Page 1

Instructions

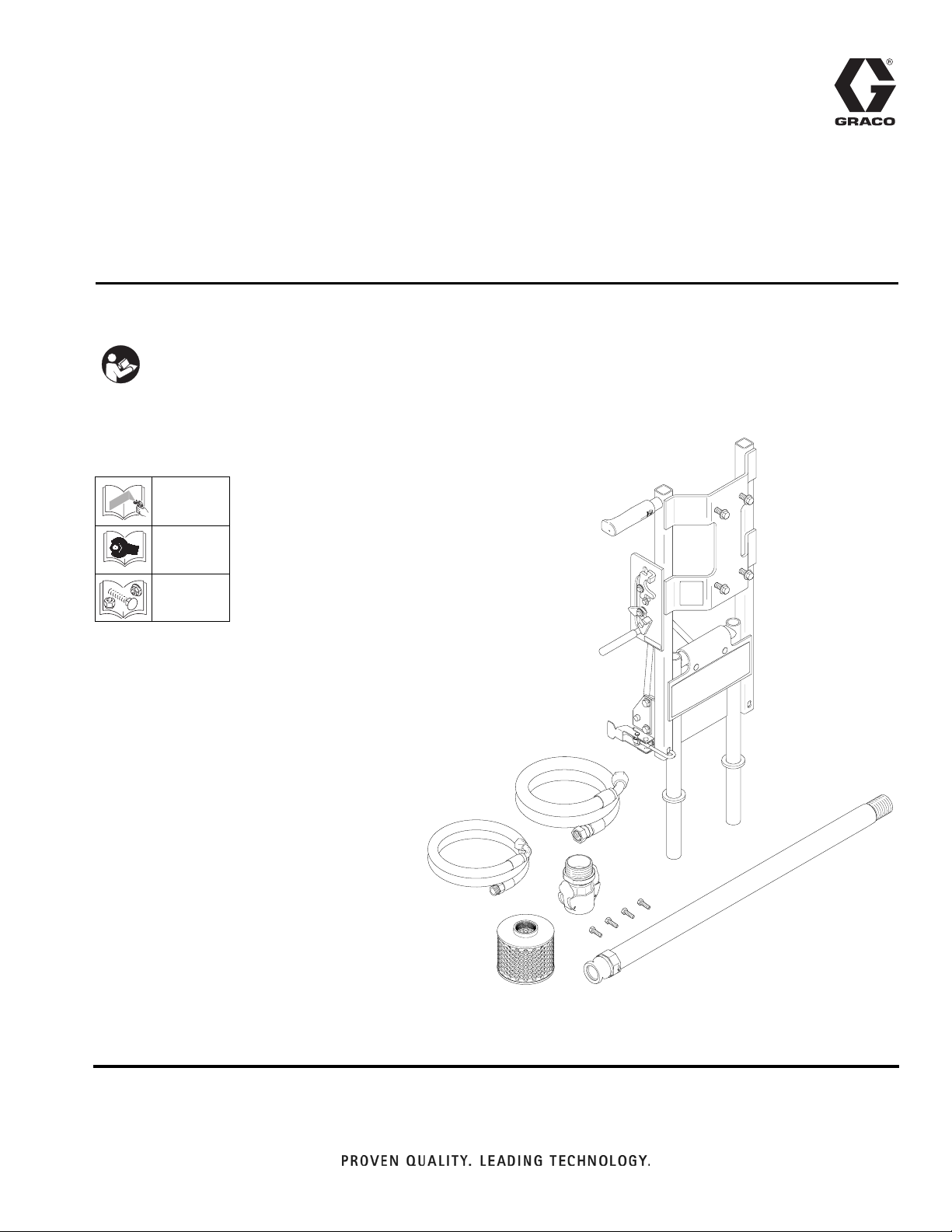

Direct Immersion Kit 16U764 for 2570

- For installation of tower/bracket -

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

2570ES Models: Refer to operation manual below.

