Non-IS Control Module 6

Inlet Manifold Outlet Manifold

Solenoid

1

2

3

4 Not Used 4 Not Used

5

6 Not Used 6 Not Used

7

8 Not Used 8 Not Used

9 Not Used 9 Not Used

Valve

(Solvent)*

Catalyst 3

Catalyst 4

Not Used

Not Used

Solenoid

1

2

3

5

7

Valve

(Dump)*

Catalyst 3

Catalyst 4

Not Used

Not Used

332455F

Page 15

Setup the Module

s

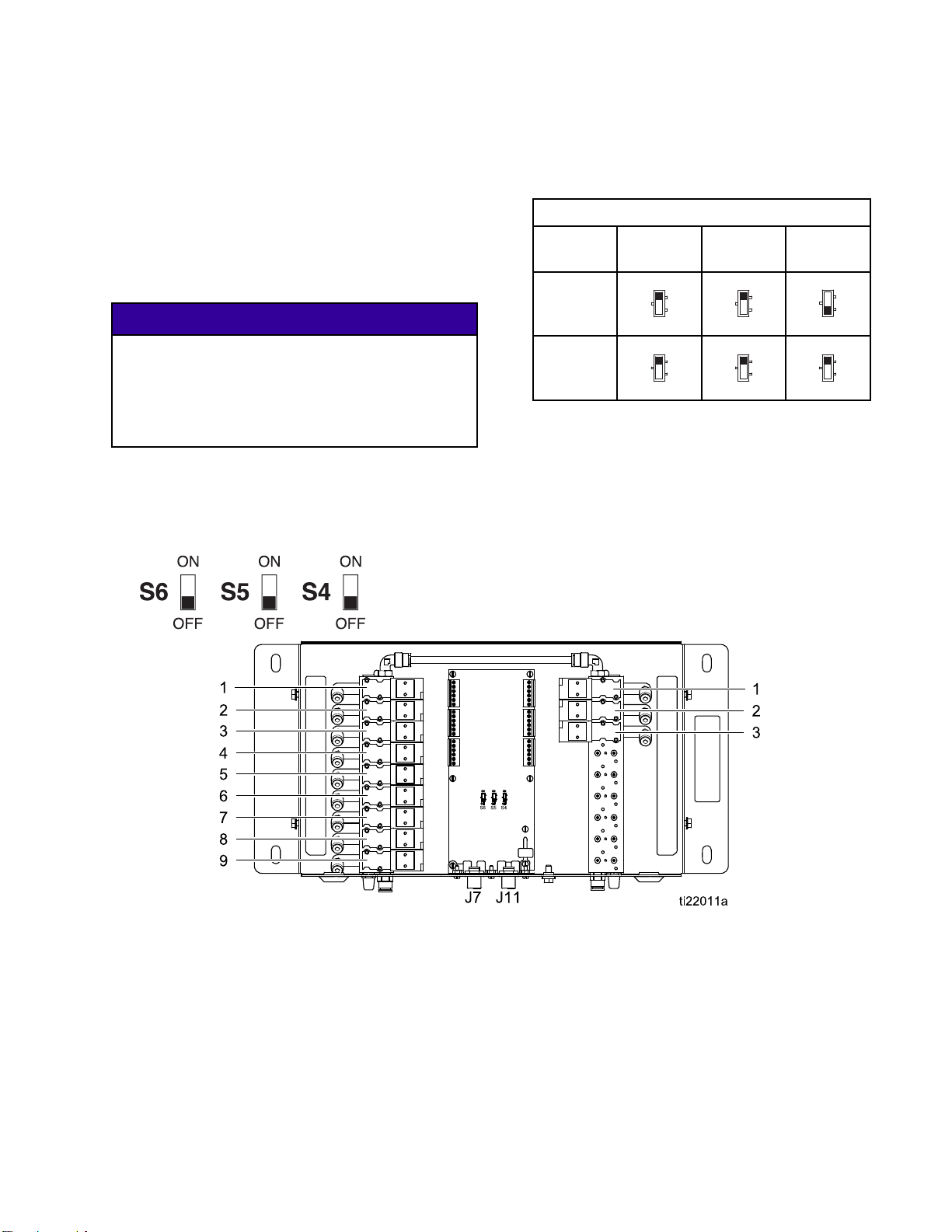

Setup IS Contr

ol Modules

NOTE: Two color change control modules may be

installed in the hazardous area. The modules are

labeled 7 or 8. An alternate label is provided with

the module kit for Module 8 (Colors 13–30). Affix the

label according to your system configuration.

Configure eac

number, as f

h module according to its designated

ollows:

NOTICE

To avoid dam

No. 112190

ground app

To avoid electrical component damage, remove all

system power before plugging any connectors.

1. Remove electrical power from the system.

2. Open the color change module. Locate switches

S4, S5, and S6 on the control module board. The

switches may be shipped in the OFF position.

aging the circuit boards, wear Part

grounding strap on your wrist and

ropriately.

3. For each module, set the switches to ON or OFF,

as shown in the following table.

IS Control Mod

Control

ule Switch Settings

S6 S5 S4

Module

Module 7

Module 8

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

4. Use the following figure and tables to determine

the solenoid valve assigned to each valve in the

valve manifold.

Figure 4 IS Control Module

332455F 15

Page 16

Setup the Module

s

Solenoid

1

2

3

4

5

6

7

8

9

IS Control Module 7

Valve

Color

Solvent

Color 1

Color 2

Color 3

Color 4

Color 5

Color 6

Color 7

Color 8

Solenoid

1

2

3

4

5

6

7

8

9

Valve

Catalyst

Solvent

Catalyst 1

Catalyst 2

Catalyst 3

Catalyst 4

Color 9

Color 10

Color 11

Color 1

2

Inlet Manifol

Solenoid

1

2

3

4

5

6

7

8

9

IS Control Module 8

d

Valve

Color 13

Color 14

Color 15

Color 16

Color 17

Color 18

Color 19

Color 2

Color 21

0

Solenoid

1

2

3

4

5

6

7

8

9

Outlet Manifo

Valve

Color 22

Color 23

Color 24

Color 25

Color 26

Color 27

Color 28

Color 2

Color 30

ld

9

16 332455F

Page 17

Installation

• To avoid electric shock, turn off power at

the main circuit breaker before opening the

enclosure.

Installation

3. Using the equipment as a template, mark the

mounting holes on the wall at a convenient height

for the operator and so the equipment is easily

accessible for maintenance.

4. Drill mounting holes in the wall. Install anchors

as needed.

• All electrical wiring must be done by a qualified

electrician and comply with all local codes and

regulations.

• Do not substitute or modify system components

as this may impair intrinsic safety.

• Do not install equipment approved only for

non-hazardous location in a hazardous location.

See the identification label for the intrinsic safety

rating for your model.