Before attempting to install kit,

follow Pressure Relief Procedure

332156

332157

332158

ES

332235A

EN

ti21168a

Page 2

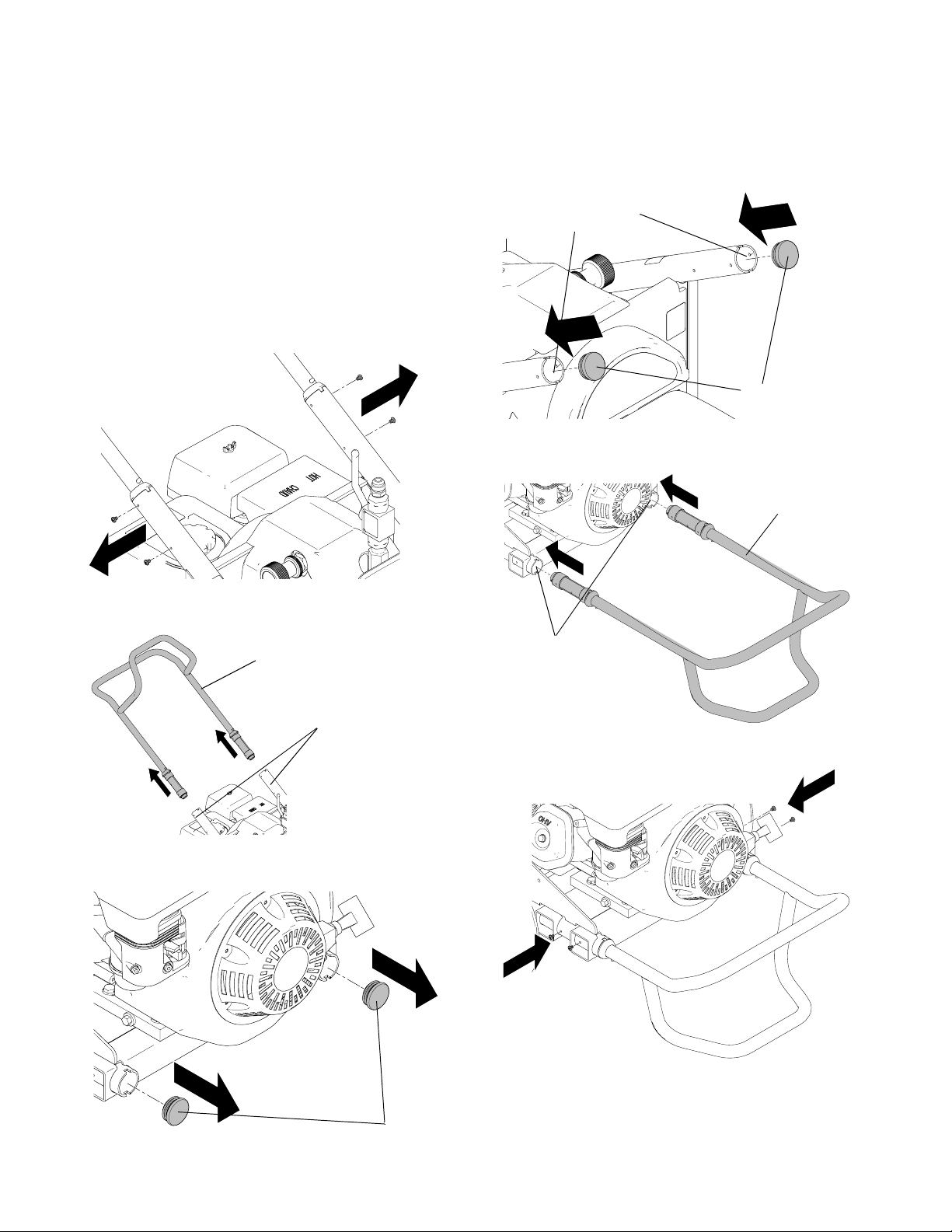

Fixed Mounting (optional)

To prevent damaging the unit when transporting it

in a truck or on a trailer, Graco recommends fixed

mounting to the vehicle.

Repositioning Handle

Before you can secure the unit to a truck or trailer bed,

you must reposition the handle.

1. Remove four handle sleeve screws.

ti7649b

2. Pull handle out of upper frame handle tubes and

remove.

4. Insert plugs in upper frame handle tubes.

upper frame handle

tubes

plugs

ti7744b

5. Insert handle into lower frame tubes. Face hose

bracket down. Adjust to appropriate in/out location.

handle

handle

upper

frame

handle

tubes

ti7651b

3. Remove two frame tube plugs located behind

wheels.

lower frame tubes

ti7653b

6. Install four sleeve screws in lower frame tubes.

ti7652b

ti7650b

plugs

2 332235A

Page 3

Securing Unit to Vehicle Bed

For fixed mounting, fasten U-bolts over sprayer frame

as indicated in the following illustration.

Sprayer is a heavy piece of equipment. To avoid bodily

injury that could result from equipment moving when

transporting, secure sprayer to vehicle.

1. Reposition handle, steps 1-5, page 2.

2. Place U-bolts over sprayer frame and through holes

in vehicle bed. Place a washer and nut over bolt

end. Tighten nut securely.