This equipment stays pressurized until pressure

is manually relieved. To help prevent serious

injury from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the

Pressure Relief Procedure in the PD2K Operation

Manual before installing the kit.

Mounting the Color Change Control Module

1. See Dimensions, page 66.

2. Ensure that the wall and mounting hardware

are strong enough to support the weight of the

equipment, fluid, hoses, and stress cause during

operation.

5. Bolt the equipment securely.

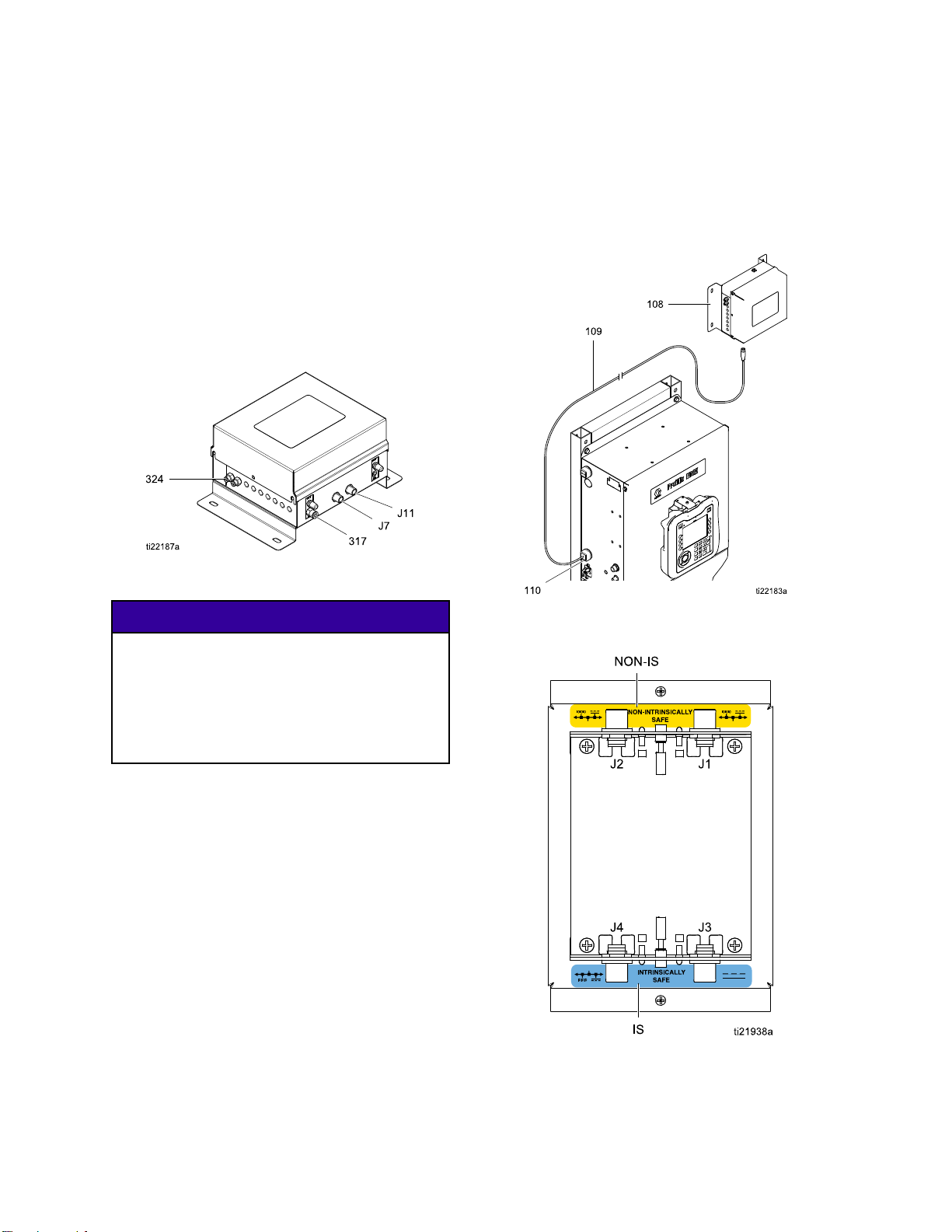

Air Supply

Connect a clean and dry air supply to the color

change control module air inlet fitting (317); the fitting

is for 1/4 in. (6 mm) OD tubing. Use a 5 micron filter.

Regulate the air pressure to 85–100 psi (0.6–0.7

MPa, 6.0–7.0 bar).

Grounding

This equipment must be grounded to reduce the

risk of static sparking and electric shock. Electric

or static sparking can cause fumes to ignite or

explode. Improper grounding can cause electric

shock. Grounding provides an escape wire for the

electric current.

Connect a ground wire from the color change module

to a true earth ground.

Intrinsically safe color change modules located in the

hazardous area must be connected to a true earth

ground in the hazardous area.

332455F

17

Page 18

Installation

Non-Hazardous Location

NOTE: Non-IS c

control for th

change valves

in the system,

be installed

1. Mount the first non-IS color control module as

described in Mounting the Color Change Control

Module, page 17.

2. Connect the 5–pin CAN cable (109) to J7 on the

color control module (108).

Figure 5 Cable Connector J7 at Non-IS Color

Control Module

olor change control modules provide

e pump’s inlet and outlet color/catalyst

. Depending on the number of valves

as many as six control modules may

in the non-hazardous location.

NOTICE

To avoid damaging the circuit boards, wear

Part No. 112190 grounding strap on your wrist

and ground appropriately.

of the previou

next control m

8. Replace the co

box before tur

Figure 6 Cable Connection at PD2K Electrical

Control Box

s color control module to J7 of the

odule.

ver of the PD2K electrical control

ning on power to the system.

To avoi

remove

conne

3. Remove electrical power from the system.

4. Remove the cover from the PD2K electrical

control box.

5. Install the supplied 2–cable grommet (110) on

the cable (109) and secure the grommet to the

side of the electrical control box.

6. Connect the cable (109) to J2 on the non-IS side

of the isolation board inside the electrical control

box. See Electrical Schematics, page 34 for a list

of M12 CAN cables for use in a non-hazardous

area.

7. To install additional color control modules (six

maximum), mount the module(s) as described

in Mounting the Color Change Control Module,

page 17. Connect a 5–pin CAN cable from J11

d electrical component damage,

all system power before plugging any

ctors.

Figure 7 Detail of Isolation Board Cable Connections

18 332455F

Page 19

Notes

Installation

332455F 19

Page 20

Installation

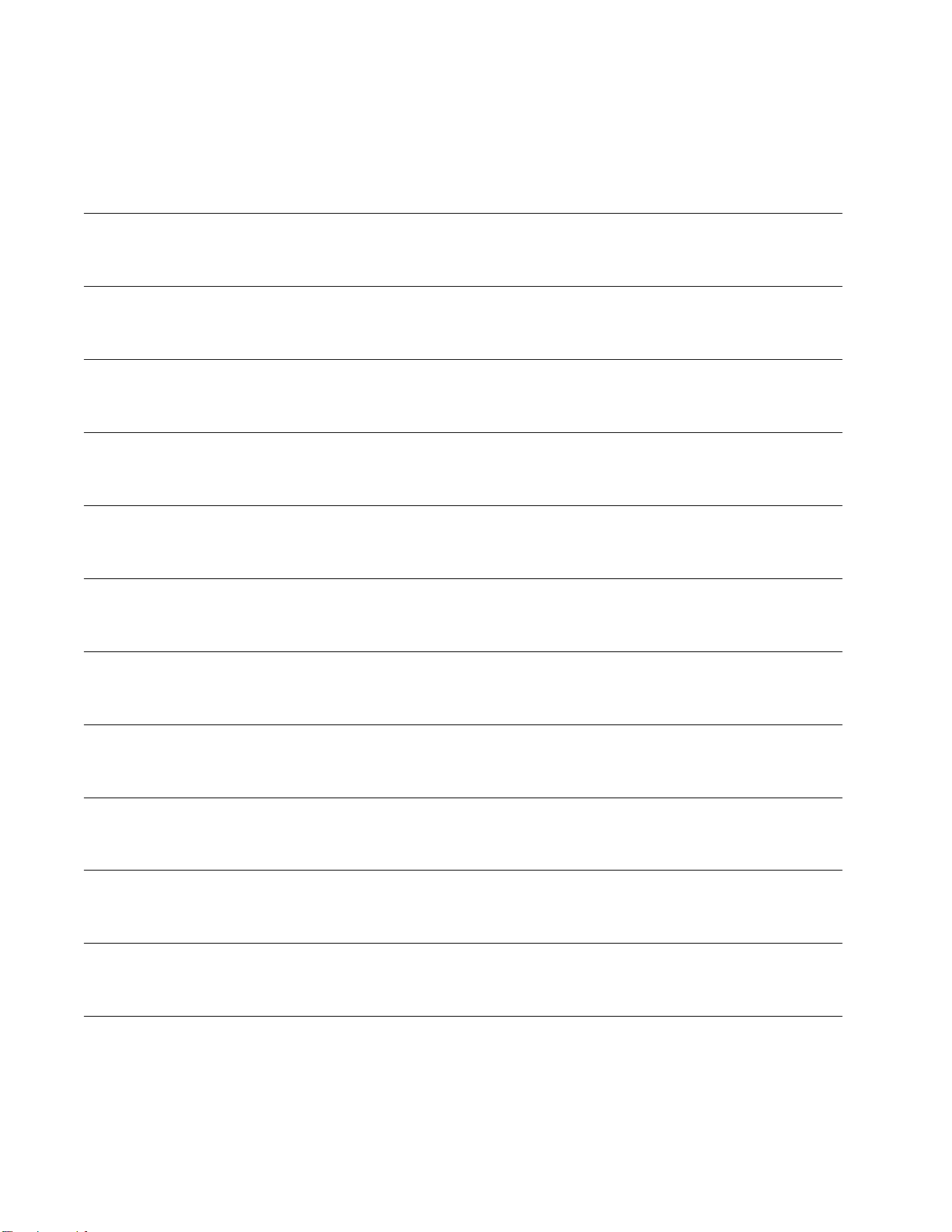

Hazardous Location

NOTE: IS color

control for co

hazardous loc

modules may be

See IS Color C

alistofmodu

hazardous lo

change control modules provide

lor/catalyst change valves located in the

ation. A maximum of two IS control

installed in the hazardous location.

hange Control Modules, page 62 for

les approved for installation in a

cation.

NOTICE

To avoid dam

No. 112190 g

ground appr

To avoid electrical component damage, remove all

system power before plugging any connectors.

Only approved cables may be used in the

hazardous location. Hazardous location cables are

marked with a light blue flag next to each connector.

See Optional Cables and Modules, page 40 for a

list of M12 CAN cables for use in a hazardous area.

1. Remove electrical power from the system.

2. Mount the first color control module as described

in Mounting the Color Change Control Module,

page 17.

aging the circuit boards, wear Part

rounding strap on your wrist and

opriately.

3. Connect the ha

on the color co

Figure 9 Cable Connectors J7 and J11 at IS

Color Control Module

4. Remove the cover from the PD2K electrical

control box. Install the grommet (G) on the

supplied cable (C1) and secure the grommet

to the side of the electrical control box. Locate

J4ontheISsideoftheisolationboardinthe

electrical control box. Connect the cable (C1) to

J4. See Electrical Schematics, page 34.

zardous location cable (C1) to J7

ntrol module (108).

Figure 10 Detail of Isolation Board Cable

Connections

Figure 8 Intrinsically Safe Cable Connections

20 332455F

Page 21

Installation

5. Mount a second color control module as

described in Mounting the Color Change

Control Module, page 17. Connect the supplied

hazardous location cable (C2) from J11 on the

first color control module to J7 on the second

module.

6. Replace the cover of the PD2K electrical control

box before turning on power to the system.

Install the

NOTE: Always label the color connections to prevent

cross-connections. Label the inlet manifold, outlet

manifold, and each color valve with its assigned color.

The solvent and dump valves should be furthest from

the manifold stack primary inlet or outlet.

1. Install a m

with four

For stabi

(103) to t

Valve Manifolds

ounting bracket (101) on the PD2K

screws (103). High pressure systems:

lity, be sure to fasten the bottom screws

he pump bracket.

2. Install the inlet and outlet valve manifolds (102)

on the mounting bracket (101) with four screws

(104), washers (105), and nuts (106).

NOTE: On low pressure systems, the supplied

bracket (101) will accommodate a manifold

with 16 valve positions (14 colors). On high

pressure systems, the supplied bracket (101) will

accommodate a manifold with 14 valve positions

(12 colors). A larger valve stack will require a

customer supplied/sourced bracket.

3. Repeat for the opposite side of the PD2K.

4. Connect the air lines from the solenoids to the

valves. See Connect the Valve Air Lines, page 23.

NOTE: On high pressure systems, see

Install the Back Pressure Regulator (High

Pressure Systems Only), page 23.

5. Connect the fluid supply lines to the valves. See

Connect the Fluid Lines, page 24.