Reposition Handle

U-bolts

U-bolts

332235A 3

Kit.jpg

Page 4

General Information

Pressure Relief Procedure

1. Engage trigger lock.

2. Set pump valve OFF.

3. Turn engine OFF.

4. Turn pressure to lowest setting.

5. Trigger gun to relieve pressure.

6. Turn Prime valve down.

Trigger Lock

Engage trigger lock when you stop spraying to prevent

gun from being accidentally triggered by hand or if

dropped or bumped.

4 332235A

Page 5

Removing Hydraulic Head and Pump

5. Remove four mounting bolts on pump assembly and

set assembly out of the way.

BURN HAZARD

Equipment surfaces and fluid that’s heated can

become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until

equipment/fluid has cooled completely.

1. Follow Pressure Relief Procedure, page 4.

2. Allow unit to cool.

3. Remove two hydraulic lines from head and body.

hydraulic

lines

ti20953a

pump

assembly

bolts

ti7598a

4. Remove suction set from pump.

ti21178a

6. Remove two black plugs.

NOTE: Protect open hydraulic ports from debris and

contamination.

plugs

pump

suction

set

ti21180a

ti7599a

332235A 5

hydraulic

ports

Page 6

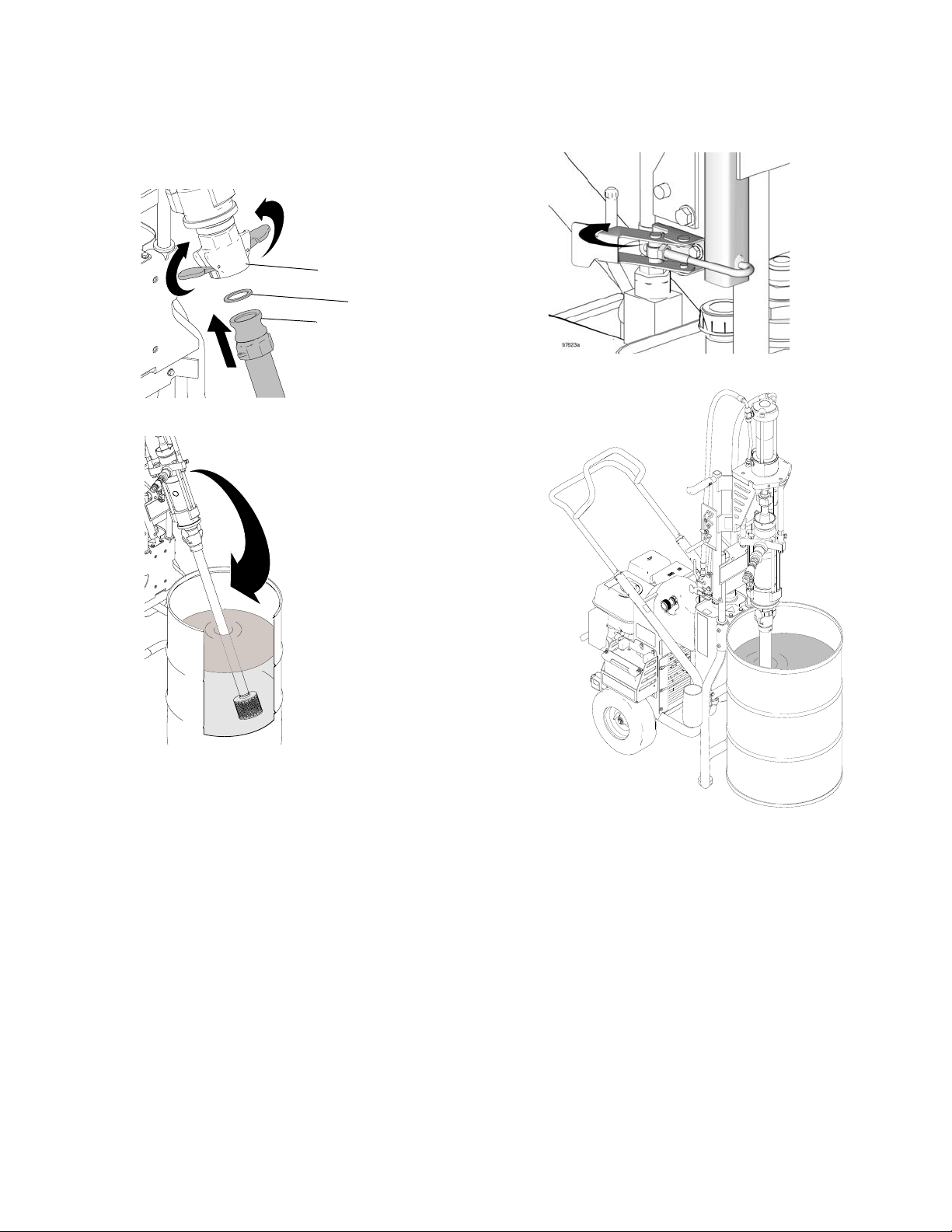

Installing Direct Immersion Kit

1. Install tower/bracket into frame holes.

tower

bracket

frame

ti7600b

holes

Pumping motion could result in bracket pulling out of

frame and cause serious injury. Always insert and

torque screws securely to insure this does not occur.