332455F

Figure 11 Install the Valve Manifolds

21

Page 22

Installation

Notes

2

2

332455F

Page 23

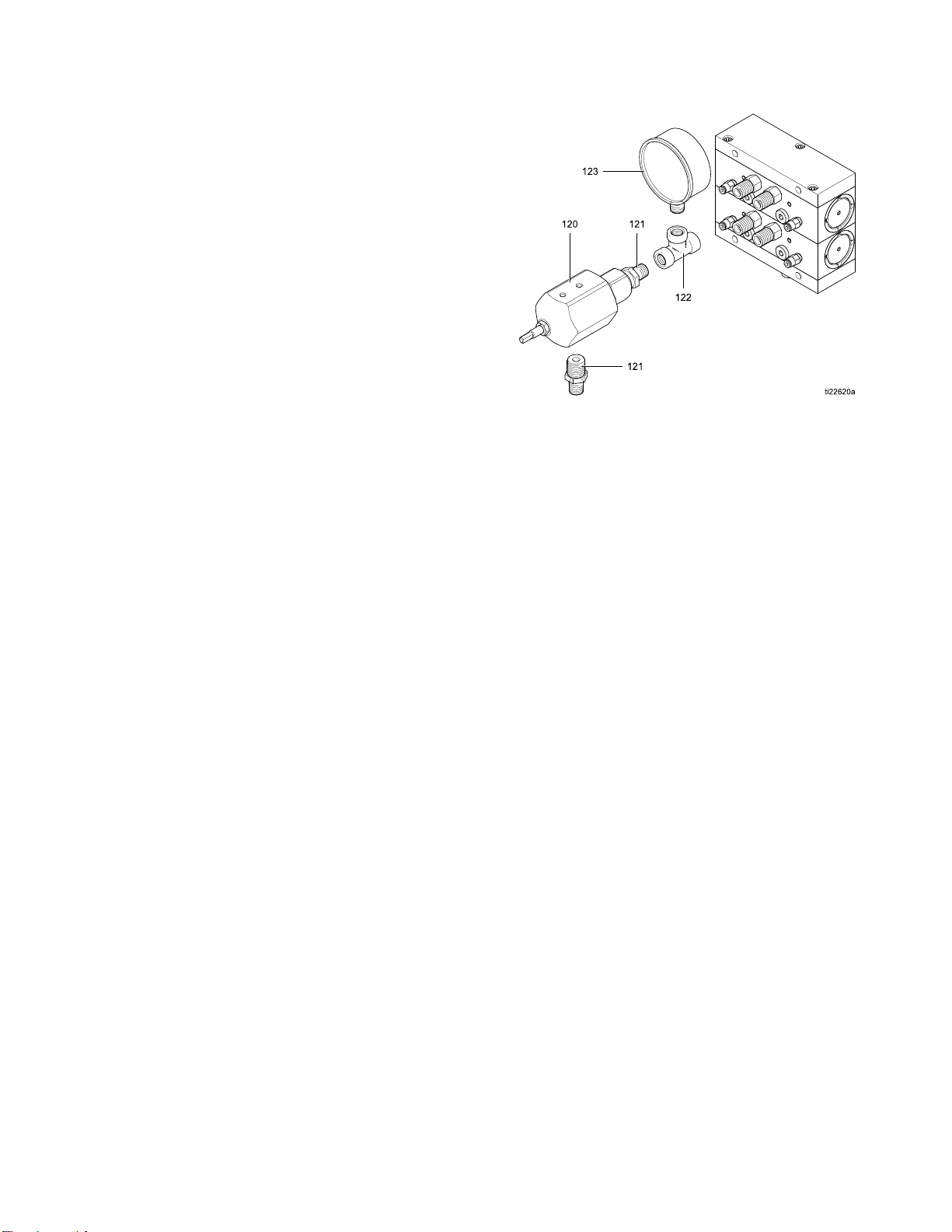

Install the Back Pressure Regulator (High Pressure Systems Only)

NOTE: The back pressure regulator is required on

high pressure systems to prevent the system’s feed

pumps from overdriving the dosing pumps during

color change pump flush and color fill operations.

Adjust the back pressure during the dump process to

be approximately 75% of the supply pressure from

the feed pumps, but never more than 300 psi (2.1

MPa, 21 bar) less than the supply pressure.

Install the back pressure regulator (120) and

attaching hardware at the dump valve of the outlet

manifold stack.

1. Screw the t

the outlet

ee (122) onto the dump valve fitting of

manifold stack.

Installation

Figure 12 Install Back Pressure Regulator at Dump

Valve of Outlet Stack

2. Assemble t

pressure

assembly

3. Install t

tee (122)

4. Connect

facing n

5. Connect

Connect

regulator (120). Screw the regulator

he gauge (123) in the open port of the

.

a 1/4 npt(f) dump line to the downward

ipple (121).

the fluid supply lines to the valves. See

the Fluid Lines, page 24.

he two nipples (121) to the back

Connect the Valve Air Lines

into the tee (122) as shown.

1. Connect 5/32 in. (4 mm) OD air tubes from the

inlet solenoids to the air inlets of each inlet valve,

using the label inside the color control module as

a guide. See Setup the Modules, page 12.

2. Repeat for the outlet valves.

332455F 23

Page 24

Installation

Connect the Fl

uid Lines

Connect Non-Circulating Fluid Lines

NOTE: There can be only one solvent valve (S) and

one dump valve (D) per pump.

NOTE: On high

Install the

Systems Onl

1. Use the top valve of the inlet valve stack as the

solvent valve (S). Connect a solvent supply line

to the 1/4 npt(m) solvent valve inlet on the color

and catalyst valve stacks.

pressure systems, see

Back Pressure Regulator (High Pressure

y), page 23.

INLET COLOR VALVE STACK OUTLET COLOR VALVE STACK

2. Usethetopvalveoftheoutlet valve stack as the

dump valve (D). Connect a waste dump line to

the 1/4 npt(m) dump valve outlet on the color and

catalyst valve stacks.

3. Connect the supply line for each color to the

corresponding color valve fitting (C1, C2, etc.) on

the inlet color valve stack.

4. Connect a supply line from the bottom fitting of

the inlet color valve stack to the inlet manifold of

the material A dosing pump.

5. Connect a supply line from the outlet manifold of

the material A dosing pump to the bottom fitting

of the outlet color valve stack.

Valve Manifold Stack Schematic

4

2

332455F

Page 25

6. Connect a dedicated gun supply line for each

color to the corresponding color valve fitting (C1,

C2, etc.) on the outlet color valve stack. Connect

theotherendofthislinetotheAsideofthemix

manifold at the gun.

7. Connect the supply line for each catalyst to the

corresponding catalyst valve fitting on the inlet

catalyst valve stack.

8. Connect a supply line from the bottom fitting of

the inlet catalyst valve stack to the inlet manifold

of the material B dosing pump.

Installation

9. Connect a supply line from the outlet manifold of

the material B dosing pump to the bottom fitting

of the outlet catalyst valve stack.

10. Connect a dedicated gun supply line for each

catalyst to the corresponding catalyst valve fitting

on the outlet catalyst valve stack. Connect the

other end of this line to the B side of the mix

manifold at the gun.

NOTE: If your system uses more colors than

catalysts, branch the catalyst line to connect it to

each mix manifold. Install a check valve on each

branch of the catalyst line.

NOTE: For ease of maintenance, install a ball

valve at all fluid line tees.

11. The mix manifold is belt-mounted. Connect a

fluid hose between the manifold outlet and the

gun inlet.

Figure 13 Color Change Connections

(Non-Circulating System)

KEY

A Air inlet

W

S Solvent fitting

C1 Color 1 fi

C2 Color 2 fitting

Seal weep and

lubrication port

tting

332455F 25

Page 26

Installation

Connect Circulating Fluid Lines

Circulation valves enable constant circulation of a

color when that color is not being sprayed:

•Whenacolorva

the dosing pum

inlet color v

a circulatio

manifold, th

• When a color v

shut off. Th

A dosing pum

sprayed, as

NOTE: There can be only one solvent valve (S) and

one dump valve (D) per pump.

NOTE: On high pressure systems, see

Install the Back Pressure Regulator (High Pressure

Systems Only), page 23.

1. Connect a

Connect N

These lin

spraying

2. Connect

a. Connect a 1/4 npt(f) circulation line for each

color from the color valve’s circulation fitting

(R1, R2, etc.) on the inlet color valve stack

(B) to the corresponding circulation fitting

(R1, R2, etc.) on the outlet color valve

stack (C). This circulation line bypasses the

material A dosing pump when the color valve

is closed, allowing continuous circulation of

that color.

b. Install a Y fitting (D) in the A side of the mix

manifold (F). Install a fluid shutoff valve (E)

in one branch of the Y fitting. Connect a fluid

lve is closed, the system bypasses

p by directing that color from the

alve to the outlet color valve through

n line, then to a Y fitting at the mix

en back to the color supply.

alve is open, the circulation line is

e color is directed through the material

p and out to the gun to be mixed and

in normal operation.

ll fluid lines as described in

on-Circulating Fluid Lines, page 24.

es are used during normal mixing and

.

the circulation lines as follows:

return line (H) to the shutoff valve, to circulate

the color back to the color supply (A).

NOTE: The fluid shutoff valve (E) must be

closed when spraying, to allow proper ratio

mixing and flow from the gun (G).

c. Connect a dedicated gun supply line for

each color to the corresponding color valve

(C1, C2, etc.) on the outlet color valve stack.

Connect the other end of this line to the open

branch of the Y fitting (D).

Figure 14 Valve Manifold Connections (Circulating

System)

KEY

SSolven

C1 Color 1 fitting

C2 Color 2 fitting

R1

R2

Colo

Color 2 circulation fitting

tfitting

r 1 circulation fitting

26 332455F

Page 27

Fluid Flow Schematic Diagram in Circulating Mode (Pump Not Shown for Clarity)

Installation

KEY

A

B Inlet color stack

C Outlet color stack

D

Color supply

Y fitting at mix manifold

Aport

KEY

E

F

G Spray gun

H

Fluid shutoff valve

Mix manifold

Returnlinetofluid

supply

332455F

27

Page 28

Installation

Install an Expansion Kit

Expansion Kits are available to add

valves or manifolds to your system. See

Expansion Kits, page 64 for available kits.

1. Remove elect

2. Relieve pres

Operation M

3. Open the con

solenoid(s

position(

Setup the M

of the tubi

4. Connect th

pins on th

Electric

NOTE: If i

necessar

shownint

step 6.

5. If your k

the scre

the rods

t order. Install the new manifold block (1).

correc

The new

in correct location of the solvent and dump

mainta

. Screw the rods (16) included in the kit

valves

e existing rods. Slide the existing manifold

into th

s onto the rods, being sure that they are in

block

me positions as before. Ensure all o-rings

the sa

) are in place, then install the screws (10).

(6, 17

rical power from the system.

sure as described in your PD2K

anual.

trol module cover. Install the

) and air fitting(s) at the appropriate

s) in the solenoid manifold. See

odules, page 12. Connect one end

ng to the solenoid’s air fitting.

e solenoid wires to the appropriate

e control module board. See

al Schematics, page 34.

nstalling a one valve kit, it is not

y to disassemble the manifold stack as

he figure. Skip step 5 and go on to

it is adding a manifold block (1), remove

ws (10). Slide the existing manifolds off

(15, 16), keeping the manifolds in the

block must be in the bottom position to

6. Install the valves as follows:

a. For a one valve kit, remove the plug

(4) and o-ring (2). Install a new o-ring

(2), the valve (3), and retainer (5),

using the valve installation tool. See

Replace a Color Valve, page 41.

b. For a manifold kit with one valve, install

the o-ring (2), valve (3), and retainer (5),

using the valve installation tool. See

Replace a Color Valve, page 41.Installthe

plug (4) in the unused manifold port.

c. For a manifold kit with two valves, install

the o-rings (2), valves (3), and retainers

(5), using the valve installation tool. See

Replace a Color Valve, page 41.

7. Install the o-ring(s) (12) and fluid fitting(s) (13).

Connect fluid lines to the fittings.

8. Install the air fitting(s) (14). Connect the tubing

from the solenoid valve(s) (see step 3) to the

fitting(s).

9. Install the control module cover.

10. Return the unit to service.

28 332455F

Page 29

Installation

Install an Exp

ansion Kit (Low Pressure

Valve Manifold Shown)

Non-Circul

ating

Circulating

332455F 29

Page 30

Troubleshootin

g

Troubleshooting

NOTE: Check all possible remedies before disassembling the system.

Color Chang

NOTE: Refer to Electrical Schematics, page 34. If the color change valves are not turning on or off correctly, it

could be caused by one of the following.

Cause Solution

1. Air regulator pressure

set too high or too low.

2. Airore

damaged o

are loos

3. Solenoid failure. Check the applicable solenoid’s LED; see Color Change Board, page 32. If lit,

e.

e Solenoid Valves

Check that air pressure is at least 85 psi (0.6 MPa, 6.0 bar). Do not go above 100

psi (0.7 MPa, 7.0 bar).

lectrical lines

r connections

Visually inspect air and electrical lines for kinks, damage, or loose connections.

Service or replace as needed.

proceed with the following checks. If not lit, go to Cause 4.

Remove

the pin

• In a non-hazardous location, replace the solenoid if voltage is 24 Vdc.

• In a hazardous location, replace the solenoid if voltage is between 9–15 Vdc.

Test the valves as explained under Maintenance Screen 4 in your PD2K

Operation manual. Valves should open and close quickly. If the valves actuate

slowly, it could be caused by:

•Airp

the connector for the applicable solenoid and measure voltage across

s on the board:

ressuretothevalveactuatorsistoolow. SeeCause1.