2. Install four retaining screws in frame to hold

tower/bracket in place. Torque to 165 +/- 10 in-lb

(13.8 ft-lb).

5. Torque bolts to 400 +/- 10 in-lb (33.3 ft-lb).

ti7603b

6. Install new, longer hydraulic lines (19, 20) from kit.

20

ti7604b

19

ti7601b

3. Install four bolts onto immersion kit.

ti20994a

4. Install pump assembly over four frame bolts.

7. To purge air from hydraulic lines, increase pressure

enough to start hydraulic motor stroking and allow

fluid to circulate for 15 seconds. Turn pressure

down, turn Prime valve horizontal (off).

+

ti7110c

ti7111b

ti7129b

-

pump

assembly

ti7602b

6 332235A

Page 7

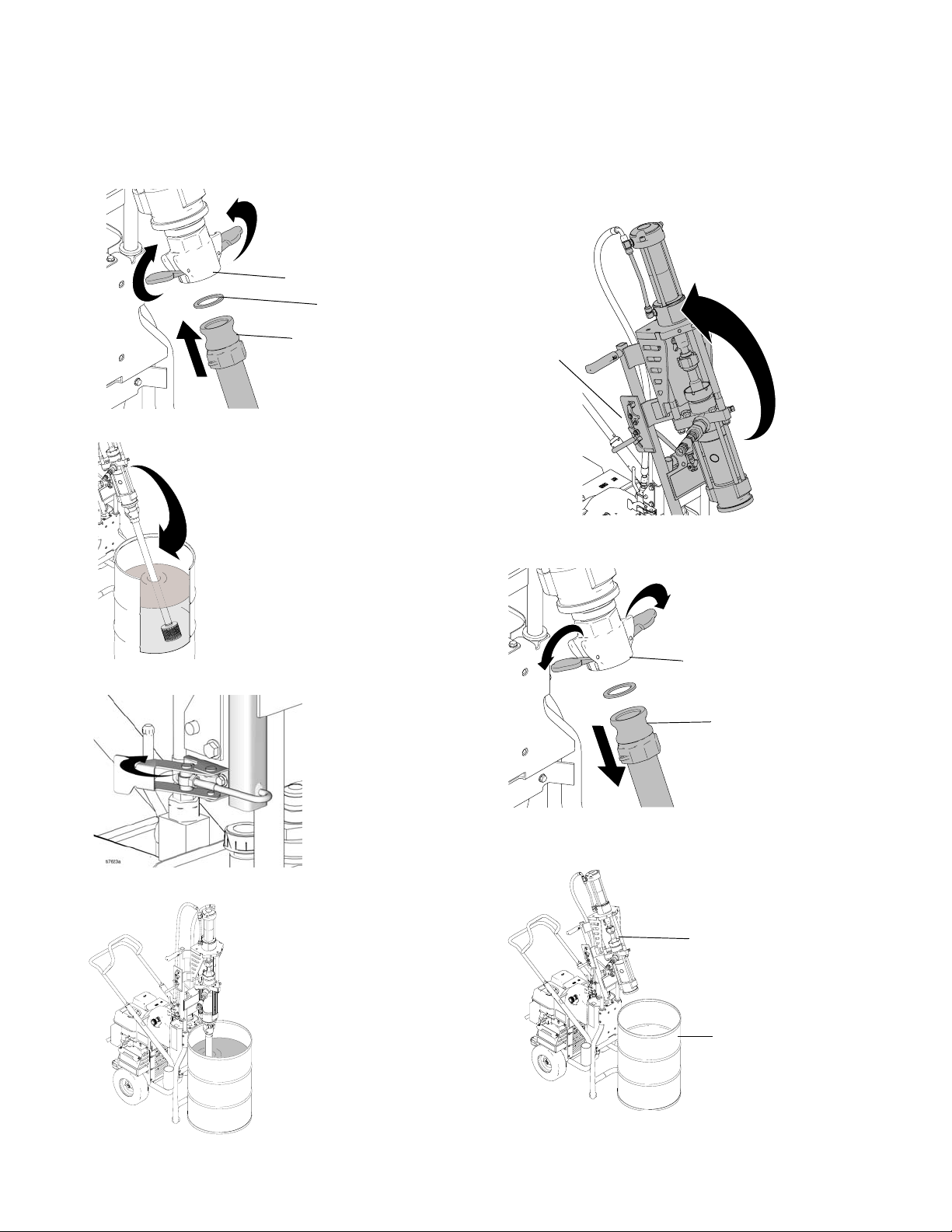

Using Direct Immersion

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other

body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards

or covers removed.

• Pressurized equipment can start without warning.

Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this

manual. Disconnect power or air supply.

4. Unclamp and tilt tower/bracket back to 1st position.

clamp

1. Apply pipe thread sealant 119400 over male

threads on pump.

34

ti21170a

2. Apply pipe sealant to bushing (34).

3. Position 55-gallon drum under pump assembly.

pump

assembly

ti21181a

5. Lock clamp into 1st position.

1st position

6. Install strainer (23) to bottom of intake tube (24).

24

23

55-gallon

drum

ti7646a

ti21169a

332235A 7

Page 8

7. Install intake tube (24). Lock female hose adapter

(22) to hold intake tube securely in place. Verify

hose adapter gasket (22a) is in place.

22

22a

24

ti21172a

8. Lower intake tube into 55-gallon drum.

Changing Drums

1. Tilt tower/bracket back and clamp securely in 1st

position.

clamp

ti21181a

2. Unlock female hose adapter (22) and remove intake

tube (24).

ti21173a

9. Lock tower/bracket in place.

10. Ready to use.

22

24

ti21179a

3. Move sprayer/tower/bracket (unit) and align new

drum under pump assembly.

pump

assembly

drum

ti21183a

ti21177a

8 332235A

Page 9

4. Ensure gasket (22a) is in place and install intake

tube (24). Lock female hose adapter (22) to hold