•Sole

•Some

noid is clogged. Make sure the air supply has a 5 micron filter installed.

thing is restricting the solenoid or tubing. Check for air output from the

ine for the corresponding solenoid when the valve is actuated. Clear the

air l

triction.

res

30 332455F

Page 31

Cause Solution

Troubleshootin

g

4. Control boa

failure.

rd or cable

Ifthereisnov

LEDs D8, D9, an

in the module a

If D9 is not lit:

• Verify the condition of the fuse (F1) and replace if necessary. See

Replace the Color Change Board Fuse, page 42.

• Check if the cable is disconnected or damaged.

• Check the isolation board. See the PD2K Repair-Parts manual.

If D8 is not b

• Cycle the system power.

• Check if the cable is disconnected or damaged.

• Check the isolation board. See the PD2K Repair-Parts manual.

If D10 is not occasionally blinking:

• Check if t

• Check the

oltage across the pins on the board or it is less than 9 Vdc, check

d D10. If they are lit and functioning properly, or other solenoids

re working properly, replace the color change board.

linking:

he cable is disconnected or damaged.

isolation board. See the PD2K Repair-Parts manual.

332455F 31

Page 32

Troubleshootin

g

Color Change B

oard

NOTICE

To avoid damaging the circuit boards, wear Part

No. 112190 grounding strap on your wrist and

ground appropriately.

To avoid electrical component damage, remove all

system power before plugging any connectors.

Figure 15 Color Change Board

32 332455F

Page 33

Color Change Board Diagnostics

Troubleshootin

g

Component or

Indicator

D8

D9

D10

D27–D39,

D41, D43–D46

F1 Fuse, 0.12

Description Diagnosis

LED (green) Blinks (heartbeat) during normal operation.

LED (green)

LED (yellow)

LED (green)

5A,125V

Turns on when

board.

Turns on when board is communicating with

electronic control.

Turn on when a signal is sent to actuate the

related solenoid valve.

power is supplied to the

332455F 33

Page 34

Electrical Sche

matics

Electrical Sc

hematics

NOTE: The electrical schematic illustrates all possible

wiring expansions in a ProMix PD2K system. Some

components shown are not included with all systems.

NOTE: See Optional Cables and Modules, page 40,

for a list of cable options.

RELAY

(16U820)

16W159

BREAKOUT MODULE PUMP 2

BREAKOUT MODULE PUMP 4

POWER MODULE

(24R257)

16W159

16W159

(24N527)

(24N527)

SPLITTER

(16P243)

4

CABLE (16T659)

CABLE (16T659)

CABLE (16T659)

CABLE (16T659)

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

POWER IN

FAN

FAN

2 POSITION

SWITCH

(16U725)

CABLE

16T658

LINE FILTER

(16V446)

CABLE

16H078

TERMINAL BLOCK

(114095)

BREAKOUT MODULE PUMP 1

BREAKOUT MODULE PUMP 3

24V

POWER

SUPPLY

(16T660)

(24N527)

(24N527)

48V-10A POWER SUPPLY

TERMINAL BLOCKS WITH FUSES

16W159

FAN

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

FAN

(24P658)

ENCODER AND MOTOR

(16P036, 16P037)

WIRE HARNESS

(24P684, 24P685)

PUMP INLET

TRANSDUCER

(16P289, 16P290)

PUMP OUTLET

TRANSDUCER

(16P289, 16P290)

PUMP V/P FOR

FLUID REG.

UP

DOWN

(16P812)

SOLENOID

MAC SERIES 46

FLOW SENSOR

(120278)

OR G3000 METER

(239716, 258718

16M510, 16M519)

Figure 16 Electrical Schematic, Sheet 1

COMMUNICATION

MODULE

(24R910)

3

COMMUNICATION

CABLE (15V206)

MODULE

(24R910)

2

CABLE

3

16T072

CAN

IS BOARD

(24M485)

CABLE

(16T280)

BARRIER

BOARD

(248192)

065161, 065159

5

CABLE

(121227)

5

(121227)

CABLE

3

(121227)

6

(24N935)

MODULE 1

COLOR CHANGE

CABLE

2

(15V206)

GCA

MODULE

EFCM

(24N913)

FLOW RATE ANALOG IN

FLOW RATE ANALOG IN

1

CABLE (16V429)

2

CABLE

(15V206)

6

(24N935)

MODULE 2

COLOR CHANGE

FLOW RATE ANALOG IN

FLOW RATE ANALOG IN

2

CABLE

(15V206)

6

6

6

(24N935)

(24N935)

MODULE 3

COLOR CHANGE

COLOR CHANGE

CABLE

2

(15V206)

GUN TRIGGER INPUTS

119159

119159

119159

119159

SOLENOID (121324)

PRESSURE SWITCH

(121323)

SOLVENT FLOW SWITCH (120278)

SOLVENT METER (258718)

3

ADVANCED

CABLE

DISPLAY MODULE

(121003)

(24E451)

CABLE

1

(24N935)

MODULE 4

MODULE 5

CATALYST CHANGE

CABLE

2

(15V206)

COLOR CHANGE MODULE 7

(24R219)

COLOR CHANGE MODULE 8

(24R219)

(16V426)

BOOTH CONTROL (24M731)

HAZARDOUS LOCATION

NON-HAZARDOUS LOCATION

6

(24N935)

MODULE 6

CATALYST CHANGE

GFB

INTERFACES

LIGHT

TOWER

(15X472)

CABLE

1

(16V426)

7

7

34 332455F

Page 35

Electrical Sche

matics

POWER

SUPPLY

(16T660)

L (BROWN)

N03 N03

2 POSITION

SWITCH

(16U725)

N04 N04

CABLE

(16T658)

L N

LINE

FILTER

(16V446)

L GRND N

CABLE

(16H078)

L N GRND

TERMINAL

BLOCK

(114095)

L N GRND

24V

GRND (GRN/YEL)

N (BLUE)

CABLE (16V429)

1

SPLITTER

(16P243)

2

345

1

UNUSED

UNUSED

UNUSED

13 A1(+) A2(-)

RELAY

14

N L GRND

48V-10A

POWER SUPPLY

(16U820)

+ -

+ - + - + - + -

F4

F3

F2

F1

+ - + - + - + -

DETAIL A, LOW PRESSURE

PUMPS (24M706, 24M714)

BREAKOUT MODULE

(24N527)

2

1 2 3 4 5 1 2 3 4

WIRE HARNESS

(24P684)

CONTINUED ON PAGE 3

2

CABLE

(15V206)

1 2 3 4 5

CAN IS BOARD

2

(NON IS)

(IS)

4

(24M485)

1 2 3 4 5

1

UNUSED

2

3

RED WIRE (065161)

BLACK WIRE (065159)

1 2 3 4 5 1 2 3 4

(24R257)

POWER MODULE

3

DRAIN/FOIL

CABLE (121227)

3

16T072

1 2 3 4 5

CABLE

1

1

2

2

3

3

4

4

5

5

(121227)

1

UNUSED

5

COMM MODULE (24R910)

GFB

INTERFACE

SOLVENT CUTOFF

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

SOLVENT

METER

(258718)

GROUND BAR

1 2 3 4 5

CABLE

(16T280)

1 2 3

BARRIER

BOARD

(248192)

3

UNUSED

BREAKOUT MODULE PUMP 1 (24N527)

2

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 1

SEE DETAIL A OR B

3

1 2 3 4 5 1 2 3 4 5 1 2

TWISTED PAIR CABLE (16W159)

5

4

PUMP 1

PUMP 1

(16P289 OR 16P290)

INLET TRANSDUCER

OUTLET TRANSDUCER

DETAIL B, HIGH PRESSURE

PUMPS (24M707, 24M715)

BREAKOUT MODULE

2

1 2 3 4 5 1 2 3 4

1

2

3

4

5

3

5

6

1 2 3 4

PUMP 1

(16P289 OR 16P290)

V/P FOR FLUID REG.

(24N527)

WIRE HARNESS

(24P685)

UNUSED

5

UNUSED

4

3

10

2

UNUSED

1

CABLE

1

2

3

4

5

3

(121227)

1

2

3

8

4

5

COMM MODULE (24R910)

+12VDC

COM

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

UNUSED

1

2

3

4

5

6

5

7

8

9

10

11

12

25 PIN D-SUB CABLE

1

7

3 4

5 6 7 8

COM

COM

+24VDC

+24VDC

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

UP

DOWN

PUMP 1

PUMP 1

MANIFOLD

G3000

METER

PUMP 1

(EITHER, 239716,

258718,16M510,

OR 16M519)

(16P812 QTY 2)

MAC SERIES 46

SCREW

GRND

3

DRAIN/FOIL

(16T659)

1 2 3 4

+48V

COM

CONTINUED ON PAGE 3

GCA MODULE

EFCM

(24N913)

12

4

252423222120191817161413121110 15987654321

BREAKOUT MODULE PUMP 2 (24N527)

2

1 2 3 4 5 1 2 3 4

+48V

COM

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 2

SEE DETAIL A OR B

(24P658)

FAN PUMP 1

252423222120191817161413121110 15987654321 252423222120191817161413121110 15987654321

3

1 2 3 4 5 1 2 3 4 5 1 2

4

PUMP 2

(16P289 OR 16P290)

INLET TRANSDUCER

5

PUMP 2

OUTLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

6

1 2 3 4

PUMP 2

(16P289 OR 16P290)

V/P FOR FLUID REG.

25 PIN

(16T659)

D-SUB CABLE

4

1

3 4

COM

COM

+24VDC

+24VDC

UP

DOWN

PUMP 2

PUMP 2

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

7

5 6 7 8

G3000

METER

PUMP 2

(EITHER, 239716,

258718,16M510,

OR 16M519)

PWR (RED)

SIG (WHITE)

COM (BLACK)

SHIELD/GRN

GRND

SCREW

1 2 3 4

+48V

88

COM

+48V

FAN PUMP 2

252423222120191817161413121110 15987654321

COM

(24P658)

DRAIN/FOIL

UNUSED UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED UNUSED

UNUSED

UNUSED UNUSED

POWER IN

UNUSED

UNUSED

DRAIN/FOIL

1 2 3 4 5 6 7 8 9

PUMP ENCODER AND MOTOR

MOTOR

MOUNTING

SCREW

UNUSED

UNUSED UNUSED

UNUSED

12

11

10

(16P037)

UNUSED

UNUSED

1 2 3 4 5 6 7 8 9

UNUSED

UNUSED UNUSED UNUSED

UNUSED

12

11

1 2

MOTOR

MOUNTING

SCREW

1 2 3 4 5 6 7 8 9

PUMP ENCODER AND MOTOR

10

10

(16P036)

1 2 3 4 5 6 7 8 9

UNUSED

10

Figure 17 Electrical Schematic, Sheet 2, Part 1

TINUED ON THE NEXT PAGE

CON

332455F 35

Page 36

Electrical Sche

matics

GUN TRIGGER INPUTS

SIG

1

COM

2

SIG

3

COM

4

SIG

5

COM

6

6

7

SIG

8

COM

9

SIG

10

COM

11

SIG

12

1

2

3

4

5

6

7

7

8

9

10

11

12

1

2

3

9

4

5

COM

FLOW RATE ANALOG IN 1

FLOW RATE ANALOG COMMON 1

FLOW RATE ANALOG IN 2

FLOW RATE ANALOG COMMON 2

FLOW RATE ANALOG IN 3

FLOW RATE ANALOG COMMON 3

FLOW RATE ANALOG IN 4

FLOW RATE ANALOG COMMON 4

UNUSED

UNUSED

UNUSED

UNUSED

CABLE

(121003)

3

GCA MODULE

EFCM

(24N913)

34

252423222120191817161413121110 15987654321 252423222120191817161413121110 15987654321

119159

GFB PRESSURE SWITCH (121323)

SOLVENT FLOW SWITCH (120278)

1

ADVANCED

2

DISPLAY MODULE

3

4

(24E451)

5

1

2

3

4

5

LIGHT

TOWER

(15X472)

25 PIN

(16T659)

D-SUB CABLE

4

1

BREAKOUT MODULE PUMP 3 (24N527)

3

2

1 2 3 4 5 1 2 3 4 1 2 3 4 5 1 2 3 4

ENCODER/MOTOR

WIRE HARNESS

PUMP 3

SEE DETAIL A OR B

1 2 3 4 5 1 2 3 4 5 1 2

AND

4

PUMP 3

(16P289 OR 16P290)

INLET TRANSDUCER

5

PUMP 3

(16P289 OR 16P290)

OUTLET TRANSDUCER

1 2 3 4

TWISTED PAIR CABLE (16W159)

e18 ElectricalSchematic,Sheet2,Part2

Figur

CONTINUED ON THE NEXT PAGE

252423222120191817161413121110 15987654321

6

PUMP 3

V/P FOR FLUID REG.

3 4

COM

+24VDC

+24VDC

UP

PUMP 3

PUMP 3

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

COM

DOWN

7

5 6 7 8

G3000

METER

PUMP 3

(EITHER, 239716,

258718,16M510,

OR 16M519)

PWR (RED)

SIG (WHITE)

COM (BLACK)

SCREW

25 PIN D-SUB CABLE

8

1 2 3 4

+48V

+48V

COM

SHIELD/GRN

FAN PUMP 3

GRND

COM

(24P658)

(16T659)

2

SEE DETAIL A OR B

4

ENCODER/MOTOR

AND

WIRE HARNESS

PUMP 4

5

PUMP 4

(16P289 OR 16P290)

OUTLET TRANSDUCER

252423222120191817161413121110 15987654321

6

1 2 3 4

PUMP 4

V/P FOR FLUID REG.