intake tube securely in place.

22

22a

24

ti21172

5. Lower intake tube into 55-gallon drum.

6. Lock tower/bracket in place.

7. Ready to use.

ti21173a

ti21177a

332235A 9

Page 10

Transporting Unit

NOTE:

When transporting unit securely tie down in vehicle or

follow instructions for fixed mounting to vehicle, page 2.

1. Unlock tower/bracket.

2. Tip tower/bracket back 90° to 2nd position for trans-

Do not transport unit with head in vertical position.

porting.

3. Lock in place.

2nd position

2nd

position

1st

position

ti21171a

10 332235A

Page 11

Parts

Parts

5

34

22

20

19

22a

24

14

13131313

1010

9

27

4

29

11

15

31

3

8

28

16

1717

6

77

ti21176a

1

23

Ref Part Description Qty

1 287897 SUPPORT, frame

2 287896 FRAME, 55 gallon lift

3 188622 SPACER

4 116630 SCREW

5 102040 NUT, lock, hex

6 15H478 PLATE, retainer

7 112395 SCREW, cap, flnghd

8 288037 BRACE, tilt, back

9 119872 SCREW, shoulder

10 120454 WASHER, flat

11 15H496 LATCH, liftkit, lower

12 15H495 LATCH, liftkit, upper

13 120226 SCREW, hex hd, flange

14 108063 GRIP, handle

15 114808 CAP, vinyl

16 195550 LATCH, adjustable

17 113796 SCREW, flanged, hex hd

18 114251 SCREW, cap, hex hd

2325232323

Ref Part Description Qty

19 15H265 HOSE, coupled

1

20 15H268 HOSE, coupled

1

21 120307 FITTING, hose adapter, male

2

22 120308 FITTING, hose adapter, female;

2

2

22a 120781 GASKET, hose adapter

1

23 187119 STRAINER

2

24 16U362 TUBE, inlet

1

25 119400 SEALANT

3

27▲ 15H619 LABEL, warning

4

28 15H618 LABEL

1

29 192840 LABEL

1

34 16U361 BUSHING

4

Includes 22a

1

▲

1

1

Replacement Warning labels, tags, and cards are

available at no cost.

2

4

332235A 11

1

1

1

1

1

1

1

2

1

1

Page 12

Parts

Dimensions

All dimensions are in inches

80

59

ti21174a

41

ti21175a

78

12 332235A

Page 13

Notes

Notes

332235A 13

Page 14

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions.

This manual contains English. MM 332235

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised January 2013

Loading...

Loading...