3 4

COM

+24VDC

+24VDC

UP

PUMP 4

PUMP 4

MANIFOLD

(16P812 QTY 2)

MAC SERIES 46

7

COM

DOWN

1

BREAKOUT MODULE PUMP 4 (24N527)

3

4

1 2 3 4 5 1 2 3 4 5 1 2 1 2 3 4

PUMP 4

(16P289 OR 16P290)

INLET TRANSDUCER

TWISTED PAIR CABLE (16W159)

5 6 7 8

PWR (RED)

SIG (WHITE)

G3000

METER

PUMP 4

(EITHER, 239716,

258718,16M510,

OR 16M519)

+48V

COM (BLACK)

SHIELD/GRN

GRND

SCREW

COM

8

+48V

COM

(24P658)

FAN PUMP 4

36 332455F

Page 37

Electrical Sche

matics

FLUSH

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

*FLUSH

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 13

COLOR 14

COLOR 15

COLOR 16

CABLE (15V206)

2

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

2

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

FROM CAN IS BOARD (24M485) ON PAGE 2

2

345

1

COLOR

CHANGE

MODULE 1

(COLORS

1

+12VDC

2

COM

3

+12VDC

J9

4

COM

5

+12VDC

6

COM

1

+12VDC

2

COM

3

+12VDC

4

COM

5

+12VDC

6

COM

1

+12VDC

2

COM

3

+12VDC

4

COM

5

+12VDC

6

COM

J8

J15

J14

1 THRU 8)

6

2

345

1

J16

J10

CABLE

J8

J15

J14

2

345

1

COLOR

CHANGE

MODULE 2

(COLORS

9 THRU 16)

6

2

345

1

J16

J10

J9

(15V206)

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

MANIFOLD

MANIFOLD

DUMP

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

DUMP*

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 13

COLOR 14

COLOR 15

COLOR 16

FLUSH

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

FROM CAN IS BOARD (24M485) ON PAGE 2

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CATALYST

CHANGE

MODULE 5

(CATALYST

1 THRU 4)

J8

J15

J14

2

1

6

345

J16

J10

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

1

2

3

J9

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

2

*FLUSH

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

CABLE

1

17 THRU 24)

2

3

4

J8

5

6

1

2

3

J15

4

5

6

1

2

3

J14

4

5

6

2

345

1

COLOR

CHANGE

MODULE 3

(COLORS

6

2

4

5

3

J9

J16

J10

1

(15V206)

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

Figure 19 Electrical Schematic, Sheet 3

* May be unused in some configurations.

CONTINUED ON THE NEXT PAGE

MANIFOLD

DUMP*

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

COLOR 22

COLOR 23

COLOR 24

2

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

CABLE (15V206)

*FLUSH

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

22

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CABLE

2

345

1

COLOR

CHANGE

MODULE 4

(COLORS

25 THRU 32)

J8

6

J15

J14

2

345

1

J9

J16

J10

(15V206)

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP*

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

332455F 37

Page 38

Electrical Sche

matics

CATALYST 3

CATALYST 4

CATALYST 1

CATALYST 2

FLUSH

FLUSH

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

22

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

CATALYST

CHANGE

MODULE 6

(CATALYST

3 THRU 4)

J8

J15

J14

2

1

CABLE

5

4

CATALYST

CHANGE

MODULE 5

(CATALYST

1 THRU 2)

J8

J15

J14

2

1

6

345

2

3

6

J16

345

J9

J16

J10

1

J9

J10

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

(15V206)

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

+12VDC

COM

+12VDC

COM

+12VDC

COM

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

UNUSED

MANIFOLD

DUMP

CATALYST 3

CATALYST 4

MANIFOLD

DUMP

CATALYST 1

CATALYST 2

Figure 20 Electrical Schematic, Sheet 3, Alternate

Configuration for Catalyst Change Control

INUED ON THE NEXT PAGE

CONT

2

CABLE

2

345

1

COLOR

CHANGE

MODULE 4

(COLORS

25 THRU 32)

(15V206)

38 332455F

Page 39

FROM CAN IS BOARD (24M485) ON PAGE 2

Electrical Sche

matics

COLOR FLUSH

COLOR 1

COLOR 2

COLOR 3

COLOR 4

COLOR 5

COLOR 6

COLOR 7

COLOR 8

COLOR 13

COLOR 14

COLOR 15

COLOR 16

COLOR 17

COLOR 18

COLOR 19

COLOR 20

COLOR 21

MANIFOLD

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

1

2

3

4

5

6

1

2

3

J15

4

5

6

1

2

3

4

J14

5

6

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

2

345

1

COLOR

CHANGE

MODULE 7

(COLORS

33 THRU 40)

J8

7

2

345

1

CABLE

2

345

1

COLOR

CHANGE

MODULE 8

(COLORS

41 THRU 48)

J8

7

J15

J14

5

3

4

J16

J10

J16

J10

2

J9

J9

1

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

(16V426)

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

NON-HAZARDOUS LOCATION

HAZARDOUS LOCATION

MANIFOLD

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

+12VDC

COM

MANIFOLD

CATALYST FLUSH

CATALYST 1

CATALYST 2

CATALYST 3

CATALYST 4

COLOR 9

COLOR 10

COLOR 11

COLOR 12

COLOR 22

COLOR 23

COLOR 24

COLOR 25

COLOR 26

COLOR 27

COLOR 28

COLOR 29

COLOR 30

1

re 21 Electrical Schematic, Sheet 3, Hazardous

Figu

ation

Loc

CABLE

5

BOOTH CONTROL

3

4

(24M731)

2

(16V426)

1

332455F 39

Page 40

Electrical Sche

matics

Optional Cabl

NOTE: Thetotallengthofallcableusedinthesystemmustnotexceed150ft(45m). See the

Electrical Schematics, page 34.

M12 CAN Cables

NOTE: The total length of cable used in the

hazardous location must not exceed 120 ft (36 m).

Cable Part N

16V423

16V424

16V425

16V426

16V427

16V428

16V429

0

16V43

M12 CA

es and Modules

, for Hazardous Locations

o.

N Cables, for Non-Hazardous

Loca

Length ft (m

2.0 (0.6)

3.0 (1.0)

6.0 (2.0)

10.0 (3.0)

15.0 (5.0)

25.0 (8

50.0 (16.0)

100.0 (32.0)

tions Only

.0)

CAN Cables, fo

Locations On

Cable Part No. Length ft (m)

)

125306

123422

121000